Analysis and Visualization of Production Bottlenecks as Part of a Digital Twin in Industrial IoT

Abstract

:1. Introduction

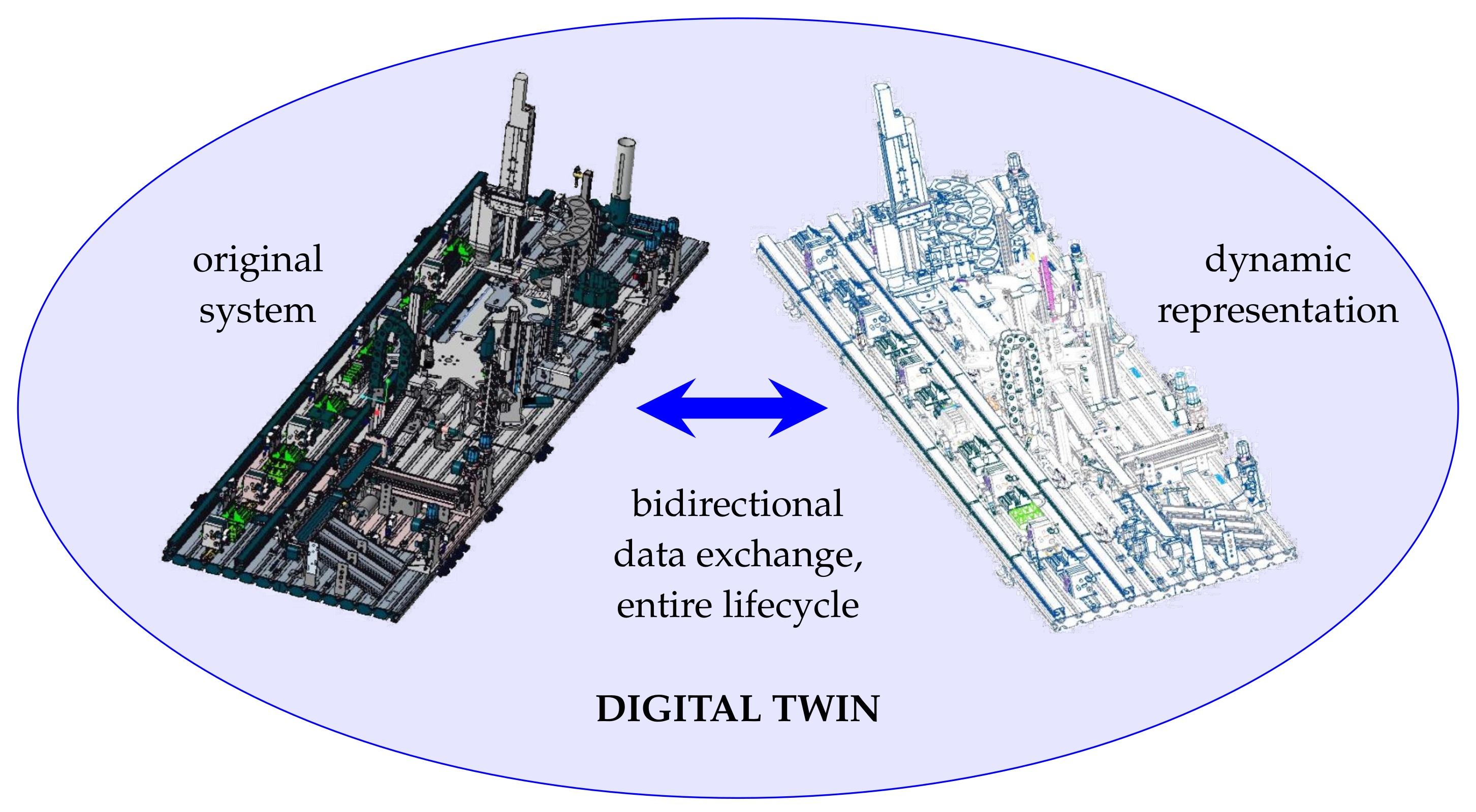

- DTs are dynamic virtual representations of real technical systems;

- DTs are connected to the real technical system over the entire life-cycle;

- Data are exchanged bidirectionally between DTs and the real technical system.

2. Literature Review

2.1. Bottleneck Detection in Manufacturing Systems

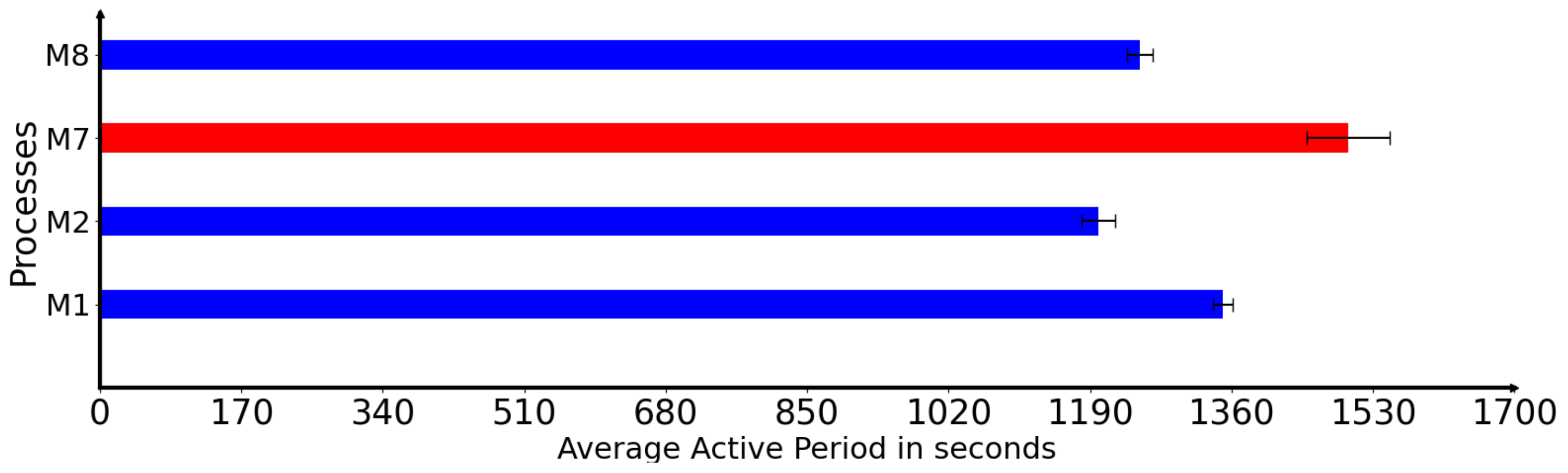

- At any given moment, the process with the longest uninterrupted active period is the bottleneck.

- During the overlap at the end of the current longest uninterrupted active period and the next one, the bottleneck shifts from one process to another.

| Algorithm 1: Algorithm for the Active Period Method |

| Input: time series of active periods |

| Output: list of bottlenecks |

| 1: sort list by starting times |

| 2: for do |

| 3: if then |

| 4: pick entry with longest duration, add to |

| 5: update , |

| 6: else |

| 7: pick entry with longest duration |

| 8: if then |

| 9: add to |

| 10: update , |

| 11: else if then |

| 12: add to |

| 13: update , |

| 14: end if |

| 15: end if |

| 16: end for |

| 17: return |

2.2. Evaluation of Bottleneck Detection Methods

- Independent of production layout;

- Requires time series data only;

- Implementable in a small prototype;

- Delivers an interpretable metric.

3. Bottleneck Detection Method by the Active Period Method

3.1. Boundaries of Active Period Method

- Correct interpretation of the operating states. Often, operating states are not recorded correctly. As an example, concrete failure states are often not detected by the system automatically but entered manually at the end of a shift. These errors have to be corrected during preprocessing, which is a time-consuming task.

- Usage of the job schedule. In case of a task change, it is important to set the operating state to free capacity in case the next task does not start immediately. Unsubstantiated downtimes need to be investigated.

- Understanding of the production process. Without any understanding of the product profile, the production layout and structure or special features of the production process, the results of the Active Period Method can hardly be understood.

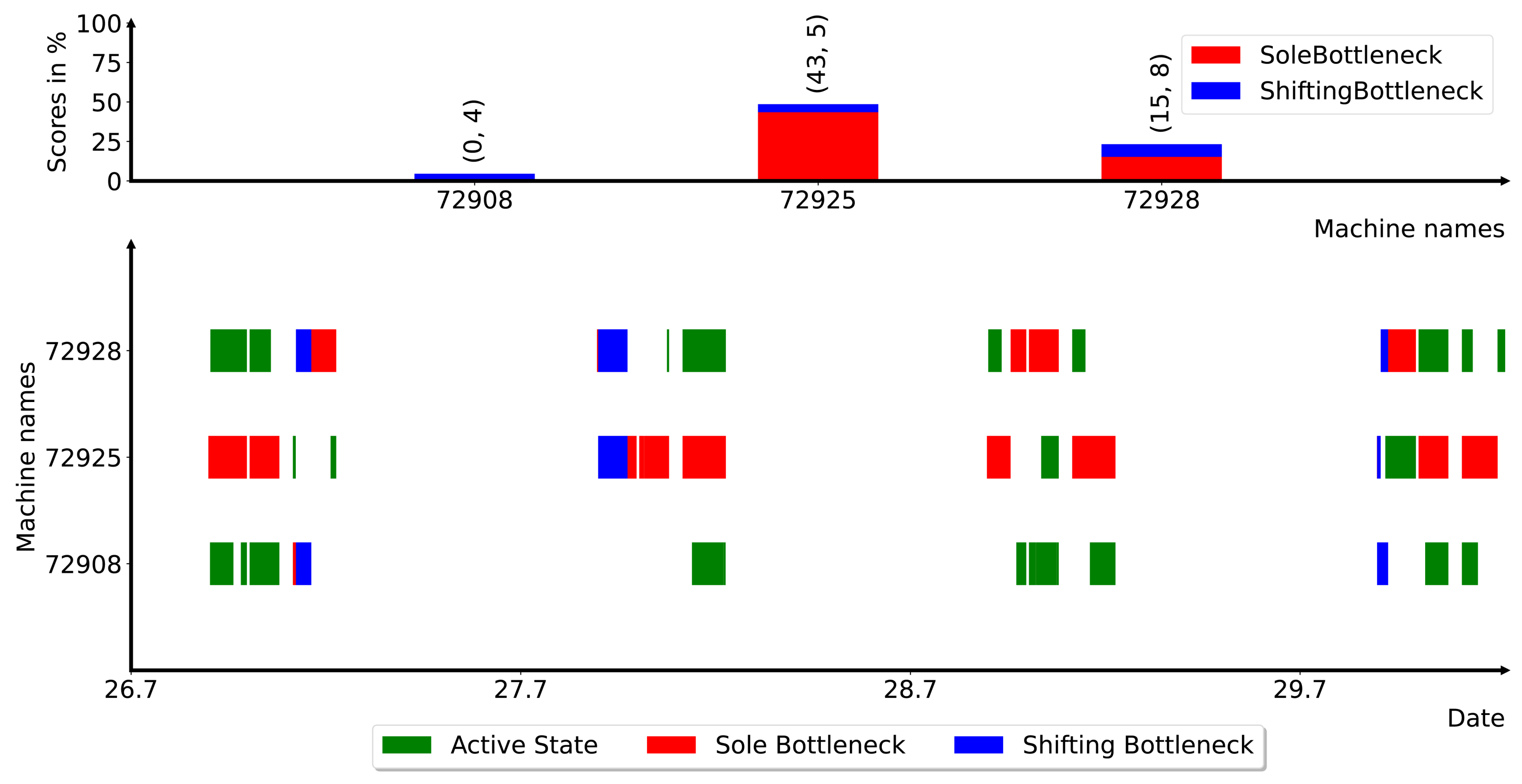

3.2. Results

- General result. The Active Period Method is an appropriate approach to supervise and measure the overall management of a production system. In addition to the sole/shifting bottleneck probabilities, the time series of active and inactive states constitutes a valuable input for production management. Together, these two results provide meaningful and expressive information to judge production quality. In general, the results mirror the experts’ personal opinion and experience on the production system.

- Expressiveness of results and visualizations. The results and presented visualizations are judged as expressive and a good foundation for discussions of potential production system improvements.

- Selection of relevant machines. It should be evaluated whether it is always the best solution to use all available machines as input to the Active Period Method, or if it is better to use an appropriately defined subset instead.

- Observation period. Different observation periods may well affect the results and the quality of the bottleneck prediction of the Active Period Method.

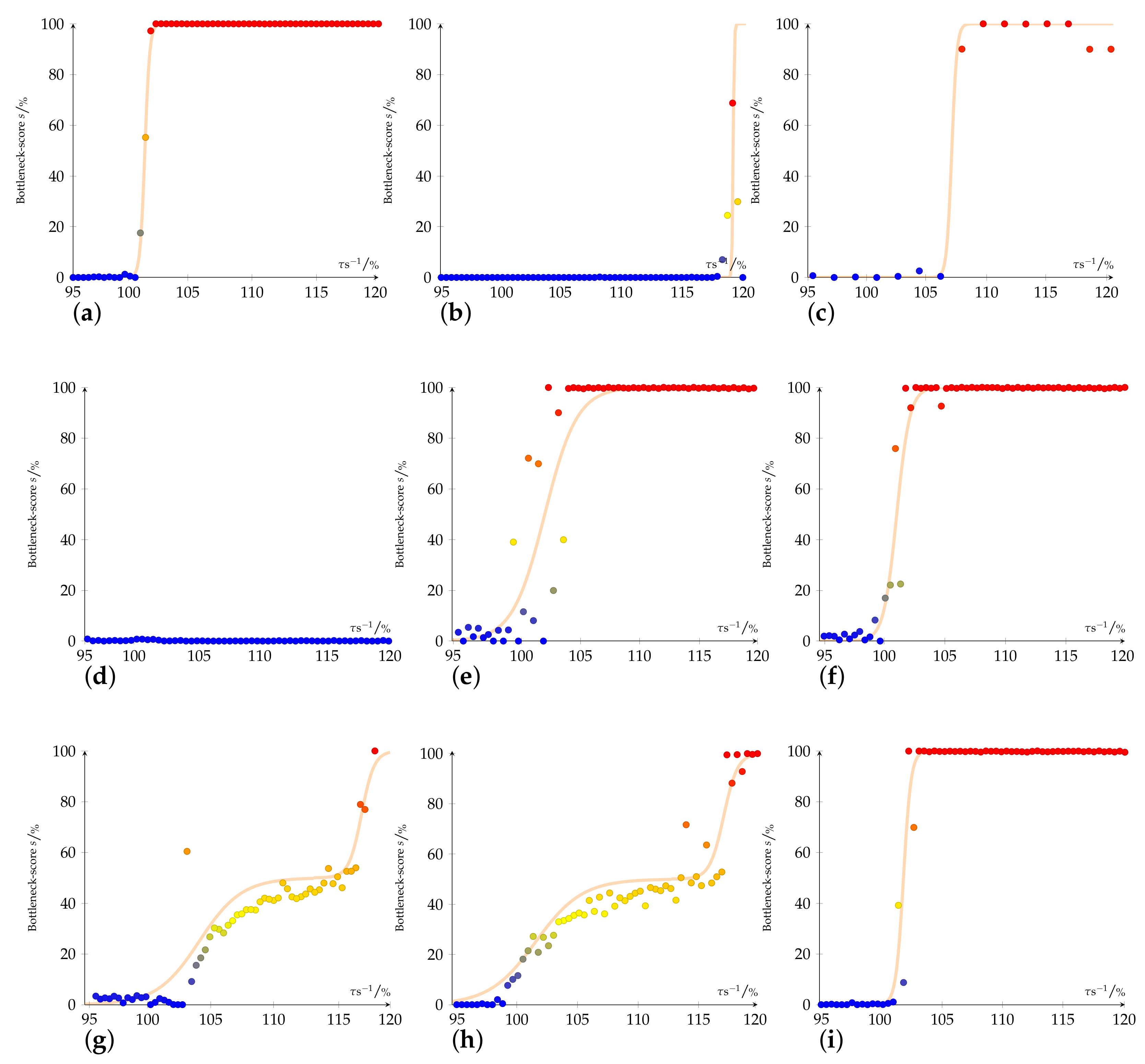

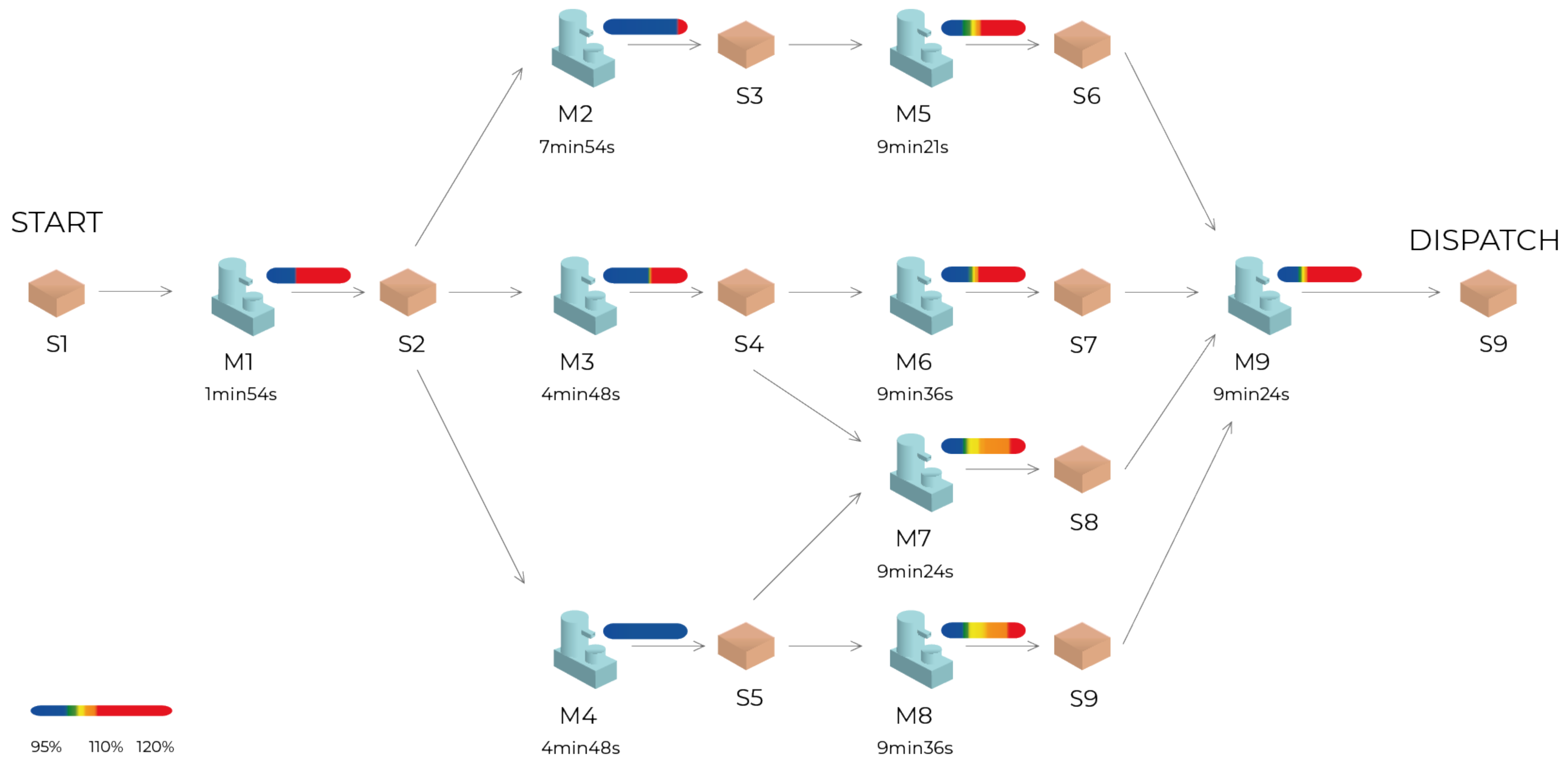

4. Process Heatmap

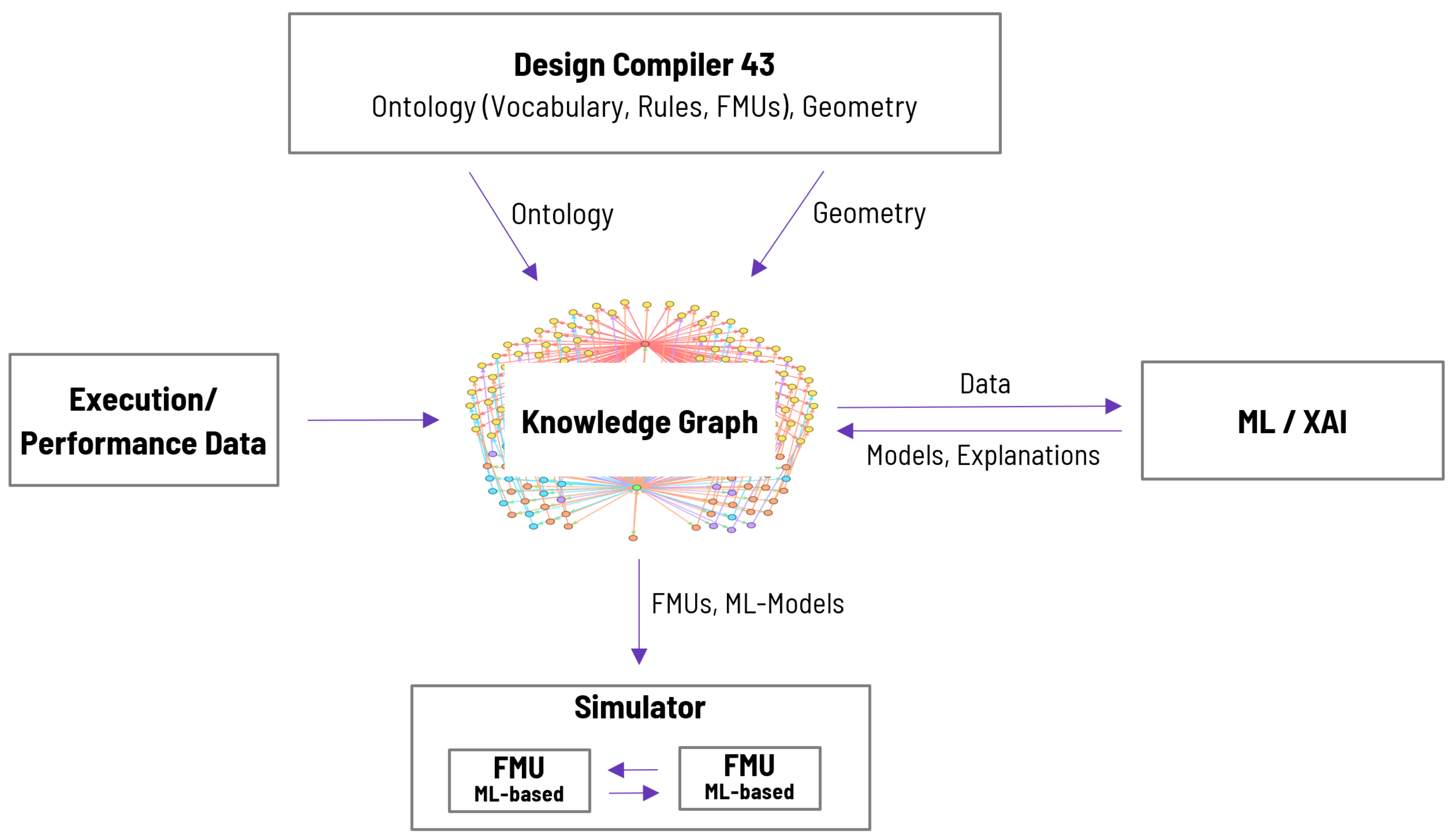

5. Integration of Analysis Results into a Digital Twin

6. Summary

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| DC43DG | Design Compiler 43 Design Language |

| DT | Digital Twin |

| FMI | Functional Mockup Interface |

| FMU | Functional Mockup Unit |

| GraphDB | Graph Database |

| GraphML | Graph Description XML |

| IoT | Internet of Things |

| IIoT | Industrial Internet of Things |

| MBSE | Model based systems engineering |

| ML | Machine Learning |

| OWL | Web Ontology Language |

| SPARQL | SPARQL Protocol and RDF Query Language |

| VDI | Verein Deutscher Ingenieure |

| XAI | Explainable Artificial Intelligence |

| XMI | XML-based Meta Data Interface |

References

- Koohang, A.; Sargent, C.S.; Nord, J.H.; Paliszkiewicz, J. Internet of Things (IoT): From awareness to continued use. Int. J. Inf. Manag. 2022, 62, 102442. [Google Scholar] [CrossRef]

- Ben-Daya, M.; Hassini, E.; Bahroun, Z. Internet of things and supply chain management: A literature review. Int. J. Prod. Res. 2019, 57, 4719–4742. [Google Scholar] [CrossRef] [Green Version]

- Trauer, J.; Mutschler, M.; Mörtl, M.; Zimmermann, M. Challenges in Implementing Digital Twins—A Survey. In Proceedings of the International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, St. Louis, MI, USA, 14–17 August 2022; Volume 2. [Google Scholar] [CrossRef]

- Tao, F.; Cheng, J.; Qi, Q.; Zhang, M.; Zhang, H.; Sui, F. Digital twin-driven product design, manufacturing and service with big data. Int. J. Adv. Manuf. Technol. 2018, 94, 3563–3576. [Google Scholar] [CrossRef]

- Hallstedt, S.I.; Isaksson, O.; Öhrwall Rönnbäck, A. The Need for New Product Development Capabilities from Digitalization, Sustainability and Servitization Trends. Sustainability 2020, 12, 10222. [Google Scholar] [CrossRef]

- Trauer, J.; Schweigert-Recksiek, S.; Engel, C.; Spreitzer, K.; Zimmermann, M. What is a digital twin?—definitions and insights from an industrial case study in technical product development. Proc. Des. Soc. Design Conf. 2020, 1, 757–766. [Google Scholar] [CrossRef]

- VDI/VDE. VDI/VDE 2006: Development of Cyber-Physical Mechatronic Systems (CPMS); Beuth: Berlin, Germany, 2020. [Google Scholar]

- Pulm, U.; Stetter, R. Systemic Mechatronic Function Development. Proc. Des. Soc. 2021, 1, 2931–2940. [Google Scholar] [CrossRef]

- Graessler, I.; Hentze, J. The new V-Model of VDI 2206 and its validation. at-Automatisierungstechnik 2020, 68, 312–324. [Google Scholar] [CrossRef]

- ISO 23247-1:2021; Automation Systems and Integration—Digital Twin Framework for Manufacturing. International Organization for Standardization: Brussels, Belgium, 2021.

- Grieves, M. Digital Twin: Manufacturing Excellence through Virtual Factory Replication. White Pap. 2015, 1, 1–7. [Google Scholar]

- Roser, C.; Nakano, M.; Tanaka, M. A practical bottleneck detection method. In Proceedings of the 2001 winter simulation conference (Cat. No. 01CH37304), Arlington, VA, USA, 9–12 December 2001; Volume 2, pp. 949–953. [Google Scholar] [CrossRef]

- Roser, C.; Nakano, M.; Tanaka, M. Time Shifting Bottlenecks in Manufacturing. In Proceedings of the Fourth International Conference on the Advanced Mechatronics (ICAM’04), Asahikawa, Japan, 3–5 October 2004. [Google Scholar]

- Li, L.; Chang, Q.; Ni, J.; Xiao, G.; Biller, S. Bottleneck Detection of Manufacturing Systems Using Data Driven Method. In Proceedings of the 2007 IEEE International Symposium on Assembly and Manufacturing, Ann Arbor, MI, USA, 22–25 July 2007; pp. 76–81. [Google Scholar] [CrossRef]

- Roser, C.; Lorentzen, K.; Deuse, J. Reliable Shop Floor Bottleneck Detection for Flow Lines through Process and Inventory Observations. Procedia CIRP 2014, 19, 63–68. [Google Scholar] [CrossRef] [Green Version]

- Thomas, T.E.; Koo, J.; Chaterji, S.; Bagchi, S. Minerva: A reinforcement learning-based technique for optimal scheduling and bottleneck detection in distributed factory operations. In Proceedings of the 2018 10th International Conference on Communication Systems & Networks (COMSNETS), Bengaluru, India, 3–7 January 2018; pp. 129–136. [Google Scholar]

- Sengupta, S.; Das, K.; VanTil, R.P. A new method for bottleneck detection. In Proceedings of the 2008 Winter Simulation Conference, Miami, FL, USA, 7–10 December 2008; pp. 1741–1745. [Google Scholar] [CrossRef]

- Subramaniyan, M.; Skoogh, A.; Salomonsson, H.; Bangalore, P.; Bokrantz, J. A data-driven algorithm to predict throughput bottlenecks in a production system based on active periods of the machines. Comput. Ind. Eng. 2018, 125, 533–544. [Google Scholar] [CrossRef]

- Roser, C.; Subramaniyan, M.; Skoogh, A.; Johansson, B. An Enhanced Data-Driven Algorithm for Shifting Bottleneck Detection. In Proceedings of the Advances in Production Management Systems. Artificial Intelligence for Sustainable and Resilient Production Systems, Nantes, France, 5–9 September 2021; Dolgui, A., Bernard, A., Lemoine, D., von Cieminski, G., Romero, D., Eds.; Springer International Publishing: Cham, Switzerland, 2021; pp. 683–689. [Google Scholar]

- Leporis, M.; Králová, Z. A simulation approach to production line bottleneck analysis. In Proceedings of the International Conference Cybernetics and Informatics, Bilbao, Spain, 1–2 September 2010; pp. 13–22. [Google Scholar]

- Neumaier, M.; Kranemann, S.; Kazmeier, B.; Rudolph, S. Automated Piping in an Airbus A320 Landing Gear Bay Using Graph-Based Design Languages. Aerospace 2022, 9, 140. [Google Scholar] [CrossRef]

- Zech, A.; Stetter, R.; Rudolph, S.; Till, M. Capturing the Design Rationale in Model-Based Systems Engineering of Geo-Stations. Proc. Des. Soc. 2022, 2, 2015–2024. [Google Scholar] [CrossRef]

- Došilović, F.K.; Brčić, M.; Hlupić, N. Explainable artificial intelligence: A survey. In Proceedings of the 2018 41st International Convention on Information and Communication Technology, Electronics and Microelectronics (MIPRO), Opatija, Croatia, 21–25 May 2018; pp. 210–215. [Google Scholar]

- Larsen, P.G.; Fitzgerald, J.; Woodcock, J.; Fritzson, P.; Brauer, J.; Kleijn, C.; Lecomte, T.; Pfeil, M.; Green, O.; Basagiannis, S.; et al. Integrated tool chain for model-based design of Cyber-Physical Systems: The INTO-CPS project. In Proceedings of the 2016 2nd International Workshop on Modelling, Analysis and Control of Complex CPS (CPS Data), Vienna, Austria, 11 April 2016; pp. 1–6. [Google Scholar]

- Elsheikh, A.; Awais, M.U.; Widl, E.; Palensky, P. Modelica-enabled rapid prototyping of cyber-physical energy systems via the functional mockup interface. In Proceedings of the 2013 Workshop on Modeling and Simulation of Cyber-Physical Energy Systems (MSCPES), Berkeley, CA, USA, 20 May 2013; pp. 1–6. [Google Scholar]

- Rackauckas, C.; Gwozdz, M.; Jain, A.; Ma, Y.; Martinuzzi, F.; Rajput, U.; Saba, E.; Shah, V.B.; Anantharaman, R.; Edelman, A.; et al. Composing modeling and simulation with machine learning in Julia. In Proceedings of the 2022 Annual Modeling and Simulation Conference (ANNSIM), San Diego, CA, USA, 18–20 July 2022; pp. 1–17. [Google Scholar]

- Falay, B.; Wilfling, S.; Alfalouji, Q.; Exenberger, J.; Schranz, T.; Legaard, C.M.; Leusbrock, I.; Schweiger, G. Coupling physical and machine learning models: Case study of a single-family house. In Proceedings of the Modelica Conferences, Linköping, Sweden, 20–24 September 2021; pp. 335–341. [Google Scholar]

| Input | Output | Bottleneck Detection Method |

|---|---|---|

| Time series data of active periods | Estimation of Sole and Shifting Bottleneck machines relative to observation period | Active Period Method [13] |

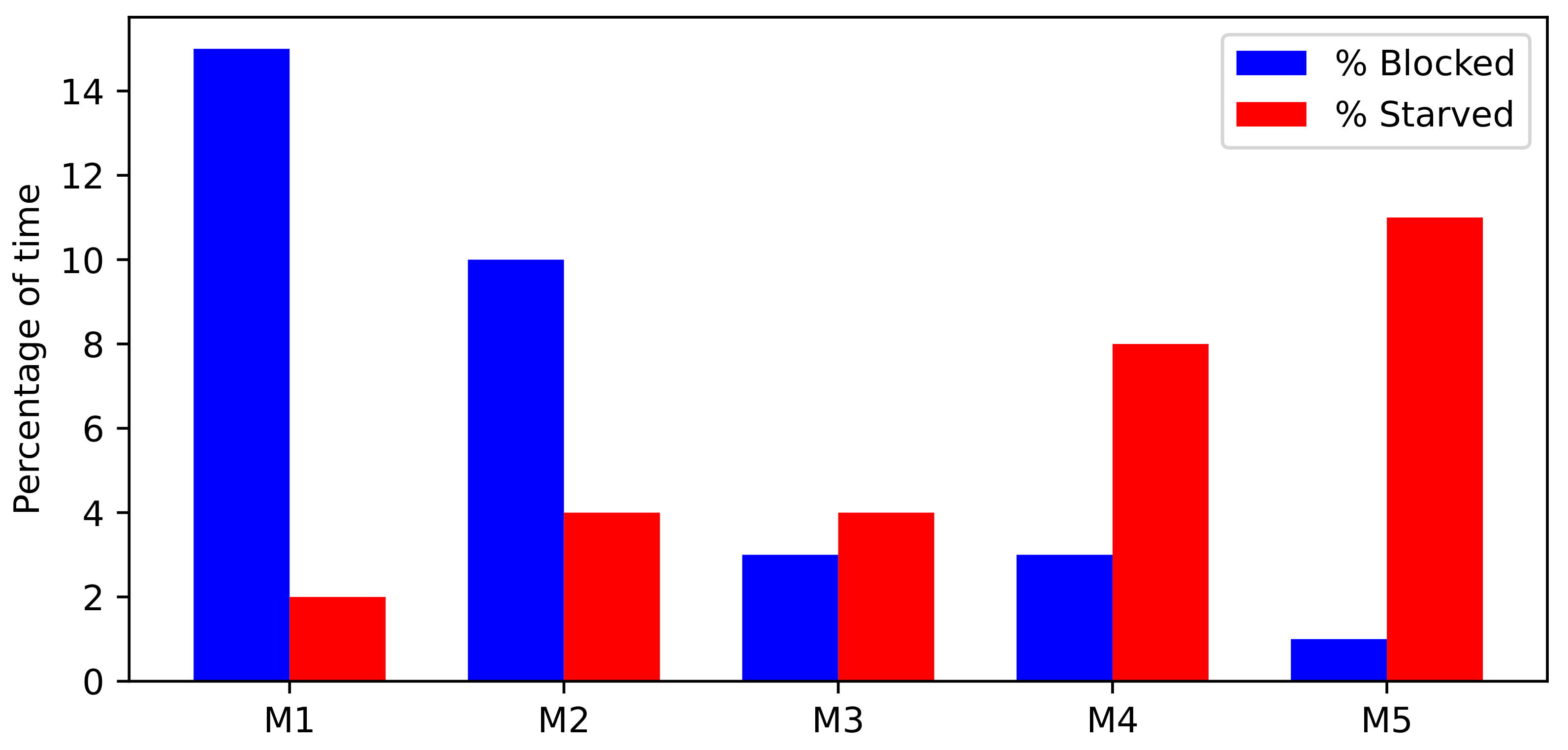

| Time series data of blockage and starvation of machines | Identification of bottlenecks through starvation of downstream machines and blockage of upstream machines | Turning Point Method [14] |

| Time series data of active periods | Average of active periods for each machine | Average Active Period Method [12] |

| Observations of process, inventory states | Ranking of bottleneck sets | Shop Floor Bottleneck Detection [15] |

| Arrival of Jobs | Identification of bottleneck machine pools through reinforcement learning | MINERVA: A Reinforcement Learning-based Technique [16] |

| Percentage | Color |

|---|---|

| 0–20 | blue |

| 20–40 | green |

| 40–60 | yellow |

| 60–80 | orange |

| 80–00 | red |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arff, B.; Haasis, J.; Thomas, J.; Bonenberger, C.; Höpken, W.; Stetter, R. Analysis and Visualization of Production Bottlenecks as Part of a Digital Twin in Industrial IoT. Appl. Sci. 2023, 13, 3525. https://doi.org/10.3390/app13063525

Arff B, Haasis J, Thomas J, Bonenberger C, Höpken W, Stetter R. Analysis and Visualization of Production Bottlenecks as Part of a Digital Twin in Industrial IoT. Applied Sciences. 2023; 13(6):3525. https://doi.org/10.3390/app13063525

Chicago/Turabian StyleArff, Benjamin, Julian Haasis, Jochen Thomas, Christopher Bonenberger, Wolfram Höpken, and Ralf Stetter. 2023. "Analysis and Visualization of Production Bottlenecks as Part of a Digital Twin in Industrial IoT" Applied Sciences 13, no. 6: 3525. https://doi.org/10.3390/app13063525

APA StyleArff, B., Haasis, J., Thomas, J., Bonenberger, C., Höpken, W., & Stetter, R. (2023). Analysis and Visualization of Production Bottlenecks as Part of a Digital Twin in Industrial IoT. Applied Sciences, 13(6), 3525. https://doi.org/10.3390/app13063525