Sowing Performance of the Seeder Drill for the 2BYG-220 Type Combined Rapeseed Planter under Vibration Conditions

Abstract

Featured Application

Abstract

1. Introduction

2. Materials and Methods

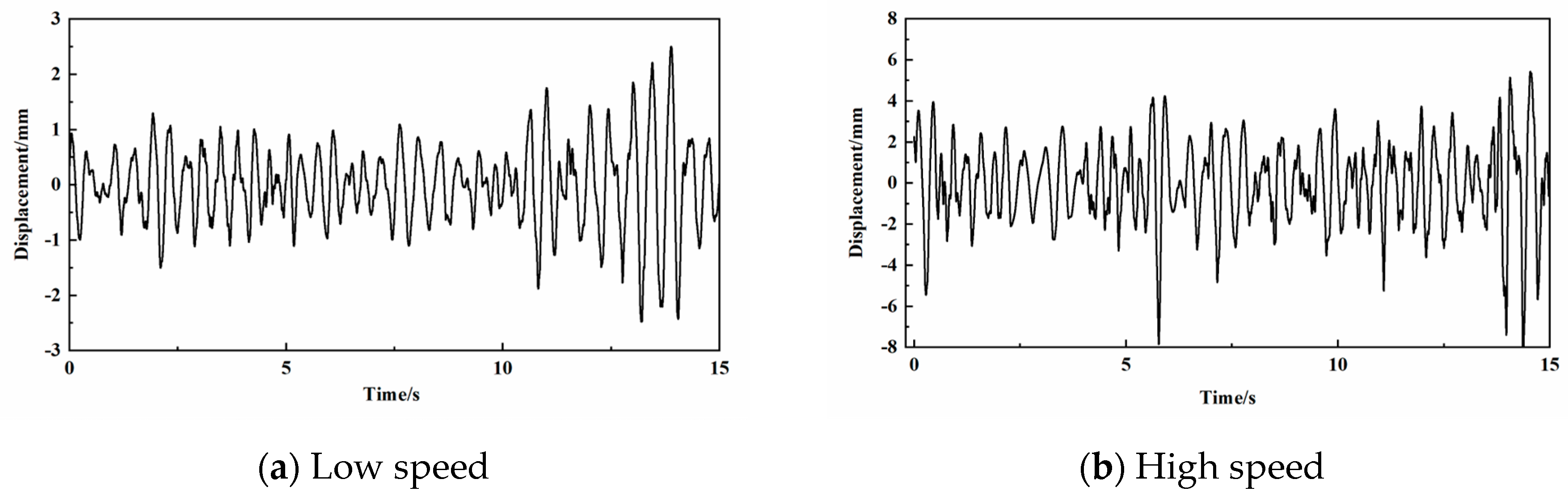

2.1. Field Vibration Data Collection and Analysis

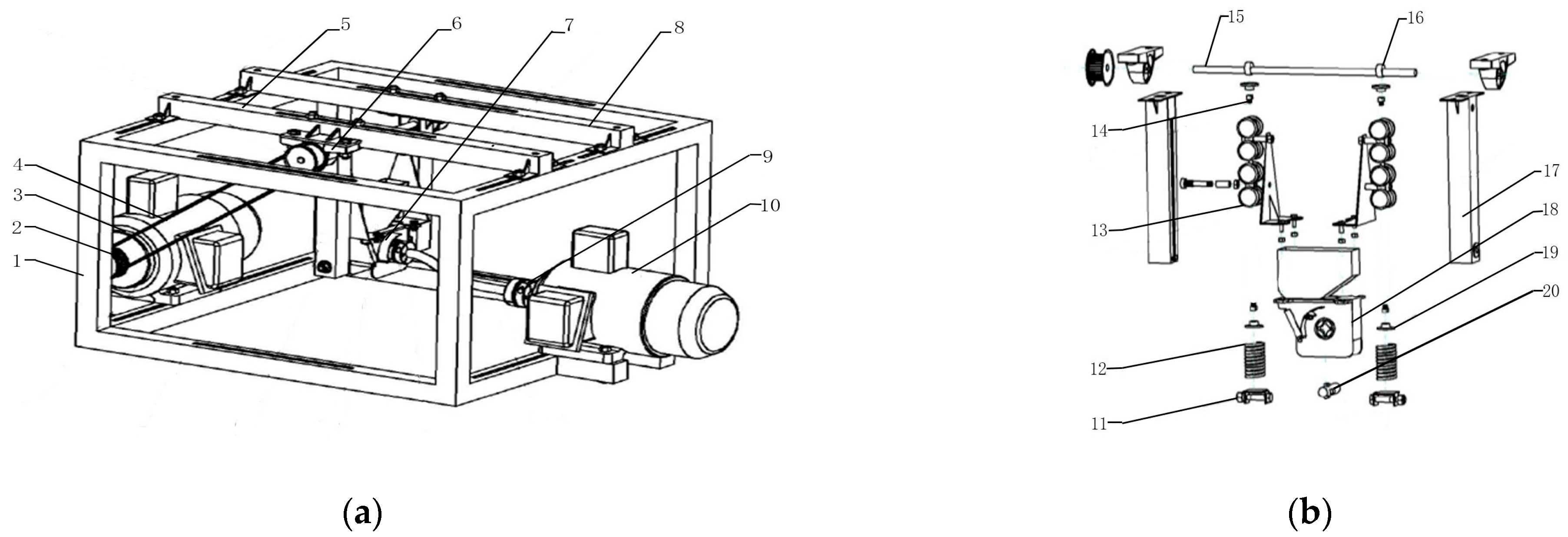

2.2. Test Bench and Method

2.3. Simulation Test by Discrete Element Method

3. Results

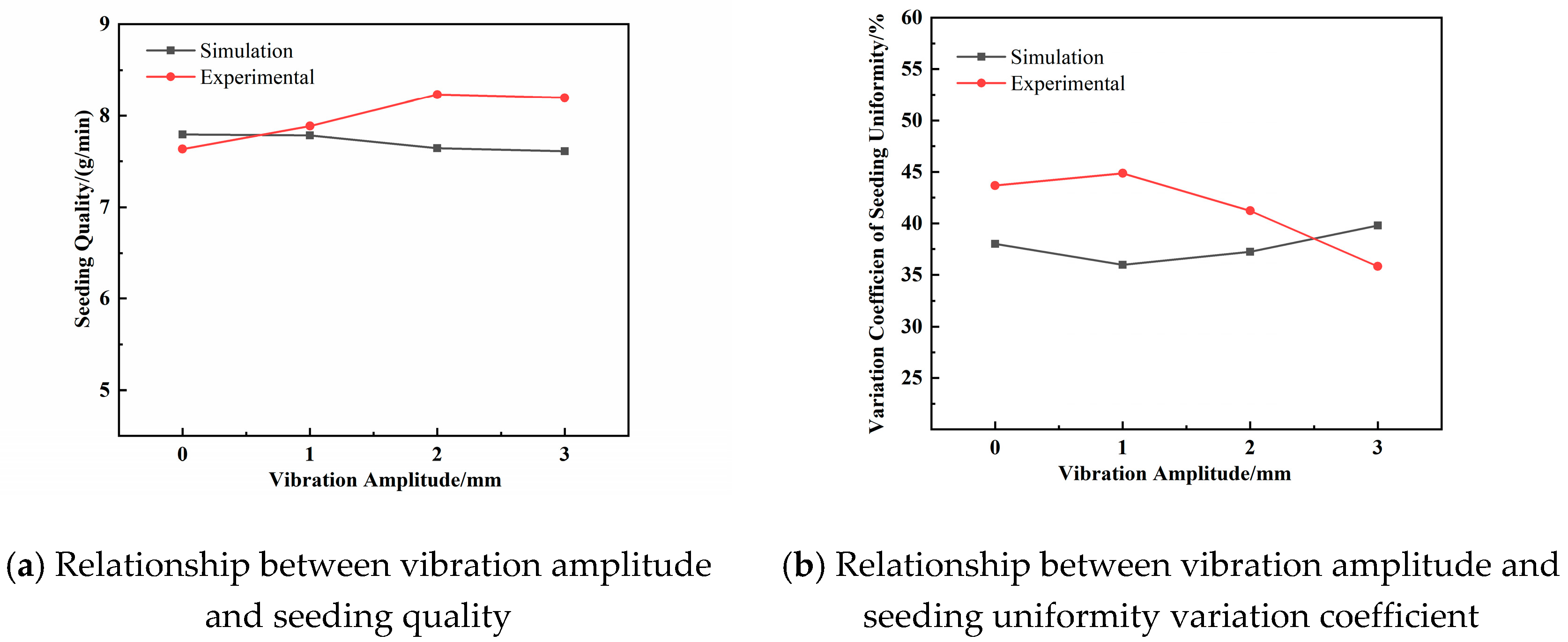

3.1. The Impact of Vibration Amplitude on the Performance of Seeder Drill

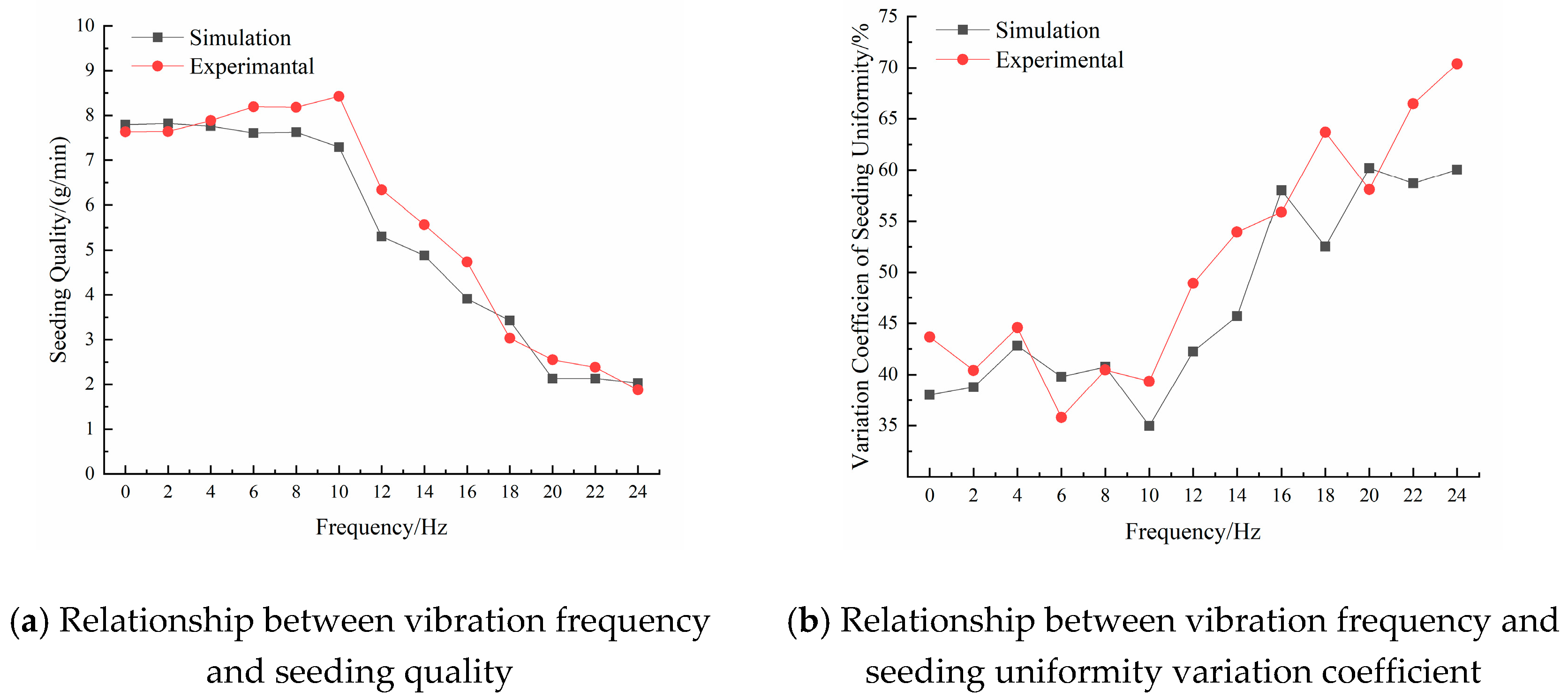

3.2. The Impact of Vibration Frequency on the Performance of the Seeder Drill

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hu, Q.; Hua, W.; Yin, Y.; Zhang, X.; Liu, L.; Zhao, Y.; Qin, L.; Chen, C.; Wang, H. Rapeseed research and production in China. Crop J. 2017, 5, 127–135. [Google Scholar] [CrossRef]

- Liao, Q.; Lei, X.; Liao, Y.; Ding, Y.; Zhang, Q.; Wang, L. Research progress of precision seeding for rapeseed. Trans. CSAM 2017, 48, 1–16. [Google Scholar]

- Li, H.; He, J.; Wang, C.; Yang, W.; Lin, H.; Wang, Q.; Yang, H.; Tan, L. Research Progress on the Development of the Planter Unit for Furrowing Control and the Depth Measurement Technology. Appl. Sci. 2023, 13, 11884. [Google Scholar] [CrossRef]

- Lei, X.; Wu, W.; Chang, C.; Li, T.; Zhou, Z.; Guo, J.; Zhu, P.; Hu, J.; Cheng, H.; Zhou, W.; et al. Seeding Performance Caused by Inclination Angle in a Centralized Seed-Metering Device for Rapeseed. Agriculture 2022, 12, 590. [Google Scholar] [CrossRef]

- Cujbescu, D.; Găgeanu, I.; Persu, C.; Matache, M.; Vlădut, V.; Voicea, I.; Paraschiv, G.; Biris, S.S.; Ungureanu, N.; Voicu, G.; et al. Simulation of Sowing Precision in Laboratory Conditions. Appl. Sci. 2021, 11, 6264. [Google Scholar] [CrossRef]

- Wu, W.; Chang, C.; Li, T.; Hu, H.; Zhou, Z.; Yang, W.; Guo, J.; Zhu, P.; Li, J.; Hu, J.; et al. Seed-Filling Characteristics of a Centralized Seed-Metering Device for Rapeseed Caused by Vibration. Agriculture 2022, 12, 965. [Google Scholar] [CrossRef]

- Yu, D.Y.; He, J.F.; Peng, F.H.; Qian, C.; Zang, Y.; Zhang, M.; Yang, W.; Zeng, G.; Chen, J.; Qin, W.; et al. Study on Vibration Characteristics of Paddy Power Chassis under Different Driving Conditions. Agriculture 2023, 13, 1842. [Google Scholar] [CrossRef]

- Yu, D.; Peng, F.; Zeng, Z.; Zhang, M.; Yang, W.; Zang, Y.; He, J.; Huang, Y.; Wu, Y.; Zhong, W.; et al. Vibrational Dynamics of Rice Precision Hole Seeders and Their Impact on Seed Dispensation Efficacy. Agriculture 2024, 14, 324. [Google Scholar] [CrossRef]

- Wang, Q.; Zhu, L.T.; Li, M.W.; Huang, D.Y.; Jia, H.L.; Zhuang, J. Vibration characteristics of finger clip no-tillage precision corn planter and its effect on seed metering performance. Trans. CSAE 2019, 35, 9–18. [Google Scholar]

- Wang, L.; Liao, Y.T.; Zhang, Q.S.; Yao, L.; Fu, Y.K.; Liao, Q.X. Study on profile chisel trench opener for oil and wheat dual-purpose precision wide-width no-tillage planter. Trans. CSAM 2019, 50, 1–12. [Google Scholar]

- Li, Y.M.; Zhao, Z.; Chen, J. Discrete Element Method Simulation of Seeds Motion in Vibrated Bed of Precision Vacuum Seeder. Trans. CSAM 2009, 40, 56–59+76. [Google Scholar]

- Chen, J.; Zhou, H.; Zhao, Z.; Li, Y.M.; Gong, Z.Q. Analysis of Rice Seeds Motion on Vibrating Plate Using EDEM. Trans. CSAM 2011, 42, 79–83+100. [Google Scholar]

- Chen, J.; Li, Y.M. Study on Seeds Movement Law in Sowing Test Stand with Suction and Vibration. Trans. CSAM 2002, 1, 47–50. [Google Scholar]

- Wang, C.H.; Ma, X. Vibrating Measurement and Analysis of Seeds Layer on Precision Seedling Planting Partsf or Super Hybrid Rice. Trans. CSAM 2010, 41, 68–72. [Google Scholar]

- Zhang, X.D.; Li, C.H.; Li, J.Q.; Zou, M. Mathematic Vibration Model of Spade Punch Planter of Maize. Trans. CSAM 2014, 45, 88–98. [Google Scholar]

- Wu, M.L.; Guan, C.Y.; Tang, C.Z.; Chen, S.Y.; Luo, H.F.; Wang, G.H.; Xie, F.P.; Li, X.; Yang, W.M. Experimental research on 2BYF-6 type no-tillage rape combine seeder in paddy stubble field. Trans. CSAE 2007, 23, 172–175. [Google Scholar]

- Xu, L.Z.; Li, Y.M.; Xun, P.P.; Pang, J. Vibration measurement and analysis of tracked-whole feeding rice combine harvester. Trans. CSAE 2014, 30, 49–55. [Google Scholar]

- Zhang, T.; Liu, F.; Zhao, M.Q.; Liu, Y.Q.; Li, F.L.; Chen, C.; Zhang, Y. Movement law of maize population in seed room of seed metering device based on discrete element method. Trans. CSAE 2016, 32, 27–35. [Google Scholar]

- Wang, J. MATLAB Signal Processing; Tsinghua University Press: Beijing, China, 2017. [Google Scholar]

- Lin, Q. Frequency Weight Power Spectrum Analysis Method Based on Hanning Window Interpolation FFT. China Instrum. 2014, 72–76. [Google Scholar]

- Liu, Y.F.; Wu, Z.L.; Nie, Y.Z.; Liu, F.P.; Wu, M.L. Seeding performance of double hole-wheel seedmeter for rapeseed based on EDEM. J. Hunan Agric. Univ. 2019, 45, 554–559. [Google Scholar]

| Material | Poisson’s Ratio | Shear Modulus/MPa | Density/kg·m3 |

|---|---|---|---|

| Rapeseed | 0.28 | 11.0 | 0.28 |

| PMMA | 0.3 | 177.0 | 11.0 |

| Nylon | 0.4 | 102.0 | 1060 |

| Belt conveyor | 0.32 | 7.8 | 1240 |

| Interaction | Coefficient of Restitution | Coefficient of Static Friction | Coefficient of Rolling Friction |

|---|---|---|---|

| Rapeseed—Rapeseed | 0.6 | 0.5 | 0.1 |

| Rapeseed—PMMA | 0.5 | 0.5 | 0.1 |

| Rapeseed—Nylon | 0.6 | 0.5 | 0.1 |

| Rapeseed—Belt conveyor | 0.001 | 0.999 | 0.999 |

| Test Plan | ||

|---|---|---|

| A | 0, 1, 2, 3 | 6 |

| B | 3 | 2, 4, 6, 8, 10, 12, 14, 16, 18, 20, 22, 24 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Liu, Y.; Wu, M.; Wu, Z. Sowing Performance of the Seeder Drill for the 2BYG-220 Type Combined Rapeseed Planter under Vibration Conditions. Appl. Sci. 2024, 14, 5091. https://doi.org/10.3390/app14125091

Zhang L, Liu Y, Wu M, Wu Z. Sowing Performance of the Seeder Drill for the 2BYG-220 Type Combined Rapeseed Planter under Vibration Conditions. Applied Sciences. 2024; 14(12):5091. https://doi.org/10.3390/app14125091

Chicago/Turabian StyleZhang, Le, Yafu Liu, Mingliang Wu, and Zhili Wu. 2024. "Sowing Performance of the Seeder Drill for the 2BYG-220 Type Combined Rapeseed Planter under Vibration Conditions" Applied Sciences 14, no. 12: 5091. https://doi.org/10.3390/app14125091

APA StyleZhang, L., Liu, Y., Wu, M., & Wu, Z. (2024). Sowing Performance of the Seeder Drill for the 2BYG-220 Type Combined Rapeseed Planter under Vibration Conditions. Applied Sciences, 14(12), 5091. https://doi.org/10.3390/app14125091