Abstract

In the frame of an extended research program dealing with wood shavings and wood sawdust utilization in mortar, thermal conductivity and thermal behavior under various temperatures of mortars containing wood shavings and sawdust as a replacement for a part of the conventional aggregates were studied. Mixes with 0, 30, 50 and 70% replacement of conventional fine limestone aggregates with wood shavings were made. Also, mixes with 0, 10 and 20% replacement of aggregates with wood sawdust were made. The density of fresh concrete and the thermal conductivity of hardened concrete were determined. Thermal conductivity was determined with the guarded hot plate method according to standard ΕΝ 12667:2001. Specimens were also submitted to 100, 200, 300, 400, 500 and 600 °C. Flexural and compressive strength were determined 24 h after thermal strain. Results showed that thermal conductivity decreased when volume replacement increased, both for the use of wood shavings and sawdust, thus improving the thermal properties of mortar. Flexural and compressive strength exponentially decrease as exposure temperature increases.

1. Introduction

Concrete has been the most predominant construction material to this day because of its strength, durability, versatility and robustness. As the building sector rapidly develops, the demand for raw aggregates and other construction materials has spiked [1]. Conventional concrete is a composite material containing natural aggregates, cement and water, and sometimes contains additives to optimize its properties. However, the mining of natural aggregates disrupts the natural environment and the production of cement has a significant contribution to the CO2 emissions [2,3]. As a result, the construction industry has started making efforts to reduce its carbon footprint. Moreover, considering the climate crisis and the rising temperatures alongside more and more wildfires, the behavior of concrete in elevated temperatures is an important parameter [4,5].

The increasing interest in sustainable construction practices has drawn attention to waste utilization as an effective strategy for waste management. Wood sawdust and wood shavings are mainly collected as byproducts of the timber industry, with a significant amount considered waste. Materials such as wood sawdust and wood shavings, previously considered waste, are now being studied by researchers as partial replacements for conventional concrete aggregates. In 2022, it was reported that approximately 510 million cubic meters (m3) of roundwood—wood removed from the forest and other wooded land, or other tree felling sites —were produced [6]. This raw material is the primary input for sawmills and wood-processing industries, where it is converted into lumber and other products. During this process, a significant portion of the roundwood volume is converted into by-products such as wood shavings, sawdust and chips. As a secondary biodegradable raw material being incorporated in concrete mixes, wood sawdust and shavings can be effectively repurposed, reducing the need for natural aggregates. Their inclusion can also improve thermal insulation, which may enhance the overall energy efficiency of the resulting structures [5,7,8]. Papers report that the preferred method for the natural aggregate was a volumetric replacement [9], either most commonly as a percentage [10,11], or as a ratio [12].

The physical and mechanical properties of the wood sawdust and shavings differ depending on the geographical origin of the wood, the type of wood, the part of the tree they are derived from and the method of production. Timber has been a preferred construction material for many centuries due to its physical and mechanical properties, particularly its insulating properties. Considering this, when used as a concrete composite material, researching these same properties poses a significant scientific interest. For that reason, researchers such as [13,14] have focused on the evaluation of the thermal conductivity of concrete containing sawdust in different sizes.

In addition to the benefits mentioned above, the inclusion of wood sawdust and shavings in concrete can enhance its acoustic performance, making it a valuable material for residential buildings where sound insulation is important [7].

However, the incorporation of wood sawdust and shaving in concrete causes a reduction in the mechanical strengths [15]. Moreover, treated and untreated wood exhibit differences in performance and are overall susceptible to biodegradation due to their organic nature, especially when exposed to high moisture environments, consequently affecting the durability of the composite material [11,16,17,18,19,20,21]. In order to mitigate these challenges, the wood byproducts are often treated, increasing the difficulty of utilization as well as the cost [20]. The treatment used by Benchouaf et al. [20] consisted of boiling the shavings in water for four hours, as the authors expected that this would be enough to change the chemical composition of the wood and thus eliminate the organic matter. Dias et al. [21] investigated the effect of aging cycles (wet–dry cycles and freeze–thaw cycles) as well as the effect of thermal shock to determine the thermal compatibility of wood and cement matrix. The conditions imposed on the specimens were aggressive, with a temperature range of about 85 °C. The lack of visual damage shows that the material remains structurally stable under typical thermal shocks, which supports the idea of moderate thermal compatibility. The issue of durability should be further investigated as a continuation of existing research.

Changes in components of concrete or mortar has, as a result, a change in the thermal properties of concrete. Since aggregate comprises about 60–80% of the volume of concrete, the type of aggregate affects the thermal conductivity coefficient. It has been reported that the thermal conductivity of lightweight concrete ranges from 0.2 to 1.9 W/m °K and from 0.6 to 3.3 W/m °K for normal weight concrete [22]. It depends upon a variety of factors such type of aggregates, silica content, water to cement ratio, density, etc. Wood exhibits a low thermal conductivity (high heat-insulating capacity). The thermal conductivity of wood is highest in the axial direction and increases with density and moisture content; thus, it has a wide variation. Ahmed et al. [7] investigated the possibility of chemical interactions between wood sawdust and concrete matrix and concluded that sawdust particles exhibited no chemical interaction with the host concrete matrix.

Overall, the use of wood sawdust and shavings in concrete or mortar offers a solution to wood waste byproduct management while also improving the thermal behavior of the composite by reducing the heat transfer through it. Nevertheless, since the way that concrete and wood behave at high temperatures varies greatly, it is crucial to conduct a thorough investigation of these two materials’ behaviors, as this research does.

In the present study, mortar mixes with 0, 30, 50 and 70% by volume replacement of conventional fine limestone aggregates with wood shavings were made. Also, mixes with 0, 10 and 20% by volume replacement of aggregates with wood sawdust were made. Thermal conductivity of hardened mortar was determined with the guarded hot plate method according to standard ΕΝ 12667:2001 [23]. One way to classify thermal conductivity methods is based on whether they are in a steady state or transient. Steady-state methods apply a constant heat flux to a sample and measure the resulting temperature difference across the sample. Transient methods apply a heat pulse or a periodic heat source to a sample and measure the temperature response over time. A steady-state method is the guarded hot plate method and it is considered a very commonly used method for building materials [24].

Specimens were also submitted to 100, 200, 300, 400, 500 and 600 °C to study their thermal behavior at those temperatures. Physical and mechanical properties such as density, ultrasonic pulse velocity and compressive strength were also measured prior to heating. These results, together with relevant data from existing literature, are intended to support future meta-analyses comparing the effects of different wood types, mix designs and materials.

This study contributes to the relatively limited body of literature concerning the use of wood shavings and sawdust as a lightweight aggregate in cementitious mortars, particularly with respect to their thermal behavior under elevated temperature exposure. While previous studies have explored the mechanical and insulating properties of bio-based aggregates, few have specifically examined the thermal coefficient and post-exposure behavior of wood shavings at elevated temperatures up to 700 °C. Most studies focus on ambient or moderately elevated temperatures, with limited attention to fire-related thermal performance. This paper addresses that gap by providing novel data on the response of wood-based mortars to high-temperature exposure, offering insight into their potential use in thermally demanding environments. Further research is needed to explore long-term durability under cyclic thermal loads, the influence of different wood species and particle sizes, and the optimization of binder-to-aggregate ratios for enhanced thermal and mechanical performance. These directions remain largely unexplored and represent key opportunities for expanding the applicability of wood-based mortars in sustainable construction.

Wood shavings and sawdust were chosen in this stage to be used as they are, without any pretreatment. Pretreatment as premixing with resins could be used to enhance the durability, but it would also increase the cost. Further study of those pretreatments and a technoeconomic study, along with the durability of concrete, is needed.

2. Materials and Methods

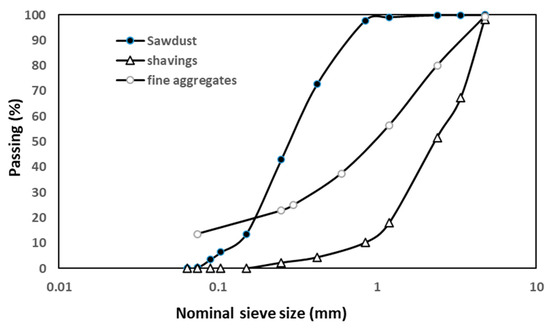

Cement used was CEM II/B-M (P-W-L) 42.5N (Lafarge, Greece) and crushed limestone aggregates with a 4.5 mm maximum size were used in all mixtures. Sieve analysis of limestone aggregates is shown in Figure 1. The bulk density of fine aggregates was 1730 ± 40 kg/m3. Wood shavings and wood sawdust used in this study were generated in a factory by mechanical processing of beech type of wood. In terms of fineness, the average grade of sawdust is 0.15–0.5 mm. Its sieve analysis is shown in Figure 1.

Figure 1.

Results of sieve analysis.

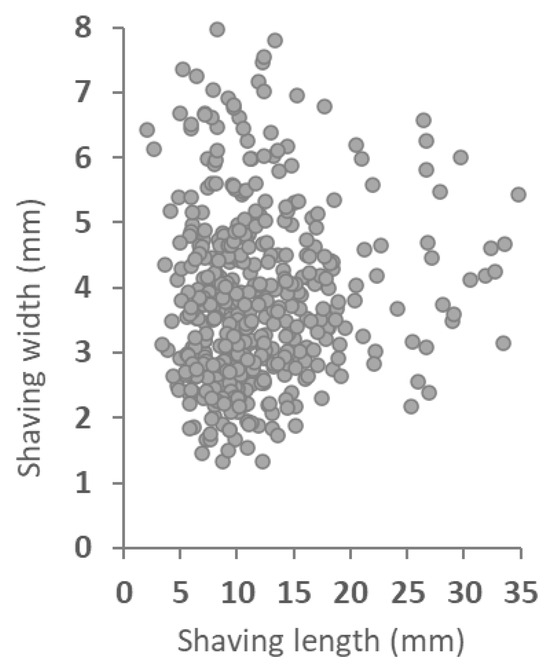

Usually, the particle distribution of materials is estimated by sieve analysis. In the case of wood shavings, a question that could be emerged is which is the actual dimension that corresponds to the nominal sieve size and if a large proportion of shavings have a longer length that width, if this affects the critical dimension, as during sieve analysis a shaving could pass the sieve by its wight and not by its length. For this reason, all shavings having a length of more than 3 mm (actually able to be optically discriminated) were measured using a high-accuracy digital calliper. Two dimensions were measured on each shaving: length, which was taken to be the maximum dimension, and width, which was taken to be the dimension of the shaving on an axis perpendicular to the length. Results are shown in Figure 2. As it is shown, a portion of the wood shavings is longer than 5 mm, and due to their elongated shape—where length significantly exceeds width—the results of the sieve analysis may be misleading. Following on the same samples that were partly measured using a caliper, sieve analysis was performed on fine aggregates, and it is shown in Figure 1.

Figure 2.

Width versus length for wood shavings.

Results of sieve analysis of wood shavings and fine limestone aggregates are shown in Figure 1. Bulk density of wood shavings was 67 ± 2 kg/m3 and bulk density of wood sawdust was 296 ± 5 kg/m3. The bulk density of wood shavings and sawdust was determined by measuring the mass of ten different samples, each occupying a fixed volume. Sika ViscoFlow superplasticizer was used in all mixes.

All mix proportions are presented in Table 1. The proportioning of mortar mixtures was conducted with consideration of their prospective applications. One potential application could be as a lightweight, thermally insulating plaster, while another could be as mortar for restoration work. A lot of trial mixes were made in order to select the best mix proportions first for the reference mixes, so the workability remains at desired levels even after the replacement of conventional aggregates by wood shavings or sawdust. Because of the fact that these two act differently, two reference mixes were selected, one for the wood shavings replacement and one for the wood sawdust replacement. Then, 30, 50 and 70% of the amount of fine aggregates was removed and it was replaced by an amount of wood shavings that was decided to have an equal bulk volume as compared to the removed amount of fine aggregates. In this way, the critical parameter of water-to-cement ratio was kept constant (equal to 0.6), and at the same time, the workability of the mixture was acceptable. The same rationale was followed for mixes containing wood sawdust. For those calculations, the bulk density of shavings and sawdust was used because this is an easy way to measure their density. The actual density of solid wood material, in many cases, is too difficult to determine if it is an unknown material. Afterwards, when the density of fresh mortar was determined, all mix proportions were reviewed to calculate the corresponding values in kg/m3. All information is given so that the experiments can be accurately reproduced and scientific progress is facilitated.

Table 1.

Mix proportions.

For wood shavings, 30, 50 and 70% replacement were chosen as to cover a wide range of replacement. Sawdust has higher bulk density than shavings (296 kg/m3 for sawdust instead of 67 kg/m3 for shavings). This means that in the case of sawdust the same replacement percentage corresponds to a much larger amount of wood which results to a great loss of workability. This is attributed to the fact that wood shavings and wood sawdust absorbs more water compared to conventional aggregates [9]. So, the percentages for sawdust were kept low, 10 and 20%.

The constituents were mixed in a mixer at a slow speed to obtain good homogenization. First, cement and aggregates mixing took place. Then, the water with superplasticizer diluted in it was added.

Density of fresh concrete (D) was determined by measuring the mass of mortar (mu) contained in a known volume (Vu) of a sample of fresh mortar as described in ASTM C138 [25]:

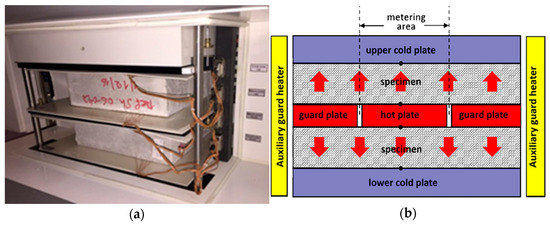

Specimens from each mixture were cast with dimensions 200 × 200 × 80 mm to perform thermal conductivity determination tests. After 48 h, the specimens were demoulded and then they were immersed in water until the age of 28 days. The curing temperature was about 20 °C. Then, specimens were left in ambient laboratory air (50% RH, 17 °C) for a month, until the determination of the thermal conductivity coefficient. The thermal conductivity coefficient was determined by means of the guarded hot plate method according to European Standard EN 12667:2001. The equipment used was the TLP-300 of TAURUS Instruments (Fridingen an der Donau, Germany) (Figure 3).

Figure 3.

(a) Equipment used for the determination of thermal conductivity coefficient, (b) general principal of the guarded hot plate apparatus.

From the same mixes, also specimens with dimensions 40 × 40 × 160 mm were cast to study their thermal behavior under 100, 200, 300, 400, 500 and 600 °C. After 48 h, the specimens were demoulded and then they were immersed in water until the age of 28 days. The curing temperature was about 20 °C. Then specimens were left in ambient laboratory air for another 28 days to balance (50% RH, 17 °C). Then, they were subjected to temperatures in an oven for 15, 30 and 60 min. The specimens were left in the oven to gradually cool down, to avoid any thermal shock. After thermal strain, a non-destructive test of ultrasonic pulse velocity was carried out by using the method described in ASTM C 597 [26], specifically using a Portable Ultrasonic Non-Destructive Digital Indicating Tester (PUNDIT). Then, the flexural strength test was carried out by center-point loading as described in ASTM C 293 [27] on three specimens. The end parts of the prisms that were left intact after failure in flexure were used to carry out compressive strength tests by applying the load through square steel plates, 40 mm in size, at a uniaxial compressive test apparatus (CONTROLS-GROUP–Automax Multitest Control Console–Automatic Compression Tester 2.000 kN).

3. Results

3.1. Density of Fresh Mortar

The density of fresh mortar mixes is shown in Table 2. For all mixes, the averages of the samples were determined, followed by the standard deviation. Standard deviation is the non-negative square root of the sum of squared deviations of random variables from their sample mean, divided by the number of terms in the sum minus one, Equation (2).

Table 2.

Density of fresh mortar.

The density of fresh mortar decreased as % by volume replacement of fine aggregates increased. This reduction is attributed to the fact that the wood shavings have less specific gravity than conventional aggregates. Wood shavings, being organic and porous in nature, contain a large volume of internal air voids and have a lower mass-to-volume ratio. As more of these lightweight particles replace denser sand particles, the overall mass of the mortar per unit volume decreases, leading to a reduction in fresh density. Additionally, the irregular shape and lower compaction characteristics of wood shavings may contribute to increased entrapped air in the mix, further lowering its density.

When the density of fresh mortar was determined, all mix proportions were reviewed to calculate the corresponding values in kg/m3. The corrected mix proportions based on the density of fresh concrete are shown in Table 3.

Table 3.

Corrected mix proportions based on density of fresh concrete.

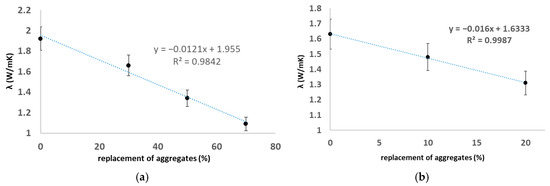

3.2. Thermal Conductivity Coefficient

The thermal conductivity coefficient exhibits a linear decrease with increasing volumetric replacement levels, for both wood shavings and wood sawdust (Figure 4). This can be attributed to the fact that wood is less heat conducting compared to conventional aggregates. The irregular shape and low density of wood particles disrupt the continuity of the cement matrix, further limiting heat transfer. This insulating effect becomes more pronounced as the volume of wood replacement increases.

Figure 4.

Thermal conductivity of mortar containing (a) wood shavings and (b) wood sawdust.

3.3. Thermal Behavior

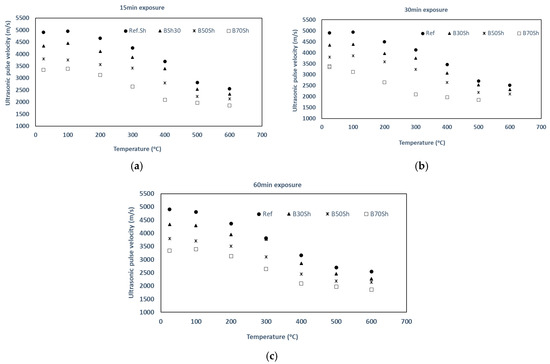

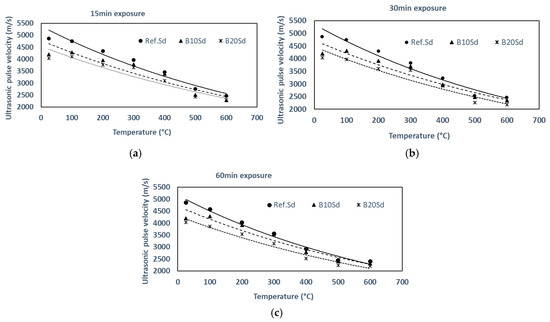

Ultrasonic pulse velocity decreases as fine aggregates are by volume replaced with wood shavings (Figure 5) or wood sawdust (Figure 6). This is attributed to the different properties of wood compared to the properties of conventional fine aggregates. The importance of ultrasonic pulse velocity is that it is significantly correlated with mortar elastic properties [21,28,29]. It is also an indirect method for quantifying homogeneity in mortar. Ultrasonic pulse velocity exponentially decreases as exposure temperature increases. R-squared at all fittings was greater than 0.86.

Figure 5.

Ultrasonic pulse velocity of mortars containing wood shavings after (a) 15 min, (b) 30 min and (c) 60 min at 25 (no exposure, reference), 100, 200, 300, 400, 500 and 600 °C.

Figure 6.

Ultrasonic pulse velocity of mortars containing wood sawdust after (a) 15 min, (b) 30 min and (c) 60 min at 25 (no exposure, reference), 100, 200, 300, 400, 500 and 600 °C.

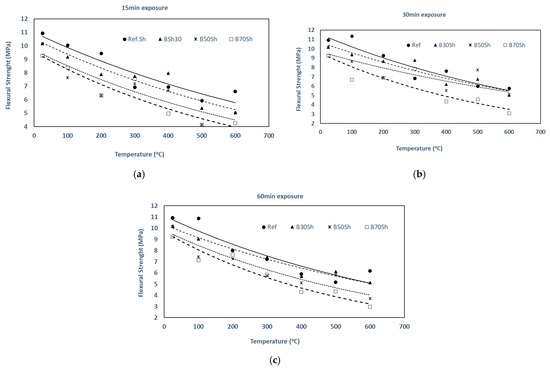

Flexural and compressive strength of mortars containing wood shavings are shown in Figure 7 and Figure 8, respectively. For flexural strength, the prevailing parameter is the exposure temperature. It seems that any contribution to flexural strength from the percentage of replacing conventional aggregates with wood shavings is not significant enough to be detected due to measurement uncertainty itself. In other words, while a trend may be theoretically expected, the magnitude of is not sufficiently large to be distinguished from the potential error inherent in the measurement process. It is shown by Figure 7 that the variability of flexural strength results is greater than the maximum difference between the trendlines of any of the replacement percentages. For example, at 200 °C, the reference mix has higher flexural strength than the 30% mix, but at 300 and 400 °C has a lower flexural strength, but again at 500 and 600 °C has a higher flexural strength than the 30% mix.

Figure 7.

Flexural strength of mortars containing wood shavings after (a) 15 min, (b) 30 min and (c) 60 min at 25 (no exposure, reference), 100, 200, 300, 400, 500 and 600 °C.

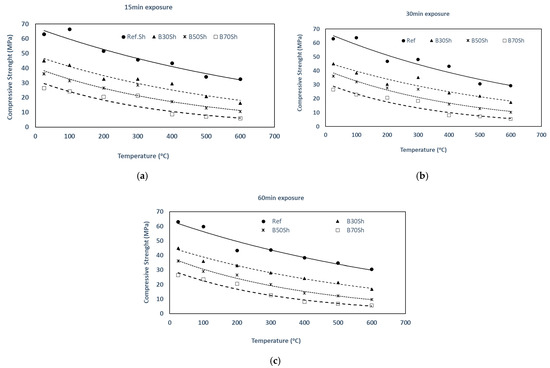

Figure 8.

Compressive strength of mortars containing wood shavings after (a) 15 min, (b) 30 min and (c) 60 min at 25 (no exposure, reference), 100, 200, 300, 400, 500 and 600 °C.

Wood shavings resulted in a decrease in compressive strength. This is an expected result [9,10,30] as wood shavings do not provide enough strength as fine aggregate in the mortar phase, and shavings may act like voids for compression. The organic nature of wood materials leads to weaker interfacial bonding with the cement paste compared to mineral aggregates. This results in a more porous and discontinuous matrix, as supported by the lower ultrasonic pulse velocity values observed in this study. Furthermore, wood particles tend to absorb water during mixing, which can alter the local water–cement ratio, potentially leading to incomplete hydration or increased microcracking upon drying [30].

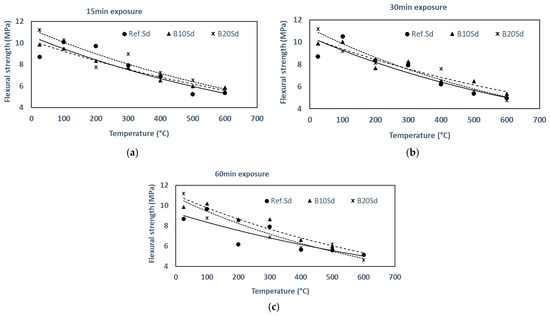

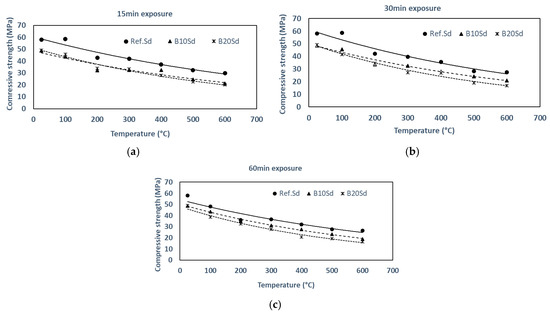

Flexural and compressive strength of mortars containing wood sawdust are shown in Figure 9 and Figure 10, respectively. For flexural strength, the prevailing parameter is the exposure temperature. It seems that any contribution from the percentage of replacing conventional aggregates is not significant enough to be detected due to measurement uncertainty itself. Wood sawdust resulted in a decrease in compressive strength. These results agreed fairly well with those obtained by other researchers [9,12]. As in the case of shavings, this is an expected result, as sawdust also does not provide enough strength as fine aggregate in the mortar phase, and sawdust particles may act like voids for compression. Up to 200 °C exposure, strength decrease can be attributed to gradual dehydration within the cement matrix, which causes changes in physical properties. At temperatures up to 600 °C, a fall in compressive strength could be due to dehydration of both calcium silicate hydrates (C–H–S) and the decomposition of calcium hydroxides that takes place at temperatures above 450 °C [12]. Microcracks also occur due to the differences in thermal expansion of sand particles and cement paste, and due to the differences in thermal expansion of wood particles and cement paste.

Figure 9.

Flexural strength of mortars containing wood sawdust after (a) 15 min, (b) 30 min and (c) 60 min at 25 (no exposure, reference), 100, 200, 300, 400, 500 and 600 °C.

Figure 10.

Compressive strength of mortars containing wood sawdust after (a) 15 min, (b) 30 min and (c) 60 min at 25 (no exposure, reference), 100, 200, 300, 400, 500 and 600 °C.

The thermal degradation of wood components in mortars begins at relatively low temperatures and progresses in distinct stages. Hemicellulose, the most thermally sensitive component, starts to decompose at temperatures around 200–250 °C. Cellulose follows, degrading primarily between 250 and 350 °C, while lignin—the most thermally stable constituent—undergoes a slower decomposition process across a broader range of 300–500 °C. As the temperature increases beyond 400 °C, the majority of volatile compounds are released, and the formation of char becomes predominant. This staged decomposition influences the thermal behavior of mortars containing wood shavings, as the breakdown of organic matter leads to changes in porosity, mechanical integrity and thermal insulation properties. In any case, mortar containing wood sawdust could have a satisfactory residual compressive strength at elevated temperatures.

Flexural and compressive strength decrease exponentially as the exposure temperature increases.

At higher temperatures of 400–500–600 °C at all exposure times, but also at 200–300 °C at 60 min, in the mixes containing wood, it was observed that the wood in the mortar had begun to turn to ash.

4. Conclusions

Based on the results presented, the following conclusions can be drawn:

- The density of fresh mortar containing wood shavings or sawdust decreases as the wood shavings content increases.

- The thermal conductivity coefficient decreases as the replacement increases, both for wood shavings and wood sawdust. The utilization of construction materials having lower thermal conductivity in buildings may help in improving the energy efficiency of the building.

- Compressive and flexural strength decreases as the replacement percentage of conventional aggregates increases, but the mix design and the use of not high percentages of replacement of conventional aggregates could compensate for this reduction in strength. The use of 30% replacement of conventional aggregates by wood shavings and 20% replacement of conventional aggregates by wood sawdust would give acceptable mixes of mortar, depending on their use and the use’s requirements.

- Flexural and compressive strength exponentially decrease as exposure temperature increases. This behavior aligns with the progressive thermal degradation of wood components (hemicellulose, cellulose and lignin) beginning around 200–250 °C, leading to loss of cohesion and increased porosity in the composite matrix.

- In addition to the specific findings of this study, the results related to density, ultrasonic pulse velocity and mechanical properties contribute valuable data that can be combined with existing literature to enable future meta-analyses comparing different types of wood aggregates, binder compositions and mortar mix designs.

Further study is needed to cover all physical and mechanical properties of mortars and concrete containing wood shavings or sawdust, in order to assess their uses. Then, testing of a full-scale application using the selected compositions is needed. To further quantify the sustainability impact of the developed mixtures, a life cycle assessment (LCA) should be carried out to compare their environmental performance against conventional mortars. This assessment should consider the specific application context and the mechanical requirements, particularly compressive strength. Additionally, the lower thermal conductivity of the developed mortars may contribute to reduced heating and cooling demands in buildings, offering long-term energy savings, so this should also be considered in LCA.

Author Contributions

Conceptualization, A.S.; methodology, S.G. and N.N.; resources, A.S.; investigation, S.G. and N.N.; writing—original draft preparation, S.G. and T.K.G.; writing—review and editing, S.G.; supervision, S.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Bendixen, M.; Iversen, L.L.; Best, J.; Franks, D.M.; Hackney, C.R.; Latrubesses, E.M.; Tusting, L.S. Sand, gravel, and UN Sustainable Development Goals: Conflicts, synergies, and pathways forward. One Earth 2021, 4, 1095–1111. [Google Scholar] [CrossRef]

- Bendixen, M.; Best, J.; Hackney, C.; Iversen, L.L. Time is running out for sand. Nature 2019, 571, 29–31. [Google Scholar] [CrossRef] [PubMed]

- Cheng, D.; Reiner, D.M.; Yang, F.; Cui, C.; Meng, J.; Shan, Y.; Liu, Y.; Tao, S.; Guan, D. Projecting future carbon emissions from cement production in developing countries. Nat. Commun. 2023, 14, 8213. [Google Scholar] [CrossRef]

- Issa, C.A.; Izadifard, R.A. Numerical simulation of the experimental behavior of RC beams at elevated temperatures. Adv. Model. Simul. Eng. Sci. 2021, 8, 12. [Google Scholar] [CrossRef]

- Lucio-Martin, T.; Roig-Flores, M.; Izquierdo, M.; Alonso, M.C. Thermal conductivity of concrete at high temperatures for thermal energy storage applications: Experimental analysis. Sol. Energy 2021, 214, 430–442. [Google Scholar] [CrossRef]

- Statistics Explained. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Wood_products_-_production_and_trade#Roundwood_production (accessed on 3 April 2025).

- Ahmed, W.; Khushnood, R.A.; Memon, S.A.; Ahmad, S.; Baloch, W.L.; Usman, M. Effective use of sawdust for the production of eco-friendly and thermal-energy efficient normal weight and lightweight concretes with tailored fracture properties. J. Clean. Prod. 2018, 184, 1016–1027. [Google Scholar] [CrossRef]

- Olaiya, B.C.; Lawan, M.M.; Olonade, K.A. Utilization of sawdust composites in construction—A review. SN Appl. Sci. 2023, 5, 140. [Google Scholar] [CrossRef]

- Sotiropoulou, A.; Gavela, S.; Nikoloutsopoulos, N.; Passa, D.; Papadakos, G. Experimental study of wood shaving addition in mortar and statistical modeling on selected effects. J. Mech. Behav. Mater. 2017, 26, 55–63. [Google Scholar] [CrossRef]

- Corinaldesi, V.; Mazzoli, A.; Siddique, R. Characterization of lightweight mortars containing wood processing by-products waste. Constr. Build. Mater. 2016, 123, 281–289. [Google Scholar] [CrossRef]

- Mohammed, B.S.; Abdullahi, M.; Hoong, C.K. Statistical models for concrete containing wood chipping as partial replacement to fine aggregate. Constr. Build. Mater. 2014, 55, 13–19. [Google Scholar] [CrossRef]

- Memon, R.P.; Achekzai, L.; Mohd Sam, A.R.; Awal, A.S.M.A.; Memon, U. Performance of sawdust concrete at elevated temperature. J. Teknol. 2017, 80, 167–171. [Google Scholar] [CrossRef]

- Hafed, S.A. Study of thermal insulation and some mechanical properties for hybrid composites (cement–wood sawdust). Int. J. Comput. Appl. Sci. IJOCAAS 2017, 3, 212–216. [Google Scholar]

- Hafidh, S.A.; Abdullah, T.A.; Hashim, F.G.; Mohmoud, B.K. Effect of Adding Sawdust to Cement on its Thermal Conductivity and Compressive Strength. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1094, 012047. [Google Scholar] [CrossRef]

- Belhadj, B.; Bederina, M.; Montrelay, N.; Houessou, J.; Quéneudec, M. Effect of substitution of wood shavings by barley straws on the physico-mechanical properties of lightweight sand concrete. Constr. Build. Mater. 2014, 66, 247–258. [Google Scholar] [CrossRef]

- Bederina, M.; Laidoudi, B.; Goullieux, A.; Khenfer, M.; Bali, A.; Quéneudec, M. Effect of the treatment of wood shavings on the physico-mechanical characteristics of wood sand concretes. Constr. Build. Mater. 2009, 23, 1311–1315. [Google Scholar] [CrossRef]

- Coatanlem, P.; Jauberthie, R.; Rendell, F. Lightweight wood chipping concrete durability. Constr. Build. Mater. 2006, 20, 776–781. [Google Scholar] [CrossRef]

- Ganiron, T. Effect of sawdust as fine aggregate in concrete mixture for building construction. Int. J. Adv. Sci. Technol. 2014, 63, 73–82. [Google Scholar] [CrossRef]

- Taoukil, D.; El-Bouardi, A.; Ezbakhe, H.; Ajzoul, T. Thermal proprieties of concrete lightened by wood aggregates. Res. J. Appl. Sci. Eng. Technol. 2011, 3, 113–116. [Google Scholar]

- Benchouaf, A.; Debieb, F.E.; Kadri, H.; Bentchikou, M. Time-dependent behavior of eco-friendly sand concrete using treated wood shavings. Mech. Time-Depend. Mater. 2023, 27, 543–558. [Google Scholar] [CrossRef]

- Dias, S.; Tadeu, A.; Almeida, J.; Humbert, P.; Antonio, J.; de Brito, J.; Pinhao, P. Physical, mechanical, and durability properties of concrete containing wood chips and sawdust: An experimental approach. Buildings 2022, 12, 1277. [Google Scholar] [CrossRef]

- Asadi, I.; Shafigh, P.; Hassan, Z.F.B.A.; Mahyuddin, B. Thermal conductivity of concrete—A review. J. Build. Eng. 2018, 20, 81–93. [Google Scholar] [CrossRef]

- EN 12667:2001; Thermal Performance of Building Materials and Products—Determination of Thermal Resistance by Means of Guarded Hot Plate and Heat Flow Meter Methods—Products of High and Medium Thermal Resistance. European Committee for Standardization: Brussels, Belgium, 2001.

- Yüksel, N. The Review of Some Commonly Used Methods and Techniques to Measure the Thermal Conductivity of Insulation Materials. In Insulation Materials in Context of Sustainability; Almusaed, A., Almssad, A., Eds.; IntechOpen: Rijeka, Croatia, 2016; pp. 113–140. [Google Scholar]

- ASTM C138/C138M; Standard Test Method for Density (Unit Weight), Yield, and Air Content (Gravimetric) of Concrete. ASTM International: West Conshohocken, PA, USA, 2024.

- ASTM C597; Standard Test Method for Pulse Velocity Through Concrete. ASTM International: West Conshohocken, PA, USA, 2023.

- ASTM C293/C293M; Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Center-Point Loading). ASTM International: West Conshohocken, PA, USA, 2016.

- Prusty, J.K.; Patro, S.K. Properties of fresh and hardened concrete using agro-waste as partial replacement of coarse aggregate—A review. Constr. Build. Mater. 2015, 82, 101–113. [Google Scholar] [CrossRef]

- Gavela, S.; Nikoloutsopoulos, N.; Papadakos, G.; Sotiropoulou, A. Combination of compressive strength test and ultrasonic pulse velocity test with acceptable uncertainty. Mater. Des. Process. Commun. 2021, 3, e171. [Google Scholar] [CrossRef][Green Version]

- Mehrez, I.; Hachem, H.; Gheith, R.; Jemni, A. Effect of the incorporation of NaOH-treated wood aggregates on thermal and mechanical properties of plaster mortar. Eur. J. Wood Wood Prod. 2023, 81, 411–420. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).