Concrete Crack Width Measurement Using a Laser Beam and Image Processing Algorithms

Abstract

1. Introduction

2. Materials and Methods

2.1. Overview of Proposed Method

2.2. Determining the Pixel to Millimeter Conversion Factor Using the Laser Beam

2.3. Image Acquisition

2.4. Image Processing

- Cropping: The images were cropped based on the region of interest, which was the area with the crack pattern that was to be measured. This was conducted to remove unnecessary information from the image that might affect the accuracy of measurements or lead to increased computation costs.

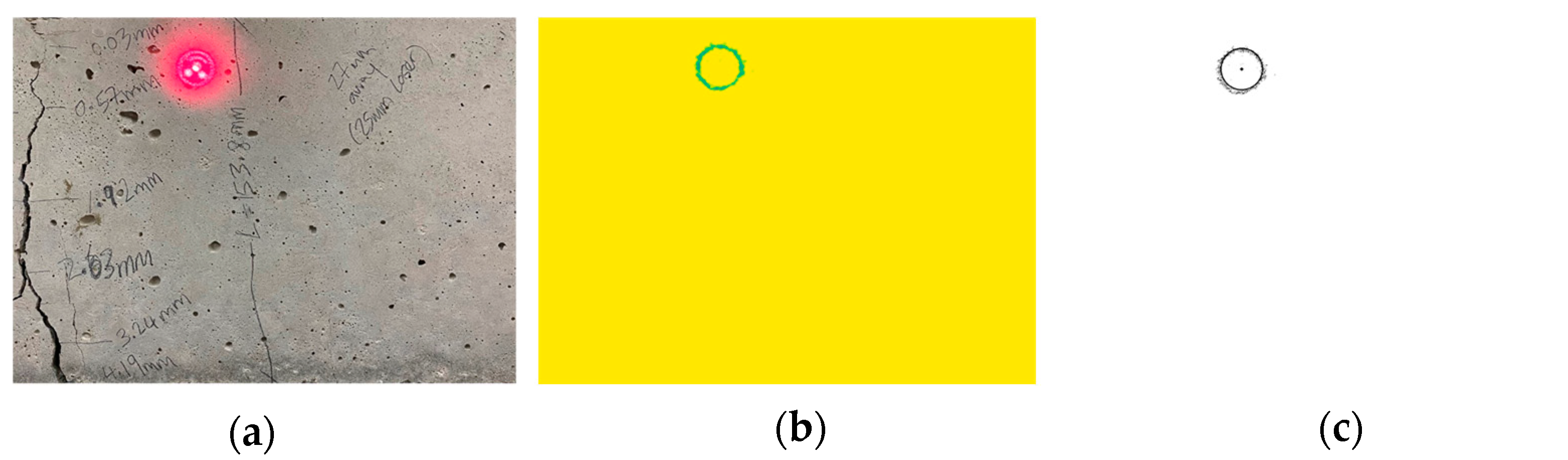

- Laser beam detection and diameter measurement: In order to detect the presence of the laser beam in the images captured in the laboratory and in the field, a color filtering technique was used to isolate the color red in the image. The projected laser beam was red in color, as shown in Figure 3a. The color filtering approach allowed for red pixels in the image to be identified, as shown in Figure 3b. Hough Circle Transform, a technique commonly used in computer vision for the task of circle detection, was then applied to the filtered image. Hough Circle Transform is defined by Equation (6) and detects circles by searching for points () in the image that satisfy Equation (6) for a given set of values of () and . Figure 3c shows the detected circle and the center of the circle.The radius of the detected circle can then be used to determine the diameter of the circle in pixels, , which is inputted into Equation (5), enabling the conversion factor, , to be calculated. This specific approach was chosen because the Hough Circle Transform is a well-established method for detecting circular shapes in images, and it has been widely used in various applications [8,31,32,33]. Additionally, filtering out the color red was the most effective approach in eliminating the chance of other objects that might resemble circles from being falsely detected.

- BGR to grayscale conversion: Images are made up of thousands of pixels, which are typically represented by three color components; red (R), green (G), and blue (B), commonly referred to as RGB. Each pixel has an R, G, and B value between 0 and 255. However, OpenCV reads images in BGR format. Converting the images from BGR to Grayscale simplifies the representation of the pixels into a single value between 0 (black) and 255 (white). The BGR images are converted to grayscale by Equation (7).

- Edge detection and morphological operations: Some of the images containing text on the surface needed removal of the text, as it could easily be mistaken for a crack. The image’s noise was reduced through image filters to improve the visibility of the cracks. These filters were chosen because they are effective in removing noise while preserving the edges of the cracks. The specific parameter values for the filters were chosen through trial and error to achieve the best results. The canny edge detection algorithm [34] was used to detect the cracks in the images by identifying gradient changes in the image intensity. After successful edge detection, morphological opening and closing operations were performed on the image to remove noise and fill small holes in the image. The initial kernel sizes used for each image differed and were chosen at random and fine-tuned until satisfactory results were achieved.

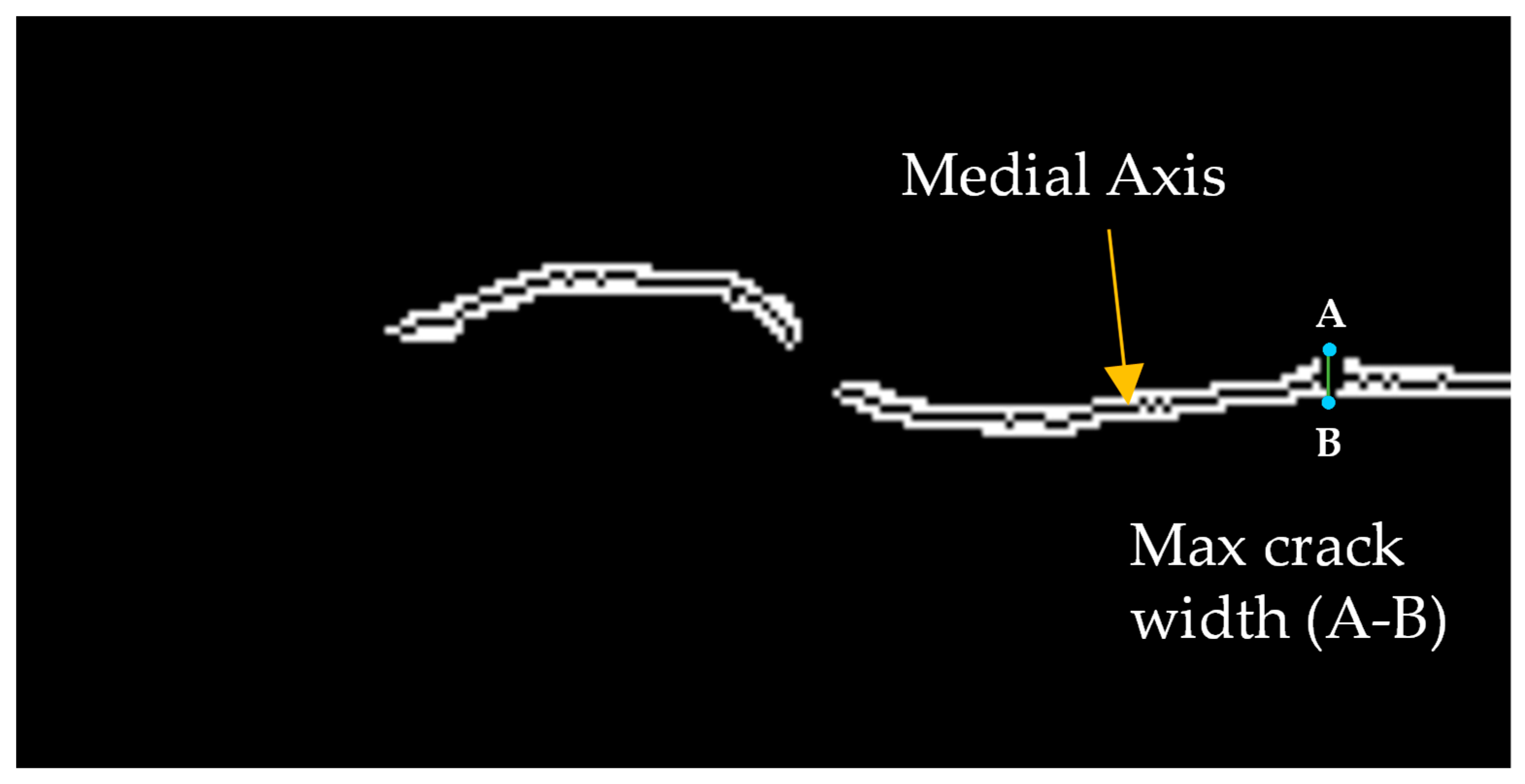

2.5. Crack Width Calculation

3. Results and Discussion

3.1. Crack Segmentation

3.2. Maximum Crack Width Measurement

3.2.1. Accuracy

3.2.2. Effect of Distance Away from Measuring Plane

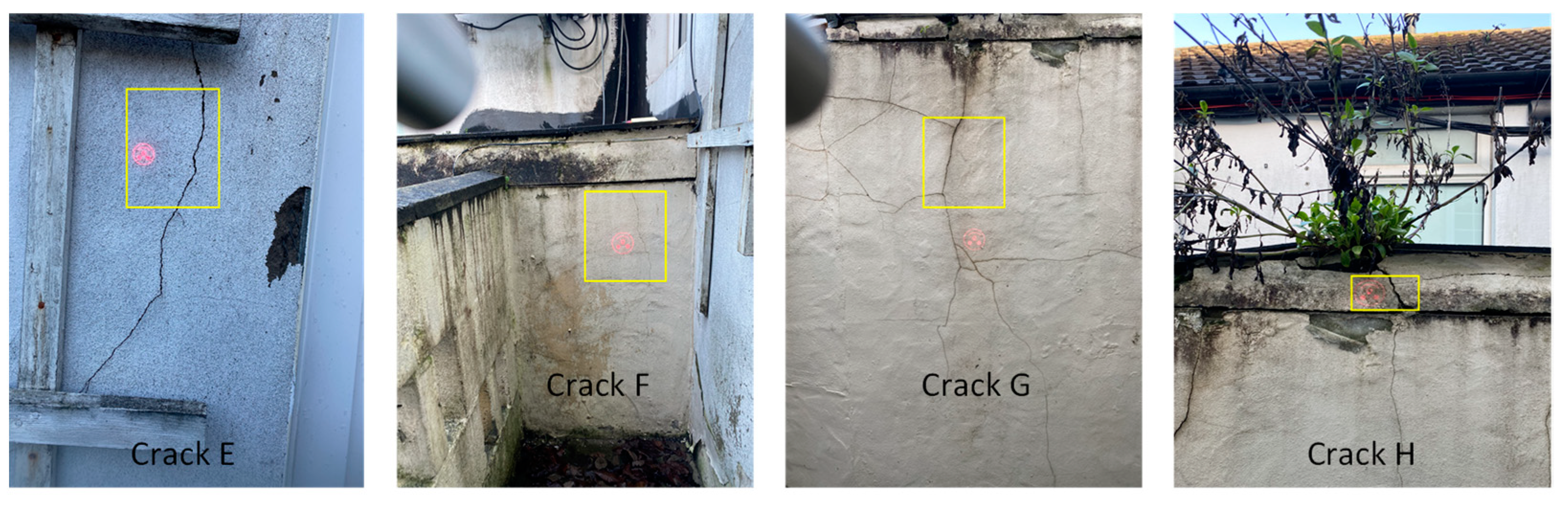

3.2.3. Performance in Outdoor Scenarios

4. Conclusions and Recommendations

- The relationship between the distance to the measurement plane and the diameter of the laser beam is well established.

- The conversion factor, αc, is defined and can be obtained using the established relationship between the distance to the plane of the measurement and the laser beam diameter, in conjunction with the laser beam diameter in pixels resulting from image processing algorithms.

- A unique method for determining the width of concrete cracks in millimeters has been devised using a laser beam and image processing algorithms through the conversion factor.

- The developed method is innovative and produced highly accurate findings that were closely in agreement with the actual crack width.

- The outcomes obtained through this method are suitable for verifying compliance with the allowable limits established in international standards, which are commonly expressed in metric or SI units.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Choudhary, G.K.; Dey, S. Crack Detection in Concrete Surfaces Using Image Processing, Fuzzy Logic, and Neural Networks. In Proceedings of the 2012 IEEE 5th International Conference on Advanced Computational Intelligence, ICACI 2012, Nanjing, China, 18–20 October 2012; pp. 404–411. [Google Scholar] [CrossRef]

- Park, S.E.; Eem, S.H.; Jeon, H. Concrete Crack Detection and Quantification Using Deep Learning and Structured Light. Constr. Build. Mater. 2020, 252, 119096. [Google Scholar] [CrossRef]

- Chen, J.; Xiong, F.; Zhu, Y.; Yan, H. A Crack Detection Method for Underwater Concrete Structures Using Sensing-Heating System with Porous Casing. Measurement 2020, 168, 108332. [Google Scholar] [CrossRef]

- Yang, X.; Li, H.; Yu, Y.; Luo, X.; Huang, T.; Yang, X. Automatic Pixel-Level Crack Detection and Measurement Using Fully Convolutional Network. Comput.-Aided Civ. Infrastruct. Eng. 2018, 33, 1090–1109. [Google Scholar] [CrossRef]

- Munawar, H.S.; Hammad, A.W.A.; Haddad, A.; Soares, C.A.P.; Waller, S.T. Image-Based Crack Detection Methods: A Review. Infrastructures 2021, 6, 115. [Google Scholar] [CrossRef]

- Peng, X.; Zhong, X.; Zhao, C.; Chen, A.; Zhang, T. A UAV-Based Machine Vision Method for Bridge Crack Recognition and Width Quantification through Hybrid Feature Learning. Constr. Build. Mater. 2021, 299, 123896. [Google Scholar] [CrossRef]

- Carrasco, M.; Araya-letelier, G.; Velázquez, R.; Visconti, P. Image-Based Automated Width Measurement of Surface Cracking. Sensors 2021, 21, 7534. [Google Scholar] [CrossRef]

- Dobson, R.J.; Brooks, C.; Roussi, C.; Colling, T. Developing an Unpaved Road Assessment System for Practical Deployment with High-Resolution Optical Data Collection Using a Helicopter UAV. In Proceedings of the 2013 International Conference on Unmanned Aircraft Systems, ICUAS 2013-Conference Proceedings, Atlanta, GA, USA, 28–31 May 2013; pp. 235–243. [Google Scholar] [CrossRef]

- Kim, B.; Cho, S. Automated Vision-Based Detection of Cracks on Concrete Surfaces Using a Deep Learning Technique. Sensors 2018, 18, 3452. [Google Scholar] [CrossRef]

- Chaiyasarn, K.; Buatik, A.; Mohamad, H.; Zhou, M.; Kongsilp, S.; Poovarodom, N. Integrated Pixel-Level CNN-FCN Crack Detection via Photogrammetric 3D Texture Mapping of Concrete Structures. Autom. Constr. 2022, 140, 104388. [Google Scholar] [CrossRef]

- Sankarasrinivasan, S.; Balasubramanian, E.; Karthik, K.; Chandrasekar, U.; Gupta, R. Health Monitoring of Civil Structures with Integrated UAV and Image Processing System. Procedia Comput. Sci. 2015, 54, 508–515. [Google Scholar] [CrossRef]

- Yoon, J.; Shin, H.; Song, M.; Gil, H.; Lee, S. A Crack Width Measurement Method of UAV Images Using High-Resolution Algorithms. Sustainability 2022, 15, 478. [Google Scholar] [CrossRef]

- Li, S.; Zhao, X. Automatic Crack Detection and Measurement of Concrete Structure Using Convolutional Encoder-Decoder Network. IEEE Access 2020, 8, 134602–134618. [Google Scholar] [CrossRef]

- Zhao, W.; Liu, Y.; Zhang, J.; Shao, Y.; Shu, J. Automatic Pixel-Level Crack Detection and Evaluation of Concrete Structures Using Deep Learning. Struct. Control Health Monit. 2022, 29, e2981. [Google Scholar] [CrossRef]

- Khosravani, M.R.; Silani, M.; Weinberg, K. Fracture Studies of Ultra-High Performance Concrete Using Dynamic Brazilian Tests. Theor. Appl. Fract. Mech. 2018, 93, 302–310. [Google Scholar] [CrossRef]

- Kim, H.; Sim, S.H.; Spencer, B.F. Automated Concrete Crack Evaluation Using Stereo Vision with Two Different Focal Lengths. Autom. Constr. 2022, 135, 104136. [Google Scholar] [CrossRef]

- Ai, D.; Jiang, G.; Lam, S.K.; He, P.; Li, C. Computer Vision Framework for Crack Detection of Civil Infrastructure—A Review. Eng. Appl. Artif. Intell. 2023, 117, 105478. [Google Scholar] [CrossRef]

- Fujita, Y.; Hamamoto, Y. A Robust Automatic Crack Detection Method from Noisy Concrete Surfaces. Mach. Vision Appl. 2010, 22, 245–254. [Google Scholar] [CrossRef]

- Kim, H.; Lee, J.; Ahn, E.; Cho, S.; Shin, M.; Sim, S.H. Concrete Crack Identification Using a UAV Incorporating Hybrid Image Processing. Sensors 2017, 17, 2052. [Google Scholar] [CrossRef]

- Sauvola, J.; Pietikäinen, M. Adaptive Document Image Binarization. Pattern Recognit. 2000, 33, 225–236. [Google Scholar] [CrossRef]

- Ioli, F.; Pinto, A.; Pinto, L. UAV PHOTOGRAMMETRY FOR METRIC EVALUATION OF CONCRETE BRIDGE CRACKS. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2022, XLIII-B2-2, 1025–1032. [Google Scholar] [CrossRef]

- Naccache, N.J.; Shinghal, R. An Investigation into the Skeletonization Approach of Hilditch. Pattern Recognit. 1984, 17, 279–284. [Google Scholar] [CrossRef]

- Lee, T.C.; Kashyap, R.L.; Chu, C.N. Building Skeleton Models via 3-D Medial Surface Axis Thinning Algorithms. CVGIP Graph. Model. Image Process. 1994, 56, 462–478. [Google Scholar] [CrossRef]

- Zhang, T.Y.; Suen, C.Y. A Fast Parallel Algorithm for Thinning Digital Patterns. Commun. ACM 1984, 27, 236–239. [Google Scholar] [CrossRef]

- Tomczak, K.; Jakubowski, J.; Fiołek, P. Method for Assessment of Changes in the Width of Cracks in Cement Composites with Use of Computer Image Processing and Analysis. Stud. Geotech. Mech. 2017, 39, 73–80. [Google Scholar] [CrossRef]

- Ito, A.; Aoki, Y.; Hashimoto, S. Accurate Extraction and Measurement of Fine Cracks from Concrete Block Surface Image. IECON Proc. (Ind. Electron. Conf.) 2002, 3, 2202–2207. [Google Scholar] [CrossRef]

- Kim, B.; Cho, S. Image-Based Concrete Crack Assessment Using Mask and Region-Based Convolutional Neural Network. Struct. Control Health Monit. 2019, 26, e2381. [Google Scholar] [CrossRef]

- Kim, H.; Ahn, E.; Cho, S.; Shin, M.; Sim, S.H. Comparative Analysis of Image Binarization Methods for Crack Identification in Concrete Structures. Cem. Concr. Res. 2017, 99, 53–61. [Google Scholar] [CrossRef]

- Jeong, H.; Jeong, B.; Han, M.; Cho, D. Analysis of Fine Crack Images Using Image Processing Technique and High-Resolution Camera. Appl. Sci. 2021, 11, 9714. [Google Scholar] [CrossRef]

- Culjak, I.; Abram, D.; Pribanic, T.; Dzapo, H.; Cifrek, M. A Brief Introduction to OpenCV. In Proceedings of the 2012 Proceedings of the 35th International Convention MIPRO, Opatija, Croatia, 21–25 May 2012. [Google Scholar]

- Supriyanti, R.; Setiawan, B.; Widodo, H.B.; Murdyantoro, E. Detecting Pupil and Iris under Uncontrolled Illumination Using Fixed-Hough Circle Transform. Int. J. Signal Process. 2012, 5, 175–188. [Google Scholar]

- Cornelia, A.; Setyawan, I. Ball Detection Algorithm for Robot Soccer Based on Contour and Gradient Hough Circle Transform. In Proceedings of the 2017 4th International Conference on Information Technology, Computer, and Electrical Engineering, ICITACEE 2017, Semarang, Indonesia, 18–19 October 2017; pp. 136–141. [Google Scholar] [CrossRef]

- Liu, T.; Lei, Y.; Mao, Y. Computer Vision-Based Structural Displacement Monitoring and Modal Identification with Subpixel Localization Refinement. Adv. Civ. Eng. 2022, 2022, 5444101. [Google Scholar] [CrossRef]

- Canny, J. A Computational Approach to Edge Detection. IEEE Trans. Pattern Anal. Mach. Intell. 1986, PAMI-8, 679–698. [Google Scholar] [CrossRef]

- Dorafshan, S.; Thomas, R.J.; Maguire, M. Benchmarking Image Processing Algorithms for Unmanned Aerial System-Assisted Crack Detection in Concrete Structures. Infrastructures 2019, 4, 19. [Google Scholar] [CrossRef]

- Kim, I.H.; Jeon, H.; Baek, S.C.; Hong, W.H.; Jung, H.J. Application of Crack Identification Techniques for an Aging Concrete Bridge Inspection Using an Unmanned Aerial Vehicle. Sensors 2018, 18, 1881. [Google Scholar] [CrossRef] [PubMed]

| Images | Distance to Measuring Plane (mm) | Acquisition Device |

|---|---|---|

| 250 | iPhone Pro Max 11 |

| 460 | Trust Webcam |

| 1150 | iPhone Pro Max 11 |

| References | Method | User Parameters |

|---|---|---|

| [6] | CW (mm) = Pixel width × | [L, f, d, D,] 1 |

| [19,27] | [Dw, Pc, Lf] 2 | |

| [29] | CW (mm) = | [L, f, Ss, SR] 3 |

| Proposed method in this paper | Distance to measuring plane (used to calculate ) |

| Crack ID | Distance to Surface (mm) | Pixel Width (Pixels) | Converted Width (mm) | Actual Width (mm) | Absolute Error (mm) | Relative Error (RE) (%) | |

|---|---|---|---|---|---|---|---|

| IndoorsA | 250 | 0.391 | 10.8 | 4.23 | 4.19 | 0.04 | 0.95 |

| B | 250 | 0.205 | 21.0 | 4.39 | 4.03 | 0.26 | 6.56 |

| C | 460 | 1.071 | 3.162 | 3.39 | 3.54 | 0.15 | 4.30 |

| D | 460 | 1.071 | 1.00 | 1.07 | 1.14 | 0.07 | 6.02 |

| OutdoorsE | 330 | 0.138 | 6.00 | 0.83 | 0.85 | 0.02 | 2.56 |

| F | 1150 | 0.357 | 7.00 | 2.50 | 2.00 | 0.50 | 25.0 |

| G | 1350 | 0.507 | 11.0 | 5.57 | 5.00 | 0.57 | 11.45 |

| H | 950 | 0.351 | 18.86 | 6.62 | 7.10 | 0.48 | 6.82 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nyathi, M.A.; Bai, J.; Wilson, I.D. Concrete Crack Width Measurement Using a Laser Beam and Image Processing Algorithms. Appl. Sci. 2023, 13, 4981. https://doi.org/10.3390/app13084981

Nyathi MA, Bai J, Wilson ID. Concrete Crack Width Measurement Using a Laser Beam and Image Processing Algorithms. Applied Sciences. 2023; 13(8):4981. https://doi.org/10.3390/app13084981

Chicago/Turabian StyleNyathi, Mthabisi Adriano, Jiping Bai, and Ian David Wilson. 2023. "Concrete Crack Width Measurement Using a Laser Beam and Image Processing Algorithms" Applied Sciences 13, no. 8: 4981. https://doi.org/10.3390/app13084981

APA StyleNyathi, M. A., Bai, J., & Wilson, I. D. (2023). Concrete Crack Width Measurement Using a Laser Beam and Image Processing Algorithms. Applied Sciences, 13(8), 4981. https://doi.org/10.3390/app13084981