Intelligent Machinery Fault Diagnosis Method Based on Adaptive Deep Convolutional Neural Network: Using Dental Milling Cutter Malfunction Classifications as an Example

Abstract

:1. Introduction

2. Basic Theory

2.1. Continuous Wavelet Transform (CWT)

2.2. Gaussian Filter

2.3. Gramian Angular Field (GAF)

2.4. Convolutional Neural Network (CNN)

2.4.1. Convolution Layer

2.4.2. Pooling Layer

2.4.3. Fully Connected Layer

3. Adaptive Data Fusion Method Based on ADCNN for Fault Diagnosis

3.1. Multi-Sensor Information

3.2. Data Preprocessing

3.3. Data Fusion and Feature Extraction

3.4. Feature Fusion

3.5. Fault Classification

4. Experiment and Discussion

4.1. Experiment Setup

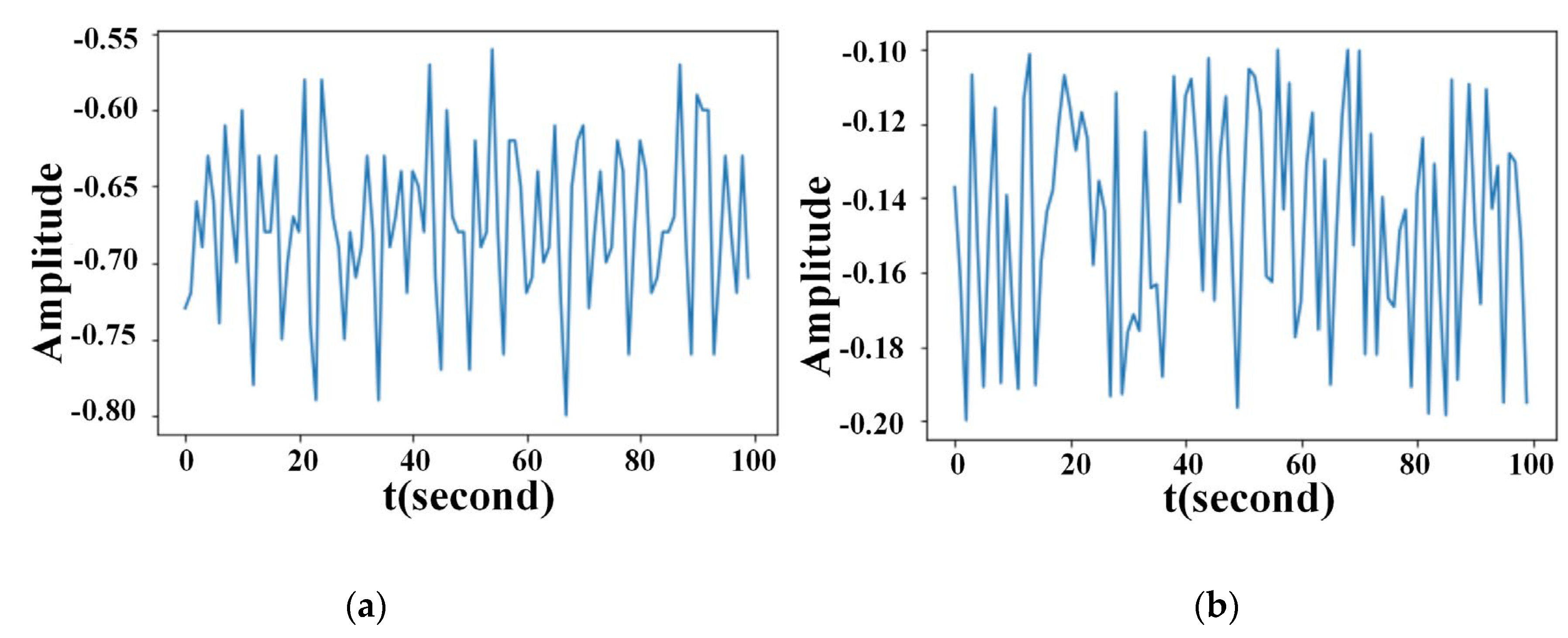

4.2. Dataset

4.3. Parameter Selection for the DCNN Model

4.4. Experimental Results

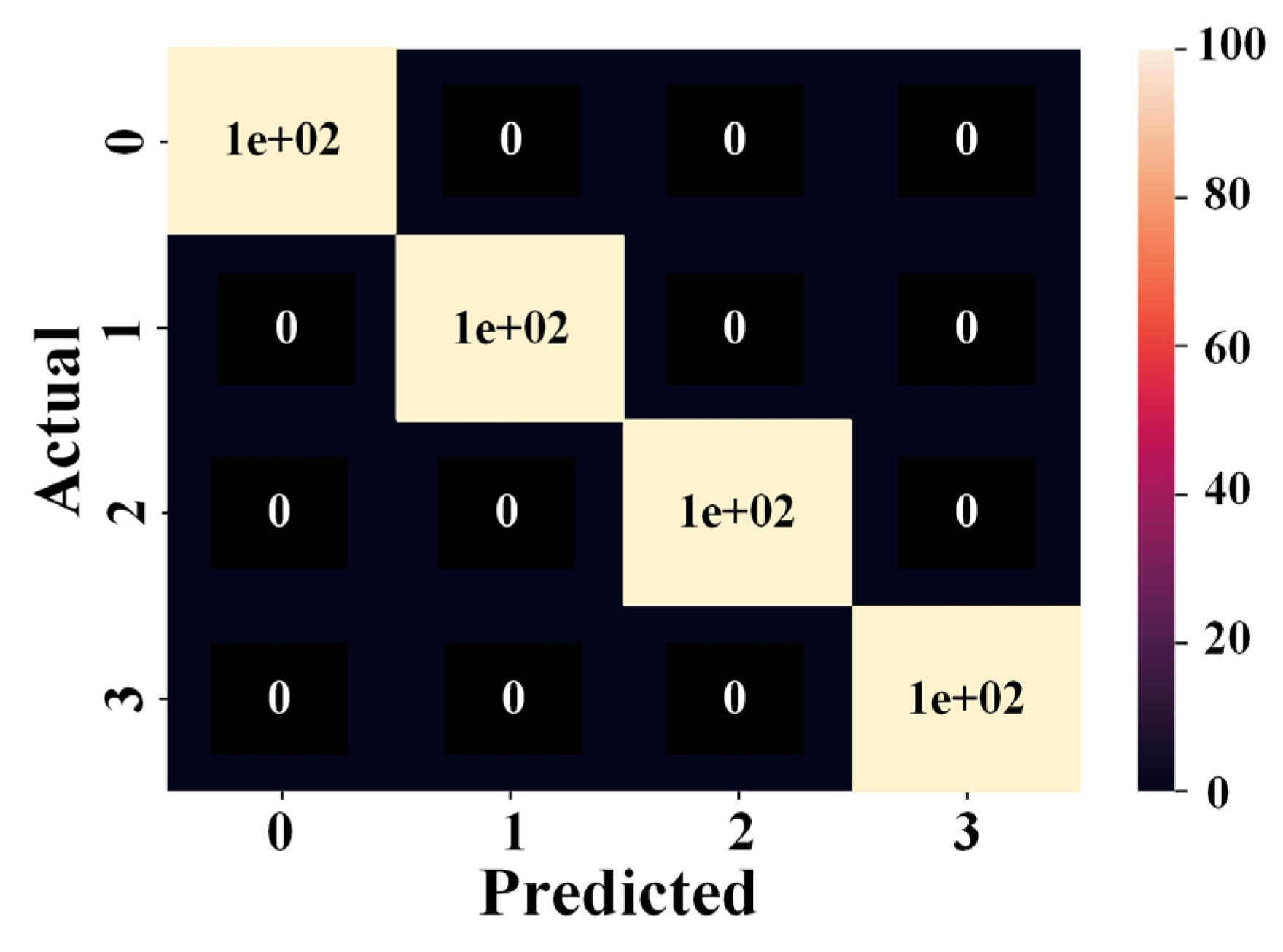

4.4.1. Performance Validation of the ADCNN Model

4.4.2. Performance Validation with Noise

4.5. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Vununu, C.; Kwon, K.R.; Lee, E.J.; Moon, K.S.; Lee, S.H. Automatic Fault Diagnosis of Drills Using Artificial Neural Networks. In Proceedings of the 2017 16th IEEE International Conference on Machine Learning and Applications (ICMLA), Cancun, Mexico, 18–21 December 2017; pp. 992–995. [Google Scholar]

- Senjoba, L.; Sasaki, J.; Kosugi, Y.; Toriya, H.; Hisada, M.; Kawamura, Y. One-Dimensional Convolutional Neural Network for Drill Bit Failure Detection in Rotary Percussion Drilling. Mining 2021, 1, 297–314. [Google Scholar] [CrossRef]

- Wu, L.; Dong, Z.; Li, W.; Jing, C.; Qu, B. Well-Logging Prediction Based on Hybrid Neural Network Model. Energies 2021, 14, 8583. [Google Scholar] [CrossRef]

- Wieczorek, G.; Chlebus, M.; Gajda, J.; Chyrowicz, K.; Kontna, K.; Korycki, M.; Jegorowa, A.; Kruk, M. Multiclass Image Classification Using GANs and CNN Based on Holes Drilled in Laminated Chipboard. Sensors 2021, 21, 8077. [Google Scholar] [CrossRef]

- Mahmood, J.; Mustafa, G.-E.; Ali, M. Accurate estimation of tool wear levels during milling, drilling and turning operations by designing novel hyperparameter tuned models based on LightGBM and stacking. Measurement 2022, 190, 110722. [Google Scholar] [CrossRef]

- Pradeep Kumar, D.; Muralidharan, V.; Ravikumar, S. Histogram as features for fault detection of multi point cutting tool—A data driven approach. Appl. Acoust. 2022, 186, 108456. [Google Scholar] [CrossRef]

- Si, Y.; Li, X.; Kong, L.; Zhen, J.; Li, Y. Improved empirical wavelet denoising algorithm with application to whirling detection in deep hole drilling process. Procedia CIRP 2021, 104, 1924–1929. [Google Scholar] [CrossRef]

- Pham, M.-T.; Kim, J.-M.; Kim, C.-H. 2D CNN-Based Multi-Output Diagnosis for Compound Bearing Faults under Variable Rotational Speeds. Machines 2021, 9, 199. [Google Scholar] [CrossRef]

- van den Hoogen, J.; Bloemheuvel, S.; Atzmueller, M. Classifying Multivariate Signals in Rolling Bearing Fault Detection Using Adaptive Wide-Kernel CNNs. Appl. Sci. 2021, 11, 11429. [Google Scholar] [CrossRef]

- Ji, M.; Peng, G.; He, J.; Liu, S.; Chen, Z.; Li, S. A Two-Stage, Intelligent Bearing-Fault-Diagnosis Method Using Order-Tracking and a One-Dimensional Convolutional Neural Network with Variable Speeds. Sensors 2021, 21, 675. [Google Scholar] [CrossRef]

- Zhai, S.; Wang, Z.; Gao, D. Bearing Fault Diagnosis Based on a Novel Adaptive ADSD-gcForest Model. Processes 2022, 10, 209. [Google Scholar] [CrossRef]

- Yang, Z.; Yang, R.; Huang, M. Rolling Bearing Incipient Fault Diagnosis Method Based on Improved Transfer Learning with Hybrid Feature Extraction. Sensors 2021, 21, 7894. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Liu, G.; Tang, X.; Lu, J.; Hu, J. An Ensemble Deep Convolutional Neural Network Model with Improved D-S Evidence Fusion for Bearing Fault Diagnosis. Sensors 2017, 17, 1729. [Google Scholar] [CrossRef] [Green Version]

- Jiang, Y.; Xia, T.; Wang, D.; Zhang, K.; Xi, L. Joint adaptive transfer learning network for cross-domain fault diagnosis based on multi-layer feature fusion. Neurocomputing 2022, 487, 228–242. [Google Scholar] [CrossRef]

- Zhang, Y.; He, L.; Cheng, G. MLPC-CNN: A multi-sensor vibration signal fault diagnosis method under less computing resources. Measurement 2022, 188, 110407. [Google Scholar] [CrossRef]

- Pacella, M.; Papadia, G. Fault Diagnosis by Multisensor Data: A Data-Driven Approach Based on Spectral Clustering and Pairwise Constraints. Sensors 2020, 20, 7065. [Google Scholar] [CrossRef] [PubMed]

- Zhang, N. Research on Automatic Fault Diagnosis System of Coal Mine Drilling Rigs based on Drilling Parameters. In Proceedings of the 2019 IEEE 4th Advanced Information Technology, Electronic and Automation Control Conference (IAEAC), Chengdu, China, 20–22 December 2019; pp. 2373–2377. [Google Scholar]

- Oh, D.C.; Jo, Y.U. EMG-based hand gesture classification by scale average wavelet transform and CNN. In Proceedings of the 2019 19th International Conference on Control, Automation and Systems (ICCAS), Jeju, Republic of Korea, 15–18 October 2019; pp. 533–538. [Google Scholar]

- Xie, Y.; Zhang, T. Feature extraction based on DWT and CNN for rotating machinery fault diagnosis. In Proceedings of the 2017 29th Chinese Control and Decision Conference (CCDC), Chongqing, China, 28–30 May 2017; pp. 3861–3866. [Google Scholar]

- Eltotongy, A.; Awad, M.I.; Maged, S.A.; Onsy, A. Fault Detection and Classification of Machinery Bearing Under Variable Operating Conditions Based on Wavelet Transform and CNN. In Proceedings of the 2021 International Mobile, Intelligent, and Ubiquitous Computing Conference (MIUCC), Cairo, Egypt, 26–27 May 2021; pp. 117–123. [Google Scholar]

- Huang, D.; Zhang, W.A.; Guo, F.; Liu, W.; Shi, X. Wavelet Packet Decomposition-Based Multiscale CNN for Fault Diagnosis of Wind Turbine Gearbox. IEEE Trans. Cybern. 2021, 53, 443–453. [Google Scholar] [CrossRef]

- Wang, T.; Lu, C.; Sun, Y.; Yang, M.; Liu, C.; Ou, C. Automatic ECG Classification Using Continuous Wavelet Transform and Convolutional Neural Network. Entropy 2021, 23, 119. [Google Scholar] [CrossRef]

- Kahr, M.; Kovács, G.; Loinig, M.; Brückl, H. Condition Monitoring of Ball Bearings Based on Machine Learning with Synthetically Generated Data. Sensors 2022, 22, 2490. [Google Scholar] [CrossRef]

- Zhu, Y.; Li, G.; Wang, R.; Tang, S.; Su, H.; Cao, K. Intelligent Fault Diagnosis of Hydraulic Piston Pump Based on Wavelet Analysis and Improved AlexNet. Sensors 2021, 21, 549. [Google Scholar] [CrossRef]

- Gao, D.; Zhu, Y.; Wang, X.; Yan, K.; Hong, J. A Fault Diagnosis Method of Rolling Bearing Based on Complex Morlet CWT and CNN. In Proceedings of the 2018 Prognostics and System Health Management Conference (PHM-Chongqing), Chongqing, China, 26–28 October 2018; pp. 1101–1105. [Google Scholar]

- Tang, S.; Zhu, Y.; Yuan, S.; Li, G. Intelligent Diagnosis towards Hydraulic Axial Piston Pump Using a Novel Integrated CNN Model. Sensors 2020, 20, 7152. [Google Scholar] [CrossRef]

- Wen, L.; Li, X.; Gao, L.; Zhang, Y. A New Convolutional Neural Network-Based Data-Driven Fault Diagnosis Method. IEEE Trans. Ind. Electron. 2018, 65, 5990–5998. [Google Scholar] [CrossRef]

- Xu, G.; Liu, M.; Jiang, Z.; Söffker, D.; Shen, W. Bearing Fault Diagnosis Method Based on Deep Convolutional Neural Network and Random Forest Ensemble Learning. Sensors 2019, 19, 1088. [Google Scholar] [CrossRef] [Green Version]

- Junior, R.F.R.; Areias, I.A.d.S.; Campos, M.M.; Teixeira, C.E.; da Silva, L.E.B.; Gomes, G.F. Fault detection and diagnosis in electric motors using 1d convolutional neural networks with multi-channel vibration signals. Measurement 2022, 190, 110759. [Google Scholar] [CrossRef]

- Mao, G.; Zhang, Z.; Qiao, B.; Li, Y. Fusion Domain-Adaptation CNN Driven by Images and Vibration Signals for Fault Diagnosis of Gearbox Cross-Working Conditions. Entropy 2022, 24, 119. [Google Scholar] [CrossRef] [PubMed]

- Lin, S.-L. Application Combining VMD and ResNet101 in Intelligent Diagnosis of Motor Faults. Sensors 2021, 21, 6065. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Liu, C.; Du, W.; Wang, S. Intelligent Diagnosis of Rotating Machinery Based on Optimized Adaptive Learning Dictionary and 1DCNN. Appl. Sci. 2021, 11, 11325. [Google Scholar] [CrossRef]

- Oh, Y.; Kim, Y.; Na, K.; Youn, B.D. A deep transferable motion-adaptive fault detection method for industrial robots using a residual–convolutional neural network. ISA Trans. 2021, 128, 521–534. [Google Scholar] [CrossRef]

- Zhang, K.; Tang, B.; Deng, L.; Tan, Q.; Yu, H. A fault diagnosis method for wind turbines gearbox based on adaptive loss weighted meta-ResNet under noisy labels. Mech. Syst. Signal Process. 2021, 161, 107963. [Google Scholar] [CrossRef]

- Zhang, G.; Li, Y.; Jiang, W.; Shu, L. A fault diagnosis method for wind turbines with limited labeled data based on balanced joint adaptive network. Neurocomputing 2022, 481, 133–153. [Google Scholar] [CrossRef]

- Li, W.; Shang, Z.; Gao, M.; Qian, S.; Zhang, B.; Zhang, J. A novel deep autoencoder and hyperparametric adaptive learning for imbalance intelligent fault diagnosis of rotating machinery. Eng. Appl. Artif. Intell. 2021, 102, 104279. [Google Scholar] [CrossRef]

- Zhang, T.; Liu, S.; Wei, Y.; Zhang, H. A novel feature adaptive extraction method based on deep learning for bearing fault diagnosis. Measurement 2021, 185, 110030. [Google Scholar] [CrossRef]

- Ye, Z.; Yu, J. AKSNet: A novel convolutional neural network with adaptive kernel width and sparse regularization for machinery fault diagnosis. J. Manuf. Syst. 2021, 59, 467–480. [Google Scholar] [CrossRef]

- Niu, G.; Wang, X.; Golda, M.; Mastro, S.; Zhang, B. An optimized adaptive PReLU-DBN for rolling element bearing fault diagnosis. Neurocomputing 2021, 445, 26–34. [Google Scholar] [CrossRef]

- Kumar, P.; Hati, A.S. Deep convolutional neural network based on adaptive gradient optimizer for fault detection in SCIM. ISA Trans. 2021, 111, 350–359. [Google Scholar] [CrossRef]

- Liang, H.; Cao, J.; Zhao, X. Multi-scale dynamic adaptive residual network for fault diagnosis. Measurement 2022, 188, 110397. [Google Scholar] [CrossRef]

- Jing, L.; Wang, T.; Zhao, M.; Wang, P. An Adaptive Multi-Sensor Data Fusion Method Based on Deep Convolutional Neural Networks for Fault Diagnosis of Planetary Gearbox. Sensors 2017, 17, 414. [Google Scholar] [CrossRef] [Green Version]

- Ainapure, A.; Siahpour, S.; Li, X.; Majid, F.; Lee, J. Intelligent Robust Cross-Domain Fault Diagnostic Method for Rotating Machines Using Noisy Condition Labels. Mathematics 2022, 10, 455. [Google Scholar] [CrossRef]

- Li, S.; Wang, H.; Song, L.; Wang, P.; Cui, L.; Lin, T. An adaptive data fusion strategy for fault diagnosis based on the convolutional neural network. Measurement 2020, 165, 108122. [Google Scholar] [CrossRef]

- Wang, C.; Li, H.; Zhang, K.; Hu, S.; Sun, B. Intelligent fault diagnosis of planetary gearbox based on adaptive normalized CNN under complex variable working conditions and data imbalance. Measurement 2021, 180, 109565. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, C.; Wang, R.; Qian, J. A novel fault diagnosis method based on multi-level information fusion and hierarchical adaptive convolutional neural networks for centrifugal blowers. Measurement 2021, 185, 109970. [Google Scholar] [CrossRef]

- Chen, P.; Li, Y.; Wang, K.; Zuo, M.J. An automatic speed adaption neural network model for planetary gearbox fault diagnosis. Measurement 2021, 171, 108784. [Google Scholar] [CrossRef]

- Shankar, A.; Dandapat, S.; Barma, S. Seizure Type Classification Using EEG Based on Gramian Angular Field Transformation and Deep Learning. In Proceedings of the 2021 43rd Annual International Conference of the IEEE Engineering in Medicine & Biology Society (EMBC), Virtual, 1–5 November 2021; pp. 3340–3343. [Google Scholar]

- Xu, H.; Li, J.; Yuan, H.; Liu, Q.; Fan, S.; Li, T.; Sun, X. Human Activity Recognition Based on Gramian Angular Field and Deep Convolutional Neural Network. IEEE Access 2020, 8, 199393–199405. [Google Scholar] [CrossRef]

- Sreenivas, K.V.; Ganesan, M.; Lavanya, R. Classification of Arrhythmia in Time Series ECG Signals Using Image Encoding And Convolutional Neural Networks. In Proceedings of the 2021 Seventh International conference on Bio Signals, Images, and Instrumentation (ICBSII), Chennai, India, 25–27 March 2021; pp. 1–6. [Google Scholar]

- Wikimedia. Gaussian Filter. 2023. Available online: https://en.wikipedia.org/wiki/Gaussian_filter (accessed on 5 March 2023).

| Type Label | Health Condition | Description | Processing Speed (rpm) |

|---|---|---|---|

| 0 | Normal | Normal processing | 20,000 |

| 1 | Breaking | Overheated or too dull and resulted in breaking | 20,000 |

| 2 | Wear | Poor quality of dentures due to wear that is visually undetectable | 20,000 |

| 3 | Tipping | Overheating or too dull and resulted in tipping | 20,000 |

| Layer | Parameter Name | Parameter Size | Output Size |

|---|---|---|---|

| Input | / | / | 127 × 127 × 3 |

| Conv1 | Convolutional kernel | 5 × 5 | 123 × 123 × 32 |

| Dropout | Dropout neuron ratio | 30% | / |

| Max-p1 | Max pooling kernel | 2 × 2 | 61 × 61 × 32 |

| Conv2 | Convolutional kernel | 5 × 5 | 57 × 57 × 64 |

| Dropout | Dropout neuron ratio | 30% | / |

| Max-p2 | Max pooling kernel | 2 × 2 | 28 × 28 × 64 |

| Conv3 | Convolutional kernel | 5 × 5 | 24 × 24 × 64 |

| Dropout | Dropout neuron ratio | 20% | / |

| Max-p3 | Max pooling kernel | 2 × 2 | 12 × 12 × 64 |

| FC1 | Fully connected neuron | 1000 | 9216 × 1000 + 1000 |

| FC2 | Fully connected neuron | 4 | 1000 × 4 + 4 |

| Output | Weight matrix | 4004 × 4 | 4 × 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, M.-H.; Chen, S.-L.; Lin, Y.-S.; Chen, Y.-J. Intelligent Machinery Fault Diagnosis Method Based on Adaptive Deep Convolutional Neural Network: Using Dental Milling Cutter Malfunction Classifications as an Example. Appl. Sci. 2023, 13, 7763. https://doi.org/10.3390/app13137763

Chen M-H, Chen S-L, Lin Y-S, Chen Y-J. Intelligent Machinery Fault Diagnosis Method Based on Adaptive Deep Convolutional Neural Network: Using Dental Milling Cutter Malfunction Classifications as an Example. Applied Sciences. 2023; 13(13):7763. https://doi.org/10.3390/app13137763

Chicago/Turabian StyleChen, Ming-Huang, Shang-Liang Chen, Yu-Sheng Lin, and Yu-Jen Chen. 2023. "Intelligent Machinery Fault Diagnosis Method Based on Adaptive Deep Convolutional Neural Network: Using Dental Milling Cutter Malfunction Classifications as an Example" Applied Sciences 13, no. 13: 7763. https://doi.org/10.3390/app13137763

APA StyleChen, M.-H., Chen, S.-L., Lin, Y.-S., & Chen, Y.-J. (2023). Intelligent Machinery Fault Diagnosis Method Based on Adaptive Deep Convolutional Neural Network: Using Dental Milling Cutter Malfunction Classifications as an Example. Applied Sciences, 13(13), 7763. https://doi.org/10.3390/app13137763