Abstract

An economy based on renewable energy sources is the hallmark of responsible companies. Climate policy and energy crisis commitments have led to a search for alternative ways to produce energy. Bioenergy is considered the most consistent renewable energy source due to its economic and environmental benefits. Biogas and biomethane are promising forms of renewable energy derived from widely available evergreen raw materials. Agricultural, animal, industrial and food wastes are excellent substrates used to produce clean and sustainable energy in a circular economy context. Their conversion into biogas and biomethane through the anaerobic digestion (AD) process is an efficient solution to the treatment of waste of different origins. The production and use of biomethane favor important environmental advantages, such as the reduction in greenhouse gas emissions compared with those deriving from the use of conventional fossil fuels. This review would like to highlight modern trends and approaches to evaluate processes and strategies to control biogas and biomethane production. In particular, the use of livestock waste for the digestion process and the reuse of the by-product as fertilizer, as well as the potential development of biogas and biomethane as prospects for the improvement and optimization of renewable energy sources, are discussed.

Keywords:

anaerobic digestion; biogas; biomethane; liquefaction; manure; digestate; circular economy; bioenergy 1. Introduction

Energy plays a key role in both the lives of human beings and the development of economies. In recent decades, technological progress has determined a relevant change in people’s lifestyles. Furthermore, the increase in human population as well as the overall industrial development have led to an exponential increase in global energy demand [1]. Particularly, energy reserves will be depleted in the coming decades due to the increase in energy demand. Therefore, worldwide energy sectors have to identify new alternative sources of energy for replacing fossil-derived fuels. This is also fundamental from an environmental point of view. It is, in fact, well documented that fossil-derived fuels are the most important sources of pollution and global warming, which are mainly caused by the production of CO2 and sulfur compounds [2,3,4]. However, fossil fuels (e.g., coal, oil, gas) are still used worldwide due to the relevant technological, economic and social advances [5]. Recent energy crises and the prospect of the near depletion of fossil or non-renewable fuel reserves have led industrialized countries to promote renewable energy production, distributed generation and energy efficiency interventions. Currently, a global priority for sustainable development is access to renewable energy and other energy issues (e.g., energy efficiency). A transition to more efficient energy systems requires actions involving all political levels, from the local one to the global one. The European Union’s energy policy reform and subsequent legislation and regulations at the national level have provided a strong incentive for the development of increasingly competitive renewable energy generation technologies. The European Union has, in fact, provided a number of regulations for their goal of achieving “no net greenhouse gas emissions by 2050” [6]. The transition from carbon-free fossil fuels in key sectors, such as industry, transport, agriculture and other sectors, will be supported by the European Green Deal investment plan. With this new European Commission initiative, the European Union would like to be the first climate-neutral continent by 2050 [7]. In this view, the cooperation among the European Commission, EU member countries and stakeholders will allow climate neutrality to be achieved.

A transition to renewable energy together with a decarbonized industrial sector can be completed before 2050, if investments from 2030 onwards are sustainable and grid electricity is fully decarbonized [8]. Unfortunately, the environment is currently suffering from problems such as several energy crises, depletion of fossil fuel resources, high costs and environmental pollution [9,10]. Particularly, the energy crisis is one of the issues that has imposed many changes in the development of various technologies around the world and requires policies and governance on energy resources [11]. Each year, the renewal of these crises has led several countries to shift to alternative resources, such as renewable energy. Furthermore, recent events, such as the Ukraine war, underlined the problem of national self-sufficiency in energy supply for some countries. Sometimes, society, in fact, does not manage the decreasing and controlling effects of large industrial activities on energy needs [12].

Ultimately, the issue has become even more apparent due to the overwhelming dependence of some EU member states on Russian gas and coal supply. In this context, it is clear that the issue of reducing climate-altering gas (GHG) emissions has now become an issue of paramount importance. Particularly, the commitment to low-carbon practices, including energy efficiency and the replacement of conventional energy sources with green energy sources, will be the most important purpose of the European Union.

Circular economy and bioeconomy are the prospects for addressing these challenges and achieving environmental and socioeconomic goals around the world [13,14].

The key components of the circular economy concept can be found in Figure 1.

Figure 1.

Concept of circular economy: a model of production and consumption capable of regenerating itself and extend the life cycle of materials, minimizing waste.

Thus, energy generation from alternative sources will help climate change mitigation and the minimization of risks posed to the environment, so as to provide a clean and sustainable environment for our modern society. Recently, the scientific community has significantly focused on this topic, as it is becoming a topic of a great concern.

In fact, the prospects for biogas and biomethane, as well as their methods of generation, have increased exponentially, always aiming at sustainable energy development in support of the green transition.

This paper aims to examine the potential of “renewable energy”, highlighting current trends and approaches of biogas and biomethane production processes. The paper also focuses on the potential achieving of defined objectives for sustainable development to meet environmental, social and economic needs. In addition, the review provides a comprehensive overview of the biogas and biomethane production processes, evaluating the different substrate options that result in profitable yield in order to provide a basis for further investigations.

2. Materials and Methods

Scientific studies were searched on the Scopus database and Google Scholar, considering studies published from 2017 to 2023.

The research strategy was based on the selection of keywords, combined using the Boolean operators “OR” and “AND”: “biogas” OR “biomethane” AND “liquefaction”, “biogas upgrading” OR “biomethane” AND “liquefaction”, “biogas upgrading” OR “bio-methane” AND “manure” AND “co-digestion”. Book chapters that emerged during the search were taken into account. On the other hand, for the legislative aspects, validated documents available online were considered.

Scientific studies and book chapters were firstly screened by title and abstract. Afterwards, a second screening step was conducted to check the compliance of the studies with this review by reading the full text.

3. Results and Discussions

From the literature search conducted, 301 documents (i.e., scientific studies, book chapters and legislative documents) resulted. Regarding the scientific studies (book chapters included) from the Scopus and Google Scholar databases, 197 articles resulted using “biogas” OR “biomethane” AND “liquefaction” as keywords, and 46 articles, using “biogas upgrading” OR “biomethane” AND “liquefaction” as keywords; finally, 33 articles were found using “biogas upgrading” OR “biomethane” AND “manure” AND “co-digestion” as keywords. Twenty-five documents were related to legislative aspects.

After the screening of scientific studies and book chapters by title, abstract and full text, 152 scientific studies, 3 book chapters and 14 legislative documents were included in this review.

3.1. Biogas and Biomethane as Energy Resources

Carbon dioxide or in general greenhouse gas emissions represent the main cause of global climate change. The scientific community is, in fact, significantly focused on the search for alternative and permanent solutions to achieve in view of the looming energy crisis.

Current global policies and guidelines for country development show an increasing focus on global change. The latter is mainly caused by consumerism, liable for accelerating the natural resource extraction rate and generating enormous quantities of waste, which, at the current rate of production and consumption, are estimated to double by 2050 [15]. Environmental and energy security issues are the main reasons for stimulating the search for alternative fuels. In the current scenario, renewable technologies produce electrical, thermal or mechanical energy using biomass (i.e., energy crops, agricultural or forest residues, municipal waste, etc.), wind, solar (i.e., thermal and photovoltaic), hydroelectric (i.e., river flow, tidal, wave) and geothermal energy and are considered the best alternative sources [16,17]. Therefore, it is reasonable to assume that gases produced from other sources (such as biomass) will continue to grow in importance as the need to replace fossil fuels as an energy source continues to grow. Biomass is the most abundant renewable resource on Earth [18]. It is considered the leading emerging alternative to fossil fuel resources, and it can provide energy and multiple products [19]. Indeed, it will play an increasingly important role not only in the future global energy infrastructure for the generation of energy and heat but also in the production of gaseous and liquid products for the production of fuels [16,20]. In recent years, the production of energy from biomass has shown significant growth and increasing weight among renewable energies [21]. Efficiently converting biomass into energy requires investment in research and the development of innovative technologies. The knowledge of the biological and technical mechanisms that are at the basis of biomass production and transformation processes is essential to favoring the introduction of increasingly advanced and efficient techniques and methods in terms of energy, economic and environmental sustainability. There are various ways to use agricultural biomass, and scholars worldwide are busy studying methods for using agricultural biomass resources to obtain high yield and maximum benefit from the products. Various processes can be used to convert biomass into energy. Biomass can be burned and transformed into fuel gas through partial combustion; into biogas through fermentation; into bioalcohol through biochemical processes; into biodiesel; and into bio-oil or syngas, from which chemicals and fuels can be synthesized.

Among the various energy production chains, biogas has the greatest potential for development due to its strong compatibility with the Italian agricultural system [22]. Furthermore, novel approaches matured under the European Green Deal, such as EU Methane Strategy [23], Energy System Integration Strategy [24] and From Farm to Fork Strategy [25], put biogas in a leading view [26]. In this regard, biogas has indeed emerged as a promising green energy source and appears to have high future potential for replacing fossil fuel-based energy sources [27]. The increasing use of by-products and residues for energy production is the basis for a sustainable bioeconomy to reduce dependence on fossil fuels [28]. The correct management and transformation of by-products and organic waste represents a winning strategy, since disposal costs are reduced and the resources considered waste are valorized through the production of renewable energy and biofuels [29]. Therefore, biofuel and biomass are renewable sources that can directly replace fossil fuels for present and future energy restriction, due to their environmentally friendly and renewable energy nature [30]. Biogas is a gaseous biofuel obtained from the fermentation of biomass, in the absence of oxygen and at a controlled temperature, by microorganisms. It is a mixture of several gases, made up especially of two main components, that is, methane (CH4) and carbon dioxide (CO2), and to a lesser extent of water vapor (H2O), hydrogen sulfide (H2S), nitrogen (N2) and oxygen (O2). In addition to these, trace elements may also be present. The typical composition of biogas is reported in Table 1. Biogas contains variable concentrations of components as a function of the biogas source.

Table 1.

Biogas constituents [31,32].

The relative content of CH4 and CO2 in biogas mainly depends on the substrate being digested. CO2 is now considered the main greenhouse gas responsible for global warming, but CH4 has a Global Warming Potential (GWP) 85 times that of CO2 over a 20-year timescale [33,34]. Thus, methane (CH4) is the second largest contributor to global warming [35], and after CO2, it is the gas with the greatest impact on emissions, contributing 1/4 of today’s man-made warming [36]. Moreover, methane is a potent air-polluting agent and contributor to ozone formation, which itself causes serious health problems. Methane can be released at various times during production and distribution, but it is still not fully understood where, when and how much methane is released. CH4 emissions are increasingly recognized as a key factor for the climate; therefore, a careful assessment of any fugitive and diffuse emissions is needed [37]. Mitigation of these gases is critical to supporting the global goal of limiting warming by reaching a global temperature limit of 1.5 or 2 °C [38]. The global average temperature in 2020 was 1.2 °C higher than pre-industrial temperatures, and the effects of this warming are being felt globally [38]. Based on current climate data, there is an urgent need to accelerate our efforts to reduce atmospheric concentrations of greenhouse gases to reverse global climate change [10].

Biogas originates from a biochemical process, the anaerobic digestion (AD) of biodegradable biological materials through microbial activity. Both the composition of biogas and its properties depend on the type of substrate to be digested, the type of plant and the process conditions. Its chemical composition also influences the production operations to maximize its utilization characteristics [39]. Other elements that affect its composition are pH, operating temperature, organic loading rate, hydraulic retention time and reactor structure [40]. In any case, the choice of the starting substratum is extremely important, as the activities of microorganisms are directly related to its nutritional composition. Substrates used for biogas production vary considerably from region to region and often vary with the availability of specific feedstocks in a given area.

The composition of substrates influences biogas yield, the amount of methane, biodegradability and the biomass degradation rate [41]. The most important nutrients in substrates are carbohydrates, proteins and lipids [42]. Usually, materials with large amounts of fat and protein have a higher methane yield than those with high carbohydrate content. High fat content, however, can cause failure of anaerobic digestion due to the formation of long-chain fatty acids [43]. However, carbohydrate-rich substrates can counteract the process, negatively impacting the C/N ratio (the optimal ratio of carbon to nitrogen for the AD process is between 20 and 30) [40]. The C/N ratio of fermentation substrates is important for an optimal biogas process. In order for microorganisms to form new cells, nitrogen must be present. For this reason, the ratio should not be higher than 30. If it is, the nitrogen deficit leads to a decrease in biomass production. In contrast, if the ratio is less than 20, there could be problems with process inhibition due to the presence of ammonia.

Common production sources for biogas production are included in Table 2.

Table 2.

Use of various matrices for biogas production [44,45].

Besides these, because of their abundance, lignocellulosic biomass materials such as straw and shells are taken into consideration for methane production [46]. Cattle and pig waste in the form of manure is often used as the main source for biogas production, because it contains the microorganisms needed to degrade the substrate and produce biogas [47]. The use of biogas on farms has a positive effect on the daily operations of farms. Biogas plants can reduce the carbon footprint of farms, improve and aid in manure management, and provide a source of income for owners.

The biogas produced has a wide range of applications, which are mainly associated with energy generation.

Recently, there has been a growing interest in biogas purification for the production of biomethane, which is characterized by higher calorific value (i.e., 20–30 MJ/m3 for biogas, >35 MJ/m3 for biomethane) [48]. Biomethane is defined as all methane of organic/renewable origin. It can be obtained by means of separation from biogas or through methanation of hydrogen and carbon dioxide. Biomethane has characteristics comparable to those of natural gas, making it attractive for feeding into the natural gas grid for a variety of applications. To be defined as such, biomethane must be at least 98% pure. In the literature, however, gas with a concentration of CH4 >95% is defined as biomethane. Biomethane can be used as fuel for automotive transportation. In fact, compared with other biofuels, such as ethanol and biodiesel, which require blending with conventional gasoline and diesel, respectively, biomethane can be directly used in existing engines.

The use of biogas and biomethane as energy sources presents environmental benefits, ranging from decreasing greenhouse gas emissions to replacing fossil fuels and increasing efficiency in energy production. The uses of biogas and biomethane are shown in Table 3.

Table 3.

Range of applications of biogas and biomethane [48,49,50].

Currently, biogas and biomethane are considered the centerpiece of the circular economy [51,52]. In fact, although wind and photovoltaic are the most used technologies so far (with 432.56 GW and 227 GW of global installed capacity, respectively) and are already able to supply electricity at low cost, they are intermittent and difficult to predict due to their nature [53]. On the other hand, biogas provides a continuous and stable source of energy, as it is produced using the consolidated technology of anaerobic digestion of organic material [48]. Moreover, biogas can be stored and used on request. This is an important advantage of biogas over solar and wind systems. Biogas production is also climate-independent (solar radiation and wind) and is thus a very reliable renewable energy source. Biogas as an intermediate fuel and as a final fuel is highly versatile in all energy sectors [54]. In any case, coordination between stakeholders, and energy, environmental (including waste management), transport, agriculture and food policies is essential to the success of biogas and biomethane. All of this is essential to harmonizing regulation and standards at the EU level [55].

European Union Legislative Framework on Biogas

The development of renewable energy has long been a primary goal of the EU energy policy, which has highlighted the promotion of renewable energy sources as one of its energy priorities since the 1990s. The basis of the European Union (EU) policy focused on renewable energy and biogas generation was made in 1997 with the adoption of the “White Paper for a Community Strategy and Action Plan” by the European Council and the European Parliament [56]. Table 4 summarizes the main EU legislation and regulations on renewable energy sources. The European Union’s legislative framework on biogas and biomethane plays an essential role in shaping the sector. EU legislation focuses on increasing the amount of renewable energy and reducing greenhouse gas emissions, and this is crucial to the expansion of energy decarbonization.

Table 4.

Summary European legislation on renewable energy sources.

3.2. Anaerobic Digestion and Co-Digestion

Biogas as a renewable energy source is obtained through the anaerobic digestion of organic substances. Anaerobic digestion (AD) is the biochemical process of decomposing complex organic matter into simpler chemical components under anaerobic conditions [73]. Various waste materials are used in the AD process for sustainable conversion to biogas, including the organic components of municipal solid waste, industrial waste, wastewater production waste and solid waste from agriculture, and process water and agricultural waste from livestock and agricultural activities [74]. Some examples may be grass, leaves, cereal straw, hay, fruit, vegetables, mills, pruning, cellars, fruit processing, livestock waste affecting poultry farms, stable washing water from cattle and pigs supporting biogas production [75,76].

The biological dissolution of organic matter during anaerobic digestion is a multi-step chemical process involving the four steps described in Equations (1)–(5):

CH3COO− + H2O → CH4 + HCO3−

HCO3− + H+ → CH4 + 3H2O

4CH3OH → CO2 + 2H2O

4HCOO− + 2H+ → CH4 + CO2 + 2HCO3−

4H2 + CO2 → CH4 + 2H2O

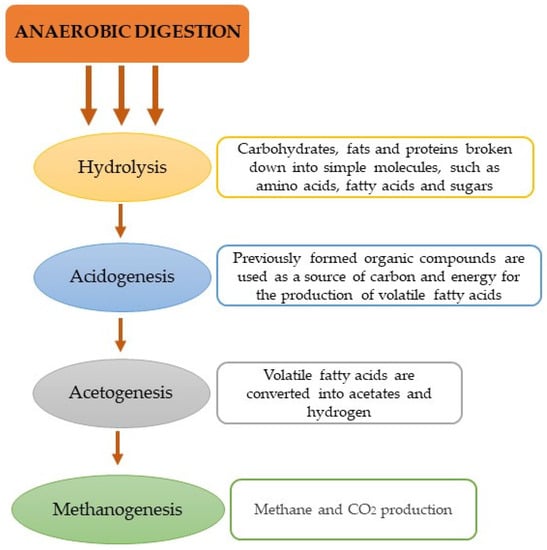

Equations (1)–(3) are related to hydrolysis, acidogenesis (acid production) and the acetogenesis phase (acetic acid production), respectively. Equations (4) and (5) are related to the methanogenesis phase (methane production) [77]. Different groups of microorganisms are involved in each of these steps.

The flow diagram of the AD process is shown in Figure 2.

Figure 2.

Schematic diagram of the biogas production process through anaerobic digestion.

Each step in the process differs in the reaction pathways and metabolites of the microorganisms involved [78]. Biochemical steps occur simultaneously in an anaerobic context, generating the production of biogas and digestate [42]. Microorganisms, which play an essential role during this process, are distinguished among the four phases [79]. The AD process, in fact, depending on the operational phase, requires different associations of bacteria, namely, aceticlastic and hydrogenotrophic methanogenic bacteria, sintrophic acetogens, and fermentative and homoacetogenic bacteria [80]. Therefore, the gradual decomposition of organic matter does not occur uniformly, since the different bacterial groups work at different rates [81].

The microbial decomposition of organic residues in an anaerobic environment is a process that occurs spontaneously in nature. However, knowledge of the factors involved in biological processes is necessary to optimize fermentation and subsequent biogas production. The disintegration of organic substances into components until they are converted into methane can only occur in the aquatic environment [81]. The anaerobic digestion process is considered advantageous for its economic availability, for the stabilization of waste, for the reduction in odors generated by farms, for the mitigation of biomethane emissions, for the recycling of nutrients using fertilizers and for the potential for local production of renewable energy [82]. Furthermore, anaerobic fermentation of the organic substrate allows for the reduction in the use of non-renewable sources, the reduction in greenhouse gas emissions and the increase in soil fertility thanks to the use of unconventional digestate-based fertilizers. In addition to improving waste management, AD can avoid potential environmental problems and provide clean energy [83]. AD plays an important role in reducing the use of fossil fuels in transport and industry, while managing organic waste and producing renewable fertilizers [84].

Mutual and syntrophic interactions among functionally distinct anaerobic microorganisms involved in each phase and the stability of the AD process are fundamental for the efficient conversion of organic matter; this can be obtained by preserving the delicate equilibrium between production and consumption of intermediate products [85]. Therefore, a detailed understanding of the properties and influence variables of the different degradation paths is of decisive importance for the process.

As shown in Equations (1)–(5), biogas production through anaerobic digestion includes four phases. Each degradation steps simultaneously occurs in a single-stage continuous reactor. This results in narrow limits and high requirements under specific environmental and operating conditions for the degradation of complex substrates [78]. The development of the two-stage digestion process (i.e., separation of acid and methanogenic phases) is reported in the literature as an interesting alternative for increasing the stability and overall performance of the process [32]. Biomass generally contains complex polymers that must be broken down before microbial treatment. The initial stage of fermentation, i.e., hydrolysis, decomposes the complex species of the substrate (proteins, carbohydrates, lipids) into simple organic molecules, such as amino acids, fatty acids and sugars [86]. This stage of the process passes through extracellular enzymes of the hydrolase group (amylase, protease, lipase) produced by appropriate strains of hydrolyzing bacteria. It emerged that hydrolysis is supposed to be a limited-rate phase in anaerobic digestion. This is due to the limitation of the availability of soluble molecules to bacterial cells. Therefore, most reviews have focused on advances in improving hydrolysis using physical, thermochemical and biological pretreatments [87]. In the next stage of acidogenesis, acidifying bacteria absorb hydrolysis products to produce volatile fatty acids, such as acetic acid, propionic acid and butyric acid [88]. In the phase of acetogenesis, the volatile fatty acids produced in acidogenesis are converted into acetates, together with the production of hydrogen. Finally, in the final phase of the AD process, methanogenesis or biomethanation, there is the consumption of intermediates by methanogenic microorganisms [89], and there is the division into two processes of methane generation: reduction of CH3COO− and conversion of H2 with CO2. Acetotrophic methanogenic bacteria are responsible for reducing acetate (CH3COO−) to methane, while hydrogen methanogenic bacteria convert H2 and CO2 into CH4, water and carbon dioxide. Acetogenesis and methanogenesis often occur simultaneously. Methane can also be formed through the reduction of carbon dioxide with formate or through the disproportion of methanol or various methylamines. The presence of CO2, H2O, NOx and N2 leads to a reduction in calorific value [90]. Thus, these constituents could be separated or enhanced by increasing the CH4 content. Process-critical components are H2S, NH3, halogenated components and siloxanes. The methanogenic phase can also become the limiting step in the process, as methanogenic microorganisms are extremely sensitive to acid accumulation in the medium.

The transformation of biomass into biogas requires a complex microbiological activity. Indeed, AD requires a number of microbial steps and leads to the formation of various intermediates. Digestion is performed by bacteria. Organic matter, such as cellulose, proteins and fats, as well as some insoluble organic compounds, is degraded by microorganisms [91]. In the process, there are distinct metabolic groups of microorganisms that differ both in substrates and in the products of their metabolism. Facultative anaerobic bacteria absorb dissolved oxygen in water, reducing the redox potential. Complex organic compounds, converted into the simplest form, can be further transformed into volatile fatty acids, such as acetic, propionic acid, butyric acid, formic acid and lactic acid. In addition, the concentration of the generated H+ ions directly affects fermentation, since the high concentration hinders the production of acetate. In this fermentation stage, monomeric sugars, fats and amino acids are transformed into organic acids and alcohol. Simultaneously, intermediate substrates are transformed into H2, CO2 and acetate [92]. During the AD process, acetogenic bacteria grow together with methanogenic bacteria; methane is produced in complete absence of O2, and the reaction is highly exothermic. With the advent of high-throughput sequencing, several microbial groups involved in biogas production have emerged [93]. Several factors influence the AD process, among which are temperature, pH, C/N ratio and substrate particle size. Smaller particles can be expected to decompose more rapidly, resulting in faster generation of biogas.

The identified multiple factors that intervene in the anaerobic digestion process and that allow for the control of its efficiency are the fundamental elements for the proper functioning of biogas plants.

Digestion processes can take place under very different operating conditions, which are reported in Table 5.

Table 5.

Process parameters of anaerobic digestion [73].

AD can be conducted in three different temperature ranges. The temperature should be kept as constant as possible to ensure process stability. Mesophilic and thermophilic temperatures are the most used and range from 20 to 40 °C (usually 35 °C) and from 50 to 65 °C (usually 45 °C), respectively. Lower temperatures, in fact, reduce biogas production. pH is another factor that affects the stability and performance of the AD process. pH, as well as temperature, affects the metabolic activity of different microbial populations. Since microorganisms are sensitive to pH, the ideal pH range for the process is about 6.0 to 7.5 [73]. The mentioned parameters have an impact on the performance of the bacteria in the anaerobic digester, influencing the efficiency of the AD process and the final biogas production.

Anaerobic digestion can be applied to semi-solid, liquid and gaseous wastes. It can be carried out on single materials (mono-digestion) or mixtures of numerous materials (mixed digestion or co-digestion). In the past, only one substrate was used in the process, but today, the tendency is to prefer a combination of different substrates (co-digestion). Anaerobic co-digestion offers the opportunity to overcome the disadvantages of mono-digestion by simultaneously digesting two or more raw materials, improves digestion and is often used in larger biogas plants that treat organic waste of various origins. Co-digestion of various substrates improved biogas production potentials compared with individual substrates [94,95], leading to higher gas production per tons of substrate. The combination of these substrates is an excellent method for the coincident management of solid and liquid organic wastes. This helps to solve the problem of nutrient imbalance linked to the anaerobic use of individual substrates and the consequences of the accumulation of dangerous compounds during digestion. As a result, biogas production is greatly improved by co-digestion compared with mono-digestion. Co-digestion of faceted biomaterials with animal manure and other biodegradable organic substances provides sufficient access and potential for microorganisms to promote optimized degradation [96]. The main advantage of co-digestion is the improvement in biogas yield and its methane content. Despite the many benefits of co-digestion, antagonistic effects due to an incompatible raw-material mixing ratio can result in organic overload, acidification and system failure [97]. Some of the major disadvantages of co-digestion that hinder the application of the technology with large-scale commercial reactors include the accumulation of non-digestible solids within the digester, a high nitrogen load and the accumulation of acids from other co-substrates [98]. However, these contests can be addressed by depicting heterogeneous organic compounds in digester feedstocks and understanding their inherent biodegradability patterns [99].

In addition, the synergistic effects of the co-substrate mixture that are caused by the dynamics of the co-digestion process as well as the microorganisms involved outweigh the disadvantages of the technology. With process regulation and control, as well as pretreatment, the benefits of anaerobic co-digestion can be fully realized. Different in situ and ex situ preparation strategies are involved in optimizing products [100,101]. Animal manure is co-digested with other biodegradable materials to increase economic effectiveness while ensuring the stability of the anaerobic digestion system on a commercial scale [102].

The overall environmental impact of anaerobic digestion is considerably lower than that of the composting process, i.e., 6.5% in all categories, with the exception of agricultural soil pollution, where the percentage is higher by 1%. The results proved significant [103]. However, research and development of co-substrate mixing proportions need to be further investigated for a wide variety of co-digestion substrates. Further research on a wide range of co-digestion feedstock combinations and their mixture ratios is needed.

Zootechnical Slurry for Biogas Generation

A wide variety of biomass available on Earth is used as a component for renewable energy production. For instance, wood, energy crops, agricultural residues, food waste, livestock manure and industrial waste are promising solutions to reducing the negative impact of waste on the environment [104]. Particularly, livestock manure and slurry are considered valuable feedstocks for biogas generation [105]. Their conversion to energy using Waste-to-Energy technologies promotes their use as a clean energy resource to decrease the uncontrolled decomposition of animal waste [106,107]. The improper management and disposal of waste from the livestock industry could represent a significant threat to the environment. Unprotected manure, in fact, contributes to the release of a large amount of biomethane and thus to global warming [108]. Furthermore, this material is also a reservoir of pathogens that can spread and enter the surrounding groundwater [109]. Animal waste management involves several key processes, including thermal (incineration), chemical (hydrolysis) and biological (anaerobic digestion) methods.

Ammonia and nitrous oxide emissions, as well as the presence of phosphates, heavy metals and pathogenic agents from livestock effluents, can promote ecosystem dysfunction, resulting in adverse effects on animals’ and farm workers’ health [110,111]. Therefore, controlled anaerobic digestion (AD) is one of the most suitable technologies for the treatment of manure. Nutrient-rich digested manure becomes efficient matter for clean energy source production to reduce the employment of conventional fossil fuels and hazardous gas emission [105]. It is also applied as a natural fertilizer to replace synthetic fertilizers and to improve soil fertility [112]. However, some limitations of anaerobic manure digestion can affect biogas production. For example, the low concentration of organic load and ammonia production due to high nitrogen can cause the reduction in microbial activity, decreasing biogas production [113]. In addition, temperature and process type can be limitations for the net energy balance of biogas production; just as in the co-digestion of manure with lignocellulosic biomass, the degree of crystallinity of cellulose can slow down the hydrolysis step of DA and act as an inhibitor of anaerobic microorganisms [114,115]. Several technologies for raw biomass feedstock pretreatment have been proposed by researchers to overcome AD inconveniences and improve access to biomass for enzymes as well as bacteria [116]. Particularly, different techniques, such as thermal, chemical, biological and physical methods, are available to optimize the fermentation of animal manure.

For example, it was found that cattle manure AD coupled with thermal hydrolysis pretreatment (THP) at 160 °C with 2% (dry wt.) sodium hydroxide (NaOH) addition produced a higher biochemical methane potential (BMP), 227.0 ± 11.0 mL-CH4/g-volatile solid, with approximately 8.8% biodegradability, compared with the BMP of the intact cattle manure (CM) sample (182.2 ± 2.5 mL-CH4/g-volatile solid) [117]. Furthermore, the CO2 emitted during the production of biomethane could represent a sustainable solution to the use of chemical solvents in the biomass preparation process, minimizing its emissions into the atmosphere. The use of this by-product can have advantages, such as the optimization of biogas production and the kinetics of the fermentation process in the bioreactor, resulting in an increase in the energy value of manure obtained from the raw material after CO2 pretreatment [118]. The potential of biogas produced through anaerobic digestion also depends on the type of manure used. In detail, the species, breed, age, body weight, feed of the animal can influence chemical and physical composition and thus the content of organic matter, carbohydrates and fats [107]. The ideal carbon–nitrogen balance for anaerobic digestion is in the range of 20:1 to 30:1 [119]. However, the use of animal waste (cattle, swine, poultry) as mono-substrate is not very convenient to produce biogas due to the low carbon ration and low efficacity [120]. Co-digestion is a preferable strategy to mono-digestion, because it improves the C/N ratio, nutrient supply and buffering capacity by overcoming the limitations of AD. By taking into account the synergistic effects of using various raw materials, process stabilization is positively influenced. Due to the positive synergies in the digestion medium and the required nutrient supply, the use of co-substrates increases biogas yields compared with the mono-digestion of the same substrates. Different co-digestion strategies are shown in Table 6.

Table 6.

Summary of different types of co-digestion and their impact on biogas yields.

3.3. Purification and Improvement of Biogas

Biogas upgrading is a widely studied and debated topic. Its use as a substitute for natural gas has gained, in fact, considerable interest in recent years. Biomethane is produced through anaerobic digestion, followed by an upgrading of biogas that aims to increase the concentration of CH4 by separating it from other biogas compounds. Biomethane is typically 97–99% methane and 1–3% CO2. It is a renewable gas that can be transformed into a resource by means of its conservation in depots. Storage of biomethane allows it to be used at any time and place; thus, it is useful as transportation fuel or for injection into the national natural gas grid [130]. To increase the exploitation of biogas, it is necessary to remove various impurities using upgrading technologies. We usually refer to impurities such as water (H2O), carbon dioxide (CO2), hydrogen sulfide (H2S), dioxygen (O2), dinitrogen (N2), carbon monoxide (CO), ammonia (NH3), volatile organic compounds (VOCs), siloxanes, hydrocarbons, and aromatic and halogenated compounds. The biogas upgrading process generates new possibilities for its use, as it can replace natural gas, which is widely used in many countries. Most of the biomethane produced worldwide is obtained with the AD process, followed by the processes of carbon dioxide removal and desulfurization of raw biogas. However, upgrading processes add to the costs of biogas production. Therefore, it is important that the upgrading process be optimized in terms of low energy consumption, high efficiency and high methane yield [131]. Biogas upgrading technologies are mainly based on absorption, adsorption and membrane separation processes. These purification techniques allow for high methane concentration and high efficiency of removal of various impurities. The primary objective is to enhance the low calorific value of biogas and convert it into valuable fuel. The end result of biogas upgrading is pure methane [132]. Currently, different upgrading technologies, such as solvent scrubbing, adsorption processes and so on, are commercially available. The biogas upgrading technologies are summarized in Table 7 and are then discussed below.

Table 7.

Comparison of technologies in use in biogas upgrading [133,134,135].

The upgrading processes of biogas can be conducted using several techniques, such as (1) solvent scrubbing, (2) adsorption processes, (3) cryogenic separation, (4) hydrogenation processes and (5) membrane separation. Advantages and disadvantages of CO2 removal techniques are indicated in Table 8.

Solvent scrubbing is the most commonly used process. It can occur either by physical absorption, with water or specific solvents that absorb the contaminants of biogas, or by chemical absorption, with the use of chemical means. The cleaning procedure using water is based on the higher solubility of H2S and CO2 in water than CH4 [136]. For instance, CO2 is 26 times more soluble in water than methane at 25 °C. Physical washing with water is carried out at a pressure between 6 and 10 bar [137]. During the upgrading process, the biogas is pressurized to 8–12 bar up to 40 °C and fed through the bottom of the scrubber, while water is fed into the scrubber from above. The absorption column is usually filled with random packing material to increase the gas–liquid mass transfer. There is a countercurrent interaction between gas and water, which increases the contact time and mass transfer between gas and water. CO2 is absorbed in the downward-flowing water, and biomethane is obtained as over-90%-pure CH4. The exhaust water containing the absorbed CO2 and H2S is sent to a flash column to recover the CO2-rich exhaust gas. There are two types of water scrubbing, namely, single-pass water scrubbing, where water comes from sewage treatment plants, and regenerative absorption, where water can be regenerated in a desorption column by decompressing it at atmospheric pressure, resulting in the removal of CO2 and H2S. In single-pass water scrubbing, the treated water is used to absorb CO2 and H2S from the raw biogas and is then returned to the treatment systems. In regenerative absorption, fresh water is used for the absorption of impurities from raw biogas. Water regeneration is crucial to the economic sustainability of this technology, due to the considerable water quantities required for biogas upgrading [138]. Subsequent to washing with water, the drying of biomethane is necessary due to the increase in water content [139]. Finally, after a drying phase, CH4 can reach a purity of up to 99%. It has recently been revealed that it is possible to lower the cost of high-pressure water washing (HPWS) by including residual heat recovery [139]. In addition, CO2 desorption in the biogas upgrading process has recently been improved by using vacuum and ultrasound, positively influencing the effectiveness and efficiency of the HPWS process [140]. Washing can also be performed with organic solvents. This procedure is a physical absorption process similar to water scrubbing; however, it uses organic solvents instead of water not only to absorb CO2 from the biogas but also for the absorption of H2S and H2O. Polyethylene glycol ether (PEG), methanol and N-methyl pyrrolidone are the commonly used organic solvent mixtures to absorb CO2 and H2S from raw biogas [141]. These organic solvents have higher solubility of CO2 in the solvent than in water. During this organic solvent-scrubbing process, raw biogas is initially compressed to 7–8 bar and cooled to 20 °C, before being injected from the bottom of the absorption column [138]. The organic solvent is also cooled before being injected. After washing, the organic solvent is regenerated by heating and depressurizing it in a secondary desorption column [142]. Another technology is chemical washing. Chemical washing is based on a chemical reaction in a countercurrent flow between the absorbed gases and a chemical solvent (amine reagent). The following chemical solvents are used: mono-, di- and tri-ethanolamines, mainly mono-ethanolamine (MEA), diglycolamine (DGA), diethanolamine (DEA), triethanolamine (TEA), methyldiethanolamine (MDEA), and 2-amino -2-methyl-1-propanol (AMP) or piperazine (PZ). These react with gases to separate them from the gaseous mixture. MEA is among the most commonly used, thanks to its greater selectivity for CO2 and greater absorption capacity, ensuring efficiency of CO2 removal of 80–95% [142,143,144]. Chemical washing requires a considerable amount of heat compared with the physical absorption process.

Adsorption processes are based on the selective adsorption of biogas contaminants. Pressure Swing Adsorption (PSA), Temperature Swing Adsorption (TSA) and the Oscillating Vacuum Adsorption (VSA) are used. PSA is the most frequently used method for biogas upgrading [133]. It is based on the ability of a porous material to adsorb target molecules from a gas mixture under the application of high pressure; these are then released at lower pressures [134]. Basically, the process consists of an adsorption phase during which the biogas, after preliminary removal of H2S and water vapor/moisture, is injected from the bottom of an adsorption column. During passage through the column, CO2 and/or O2 and/or N2 can be adsorbed, and the gas is then expelled as a flow of more or less pure CH4.

The cryogenic separation process is different, as it exploits the diversity of the gas boiling points of the gases in biogas. This process is, in fact, based on the principle that gases such as CO2 and H2S are liquefied at different pressures and temperatures. The boiling point of CH4 is the lowest of all biogas constituents. As a result, a gradual decrease in temperature allows for the removal of impurities in order to obtain extremely pure biomethane. Methane has a boiling point of −161.5 °C, while CO2 has a boiling point of −78.2 °C, and this ensures the separation of CO2 as a liquid by cooling biogas at high pressures [141]. In this separation, the temperature is reduced (to −170° C), and the pressure (80 bar) is increased incrementally to achieve pure CO2 and CH4 flows. A combination of direct and indirect cooling is used to ensure optimal operating conditions [136]. All variations of these technologies have recently been examined [145,146]. Cryogenic technology is, among all, the most energy- and cost-consuming technology.

In hydrogenation processes, CO2 is used to produce synthetic methane in combination with H2 produced from clear renewable sources. At the present time, the technology for obtaining methane on a large scale is to produce natural gas from synthetic gas (H2, CO2 and CO) obtained from the conversion of coal using metal-based catalysts at a temperature between 150 and 500 °C and pressure between 1 and 100 bar. The most commonly used catalysts are nickel, copper, iron, cobalt, palladium, ruthenium, rhodium, platinum, molybdenum and tungsten, supported by a support material consisting of silicon oxide and carbide, or oxides of aluminum, cerium, titanium and zirconium. Temperature, pressure and physical state are fundamental factors for these elements, which would otherwise gradually hinder the reaction and generate problems of selectivity, cause the production of harmful by-products and the formation of other hydrocarbons other than methane and finally show poor efficiency. Due to the remarkable selectivity, it is indeed possible to achieve complete transformation of CO2 and H2 [142]. The positive aspect of this technology is that methane produced through hydrogenation is easy to transport, fully compliant with current natural gas networks and suitable for regions with low natural gas availability.

Membrane separation uses semi-permeable membranes to separate the different components of biogas, based on their actual size. Membrane technology is a viable alternative to the traditional biogas upgrading system based on adsorption, presenting competitive efficiency. The operation of this technique is based on the properties of selective permeability of the membranes that allow the separation of the various components of biogas. Commercially successful membranes, such as polyimide and cellulose acetate membranes, are used [142]. Membrane fiber materials used in the gas separation technique can be classified into three groups: inorganic membranes, polymer membranes and membranes in a combined form. Drawbacks related to the use of membranes include their high cost and their degradation over time, including damage caused by vibration of colloidal solids [142,147].

Table 8.

Advantages and disadvantages of techniques for removal of CO2 [133,134,142,147].

Table 8.

Advantages and disadvantages of techniques for removal of CO2 [133,134,142,147].

| Method | Advantages | Disadvantages |

|---|---|---|

| Solvent scrubbing | High efficiency and low losses | Expensive investment, high consumption of water and biomethane contamination from N2 and O2 desorbed from water, high amount of heat and foaming problems |

| Adsorption processes | Highly efficient technology, lower energy requirement and no chemicals required | High energy consumption and high operating conditions (high pressure and low temperature) |

| Hydrogenation processes | Highly selective technology and easy transportation of methane produced | High energy consumption and high operating conditions |

| Cryogenic separation | Efficient treatment, lower methane losses and high methane purity | Very high energy consumption and complex process |

| Membrane separation | Low operational requirements and non-chemical process | High initial investment costs, high cost of membranes and degradation of membranes over time |

3.4. Recovery of Digestate

Another relevant issue related to biogas production concerns the by-product of the process, i.e., digestate. Digestate is the residue of the anaerobic digestion process. It can result from the digestion of livestock manure, plant biomass (waste or dedicated), animal by-products, sewage sludge or organic fraction of municipal solid waste. Promising applications for digestate have been found in the agricultural sector, where it is used both as a soil amendment and a fertilizer [148]. The content of biogas digestate has been studied by many researchers. As a result of this study, it was found that the content of digestate is rich in nutrients useful for the plant. In fact, digestate is a potential biofertilizer and source for several biogas plants all around the world [130]. Therefore, the increase in the demand for biogas will result in a significant increase in the amount of digestate produced each year [149]. Given the many different substances and wide range of compounds contained in digestate, the main recommended use for its management is its direct use as a fertilizer [150]. The resulting digestate has higher moisture content than the starting biomass, because some of the dry matter is biologically degraded for biogas production. The residual organic matter is more stable and contains nutrients such as nitrogen, phosphorus and potassium, which can return to the soil to provide nutrients for crops. Digestate is, in fact, an excellent fertilizer for plants, rich in both organic matter and macro- and micro-nutrients. The physicochemical characteristics of digestate vary considerably depending on the nature and composition of the digested substrates as well as the operating parameters of the biogas processes. The general components of digestate are dry matter, organic matter, total and ammoniacal nitrogen, diphosphorus pentoxide and potassium oxide and vary depending on the origin. In digestate derived from livestock manure, the highest rate of nitrogen is in ammonia form [151]. Precisely because the natural composition of the raw materials of the process can be varied, the digestate produced also has different physicochemical properties. Other elements that may affect the final composition of digestate include the fragmentation of the substrate and the technologies used in the fermentation process [151,152]. All the factors influencing the biogas system, directly and indirectly, affect the quality of biogas digestate. The use of digestate as a fertilizer offers significant advantages for agriculture. However, to guarantee a safe use, abuse and inefficient uses should be avoided. Table 9 summarizes the advantages and disadvantages of using digestate from biogas, which will be described in detail below.

Table 9.

Positive and negative aspects of using digestate from biogas.

Digestate consists of a solid fraction in suspension and a liquid fraction containing soluble nutrients [153]. It is made up of organic and inorganic nutrients, enriching the soil and improving its structure and absorption capacity [154]. Due to the high plant nutrient content, digestate can be effectively used as a fertilizer in plants and can be complementary or alternative to mineral fertilization, providing those essential plant macronutrients needed to sustain the food supply of a constantly growing population. Its use can alter the soil ecosystem or have a direct impact on plant growth. Evidence has been documented regarding digestate as a high-quality biological fertilizer, rich in key components and nutrients (N, P, K, Cu and Zn). In addition, organic matter, amino acids, vitamins and some favorable microorganisms can increase the amount of humic substance in the soil and improve its fertility, providing an adequate defense [155]. Its use for the fertilization of plants allows for the diversification of and increase in the economic efficiency of agricultural activities [156]. However, its impact on soil characteristics and biomass yield has not yet been investigated [157]. Its use as an organic fertilizer closes the carbon and nutrient cycles and seeks to reduce the dependence on inorganic fertilizers; besides arousing interest in this regard, it also contributes to improving soil structure and fertility. Digestate turns out to be a clean, easily available and convenient fertilizer that can be reintroduced into crops to improve agriculture. It plays a better role than directly using animal manure as a fertilizer, because it has higher homogeneity and nutrient availability, and better C/N ratio, and it significantly reduces odor [158]. However, digestate contains odors, pathogens and other pollutants. Therefore, it is necessary to implement technical and effective strategies for the treatment of biodigestate and for its use in the environment [159]. It also contains contaminants such as heavy metals, including Cd, Cr, Cu, Pb, Ni, Zn and As [160], and the greenhouse gas (GHG) emissions derived from digestate have underlined the need for appropriate management of digestate before its safe discharge into the receiving environment [161]. Prior to the use of digestate, the content of heavy metals and the presence of pathogens should be checked [150]. Depending on the type of raw material and the operating conditions (thermophilic/mesophilic temperature), the digestate may require sanitization, deodorization and neutralization phases [153]. According to the sanitation standard of the European Union, for the safe use of biogas digestate, it should be treated in a continuous mixing tank at 70 °C for 1 h. The disadvantage of the sanitization process is that it is removed from the N fertilizer in ammonia at the applied temperature. This loss can be compensated for by adding ammonium sulphate to biogas digestate [162]. The fertilizer can be used after enrichment. It also can be used as feedstock for further nutrient applications in agriculture and the chemical industry, but this usually requires additional treatment [163]. An essential aspect of the agricultural applications of digestate is the need to inactivate pathogens present in digestate and reduce the risk of them entering the soil environment. Before foliar or soil application, conditioning (e.g., with inorganic acids) and neutralization (e.g., with potassium hydroxide (KOH)) are required to eliminate odorous compounds and microorganisms [163].

Digestate can be used directly or separated into its fractions, i.e., solid and liquid fractions; in the first case, high investment and operating costs are required, but costs related to storage and transportation tariffs are greatly reduced [157], increasing the resource recovery potential with the use of advanced technologies. Both fractions can be applied to agricultural land. In any case, the liquid fraction includes higher volatile total ammonia nitrogen (TAN) concentrations; this could result in possible negative consequences related to ammonia emissions. The direct application of digestate to soil causes nitrogen loss through ammonia volatilization. Volatilized ammonia nitrogen enters the atmosphere, causing an increase in nitrogen content in natural soil and water, resulting in eutrophication [164].

Recently, digestate has gained importance, in part due to the rising cost of mineral fertilizers and the problems related to their availability and purchasing. The many benefits of using digestate are gaining increasing recognition and are linked to the promotion of sustainable development and the circular economy. Scientific research indicates that biogas digestate can also be used in animal husbandry, aquaculture and algae production.

The production and recycling of digestate as fertilizer requires quality, management and quality control throughout the life cycle of AD, from the production of feedstocks to the final use of digestate as fertilizer [165].

Waste Framework Directive 2008/98/EC introduced the “end of waste” criteria, indicating that waste ceases to be waste when the required criteria are met. Digestate, conventionally recognized as waste, can be legally used in agriculture and other land applications if it meets legal requirements. Despite the high potential for closing nutrient loops in agriculture and reducing external inputs of mineral fertilizers, the application of digestate on agricultural land has some potential drawbacks [166]. In fact, its uncontrolled disposal can cause nutrient runoff; the anaerobic degradation of protein-rich biomass enriches the concentration of total ammonia nitrogen (TAN) in digestate, limiting its use in areas classified as vulnerable to nutrient pollution of underground and surface waters. Similarly, the content of phosphorus (P) is of concern in digestate management, being responsible for the phenomenon of eutrophication (Water Framework Directive, 2000/60/EC). Traditional methods of digestate application, such as spray irrigation, can cause emissions of ammonia, carbon dioxide and nitrous oxide [167]. In Europe, national legislation establishes the maximum nitrogen (N) loads to be applied to fields, the minimum required digestate storage capacity and the obligatory spreading season to adequately fertilize agricultural fields without posing environmental risks (Directive 91/676/EEC). In Europe, environmental regulations regarding pathogens (EU Commission Regulation No. 142/2011) and heavy metals (Directive 86/278/EEC) also apply to the quality of digestate.

Due to the profligate utilization of biogas digestate, there is evidence of a harmful effect on agriculture. In fact, despite the fact that its use promotes plant growth at small doses, at high doses, instead, it can produce a harmful effect [168]. This negative effect can be resolved by controlling the dilution or planting time in the fertilizer concentration [169,170].

Biogas digestate is an ecological and advantageous product for sustainable production due to climate change and limited fossil resources. In any case, the advantages of the product can only be achieved with the appropriate use of the product and proper control before its use.

Another aspect related to its use concerns the economic evaluation. Transport distances have a crucial impact on the economic feasibility of using anaerobic digestate for land application; therefore, the correspondence between the location of existing digesters and neighboring agricultural land should always be checked.

In the scientific literature, there are few studies on the ecology of soil where digestate is used. Furthermore, scarce information is available on the quality, treatment, valorization and integration of its production with an economic evaluation in the agricultural sector. Some studies have discussed digestate valorization, while others have examined different alternatives to digestate treatment, as well as the economic evaluation of digestate treatment methods. The utility of mechanical, thermal and biological processes for nutrient recovery has been discussed, and the potential of industrial-scale technologies has been indicated [171].

Despite extensive studies on the elemental composition of biogas digestate, the knowledge of its impact on soil processes, however decisive for the state of fertility and crop response, is still scarce. Numerous scientific studies indicate that digestate can be successfully used as a fertilizer. However, more research is needed, especially on the diversity of feedstocks used for biogas production and their effects on digestate composition and performance. A standardized risk assessment for agricultural applications of digestate is lacking, indicating the need for research in this field [172].

4. Conclusions

This review aimed to summarize the main knowledge about the use and production of biogas and biomethane particularly from zootechnical slurry. Renewable energy has, in fact, become a priority for organizations worldwide, as the currently employed fossil fuels will soon run out. Furthermore, bioenergy supply can meet climate change objectives. By reviewing the literature, it emerged that AD is an efficient process for the production of biogas from waste of different origins. Animal waste products provide nutrient-rich and highly valuable raw material for renewable fuel generation through the AD process. Co-digestion of multiple feedstocks is an excellent way to improve biogas production. Contrary to the mono-digestion of manure alone, it has recently been suggested that the combination of agricultural and livestock wastes is an advantageous alternative that fully exploits the qualities of both feedstocks and, as a result, increases the biogas yield. Through alkaline pretreatment, tested with NaOH, the optimization of the digestion process was found to be able to increase the production of biogas and thus biomethane. However, further research on substrate mixing is needed to advance process design and optimization and to keep process costs down. Various upgrading technologies have also been developed to purify the biogas produced. With the improvement in biogas production and biogas upgrading in the future, the demand for biogas as an alternative energy source is expected to be met by replacing conventional fossil fuels. The by-product of the AD process, known as digestate, can be further used as a natural fertilizer in agriculture, providing plants with organic matter and ensuring the replacement of synthetic fertilizers.

In conclusion, the road to the green transition of the industry and the diversification of energy supply sources is still uphill. Biogas is one of the solutions to global greenhouse gas emissions, and its importance in waste management is well established and will continue to develop in the future. What is certain is that renewable sources represent a pillar in this process, which will be strengthened through targeted investments. Environmental protection is an urgent and common problem that must be solved by all parts of society. On this front, much has been achieved, thanks to a mix of technological progress and incentives that have made renewable energies an increasingly convenient choice, and much more will be performed through further research and significant investigations that will perfect the best use of these energies.

Author Contributions

Conceptualization, D.M. and P.A.; methodology, D.M. and P.C.; software, C.C. and G.C.; validation, D.M. and P.C.; formal analysis, C.C.; investigation, D.M.; resources, P.C. and G.C.; data curation, D.M.; writing—original draft preparation, D.M.; writing—review and editing, P.C. and P.A.; supervision, P.A.; funding acquisition, P.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by an agreement between University of Molise and Italian National Research Council (Istituto sull’Inquinamento Atmosferico) under the grant “L’utilizzo delle Biomasse emergenti nel processo di transizione ecologica: caratterizzazione e confronto degli impatti ambientali rispetto alle fonti energetiche tradizionali e rinnovabili”.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Acknowledgments

The authors wish to thank the CNR for funding the Ph.D. course and Aristide Giuliano (ENEA) for his helpful and important contribution to the discussion.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Kang, M.; Zhao, W.; Jia, L.; Liu, Y. Balancing carbon emission reductions and social economic development for sustainable development: Experience from 24 countries. Chin. Geogr. Sci. 2020, 30, 379–396. [Google Scholar] [CrossRef]

- Martins, F.; Felgueiras, C.; Smitková, M. Fossil fuel energy consumption in European countries. Energy Procedia 2018, 153, 107–111. [Google Scholar] [CrossRef]

- Lelieveld, J.; Klingmüller, K.; Pozzer, A.; Burnett, R.T.; Haines, A.; Ramanathan, V. Effects of fossil fuel and total anthropogenic emission removal on public health and climate. Proc. Natl. Acad. Sci. USA 2019, 116, 7192–7197. [Google Scholar] [CrossRef]

- Kularathne, I.W.; Gunathilake, C.A.; Rathneweera, A.C.; Kalpage, C.S.; Rajapakse, S. The effect of use of biofuels on environmental pollution—A review. Int. J. Renew. Energy Res. 2019, 9, 1355–1367. [Google Scholar]

- Montt, G.; Fraga, F.; Harsdorff, M. The Future of Work in a Changing Natural Environment: Climate Change, Degradation and Sustainability; ILO Research Paper Series; International Labour Office: Geneva, Switzerland, 2018. [Google Scholar]

- Cifuentes-Faura, J. European Union policies and their role in combating climate change over the years. Air Qual. Atmos. Health 2022, 15, 1333–1340. [Google Scholar] [CrossRef] [PubMed]

- Cambini, C.; Congiu, R.; Jamasb, T.; Llorca, M.; Soroush, G. Energy systems integration: Implications for public policy. Energy Policy 2020, 143, 111609. [Google Scholar] [CrossRef]

- Johannsen, R.M.; Mathiesen, B.V.; Kermeli, K.; Crijns-Graus, W.; Østergaard, P.A. Exploring pathways to 100% renewable energy in European industry. Energy 2023, 268, 126687. [Google Scholar] [CrossRef]

- Singh, R.S.; Singh, R.K.; Tripathi, N. Food Waste Utilization for the Production of Biogas by Anaerobic Digestion: A Case Study in Coal Capital of India. In Environmental Management in India: Waste to Wealth, 1st ed.; Springer International Publishing: Cham, Switzerland, 2022; pp. 147–166. [Google Scholar]

- Wang, Q.; Xia, C.; Alagumalai, K.; Le, T.T.N.; Yuan, Y.; Khademi, T.; Berkani, M.; Lu, H. Biogas generation from biomass as a cleaner alternative towards a circular bioeconomy: Artificial intelligence, challenges, and future insights. Fuel 2023, 333, 126456. [Google Scholar] [CrossRef]

- Fortuński, B. Sustainable development and energy policy: Actual CO2 emissions in the european union in the years 1997–2017, considering trade with china and the USA. Sustainability 2020, 12, 3363. [Google Scholar] [CrossRef]

- D’Adamo, I.; Sassanelli, C. Biomethane community: A research agenda towards sustainability. Sustainability 2022, 14, 4735. [Google Scholar] [CrossRef]

- Biber-Freudenberger, L.; Basukala, A.; Bruckner, M.; Börner, J. Sustainability Performance of National Bio-Economies. Sustainability 2018, 10, 2705. [Google Scholar] [CrossRef]

- Stark, S.; Biber-Freudenberger, L.; Dietz, T.; Escobar, N.; Förster, J.J.; Henderson, J.; Laibach, N.; Börner, J. Sustainability implications of transformation pathways for the bioeconomy. Sustain. Prod. Consum. 2022, 29, 215–227. [Google Scholar] [CrossRef]

- Krausmann, F.; Schandl, H.; Eisenmenger, N.; Giljum, S.; Jackson, T. Material flow accounting: Measuring global material use for sustainable development. Annu. Rev. Environ. Resour. 2017, 42, 647–675. [Google Scholar] [CrossRef]

- Kasinath, A.; Fudala-Ksiazek, S.; Szopinska, M.; Bylinski, H.; Artichowicz, W.; Remiszewska-Skwarek, A.; Luczkiewicz, A. Biomass in biogas production: Pretreatment and codigestion. Renew. Sustain. Energy Rev. 2021, 150, 111509. [Google Scholar] [CrossRef]

- Bhanuprakasha, P.; Babua, T.H.; Ramakrishnab, S.; Ramesha, A. Need to shift towards clean, reliable, accessible and affordable renewable energy resources for a sustainable future. In Proceedings of the Pollution Control and Sustainable Environment, New Delhi, India, 24–25 February 2023; p. 1. [Google Scholar]

- Shen, F.; Xiong, X.; Fu, J.; Yang, J.; Qiu, M.; Qi, X.; Tsang, D.C. Recent advances in mechanochemical production of chemicals and carbon materials from sustainable biomass resources. Renew. Sustain. Energy Rev. 2020, 130, 109944. [Google Scholar] [CrossRef]

- Awasthi, M.K.; Sarsaiya, S.; Patel, A.; Juneja, A.; Singh, R.P.; Yan, B.; Awasthi, S.K.; Jain, A.; Liu, T.; Duan, Y.; et al. Refining biomass residues for sustainable energy and bio-products: An assessment of technology, its importance, and strategic applications in circular bio-economy. Renew. Sustain. Energy Rev. 2020, 127, 109876. [Google Scholar] [CrossRef]

- Speight, J.G.; Radovanovic, L. Biogas-A Substitute for Natural Gas. Ann. Fac. Eng. Hunedoara 2020, 18, 95–99. [Google Scholar]

- Magazzino, C.; Toma, P.; Fusco, G.; Valente, D.; Petrosillo, I. Renewable energy consumption, environmental degradation and economic growth: The greener the richer? Ecol. Indic. 2022, 139, 108912. [Google Scholar] [CrossRef]

- Pappalardo, G.; Selvaggi, R.; Pecorino, B. Biomethane production potential in Southern Italy: An empirical approach. Renew. Sustain. Energy Rev. 2022, 158, 112190. [Google Scholar] [CrossRef]

- Reducing Greenhouse Gas Emissions: Commission Adopts EU Methane Strategy as Part of European Green Deal. Available online: https://ec.europa.eu/commission/presscorner/detail/en/ip_20_1833 (accessed on 7 September 2023).

- Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and Committee of the Regions Powering a Climate-Neutral Economy: An EU Strategy for Energy System Integration. Available online: https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=CELEX%3A52020DC0299 (accessed on 20 April 2023).

- Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and Committee of the Regions A Farm to Fork Strategy for a Fair, Healthy and Environmentally-Friendly Food System. Available online: https://food.ec.europa.eu/horizontal-topics/farm-fork-strategy_en (accessed on 18 April 2023).

- Gustafsson, M.; Anderberg, S. Biogas policies and production development in Europe: A comparative analysis of eight countries. Biofuels 2022, 13, 931–944. [Google Scholar] [CrossRef]

- Haque, S.; Singh, R.; Pal, D.B.; Harakeh, S.; Alghanmi, M.; Teklemariam, A.D.; Abujamel, T.S.; Srivastava, N.; Gupta, V.K. Recent Update on anaerobic digestion of paddy straw for biogas production: Advancement, limitation and recommendations. Environ. Res. 2022, 215, 114292. [Google Scholar] [CrossRef]

- Tena, M.; Buller, L.S.; Sganzerla, W.G.; Berni, M.; Forster-Carneiro, T.; Solera, R.; Pérez, M. Techno-economic evaluation of bioenergy production from anaerobic digestion of by-products from ethanol flex plants. Fuel 2022, 309, 122171. [Google Scholar] [CrossRef]

- Ocak, S.; Acar, S. Biofuels from wastes in Marmara Region, Turkey: Potentials and constraints. Environ. Sci. Pollut. Res. 2021, 28, 66026–66042. [Google Scholar] [CrossRef]

- Deora, P.S.; Verma, Y.; Muhal, R.A.; Goswami, C.; Singh, T. Biofuels: An alternative to conventional fuel and energy source. Mater. Today Proc. 2022, 48, 1178–1184. [Google Scholar] [CrossRef]

- Korbag, I.; Omer, S.M.S.; Boghazala, H.; Abusasiyah, M.A.A. Recent advances of biogas production and future perspective. In Biogas—Recent Advances and Integrated Approaches, 1st ed.; Abomohra, A.E.-F., Elsayed, M., Qin, Z., Ji, H., Liu, Z., Eds.; IntechOpen: London, UK, 2020; pp. 1–3. [Google Scholar]

- Neshat, S.A.; Mohammadi, M.; Najafpour, G.D.; Lahijani, P. Anaerobic co-digestion of animal manures and lignocellulosic residues as a potent approach for sustainable biogas production. Renew. Sustain. Energy Rev. 2017, 79, 308–322. [Google Scholar] [CrossRef]

- Ivanovs, K.; Spalvins, K.; Blumberga, D. Approach for modelling anaerobic digestion processes of fish waste. Energy Procedia 2018, 147, 390–396. [Google Scholar] [CrossRef]

- Methane Emissions—Energy—European Union. Available online: https://energy.ec.europa.eu/topics/oil-gas-and-coal/methane-emissions_en (accessed on 13 June 2023).

- Seong, M.S.; Kong, C.I.; Park, B.R.; Lee, Y.; Na, B.K.; Kim, J.H. Optimization of pilot-scale 3-stage membrane process using asymmetric polysulfone hollow fiber membranes for production of high-purity CH4 and CO2 from crude biogas. Chem. Eng. J. 2020, 384, 123342. [Google Scholar] [CrossRef]

- Balcombe, P.; Heggo, D.A.; Harrison, M. Total methane and CO2 emissions from liquefied natural gas carrier ships: The first primary measurements. Environ. Sci. Technol. 2022, 56, 9632–9640. [Google Scholar] [CrossRef]

- Bakkaloglu, S.; Cooper, J.; Hawkes, A. Methane emissions along biomethane and biogas supply chains are underestimated. One Earth 2022, 5, 724–736. [Google Scholar] [CrossRef]

- World Meteorological Association. State of the Global Climate 2021; World Meteorological Association: Geneva, Switzerland, 2022; Available online: https://policycommons.net/artifacts/2434625/1290_statement_2021_en/3456217/ (accessed on 20 July 2023).

- Pavičić, J.; Novak Mavar, K.; Brkić, V.; Simon, K. Biogas and Biomethane Production and Usage: Technology Development, Advantages and Challenges in Europe. Energies 2022, 15, 2940. [Google Scholar] [CrossRef]

- Haryanto, A.; Triyono, S.; Wicaksono, N.H. Effect of hydraulic retention time on biogas production from cow dung in a semi continuous anaerobic digester. Int. J. Renew. Energy Dev. 2018, 7, 93–100. [Google Scholar] [CrossRef]

- Nwokolo, N.; Mukumba, P.; Obileke, K.; Enebe, M. Waste to energy: A focus on the impact of substrate type in biogas production. Processes 2020, 8, 1224. [Google Scholar] [CrossRef]

- Atelge, M.R.; Krisa, D.; Kumar, G.; Eskicioglu, C.; Nguyen, D.D.; Chang, S.W.; Atabani, A.E.; Al-Muhtaseb, A.H.; Unalan, S. Biogas production from organic waste: Recent progress and perspectives. Waste Biomass Valorization 2020, 11, 1019–1040. [Google Scholar] [CrossRef]

- Abomohra, A.; Faisal, S.; Ebaid, R.; Huang, J.; Wang, Q.; Elsayed, M. Recent advances in anaerobic digestion of lipid-rich waste: Challenges and potential of seaweeds to mitigate the inhibitory effect. Chem. Eng. J. 2022, 449, 137829. [Google Scholar] [CrossRef]

- Jiang, B.; Zhang, Y.; Guo, T.; Zhao, H.; Jin, Y. Structural Characterization of Lignin and Lignin-Carbohydrate Complex (LCC) from Ginkgo Shells (Ginkgo biloba L.) by Comprehensive NMR Spectroscopy. Polymers 2018, 10, 736. [Google Scholar] [CrossRef]

- Hernández-Beltrán, J.U.; Lira, I.O.H.-D.; Cruz-Santos, M.M.; Saucedo-Luevanos, A.; Hernández-Terán, F.; Balagurusamy, N. Insight into Pretreatment Methods of Lignocellulosic Biomass to Increase Biogas Yield: Current State, Challenges, and Opportunities. Appl. Sci. 2019, 9, 3721. [Google Scholar] [CrossRef]

- Khan, M.U.; Ahring, B.K. Anaerobic digestion of biorefinery lignin: Effect of different wet explosion pretreatment conditions. Bioresour. Technol. 2020, 298, 122537. [Google Scholar] [CrossRef] [PubMed]

- Qiao, W.; Yan, X.; Ye, J.; Sun, Y.; Wang, W.; Zhang, Z. Evaluation of biogas production from different biomass wastes with/without hydrothermal pretreatment. Renew. Energy 2011, 36, 3313–3318. [Google Scholar] [CrossRef]

- Barbera, E.; Menegon, S.; Banzato, D.; D’Alpaos, C.; Bertucco, A. From biogas to biomethane: A process simulation-based techno-economic comparison of different upgrading technologies in the Italian context. Renew. Energy 2019, 135, 663–673. [Google Scholar] [CrossRef]

- Scarlat, N.; Dallemand, J.F.; Fahl, F. Biogas: Developments and perspectives in Europe. Renew. Energy 2018, 129, 457–472. [Google Scholar] [CrossRef]

- Samun, I.; Saeed, R.; Abbas, M.; Rehan, M.; Nizami, A.S.; Asam, Z.Z. Assessment of bioenergy production from solid waste. Energy Procedia 2017, 142, 655–660. [Google Scholar] [CrossRef]

- Diamantis, V.; Eftaxias, A.; Stamatelatou, K.; Noutsopoulos, C.; Vlachokostas, C.; Aivasidis, A. Bioenergy in the era of circular economy: Anaerobic digestion technological solutions to produce biogas from lipid-rich wastes. Renew. Energy 2021, 168, 438–447. [Google Scholar] [CrossRef]

- Le Pera, A.; Sellaro, M.; Bencivenni, E.; D’Amico, F. Environmental sustainability of an integrate anaerobic digestion-composting treatment of food waste: Analysis of an Italian plant in the circular bioeconomy strategy. Waste Manag. 2022, 139, 341–351. [Google Scholar] [CrossRef] [PubMed]

- Notton, G.; Nivet, M.L.; Voyant, C.; Paoli, C.; Darras, C.; Motte, F.; Fouilloy, A. Intermittent and stochastic character of renewable energy sources: Consequences, cost of intermittence and benefit of forecasting. Renew. Sustain. Energy Rev. 2018, 87, 96–105. [Google Scholar] [CrossRef]

- Korberg, A.D.; Skov, I.R.; Mathiesen, B.V. The role of biogas and biogas-derived fuels in a 100% renewable energy system in Denmark. Energy 2020, 199, 117426. [Google Scholar] [CrossRef]

- Eyl-Mazzega, M.A.; Mathieu, C. (Eds.) Biogas and Biomethane in Europe: Lessons from Denmark, Germany and Italy; Institut Français des Relations Internationales; Etudes de l’Ifri (IFRI): Paris, France, 2019; Available online: https://policycommons.net/artifacts/1406133/biogas-and-biomethane-in-europe/2020400/ (accessed on 24 July 2023).