Abstract

Agricultural supply chains face growing scrutiny due to rising concerns over food authenticity, safety, and sustainability. These challenges stem from issues such as contamination risks, fraudulent labelling, and the absence of reliable, real-time tracking systems. Existing systems often rely on centralised databases and fragmented data flows, limiting traceability, data integrity, and end-to-end visibility. While blockchain technology offers potential, most research focuses narrowly on traceability, overlooking its role in establishing secure product identity and its integration with emerging tools. This review investigates how Decentralised Identifiers (DIDs), digital twins, and smart contracts—in conjunction with blockchain—can create verifiable digital representations of agricultural products and automate trust mechanisms. Through an analysis of over sixty recent sources and leading standards (e.g., W3C DIDs, Hyperledger Aries), the study identifies key gaps in interoperability, governance, and system maturity. A layered system architecture is proposed, and its application is demonstrated in a cold-chain case scenario. The paper concludes with a roadmap for empirical validation and policy alignment, contributing a practical and scalable framework for researchers, practitioners, and regulators advancing blockchain-enabled traceability systems.

1. Introduction

The agricultural sector faces mounting challenges due to increasingly complex supply chains and growing concerns regarding food authenticity, safety, and sustainability [1,2]. In the current landscape, global consumers, regulators, and retailers demand reliable information on food provenance, production practices, and ethical sourcing. These concerns are driven by public health risks, contamination incidents, foodborne illnesses, potential fraud, and regulatory compliance pressures [3,4]. Therefore, ensuring trust in agricultural products has become essential for market access and brand integrity [5].

Traceability in agricultural supply chains is a critical enabler of food safety, quality assurance, transparency, and sustainability. Traditional traceability systems, typically based on centralised Enterprise Resource Planning (ERP) platforms, barcodes, RFID tags, and institutional certifications, have long served as the backbone for managing product movement and compliance. Over time, these systems have evolved to incorporate digital labelling, audit trails via web portals, and consumer-facing mobile apps. Initiatives such as GS1 data-sharing platforms and QR code-enabled traceability solutions represent notable efforts to improve visibility from farm to fork.

Despite these advancements, current traceability infrastructures reveal several critical limitations:

Data vulnerability: Centralised databases are prone to tampering and data breaches [6], lacking the necessary tamper-proof mechanisms for accountability and data integrity across complex supply chains [7].

Limited real-time visibility: Traditional systems struggle to provide real-time tracking, which is essential for managing perishable goods and effectively responding to contamination outbreaks [6,8].

Supply chain fragmentation: Diverse stakeholders operate isolated, non-interoperable systems, resulting in data silos that hinder seamless information flow and comprehensive product journey visibility [9].

These limitations manifest in several ways:

- Traditional identification technologies (e.g., barcodes, RFID tags) demonstrate inadequate traceability guarantees [10].

- Current systems exhibit vulnerabilities in identity management and data integrity [10].

- Existing frameworks lack transparency and efficient provenance information retrieval [11].

- The absence of unified data standards between supply chain partners increases data collation costs [11].

- Reliance on paper-based, labour-intensive processes reduces efficiency [12].

- Prevalent issues include responsibility avoidance, documentation tampering, and information loss [13].

As regulatory frameworks such as the EU Green Deal, the U.S. Food Safety Modernization Act (FSMA), and national agricultural digitalisation programmes increase the demand for trusted traceability, decentralised technologies have emerged as promising enablers. Blockchain technology provides auditability and tamper resistance, Decentralised Identifiers (DIDs) enable verifiable digital identities, and digital twins facilitate real-time synchronisation of physical product states with digital representations.

However, prior studies and industry implementations of blockchain in food traceability have largely focused on transaction logging and logistics tracking, overlooking a foundational aspect: product identity. The ability to securely and verifiably associate a digital representation with a physical agricultural product is critical for ensuring trustworthy traceability. Current approaches often examine blockchain, DIDs, and digital twins in isolation, lacking integrated, standards-based frameworks that holistically address supply chain challenges.

This paper contributes to bridging this gap by conducting the following:

- Identifying limitations of current agricultural traceability systems, including data fragmentation, lack of real-time tracking, and susceptibility to fraud.

- Proposing blockchain as a comprehensive solution to enhance data integrity, transparency, and supply chain efficiency through decentralised ledgers, smart contracts, DIDs, and digital twins.

- Analysing real-world industry implementations (e.g., Walmart, Carrefour, Provenance) to assess benefits, challenges, and lessons learned.

- Discussing key barriers to adoption, including scalability, interoperability, economic costs, and regulatory constraints.

- Highlighting future trends such as hybrid blockchain models, AI-driven predictive analytics, IoT-enabled traceability, and evolving regulatory landscapes to offer a roadmap for advancing blockchain adoption in agricultural supply chains.

The motivation for this study is to address the conceptual and practical gap in current blockchain-based traceability models by introducing a system-level approach to digital product identity. Specifically, the proposed framework integrates DIDs, digital twins, and smart contracts to establish and manage product identities across agricultural supply chains. This approach goes beyond simple record-keeping, enabling dynamic, autonomous validation of certifications, provenance, and quality attributes.

This research approach involves a synthesis of technological enablers, evaluation of current system limitations, and structured case study analysis. By critically assessing technical and organisational requirements, identifying gaps and opportunities, and proposing an operational framework, the aim is to provide a clear roadmap for stakeholders to transition toward verifiable, efficient, and trustworthy agricultural traceability systems.

The paper is structured as follows: Section 2 reviews existing traceability models and technologies and their limitations. Section 3 presents the proposed architectural framework and its implementation components. Section 4 discusses validation, governance, and adoption considerations. Section 5 concludes with implications and future research directions.

2. Literature Review

A systematic literature review was conducted following the PRISMA 2020 guidelines [14]. A comprehensive search was performed in two academic databases—Scopus and Web of Science—for peer-reviewed articles published between 2019 and 2024. Keywords such as “blockchain”, “food/agriculture traceability”, “smart contract”, “DID”, and “digital twin” were used. Records were screened for relevance (English language, focused on agri-food supply chains) and de-duplicated.

A total of 144 records were initially identified: 78 from Scopus and 66 from Web of Science. After removing duplicates, 118 unique records remained. These were screened based on titles and abstracts, resulting in the exclusion of 49 records. The remaining 69 articles underwent full-text assessment for eligibility.

Following the full-text review, 25 articles were excluded for not meeting the inclusion criteria, specifically, they were not related to agriculture or were not peer-reviewed. As a result, 44 studies were included in the final review.

In this section, twenty of these studies will be analysed; the remaining twenty-four will be discussed in Section 3.

Supply chain challenges and traditional traceability limits: Agri-food supply chains face fraud, contamination, and opacity. Globalised trade heightens risks of adulteration, fake products, and disease outbreaks [15]. Traditional traceability (barcodes, manual logs) is limited by centralised databases, single points of failure, data silos, and lack of interoperability [13]. Centralised systems often produce “information islands” and are vulnerable to data tampering [13]. As one review notes, legacy food chains suffer from “inadequate monitoring” and “insufficient policies” in the face of fraud, undermining product provenance [13]. In sum, existing systems cannot guarantee end-to-end accuracy or real-time access.

Blockchain applications in agri-food: Blockchain’s immutable ledger and decentralised trust address many gaps [15]. Major initiatives include the IBM Food Trust, a Hyperledger fabric network adopted by Walmart, Carrefour, Albertsons, and others to trace commodities (e.g., pork, lettuce) in seconds [15]. TE-FOOD is a mobile-based system (used in Vietnam) that assigns QR-coded IDs to animals (pork, poultry, eggs) at each stage, enabling consumers to scan and verify the origin. Pilot projects also include Waltonchain, XinFin, and AntGroup’s AntChain for food product tracking. Blockchain consortia integrate with IoT: RFID tags and sensors, which record temperature, humidity, and location on-chain or via linked storage, enable cold-chain monitoring and real-time auditing of perishable goods.

Smart contracts and other technologies: Ethereum and Hyperledger platforms use smart contracts (self-executing code) to automate workflows. A smart contract is “a self-executable, self-enforceable… piece of source code” on blockchain. For example, contracts can release payments when IoT data confirm delivery conditions. Decentralised Identifiers (DIDs) enable self-sovereign identity for entities or assets; DIDs are URI-based IDs decoupled from central registries, allowing any party (farmer, product) to prove control of its identity. Digital twins (virtual replicas of crops or facilities) can interface with blockchain to ensure secure, real-time data sharing. Blockchain “facilitates transparency (through the supply chain), security, quality, plant health and data storage” for IoT-enabled twins, enabling resilient simulation and monitoring.

Interoperability and governance: Multiple blockchains and legacy systems pose interoperability challenges. Cross-chain architectures are emerging to bridge permissioned and public networks, using smart contracts as oracles or bridges. Without standards, data exchange between platforms remains limited; one review notes that “interoperability between different blockchain networks… is essential for creating integrated supply chains”. Various governance model: Public chains (Ethereum) have open, community-driven governance, whereas enterprise or consortia platforms (Hyperledger) use permissioned, consortium-based control. This dichotomy affects data privacy, energy use, and regulatory alignment. Clear rules for roles and consensus are still under development.

Architectural models and case studies: Recent studies propose layered frameworks to organise blockchain systems. For example, Vo et al. introduced a four-layer architecture for food chains: business (supply chain actors), traceability (data services), blockchain (ledger and smart contracts), and application (user interfaces) layers. This model ensures that each layer supports traceable metrics and stakeholder needs. Other works use three-tier or IoT/blockchain layers. For cold-chain specifically, integrated IoT–blockchain prototypes (with RFID temperature tagging) allow real-time monitoring; tagged records are hashed to the ledger for auditability. Layered designs help modularise security, data storage (often using on-chain/off-chain hybrids like IPFS), and interface logic.

Future directions and Digital Product Passports (DPPs): Despite pilot successes, blockchain in agriculture needs further study. Key research gaps include scalability, data privacy (e.g., zero-knowledge proofs) and governance frameworks. As one review observes, many pilot projects lack a “comprehensive roadmap” for broad adoption. Emerging topics include the integration of blockchain with AI for decision support and strengthening data governance across the Internet of Everything. Aligning with sustainability, Digital Product Passports (DPPs) are an EU initiative to digitally record product lifecycle data (raw materials, certifications, recycling). Blockchain underpins DPPs by ensuring immutable records and decoupling from centralised ERPs: DPPs remedy “centralized vulnerabilities, data silos, and limited interoperability” of traditional systems. Future work should explore blockchain-driven DPPs for agri-food, mapping traceability to environmental/social metrics. Table 1, shows implementations done, with associated technology, region and Table 2 a scientific comparative analysis of major selected papers.

Table 1.

Comparison of key blockchain platforms and their features.

Table 2.

Comparative analysis of selected articles and their contributions.

2.1. Product Identity vs. Traceability: Conceptual Distinction

In agricultural supply chains, the terms traceability and product identity are often used interchangeably. However, they represent distinct but complementary concepts that must be clearly differentiated to understand the value proposition of blockchain, Decentralised Identifiers (DIDs), and digital twins.

Traceability refers to the ability to track the history, application, or location of a product as it moves through the supply chain [33]. This includes capturing data about inputs, processes, transportation, storage, and handling. Traditional traceability systems focus on the “where” and “when” of products, providing visibility into the supply chain flow for purposes such as quality control, recall management, and regulatory compliance [34].

“Traceability is primarily concerned with tracking and documenting the path a product follows from origin to end-user, typically through logistics and process data.” [35].

2.2. Product Identity

In contrast, product identity pertains to the unique and persistent identification of a product unit, encompassing its intrinsic attributes (e.g., origin, composition, certification, batch-specific qualities) that define “what” the product is. Product identity ensures that each unit can be verifiably linked to its original characteristics and certifications, even as it moves through fragmented and multi-actor supply chains [30].

Product identity addresses challenges such as the following:

- Authenticity verification (e.g., PDO/PGI certifications);

- Fraud prevention (e.g., substitution, mislabelling);

- Guaranteeing attribute claims (e.g., organic, fair trade, carbon-neutral).

2.3. The Role of DIDs and Digital Twins

While traditional traceability often relies on centralised databases prone to silos and tampering, DIDs and digital twins offer a more robust approach to managing product identity.

DIDs provide a globally unique, verifiable, and self-sovereign identifier for each product or batch, independent of centralised authorities [4]. They enable secure, cryptographically verifiable relationships between physical products and their digital representations.

Digital twins act as real-time, virtual counterparts of physical products, maintaining up-to-date states of the product’s attributes, conditions, and certifications across its lifecycle [36].

Unlike generic tracking IDs (e.g., barcodes, QR codes), DIDs and digital twins support:

- Immutable provenance data linked to the product identity;

- Dynamic updates reflecting transformations (e.g., processing, packaging);

- Secure, interoperable data exchange between stakeholders.

Thus, while traceability answers “where has the product been?”, product identity answers “what exactly is this product, and can its claimed attributes be verified?”. Both are essential for transparent, trustworthy supply chains, but product identity adds an additional layer of authenticity assurance.

3. The Critical Importance of Product Identity in Agricultural Supply Chains

The analysis of existing systems reveals significant deficiencies in product identity management, representing a major gap in the current literature [12,19,20]. These limitations manifest across multiple dimensions:

3.1. Systemic Deficiencies in Current Traceability Systems

Current traceability systems demonstrate persistent challenges in maintaining reliable product identity throughout supply chains [21]. Three fundamental weaknesses contribute to this deficiency:

3.1.1. Infrastructure Limitations

The sources consistently show that current traceability systems struggle to maintain a clear and reliable product identity throughout the supply chain [19]. This is largely due to the vulnerabilities of centralised databases, information asymmetry, and unreliable verification methods, all of which contribute to a lack of a robust way to establish, maintain, and verify a product’s identity [22].

- Centralised databases: Controlled by a single entity and vulnerable to manipulation. They represent single points of failure, which can compromise product data. This makes it hard to ensure the integrity of product information and thus a solid product identity [23].

- Information asymmetry: The fragmentation of data across different stakeholders results in a lack of a comprehensive and unified view of product information [24]. This lack of a holistic view makes it hard to maintain a cohesive product identity.

- Unreliable verification: The ease with which labels and certifications can be forged undermines the ability to verify the authenticity of a product, meaning there is no guarantee that a product is what it claims to be, and it further compromises the establishment of a clear product identity [25].

3.1.2. Digital–Physical Interface Challenges

As for challenges regarding digital–physical interfaces, the main ones should be the implementation of digital twins, the physical–digital connection, and the complexities inherent to verification:

- Implementation of digital twins: The sources indicate that creating a “digital twin” of a product is essential for effective traceability. This means that a digital representation must be accurately linked to the physical product. Without this, efforts to maintain and verify a product’s identity are severely hampered [25].

- Linking physical and digital: A key challenge is to create a secure link between the physical product and its digital representation. This linkage is critical to establish a clear and verifiable identity for the product in the digital space [26].

- Verification issues: The difficulty in verifying that digital data truly reflect the physical product and its journey through the supply chain creates uncertainty and devalues the usefulness of product identity [27].

3.1.3. Identification and Traceability Issues

- Unique identification for traceability: For effective traceability, each product unit must be uniquely identified [28]. The sources highlight that current systems struggle with this due to inconsistent or lost lot identities [29]. This inability to uniquely identify products leads to a significant gap in product identity, hindering the ability to trace products [29].

- Bulk product challenges: Bulk agricultural products are especially hard to trace due to the mixing of product lots during transportation and trade. This makes it difficult to maintain a unique identity for these types of products [12].

- Identification consistency: Inconsistent product identification is a major cause of traceability failures and disconnects. This is because a robust digital identification model is often lacking and it is difficult to track products effectively when they lose their unique identifiers [12].

3.2. Conceptual Development

Blockchain technology serves as a decentralised ledger that can assign and maintain a unique digital identity for products in agricultural supply chains. Each physical item or batch can be linked to a tamper-proof record on the blockchain, often via tags such as QR codes or RFID, creating a “digital twin” of the product [37]. This secure product identity enables recording every transaction or transformation the product undergoes (from farm to processing to retail) in an immutable, time-stamped chain of data [31]. The result is an auditable trail that stakeholders can trust for its integrity and transparency: once data are recorded, they cannot be altered without detection, preserving the authenticity of product information [32].

The importance of secure and verifiable product identities in agriculture cannot be overstated. Food supply chains are highly sensitive to issues of origin, safety, and quality. A reliable digital identity allows producers, regulators, and consumers to verify a product’s provenance and attributes (e.g., organic certification, harvest date) with confidence [38]. For instance, a blockchain-based identity can assure a consumer that a package of organic tomatoes indeed came from a certified farm and was handled according to standards because every step is recorded and verified by the network. In essence, blockchain’s role in product identity is to serve as the trust infrastructure, often dubbed “the trust machine” that underpins next-generation traceability systems, ensuring that each product’s history is securely shared and verifiable by all authorised parties [32]. This conceptual foundation is critical for building transparency and accountability in farm-to-fork supply chains.

3.3. Current Landscape: Traceability Systems and Limitations

Traditional agricultural traceability systems rely on centralised databases and paper records, which suffer from several limitations. Data about farm inputs, processing, transport, among others is often siloed within each company’s system, leading to fragmented records that are hard to integrate [38]. As a result, supply chain information becomes incomplete and disjointed, making end-to-end tracking slow and error prone. For example, one study notes that conventional supply chains create “fragmented data silos” that are vulnerable to single points of failure [38]. If a central server is hacked or goes down, critical traceability information could be lost or compromised.

Key concerns in the current landscape include the following:

- Data vulnerability: Centralised or paper-based records can be tampered with or lost, and data manipulation or inaccuracies may go undetected. This undermines trust in the authenticity of products (e.g., labels can be falsified) and opens the door to fraud. Companies find it challenging to verify claims such as organic origin or fair trade status with high confidence under current systems [38].

- Lack of real-time visibility: Because each stakeholder (farmer, distributor, retailer) maintains their own logs, obtaining a real-time view of a product’s status is difficult. There is often a time lag in information sharing. As reported in European supply chains, stakeholders struggle to obtain timely, accurate data on the movement of goods and inventory levels [39]. This lack of visibility can delay responses to issues (such as contamination or delays) and leads to inefficiencies such as overstock or stockouts.

- Supply chain fragmentation: Agricultural supply chains typically involve many independent actors (producers, processors, transporters, wholesalers, retailers) often across regions or countries. Without a unifying platform, information becomes fragmented across disparate systems [32]. This fragmentation makes it hard to trace a product’s journey end-to-end. For instance, if a food safety recall is needed, tracing the origin through a fragmented chain can take days or weeks, as data must be manually collected from each link.

These limitations have tangible consequences. One notable example was a trace-back exercise where a retailer’s team took nearly a week to trace the source farm of a mango shipment using traditional methods [40]. Such delays in identifying contamination sources or verifying authenticity can lead to larger public health risks, higher waste, and loss of consumer confidence. Overall, the current traceability landscape is opaque, slow, and prone to errors, highlighting the need for more robust solutions to secure product identity and improve transparency.

3.4. Blockchain as a Solution for Traceability and Product Identity

Blockchain technology addresses many of the above challenges by providing a decentralised, tamper-resistant, and shared ledger for supply chain transactions.

Blockchain technology provides a transparent and immutable ledger, enhancing trust among supply chain stakeholders by ensuring all transactions are visible and tamper-proof [41,42,43,44].

This transparency is particularly beneficial in verifying the authenticity and origin of products, which is crucial for industries like luxury goods and food safety [45,46].

Blockchain also creates an irreversible and permanent ledger of a product’s entire lifespan, ensuring transparency and authenticity at every supply chain level.

Smart contracts can be utilized to notarize traceability activities, reinforcing immutability and transparency.

Improved Efficiency and Cost Reduction

Automation of processes via blockchain reduces manual tasks and operational delays, leading to efficiency gains and cost savings [44].

It streamlines supply chain operations, making them more agile and responsive [44].

Fraud Prevention and Security

Blockchain’s tamper-resistant nature significantly reduces incidents of fraud and enhances the security of supply chain data [44].

This is especially important for sectors dealing with high-value or sensitive products, such as electronics and automotive [47,48].

Consumer Trust and Decision-Making

Blockchain traceability addresses information asymmetry, influencing consumer purchasing decisions by offering reliable data on product origins and safety [46,49].

It reduces reliance on potentially unreliable electronic word-of-mouth [49].

This can help build consumer trust, expand market demand, and increase product sales [50,51].

Sustainability and Compliance

Blockchain enhances visibility into environmental and social impacts, ensuring adherence to sustainability practices [52].

It supports automated regulatory compliance checks, aiding companies in meeting legal requirements [50].

Challenges of Using Blockchain for Traceability and Product Identity

Scalability and Performance Issues

Blockchain systems face limitations due to restricted block size and low transaction throughput, hindering scalability for large, global supply chains [51,53].

Performance bottlenecks and the inability to effectively protect enterprise-sensitive data are ongoing issues.

Interoperability and System Complexity

The lack of standardization and the presence of multiple platforms complicate interoperability between systems [51,53].

The complexity increases further due to the global and fragmented nature of many supply chains.

Integration with the Physical Domain

Blockchain alone does not guarantee accurate tracing of goods. Mechanisms to reliably anchor physical objects into blockchain systems are essential [45].

Data Accuracy and Completeness

The accuracy and completeness of data recorded on the blockchain are critical to maintaining trust and system effectiveness [46].

Motivating all supply chain actors to provide high-quality, verifiable data remains a major challenge [46].

Cost and Complexity of Implementation

High initial costs and technical complexity in setting up and maintaining blockchain systems can deter adoption, especially among smaller firms [42,54].

Privacy and Information Disclosure

The use of public or semi-public blockchains raises concerns about privacy and potential exposure of trade secrets [46,53].

Balancing transparency with protection of sensitive data is crucial [46].

Regulatory and Ethical Considerations

Current systems often overlook government regulations and ethical implications. Blockchain traceability must be designed with compliance in mind.

Addressing the ethical dimension includes managing information asymmetry and ensuring equitable access to verified data.

In summary, while blockchain technology offers significant potential in enhancing traceability and product identity by addressing challenges such as complexity and interoperation, it also presents technical, ethical, and security considerations that need to be carefully addressed. The use of blockchain can provide transparency, reduce fraud, and increase consumer trust, but it also requires careful management of data security and privacy to ensure the integrity and security of the system. However, it is important to note that while the abstracts provide insights into the technical challenges, potential benefits, ethical implications, and data integrity ensured by blockchain technology, they do not directly address all aspects of the query, such as the specific ethical implications and the detailed mechanisms through which blockchain ensures data integrity in traceability and product identity. For Resume see Table 3 and Table 4.

Table 3.

Summary: Blockchain for Traceability and Product Identity.

Table 4.

Identify Challengers.

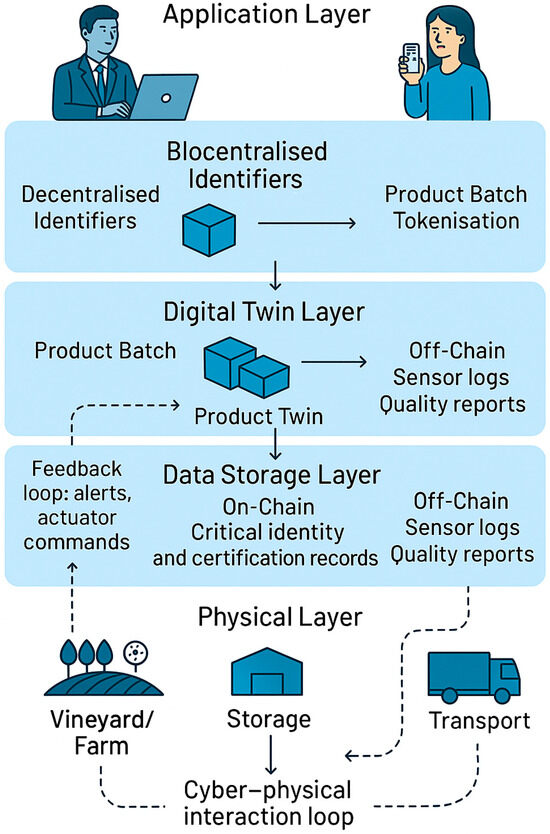

Figure 1 illustrates the end-to-end data flow and feedback mechanisms in a blockchain-enabled cyber–physical system. Data originates in the physical layer (e.g., farm, storage, transport), where IoT devices collect sensor data and status updates. This information is processed in the data storage layer with critical identity and certification records stored on-chain and sensor logs off-chain. The digital twin layer creates a virtual representation of the physical product batch, enriched with off-chain data. The blockchain layer ensures integrity and traceability via Decentralised Identifiers and tokenisation. At the top, the application layer enables users to interact with the system through interfaces such as QR codes or dashboards. Feedback loops—from the application back to the physical world—are enabled via smart contracts that can trigger alerts or actuator commands, closing the cyber–physical interaction loop and enhancing automation, transparency, and trust in supply chains.

Figure 1.

Cyber–physical blockchain architecture for transparent supply chain traceability. Data Flow and Stakeholder Interaction in the Proposed Layered Architecture.

To enhance the understanding of the proposed blockchain-based product identity architecture, this section provides a detailed walkthrough of how data flow between layers and how various stakeholders interact within the system. The architecture is composed of four primary layers: (1) physical layer; (2) digital layer (digital twins and DIDs); (3) blockchain layer (smart contracts and ledger); (4) application layer (user interfaces and services).

Key stakeholders interacting with the architecture include the following: (1) producers (farmers, cooperatives); (2) processors (factories, packaging); (3) distributors and logistics providers; (4) retailers; (5) regulatory authorities; (6) consumers.

Each stakeholder plays a role in enriching and verifying product identity data as the product moves through the supply chain.

Data flow walkthrough: From farm to consumer. A Protected Designation of Origin (PDO) olive oil will be used as a case example.

Step 1: Data capture at the physical layer—The producer records primary product attributes (e.g., olive variety, harvest date, GPS coordinates of the farm). IoT devices (e.g., soil sensors, temperature loggers) capture environmental conditions. These data points are transmitted to the digital layer, linked to a unique DID representing this olive oil batch.

Step 2: Digital layer—creation of the digital twin. A digital twin of the product batch is instantiated, encapsulating static attributes (e.g., origin, certifications) and dynamic attributes (e.g., storage temperature, transport conditions). The DID serves as the persistent identifier, ensuring each data update corresponds unambiguously to the physical batch.

Step 3: Blockchain layer—smart contracts and immutable records. The data from the digital twin are anchored on the blockchain via smart contracts. Provenance proof (farm location, harvest certification). Transformation events (e.g., pressing, bottling at processor level). Transfer of custody (from producer to distributor). Each transaction represents a verifiable event in the product’s lifecycle, creating a tamper-proof audit trail.

Step 4: Application layer—access by stakeholders. Regulators verify compliance data (e.g., organic certification, PDO validity) through dedicated dashboards. Retailers access product identity data to ensure authenticity and communicate to consumers. Consumers scan a QR code on the product packaging, retrieving the product’s digital twin information (origin, journey, certifications) in a user-friendly interface. Logistics providers can also access real-time data (e.g., storage temperature anomalies) for quality assurance. Data integrity and feedback loops. Each stakeholder can append verified data but cannot modify historical records, preserving data integrity.

Feedback mechanisms allow for (1) quality alerts (e.g., deviations in storage conditions) and (2) consumer feedback loops, where end-users can validate product experience, adding trust signals to the product’s digital twin.

The architecture supports interoperability with external systems, such as (1) government certification databases (PDO/PGI registries) and (2) logistics tracking systems via API integrations. This ensures data consistency across platforms, reinforcing product identity authenticity.

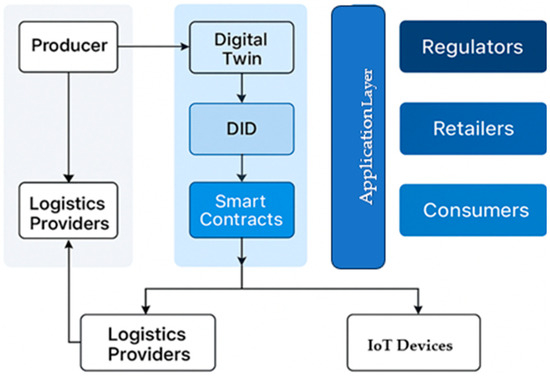

Figure 2 illustrates the interaction among the four architectural layers: physical (producers, logistics providers, IoT devices), digital (digital twins, DIDs), blockchain (smart contracts), and application (interfaces for regulators, retailers, consumers. Data are captured from the physical world, represented through digital twins and Decentralised Identifiers, secured on the blockchain via smart contracts, and accessed by stakeholders through application interfaces. This layered approach ensures end-to-end product identity verification, traceability, and transparency across the supply chain.

Figure 2.

Data flow in blockchain-based product identity architecture for agricultural supply chains.

At the base is the physical layer, which includes vineyards, farms, storage facilities, and transport mechanisms. This layer is equipped with sensors and IoT devices that capture real-time environmental and operational data such as temperature, humidity, and location.

Above this is the data storage layer, which separates information into on-chain and off-chain categories. On-chain data include critical identity and certification records that require immutability, while off-chain data, such as large sensor logs or quality reports, are stored using decentralised solutions such as IPFS or Arweave.

Next is the digital twin layer, which represents physical product batches with virtual counterparts. These digital twins track the movement and transformation of goods through the supply chain. This layer also supports the tokenisation of product units for secure digital identification.

The blockchain layer functions as the core of the system. It leverages DIDs to assign unique, verifiable identities to products, stakeholders, and transactions. Smart contracts are used to automate workflows and enforce predefined rules across the supply chain.

At the top of the architecture is the application layer, where stakeholders such as regulators, consumers, and analytics platforms interact with the system. Regulators can verify compliance data, consumers can scan QR codes to trace product provenance, and analysts can generate insights from aggregated, tamper-proof data.

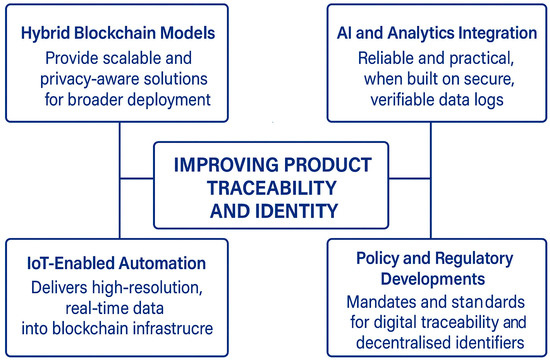

Each layer is vertically connected by arrows, showing the flow of data from the field to the blockchain and eventually to end-users. The system ensures transparency, accountability, and traceability throughout the agricultural supply chain. Figure 3 illustrates four thematic drivers—hybrid blockchain models, AI and analytics integration, IoT-enabled automation, and policy and regulatory developments—and their interconnected roles in enhancing traceability, establishing robust product identity, and fostering trust across agricultural supply chains. Each component contributes uniquely to overcoming current limitations and advancing blockchain adoption at scale.

Figure 3.

Key enablers for improving traceability and product identity in agricultural supply chains using blockchain.

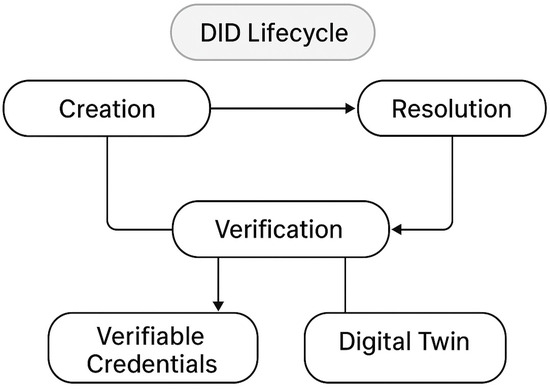

3.5. Implementation Considerations for DIDs and Digital Twins

The deployment of Decentralised Identifiers (DIDs) and digital twins in agricultural supply chains requires a thorough understanding of their technical foundations, standardisation efforts, and operational viability. This section offers a detailed analysis of how DIDs are created, resolved, and linked to physical assets through digital twins, addressing critical concerns from stakeholders. DIDs are generated following specific DID methods, such as did:ion, did:ethr, or did:key, which dictate the processes for identifier creation, registration, and resolution. In the presented framework, every supply chain entity, including farms, distributors, and product batches, receives a DID issued by a decentralised ledger system aligned with W3C standards. The issuance process may be managed by trusted authorities or automated via smart contracts triggered by verifiable production or certification events. The DID document holds important metadata, including public keys for authentication and encryption, service endpoints for interacting with digital twins or metadata APIs, and proof of control mechanisms. Resolving a DID involves querying a DID resolver that retrieves the associated DID document from the distributed ledger using protocols such as REST APIs or universal resolvers, enabling real-time verification of identity, and authorisation and credential validity across the supply chain. Digital twins in this model serve as virtual representations of physical products, such as grape batches or coffee sacks, augmented with IoT data such as temperature, humidity, and location. These digital twins are continuously updated with the physical state through sensor data streams, including RFID, GPS, and thermal probes, as well as manual verification logs such as quality control scans and video uploads. To securely associate physical and digital identities, cryptographic tags such as QR codes, NFC, or RFID embed unique nonces that are hashed and stored on-chain. Tag verification algorithms confirm that scanned tags correspond to the digital twin’s DID, while anomaly detection methods, including geofencing checks and detection of duplicate tag reads, identify tampering attempts such as spoofing or tag switching. In Figure 4, the DID lifecycle—creation, resolution, and verification—is shown in conjunction with verifiable credentials and digital twins, highlighting how these components interoperate to ensure secure, standards-based identity and traceability.

Figure 4.

Diagram illustrating emerging role of DIDs in agri-food supply chains.

These mechanisms enable robust authentication and traceability of agricultural goods from origin to point-of-sale.

This implementation follows the W3C DID core specification and incorporates several key components. verifiable credentials (VCs) are used as tamper-evident claims, such as organic certification, issued by recognised authorities and cryptographically linked to the DID. The universal resolver (UR) is employed as a protocol-agnostic tool compatible with multiple DID methods, enabling flexible resolution. Additionally, DIDComm is utilised as a protocol for secure peer-to-peer messaging between supply chain participants, relying on DID-based authentication. Among the example frameworks and tools, DIDChain [55] illustrates supply chain DID workflows, including role-based access, credential issuance, and verification. Hyperledger Indy and Aries offer open-source tools that support the construction of interoperable DID and VC ecosystems, facilitating peer DIDs, credential exchanges, and integration with distributed ledgers.

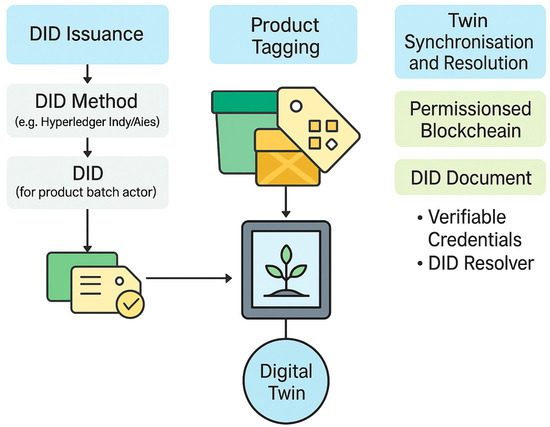

Figure 5 illustrates the sequential steps: DID issuance via standardised methods (e.g., Hyperledger Indy/Aries), product tagging and physical–digital linkage, creation of the digital twin, and synchronisation through a permissioned blockchain using verifiable credentials and DID resolution protocols.

Figure 5.

Process flow for implementation of DIDs and digital twins in agricultural supply chains.

3.6. Industry Implementations in Agricultural Supply Chains

Blockchain applications in agriculture have moved from concept to practice in recent years, with numerous case studies and pilot projects demonstrating its value. Below, some notable implementations by industry and government are highlighted.

Global retailers and food companies: One of the most cited examples is Walmart’s use of blockchain for food traceability. In partnership with IBM’s Food Trust platform (built on Hyperledger Fabric), Walmart conducted trials tracking mangoes and pork. The results were dramatic—tracing the source of sliced mangoes went from taking nearly seven days with traditional systems to just 2.2 s using the blockchain solution [7]. Every step of the mango supply chain (farm, import, distribution centre, store) was recorded on the ledger, allowing instant lookup of origin and handling data. Following these pilots, Walmart mandated its leafy green suppliers to join the blockchain system to enable rapid recalls and improve food safety. Similarly, Carrefour, a large European retailer, has implemented blockchain tracking for a range of products (chicken, eggs, milk, cheese, fruits, among others) in collaboration with IBM [4]. Consumers can scan QR codes on Carrefour products to see detailed provenance information—for example, the exact farm where a chicken was raised, what it was fed, slaughter date, and transport details [4]. This level of transparency has reportedly boosted consumer trust and even increased sales for those products. Carrefour noted a “halo effect” where shoppers’ confidence in one blockchain-tracked product (say, free-range chicken) positively influenced their trust in other Carrefour products [4]. The company saw pomelo grapefruit sales climb after introducing blockchain traceability, as customers felt assured of the fruit’s origin and quality. These real-world outcomes underscore that blockchain can enhance brand reputation and consumer confidence when applied to food quality and safety verification.

Producers and exporters: Agricultural producers and exporters have also adopted blockchain to differentiate their products and meet import requirements. For example, the coffee industry has seen blockchain pilots to certify origin and fair payment. Startups such as Provenance worked on projects linking coffee farmers to consumers. Coffee beans are tagged and logged on blockchain from the farm, through cooperatives, to the roaster, using RFID/QR codes to create a digital identity for each lot [30]. This ensures that claims about sustainable farming practices or single-origin status are backed by an unbroken record. In one Provenance pilot, small-scale fishermen in Indonesia registered their tuna catches via text message to a blockchain, which generated a unique ID for each fish and logged subsequent processing steps [30]. This system allowed end consumers in Europe to scan a package of tuna and see its journey, verifying that it was caught legally and met sustainability standards (with fisher IDs and compliance info on record). Another notable implementation is by Bumble Bee Foods, which used blockchain to trace yellowfin tuna from Indonesian fisheries to North American dinner tables, enabling consumers to verify the seafood’s authenticity and sourcing with a QR code scan. In the produce sector, growers and exporters of high-value foods (like organic bananas, specialty grains) are using blockchain-based platforms to meet stringent import regulations and prove that their products are exactly what their labels claim.

Government and regulatory initiatives: Governments have recognised the potential of blockchain to improve food safety oversight and have launched supportive initiatives. In China, after several high-profile food safety scandals, major e-commerce players such as JD.com and Alibaba partnered with producers to implement blockchain tracking for products like beef, milk powder, and cooking oil as part of broader government-endorsed food traceability programmes. For instance, JD.com worked with an Australian beef supplier to record every step of beef production on a blockchain, so Chinese consumers buying the meat could trace its farm of origin, slaughter, and shipping details via an app [56]. This was aimed at restoring trust in imported meats. In another example, the European Union has been exploring blockchain through its European Blockchain Services Infrastructure (EBSI) initiative. While EBSI covers many use cases (from digital credentials to customs), one focus area is supply chain traceability for agricultural goods to enhance cross-border transparency and compliance. Some governments are also leveraging blockchain for specific agricultural supply chains, e.g., tea producers in Malawi have piloted blockchain to track tea from estates to auctions to buyers, improving fair-trade claims verification; the Indian state of Andhra Pradesh tested blockchain for monitoring crop supply and connecting farmers with markets as a means to prevent price manipulation by intermediaries.

Success factors and lessons: Across these implementations, a few success factors stand out. Stakeholder collaboration is crucial—the entire chain (farmers, processors, distributors, retailers) needs to participate and input data for the blockchain to provide end-to-end visibility. Many successful projects started with a consortium or a dominant buyer driving adoption (like Walmart enforcing supplier participation or a government creating incentives). Another factor is user-friendly integration, that is, solutions that succeeded tended to integrate with existing workflows (e.g., mobile apps for farmers or IoT sensors auto-uploading data) so that using the blockchain does not become a burden. The Carrefour case also highlighted the importance of consumer engagement: informing customers about the ability to scan products and see provenance helped translate transparency into brand loyalty and sales [4]. On the other hand, barriers such as limited connectivity in rural areas or reluctance to share data have stalled some pilots. Nonetheless, the growing list of real-world applications suggests that blockchain is gaining traction in agri-food supply chains, transforming how product identity and traceability are managed in practice.

3.7. Economic Impact and ROI of Blockchain Traceability

While blockchain implementation in agriculture incurs upfront investment, such as platform development, integration with legacy systems, and IoT sensor deployment, the long-term Return On Investment (ROI) can be significant. The economic benefits stem from reduced fraud, faster recalls, streamlined data sharing, improved consumer trust, and brand differentiation.

Pilot projects from major retailers provide empirical support, as seen in Table 5:

Table 5.

Cost–benefit summary of blockchain traceability (pilot studies).

- Walmart, in partnership with IBM Food Trust [56], reduced the time required to trace the origin of sliced mangoes from almost seven days to 2.2 s, significantly improving operational efficiency and recall readiness. This speed not only reduces health risk exposure and potential legal costs but also protects brand reputation [57].

- Carrefour implemented blockchain for traceability on various food items (e.g., chicken, eggs, milk, citrus fruits). The result was a measurable increase in sales of tracked products due to enhanced consumer trust. Shoppers were willing to pay a premium for blockchain-verified transparency, particularly for organic or regionally certified goods [55].

- Provenance and Bumble Bee Foods demonstrated how traceability using blockchain and digital product IDs (QR codes) can increase export readiness, reduce disputes, and attract buyers in premium markets with traceability mandates (e.g., EU organic, fair trade) [58].

A comparation was performed between traditional traceability systems and blockchain-based approaches in agricultural supply chains (see Table 6). The comparison is structured across several key dimensions including data transparency, real-time tracking, verification effort, scalability, cost, and stakeholder trust. This matrix illustrates the enhanced capabilities and benefits of blockchain while also acknowledging the challenges in adoption relative to conventional methods.

Table 6.

Comparative analysis for blockchain solution with traditional systems.

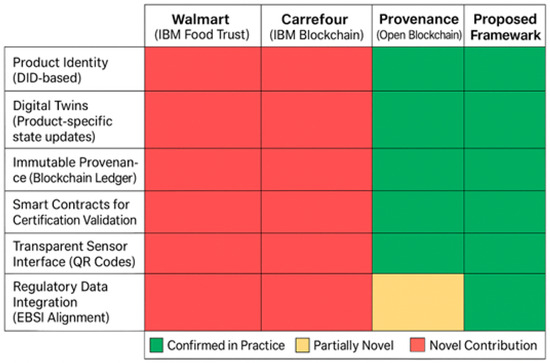

Several companies have implemented blockchain solutions to enhance transparency and traceability in agricultural supply chains. However, these implementations typically focus on logistics traceability rather than addressing product identity in a holistic manner. This section compares the proposed framework’s components with real-world initiatives to highlight its unique contributions and assess its practical feasibility.

The analysis reveals several important observations. Elements such as immutable provenance and consumer transparency interfaces (e.g., QR codes) are already well established and validated in large-scale deployments by companies such as Walmart and Carrefour, confirming their practical feasibility. However, the use of digital twins at product-level granularity, capable of dynamic state updates such as condition monitoring, represents a partially novel contribution that extends beyond current batch-level implementations.

The most significant novel contributions of the proposed framework lie in the integration of Decentralised Identifiers (DIDs), self-sovereign access control mechanisms, and smart contracts for automated certification validation. These components introduce new functionalities not yet fully explored or adopted in existing blockchain-based supply chain solutions. On the other hand, aspects such as regulatory data integration aligned with EBSI standards and the development of open interoperability frameworks remain conceptual at this stage, requiring further development and practical validation.

From a practical perspective, the proposed framework offers multiple advantages for the agricultural supply chain sector. By providing a persistent product identity, it enhances authenticity assurance and mitigates risks of substitution and mislabelling fraud. The automation of certification verification through smart contracts reduces the manual workload for regulators and retailers, thereby improving operational efficiency. Additionally, the framework fosters greater consumer trust by offering transparent and verifiable product information, supporting claims such as organic production, fair trade certification, or PDO (Protected Designation of Origin) status. Nevertheless, its successful adoption will depend on overcoming scalability challenges, including the establishment of governance structures, onboarding of diverse stakeholders, and ensuring interoperability with existing platforms and national-level information systems.

Figure 6 compares the proposed blockchain-based product identity framework against existing implementations by Walmart (IBM Food Trust), Carrefour (IBM Blockchain), and Provenance (Open Blockchain). The components assessed include product identity management, digital twins, immutable provenance, decentralised access control, smart contract validation, consumer interfaces, and regulatory integration. Colour coding distinguishes among confirmed practices (green), partially novel approaches (yellow), and novel contributions introduced by the proposed framework (red).

Figure 6.

Comparison of proposed framework with real-world cases.

3.8. Challenges and Barriers to Adoption

Despite its promise, implementing blockchain in agricultural supply chains comes with significant challenges. The literature and industry reports point to several barriers that must be addressed:

- Technical scalability and performance: Public blockchains such as Bitcoin or Ethereum are not designed to handle the high volume of transactions that a busy supply chain could generate (every farm harvest, truck shipment, warehouse check-in, among others). Throughput and latency can become issues if every supply chain event were recorded on-chain. Even in private or permissioned blockchains, transaction processing capacity is a concern [8]. Storing large datasets (sensor readings, certificates, images) directly on the blockchain is impractical due to the “data explosion” it would cause [8]. Solutions like off-chain storage (e.g., using IPFS or cloud databases for heavy data and storing only hashes on-chain) are being explored to alleviate this [8]. Nonetheless, designing a system that scales to millions of products while keeping performance acceptable is non-trivial. Technical improvements (such as more efficient consensus algorithms, sharding or layer-2 networks) are still evolving to meet these needs.

- Integration and interoperability: Agricultural businesses have existing ERP systems, databases, and IoT platforms for supply chain management. Introducing blockchain should ideally complement these, not entirely replace them. A major barrier is connecting legacy systems to blockchain networks in a seamless way. Data standards become important, as different parties might use different formats for product IDs, batch numbers, or timestamps. Without common standards (for example, GS1 standards for product identification), feeding data into a blockchain and retrieving them for various enterprise systems can be challenging. Interoperability is also a concern between different blockchain platforms: if one supplier uses one blockchain system and another uses a different one, linking those for a unified view is complex. Companies worry about vendor lock-in and whether a chosen blockchain solution will be compatible with others in the future. Efforts are underway to develop interoperability protocols and unified data standards for blockchain traceability, but this remains a barrier to frictionless adoption.

- Data privacy and confidentiality: While transparency is a benefit, supply chain participants often have legitimate concerns about protecting sensitive business information. A farmer or trader might be reluctant to put pricing, exact locations, or client details on a ledger that others (even permissioned parties) can see. Public blockchains are fully transparent, which is usually unacceptable for proprietary supply chain data. Permissioned (consortium) blockchains limit visibility to approved members, but even then, companies may want to keep certain data (such as formulas or supplier identities) confidential. Privacy-enhancing techniques are thus crucial, including encryption of data, hashing sensitive attributes (only storing a digest on-chain), or using permissioned channels where only relevant parties see certain transactions. Research has proposed hybrid solutions, such as combining a public blockchain for overall auditability with off-chain or private side-chains for sensitive details [59]. Another approach is using zero-knowledge proofs to validate events (e.g., a compliance check passed) without revealing the underlying data. Ensuring that blockchain implementation complies with data protection laws (like GDPR in Europe) is an added challenge, requiring careful design so that personal data are not inadvertently exposed on an immutable ledger.

- Economic costs and incentives: Adopting blockchain can be expensive, at least initially. There are costs for developing or subscribing to the platform, integrating IT systems, and possibly investing in new hardware (such as scanners or IoT sensors for data input). For small farmers or producers in developing regions, the cost and complexity can be prohibitive. They may lack the needed digital infrastructure or funding to participate [1]. Moreover, if the benefits (e.g., better prices or market access) are not immediately clear to them, they have little incentive to incur extra effort for data entry. Thus, equitable value distribution is a concern: downstream actors (like retailers) might reap the rewards of improved consumer trust, but upstream farmers might not see direct profit gains. Aligning incentives, for example, by offering premiums for blockchain-verified goods or providing free tools and training can help, but it requires coordination. The ROI for blockchain traceability can be hard to quantify, especially when many benefits are intangible (trust, risk reduction) or long-term. This uncertainty can make companies hesitant to invest heavily in a technology that is still relatively new to the sector.

- Regulatory and organisational barriers: The regulatory environment for blockchain in supply chains is still maturing. There is often legal ambiguity around smart contracts (are they recognised as legally binding?), electronic records, and data ownership on a distributed ledger. Different countries have varying stances on blockchain use and data sovereignty, which can complicate cross-border supply chains. Additionally, the lack of clear governance frameworks for industry consortia can be a barrier, as participants need to agree on who operates the network, how decisions are made, and how disputes are handled if the blockchain says one thing and a physical audit says another. Organisationally, change management is a hurdle: implementing blockchain may require redesigning business processes. Resistance to change and lack of blockchain expertise among staff can slow down adoption. Stakeholder buy-in is critical; if some key players refuse to participate, the usefulness of the system diminishes. Building trust in the technology itself is also an issue, as some stakeholders might not trust a system which they do not fully understand. Ironically, the very problem blockchain is meant to solve for data can exist as a barrier for its adoption. In summary, beyond the technology, human and institutional factors (policies, laws, skills, and trust between partners) pose significant barriers that must be navigated for successful blockchain implementation in agricultural supply chains.

Table 7 summarises the main adoption barriers for blockchain in agricultural supply chains, indicating their severity and frequency of occurrence based on the recent literature and industry reports. Severity reflects the potential impact on adoption if unaddressed, while frequency indicates how commonly the barrier is reported across studies.

Table 7.

The main adoption barriers for blockchain in agricultural supply chains.

- Severity: High = major blocker for adoption; medium–high = significant challenge; medium = manageable with mitigation strategies.Frequency: High = Frequently reported in >70% of reviewed sources; medium = reported in ~40–70%; low = reported in <40%.

4. Future Directions and Emerging Trends

The intersection of blockchain with agriculture is evolving rapidly. Ongoing research and pilot programmes suggest several future directions that could further enhance product identity and traceability in supply chains:

- Hybrid and scalable blockchain models: To overcome current technical limitations, more hybrid architectures that combine the strengths of different systems are expected. For example, hybrid blockchains (part public, part private) can allow a level of openness for generic data while keeping sensitive details in a restricted environment [59]. This can achieve both transparency and privacy by design. Side-chains or layer-2 networks might be employed for handling large volumes of IoT data, anchoring critical summaries or hashes back to the main chain for integrity. There is also exploration into more energy-efficient and scalable consensus mechanisms (moving beyond Proof-of-Work to Proof-of-Stake or even DAG-based ledgers) to make blockchain systems faster and more suitable for real-time supply chain operations. These innovations aim to ensure that as adoption grows, the performance and cost of using blockchain will meet industry needs.

- AI and analytical integration: The combination of blockchain with Artificial Intelligence (AI) and machine learning is a promising frontier. Once supply chain data are reliably captured on blockchain, AI can be applied to this trusted dataset to extract insights and optimise operations. For instance, machine learning models could analyse blockchain-logged data on crop conditions and logistics to predict risks (like spoilage or delays) and automatically adjust plans. Some projects [60], such as Bext360, are already using AI-driven devices to grade agricultural products (coffee bean quality) and then tokenising those products on blockchain for immediate payment and tracking. In the future, AI could verify data consistency on the blockchain (spotting anomalies that might indicate fraud or error) or even manage smart contracts (e.g., adaptive pricing contracts triggered by market AI forecasts). Additionally, predictive analytics on supply chain blockchains could improve food safety—AI might detect a pattern in sensor data indicating contamination and trigger preventative actions earlier. The synergy of AI with blockchain’s secure data can thus lead to smarter, self-correcting supply chains that improve efficiency and reduce waste. It will also be possible to see AI algorithms for decision support being shared across supply chain partners using blockchain as a trusted platform, ensuring that everyone is basing decisions on the same verified data.

- IoT-enabled traceability and automation: The proliferation of IoT in agriculture (smart sensors, GPS, RFID, drones) goes hand-in-hand with blockchain adoption. Future traceability systems will likely feature end-to-end automation, where data are captured by IoT devices and written to blockchain with minimal human intervention. This could mean every truck is equipped with GPS and temperature sensors that automatically log transport conditions to a blockchain as it moves; every silo or cold storage unit could have sensors that log stock levels and quality metrics in real-time. This real-time streaming of data into blockchain will further enhance visibility. It also improves reliability of data (since sensor-fed data remove the possibility of human error or intentional misreporting). Blockchain can provide a secure environment for IoT data, ensuring that sensor readings are tamper-evident and attributable. Moreover, smart contracts can act on IoT data, for example, if a grain storage humidity sensor (IoT) reports levels above a threshold, a smart contract on the blockchain could automatically flag that batch as suspect and notify quality inspectors. In the future, autonomous supply chain operations could emerge, including imagine automated drones or robots in a warehouse that check product IDs on blockchain and route them appropriately without human guidance. IoT integration will also extend traceability to the first mile: farmers with smartphones or IoT farm equipment could seamlessly record planting, inputs, and harvest data on-chain, giving a much richer picture of a food product’s origin. As 5G and rural internet connectivity improve, the barrier of digital infrastructure for small producers may diminish, allowing IoT–blockchain ecosystems to flourish even in developing regions.

- Policy and regulatory developments: The coming years are likely to bring more formal recognition and frameworks for blockchain in supply chains. Regulators in food safety are already pushing for enhanced traceability, for example, the U.S. FDA’s Food Safety Modernization Act (FSMA) Section 204 requires digital traceability records for certain high-risk foods, which is motivating companies to consider technologies such as blockchain to comply with the new rules. Standard bodies, such as ISO, IEEE, and W3C, might start developing standards for blockchain use in supply chain traceability and identity (indeed, W3C’s standards on DIDs and verifiable credentials are steps in this direction). Governments might also invest in national or regional blockchain platforms for agriculture to ensure interoperability. The European Union’s efforts with EBSI and projects under its blockchain observatory could lead to cross-country traceability networks for tracking imports and exports with a high level of trust. Legal frameworks are expected to evolve to clarify smart contract enforceability and liability issues when using decentralised systems. All these developments would reduce uncertainty and risk for companies adopting blockchain and could even mandate digital traceability in ways that actually encourage blockchain use. In addition, sustainability regulations, such as carbon reporting requirements, could use blockchain to reliably track emissions or resource usage across a product’s lifecycle, given the technology’s strength in maintaining auditable records.

- Enhancing consumer trust and food safety: Ultimately, the goal of these innovations is to create food systems that are safer and more trusted by the public. In the future, consumers might come to expect a high level of transparency as a default. Blockchain could enable consumer apps where one scans any produce or meat and instantly sees its “identity card”—origin farm, journey, certifications, even videos or images from the farm—fostering a strong connection and trust in the food. Such transparency can drive more informed consumer choices and reward producers who invest in quality and sustainability. From a food safety standpoint, if blockchain traceability becomes widespread, outbreaks of foodborne illness could be contained much more rapidly. Health agencies could pinpoint the contaminated batch within minutes and use the blockchain’s data to quickly identify all distribution points, ensuring swift recalls. Over time, the rich data collected might allow pro-active prevention, as patterns in the supply chain data could reveal risks before they manifest (for example, noticing that a certain supplier consistently has temperature excursions in shipping and working to fix that). The vision for the future is a “farm-to-fork” digital trail for every food item, enhancing accountability at each step. Blockchain, especially in combination with other technologies, is poised to be a backbone for this vision—improving not just efficiency for businesses but also delivering societal benefits in terms of food safety, sustainability, and trust. As these systems mature, they hold the potential to transform consumers’ relationship with their food, enabling a level of transparency and assurance that was not possible before.

5. Conclusions

Blockchain technology presents a transformative solution for enhancing product identity and traceability in agricultural supply chains. The ability to create secure, tamper-proof digital records ensures that each agricultural product maintains a verifiable history, thereby increasing transparency and reducing fraud. Industry implementations, such as Walmart’s IBM Food Trust and Carrefour’s blockchain-based consumer traceability, illustrate the practical benefits of the technology in improving food safety and consumer confidence.

Despite its advantages, several technical, economic, and regulatory barriers must be addressed. Scalability issues, interoperability with legacy systems, data privacy concerns, and high implementation costs present significant challenges. However, emerging solutions such as hybrid blockchain models, Decentralised Identifiers (DIDs), and smart contract automation offer promising approaches to overcoming these obstacles. Furthermore, regulatory support and advancements in IoT integration could facilitate the broader adoption of blockchain in agricultural supply chains.

Looking ahead, blockchain’s role in agricultural supply chains is expected to expand through its convergence with AI, IoT, and machine learning-driven analytics. As blockchain frameworks evolve to balance transparency, security, and efficiency, they have the potential to redefine how agricultural products are tracked, verified, and trusted worldwide. Ultimately, blockchain technology will play a critical role in building a more accountable, efficient, and sustainable global food supply chain.

This study presents a structured framework for enhancing agricultural supply chain transparency through blockchain-enabled product identity systems. In contrast to the existing literature that often focuses narrowly on logistics or static traceability, this work elevates digital product identity—anchored in technologies such as DIDs, digital twins, and smart contracts—as a critical enabler of trust and efficiency in food systems.

The layer architecture presented (Figure 1) that distinguishes among physical data capture, off-chain/on-chain storage, and application-level functionality is distinguished. Furthermore, the synthesis of industry cases (Walmart, Carrefour, Bumble Bee) further demonstrates how real-world deployments align with the model. Additionally, Figure 3 and Figure 4 offer strategic visual summaries that guide both researchers and practitioners through current challenges, future enablers, and expected applied benefits.

The scientific novelty of this work lies in unifying these elements into a holistic and scalable design that treats product identity as central—not peripheral—to traceability. Practically, this framework supports regulatory compliance, fraud reduction, automation, and enhanced consumer trust.

Future research will focus on operationalising the proposed framework into implementable workflows and algorithms. This involves designing smart contract templates for product identity verification and compliance automation, developing identity binding algorithms to ensure robust digital–physical linkages using Decentralised Identifiers (DIDs) and IoT data, and prototyping a reference implementation in collaboration with industry partners to validate performance, scalability, and user acceptance. Additionally, workflow simulations and pilot deployments will be conducted to assess practical feasibility and fine-tune system design. These efforts will transform the conceptual framework into a fully operationalised solution, enabling practical adoption in real-world agricultural supply chains.

Author Contributions

Formal Analysis, M.C.; Investigation, M.C.; Writing—Review and Editing, M.C. and J.C.F.; Supervision, J.C.F. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Haider, A.; Iqbal, S.Z.; Bhatti, I.A.; Alim, M.B.; Waseem, M.; Iqbal, M.; Mousavi Khaneghah, A. Food Authentication, Current Issues, Analytical Techniques, and Future Perspectives: A Comprehensive Review. Compr. Rev. Food Sci. Food Saf. 2024, 23, e13360. [Google Scholar] [CrossRef] [PubMed]

- Alves, L.; Hoffman, L.C.; Schreuder, J.; Cozzolino, D. Food Authenticity and the Interactions with Human Health and Nutrition: A Comprehensive Review. Crit. Rev. Food Sci. Nutr. 2024, 23, 87329. [Google Scholar] [CrossRef]

- Vargas, D.A.; Betancourt-Barszcz, G.K.; Blandon, S.E.; Applegate, S.F.; Brashears, M.M.; Miller, M.F.; Gragg, S.E.; Sanchez-Plata, M.X. Rapid Quantitative Method Development for Beef and Pork Lymph Nodes Using BAX® System Real Time Salmonella Assay. Foods 2023, 12, 822. [Google Scholar] [CrossRef]

- Decentralized Identifiers (DIDs) v1.0. Available online: https://www.w3.org/TR/did-1.0/ (accessed on 18 May 2025).

- Anwar, A.R.; Mur, M.; Michailidou, G.; Bikiaris, D.N.; Humar, M. Edible Microlasers for Monitoring Authenticity and Quality of Food and Pharmaceuticals 2024. arXiv 2024, arXiv:2405.20937. [Google Scholar]

- Ren, X.Y.; Zheng, Y.X.; Zhou, N. Research on the Influencing Factors of Traceability Information Sharing of Agricultural Product Supply Chain under the Background of Blockchain. Int. J. Ind. Eng. Comput. 2024, 15, 965–976. [Google Scholar] [CrossRef]

- Luo, Q.; Liao, R.; Li, J.; Ye, X.; Chen, S. Blockchain Enabled Credibility Applications: Extant Issues, Frameworks and Cases. IEEE Access 2022, 10, 45759–45771. [Google Scholar] [CrossRef]

- Sodamin, D.; Vaněk, J.; Ulman, M.; Šimek, P. Fair Label versus Blockchain Technology from the Consumer Perspective: Towards a Comprehensive Research Agenda. Agris Line Pap. Econ. Inform. 2022, 14, 111–119. [Google Scholar] [CrossRef]

- Yang, S.; Li, S.; Chen, W.; Zhao, Y. A Redactable Blockchain-Based Data Management Scheme for Agricultural Product Traceability. Sensors 2024, 24, 1667. [Google Scholar] [CrossRef]

- Xiao, J.; Luo, T.; Li, C.; Zhou, J.; Li, Z. CE-PBFT: A High Availability Consensus Algorithm for Large-Scale Consortium Blockchain. J. King Saud Univ. Comput. Inf. Sci. 2024, 36, 101957. [Google Scholar] [CrossRef]

- Urtecho, R.L.P.; Rodríguez-Molina, J.; Martínez-Núñez, M.; Garbajosa, J. Enhancing Agriculture Through IoT and Blockchain: A VeChain-Enhanced Sustainable Development Approach for Small-Scale Agricultural Exploitations. IEEE Access 2024, 12, 179962–179980. [Google Scholar] [CrossRef]

- Pang, S.; Teng, S.W.; Murshed, M.; Van Bui, C.; Karmakar, P.; Li, Y.; Lin, H. A Survey on Evaluation of Blockchain-Based Agricultural Traceability. Comput. Electron. Agric. 2024, 227, 109548. [Google Scholar] [CrossRef]

- Yao, Q.; Zhang, H. Improving Agricultural Product Traceability Using Blockchain. Sensors 2022, 22, 93388. [Google Scholar] [CrossRef] [PubMed]

- The PRISMA 2020 Statement: An Updated Guideline for Reporting Systematic Reviews | The BMJ. Available online: https://www.bmj.com/content/372/bmj.n71 (accessed on 18 May 2025).

- Ellahi, R.M.; Wood, L.C.; Bekhit, A.E.-D.A. Blockchain-Based Frameworks for Food Traceability: A Systematic Review. Foods 2023, 12, 3026. [Google Scholar] [CrossRef]

- Malusare, P.S.; Das, S. Tracing the Journey of Soybeans: Implementing Blockchain in Agricultural Supply Chain Management. In Proceedings of the 2024 IEEE 9th International Conference for Convergence in Technology (I2CT), Pune, India, 5–7 April 2024; IEEE: Piscataway Township, NJ, USA, 2024; pp. 1–4. [Google Scholar]

- Kanthavel, R.; Venket, S.K.; Anju, A.; Adline, F.R.; Dhaya, R.; Vijay, F.; Fisher, J. Blockchain and Digital Twin Applications in Precision Agriculture: A Comprehensive Approach. In Blockchain and Digital Twin Applications in Smart Agriculture; Auerbach Publications: Boca Raton, FL, USA, 2025; pp. 308–315. [Google Scholar]

- Rishikesh; Ajay, S.K.; Sinha, D. AgriBlockchain: Agriculture Supply Chain Using Blockchain. In Intelligent Data Engineering and Analytics; Bhateja, V., Yang, X.-S., Chun-Wei Lin, J., Das, R., Eds.; Smart Innovation, Systems and Technologies; Springer Nature: The Gateway, Singapore, 2023; Volume 327, pp. 35–47. ISBN 978-981-19752-3-3. [Google Scholar]

- Wu, Y.; Jin, X.; Yang, H.; Tu, L.; Ye, Y.; Li, S. Blockchain-Based Internet of Things: Machine Learning Tea Sensing Trusted Traceability System. J. Sens. 2022, 2022, 8618230. [Google Scholar] [CrossRef]

- Lin, X. Analysis of Agricultural Product Information Traceability and Customer Preference Based on Blockchain. Wirel. Commun. Mob. Comput. 2022, 2022, 1935233. [Google Scholar] [CrossRef]

- Zhang, G.; Chen, X.; Feng, B.; Guo, X.; Hao, X.; Ren, H.; Zhang, Y. BCST-APTS: Blockchain and CP-ABE Empowered Data Supervision, Sharing, and Privacy Protection Scheme for Secure and Trusted Agricultural Product Traceability System. Secur. Commun. Netw. 2022, 2022, 963. [Google Scholar] [CrossRef]

- Ahmed, W.A.H.; Maccarthy, B.L. Blockchain-Enabled Supply Chain Traceability in the Textile and Apparel Supply Chain: A Case Study of the Fiber Producer, Lenzing. Sustain. Switz. 2021, 13, 496. [Google Scholar] [CrossRef]

- Xie, Z.; Kong, H.; Wang, B. Dual-Chain Blockchain in Agricultural E-Commerce Information Traceability Considering the Viniar Algorithm. Sci. Program. 2022, 2022, 4216. [Google Scholar] [CrossRef]

- Pakseresht, A.; Ahmadi Kaliji, S.; Xhakollari, V. How Blockchain Facilitates the Transition toward Circular Economy in the Food Chain? Sustain. Switz. 2022, 14, 1754. [Google Scholar] [CrossRef]

- Bułkowska, K.; Zielińska, M.; Bułkowski, M. Implementation of Blockchain Technology in Waste Management. Energies 2023, 16, 7742. [Google Scholar] [CrossRef]

- Prasad, C.G.V.N.; Mallareddy, A.; Pounambal, M.; Velayutham, V. Edge Computing and Blockchain in Smart Agriculture Systems. Int. J. Recent Innov. Trends Comput. Commun. 2022, 10, 265–274. [Google Scholar] [CrossRef]

- Wang, Z.; Gao, M.; Lu, G. Research on Oracle Technology Based on Multi-Threshold Aggregate Signature Algorithm and Enhanced Trustworthy Oracle Reputation Mechanism. Sensors 2024, 24, 502. [Google Scholar] [CrossRef]

- Jiang, Y.; Lei, Y. Implementation of Trusted Traceability Query Using Blockchain and Deep Reinforcement Learning in Resource Management. Comput. Intell. Neurosci. 2022, 2022, 9517. [Google Scholar] [CrossRef] [PubMed]