The Effect of Conductive Alginate Capsules Encapsulating Rejuvenator (HealRoad Capsules) on the Healing Properties of 10 mm Stone Mastic Asphalt Mix

Abstract

:Featured Application

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

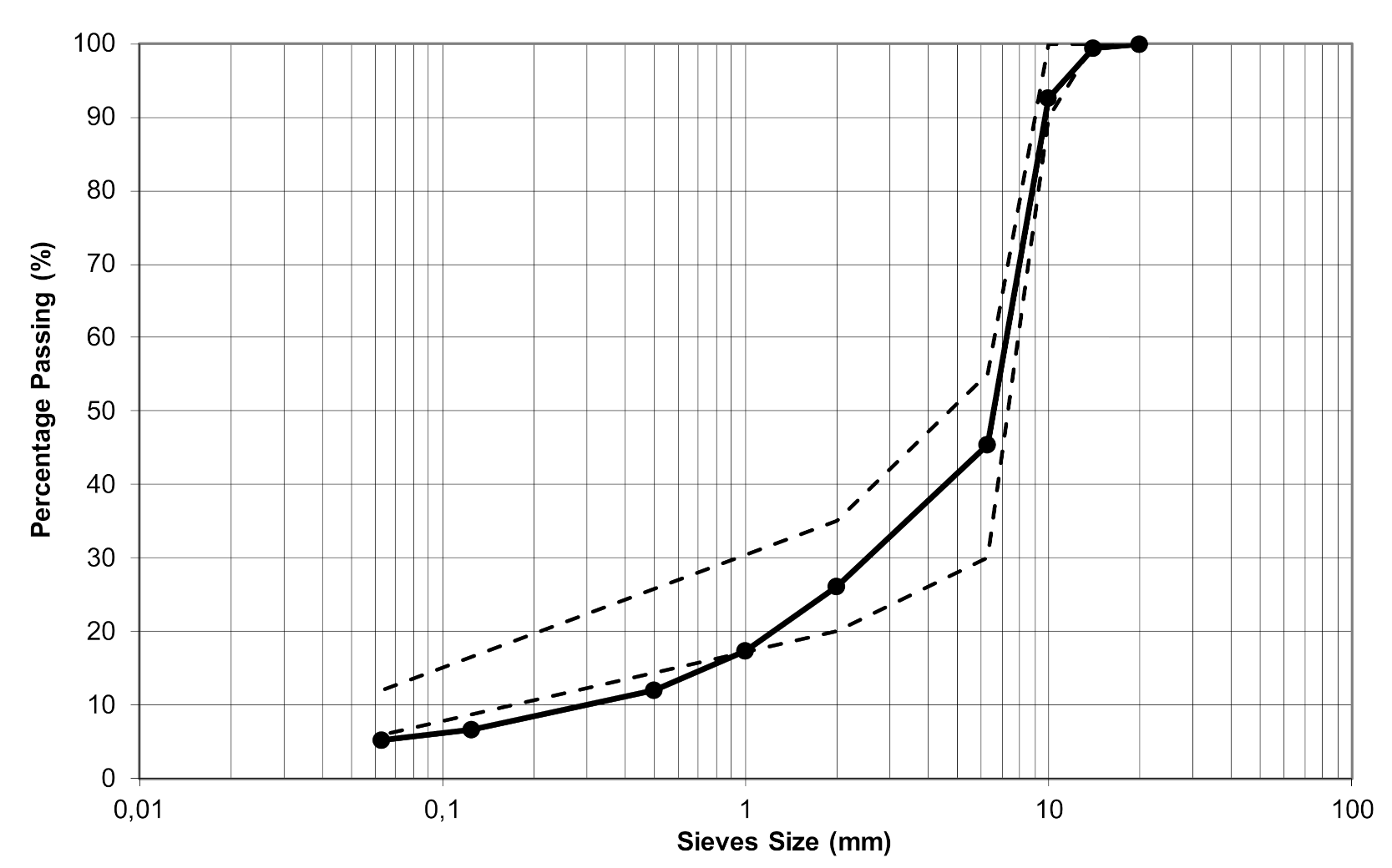

2.1.1. The 10 mm Stone Matic Asphalt Mix

2.1.2. Capsule Design

2.1.3. Test Specimen Compaction

2.2. Methods

2.2.1. Binder Drainage Test

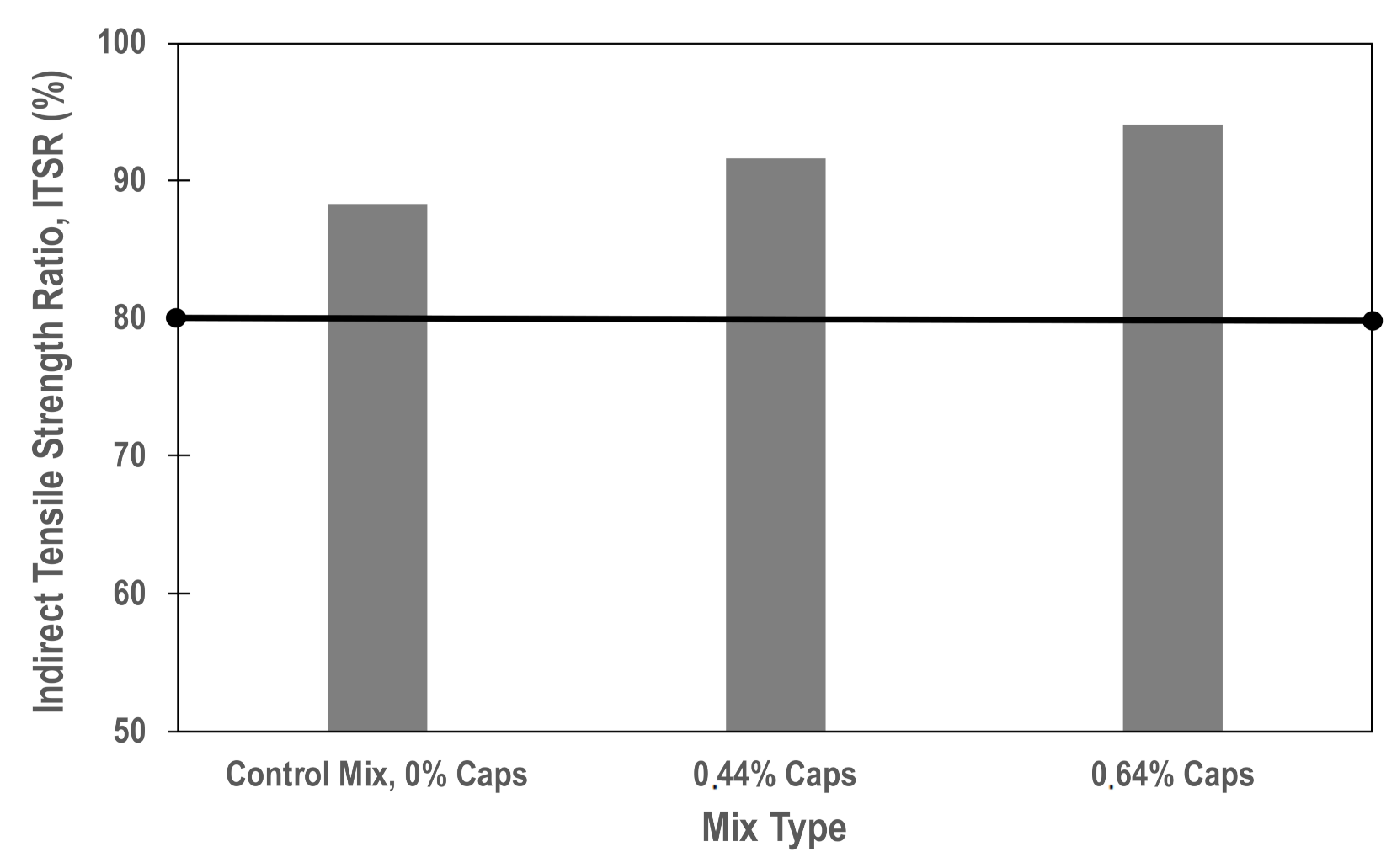

2.2.2. Water Sensitivity Test—Indirect Tensile Strength Ratio (ITSR)

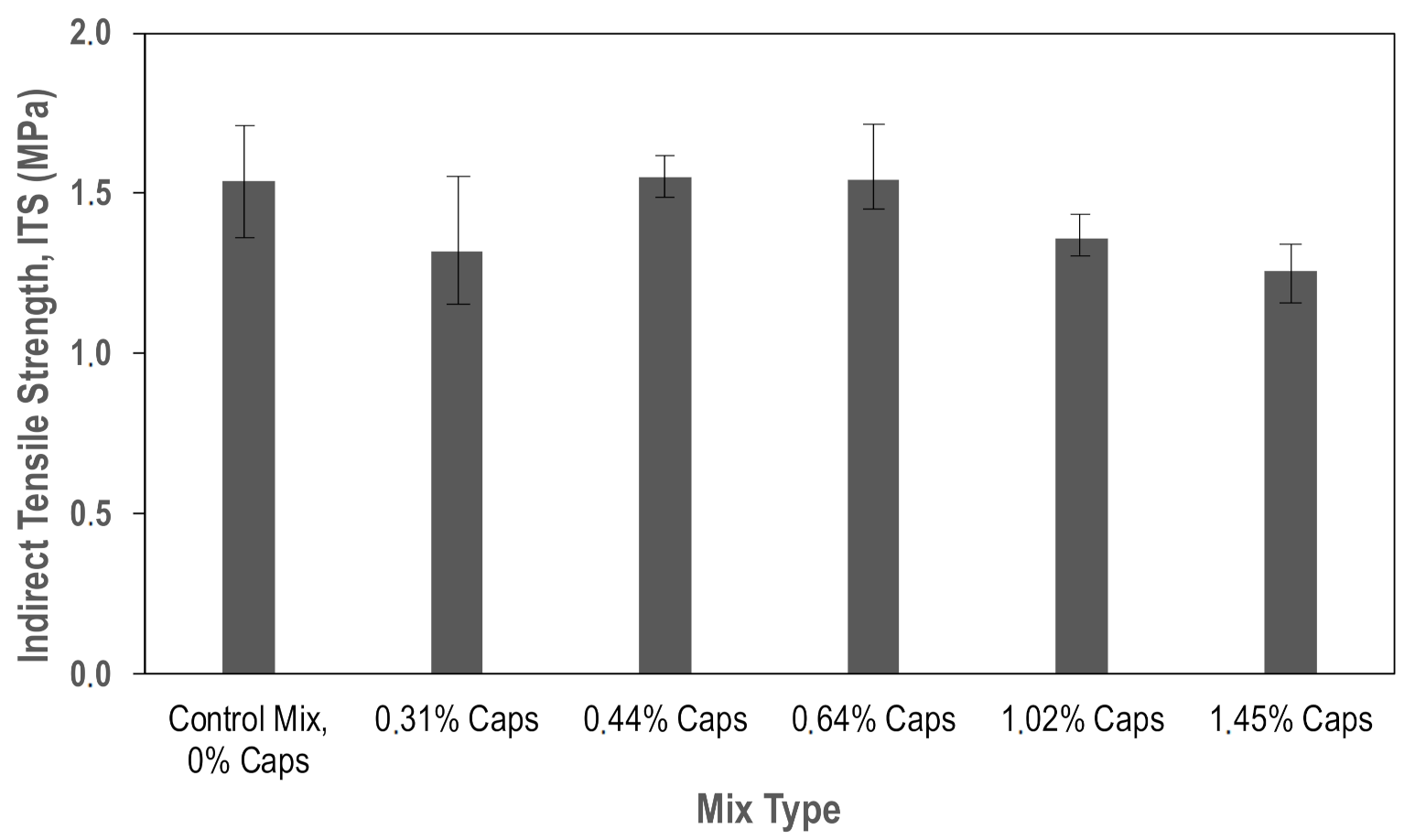

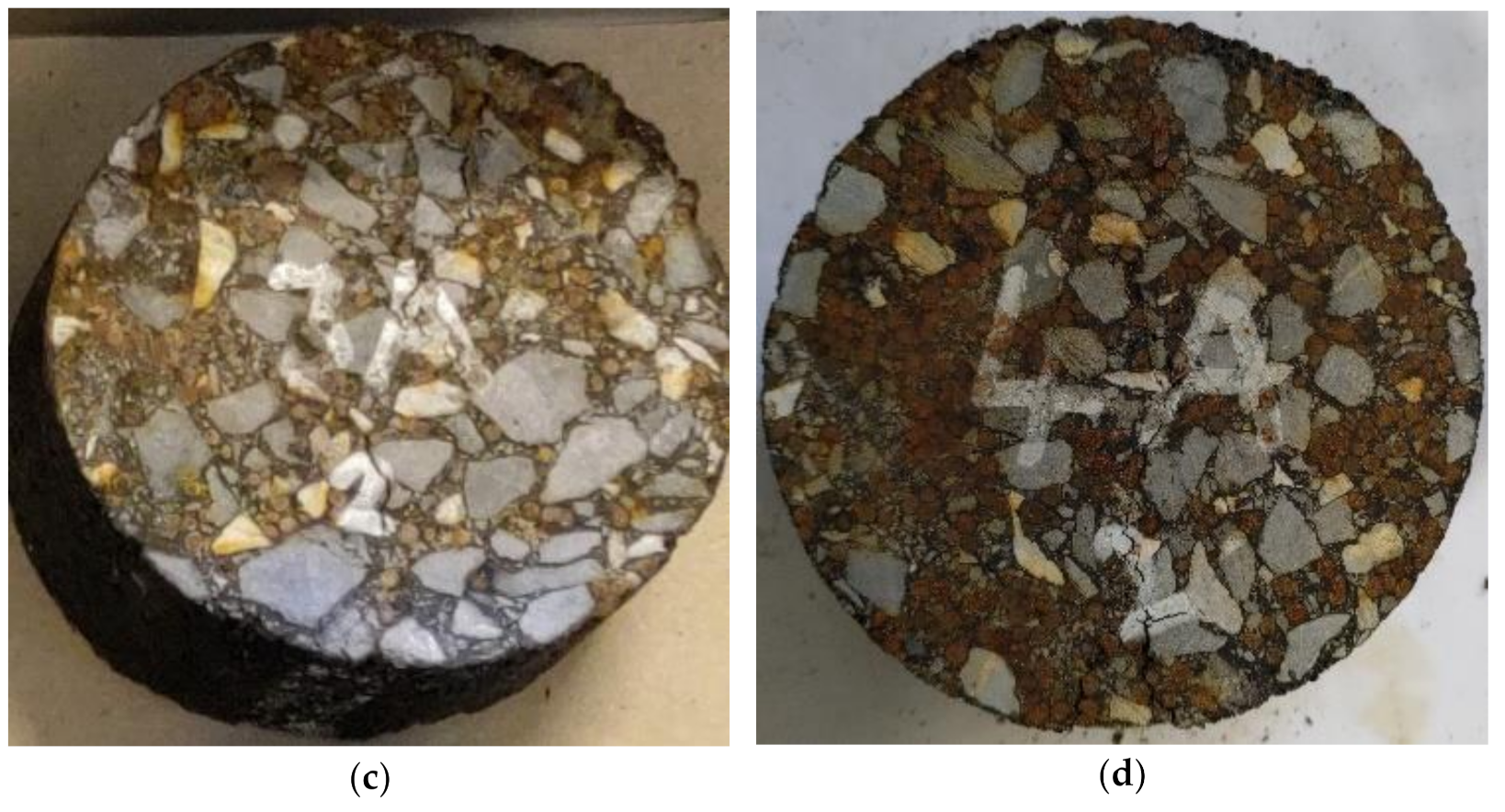

2.2.3. Indirect Tensile Strength Test

2.2.4. Wheel Tracking Test

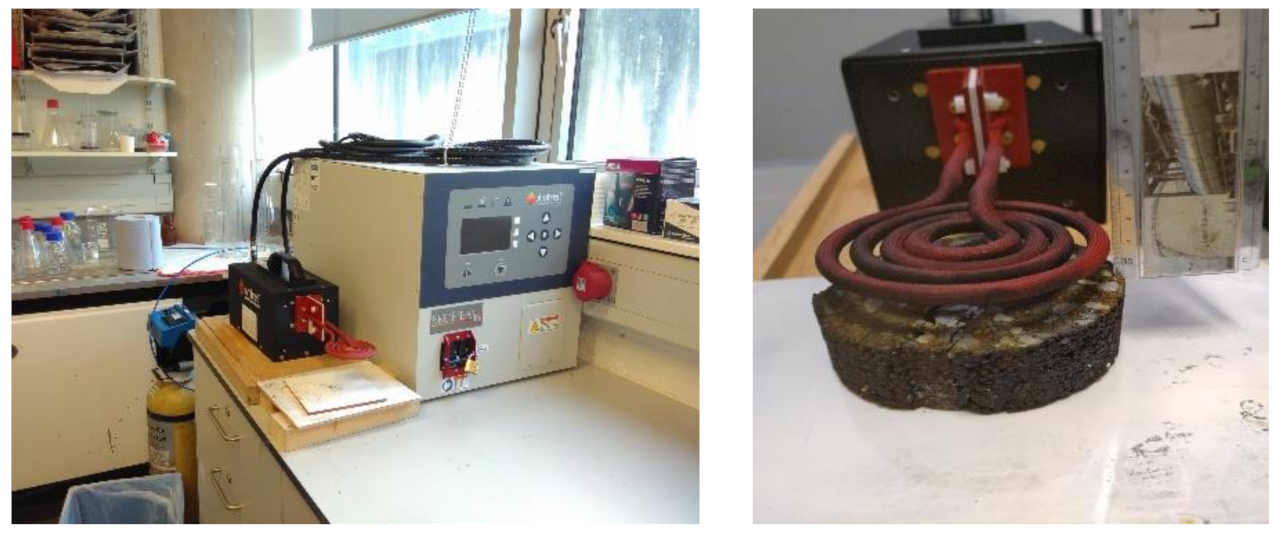

2.2.5. Extrinsic Healing Regime

3. Results

3.1. Binder Drainage Test

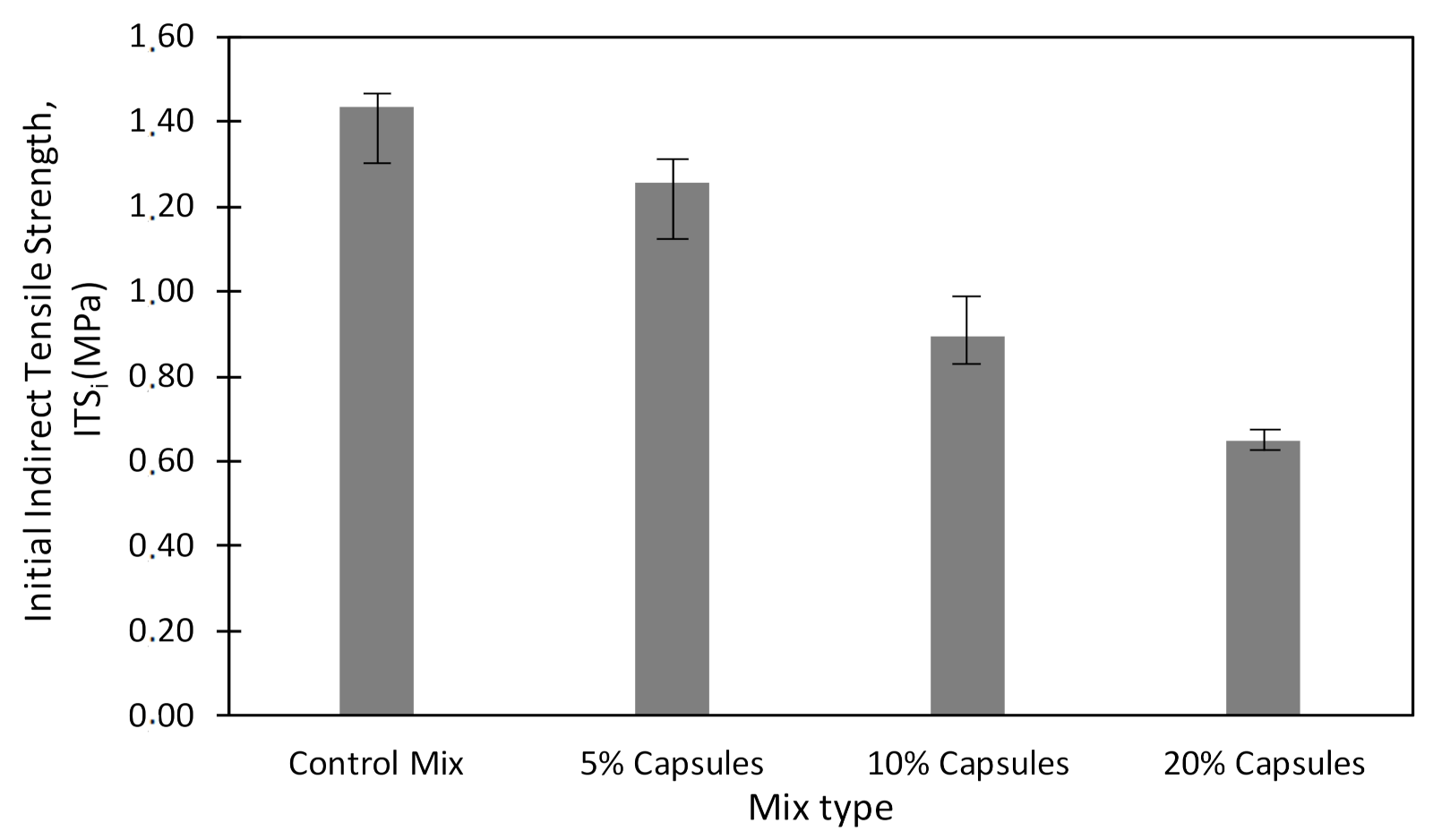

3.2. Indirect Tensile Strenght Test

3.3. Water Sensitivity Test

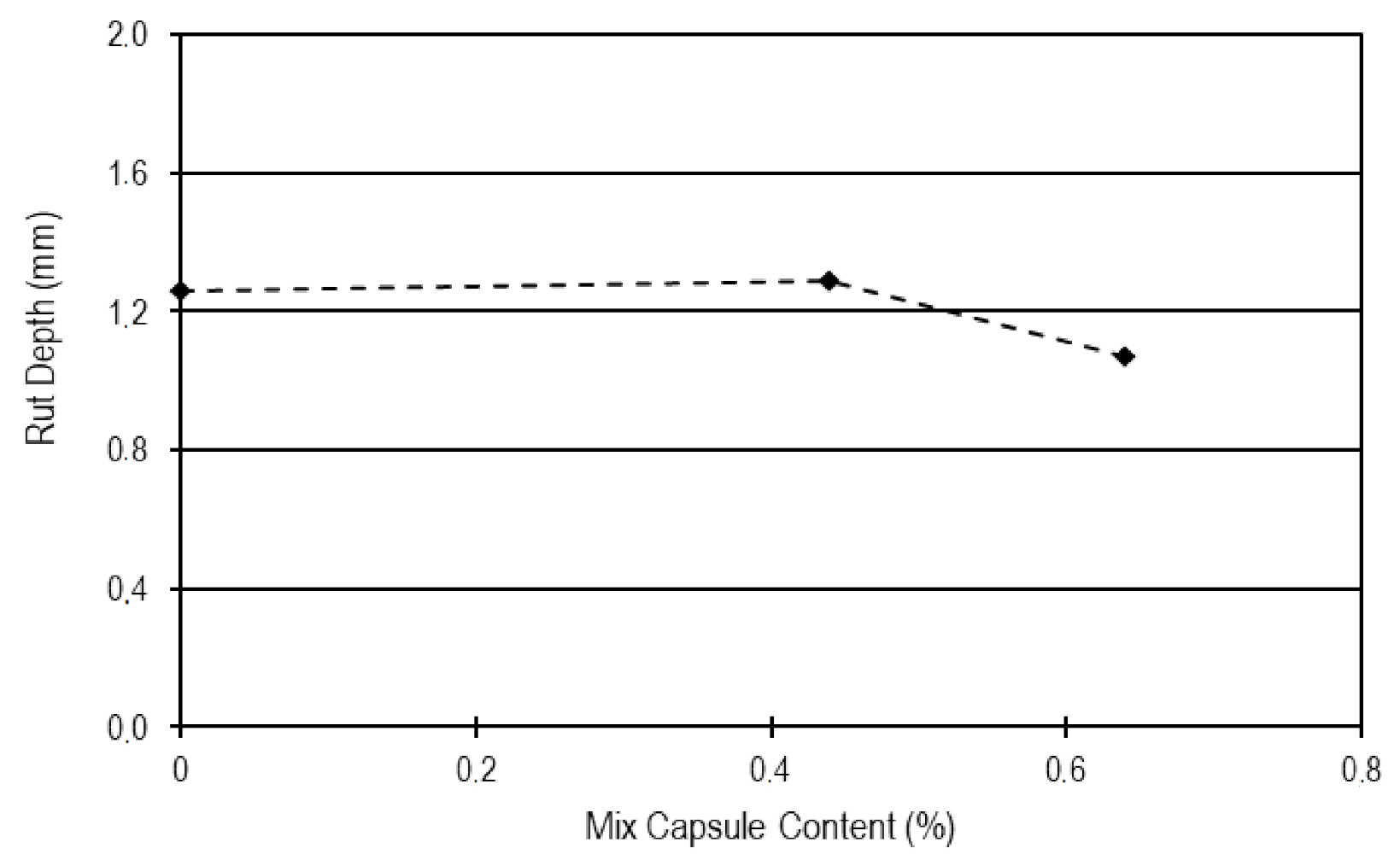

3.4. Wheel Tracking Test

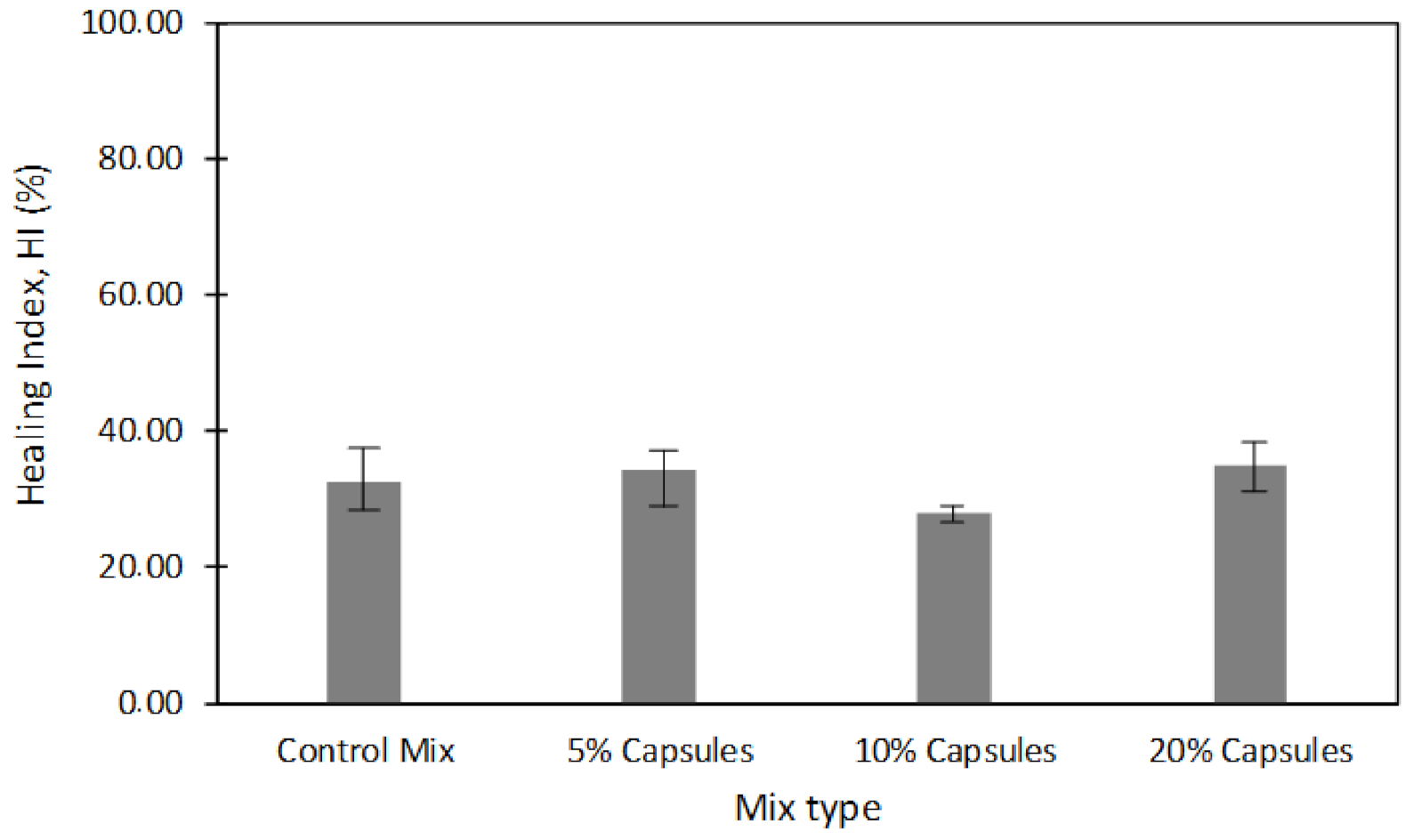

3.5. Extrinsic Healing

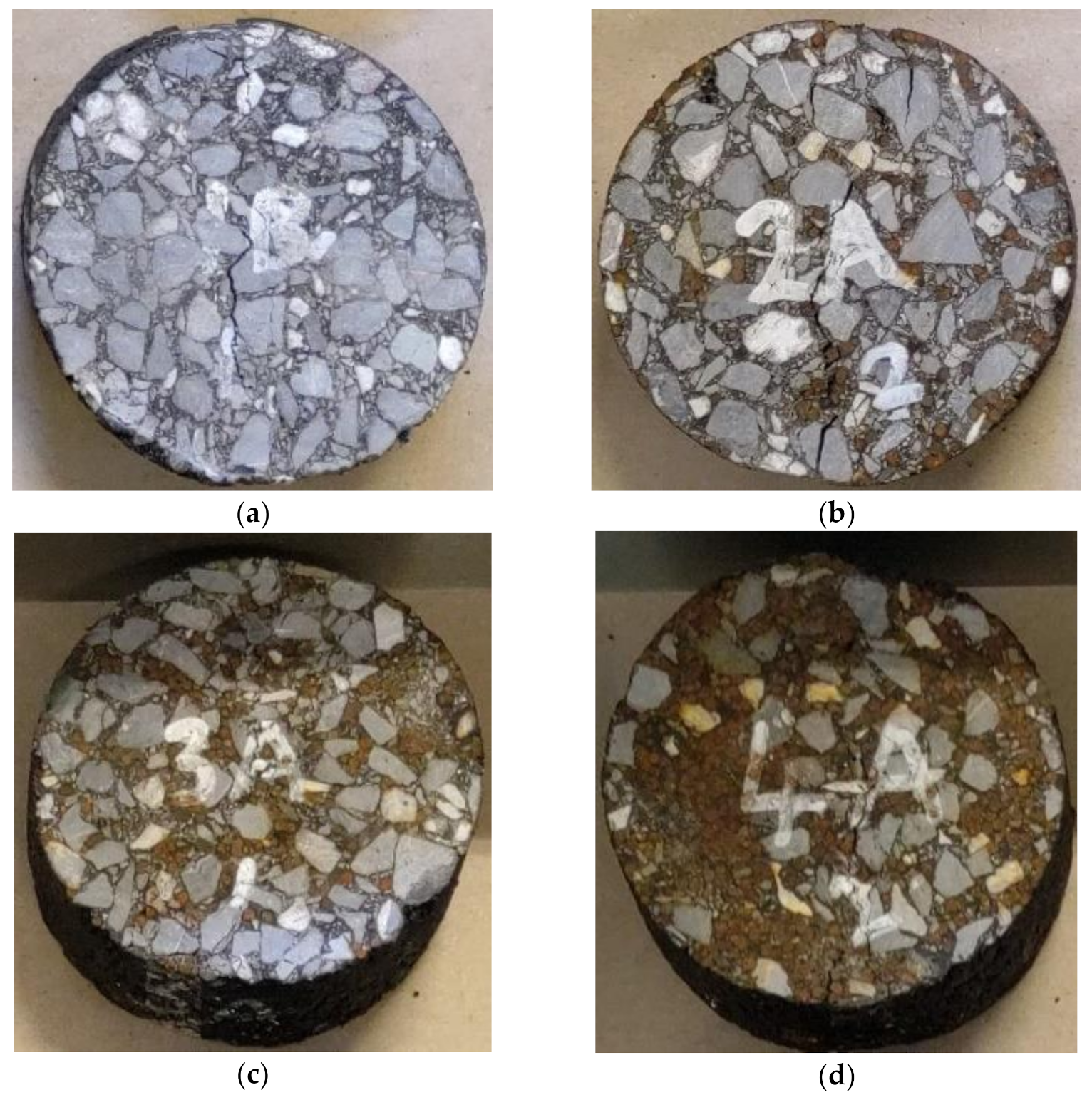

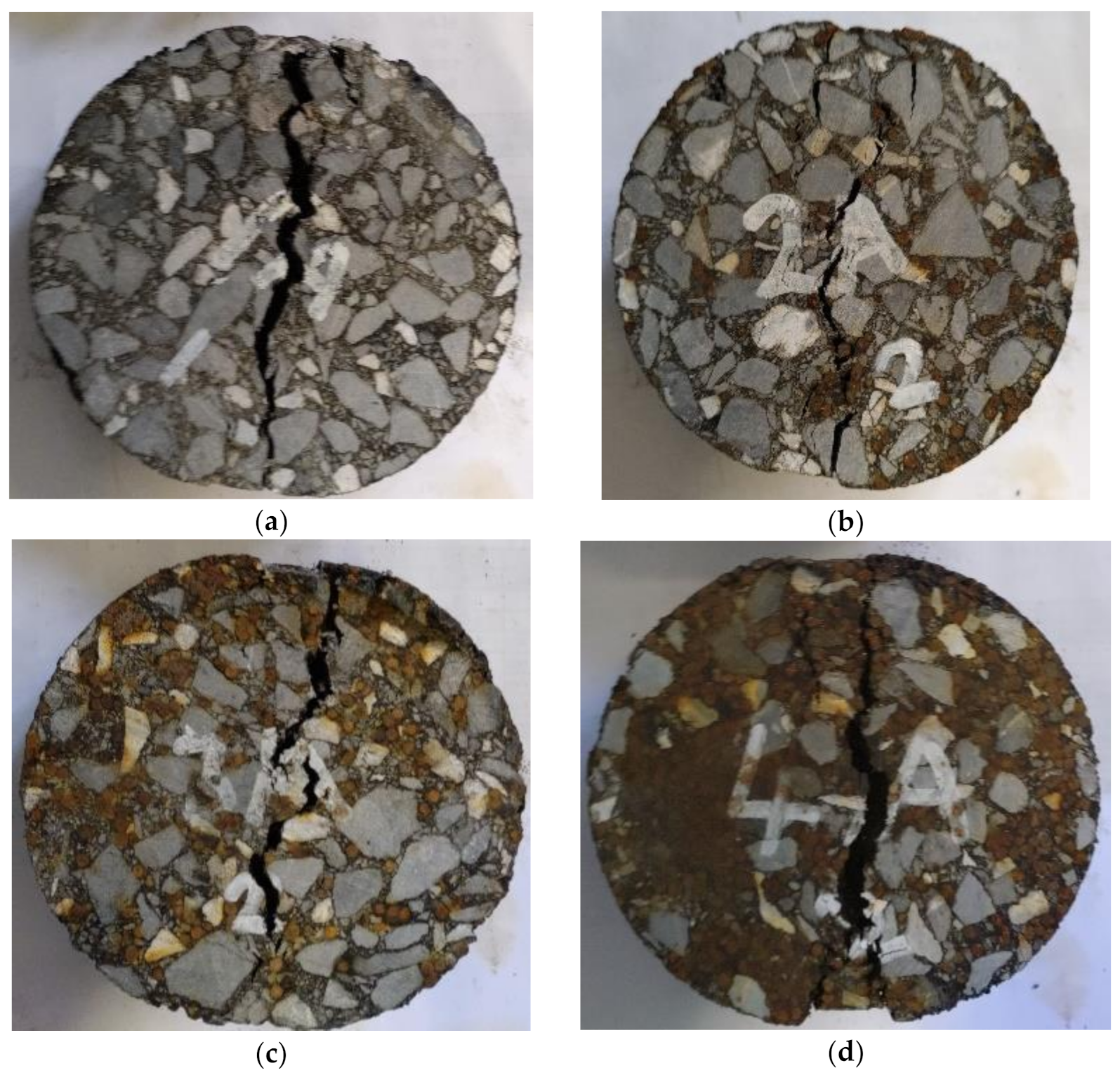

3.5.1. SMA Mix with Low Capsule Content

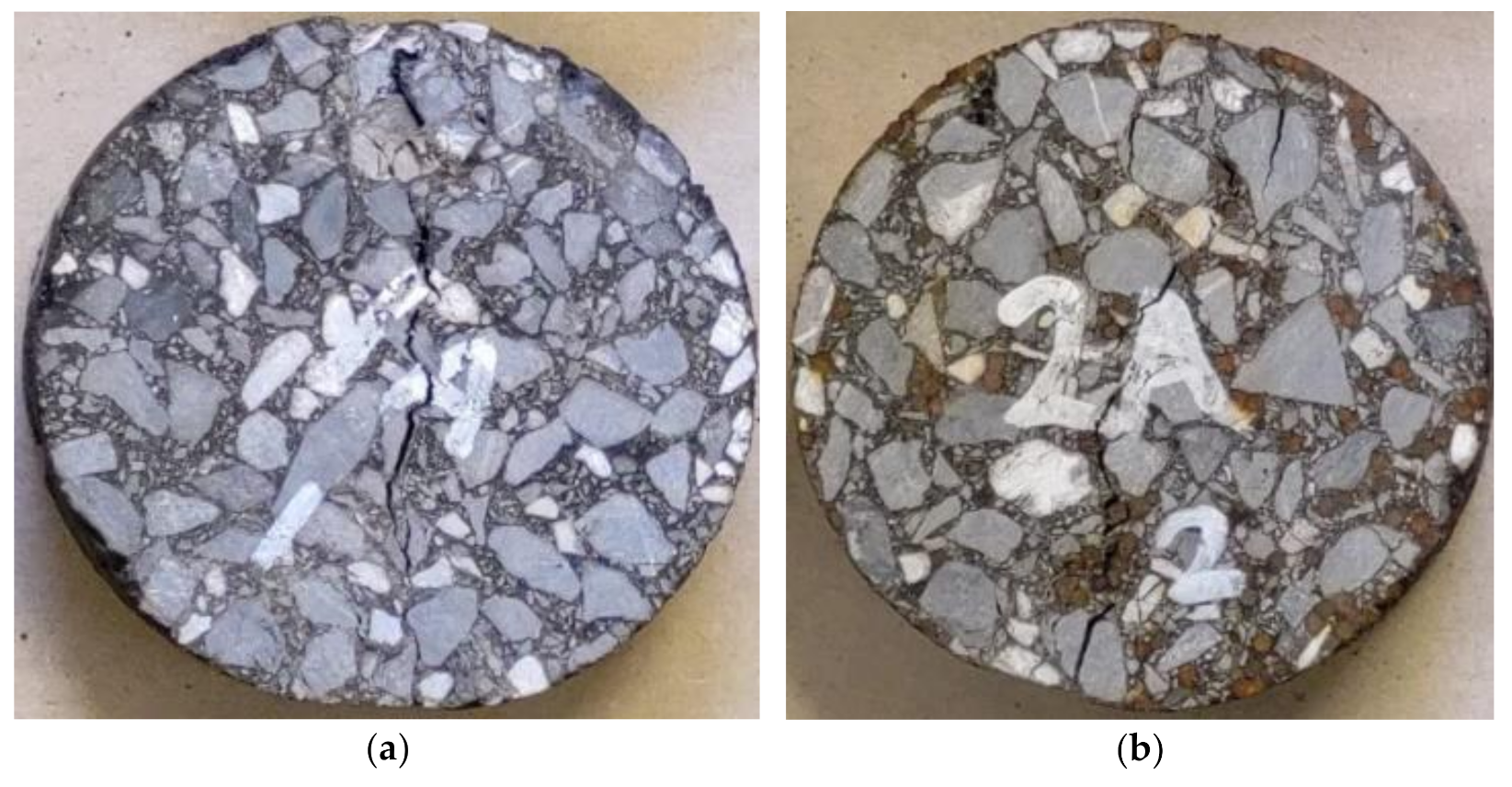

3.5.2. High Capsule Content SMA Mix

- The increased amounts of circular aggregates in the mix reduces the quantity of large aggregates, thereby reducing the interlocking strength of the material,

- The release of the rejuvenator during the mixing stage results in the softening of the bitumen.

4. Conclusions

5. Patents

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Xu, S.; García, A.; Su, J.; Liu, Q.; Tabaković, A.; Schlangen, E. Self-Healing Asphalt Review: From Idea to Practice. Adv. Mater. Interfaces 2018, 5, 1800536. [Google Scholar] [CrossRef]

- Xu, S.; Liu, X.; Tabaković, A.; Schlangen, E. A novel self-healing system: Towards a sustainable porous asphalt. J. Clean. Prod. 2020, 259, 120815. [Google Scholar] [CrossRef]

- Tabaković, A.; Mohan, J.; Karač, A. Conductive Compartmented Capsules Encapsulating a Bitumen Rejuvenator. Processes 2021, 9, 1361. [Google Scholar] [CrossRef]

- Wan, P.; Liu, Q.; Wu, S.; Zhao, Z.; Chen, S.; Zou, Y.; Rao, W.; Yu, X. A novel microwave induced oil release pattern of calcium alginate/ nano-Fe3O4 composite capsules for asphalt self-healing. J. Clean. Prod. 2021, 297, 126721. [Google Scholar] [CrossRef]

- Seneviratne, S.; Tabaković, A. Self-healing Asphalt HealRoad Customer Discovery and Needs Analysis Report. 2020; Unpublished. [Google Scholar]

- United Kingdom Government. Road Accidents and Safety Statistics. 2021. Available online: https://www.gov.uk/government/collections/road-accidents-and-safety-statistics (accessed on 18 February 2022).

- National Work Zone Safety. Work Zone Fatal Crashes and Fatalities. 2021. Available online: https://www.workzonesafety.org/crash-information/work-zone-fatal-crashes-fatalities/#national (accessed on 18 February 2022).

- Butt, A.A.; Birgisson, B.; Kringos, N. Optimizing the Highway Lifetime by Improving the Self Healing Capacity of Asphalt. Procedia-Soc. Behav. Sci. 2012, 48, 2190–2200. [Google Scholar] [CrossRef] [Green Version]

- García, Á.; Schlangen, E.; van de Ven, M.; Liu, Q. Electrical conductivity of asphalt mortar containing conductive fibers and fillers. Constr. Build. Mater. 2009, 23, 3175–3181. [Google Scholar] [CrossRef]

- García, Á.; Schlangen, E.; van de Ven, M.; Liu, Q. A simple model to define induction heating in asphalt mastic. Constr. Build. Mater. 2012, 31, 38–46. [Google Scholar] [CrossRef]

- Liu, Q. Induction healing of porous asphalt concrete. In Faculty of Civil Engineering and Geosciences; TU: Delft, The Netherlands, 2012. [Google Scholar]

- Bueno, M.; Arraigada, M.; Partl, M.N. Damage detection and artificial healing of asphalt concrete after trafficking with a load simulator. Mech. Time-Dependent Mater. 2016, 20, 265–279. [Google Scholar] [CrossRef]

- Norambuena-Contreras, J.; Garcia, A. Self-healing of asphalt mixture by microwave and induction heating. Mater. Des. 2016, 106, 404–414. [Google Scholar] [CrossRef]

- Norambuena-Contreras, J.; Serpell, R.; Vidal, G.V.; Gonzalez, A.; Schlangen, E. Effect of fibres addition on the physical and mechanical properties of asphalt mixtures with crack-healing purposes by microwave radiation. Constr. Build. Mater. 2016, 127, 369–382. [Google Scholar] [CrossRef]

- Tabaković, A.; Post, W.; Cantero, D.; Copuroglu, O.; Garcia, S.; Schlangen, E. The reinforcement and healing of asphalt mastic mixtures by rejuvenator encapsulation in alginate compartmented fibres. Smart Mater. Struct. 2016, 25, 084003. [Google Scholar] [CrossRef] [Green Version]

- Xu, S.; Tabaković, A.; Liu, X.; Schlangen, E. Calcium alginate capsules encapsulating rejuvenator as healing system for asphalt mastic. Constr. Build. Mater. 2018, 169, 379–387. [Google Scholar] [CrossRef] [Green Version]

- Gonzalez-Torre, I.; Norambuena-Contreras, J. Recent advances on self-healing of bituminous materials by the action of encapsulated rejuvenators. Constr. Build. Mater. 2020, 258, 119568. [Google Scholar] [CrossRef]

- Tabaković, A.; Schuyffel, L.; Karač, A.; Schlangen, E. An Evaluation of the Efficiency of Compartmented Alginate Fibres Encapsulating a Rejuvenator as an Asphalt Pavement Healing System. Appl. Sci. 2017, 7, 647. [Google Scholar] [CrossRef] [Green Version]

- Tabaković, A.; Schlangen, E. Self-Healing Technology for Asphalt Pavements. In Self-Healing Materials; Hager, M.D., van der Zwaag, S., Schubert, U.S., Eds.; Springer International Publishing: Switzerland, Cham, 2016; pp. 285–306. [Google Scholar]

- Xu, S.; Liu, X.; Tabaković, A.; Schlangen, E. The influence of asphalt ageing on induction healing effect on porous asphalt concrete. RILEM Tech. Lett. 2018, 3, 98–103. [Google Scholar] [CrossRef]

- Wan, P.; Wu, S.; Liu, Q.; Xu, H.; Wang, H.; Peng, Z.; Rao, W.; Zou, Y.; Zhao, Z.; Chen, S. Self-healing properties of asphalt concrete containing responsive calcium alginate/nano-Fe3O4 composite capsules via microwave irradiation. Constr. Build. Mater. 2021, 310, 125258. [Google Scholar] [CrossRef]

- Zemskov, S.V.; Jonkers, H.M.; Vermolen, F.J. Two analytical models for the probability characteristics of a crack hitting encapsulated particles: Application to self-healing materials. Comput. Mater. Sci. 2011, 50, 3323–3333. [Google Scholar] [CrossRef]

- Tabaković, A.; Braak, D.; van Gerwen, M.; Copuroglu, O.; Post, W.; Garcia, S.J.; Schlangen, E. The compartmented alginate fibres optimisation for bitumen rejuvenator encapsulation. J. Traffic Transp. Eng. 2017, 4, 347–359. [Google Scholar] [CrossRef]

- Tabaković, A.; Karač, A.; Ivanković, A.; Gibney, A.; McNally, C.; Gilchrist, M.D. Modelling the quasi-static behaviour of bituminous material using a cohesive zone model. Eng. Fract. Mech. 2010, 77, 2403–2418. [Google Scholar] [CrossRef]

- Xu, S.; Liu, X.; Tabaković, A.; Lin, P.; Zhang, Y.; Nahar, S.; Lommerts, B.J.; Schlangen, E. The role of rejuvenators in embedded damage healing for asphalt pavement. Mater. Des. 2021, 202, 109564. [Google Scholar] [CrossRef]

- Fladvad, M.; Arnhild, U. Large-size aggregates for road construction—a review of standard specifications and test methods. Bull. Eng. Geol. Environ. 2021, 80, 8847–8859. [Google Scholar] [CrossRef]

| Mix Constituent | Mix Constituent Proportions | |||||

|---|---|---|---|---|---|---|

| Aggregates | 94.2 | 93.9 | 93.8 | 93.6 | 93.2 | 92.8 |

| Bitumen | 5.8 | 5.8 | 5.8 | 5.8 | 5.8 | 5.8 |

| Capsules | 0 | 0.31 | 0.44 | 0.64 | 1.02 | 1.45 |

| Total % of constituents in the mix | 100 | 100 | 100 | 100 | 100 | 100 |

| Capsules + bitumen percentage in the mix | 5.80 | 6.11 | 6.24 | 6.44 | 6.82 | 7.25 |

| Capsule percentage in capsule + bitumen mix proportion | 0 | 5 | 7 | 10 | 15 | 20 |

| Mix No. | Capsule Content in the Mix (%) | Capsule/Bitumen Ratio (%) | Mix Binder Drainage (%) |

|---|---|---|---|

| 1 | 0 | 0 | 0.03 |

| 2 | 0.31 | 5 | 0.04 |

| 3 | 0.44 | 7 | 0.03 |

| 4 | 0.64 | 10 | 0.05 |

| 5 | 1.02 | 15 | 0.04 |

| 6 | 1.45 | 20 | 0.05 |

| Aggregate Type | Constituent Content in the Mix (%) | |||

|---|---|---|---|---|

| Mix 1 (Control Mix) | Mix 2 | Mix 3 | Mix 4 | |

| 14 | 4.02 | 4.01 | 3.79 | 3.34 |

| 10 | 47.21 | 44.60 | 42.10 | 37.11 |

| 6.3 | 7.55 | 7.14 | 6.74 | 5.92 |

| Dust | 32.10 | 30.33 | 28.63 | 25.23 |

| Filler | 3.30 | 3.12 | 2.95 | 2.60 |

| Capsules | 0.00 | 5.00 | 10.00 | 20.0 |

| Binder | 5.8 | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tabaković, A.; Faloon, C.; O’Prey, D. The Effect of Conductive Alginate Capsules Encapsulating Rejuvenator (HealRoad Capsules) on the Healing Properties of 10 mm Stone Mastic Asphalt Mix. Appl. Sci. 2022, 12, 3648. https://doi.org/10.3390/app12073648

Tabaković A, Faloon C, O’Prey D. The Effect of Conductive Alginate Capsules Encapsulating Rejuvenator (HealRoad Capsules) on the Healing Properties of 10 mm Stone Mastic Asphalt Mix. Applied Sciences. 2022; 12(7):3648. https://doi.org/10.3390/app12073648

Chicago/Turabian StyleTabaković, Amir, Christopher Faloon, and Declan O’Prey. 2022. "The Effect of Conductive Alginate Capsules Encapsulating Rejuvenator (HealRoad Capsules) on the Healing Properties of 10 mm Stone Mastic Asphalt Mix" Applied Sciences 12, no. 7: 3648. https://doi.org/10.3390/app12073648

APA StyleTabaković, A., Faloon, C., & O’Prey, D. (2022). The Effect of Conductive Alginate Capsules Encapsulating Rejuvenator (HealRoad Capsules) on the Healing Properties of 10 mm Stone Mastic Asphalt Mix. Applied Sciences, 12(7), 3648. https://doi.org/10.3390/app12073648