Abstract

In this study, sea buckthorn (Hippophae rhamnoides L.) pomace resulting from juice extraction was dried and ground in order to obtain a powder that was further used in bread making. Sea buckthorn pomace, an invaluable by-product of the industry, contains bioactive compounds and dietary fibers that promote health. Dried by-products of sea buckthorn are rich sources of nutritional and bioactive compounds, offering great potential for use as nutraceuticals in animal feed, ingredients in functional food, and the pharmaceutical industry. The utilization of sea buckthorn by-products promotes a circular and sustainable economy by implementing innovative methods and strategic approaches to recover high-value products and minimize waste in multiple ways. For this purpose, three organic sea buckthorn varieties were used, namely Mara (M), Clara (C), and Sorana (S). Further, 6%, 8%, and 10% pomace powder were added to wheat flour to prepare functional bread, and its effects on structural, nutritional, and sensorial characteristics were investigated. The volume, porosity, and elasticity of the obtained bread samples were slightly lower compared to the control sample (white bread). The nutritional characteristics revealed that the developed bread presented higher antioxidant activity, polyphenolic content, and crude fiber compared to the control sample. The acceptability test showed that consumer preferences were directed toward the bread samples containing 8% sea buckthorn powder, regardless of the variety, while the addition of 10% pomace powder led to major sensorial changes. The results of this study showed that sea buckthorn pomace powder can be successfully incorporated into bread in order to obtain a food product with enhanced properties.

1. Introduction

Recent interest by consumers for fresh, local, and nutritionally enriched food products with a low impact on the environment has led to the development of foods with enhanced properties using functional ingredients obtained from fruit and vegetable by-products. In this context, valorization of food by-products and waste is important both at national and regional levels to help achieve the targets established by the United Nations Sustainable Development Goals in order to fulfill green and circular economy principles and efficient management of resources [1].

The appropriate utilization of food waste and by-products as raw materials or food additives has the potential to yield economic benefits for the industry. Additionally, it can contribute to the mitigation of nutritional issues, generate positive health effects, and reduce the environmental consequences associated with waste mismanagement. Currently, industries are actively seeking innovations to achieve zero waste, wherein generated waste is repurposed as raw materials for new products and applications. Such actions can directly influence the attainment of the Millennium Development Goals, the forthcoming Sustainable Development Goals, the Post-2015 Agenda, and the Zero Hunger Challenge [2]. The nutritional challenges faced by contemporary society emphasize the necessity for alternative sources of nutrients and functional compounds. The significant quantity of waste generated by the food industry not only results in the loss of valuable materials but also presents substantial management difficulties, both in economic and environmental terms. Nevertheless, numerous food waste residues have the potential to be repurposed in alternative production systems. These residues can be utilized directly as powders after the removal of antinutritional factors, or their lipids and antioxidants can be extracted for further use [3].

Bread is a staple food [4,5] and is one of the most consumed foods all over the world [6]. Over the years, studies have been performed for bread enrichment in nutritional composition by adding different flours or ingredients with high amounts of bioactive compounds [7] and health benefits [8].

Sea buckthorn (Hippophae rhamnoides L.) belongs to the Elaeagnaceae family. It is a deciduous shrub that is widely found in Northwestern Europe and Asia and is distributed from the coastal regions to the mountains [9]. Its use and processing gained more and more attention recently due to its nutritional properties and health benefits; it is rich in ascorbic acid, carotenoids, tannins, tocopherols, fatty acids, and flavonoids and improves blood circulation, relieving irritability. It is a good immunity enhancer, protecting the cardiovascular system, resisting oxidation, and presenting great antimicrobial properties [9,10,11]. Sea buckthorn berries can be consumed in their natural state or be processed into juice, with the latter resulting in a significant amount of pomace. Unfortunately, pomace is often regarded as waste [12].

Fruit and vegetable pomace can serve as an excellent source of fiber for enriching bakery products due to its favorable properties, including a balanced soluble/insoluble fiber ratio, good hydration, fermentability, and phytochemical content. The origin and processing of pomace into powder form through various pre-treatment, drying, and size reduction methods can affect its functional properties. The functional properties of fruit and vegetable pomace can enhance the quality of food, and they can be used to enrich a wide range of bakery products such as biscuits, buns, cookies, crackers, cakes, muffins, wheat rolls, and scones. Fruit pomaces are particularly suitable for bakery products as they enhance sensory attributes. In addition, fruit and vegetable pomace contains antioxidants that can improve the storage stability of baked goods. Therefore, fruit and vegetable pomace can be effectively used as a functional ingredient for the development of fiber-rich bakery products [13].

The addition of dried fruit pomace to bakery products can replace flour, sugar, or fat, resulting in reduced energy load while increasing fiber and antioxidant levels. Nonetheless, the high fiber content of fruit pomace can lead to techno-functional interactions that influence physicochemical and sensory characteristics [14].

Sea buckthorn pomace contains dietary fibers that are bioactive and promote health. However, due to the lack of suitable handling or processing facilities, this pomace is often either used as animal feed or discarded [15].

Fortification of bakery-based products with bioactive compounds extracted from sea buckthorn has been reported to inhibit starch digestion, which is beneficial for people with diabetes [16]. Sea buckthorn pomace flour has been shown to increase the porosity of pastries and decrease the wet gluten content, leading to moisture loss. However, the addition of sea buckthorn flour has been found to improve the appearance, color, and consistency of pastries according to organoleptic assessments. Furthermore, samples containing sea buckthorn flour have exhibited microbiological stability due to the chemical composition of sea buckthorn [17].

Therefore, the objective of this study was to enhance the technology of bakery products by incorporating sea buckthorn pomace flour, thereby expanding the range of functional products. The investigation focused on assessing the impact of varying concentrations of sea buckthorn berry flour on the sensory attributes, physicochemical properties, polyphenol content, antioxidant properties, and shelf-life of wheat bread. The aim was to diversify the assortment of bakery products and explore the potential benefits of incorporating sea buckthorn pomace flour. The novelty of this study consists of the studied organic sea buckthorn varieties and the sustainability of the processing method for sea buckthorn pomace powder obtained (from waste resulting after sea buckthorn processing) using the entire quantity of waste (seeds, pulp, and skin).

2. Materials and Methods

2.1. Raw Materials and Chemicals

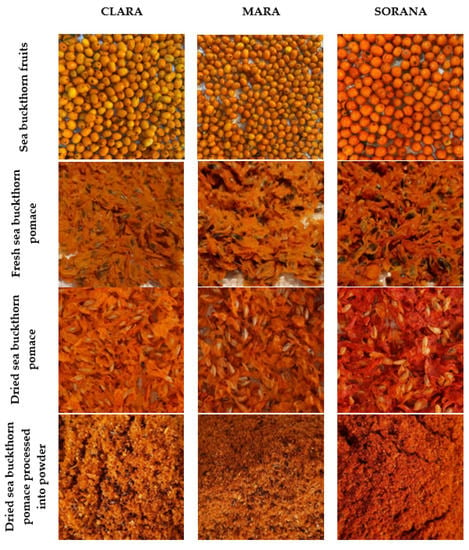

Wheat flour (type 650) of superior quality (Baneasa, Romania), compressed Saccharomyces cerevisiae yeast (Dr. Oetker, Curtea de Argeș, Romania), iodized salt, and water were used in bread making. The ingredients were purchased from local stores. Organic sea buckthorn varieties (Mara, Clara, Sorana) were purchased from Bio Cătina Cooperativa Agricolă—Dâmbovița, Romania. Briefly, sea buckthorn berries were processed using a screw press (Biovita), resulting in the extraction of pomace consisting of skin, pulp, and seeds. This pomace accounted for 20% of the total fruit weight. The obtained pomace was then dried in a hot air dryer, specifically the DEH600D BIOVITA model equipped with 9 stainless trays. The drying process took place for 12 h at a temperature of 50 °C. Subsequently, the dried pomace was ground in a Biovita blender with a power of 1000 W using the maximum speed setting for 2 min and ensuring a thorough blend. To remove any hard seed components, the resulting powder was sifted through a 7 mm sieve. The resulting pomace powder was then used as an ingredient in the recipe for functional bread making. The process of obtaining sea buckthorn pomace powder is presented in Figure 1, illustrating the different stages involved.

Figure 1.

Aspects of various stages of the technological flow for obtaining sea buckthorn pomace powder.

All chemical reagents (DPPH, Folin–Ciocalteu’s reagent, quercitin, gallic acid, α—amylase, protease, HCl, NaOH, HNO3, and solvents) were of analytical grade or chromatographic grade and were purchased from Sigma Aldrich (St. Louis, MO, USA).

2.2. Bread Making

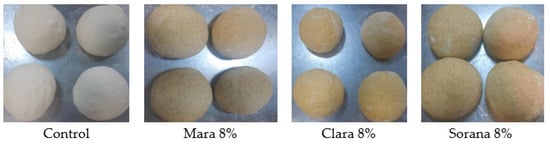

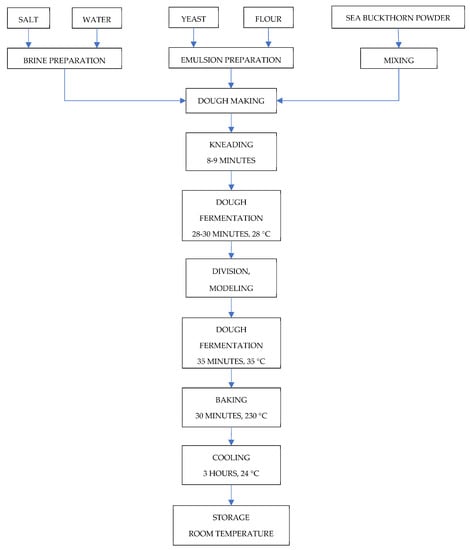

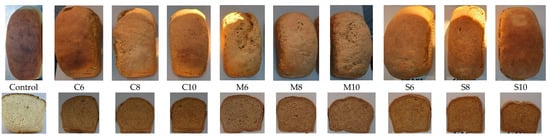

Samples of bread were obtained using 650 type flour and 6%, 8%, and 10% sea buckthorn pomace powder to determine its influence on organoleptic, physical–chemical, and nutritional indicators, as well as the structural parameters of bread. Previously, an initial study was performed using 1% to 5% sea buckthorn pomace powder. The obtained results combined with data in the literature showed that an increase in powder content can be applied, which has a beneficial effect on the nutritional value of the product. Higher amounts of added powder favor the increasing of antioxidants and fiber content within the product. However, concentrations higher than 8–10% lead to the sensory modification of the product, having an aftertaste that is slightly sour, bitter, and not specific to the product. The obtained samples were coded as follows: the control (wheat bread), C6, C8, and C10 (bread with 6%, 8%, and 10% sea buckthorn pomace powder from the Clara variety), M6, M8, and M10 (bread with 6%, 8% and 10% sea buckthorn pomace powder from the Mara variety), and S6, S8, and S10 (bread with 6%, 8% and 10% sea buckthorn pomace powder from the Sorana variety). The amount of sea buckthorn pomace powder was reported per 100 g of flour. The control sample was prepared using only wheat flour. Briefly, each batch of dough was kneaded for 8–9 min in a mixer and fermented at 28 °C for 28–30 min (Figure 2). Afterward, the dough was divided, shaped, and left to rest for the final fermentation at a temperature of 35 °C for 35 min. The bread samples were then baked in a preheated oven at a temperature of 130 °C for 30 min and were then cooled 24 °C for 3 h. Afterward, the bread samples were further analyzed. The technological scheme of bread making is presented in Figure 3 and the aspect of bread samples is presented in Figure 4.

Figure 2.

The appearance of the obtained dough samples with the addition of sea buckthorn pomace powder.

Figure 3.

Technological scheme for functional bread preparation.

Figure 4.

The aspect of the developed bread samples.

2.3. Structural and Physical–Chemical Characteristics Determination

The functional bread weight was established by using an analytical balance with an accuracy of four decimal places to weigh the samples.

The Fornet bread volumeter (Chopin, France) and the rapeseed displacement method [18] were used to measure the bread volume. The volume of the bread was calculated using Equation (1) and expressed as cm3 per 100 g of product.

where V1 is the determined volume of the sample (cm3) and m is the mass of the sample used (g).

V = (V1/m) × 100

To determine the core elasticity of the bread, a specific-shaped piece of the bread core is pressed, and the rebound to the original position after removing the pressing force is measured [19]. Elasticity is expressed as a percentage ratio between the height after pressing and the rebound to the initial height of the core cylinder.

The porosity of the bread samples was measured according to Romanian standard SR 91:2007 [19] and expressed as a volume percentage. It was calculated using Equation (2).

where V is the volume of the core cylinder [cm3], m is core cylinder mass [g], and ρ is the density of the compact core [g/cm3]. The compact core density for white flour bakery products has an average value of ρ = 1.31 g/cm3.

Porosity = [(V − m/ρ)/V] × 100

To determine the acidity of the bread samples, the Romanian standard SR 91:2007 [19] was followed. An aqueous extract of the bread was titrated with a 0.1 N sodium hydroxide (NaOH) solution in the presence of phenolphthalein as an indicator. The acidity was then calculated using Equation (3).

where V is the volume of the 0.1 N NaOH solution used in the titration, m is the mass of the sample taken for analysis, in g, and 0.1 is the normality of the NaOH solution.

Acidity = [V × (0.1/m)] × 100

To determine the moisture content of the bread samples, the AOAC Official Method 934.06 [20] was used. This involved evaporating water from the sample by heating it in an oven at a constant temperature of 103 ± 2 °C until a constant mass was achieved. The moisture content was then calculated as a percentage using Equation (4).

where M0 is the mass, in grams, of the dish and lid, M1 is the mass, in grams, of the dish, lid and test portion before drying, and M2 is the mass, in grams, of the dish, lid, and test portion after drying.

Moisture content = [(M1 − M0)/(M1 − M2) × 100

The water activity index was determined using NOVASINA AG (Lachen, Switzerland) equipment. Briefly, the samples were introduced to specific recipients of the equipment and the value of the aw index was read when stable at 25 °C.

2.4. Nutritional Parameters Determination

To measure the protein content, the Kjeldahl method [21] was used along with a conversion factor of nitrogen to protein of 6.25. The protein content was then calculated using Equation (5).

where V0 is the volume of the hydrochloric acid (HCl) used in the control sample (mL), V1 is the volume of HCl used in the sample (mL), T is the normality of HCl, m is the mass of the sample (g), and w is the moisture of the sample; the protein conversion factor is 6.25.

N = [(V1 − V0) × T × 0.014 × 100]/m × (100/100 − w) = 140T (V1 − V0)/m × (100 − w)

The fat content was determined using the AOAC 963.15 [22] method by extracting it with a petroleum ether under reflux conditions in Soxhlet equipment. The fat content was then calculated using Equation (6).

where m1 is the mass of the empty balloon (g), m2 is the mass of the balloon with fat (g), m is the mass of the sample taken for analysis (g), and w is the moisture of the sample determined according to the procedure described for moisture (%).

Fat content = (m2 − m1)/m × 100 × 100/(100 − w)

The fiber content was performed using the gravimetric-enzymatic method AOAC 991.43 [23] with a Tris-Mes buffer. In this method, the sample undergoes successive enzymatic digestions using thermally stabilized α-amylase, protease, and amyloglucosidase. Fibertec 1023 equipment (FOSS Analytics, Hillerod, Denmark) was used to carry out the determinations.

The AOAC 923.03 [24] method was used to determine the total ash content, which involved burning the samples in a muffle furnace at 550 °C. The value for this parameter was obtained by applying Equation (7).

where m0 is the mass of the working sample (g), m1 is calcination crucible mass (g), m2 is the mass of the calcining crucible and the calcined residue (g), and w is the moisture of the sample (%).

Total ash content = (m2 − m1) × (100/m0) × 100/(100 − w)

The AACC method 10-05.01 [18] was used to express the total carbohydrates as a percentage, which was then calculated using Equation (8). The calorie content was estimated using conversion factors of 9 for fat, 4 for carbohydrates, and 4 for protein, as per the AACC method 10-05.01 [19].

Carbohydrate = 100 − (% protein + % fat + % fiber + % ash)

To determine the heavy metals, microelements, and minerals, the samples were dry ashed in a muffle furnace L1206 (Caloris, Bucharest, Romania) at 550 °C. The heavy metals (Pb, Cd, and Cr) and the microelement (Mn, Cu, Zn, and Fe) content were analyzed using Inductively Coupled Plasma Mass Spectrometry, NexION 300Q (Perkin Elmer, Waltham, MA, USA). The content of minerals, on the other hand, was determined using HR-CS-AAS high-resolution continuum source atomic absorption spectrometry with ContrAA700 (Analytik Jena, Jena, Germany).

To determine the content of total phenols, the Folin–Ciocalteu method was used [25,26]. The concentration of polyphenols reported in gallic acid equivalents per 100 g of product was calculated according to Equation (9).

where A765 is the sample absorbance read at 765 nm, GAE is the concentration in gallic acid equivalents (mg/L), and R2 = 0.9995 is the correlation coefficient.

Total polyphenols (GAE) mg/100 g = (A765 − 0.0082)/0.001 (R2 = 0.9995)

For antioxidant activity determination, the free radical scavenging effect on the 1,1-diphenyl-2-picrylhydrazyl (DPPH) radical was evaluated [25,26]. The samples were prepared by macerating them in ethanol (75%) for 48 h at room temperature in the dark. The results were expressed in quercetin equivalents per 100 g of product using Equation (10).

where AAR (QE) is the antiradical activity expressed in quercetin equivalents, %ΔA515 = [(A515(t=0) − A515(t=30))/A515(t=0)] × 100.

AAR (QE) = (%∆A515 − 3.4954)/0.0811

2.5. Sensory Analysis

A group of ten trained panelists, consisting of 70% females and 30% males, conducted a sensory evaluation of bread to assess its overall acceptability using a five-point hedonic scale. The bread samples were placed on white plates and labeled with random three-digit numbers. The sensory evaluation criteria are outlined in Table 1.

Table 1.

Criteria for the sensory evaluation of bread containing sea buckthorn pomace powder.

2.6. Statistical Analysis

The functional bread parameters were determined by averaging the results from three parallel extraction experiments and calculating their standard deviations. To compare the means, one-way ANOVA with Tukey’s test and Fisher’s test was applied, with a significance level of p < 0.05. The statistical calculations were performed using Minitab 15 (Minitab LTD., Coventry, UK) and Microsoft Excel 2010.

3. Results and Discussion

3.1. Structural and Physical–Chemical Characteristics of Functional Bread

The characteristics regarding the structural parameters of the obtained functional bread samples are presented in Table 2.

Table 2.

The characteristics of functional bread with sea buckthorn pomace powder (mean ± SD).

3.1.1. Weight of Functional Bread

The functional bread samples with sea buckthorn pomace powder showed varying weights in the range of 740.03 g to 724.66 g, as presented in Table 2. The addition of sea buckthorn flour significantly influenced (p < 0.05) the weight of the obtained samples. The bread samples with a 10% sea buckthorn powder addition from the Mara variety (740.03 g) and the control sample (738.13 g) had the highest weights, followed closely by the bread sample with an 8% sea buckthorn powder addition from the Sorana variety (735.56 g), the bread sample with an 8% sea buckthorn powder addition from the Clara variety (733.87 g), and the bread sample with a 6% sea buckthorn powder addition from the Clara variety (732.15 g). On the other hand, the samples of bread with 6% added sea buckthorn powder from the Mara variety (724.66 g), 10% added sea buckthorn powder from the Sorana variety (726.05 g), and 6% added sea buckthorn powder from the Sorana variety (726.83 g) registered the lowest weights.

3.1.2. Specific Volume

The addition of sea buckthorn powder to functional bread resulted in varying volumes from 166.66 to 226.72 cm3 m−1 (Table 2). The control sample had a volume of 249.28 cm3 m−1, which was significantly different (p < 0.05) from the samples with sea buckthorn powder. The C6 sample had the highest volume (226.72 cm3 m−1), followed by the C10 sample (209.96 cm3 m−1), the C8 sample (208.48 cm3 m−1), and the S6 sample (208.44 cm3 m−1). On the other hand, the S10 (166.66 cm3 m−1) and M10 (171.61 cm3 m−1) samples had lower volumes. The rise in specific volume could be attributed to changes in the dough’s strength, allowing for more extensive deformation and better correlation to increase dough height. Enhancing the specific volume of bread may lead to better gas retention, thereby allowing the dough to rise to a greater volume [12]. However, Nilova and Malyutenkova’s [27] findings revealed that incorporating sea buckthorn seed powder, marc powder, and peel powder in bakery products improved their specific volume. Similarly, in 2019 a study by Guo et al. [12], sea buckthorn pulp was found to increase the specific volume of bread, with the highest value observed for bread with 10% sea buckthorn pulp. In addition to sea buckthorn, Nilova and Malyutenkova, 2021 [28] also reported that incorporating marc powder obtained from blueberry, cloudberry, and rowan increased the specific volume of bakery products. The highest specific volume was observed for products with cloudberry (380.40 ± 8.0%), followed by those with sea buckthorn (372.5 ± 8.6%).

3.1.3. Porosity

In terms of porosity, the analysis of functional bread samples (Table 2) revealed that the S6 sample had a higher porosity (73.2%) compared to the control sample (72.9%). The addition of sea buckthorn pomace powder significantly influences the porosity of bread obtained from the Mara and Sorana varieties (p < 0.05). Conversely, all other functional bread samples had lower porosity values, ranging from 67.3% to 58.6%, compared to the control. The bread sample with a 10% addition of Sorana variety sea buckthorn pomace powder (S10) had the lowest porosity (58.6%).

Porosity plays a crucial role in the digestibility of bakery products since higher porosity in the bread core makes it easier for the consumer’s body to digest it. The vitamins and simple carbohydrates found in sea buckthorn stimulate the fermentative activity of bakery yeast, which affects the porosity of the bread core [29].

Similar to the results obtained in this research, a study conducted by Sturza et al., 2016 [17], showed that the addition of sea buckthorn flour at 2% and 4% increased the porosity of pastry crumbs from 70% in the control sample to 72.2% and 72.1%, respectively. Additionally, Nilova and Malyutenkova, 2018 [27] found that the porosity of bakery products increased when seed powder, marc powder, and peel powder from sea buckthorn fruits were added. The porosity of the samples ranged from 74.5 ± 1.3% to 72.8 ± 1.8%, which was higher than the control sample. The addition of marc powder obtained from blueberry, cloudberry, rowan, and sea buckthorn also increased the porosity of bakery products, with cloudberry showing the highest porosity (75.4 ± 1.4%) followed by sea buckthorn (73.8 ± 1.8%) [28]. In contrast, Ghendov-Mosanu et al., 2020 [29] found that the porosity of the samples decreased by 5.7% and 17.4% in the samples with 3% and 5% sea buckthorn, respectively, compared to the control. This indicates that as the percentage of added by-products increased, the porosity decreased. This may be due to the low extensibility of the dough, which contributed to the reduction in gas retention capacity during fermentation [29].

3.1.4. Elasticity

In terms of the elasticity of the analyzed bread samples (Table 2), it was noted that the control sample exhibited the highest elasticity (96.7%), followed closely by the C6 sample (85.2%). The elasticity of the functional bread samples ranged from 63.3% to 85.2%. The S10 bread sample (63.3%) and the M10 bread sample (64.4%) had the lowest elasticity. The addition of sea buckthorn pomace powders significantly influences (p < 0.05) the elasticity of the obtained bread samples.

Table 3 presents the physical–chemical characteristics of the obtained functional bread with sea buckthorn pomace powder.

Table 3.

The physical–chemical characteristics of functional bread with sea buckthorn pomace powder (mean ± SD).

3.1.5. Moisture Content

Regarding the moisture content of the analyzed bread samples (as shown in Table 3), it was observed that the control sample had the lowest moisture content of 34.23%. However, all functional bread samples with added sea buckthorn pomace powder had significantly (p < 0.05) higher moisture content than the control sample, ranging between 45.24% and 43.89%. There were no significant differences in the moisture content observed among the functional bread samples with added sea buckthorn pomace powder.

Guo et al., 2019 [12] also found that the moisture content in bread samples increased as the percentage of sea buckthorn pulp added increased, with values ranging from 32.84 ± 0.56% for the control sample to 36.23 ± 0.32% for bread with 10% sea buckthorn pulp added. This suggests that an increase in the percentage of sea buckthorn leads to higher moisture content. In biscuits with sea buckthorn by-products, Muresan et al., 2019 [30] found that the moisture content was 95.23 ± 0.57% for those obtained at 50 °C for 12 h and 96.55 ± 0.57% for those with thermal treatment at 80 °C for 5 h. In contrast, Nilova and Malyutenkova, 2021 [28] found that the moisture content of bakery products obtained by adding marc powder obtained from blueberry, cloudberry, rowan, and sea buckthorn was similar to or slightly lower than the control sample. Furthermore, Sturza et al., 2016 [17] noted that as the proportion of sea buckthorn flour increased in pastry products; the moisture content decreased from 22% in the control sample to 20% for gingerbread with 4% sea buckthorn, while for sponge cakes, the moisture content decreased from 36.6% in the control sample to 36.12% in the sample with 4% sea buckthorn flour. The authors explained that the addition of sea buckthorn flour led to a decrease in the amount of wet gluten in the product, which resulted in a reduction in moisture in the final product.

3.1.6. Acidity

In terms of acidity, the bread samples analyzed showed that the control sample had the lowest acidity value of 1.30, while the functional bread samples had significantly higher (p < 0.05) acidity values ranging from 1.5 to 2.8 degrees. Based on the data presented in Table 3, it can be observed that the bread samples with the lowest acidity values were those with an 8% addition of sea buckthorn powder from the Clara variety (C8) (1.50 deg. acidity) and those with a 10% addition of sea buckthorn powder from the Mara variety (M10) (1.70 deg. acidity). On the other hand, the bread samples with the highest acidity values were the S8 and S10 bread samples with values of 2.60 acidity and 2.80 acidity, respectively. According to Ghendov-Mosanu et al., 2020 [29], there is a positive correlation between the acidity of bakery products and the concentration of added sea buckthorn berry flour. This can be attributed to the presence of organic acids and sugars in the berry flour, which speeds up the fermentation of the dough.

Furthermore, Nilova and Malyutenkova, 2018 [27], Ghendov-Mosanu et al., 2020 [29], and Nilova and Malyutenkova, 2021 [28] demonstrate that the addition of sea buckthorn in bakery products increases their acidity. The study by Nilova and Malyutenkova, 2018 [27] showed an increase in acidity from 1.7 ± 0.1 to 3.2 ± 0.1, 3.4 ± 0.1, and 3.6 ± 0.1 for bakery products made with sea buckthorn seeds powder, marc powder, and peel powder, respectively; values that are close to the ones obtained in this study. Similarly, the research conducted by Ghendov-Mosanu et al., 2020 [29] reported a significant increase in acidity by 100–291.7% compared to the control samples. Nilova and Malyutenkova, 2021 [28] found that the addition of marc powder obtained from blueberry, cloudberry, rowan, and sea buckthorn in bakery products resulted in higher acidity than the control sample, with the highest acidity of 3.4 ± 0.1 recorded for the bakery products with sea buckthorn marc powder.

3.1.7. Water Activity

The aw index (Table 3) did not significantly (p > 0.05) vary between the developed bread samples. In general, a higher value of this index was obtained for the samples prepared using sea buckthorn pomace powder. Rajeswari et al., 2018 [31] observed that the water activity of bread samples enriched with banana, aonla, and sapota powders varied between 0.77 (for 5% aonla powder) and 0.82 (for 20% banana and 20% sapota powder). In contrast, Nikolau et al., 2022 [32] found that the water activity of bakery products with bioactive compounds from black Corianthian grape was lower than that of the respective dough, due to direct heat contact during baking. The authors noted that water activity was highly dependent on the enrichment type and leavening agent. Conversely, Costa et al., 2018 [33] did not observe any significant difference in water activity for pan bread containing pumpkin seed flour. Lim et al., 2011 [34] reported a significant decrease in the water activity of bread as the turmeric powder level in the recipe increased.

3.2. Nutritional Characteristics of Functional Bread

3.2.1. Protein Content

Changes were observed in the protein content, which ranged between 13.07% and 13.82%, obtaining higher values for the bread samples containing sea buckthorn pomace powder than those of the control sample (Table 4). However, with the exception of the S8 sample, it was observed that the protein content increased as the amount of sea buckthorn powder added to the samples increased.

Table 4.

The content of crude fiber, total ash, protein, fat, and the energy value of the developed bread samples.

Similar results were obtained by Guo et al., 2019 [12], who found that adding 5% sea buckthorn pulp to bread resulted in a protein content similar to the control sample, but adding 10% sea buckthorn pulp decreased the protein content to 11.11 ± 0.32 compared to 11.23 ± 0.08 in the control sample. On the other hand, Odunlade et al., 2017 [35] observed an increase in protein content from 9.5% to 13.09% as the substitution level of leafy vegetable powder increased.

3.2.2. Fat Content

The functional bread samples showed a significant increase (p < 0.05) in fat content when compared to the control sample (Table 4). The control sample had a fat content of 0.17%, while the functional bread samples had values ranging from 0.68% to 1.6%. The sample with the lowest lipid content was the one with a 6% addition of the Mara variety, while the sample with the highest lipid content was the sample with a 10% addition of Sorana sea buckthorn powder. It can be observed that the functional bread with the addition of sea buckthorn powder from the Sorana variety was richer in lipids compared to the samples that had sea buckthorn powder from the Mara and Clara varieties added. The fat content obtained in the present study was lower than the findings of Odunlade et al., 2017 [35], who reported an increase in fat content from 1.3% to 2.0% in bread enriched with leafy vegetable powder.

Furthermore, Janotkova et al., 2021 [36] found that the total fat content in biscuits with a 10% addition of sea buckthorn biomass was 16.7% compared to the control. They attributed these differences to the higher thermal treatment of the biscuits. The seeds and fruits of sea buckthorn are rich in fatty substances and acids, which make the biscuits containing this by-product have a higher fat content than other types of biscuits. Muresan et al., 2019 [30] reported that the fat content of biscuits made with sea buckthorn by-products was 30.11 ± 0.65 when baked at 50 °C for 12 h, and 30.48 ± 0.06 when baked at 80 °C for 5 h. This is due to the high fat content of sea buckthorn fruits and seeds. Biscuits containing dried by-product powder had higher fat content compared to other types of biscuits, and samples with powders dried at 80 °C contained more fat than those dried at 50 °C.

3.2.3. Total Ash Content

There were no significant differences (p > 0.05) in the ash content among the bread samples analyzed (Table 4), which ranged from 1.18% to 1.63%. The sample with a 6% addition of Sorana sea buckthorn pomace powder had the lowest ash content, while the sample with a 10% addition of Clara sea buckthorn pomace powder had the highest ash content. The ash content values obtained in the present study were higher than those reported by Muresan et al., 2019 [30] for biscuits containing sea buckthorn by-products, with ash content ranging from 0.23 ± 0.02 to 0.25 ± 0.03, depending on the thermal treatment conditions. On the other hand, Odunlade et al., 2017 [35] reported a significant increase (p < 0.05) in ash content from 1.1 to 2.4% when adding leafy vegetable powders to bread samples, attributing this increase to the content of green leafy vegetables.

3.2.4. Crude Fiber

Concerning the crude fiber, the results indicate a significant increase (p < 0.05) in crude fiber content in the functional bread samples compared to the control sample. Specifically, the control sample had a raw fiber content of 0.12%, whereas the functional bread samples showed values ranging from 1.07 to 2.04%. The results are in accordance with the findings of Guo et al., 2019 [12], who demonstrated that bread samples containing 10% sea buckthorn pulp had twice the amount of total dietary fiber content compared to the control sample. Meanwhile, Odunlade et al., 2017 [35] observed that the crude fiber content of their bread samples ranged from 1.8% to 4.0%. They also reported a significant (p < 0.05) increase in fiber content with the addition of leafy vegetable powder.

The functional characteristics of food are linked to the presence of non-digestible carbohydrates in the form of dietary fiber, which serves as a source of nourishment for symbiotic bacteria in the large intestine. The role of dietary fiber in the human body is influenced by its quantity in the diet, as well as its fractional composition, which can vary based on factors such as plant species, developmental stage, anatomical part of the plant, and the specific technological processes employed [37]. For example, adding apple pomace to bakery products is believed to enhance their dietary fiber content and health benefits. However, in most cases, the addition of pomace leads to a decrease in the quality and sensory properties of the baked products. The incorporation of apple pomace has been shown to increase the total dietary fiber (TDF), total phenolics content (TPC), antioxidant activity, total flavonoid content (TFC), and proanthocyanidins content (PAC) [38].

Sea buckthorn berries are rich in dietary fiber, with a substantial amount of 6.55 g per 100 g. This content exceeds 25% of the recommended daily intake of dietary fiber [39]. The amount of dietary fiber and the proportion of soluble and insoluble fiber in pomace are influenced by the origin of the pomace and the specific processing conditions employed during fiber extraction [40]. Furthermore, the fiber content of sea buckthorn depends on weather conditions and the maturity stage of the berries. The crude fiber level in sea buckthorn typically ranges from 62 g/kg to 100 g/kg of dry weight [41]. According to a study by Jaroszewska et al., 2018 [42], sea buckthorn berries are rich in dietary fibers. The distribution of dietary fiber fractions in sea buckthorn berries is as follows: 160–200 g/kg dry weight of neutral detergent fiber, 120–145 g/kg dry weight of acid detergent fiber, 50–70 g/kg dry weight of acid detergent lignin, 45–55 g/kg dry weight of hemicellulose, and 60–75 g/kg dry weight of cellulose. The raw fiber content in sea buckthorn seeds was measured to be 130 g/kg dry weight, while the peel and the pulp contained 66 g/kg dry weight and 47 g/kg dry weight of raw fiber [43]. The dried sea buckthorn pomace exhibited a significant crude fiber content, with values of 19.86% [44].

Considering the high fiber content in sea buckthorn berries and pomace, their incorporation in bread significantly enhances the crude fiber content of the final product.

3.2.5. Energetic Value

The energetic value of the obtained bread samples ranged between 217 ± 0.12 and 260 ± 0.15 Kcal/100 g (Table 4). It was observed that all samples containing sea buckthorn pomace powder presented lower energetic values compared to the control sample. Between these samples, the highest energetic value was obtained for the S10 bread sample (224 ± 0.18) and the lowest value was obtained for sample C6 (217 ± 0.12). However, no significant differences were observed between the bread samples containing sea buckthorn pomace powder.

3.2.6. Contaminants

Table 5 shows that samples C8 and M10 had higher levels of lead, with 23.08 ± 0.10 µg/kg and 25.59 ± 0.17 µg/kg, respectively, compared to the control sample. All samples had higher levels of cadmium than the control sample, with sample S6 having the highest level of cadmium at 18.88 ± 0.18 µg/kg. Regarding Cr levels, C10 and S8 had higher Cr content than the control sample, with levels of 301.66 ± 2.36 µg/kg and 343.08 ± 1.02 µg/kg, respectively. The Clara variety pomace powder incorporated in bread samples had lower lead content compared to the Mara and Sorana varieties. The samples added with Mara variety pomace powder were the least contaminated with cadmium. The addition of sea buckthorn powder increased the cadmium levels in the bread samples, which may have been due to the contamination of sea buckthorn with cadmium. Therefore, it is necessary rigorously control the powders and flours obtained from different vegetable and fruit residues used in the development of new food products.

Table 5.

The content of heavy metals in functional bread samples (mean ± SD).

According to studies conducted by Petrescu-Mag et al., 2021 [45] and Dudarev et al., 2019 [46], it was found that the levels of Pb, Cd, and Cr were higher in cultivated sea buckthorn compared to wild berries. Additionally, Petrescu-Mag et al., 2021 [45] reported that the heavy metal levels in sea buckthorn samples collected from non-mining areas were lower than those from mining areas, indicating contamination of wild berries due to soil contamination. Furthermore, Vaitkeviciene et al., 2019 [47] showed that lead and cadmium content was higher in cultivated sea buckthorn samples compared to wild sea buckthorn berries.

Concerning the microelements content, Table 6 presents the results for Cu, Zn, Mn, and Fe. All samples showed higher levels of Cu compared to the control samples. The bread samples with sea buckthorn pomace powder from the Mara variety had the highest copper content (9.25 mg Cu/kg), zinc content (11.55 mg Zn/kg), and manganese content (21.75 mg Mn/kg). On the other hand, the bread samples with sea buckthorn pomace powder from the Clara variety had the highest iron content (54.89%).

Table 6.

The content of microelements in functional bread samples (mean ± SD).

The findings revealed that all three sea buckthorn varieties used in the functional bread samples exhibited an increase in copper and iron content, while a decrease was observed in zinc content compared to the control sample. With regard to manganese content, a decline was noted in the functional bread samples, except for those containing 6% and 8% sea buckthorn pomace powder from the Clara variety, as well as 8% and 10% sea buckthorn pomace powder from the Mara variety.

The amount of Zn detected in the current study is higher than the levels found in bread samples fortified with beetroot powder (2–15%), as reported by Ani et al., 2022 [48]. On the other hand, the levels of Fe in the present study are lower than those reported by Ani et al., 2022 [48]. The study demonstrated that the Fe and Zn content in bread enriched with beetroot powder was lower than those in the control sample. In contrast, the results of the current study indicate that sea buckthorn pomace powder is a viable option for enhancing bread with Fe and Cu. However, the values of Zn and Mn in the sea buckthorn-enriched bread are similar or lower compared to those in the control samples.

The iron content observed in the current study is lower than the iron content found in bread fortified with fluted pumpkin, amaranth, or African eggplant leafy powders, as reported by Odunlade et al., 2017 [35]. However, the levels of zinc obtained in this study are similar to those reported by Odunlade et al., 2017 [35]. The authors showed that the iron and zinc content increased as the percentage of leafy powder added increased.

According to Luntraru et al., 2022 [49], the microelement content of sea buckthorn by-products is 4.51 ± 0.090 mg/100 g for Zn, 1.23 ± 0.073 mg/100 g for Cu, 3.51 ± 0.098 mg/100 g for Mn, and 3.6 ± 0.079 mg/100 g for Fe. Vaitkeviciene et al., 2019 [47] reported that the microelement content of sea buckthorn varies depending on the source of the raw material. They demonstrated that the tested cultivated sea buckthorn had higher Fe and Mn content compared to wild sea buckthorn. On the contrary, wild berries were found to have higher Cu, Zn, and Ni content.

In terms of sodium and potassium content (Table 7), it is noticeable that the bread samples added with sea buckthorn pomace powder from the Sorana variety contain the highest amount (227.1 mg Na/100 g and 360.3 mg K/100 g, respectively). As for calcium content, the highest amount is found in the bread samples containing sea buckthorn pomace powder from the Clara variety (23.87 mg Ca/100 g), while the bread samples containing sea buckthorn pomace powder from the Mara variety has the highest magnesium content (77.94 mg Mg/100 g).

Table 7.

The content of minerals in functional bread samples (mean ± SD).

The analyzed bread samples exhibited noteworthy distinctions in sodium content when compared to the control sample, ranging from 61.06 to 64.41 mg Na/100 g. Similar observations were noted for magnesium content, which varied between 10.81 and 11.19 mg Mg/100 g. Conversely, the potassium content of the functional bread was greater than that of the control sample. Specifically, the control sample contained 52.99 mg K/100 g, whereas the functional bread demonstrated an elevated content ranging from 53.63 to 84.15 mg K/100 g. With respect to calcium content, all functional bread samples exhibited higher values than the control sample, except for the bread containing 8% sea buckthorn pomace powder from the Sorana variety. The control sample had a value of 5.58 mg Ca/100 g, while the functional bread samples recorded higher values ranging from 5.66 to 7.09 mg Ca/100 g.

The sodium content found in this study was higher than the sodium content reported by Odunlade et al., 2017 [35], who added leafy powder to bread samples. On the other hand, the levels of calcium and magnesium obtained in the present study were significantly lower than those obtained by Odunlade et al., 2017 [35]. Their results showed that an increase in the percentage of leafy powder led to an increase in the content of sodium, magnesium, and calcium.

According to Vaitkeviciene et al., 2019 [47], cultivated sea buckthorn contains 10.30 ± 0.42 g/kg of potassium (K), 0.844 ± 0.07 g/kg of calcium (Ca), and 0.701 ± 0.03 g/kg of magnesium (Mg). Therefore, sea buckthorn can be considered a valuable source of minerals for food products with high mineral content.

3.2.7. Total Polyphenolic Content

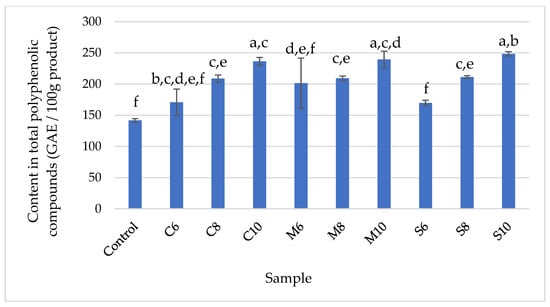

The polyphenolic content of the bread samples increased as the amount of sea buckthorn powder added to them increased, as shown in Figure 5. Additionally, the bread samples containing sea buckthorn powder had a higher polyphenolic content compared to the control sample.

Figure 5.

The content of polyphenols for the samples of functional bread with the addition of sea buckthorn pomace powder. Means followed by a common letter are not significantly different (p > 0.05). Values followed by different superscript letters in the same column are significantly different (p < 0.05). Means that do not share a letter in a column are significantly different (p < 0.05).

Similar to the results obtained in this study, Nilova and Malyutenkova, 2018 [27] discovered that the addition of sea buckthorn to bread samples increased the phenolic content in both the crust and crumb. Additionally, they found that decreasing the baking temperature resulted in a higher number of phenolic compounds and flavonoids in both the crust and crumb. At a temperature of 220 °C, the loss of phenolic compounds was between 23.8 and 25.6%, while at 200 °C, the loss was between 7 and 13%, which was significantly lower. They also demonstrated that a high baking temperature completely destroyed the ascorbic acid in all enriched samples. In a separate study by Akbas and Kilmanoglu, 2022 [50], they observed a significant increase (p < 0.05) in the phenolic content of all bread that had fruit and vegetables added when compared to the control group.

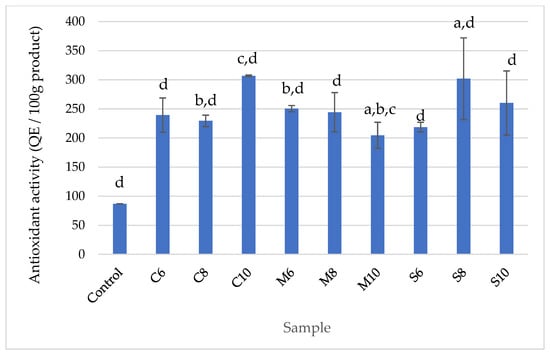

3.2.8. Antioxidant Activity

After assessing the antioxidant activity of the bread samples (as depicted in Figure 6), it was observed that all samples incorporated with sea buckthorn pomace powder exhibited elevated values for this parameter (over 200 QE/100 g product) in comparison to the control sample. This augmentation is attributed to the presence of polyphenols, such as phenolic acid and flavonoids, which are acknowledged as the most active components responsible for the antioxidant characteristics of various sea buckthorn varieties. In addition to polyphenols, the antioxidant ability of sea buckthorn is linked to the combined influence of ascorbic acid and carotenoids [36]. Based on the obtained results, it can be concluded that the addition of sea buckthorn pomace powder led to a significant (p < 0.05) escalation in the antioxidant activity of the developed products. The C10 bread sample had the highest value, whereas the M10 sample had the lowest value. Similar results were obtained by Janotkova et al., 2021 [36]; namely, when the percentage of sea buckthorn was increased to 20% in cereal biscuits, a noticeable decrease in antioxidant activity was observed. This decline may be due to some antioxidants that can act as prooxidants at higher concentrations [36]. The antioxidant analysis of the bread samples confirmed that the products exhibit substantial antioxidant potential and constitute a rich source of antioxidant compounds, which may impart many beneficial effects on the human body.

Figure 6.

Antioxidant activity of functional bread samples with the addition of sea buckthorn pomace powder. Means followed by a common letter are not significantly different (p > 0.05). Values followed by different superscript letters in the same column are significantly different (p < 0.05). Means that do not share a letter in a column are significantly different (p < 0.05).

Sturza et al., 2016 [17] reported that the presence of antioxidants in bread samples with sea buckthorn reduces the degree of lipid oxidation due to the fat content of sea buckthorn. Additionally, Janotkova et al., 2021 [36] found that cereal biscuits with 15% sea buckthorn biomass had increased antioxidant activity.

According to the study conducted by Sturza et al., 2016 [17], the antioxidant activity (expressed as the percentage of free inhibited DPPH radicals) of pastry products increased from −18.08 ± 1.21% to 73.52 ± 0.63% for 4% sea buckthorn flour gingerbread, and from −12.98 ± 0.91% to 17.86 ± 0.61% for 4% sea buckthorn flour sponge cake. On the other hand, Ghendov-Mosanu et al., 2020 [29] demonstrated that the addition of 1% sea buckthorn berry flour slightly increased the antioxidant activity of their samples, but it remained negative (−8.65 ± 0.62%). When 5% sea buckthorn biomass flour was added, the antioxidant activity of the samples increased to 20.05 ± 0.51%, which was significantly lower than the antioxidant activity observed in the study conducted by Sturza et al., 2016 [17].

Muresan et al., 2019 [30] showed that the antioxidant activity of sea buckthorn powder used in biscuit preparation was affected by the drying temperature. Specifically, biscuits made with sea buckthorn powder dried at 50 °C for 12 h exhibited an antioxidant activity of 88.97 ± 0.82, while those made with powder dried at 80 °C for 5 h had an activity of 89.14 ± 0.27.

In a separate study by Nilova and Malyutenkova, 2018 [27], it was observed that the type and amount of sea buckthorn powder used in bakery products influenced their antioxidant activity. Bakery products made with sea buckthorn peel powder had the highest antioxidant activity, followed by those made with marc powder and seed powder. This was due to the peel powder’s high content of ascorbic acid, total phenolic content, and total flavonoid content, followed by the marc powder and seed powder.

3.3. Sensory Analysis

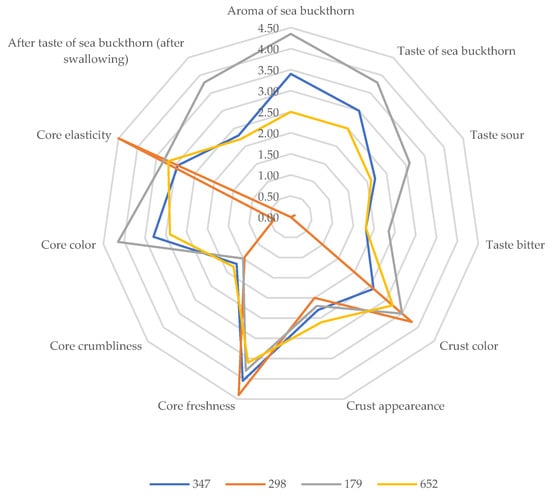

Based on the data presented in Figure 7 for bread samples added with Clara sea buckthorn pomace powder, it can be observed that the sample with 10% sea buckthorn had a strong aroma and taste of sea buckthorn, with a slightly sour taste and a distinct aftertaste. The internal appearance of the bread with 10% sea buckthorn was judged to be the darkest, but it showed good elasticity and a compact, non-crumbling core. In contrast, the sample with 8% sea buckthorn had a pleasant appearance, with a crispy crust and the lightest crust color among the samples with powder from the Clara variety.

Figure 7.

Graphic representation of the sensory characteristics of the functional bread samples obtained by adding 6%, 8%, and 10% sea buckthorn powder from the Clara variety (legend: 347—C8 sample, 298—control sample, 179—C10 sample, 652—C6 sample).

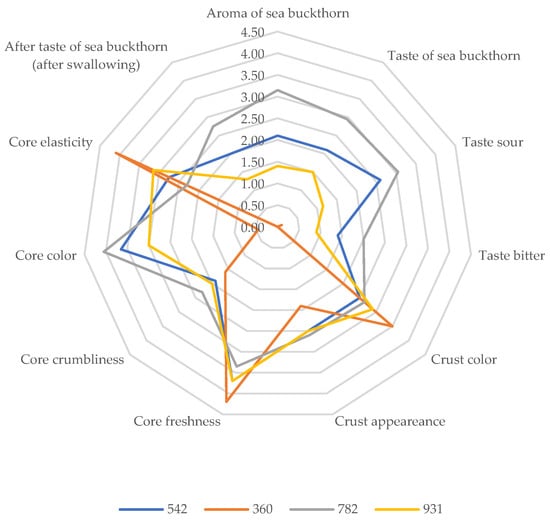

Based on the data presented in Figure 8 for bread added with Mara sea buckthorn pomace powder, it was observed that the sample containing 10% sea buckthorn pomace powder had a robust sea buckthorn aroma and a taste that was slightly sour and bitter, with a potent aftertaste. On the other hand, the sample with 8% sea buckthorn powder had a light-colored crust that was crisp and fresh, while the core was compact and non-crumbly.

Figure 8.

Graphic representation of the sensory characteristics of the functional bread samples obtained by adding 6%, 8%, and 10% sea buckthorn powder from the Mara variety (legend: 542—M8 sample, 360—control sample, 782—M10 sample, 931—M6 sample).

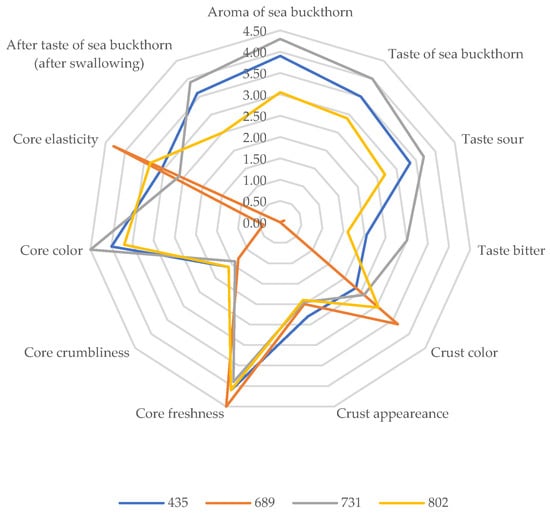

Based on the presented data in Figure 9 for bread added with Sorana sea buckthorn pomace powder, it is observed that the samples containing sea buckthorn powder had a mild sea buckthorn aroma and a distinctive sea buckthorn flavor, with a slightly sour and bitter undertone. In particular, the sample with 8% sea buckthorn pomace powder had a pale crust and a dark, dense, and elastic core that did not crumble easily.

Figure 9.

Graphic representation of the sensory characteristics of the functional bread samples obtained by adding 6%, 8%, and 10% sea buckthorn powder from the Sorana variety (legend: 435—S8 sample, 689—control sample, 731—S10 sample, 802—S6 sample).

According to the organoleptic analysis conducted by the panelists, a specific smell of yeast was noted in the samples, and when a larger amount of sea buckthorn powder was added, a slight smell of fermentation was also detected. However, the sea buckthorn flavor was found to be generally pleasant.

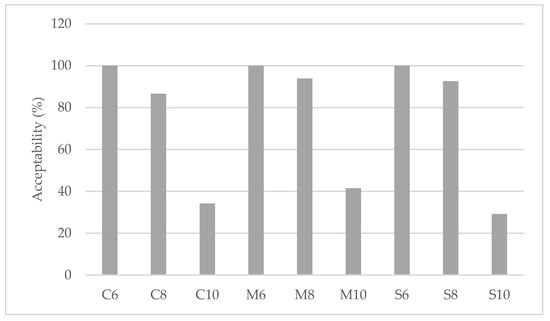

Regarding the assessment of the overall acceptability of functional bread samples produced by adding 6%, 8%, and 10% sea buckthorn pomace powder, the findings are illustrated in Figure 10. The samples with a 6% addition of sea buckthorn pomace powder received a unanimous acceptance with a maximum score of 100%. The samples containing 8% sea buckthorn powder showed a high level of acceptability, with the sample containing sea buckthorn powder from the Mara variety being the most preferred, scoring 93.9%. The sample with 8% sea buckthorn pomace powder from the Clara variety was also highly appreciated, with a score of 92.6%. The sample with 8% sea buckthorn powder from the Sorana variety received a slightly lower score of 86.58%. However, consumer preferences were not met by the samples containing 10% sea buckthorn pomace powder, as their scores were below 42%, with the sample containing 10% sea buckthorn pomace powder from the Mara variety obtaining a score of 41.46%, the sample with 10% sea buckthorn pomace powder from the Sorana variety obtaining a score of 34.14%, and the sample with 10% sea buckthorn pomace powder from the Clara variety obtaining a score of 29.2%.

Figure 10.

Acceptability test results of functional bread samples obtained by adding 6%, 8%, and 10% sea buckthorn powder.

Furthermore, the addition of wine grape pomace (WGP) to food products can enhance the dietary fiber (DF) and polyphenol content in the diet of consumers. However, the addition of WGP may have negative impacts on the sensory characteristics of food, such as flavor, color, and texture, as well as water and fat absorption. To mitigate these potential negative effects, strategies such as increasing hydration, using other ingredients to mask WGP flavors, reducing the particle size of WGP powders, and optimizing the formulation can be employed [51].

According to Sturza et al., 2016 [17], the addition of 2% sea buckthorn flour to gingerbread improved its external appearance, color, and texture in comparison to the control. Guo et al., 2019 [12] demonstrated that consumers favored the soft texture of bread with a larger volume obtained with sea buckthorn. The bread sample with 5% sea buckthorn pulp was rated the highest in terms of taste (5.6), indicating it was the most palatable among the samples. However, bread with 8% sea buckthorn pulp received a lower score (4.47) compared to the control (4.67), indicating that flavor might not be favored by consumers when higher concentrations of residues are added. In terms of appearance, sea buckthorn pulp addition had a negative effect on the bread’s appearance, which could be attributed to the high crude fiber content of the residues.

Ghendov-Mosanu et al., 2020 [29] found that adding 1% sea buckthorn concentration to the sample had a favorable effect on the organoleptic index, resulting a product with a golden crust, an elastic core, well-developed porosity, and pleasant taste and aroma. In contrast, samples with 3% and 5% sea buckthorn berry flour had a dark crust, dry crumb, poorly developed porosity, and a specific sea buckthorn berry flavor and odor. However, the total scores for the organoleptic analysis of the samples containing 3% and 5% sea buckthorn berry flour were within the range of 24.1–30.0, indicating that the products were of very good quality. The values for product shape and volume, crust appearance and color, baking degree, state and appearance of the bread core, bread core porosity and pore structure, aroma, and taste of the bread obtained with 1% sea buckthorn berry flour were identical to those of the control sample, indicating that this percentage did not significantly affect the characteristics of the obtained product. As the percentage of sea buckthorn berry flour added increased, the values of these parameters decreased.

Muresan et al., 2019 [30] observed that the taste and odor of by-products used in bakery products are influenced by the temperature of by-product drying. By-product samples dried at both 50 °C and 80 °C retained a characteristic odor and taste of fresh berries. In terms of sensory analysis, the biscuits made with sea buckthorn biomass powder obtained the highest score of 9, while those made with blueberry powder obtained a score of 8. The sensory analysis revealed that all three fruit pastes (including sea buckthorn and blueberry) had very good acceptability in terms of appearance, flavor, consistency, and overall aspect.

Janotkova et al., 2021 [36] demonstrated that the addition of 20% sea buckthorn to biscuits resulted in the most pleasant acidity and taste. The authors also observed that the addition of sea buckthorn biomass increased the acidity of the biscuits, which can be attributed to the presence of organic acids and sugars. Biscuits without any biomass addition were the hardest and most fragile, while those with 20% sea buckthorn were considered hard and brittle at a minimum level.

According to Stoin et al., 2014 [52], adding 10% sea buckthorn into digestive cookies resulted in a crispy texture, as opposed to the hard and brittle control sample. Furthermore, adding 15% sea buckthorn biomass resulted in the most enjoyable overall experience. The authors concluded that the digestive cookies with 10% sea buckthorn had higher scores (up to 19.71 out of a possible maximum of 20 points) compared to the control sample (17.85 points). The authors reported that adding 10% fresh sea buckthorn, dried sea buckthorn fruit powder, and sea buckthorn syrup to digestive cookies resulted in a brownish color, as opposed to the brighter (golden yellow) color of the control sample.

Based on the presented results, the bread samples containing 8% sea buckthorn pomace powder had the most favorable properties in terms of nutritional parameters and sensorial acceptability and were chosen as having the optimum quantity of sea buckthorn pomace. Therefore, these samples were further subjected to shelf-life analysis consisting of microbiological evaluation and textural analysis in order to determine the aging degree of the enriched bread samples.

3.3.1. Microbiological Evaluation

The microbiological safety of the developed bread samples consisted of the evaluation of the appearance of mold on the surface of the bread samples during storage at 21 °C (room temperature). Therefore, the obtained bread samples were packed individually in polyethylene bags and evaluated daily for signs of mold on the surface of the bread sample. As the sample evaluation revealed (Table 8), the bread samples containing sea buckthorn pomace powder presented lower mold spoilage on the surface compared to the control sample. Molds appeared on the sample surface after 72 h for the control sample, 96 h for the M8 sample, and 120 h for the C8 and S8 samples. This fact could be due to the polyphenolic content and antioxidant activity of the bread samples containing sea buckthorn powder, properties that could lead to a reduction in microbial development. As stated in many studies, polyphenols present inhibitory effects over both food-borne pathogens and food spoilage microorganisms [53,54,55]. Therefore, the addition of sea buckthorn pomace powder led to an increased shelf-life of 24 h for the M8 sample and 48 h for the C8 and S8 samples. Similar results were obtained by Ghendov-Mosanu et al., 2020 [29], who added sea buckthorn flour to wheat bread and observed an increased shelf-life of 3 (1% sea buckthorn flour), 4 (3% sea buckthorn flour), and 5 days (5% sea buckthorn flour) for the obtained bread samples.

Table 8.

Spoilage characteristics of the bread samples containing 8% sea buckthorn pomace powder.

3.3.2. Texture Analysis

The texture characteristics of the crumb were assessed using the Instron Texture Analyzer (Illinois Tool Works Inc., Norwood, MA, USA) as per the procedure outlined by Stamatie et al., 2022 [56]. A compression piston with a 12 mm diameter and a 50 N load cell were used to conduct the test, which involved compressing the middle of a 20 mm slice of bread with a compression speed of 2 mm/min. The test comprised two cycles with 20 mm depth compressions. The analysis was carried out at room temperature on the 3rd and 5th days of storage. The results of the texture analysis of functional bread enriched with 8% sea buckthorn pomace powder are presented in Table 9.

Table 9.

Texture properties of functional bread samples with 8% sea buckthorn pomace powder (mean ± SD).

During the two days of analysis, the M8 bread sample exhibited the highest firmness (7.31 N day 3 and 8.55 N day 5), followed by the C8 bread sample (7.14 N day 3 and 7.01 N day 5), while the S8 bread sample had the least firmness (4.77 N day 3 and 5.63 N day 5). The control sample showed the lowest firmness, indicating the highest softness (3.7 N day 3 and 4.23 N day 5). The elasticity of the samples was similar among the samples and between the two days of analysis, with values ranging from 0.97 for the M8 sample on day 3 to 1.18 for the control sample on day 5. The C8 bread sample (1.08 on day 3) exhibited the values closest to the control sample (1.06 on day 3). The cohesiveness of the samples decreased significantly (p < 0.05) between the two days of analysis, indicating that the samples offered less resistance during the second deformation. The highest cohesiveness was observed in the C8 bread sample on day 3, with a value of 0.35, while the lowest cohesiveness was recorded in the control sample on day 5, with a value of 0.04. The S8 bread sample (0.28 day 3) exhibited worse cohesiveness than the control sample (0.25 day 3). The C8 bread sample exhibited the highest chewiness (2.69 N day 3), while the S8 bread sample (1.38 N day 3) showed values closest to the control sample (0.98 N day 3). The addition of sea buckthorn pomace powder at 8% increased the texture of the samples. On the 3rd day of storage, the M8 bread sample exhibited the highest values for hardness, elasticity, cohesiveness, and chewiness. The S8 sample showed values closest to the control sample.

According to Guo et al., 2019 [12], the bread samples enriched with sea buckthorn pulp showed increased values of springiness, cohesiveness, and resilience, while the values of hardness, gumminess, and chewiness were lower compared to the control sample. The addition of sea buckthorn pulp led to a significant decrease in the hardness of bread, which could be attributed to the denser crumb structure formed during the fermentation process. The cohesiveness of the bread was increased to 38.03% in bread samples containing 5% sea buckthorn pulp compared to the control. The chewiness of the bread obtained with 10% sea buckthorn pulp was similar to that of the control. However, the resilience decreased with the increasing addition of residues, indicating a less elastic gluten structure of bread. The bread sample containing 5% sea buckthorn pulp showed the most significant effect on resilience, with a difference of 65.17% compared to the control. On the contrary, the addition of sea buckthorn biomass to biscuits led to a decrease in their hardness, most likely due to a gradual decrease in gluten content, which hindered the formation of gluten matrices, as well as competition for water between sugar and flour, as mentioned by Janotkova et al., 2021 [36]. The reduction in hardness of bakery products enriched with sea buckthorn may also be due to the presence of organic acids, such as malic acid, fumaric acid, or citric acid, as well as limited activity of amylases in the dough, along with the content of phenolic compounds [36]. According to a study conducted by Sturza et al. (2016) [17], the addition of sea buckthorn flour in sponge cakes resulted in a decreased occurrence of starch and protein modifications, leading to a slower progression of changes in the structural, mechanical, and sensory characteristics of the fortified samples.

Furthermore, according to the research conducted by Muresan et al., 2019 [30], the hardness of biscuits was impacted by the drying temperature of the powder they contained. The biscuits that contained powder dried at 80 °C had higher hardness values but lower total work at the same temperature. This was attributed to the formation of more brittle structures, which led to product fracture.

Janotkova et al., 2021 [36] highlighted that texture analysis parameters, such as hard-ness and brittleness, should be kept as low as possible in bakery products since they are closely linked to consumers’ perception of freshness. These parameters are crucial for evaluating the quality of bakery products.

4. Conclusions

The increasing demand from consumers for healthier food products, capable of preventing nutrition-related diseases and enhancing physical and mental well-being, has determined the rapid growth of the functional foods market. In response, the bakery industry is shifting its focus toward enhancing the health attributes of its products.

This study presented a novel approach to bread baking by adding sea buckthorn pomace powder. The bread was prepared by a direct method by adding 6, 8, and 10% sea buckthorn powder. The obtained products were subjected to physical–chemical, nutritional, organoleptic, and consumer acceptability analyses.

The resulting bread contained high amounts of fibers, proteins, and lipids, with a lower energy value than white bread. The analysis revealed strong antioxidant and antimicrobial properties, which increased as the percentage of sea buckthorn in the bread increased. The phenolic fraction and aroma substances in the raw materials were attributed to the prolonged shelf-life of the product due to the known antimicrobial activity of polyphenols.

Additionally, the results obtained indicate that sea buckthorn by-products are a viable way to enhance the mineral and microelement content of functional food.

Sensory tests showed that bread samples with an 8% addition of sea buckthorn powder were widely accepted, but high concentrations could lead to negative sensory attributes. In summary, this study recommends adding Hippophae rhamnoides pomace powder to wheat bread to obtain a product enriched in health-promoting biomolecules, with better sensorial properties and a longer shelf-life. Additionally, future research could explore the addition of sea buckthorn pomace powder to other bakery products, including gluten-free options.

There are many future research possibilities that could be explored in the bakery industry in order to obtain fortified products with enhanced properties regarding their nutritional value. One of these applications could be encapsulation technology to obtain better preservation of bioactive compounds. Furthermore, given the potential of microalgae as a promising candidate to be used in food products manufacturing, a future approach involves the development of bakery products incorporating microalgae due to its ability to prevent oxidative deterioration and enhance the nutritional value of food products. Another application involves the development of bakery products using cricket powder as a novel source of innovative ingredients, a powder that has the potential to serve as a protein-enriching ingredient, providing essential amino acids and minerals for improved nutritional value in bakery products.

Author Contributions

Conceptualization, E.E.P., M.E.P. and A.C.M.; methodology, I.S., E.L.U., E.E.P. and M.G.-C.; resources, I.S., E.L.U. and E.E.P.; data curation, M.D., A.C.M. and G.M.; writing—original draft preparation, I.S., E.L.U. and M.G.-C.; writing—review and editing, E.L.U. and E.E.P.; project administration, M.E.P. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by contract 186/2020, project acronym MILDSUSFRUIT. The authors acknowledge the financial support for this project provided by transnational funding bodies, partners of the H2020 ERA-NETs SUSFOOD2 and CORE Organic Cofund, under the Joint SUSFOOD2/CORE Organic Call 2019.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Sharma, M.; Shehzad, H.; Tatsiana, S.; Riina, A.; Rajeev, B. Valorization of sea buckthorn pomace to obtain bioactive carotenoids: An innovative approach of using green extraction techniques (ultrasonic and microwave-assisted extractions) synergized with green solvents (edible oils). Ind. Crops Prod. 2023, 175, 114257. [Google Scholar] [CrossRef]

- Torres-Leon, C.; Ramirez-Guzman, N.; Londono-Hernandez, L.; Martinez-Medina, G.A.; Diaz-Herrera, N.; Navarro-Macias, V.; Alvarez-Perez, O.B.; Picazo, B.; Villarreal-Vazquez, M.; Ascacio-Valdes, J.; et al. Food Waste and Byproducts: An Opportunity to Minimize Malnutrition and Hunger in Developing Countries. Front. Sustain. Food Syst. 2018, 2, 52. [Google Scholar] [CrossRef]

- Torres-Leon, C.; Rojas, R.; Contreras-Esquivel, J.C.; Serna-Cock, L.; Belmares-Cerda, R.E.; Aguilar, C.N. Mango seed: Functional and nutritional properties. Trends Food Sci. Technol. 2016, 55, 109–117. [Google Scholar] [CrossRef]

- Compaore-Sereme, D.; Fatoumata, H.B.; Fidèle, W.B.T.; Heikki, M.; Ndegwa, H.M.; Mamoudou, H.D.; Hagrétou, S.L. Production and sensory evaluation of composite breads based on wheat and whole millet or sorghum in the presence of Weissella confusa A16 exopolysaccharides. Heliyon 2023, 9, e13837. [Google Scholar] [CrossRef]

- Mafu, A.; Ketnawa, S.; Phongthai, S.; Schonlechner, R.; Rawdkuen, S. Whole Wheat Bread Enriched with Cricket Powder as an Alternative Protein. Foods 2022, 11, 2142. [Google Scholar] [CrossRef]

- Dymchenko, A.; Milan, G.; Tomáš, G. 2023. Trends in bread waste utilization. In Trends in Food Science & Technology, 1st ed.; Toldra, F., Yada, R.Y., Eds.; Elsevier Ltd.: Amsterdam, The Netherlands, 2023; Volume 132, pp. 93–102. [Google Scholar]

- Ivanišová, E.; Čech, M.; Hozlár, P.; Zaguła, G.; Gumul, D.; Grygorieva, O.; Makowska, A.; Kowalczewski, P.Ł. Nutritional, Antioxidant and Sensory Characteristics of Bread Enriched with Wholemeal Flour from Slovakian Black Oat Varieties. Appl. Sci. 2023, 13, 4485. [Google Scholar] [CrossRef]

- Pinto, D.; Castro, I.; Vicente, A.; Bourbon, A.I.; Cerqueira, M.A. Functional Bakery Products—An Overview and Future Perspectives. In Bakery Products Science and Technology, 2nd ed.; Zhou, W., Hui, H., De Leyn, I., Pagani, M.A., Rosell, C.M., Selman, D., Therdthai, N., Eds.; John Wiley & Sons: Hoboken, NJ, USA, 2014; pp. 431–452. [Google Scholar]

- Xie, X.; Yongcheng, S.; Xiufang, B.; Xiaocui, L.; Yage, X.; Zhenming, C. Characterization of sea buckthorn polysaccharides and the analysis of its regulatory effect on the gut microbiota imbalance induced by cefixime in mice. JFF 2023, 104, 105511. [Google Scholar] [CrossRef]

- Kumar, A.; Pankaj, K.; Ajit, S.; Dharam, P.S.; Manisha, T. Scientific insights to existing know-how, breeding, genetics, and biotechnological interventions pave the way for the adoption of high-value underutilized super fruit Sea buckthorn (Hippophae rhamnoides L.). S. Afr. J. Bot. 2022, 145, 348–359. [Google Scholar] [CrossRef]

- Ursache, F.M.; Ghinea, I.O.; Turturică, M.; Aprodu, I.; Râpeanu, G.; Stănciuc., N. Phytochemicals content and antioxidant properties of sea buckthorn (Hippophae rhamnoides L.) as affected by heat treatment–Quantitative spectroscopic and kinetic approaches. Food Chem. 2017, 233, 442–449. [Google Scholar] [CrossRef]

- Guo, X.; Shi, L.; Yang, S.; Yang, R.; Dai, X.; Zhang, T.; Liu, R.; Chang, M.; Jin, Q.; Wang, X. Effect of sea-buckthorn pulp and flaxseed residues on quality and shelf life of bread. Food Funct. 2019, 10, 4220. [Google Scholar] [CrossRef]

- Prashant, S.; Shere, D.M. Utilization of fruit and vegetable pomace as functional ingredient in bakery products: A review. Asian J. Diary Food Res. 2018, 37, 202–211. [Google Scholar]

- Quiles, A.; Campbell, G.M.; Struck, S.; Rohm, H.; Hernando, I. Fiber from fruit pomace: A review of applications in cereal-based products. Food Rev. Int. 2016, 34, 162–181. [Google Scholar] [CrossRef]

- Hussain, S.; Sharma, M.; Bhat, R. Valorisation of Sea Buckthorn Pomace by Optimization of Ultrasonic-Assisted Extraction of Soluble Dietary Fibre Using Response Surface Methodology. Foods 2021, 10, 1330. [Google Scholar] [CrossRef] [PubMed]

- Gani, A.; Jan, R.; Ashwar, B.A.; Ashraf-ul, Z.; Shah, A.; Gani, A. Encapsulation of saffron and sea buckthorn bioactives: Its utilization for development of low glycemic baked product for growing diabetic population of the world. LWT Food Sci. Technol. 2021, 142, 111035. [Google Scholar] [CrossRef]

- Sturza, R.A.; Ghendov-Mosanu, A.A.; Deseatnicov, O.I.; Suhodol, N.F. Use of sea buckthorn fruits in the pastry manufacturing. Sci. Study Res. Chem. Chem. Eng. Biotechnol. Food Ind. 2016, 17, 35–43. [Google Scholar]

- AACC Method 10-05.01 Guidelines for Measurement of Volume by Rapeseed Displacement, 11th ed.; AACC International: Washington, DC, USA, 2010.

- SR 91:2007; Bread and Fresh Pastries. Analysis Methods. ASRO—Romanian Standardization Association: Bucharest, Romania, 2007.

- AOAC Official Method 934.06 Moisture in Dried Fruits; AACC International: Washington, DC, USA, 1935.

- AOAC Official Method 979.09 Protein in Grains; AACC International: Washington, DC, USA, 1994.

- AOAC Official Method 963.15 Fat in Cacao Products-Soxhlet Extraction Method; AACC International: Washington, DC, USA, 1973.

- AOAC Official Method 991.43 Total, Soluble, and Insoluble Dietary Fibre in Foods; AACC International: Washington, DC, USA, 1994.

- AOAC Method 923.03 Ash of Flour (Direct Method). In Official Methods of Analysis, 18th ed.; AOAC International Publisher: Gaithersburg, MD, USA, 2005.

- Popa, M.E.; Stan, A.; Popa, V.; Tanase, E.E.; Mitelut, A.C.; Badulescu, L. Postharvest quality changes of organic strawberry Regina cultivar during controlled atmosphere storage. Qual. Assur. Saf. Crops Foods 2019, 11, 631–638. [Google Scholar] [CrossRef]

- Stanciu, I.; Dima, R.; Popa, E.E.; Popa, M.E. Nutritional characterization of organic sea buckthorn pomace. Sci. Pap. Ser. B Hortic. 2022, LXVI, 913–918. [Google Scholar]

- Nilova, L.; Malyutenkova, S. The possibility of using powdered sea-buckthorn in the development of bakery products with antioxidant properties. Agron. Res. 2018, 16, 1444–1456. [Google Scholar]

- Nilova, L.; Malyutenkova, S. The influence of plant ingredients on the composition of antioxidants in bakery products. JHED 2021, 34, 77–82. [Google Scholar]

- Ghendov-Mosanu, A.; Cristea, E.; Patras, A.; Sturza, R.; Padureanu, S.; Deseatnicova, O.; Turculet, N.; Boestean, O.; Niculaua, M. Potential Application of Hippophae Rhamnoides in Wheat Bread Production. Molecules 2020, 25, 1272. [Google Scholar] [CrossRef]

- Muresan, E.A.; Chis, S.; Cerbu, C.G.; Man, S.; Pop, A.; Marc, R.; Muresan, V.; Muste, S. Development and characterization of biscuits based on sea buckthorn and blueberries by-products. JAP&T 2019, 25, 59–63. [Google Scholar]

- Rajeswari, H.; Jagadeesh, S.L.; Suresh, G.J. Physicochemical and sensory qualities of bread fortified with banana, aonla and sapota powders. JNHFE 2018, 8, 487–492. [Google Scholar]

- Nikolau, E.N.; Karvela, E.D.; Marini, E.; Panagopoulou, E.A.; Chiou, A.; Karathanos, V.T. Enrichment of bakery products with different formulations of bioactive microconstituents from black Corinthian grape: Impact on physicochemical and rheological properties in dough matrix and final product. J. Cereal Sci. 2022, 108, 103566. [Google Scholar] [CrossRef]

- Costa, L.L.; Tome, P.H.F.; Jardim, F.B.B.; Silva, V.P.; Castilho, V.P.; Damasceno, K.A.; Campagnol, P.C.B. Physicochemical and rheological characterization of pan bread made with pumpkin seed flour. Int. Food Res. J. 2018, 25, 1489–1496. [Google Scholar]

- Lim, H.S.; Park, S.H.; Ghafoor, K.; Hwang, S.Y.; Park, J. Quality and antioxidant properties of bread containing turmeric (Curcuma longa L.) cultivated in South Korea. Food Chem. 2011, 124, 1577–1582. [Google Scholar] [CrossRef]

- Odunlade, T.V.; Famuwagun, A.A.; Taiwo, K.A.; Gbadamosi, S.O.; Oyedele, D.J.; Adebooye, O.C. Chemical Composition and Quality Characteristics of Wheat Bread Supplemented with Leafy Vegetable Powders. J. Food Qual. 2017, 2017, 9536716. [Google Scholar] [CrossRef]

- Janotkova, L.; Potocnakova, M.; Kreps, F.; Krepsova, Z.; Acsova, A.; Haz, A.; Jablosky, M. Effect of sea buckthorn biomass on oxidation stability and sensory attractiveness of cereal biscuits. Bioresources 2021, 16, 5097–5105. [Google Scholar] [CrossRef]

- Biel, W.; Jaroszewska, A. The nutritional value of leaves of selected berry species. Sci. Agric. 2016, 74, 405–410. [Google Scholar] [CrossRef]

- Lyu, F.; Luiz, S.F.; Perdomo Azeredo, D.R.; Cruz, A.G.; Ajlouni, S.; Renadheera, C.S. Apple Pomace as a Functional and Healthy Ingredient in Food Products: A Review. Processes 2020, 8, 319. [Google Scholar] [CrossRef]

- El-Sohaimy, S.A.; Shehata, M.G.; Mathur, A.; Darwish, A.G.; El-Aziz, N.M.; Gauba, P.; Upadhyay, P. Nutritional Evaluation of Sea Buckthorn “Hippophae rhamnoides” Berries and the Pharmaceutical Potential of the Fermented Juice. Fermentation 2022, 8, 391. [Google Scholar] [CrossRef]

- Jureviciute, I.; Kersiene, M.; Basinskiene, L.; Leskauskaite, D.; Jasutiene, I. Characterization of Berry Pomace Powders as Dietary Fiber-Rich Food Ingredients with Functional Properties. Foods 2022, 11, 716. [Google Scholar] [CrossRef] [PubMed]

- Gatlan, A.M.; Gutt, G. Sea Buckthorn in Plant Based Diets. An Analytical Approach of Sea Buckthorn Fruits Composition: Nutritional Value, Applications, and Health Benefits. Int. J. Envion. Res. Public Health 2021, 18, 8986. [Google Scholar] [CrossRef] [PubMed]

- Jaroszewska, A.; Biel, W.; Telesiński, A. Effect of mycorrhization and variety on the chemical composition and antioxidant activity of sea buckthorn berries. J. Elem. 2018, 23, 673–684. [Google Scholar]

- Piłat, B.; Bieniek, A.; Zadernowski, R. Chemical composition of individual morphological parts of the sea buckthorn fruit (Hippophae rhamnoides, L.). In Producing Sea Buckthorn of High Quality, Proceedings of the 3rd European Workshop on Sea Buckthorn, Helsinki, Finland, 10–14 October 2014; Kauppinen, S., Petruneva, E., Eds.; Natural Resources Institute Finland: Helsinki, Finland, 2014; pp. 79–82. [Google Scholar]

- Nour, V.; Panaite, T.D.; Corbu, A.R.; Ropota, M.; Turcu, R.P. Nutritional and Bioactive Compounds in Dried Sea-Buckthorn Pomace. Erwebsobstbau 2021, 63, 93–98. [Google Scholar] [CrossRef]

- Petrescu-Mag, R.M.; Vermeir, I.; Roba, C.; Petrescu, D.C.; Bican-Brisan, N.; Martonos, I.M. Is “Wild” a Food Quality Attribute? Heavy Metal Content in Wild and Cultivated Sea Buckthorn and Consumers’ Risk Perception. Int. J. Environ. Res. Public Health 2021, 18, 9463. [Google Scholar] [CrossRef]