Featured Application

Extrusion-cooked corn-based crisps with apple, white mulberry, goji berry, elderberry or/and blackberry addition may be attractive and natural products popular in the snack food market. The results presented in the paper reveal the effects of fruit type and amount and processing screw speed on expansion, bulk density, textural characteristics and color profiles of ready-to-eat snack products. The recommended levels of fruit additives allow selecting appropriate recipes suitable for being scaled up to industrial levels.

Abstract

The market of extruded products is constantly growing and the incorporation of fruit items into their recipe, can made a crisp snack product a healthy one of acceptable flavor. The subject of this work is the evaluation of the effects of production screw speed, fruit type and amount on selected physical properties (expansion index, bulk density, water absorption and solubility, texture profile and color balance) of corn-based gluten-free crisps supplemented with various amounts (0–20%) of dried fruits (apple, white mulberry, goji berry, elderberry, blackberry) processed at variable screw speeds (80, 100 and 120 rpm). This work demonstrates that it is possible to obtain marketable extruded snacks with natural color coming from the incorporated dried fruits and with adequate expansion and texture if addition was up to 10% of all the tested fruits. Moreover, very good aeration, crispy texture and acceptable natural color was found if dried elderberry and blackberry were added to snacks even at 15 and 20%. Application of 15 or 20% of apple, white mulberry and goji berries showed similar color profiles and caused decrease in texture and expansion of snacks. The rotational screw speed effect differs significantly only in hardness and cutting force of the supplemented corn crisps.

Keywords:

apple; white mulberry; goji berry; elderberry; blackberry; snacks; extrusion; texture; color 1. Introduction

The food market has grown significantly in recent times, especially in term of “clean label” healthy snacks [1]. Modern applied food science and technology allows to process food products with reduced fat and sugar content, as well as dedicated to those following vegetarian and vegan lifestyles [2]. Special group of consumers need to have dedicated diet according to gluten intolerance or celiac disease, that causes adverse symptoms after eating gluten-containing foods. Currently, the only effective treatment for celiac disease is a lifetime gluten-free diet [3,4]. The range of gluten-free products, however, is constantly expanding, and their availability for people on a gluten-free diet is also improving. One of the solution to prevent low nutrition quality of gluten-free products may be food supplementation and application of modern techniques of processing. Extrusion is a suitable process for producing snack foods for consumers suffering from celiac disease since starch is the main component providing the desirable expanded structure in the final product [5].

Extrusion-cooking is a high-temperature process that brings about a short processing time with regard to raw materials of plant and/or animal origin [6]. Through the extrusion-cooking, it is possible to produce breakfast cereals, instant noodles, expanded snacks, instant porridges and gruels, soy textures, as well as biodegradable materials [7]. The extrusion technique enables obtaining new products with specific characteristics from various raw materials and additives, also gluten-free [6,8,9,10,11,12]. Enhancing a base material with fruits, vegetables, herbs, seeds or by-products of the agri-food industry increases the nutritional value of the extruded food end-product by providing antioxidants, polyphenols, vitamins and minerals [12]. Moreover, the choice of process conditions allows preservation of their nutritional value and may increase the bioavailability of some bioactive ingredients as confirmed by the studies of Amer and Rizk [13], whose work showed an increase in the content of phenolic compounds in food end-products extruded from base material and plant additives.

Corn, useful to produce gluten-free food, is characterized by a high starch content, but it is low in flavonoids, folic acid, fiber and microelements [14]. Corn-based crisps made by the extrusion-cooking are products especially liked by children [15]. To enrich the gluten-free snacks other ingredients fresh, dried or lyophilized powders of fruit, vegetable or herbs are added to the raw material mix [13,14,15]. The high temperature in the extruder does not affect the content of bioactive ingredients, because the processing time is short, but it causes many physicochemical changes in processed blends [6,8,9,10]. Enriched corn-based crisps are a suitable snack also for people with gluten intolerance [16].

Fruits and vegetables can be easily added to a daily diet as valuable additives that improve the nutritional value of food products, but also affect the color or texture of supplemented products [9,10,11,13,16,17]. Apple is an excellent fruit due to its availability, high nutritional value, and beneficial effect on human health [18,19]. The presence of valuable ingredients in mulberry fruit makes this plant suitable for placing in the category of functional food [20]. Goji berries have gained popularity as a superfruit, improving well-being and metabolism because of the high content of antioxidants and vitamin C [21]. Taking into account the health-promoting properties of elderberry fruit and its dark color, it will increase its importance as a beneficial component of any functional food intended for healthy diet [22,23]. Blackberry fruits can be considered as natural functional food or superfruits, especially as an additive and natural colorant to food products [24]. Hence, the growing awareness of the potential benefits of fresh or dry fruit consumption is due to nutritional profile and anticancer, antioxidant, and anti-inflammatory [25]. For this reason, additives such as apple, mulberry, goji berry, elderberry or blackberry are proposed as valuable supplements to extruded products [11,26,27].

Such enriching additives can, however, have a varied influence on the appearance and texture of snack products [28]. Although the nutritional properties are important, the physical and organoleptic properties of the snacks are important as the expansion ratio, density, texture, and appearance. These parameters are related to the proportion and type of the available starch which affects the number and size of air cells developed during extrusion [5,6]. Both the expansion and structure of extruded products depend on starch gelatinization, which is affected by processing conditions and raw material composition [28,29]. Pectin coming from dry fruits decreased radial expansion less than wheat fiber [17]. Yanniotis et al. [29] showed the surface of the extrudates with 10% pectin had more pores than that of pure starch. The degree of expansion of extrudate is related to the size, number and distribution of the air cells surrounded by the cooked matrix and pectin slightly decreased radial expansion by increasing the melt viscosity and reducing the availability of water for the gelatinization process [29]. Since diametric expansion decreased as pectin content increased, the increase in porosity with pectin content is probably an indication of longitudinal expansion because of lubricating effect on the extruded dough. Various fruits as fresh or powdered can be viewed as constituting the natural source of coloring matters. Różyło et al. [30] found freeze-dried chokeberry and elderberry as natural colorants and valuable functional components for gluten-free wafers. Kita et al. [31] showed that addition of cranberry, chokeberry and blackcurrant juice powders to expanded products exhibited more attractive color, while their texture was harder (when cranberry and chokeberry powders were added). Potter et al. [15] reported the addition of 11% fruit powder (apple, banana, strawberry and tangerine spray dried powder) has significant effect on expansion and density of the extrudates. Camire et al. [32] used 1% dehydrated fruit powder (blueberry, cranberry, grape and raspberry) in extruded corn breakfast cereals and found that extruded corn cereals containing blueberry or grape juice concentrates had lower bulk density than a control product. Attenborough et al. [33] found that both freeze-dried ripe and unripe jackfruit (up to 30%) can be used to provide optimal structure, flavor and nutritional content of expanded extrudates.

The aim of the work was to investigate the application of various dried fruits in gluten-free corn-based crips processed by extrusion-cooking, and to evaluate selected properties of the final product such as physical properties, texture and color depending on the type of fruit, its quantity in the recipe and the screw speed applied during processing.

2. Materials and Methods

2.1. Raw Materials

The crisps were prepared from corn grits, ground rice and xylitol (77:20:3) purchased on local market. Freeze-dried apple slices and whole blackberry fruits, as well as air-dried white mulberry, elderberry and goji berries (purchased from RAFEX, Ciecierzyn, Poland) were ground using an LMN-100 knife mill (TestChem, Radlin, Poland) to powder. Particle size distribution was checked using a laboratory sifter AS200 (Retsch GmbH, Haan, Germany) and moisture content was tested with a moisture analyzer MA.50.R.WH (Radwag, Radom, Poland). Granulation of raw materials and its moisture content are presented in Table 1.

Table 1.

Particle size distribution and moisture content of raw materials.

2.2. Processing of Gluten-Free Crisps

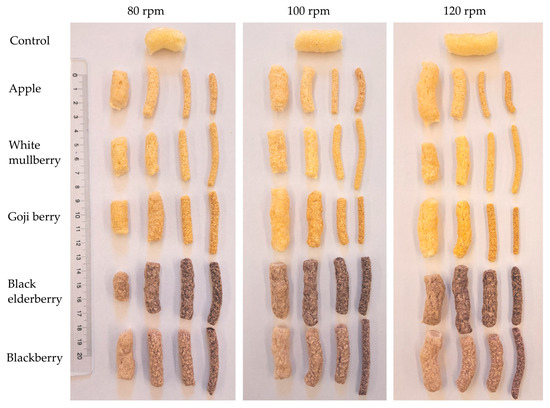

Fruits were added in the amount of 5, 10, 15 and 20% by weight to the basic recipe and all dry components were mixed together. The blends were extruded using a TS-45 single-screw extruder (ZMCh Metalchem, Gliwice, Poland) with the L/D = 12 with a die of 3 mm in diameter at the screw speeds of 80, 100 and 120 rpm. The extrusion-cooking process of crisps enriched with fruits was carried out at the temperature of 80/120/135 °C in individual zones of the extruder. View of the obtained crisps depend on additive and screw speed applied in presented in Figure 1.

Figure 1.

View of extruded gluten-free corn-based crisps with addition of various fruits processed at variable screw speed (rpm); fruit amount from left to right: 5, 10, 15, 20%, respectively.

2.3. Physical Properties

The radial expansion index (EI) was determined as the ratio of the extrudate diameter to the diameter of the die opening (3 mm). The test was carried out in 5 replications using an electronic digital caliper [11]. The bulk density (BD) was defined as the ratio of the loosely poured extrudate to its occupied volume by using a 1 L cylinder in 5 replications [10].

For determination of water absorption index (WAI), 0.7 g of extrudate was weighed into a test tube and 7 mL of distilled water at room temperature was poured over it. The samples prepared in this way were left to soak for 10 min while being stirred. The tubes with their contents were centrifuged for 10 min at 15,000 rpm in a Digicen 21 type centrifuge (Labsystem, Kraków, Poland). After centrifugation, the resulting gel was weighed. WAI was determined as the amount of water bound by the material in 3 replications [34].

For water solubility index (WSI) evaluation, weighing vessels were filled with the centrifugation filtrate after the WAI test. The content was dried using a laboratory dryer type SLW 53 STD (POL-EKO, Wodzisław Śląski, Poland) for about 1 h at 105 °C until complete evaporation of water. Then the residue was weighed and determined as a percentage of water-soluble components, performing the test in triplicate [34].

2.4. Texture Measurements

The texture profile of the extrudates was ascertained using a Zwick/Roell type BDO-FBO.5TH testing machine (Zwick GmbH & Co., Ulm, Germany). The cutting force (the highest peak) was measured in 5 repetitions by using the Warner-Bratzler flat knife with the working head test speed of 500 mm/min until the sample was completely cut [34]. The texture was tested by means of a five-blade Kramer chamber by placing five pieces in one layer at the bottom of the chamber in a direction perpendicular to the blades and subjected it to compression with the head speed of 500 mm/min. During the test, hardness (H), fracturability (FR) and crispness (CR) were determined in 5 repetitions [11].

2.5. Color Profile Evaluation

Color measurement was performed using a NH310 colorimeter (3NH Technology Co., Ltd., Shenzhen, China) using a CIE-Lab scale. It included 3 parameters responsible for lightness (L*), red-green balance (a*) and yellow-blue balance (b*). The mean of 5 repetitions was adopted as the final result for each of the individual parameters [10].

2.6. Statistical Analysis

The statistical analysis was aimed at addressing the effect of three factors: fruit supplement (apple, white mulberry, goji berry, elderberry, blackberry), percentage of fruit supplement (0% as control, 5%, 10%, 15%, 20%) and rotational speed of the screw in the extruder (80, 100 and 120 rpm) on such features of corn snacks as: expansion index (EI), bulk density (BD), water absorption index (WAI), water solubility index (WSI), cutting force (CF), texture profile and color. Since the data did not follow the normal distribution (Shapiro-Wilk test) and did not meet the assumption of homogeneity of variance (Levene’s test), they were subjected to non-parametric analysis using the Kruskal-Wallis test. Post-hoc analysis in the form of multiple comparisons was performed to examine whether statistically significant differences exist between individual data groups. Cluster analysis was then applied to identify groups with similar properties. This procedure is especially useful for comparing multi-feature objects [35]. To perform this analysis, two algorithms are most often employed: hierarchical agglomeration procedures (which create a similarity matrix of classified objects, and then in subsequent steps combine the most similar objects into clusters) and non-hierarchical procedures, e.g., the k-means method (where the population is divided into a given number of k classes and then the elements are moved about to minimize the variance within the groups). Regression analysis was also conducted to investigate the mechanism of the relationship between the variables, and, subsequently, determination coefficients (R2) were estimated. The analysis of the test results was performed using the STATISTICA 13.3 software (TIBCO Software Inc., StatSoft, Kraków, Poland), assuming the significance level of α = 0.05.

3. Results

Selected properties were evaluated for each composition of corn-based crisps depending on the type of fruit, its amount and the screw speed applied during the extrusion-cooking process. As a result of this work, only three characteristics: cutting force, hardness and fracturability of crisps were found to not differ significantly depending on the type of fruit added (Table 2, p-value > 0.05). For the remaining features, post-hoc tests were performed in the form of multiple comparisons. Statistical analysis showed that the percentage content of the fruit additive has a significant impact on the tested characteristics of corn snacks. The results presented in Table 2 indicate that the chromatic coordinate b* (responsible for the balance of yellow and blue) in corn crisps alone, does not differ significantly for different percentages of fruit additives. Our work also verified whether the rotational speed of the screw in the extruder has a significant impact on the tested characteristics of corn-based puffs. The results in Table 2 indicate that only two features are significantly differentiated depending on the screw speed: hardness and cutting force (p-value < 0.05).

Table 2.

The effect of experimental variables (type of fruit, fruit amount, screw speed) on the physical properties of corn-based crisps (p-value for the Kruskal–Wallis test).

3.1. Physical Properties of Corn-Based Crisps Supplemented with Fruits

The results of expansion ratio (EI) of corn crisps supplemented with addition of fruits is presented in Table 3, Table 4, Table 5, Table 6 and Table 7 and was found to depend on the type of fruit, its amount and the applied screw speed. Accordingly, the corn-based control snacks were very well expanded. The EI varied from 3.94 if low screw speed was used, up to 4.37 at the highest screw speed (120 rpm) during the extrusion-cooking (Table 3).

Table 3.

Physical properties of corn-based crisps supplemented with apple powder and control sample.

Table 4.

Physical properties of corn-based crisps supplemented with white mulberry powder.

Table 5.

Physical properties of corn-based crisps supplemented with goji berry powder.

Table 6.

Physical properties of corn-based crisps supplemented with elderberry powder.

Table 7.

Physical properties of corn-based crisps supplemented with blackberry powder.

Moreover, bulk density was low, as required for good quality extruded snacks [9], and BD decreased with higher screw speed (the effect of thermal and mechanical treatment during the extrusion-cooking process) [12,36]. Temperature (up to 135 °C) allied with intensive shearing (induced by high screw speed) enabled complete gelatinization of the starch present in the basic recipe, and even overtreatment—as suggested by the very high component solubility (WSI over 32.38%), which is very characteristic for corn extrudates [9].

Application of dried apple caused limitation of crisps expansion and lowered BD (Table 3) due to fibers and pectins replacing the starch in the recipe. Lowering the expansion was more significant with increasing apple powder addition. When 20% of dry apples were added, EI decreased to around 70%, as compared to control crisps. Limited expansion also significantly affected the bulk density of the supplemented crisps. BD was similar to control at only 5% of apple powder supplementation. Higher amounts increased mass of the same volume of product because it became less aerated and formed a denser structure. Maximum bulk density was 261.06 kg/m3 if 20% of apple powder was used. Screw speed had only a slight effect, confirming the statistical analysis of the weak effect of screw speed on the tested physical properties (Table 2). WAI and WSI values were lowered if apple powder content increased in the recipe (Table 3), and water absorption of samples with 5% of apple powder alone was slightly higher than the control. This may be the effect of limiting the starch content in recipes, especially with high levels of additive, and thus replacing starch by the pectins and fiber present in dry apples [19]. These results confirm the lower ability to absorb water [29], but the effect can be considered positive as it results in lower solubility of components into liquids such as water or milk. Hence, the addition of powdered apple in amount from 10 to 20% may be desired for extruded breakfast cereals instead of crisps, as the product will not lose extrudates components into the applied milk, juice or yoghurt.

Table 4 present the results of physical properties of crisps supplemented with white mulberry powder. A similar range of expansion index values were found in snacks with white mulberry addition (Table 4) as if apple powder (Table 3) was used.

A more intensive decrease of EI was obtained, however, if 5% of mulberry fruit was in the recipe, but further increase of mulberry content led to limited expansion of the supplemented crisps. This is also visible in the results of bulk density, which was lower than that for apple addition, with maximum BD = 206.79 kg/m3 for snacks with 20% of additive extruded at the lowest screw speed, while very small differences were found between 15 and 20% of fruit additive. As reported by Potter et al. [15], fruit powders may compete for moisture during the extrusion process, and this affects the degree of gelatinization and, therefore, the degree of expansion and the bulk density. They found DB values ranging from 209 to 311 kg/m3 when adding dried fruits in amounts of 11% to a wheat-corn-potato-milk powder recipe (50 kg/m3 for control). According to Bisharat et al. [37], the presence of sugar and soluble fiber that absorb moisture in dried fruit may affect the expansion capability of the extrudates. We found, however, that the application of various amounts of white mulberry had only a very slight effect on WSI, and these snacks showed similar results of WSI (from 16.19% to 20.95%) with an ambiguous effect of additive level and applied screw speed. Of note, WAI of the tested snacks was higher than control sample if 5 and 10% of additive was used, and more mulberry powder limited water absorption of crisps.

The next fruit used in the crisps recipes was goji berry powder. The physical properties of snacks obtained with addition of 5–20% of goji powder are presented in Table 5.

The tested snacks were very well expanded and light in weight when the amount of goji berry powder was up to 10%, and the differences in EI of crisps were very small at 5 and 10% of goji berry and lowered significantly with increasing amount of powdered fruit. Due to good expansion, the bulk density of the mentioned samples was very low, up to 74.72 kg/m3 at 10% of additive. Higher shear forces applied to the fruit increased BD to more than triple in samples with 20% of goji powder, and the results were very similar to samples supplemented with apple powder. Water absorption of supplemented snacks was higher than control once the amount of additive was 5 to 10%. However, slightly lower WAI was noted if 15 and 20% supplement was used, but differences were smaller than in previous samples with apples and white mulberries. The water solubility of the supplemented crisps was almost twice lower than control corn-based crisps, but differences between samples with various amount of additive were small. Dushkova et al. [26] tested extrudates processed by single screw extrusion from quinoa enriched with goji berries at 1, 3 and 5% and found decreased of WAI from 8.05 to 6.34 g/g of product when the two variables (moisture content and additive amount) increased simultaneously. The increase of the goji berries’ amount causes the increase of lipids in composition that can interacts with starch from quinoa and limits the gelatinization degree. Moreover, increasing the amount of goji berries in the recipe of snacks had the effect of lowering the water solubility of the extrudates but the effect of the moisture content was more pronounced.

Table 6 presents the results of selected properties of corn-based crisps supplemented with elderberry fruit powder.

In our work, the samples with various amounts of elderberry powder expanded very well and their bulk density was the lowest from all the tested snacks. This additive was very useful for achieving well expanded snacks with low bulk density. Accordingly, 5% of additive did not differ in values of EI from control samples, but in samples with even 20% of elderberry fruit, the expansion index was over 2, this was twice as more than if apple, mulberry or goji berry were used. A very good bulk density with maximum value of 109.40 kg/m3 was evident if 20% of elderberry fruit was applied. This outcome demonstrates that this additive proves excellent for obtaining highly expanded and light in weight supplemented snacks. Being connected with low density, the water absorption of the resulting crisps was very high in the whole range of additive levels and screw speeds applied. Moreover, intensive treatment brought about similar effects on treated components regardless of whether elderberry fruits varied in supplement quantity. Finally, the water solubility of the supplemented snacks was lower than control, but it also was independent of variation supplementation level or screw speed applied.

Corn-based crisps with blackberry powder addition were also well expanded, with low bulk density up to 115.43 kg/m3 if 20% of fruit additive was used (Table 7). The slightly less expansion in samples with 20% of additive did not significantly affect overall impression of the aptitude of blackberry powder supplementation in corn-based crisps recipe. Application of 5, 10 and 15% of blackberry fruit showed similar effect on EI, BD, WAI and WSI. Here, only small differences were noted regarding physical properties even if 20% of fruit powder was applied. The exception was WSI, which was insignificantly affected both by fruit addition and screw speed. This may be the effect of high content of fruit sugars (fructose and glucose), which varied from 39.90 to 45.12 g/100 g d.m. for mature and fully mature fruits, respectively, as reported by Schulz et al. [38]. In related work, Poliszko et al. [16] tested the influence of 2% and 4% of pumpkin flour addition on quality of extruded corn snacks. They found that the expansion ratio and water solubility index decreased, while the bulk density and water absorption index increased with increasing amount of additive.

3.2. Overall Analysis of the Effect of Variables on Physical Properties of Corn-Based Crisps with Fruit Powders

In analyzing the overall effect of fruits addition on the physical properties of corn crisps, the outcome of the experimental results were significantly different regarding expansion index (EI) between the additions of apple and elderberry, and white mulberry and elderberry (p-value 0.002; 0.0052 respectively). In the remaining cases, no statistically significant differences were found. The median for elderberry indicates that half of the corn snacks with this addition had an EI above 3.5, and in the case of apple—below 2.5 (results in Table 3 and Table 7, respectively). The leading position of EI for crisps with the addition of elderberry was probably due to the relatively high amount of fiber in these fruits. In turn, corn crisps with the addition of apple, white mulberry and goji berry were characterized by lower EI values, resulting from the lower content of fiber in these fruits. Effect of percentage of fruit additive showed no significant differences in the EI of supplemented corn crisps for the percentage share: 0% and 5%, as well as 15% and 20% (p > 0.05). For the other compared percentages of fruit additives, the differences for the EI were statistically significant. EI had the highest values in the control group. For a small percentage share of powdered fruits (5%), it oscillated around a value equal to 4. This means that these corn crisps were characterized by an extensive internal structure. The lower values of EI, for 15% and 20% of the additive share, were caused by the replacement of starch contained in corn grits with substances derived from dried fruit, such as fiber, or, more precisely, fruit sugars and pectins. Similar observations confirming decrease of EI have been reported by Potter et al. [15] for application of fruit powders in extruded snacks, by Bisharat et al. [37] in testing corn extrudates enriched with dehydrated vegetables, by Wójtowicz et al. [10] when testing functional snacks enriched with powdered tomato, by Dushkova et al. [26] if goji berry addition was applied up to 5% in quinoa-based extruded snack products, and by Wójtowicz et al. [9] when Moldavian dragonhead leaves were incorporated into snacks recipes up to 20%. In our work, when dried fruits were applied in corn-based snacks, screw speed had insignificant effect on the EI of the corn chip final product. Other research did find that screw speed had an effect on EI [11,13,27,37] and, in our study, when results were analyzed separately, with regard to each fruit additive, differences were noted between samples processed at various screw speed (Table 2, Table 3, Table 4, Table 5 and Table 6).

The testing of bulk density (BD) of the extruded products revealed a multi-directional extrudate expansion. With regard to produced snack final product, low values of BD suggest great expansion and aeration with regard to directly expanded products, which is desired feature [26,37]. In our study, the effect of fruit addition on the bulk density of corn snacks was compared depending on the incorporated fruit additives. Significant differences in BD were observed between certain additives: apple and elderberry, apple and blackberry, white mulberry and black elderberry, and white mulberry and blackberry (p-value 0.0005; 0.0008; 0.0106; 0.0154 respectively). In the case of other comparisons, the differences in BD were statistically insignificant. Table 6 and Table 7 show that BD was the lowest for elderberry and blackberry additives. This is probably due to the good aeration induced in the processing of the resulting crisp, and the highly porous structure of the final product with the addition of these fruits. Higher values of bulk density for apple and white mulberry indicate that gluten-free snacks with these fruits are harder, more compact and do not have a rough texture. Analysis of the effect of percentage of fruit additive in corn crisps also revealed that the BD was significantly differentiated depending on the share of the fruit additive used in the production of gluten-free snacks, with the exception of 15% and 20% addition (p-value 0.0997). The lowest values of BD were observed for the control group (0%) and 5% fruit supplement. This is due to the high porosity and aeration of these crisps. In contrast, higher BD values were recorded for 15% and 20% addition of dry fruits, because such a large replacement of the basic raw starchy material resulted in a reduction of the rough structure, as well as the creation of a compact internal structure, with little air entrainment [29,33]. Similarly as to EI, the BD analysis depending on the variables used and revealed insignificant total effect of screw speed on the BD of the supplemented corn puffs.

With regard to water absorption index (WAI), statistically significant differences were found between the additives: elderberry and apple and white mulberry (p-value 0.0001; 0.0306 respectively). In the case of other comparisons, the differences in WAI were not statistically significant. WAI had the highest values for elderberry additive (Table 6). This phenomenon may be caused by significant water absorption from the added dried fruit. Similarly to WAI, the water solubility index (WSI) differed significantly between the additives: elderberry, apple and white mulberry (p-value 0.0191; 0.0346, respectively). In the case of other comparisons, the differences in WSI were not statistically significant. Upon analyzing the effect of percentage of fruit additive on WAI, the control snacks were very similar to the WAI of snacks with 15% share of the fruit additives (p-value 0.3114). In the case of other comparisons, the differences in WAI were statistically significant. At the smallest addition of dried fruit, i.e., 5%, the WAI had the highest values (Table 3, Table 4, Table 5, Table 6 and Table 7). With the increase in the percentage share, the WAI decreased. This outcome was probably induced by the properties of the dried fruit used. Amount of fruit additive showed the greatest differences between the WSI determined for the control group (0%) and the other groups of corn snacks (5%, 10%, 15% and 20%) (p-value < 0.05). At the same time, it should be noted that in the case of the control crisps, the WSI took the highest value. This is due to the good solubility of starch derived from corn grits and rice flour, as well as the lack of fruit additive, which reduces the WSI value. The decreasing values of WSI with the simultaneous increase in the share of fruit additives indicate the presence of water-insoluble fibers of plant origin in the final product. The influence of the rotational screw speed was insignificant after analysis of the effect on the WAI and WSI of corn crisps supplemented with dried fruits.

3.3. Texture Profile of Corn-Based Crisps with Fruits

In this study, the corn-based control snacks that were extruded at various screw speeds demonstrated low values of cutting force, which varied between 7.44 N if 120 rpm and up to 8.93 N for the lowest applied screw speed (Table 8). When hardness was tested via Kramer cell, the results were quite low—from 84.09 to 106.87 N, with negligible effect of screw speed on crisp hardness.

Table 8.

Textural characteristics of corn-based crisps supplemented with apple powder and control sample.

Crispness, with the lowest force (4.03 N) was the best for samples extruded at 120 rpm due to the intensive treatment, and the resulting light weight was confirmed by high EI and low BD values. Fracturability was similar to hardness with regard to the force needed for structure destruction. Like results were reported for corn crisps by other authors [9,10,11,34]. This is the result of the contained starchy components which are desirable in directly expanded snack production due to the low gelatinization temperature under thermomechanical treatment of the structure-forming raw materials (Table 8) [6,7,8,13,15,26,27,37].

The addition of 5% of apple powder to the recipe lowered the force needed to destroy the crisps independently of the applied screw speeds, as compared to the control corn-based snacks. The textural properties of samples with 5% of apple powder showed values of CF, H, CR and FR lower than that obtained for control samples (Table 8). As compared to the control samples, the incorporation of low amounts of dried apple loosened up the internal structure and created a less dense inside consistency, with more delicate air pores. This effect was due to the presence of fiber in the dried apple, and was also confirmed by the high EI and low BD of these samples (Table 3). When the additive amount was 20%, the samples were less crispy and hard than were those with 15% of additive. This effect was because of the high content of non-starchy ingredients and less possibility to gelatinize the starch. Low screw speed and high content of apple powder brought about the effect of high surface hardness, evidenced by high cutting forces (12.88–20.52 N). Similar tendencies showing a lowering of textural characteristics in snacks supplemented with dried fruits and vegetables [9,10,11,15,26].

Quite different results were obtained for crisps samples processed with the addition of white mulberry (Table 9). When mulberry powder was added in amounts from 5 to 20% and high screw speed was applied, the CF values were quite similar to control snacks, or even lower, suggesting a resulting delicate structure within the final product. At the level of additive of 5 and 10%, all the results obtained via Kramer cell testing were lower or similar to the control. With repetition of cutting test, with regard to 15 and 20% mulberry powder content, the hardness, crispness and fracturability showed much higher results. That H and FR outcomes were almost the same, suggests that snacks supplemented with powdered mulberry had a hard and dense structure, as confirmed by the low EI and high BD at 15 and 20% of additive.

Table 9.

Textural characteristics of corn-based crisps supplemented with white mulberry powder.

The results of the testing of textural parameters of goji berry powder supplementation are presented in Table 10.

Table 10.

Textural characteristics of corn-based crisps supplemented with goji berry powder.

Snacks with the addition of 5, 10 and 15% of goji demonstrated similar or slight higher CF than controls, but at 20% of fruit additive, the necessary force under cutting test was very low—suggesting the easy-to-break characteristics of these crisps. Samples with the addition of 5 and 10% of goji berry characterized good CR with low values of force (2.37–11.90 N) needed to crush the outer structure. Samples with 5% of additive were very similar to the controls. As for previous additives in these samples, application of 15 and 20% of goji berry hardened the structure of the end product—as indicated by high H and FR.

Elderberry addition in the snack recipes showed much lower textural properties than that previously reported for apple, white mulberry and goji berry (Table 11). Cutting force of all range of addition level showed similar values as to the control samples, hence, there was insignificant effect of this additive on CF.

Table 11.

Textural characteristics of corn-based crisps supplemented with elderberry powder.

In addition, screw speed applied during processing demonstrated differential effects, with ambiguous effect of this variable on CF. Elderberry incorporated snack testing also showed lower H, CR and FR values than for crisps with other previously reported additives. Moreover, hardness and fracturability were at similar levels in crisps with the addition of 5 to 20% of elderberry powder without strong effect of both amount for additive and applied screw speed. Hardness of such crisps was the lowest, when compared with that of the other fruit additives employed in the experiment. Corn-based crisps with this additive were very well expanded, as confirmed by high EI and low BD values even if 15 and 20% of elderberry powder was used, regardless of the speeds of screw applied during extrusion-cooking (Table 11). They were delicate and very crispy in texture. According to the textural profile, our work suggests the application of the entire range of elderberry powder addition (from 5 to 20%), as doing so is without negative effect on the hardness or crispness of the end product.

Incorporation of blackberry powder into the base material did not strongly influence cutting force results of the tested single crisps, and values of CF were similar to the control in the entire range of applied addition (Table 12). Hardness of crisps with the addition of dried blackberry was lower than that of apple, white mulberry and goji berry additives. Blackberry addition, however, showed similar tendencies in texture changes as elderberry, with low values of end product H, CR and FR. Moreover, both elderberry and blackberry incorporation showed similar but lower values of textural properties than that of the other fruit powders. Crispness of snacks supplemented at amounts up to 15% was good, as the needed force was low—as indicated via Kramer cell test. H and FR of samples with 20% of blackberry were much higher than if lower amounts of this fruit supplementation were applied. The outcome of our work suggests that blackberry powder additive levels up to 15% are preferable.

Table 12.

Textural characteristics of corn-based crisps supplemented with blackberry powder.

In current literature, much research can be found on the effect of additives on snack texture, as texture is one of the most important elements in consumer acceptability. As indicated by Potter et al. [15], fruit powders from banana, apple, strawberry and tangerine have high sugar content (between 26 and 47%), which, in the extrusion process, has a negative effect on expansion due to increase in density and reduction in cell size of the fruit supplemented extrudates. This outcome, in turn, results in increased hardness. Wójtowicz et al. [11] also noted that the maximum value of fracturability was 105.14 N in corn snacks supplemented with a 20% addition of strawberry fruit processed at 120 rpm, while the minimum value of 8.35 N was the outcome of testing for this parameter for snacks enriched with a 5% addition of chokeberry fruit extruded at 120 rpm when measured via Kramer cell. Furthermore, the cutting forces of corn snacks incorporating tomato powder ranged from 8.4 N to up to 18.5 N for snacks with 30% of the additive [10]. In addition, the hardness of snacks supplemented with herbal additive (powdered Moldavian dragonhead leaves) increased almost 135% compared to the control sample when herbs were added up to 20%. This result, it was concluded, was related to the lower expansion and porosity of the extrudates amended with the addition of fibrous components, and the increased bulk density of products with high ash and fiber level. Of interest, besides the application of standard tests (cutting, compression, TPA), sound assisted methods may be used to assess texture. Poliszko et al. [16], for example, found that the acoustic properties (total loudness, crackliness, crispness and crunchiness) of the extrudates produced with pumpkin flour were different to that of the control. Accordingly, the total loudness, crackliness, crispness, as well as crunchiness in extrudates enriched with 2 and 4% of pumpkin flour significantly decreased (p-value < 0.005) with increasing percentage of pumpkin flour in the end product.

3.4. Overall Analysis of the Effect of Variables on Texture of Crisps Supplemented with Fruit Powders

In our work, statistically significant differences in the crispiness of crisps with additives were found between the following: apple and elderberry, apple and blackberry, and white mulberry and blackberry (p-value 0.0211; 0.0054; 0.0164 respectively). For the remaining fruit additives, the differences in crispness were not statistically significant. We also found that the crisps with apple and white mulberry were less hard (Table 8 and Table 9). This is due to the low porosity and low aeration of corn crisps with these fruit additives. More crispiness was noted with the addition of elderberries and blackberries, because the end products incorporating such fruit powders are characterized by having a porous internal structure, better crumbling and easier destructibility.

Regarding the effect of percentage of fruit additive corn crisps, a statistically significant difference in the cutting force of corn snacks was found only between 0% and 10% of the fruit additive (p-value 0.0001). For the other compared percentages of supplementation, the differences in cutting force were not statistically significant. For gluten-free snacks with 10% and 20% of fruit addition, a greater force was necessary to permanently deform the sample (Table 8, Table 9, Table 10, Table 11 and Table 12), and hardness did not differ significantly between the control sample and for percentage share of the fruit additive only at 5% amendment (p-value 0.9999). In the case of other comparisons, differences in the hardness of corn snacks were statistically significant. The lowest H values were observed for control samples, and with 5% and 10% of fruit incorporation, because products with minor addition of dried fruit are highly porous and well aerated, hence the force necessary for their permanent deformation is low. The higher H values for the 15% and 20% of fruit additives are due to the compact and crumbly structure of these gluten-free snacks. This is related to the high content of plant fibers originating from fruit incorporation, mainly fiber.

Our experimental results indicated no statistically significant differences in CR between the control sample and with minor shares of dried fruits (5% and 10%), as well as between 5% and 10% share of the fruit additive used in the production of corn crisps (p-value 0.9999 in each case). For the other compared percentages of fruit additives, the differences in CR were statistically significant. Crispness was low for samples without additive and with 5% fruit addition. The force required to start snack structure destruction in this case was low because the crisps had large spaces filled with air, which made them more delicate. The crisps characterized less CR if 15% and 20% addition of dried fruit was applied, the effect being related to the generation of a completely different internal structure within the end product, because they have had a compact structure and minimal air pores.

There were also no statistically significant differences regarding FR between control sample and 5% incorporation of dried fruit addition (p-value 0.9999). The differences in FR for the remaining percentages were statistically significant. FR had higher values for 15% and 20% fruit additive (Table 8, Table 9, Table 10, Table 11 and Table 12). This indicates the creation of more crunchy end-products, which makes them less prone to destruction, and fosters faster product cracking. This outcome is related to the internal structure of gluten-free snacks, and more precisely, to low aeration and compact structure. Lower breakage values for control, as well as for 5% and 10% of fruit additive testify to the low force needed to break the corn crisp end-products. This results from the large amount of air bubbles inside the snacks.

When analyzing the influence of the rotational speed of the screw on the textural properties of corn-based crisps, a significant differentiation in corn snack end-products was made evident. Rotational screw speeds of 80 and 120 rpm (p-value 0.0015) demonstrate significant effect on CF. In other comparisons, the differences were not statistically significant. On average, testing indicated a mean force of 10.0 N for crisps obtained at the speed of 80 rpm and a slightly lower force of 8.8 N at the speed of 120 rpm. In the case of H, there was a significant differentiation of corn snacks with regard to rotational screw speeds of 80 and 100 rpm (p-value 0.0040). In the case of other comparisons, differences in H were not statistically significant. The average hardness of the crisps (127.6 N) was the lowest for the speed of 80 rpm and the highest (157 N) for 100 rpm. The greatest, though moderate, variability of results occurred at 120 rpm (coefficient of variation of 53%).

3.5. Color Profile of Crisps with Dried Fruits

The results of color coordinates measurement are presented in Table 13, Table 14, Table 15 and Table 16. Accordingly, the undertaken experiment indicates that end-product color depends on the type of incorporated dried fruit. We noted that corn snacks without amendment and processed at variable screw speeds demonstrate high lightness (Table 13), low redness and intensive yellow tint. This is the result of using yellow corn grits as basic raw material.

Table 13.

Color profile of corn-based crisps supplemented with apple powder and control sample.

Table 14.

Color profile of corn-based crisps supplemented with white mulberry powder.

Table 15.

Color profile of corn-based crisps supplemented with goji berry powder.

Table 16.

Color profile of corn-based crisps supplemented with elderberry powder.

With regard to the color profile of the control snack end-product, increasing screw speed during processing generated a slight increase in lightness. This came about because more pore spaces were formed via extrusion. Moreover, the slightly higher redness and lowered yellowness are probably the effect of more intensive treatment and possible formation of Maillard reaction products [6,8,12,15,16]. Only slight changes in color profile were observed when apple powder was incorporated into the base material, with lightness significantly low when 20% of apple was used (Table 13). What is more, the creamy color of apple powder slightly increased redness with no effect on yellowness with regard to the end-product

Similar observations were found if white mulberry powder was applied in corn-based crisp recipes (Table 14). As with the control corn-based crisps, lightness was found to be not related to additive content or to applied screw speed. A slightly more intensive redness (a*) was noted, but the effect of variables was also inconsiderable. Values of yellowness (b*) increased in these samples with increasing amount of white mulberry powder in the recipe. Over all, it can be stated that both apple and white mulberry additives do not have an effect on the end-product color profile.

Because goji berries are a rich source of carotenoids [21] (being both antioxidants and natural colorants), snack end-products of corn-based raw material amended with goji berries were specific in color, having a slight orange-red tint (Table 15).

The lightness of theses snacks decreased from 78.70–79.59 if 5% of goji berry was incorporated, to 71.54–72.88 at 20% fruit powder addition. The natural color of goji powder intensified the red tint and the yellowness of the base raw material within the end-product, and a 4-times fold increase was observed for a* values and an almost double base value for the b* coordinate.

A very strong decrease in lightness L* and in yellow color b* was observed in snack samples incorporating elderberry fruit (Table 16). This is due to the dark purple, almost black, tint of elderberry dried fruits and thus the intensive darkness of supplemented products after processing via extrusion-cooking. The red coordinate was notably affected by the addition of elderberry powder into crisp recipes. Furthermore, a* values were higher by more than double than that for control snacks because of the purple color of dry fruits increasing the redness of crisps significantly—giving them even a violet color at high amounts of incorporated elderberry (20%). The most significant effect of elderberry additive was observed upon analyzing the b* color factor, where even 5% of additive brought about a doubled decrease in yellowness, and an up to four-times less yellowness at 20% additive levels, with negligible effect of applied screw speed.

Both elderberry and blackberry are dark fruits, and their color is similar when powdered, and they behave similarly with regard to color profile (Table 17). In samples with this additive, color profile changes demonstrate similar trends to that of elderberry addition, but the changes were slightly less intensive in L* and b* profiles. Higher results of redness were also found with increasing amounts of dried blackberry incorporation. Amer and Rzik [13] tested corn-based extruded snacks containing rich nutraceuticals—dried herbs including 11% of Laurus nobilis (T1), of Curcuma longa (T2), and of Zingiber officinale Roscoe (T3), as well as a mixture of these herbs (T4). Despite the fact that approximately all herbal extruded products had good texture and color characteristics, the best formulations were the T2 and T4 corn snacks. Poliszko et al. [16] tested the influence of pumpkin flour addition (2% and 4%) on quality and color of extruded corn snacks, and the outcome of this work was that the end-product was significantly affected by additive amount. In related work, in dried tomato snacks, the higher addition of tomato generated lower L* values [10]. High yellowness was also observed in corn grit snacks amended with freeze-dried tomato—due to the presence of carotenoids. Moreover, Wójtowicz et al. [11] reported that the lowering of the lightness was correlated with reduced yellowness because of the higher amount of incorporated dried fruits in corn-based snacks. Of note, the lowest L* value (30.91) was observed in corn snacks enriched with 20% of chokeberry processed at a screw speed of 120 rpm, while the lowest a* value (0.40) was observed for the same sample. In the case of the b* value of the supplemented snacks, the most intensive yellowness (16.39) was found in snacks with a 20% freeze-dried strawberry addition. Moreover, a negative correlation was observed between the a* and b* coordinates, as an increase in the prominence of the red tint decreased the yellowness intensity of the supplemented snack [11]. Finally, more greenness was observed with increasing content of Dracocephalum moldavica leaves (at up to 20%), with reduced intensity of yellowness [9].

Table 17.

Color profile of corn-based crisps supplemented with blackberry powder.

3.6. Overall Analysis of the Effect of Variables on Color Profile of Crisps Supplemented with Fruit Powders

In evaluating the effect of fruit addition on end-product corn crisp color profiles, the results of our study indicate that lightness L* did not differ significantly between the additives of: apple and white mulberry, as well as between elderberry and blackberry (p-value 0.9989 in each case). In the case of other comparisons, differences in L* brightness values were statistically significant. The results presented in Table 13, Table 14 and Table 15 reveal that the lightness coefficient L* had higher values for the additives: apple, white mulberry and goji berry, and illustrates the high lightness profile of the end-product incorporating these fruits. Dried apple and mulberry powders are slightly yellow in color, and ground goji berry powder is orange. However, when mixed with the base material, i.e., corn grits and rice, the resulting color profiles did not stand out significantly. The lower values of the lightness coefficient L* for elderberries and blackberries are due to the fact that these fruits are red-black, which made the end-product corn crisps much darker in color.

In our work, no statistically significant differences in the color index a* were found between the additives: apple and white mulberry, goji berry and elderberry, goji berry and blackberry, and elderberry and blackberry (p-value 0.9999; 0.3101; 0.9989; 0.5867, respectively). For the remaining fruit additives, the differences in color index a* were statistically significant. Base-material amended with apple and white mulberry had, for example, lower values for the color component a* (Table 13 and Table 14). This indicates a negligible share of red color in end-product corn crisps incorporating these dried fruits. In contrast, end-products with goji berry and blackberry were characterized by a* color indexes with higher values, because these fruits have a high content of red pigment.

No statistically significant differences were found for the b* coordinate between the additives of apple and white mulberry, as well as between elderberry and blackberry (p-value 0.9999 in each case). In contrast, the rest of the b* color comparisons of end-product incorporating the other fruit additives differed significantly. High values of the b* feature were shown for crisp end-products or raw material amended with apple, white mulberry, and goji berry powders, the latter being the highest. These outcomes were due to the large amount of yellow and orange dyes contained in these fruits, as well as that in the basic raw material, i.e., corn grits. Moreover, the color of the elderberry and blackberry fruit powder in the incorporated end-product is so intensely red-black that it drowned out the color of the other raw materials. This correlates with low values of the b* coordinate.

Analysis of percentage of fruit additive on color profile of supplemented corn crisps showed that there were no statistically significant differences in the L* lightness value between the amount of fruit additives: 5% and 10%, 5% and 15%, 10% and 15%, and 15% and 20% (p-value 0.9999; 0.9999; 0.9999; 0.0907, respectively). For the remaining comparisons, differences in L* were statistically significant. L* was the highest for the control (0%) and for 5% of the used fruit additive. This is due to the fact that a small percentage of dried fruit does not overpower the color of the corn grit basic raw material which makes the crisps very bright. In Table 13, Table 14, Table 15, Table 16 and Table 17 a decreasing trend of L* with increasing percentage of fruit additive is noticeable. Accordingly, gluten-free snacks with 20% fruit addition had the lowest L* value. This is the end result of large share of dried fruits being incorporated into the base-material making the end-product darker. The most pronounced difference in the color index a* emerges between the control group (0%) and the others (p-value < 0.0001 in each case), as well as between comparison of the shares of 5% and 20% (p-value 0.0041) fruit amendment. In other cases, a* was not significantly different. The lowest a* values were recorded for the control sample end product (0%), which indicates the presence of a very small share of red color in this item (Table 13). This is because these snacks are made mostly from corn grits, which are yellow. Higher a* values for the remaining percentages of fruit additives were brought about by the interference of these additives in the raw material composition of the crisps. Finally, upon analysis of the influence of the rotational speed of the screw in the extruder on the tested properties of corn puffs, the outcome was insignificant, so discussion is redundant.

3.7. Statistical Analysis of the Tested Properties of Supplemented Crisps

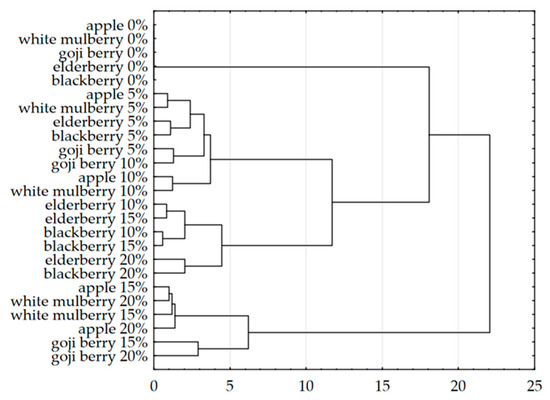

The similarity of corn snacks with fruit additives with regard to their physical properties was analyzed in order to compare snacks produced on the basis of different fruit variants and their amount in the mixtures prepared for the end product production. Herein, a multidimensional cluster analysis was performed. As in most categories, the tested features do not differ between different speeds of the screw in the extruder, they were averaged with regard to the screw speed factor. The analysis, however, omitted the features of hardness and cutting force, as they showed variations therein, as well as the feature of fracturability, as it was characterized by many outliers. In order to prevent inaccuracies in the interpretation of the results, the data were subsequently standardized, thus freeing them from the different utilized units employed to describe the studied features. In order to generate the dendrogram (Figure 2), we applied the Ward minimum variance classification algorithm, with the Euclidean distance being employed as a measure of similarity.

Figure 2.

Dendrogram of similarity of the tested supplemented corn-based crisps with factors “fruit type, share amount”.

As a result of the cluster analysis, corn snacks containing various combinations of the factors “fruit type, share amount” were divided into 2 groups (clusters). A smaller group (Figure 2, lower part of the graph) incorporates corn crisp end-products obtained through the addition of 15 or 20% of apple, white mulberry and goji berry powders to the base corn grit material. They are similar in color and have a similar expansion index, which results from the small aeration of the crisps and the negligible porosity of the structure. It can therefore be assumed that from the point of view of the tested characteristics (L*, a*, b*, BD, EI, WAI, WSI, CR), the crisps obtained as a result of these combinations have very similar properties and would probably be indistinguishable for the consumer.

Results of this study demonstrates that, while type and amount of fruit additives affects the tested physical properties of the final product, from the buyer’s point of view, some combinations of fruit additives and their shares may seem indistinguishable. It turns out that the buyers are not able to distinguish between the combinations of blackberry 10% and blackberry 15%; elderberry 10% and 15%; and apple 5% and white mulberry 5%. The dendrogram shows that the combinations of blackberry 10% and blackberry 15% are the most homogeneous in terms of the examined features; while elderberry holds a share of 10% and 15%, and apple and white mulberry indicate a share of 5% in both cases. Therefore, from the point of view of the production process, taking into account economic factors, it can be recommended to resign from the production of corn crisps incorporating blackberry and elderberry powders in the amounts of 15% and mulberry powders in the amounts of 5%. What is more, when comparing the content of 10% and 15% of fruit, a snack with a 15% share has less taste. In addition, production of snack items with higher fruit contents are more difficult due to the higher vegetable fiber contents, and, consequently, decreasing process efficiencies. Moreover, regarding crisps containing powdered apple and crisps containing powdered white mulberry, consumers will more often reach for what is familiar, i.e., those with the addition of apples. Freeze-dried apple slices are very popular, and gluten-free snacks with these fruits can become a modern version of classic crisps.

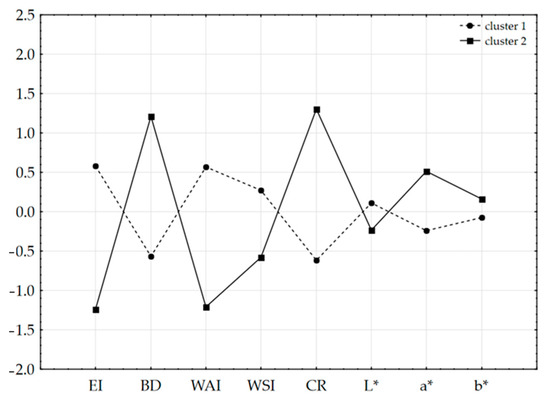

k-means clustering (in this case k = 2) revealed that the combinations of the factors “fruit type, share amount” that formed the first cluster, are the basis of determining the suitability of production of extruded crisp items containing fruit. Herein, the bulk density and friability are below the value average, and the expansion index, WAI and WSI are above the average (Figure 3). Cluster analysis indicates that the parameters that were not significant for distinguishing these two clusters (i.e., did not necessarily distinguish these clusters from each other) were lightness L* and the color components a* and b* (p-value 0.4370, 0.0776 and 0.5950, respectively). Analysis of variance results for cluster analysis showed that other tested properties were significant.

Figure 3.

Cluster averages profile plot.

In order to examine the relationships between the individual physical properties of the tested corn snacks amended with dried fruit powder, Pearson’s linear correlation coefficients were calculated (Table 18). According to the tabled information, EI significantly increases with the increase of the WAI and WSI values, while it decreases significantly with the increase of the BD, H, FR, CR and a* color component that is responsible for the red tint in the tested snacks What is more, the bulk density of crisps significantly increases with increases in texture features and significantly decreases with increases in expansion, WAI and WSI.

Table 18.

Pearson’s coefficients between the tested physical properties.

As a result of applying regression analysis, a significant mathematical model was obtained. This reveals that EI depends on BD as well as WAI and WSI, with good fit to the experimental data confirmed by the coefficient of determination of 0.92 (Table 19). According to the outcome of this application, BD significantly increases with increase in H, FR and CR, and decreases significantly with increase in EI, WAI and WSI (Table 18). A positive (moderate) correlation was also found between BD and color a* and b*. In addition, as a result of the regression analysis, a significant mathematical model was obtained describing BD dependence on EI, WAI, WSI and CR, with confirmation of its good fit to the experimental data with the coefficient of determination of 0.89 (Table 19).

Table 19.

Regression models describing the mechanism of relationships between the properties of the tested corn snacks.

No significant correlation was found between the cutting force and other features describing corn crisps with fruit additives (Table 18). Furthermore, H was found to significantly increase with increasing FR and CR, and significantly decrease with increasing WAI and WSI. A positive (but weak) correlation was also seen to exist between H, a* and b*. In addition, as a result of the regression analysis, a significant mathematical model was obtained describing hardness (H) being dependent on FR and CR, with good fit to the experimental data being confirmed by the coefficient of determination of 0.98 (Table 19). The hardness of the crisps significantly increased with increasing in FR and CR, and significantly decreased with increasing in WAI and WSI. Furthermore, FR significantly decreases with increases in WAI. In this case, the correlation is very strong. There is no significant correlation between CF and other features describing corn snacks with fruit additives. Moreover, the result of this application indicates that the L* feature is significantly correlated with a* and b*, and as a result of the regression analysis, a statistically significant regression model was established, which to 85%, explains the dependence of L* on a* and b* (Table 19).

4. Conclusions

Dried fruits as apple, mulberry, goji berry, elderberry and blackberry proposed as a valuable additive to extruded gluten-free snack products can be valuable additives that enhance the nutritional value of food, but also affect the color and texture of the end-products. Qualitative tests of selected physical properties demonstrated the possibility to apply these fruits powders up to 20% into corn-based crisps processed by extrusion-cooking. The conducted research reveals that the rotational speed of the extruder screw has significant effect only on the hardness and crispness, while the type of fruit additive and its percentage of total content had significant effect upon most of the parameters characterizing corn-based crisp. Therefore, for production purposes, it is recommended to produce crisps with up to 5% apple, 10% blackberry, and 10% elderberry at the highest screw speed, as this approach is more economically desired with no negative effect on crisp quality and sample differentiation. The findings based on mathematical models describing the variability of the expansion index, bulk density, texture and color of supplemented corn puffs can be used for optimization and prediction purposes.

The extruded crisps obtained through this study seem to be a suitable snack for consumers with gluten intolerance and for the general public. Emphasizing the health aspect, incorporation of dried fruit powders in extruded products affects the end-product physical properties, e.g., color, crispness, expansion that most often determine the customer’s choice in the first place. Further research will be focused on nutritional characteristics and sensory acceptance of corn-based crisps supplemented with various dried fruits.

Author Contributions

Conceptualization, M.R.-B., M.P. and A.W.; methodology, M.R.-B., M.P. and A.W.; software, M.R.-B. and S.I.; validation, M.R.-B., A.W. and S.I.; formal analysis, M.R.-B., A.W., M.P. and S.I.; investigation, M.P., J.S., P.L., M.M., K.K. and K.K.-D.; resources, A.W.; data curation, A.W. and M.P.; writing—original draft preparation, M.R.-B.; A.W.; M.P. and K.K.-D.; writing—review and editing, M.R.-B., A.W. and S.I.; visualization, M.R.-B. and A.W.; supervision, M.R.-B. and A.W.; project administration, A.W.; funding acquisition, A.W. All authors have read and agreed to the published version of the manuscript.

Funding

The study was financially supported by the Polish Ministry of Science and Higher Education from the state budget under the program “Student research clubs create innovation”, project title: Technical and technological aspects of the production of enriched gluten-free extruded snacks—agreement number SKN/SP/534982/2022 (SKN/4/2022).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data available at the Department of Food Process Engineering on request.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Ciurzyńska, A.; Cieśluk, P.; Barwińska, M.; Marczak, W.; Ordyniak, A.; Lenart, A.; Janowicz, M. Eating habits and sustainable food production in the development of innovative “healthy” snacks. Sustainability 2019, 11, 2800. [Google Scholar] [CrossRef]

- Lambert, L.G.; Mann, G.; Partacz, M.; Jurss, M.A. Measuring university students’ beliefs toward healthy snack selection. J. Am. Coll. Health 2022, 70, 191–198. [Google Scholar] [CrossRef]

- Artykiewicz, K.; Czarkowski, M.; Gorczyca, K.; Grodkiewicz, M.; Kozieł, P.; Krzysiek, U.; Podgórska, K.; Puła, A.; Słupczyńska, A.; Urbaś, W. Celiac disease—A review on recent advances in characteristics, diagnostic and treatments. J. Educ. Health Sport. 2022, 13, 11–17. [Google Scholar] [CrossRef]

- Caio, G.; Volta, U.; Sapone, A.; Leffler, D.A.; De Giorgio, R.; Catassi, C.; Fasano, A. Celiac disease: A comprehensive current review. BMC Med. 2019, 17, 142. [Google Scholar] [CrossRef] [PubMed]

- İbanoğlu, Ş.; Ainsworth, P.; Özer, E.A.; Plunkett, A. Physical and sensory evaluation of a nutritionally balanced gluten-free extruded snack. J. Food Eng. 2006, 75, 469–472. [Google Scholar] [CrossRef]

- Ganjyal, G.M. Extrusion Cooking. Cereal Grains Processing, 2nd ed.; Woodhead Publishing, Cereals & Grains Association, Elsevier Inc.: Duxford, UK, 2020; Available online: https://doi.org/10.1016/C2020-0-02148-1 (accessed on 14 August 2023).

- Makowska, A.; Zielińska-Dawidziak, M.; Niedzielski, P.; Michalak, M. Effect of extrusion conditions on iron stability and physical and textural properties of corn snacks enriched with soybean ferritin. Int. J. Food Sci. Technol. 2018, 53, 296–303. [Google Scholar] [CrossRef]

- Moscicki, L. Extrusion-Cooking Techniques. Application, Theory and Sustainability; Wiley-VCH: Weinheim, Germany, 2011. [Google Scholar]

- Wójtowicz, A.; Oniszczuk, A.; Oniszczuk, T.; Kocira, S.; Wojtunik, K.; Mitrus, M.; Kocira, A.; Widelski, J.; Skalicka-Woźniak, K. Application of Moldavian dragonhead (Dracocephalum Moldavica L.) leaves addition as a functional component of nutritionally valuable corn snacks. J. Food Sci. Technol. 2017, 54, 3218–3229. [Google Scholar] [CrossRef] [PubMed]

- Wójtowicz, A.; Zalewska-Korona, M.; Jabłońska-Ryś, E.; Skalicka-Woźniak, K.; Oniszczuk, A. Chemical characteristics and physical properties of functional snacks enriched with powdered tomato. Pol. J. Food Nutr. Sci. 2018, 68, 251–261. [Google Scholar] [CrossRef]

- Wójtowicz, A.; Lisiecka, K.; Mitrus, M.; Nowak, G.; Golian, M.; Oniszczuk, A.; Kasprzak, K.; Widelska, G.; Oniszczuk, T.; Combrzyński, M. Physical properties and texture of gluten-free snacks supplemented with selected fruit additions. Int. Agroph. 2019, 4, 407–416. [Google Scholar] [CrossRef]

- Prabha, K.; Ghosh, P.; Joseph, R.M.; Krishnan, R.; Rana, S.S.; Pradhan, R.C. Recent development, challenges, and prospects of extrusion technology. Future Foods 2021, 3, 100019. [Google Scholar] [CrossRef]

- Amer, S.A.; Rizk, A.E. Production and evaluation of novel functional extruded corn snacks fortified with ginger, bay leaves and turmeric powder. Food Prod. Process. Nutr. 2022, 4, 4. [Google Scholar] [CrossRef]

- Siyuan, S.; Tong, L.; Liu, R. Corn phytochemicals and their health benefits. Food Sci. Hum. Wellness 2018, 7, 185–195. [Google Scholar] [CrossRef]

- Potter, R.; Stojceska, V.; Plunkett, A. The use of fruit powders in extruded snacks suitable for children’s diets. LWT-Food Sci. Technol. 2013, 51, 537–544. [Google Scholar] [CrossRef]

- Poliszko, N.; Kowalczewski, P.Ł.; Rybicka, I.; Kubiak, P.; Poliszko, S. The effect of pumpkin flour on quality and acoustic properties of extruded corn snacks. J. Consum. Prot. Food Saf. 2019, 14, 121–129. [Google Scholar] [CrossRef]

- Dehghan-Shoar, Z.; Hardacre, A.K.; Brennan, C.S. The physico-chemical characteristics of extruded snacks enriched with tomato lycopene. Food Chem. 2010, 123, 1117–1122. [Google Scholar] [CrossRef]

- Pollini, L.; Juan-García, A.; Blasi, F.; Mañes, J.; Cossignani, L.; Juan, C. Assessing bioaccessibility and bioavailability in vitro of phenolic compounds from freeze-dried apple pomace by LC-Q-TOF-MS. Food Biosci. 2022, 48, 101799. [Google Scholar] [CrossRef]

- Zhu, J.; Liu, Y.; Zhu, C.; Wei, M. Effects of different drying methods on the physical properties and sensory characteristics of apple chip snacks. LWT-Food Sci. Technol. 2022, 154, 112829. [Google Scholar] [CrossRef]

- Jan, B.; Parveen, R.; Zahiruddin, S.; Khan, M.U.; Mohapatra, S.; Ahmad, S. Nutritional constituents of mulberry and their potential applications in food and pharmaceuticals: A review. Saudi J. Biol. Sci. 2021, 28, 3909–3921. [Google Scholar] [CrossRef]

- Vidović, B.B.; Milinčić, D.D.; Marčetić, M.D.; Djuriš, J.D.; Ilić, T.D.; Kostić, A.Ž.; Pešić, M.B. Health benefits and applications of goji berries in functional food products development: A Review. Antioxidants 2022, 11, 248. [Google Scholar] [CrossRef]

- Terzić, M.; Majkić, T.; Zengin, G.; Beara, I.; Cespedes-Acuña, C.L.; Čavić, D.; Radojković, M. Could elderberry fruits processed by modern and conventional drying and extraction technology be considered a valuable source of health-promoting compounds? Food Chem. 2023, 405, 134766. [Google Scholar] [CrossRef]

- Młynarczyk, K.; Walkowiak-Tomczak, D.; Łysiak, G.P. Bioactive properties of Sambucus nigra L. as a functional ingredient for food and pharmaceutical industry. J. Funct. Foods 2018, 40, 377–390. [Google Scholar] [CrossRef] [PubMed]

- Kostecka-Gugała, A.; Ledwożyw-Smoleń, I.; Augustynowicz, J.; Wyżgolik, G.; Kruczek, M.; Kaszycki, P. Antioxidant properties of fruits of raspberry and blackberry grown in central Europe. Open Chem. 2015, 13, 1313–1325. [Google Scholar] [CrossRef]

- Zia-Ul-Haq, M.; Riaz, M.; De Feo, V.; Jaafar, H.Z.E.; Moga, M. Rubus fruticosus L.: Constituents, biological activities and health related uses. Molecules 2014, 19, 10998–11029. [Google Scholar] [CrossRef] [PubMed]

- Dushkova, M.; Simitchiev, A.; Petrova, T.; Menkov, N.; Desseva, I.; Mihaylova, D. Physical and functional characteristics of extrudates prepared from quinoa enriched with goji berry. Appl. Sci. 2023, 13, 3503. [Google Scholar] [CrossRef]

- Drożdż, W.; Boruczkowska, H.; Boruczkowski, T.; Tomaszewska-Ciosk, E.; Zdybel, E. Use of blackcurrant and chokeberry press residue in snack products. Pol. J. Chem. Technol. 2019, 21, 13–19. [Google Scholar] [CrossRef]

- Anton, A.A.; Fulcher, R.G.; Arntfield, S.D. Physical and nutritional impact of fortification of corn starch-based extruded snacks with common bean (Phaseolus vulgaris L.) flour: Effects of bean addition and extrusion cooking. Food Chem. 2009, 113, 989–996. [Google Scholar] [CrossRef]

- Yanniotis, S.; Petraki, A.; Soumpasi, E. Effect of pectin and wheat fibers on quality attributes of extruded cornstarch. J. Food Eng. 2007, 80, 594–599. [Google Scholar] [CrossRef]

- Różyło, R.; Wójcik, M.; Dziki, D.; Biernacka, B.; Cacak-Pietrzak, G.; Gawłowski, S.; Zdybel, A. Freeze-dried elderberry and chokeberry as natural colorants for gluten-free wafer sheets. Int. Agrophys. 2019, 33, 217–225. [Google Scholar] [CrossRef]

- Kita, A.; Nowak, J.; Michalska-Ciechanowska, A. The effect of the addition of fruit powders on the quality of snacks with Jerusalem artichoke during storage. Appl. Sci. 2020, 10, 5603. [Google Scholar] [CrossRef]

- Camire, M.E.; Dougherty, M.P.; Briggs, J. Functionality of fruit powders in extruded corn breakfast cereals. Food Chem. 2007, 101, 765–770. [Google Scholar] [CrossRef]

- Attenborough, E.; Creado, J.; Tiong, A.; Michalski, P.; Dhital, S.; Desai, K.; van ‘t Hag, L. Feed composition and particle size affect the physicochemical properties of jackfruit-corn extrudates. LWT-Food Sci. Technol. 2023, 185, 115148. [Google Scholar] [CrossRef]

- Lisiecka, K.; Wójtowicz, A. The influence of fresh kale addition on selected properties of corn snacks. Int. J. Food Eng. 2019, 15, 1–11. [Google Scholar] [CrossRef]

- Polak-Berecka, M.; Kubik-Komar, A.; Gustaw, K.; Michalak, M.; Kazimierczak, W.; Waśko, A. Functional traits of Lactobacillus plantarum from fermented Brassica oleracea var. capitata L. in view of multivariate statistical analysis. Eur. Food Res. Technol. 2018, 244, 1719–1727. [Google Scholar] [CrossRef]

- Lazou, A. Food extrusion: An advanced process for innovation and novel product development. Crit. Rev. Food Sci. Nutr. 2022, 1–29. [Google Scholar] [CrossRef]

- Bisharat, G.I.; Oikonomopoulou, V.P.; Panagiotou, N.M.; Krokida, M.K.; Maroulis, Z. Effect of extrusion conditions on the structural properties of corn extrudates enriched with dehydrated vegetables. Food Res. Int. 2013, 53, 1–14. [Google Scholar] [CrossRef]

- Schulz, M.; Seraglio, S.K.T.; Della Betta, F.; Nehring, P.; Valese, A.C.; Daguer, H.; Gonzaga, L.V.; Costa, A.C.O.; Fett, R. Blackberry (Rubus ulmifolius Schott): Chemical composition, phenolic compounds and antioxidant capacity in two edible stages. Food Res. Int. 2019, 122, 627–634. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).