Wind-Induced Response and Its Controlling of Long-Span Cross-Rope Suspension Transmission Line

Abstract

1. Introduction

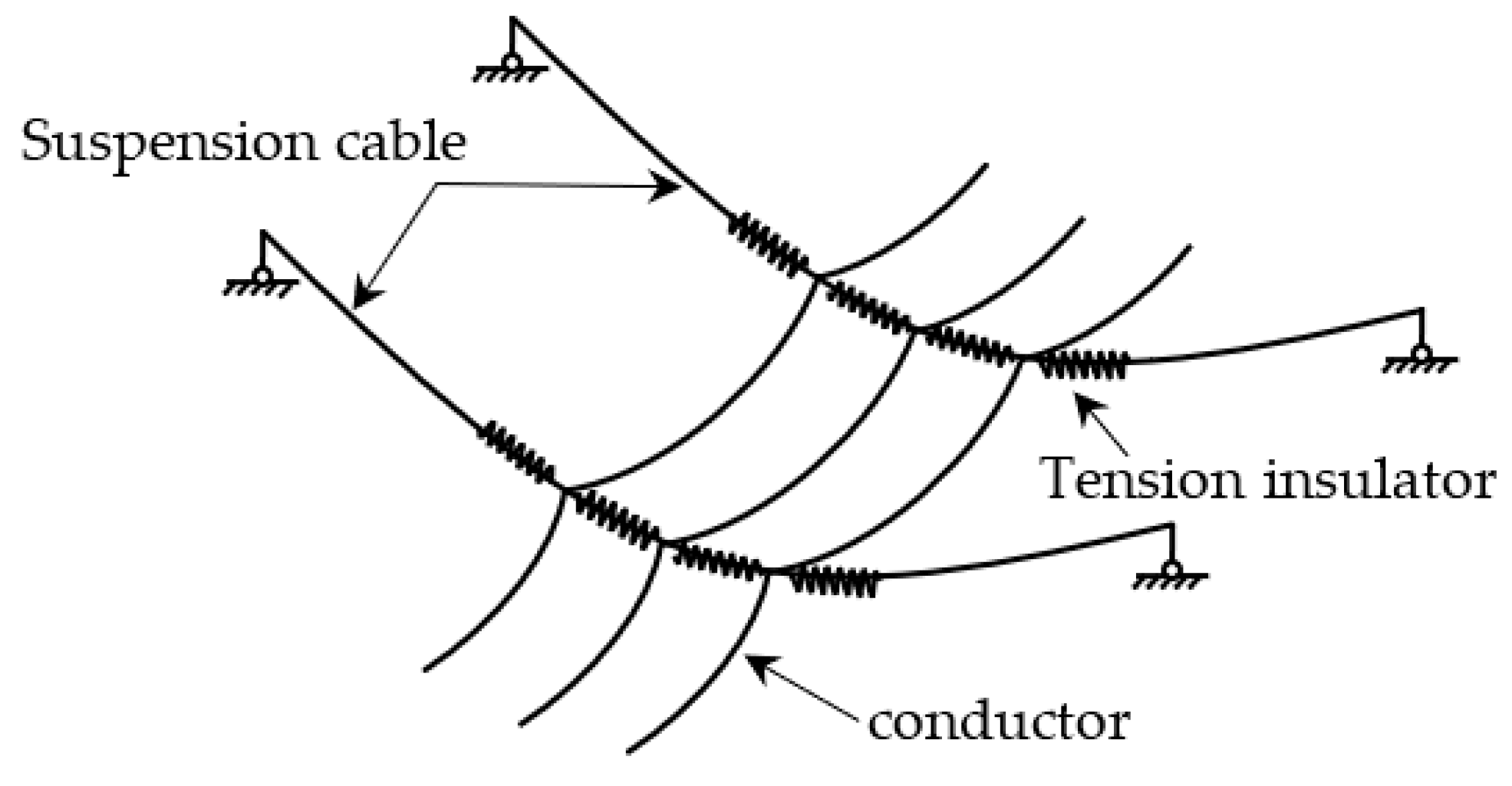

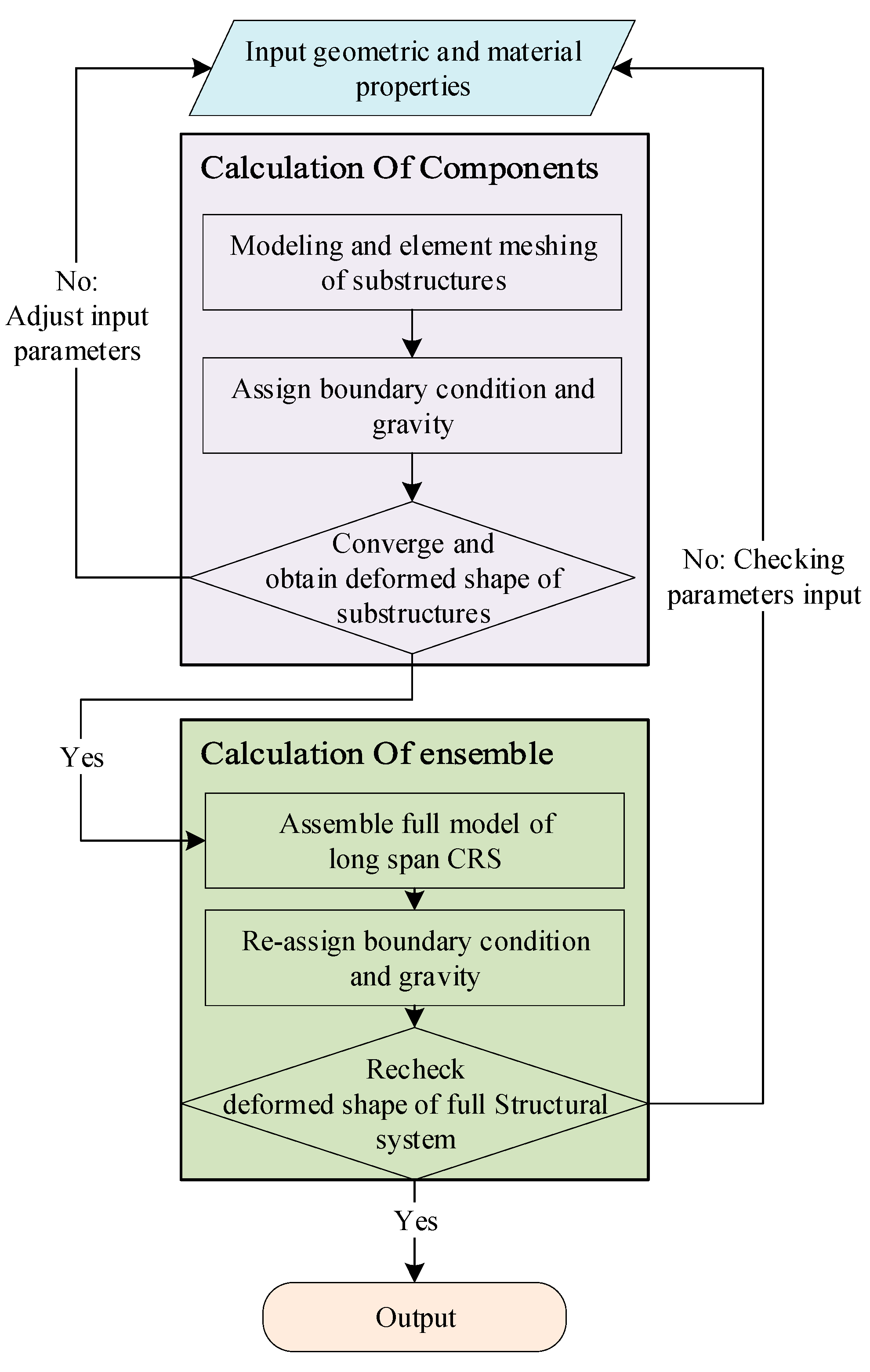

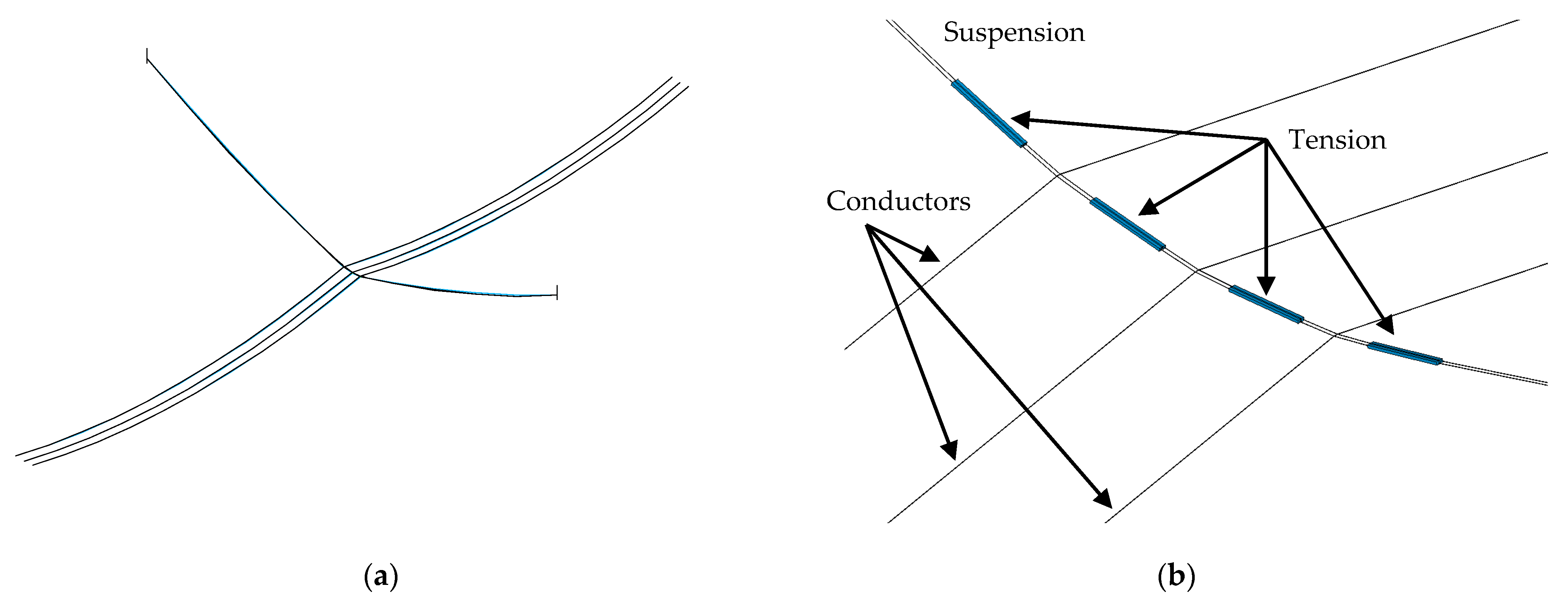

2. Modeling of Long-Span CRS

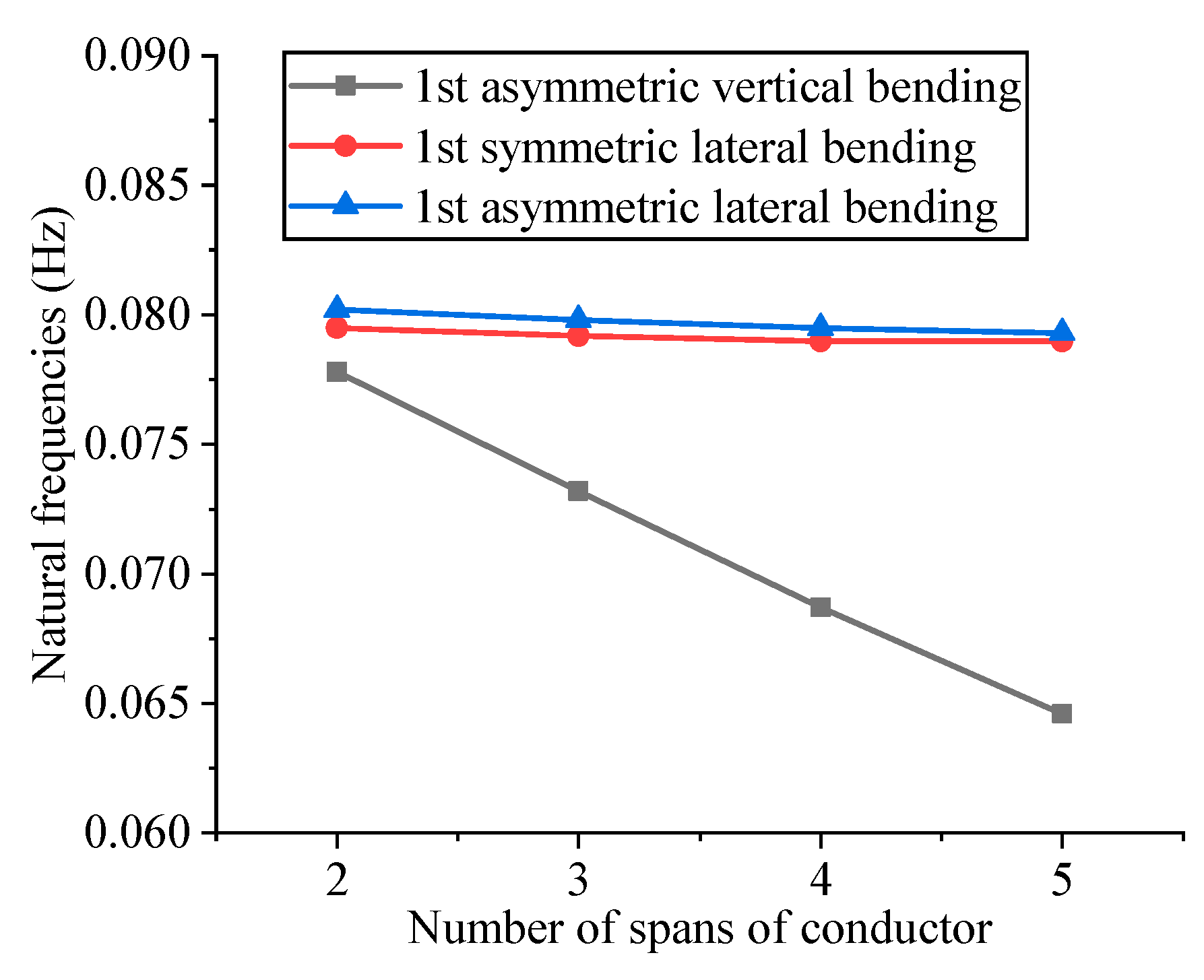

3. Dynamic Properties

4. Comparison of Wind Loads on Bare and Ice-Covered Overhead Conductors

4.1. Expression of Wind Load

4.2. Ice Load on Conductor and Suspension Cable

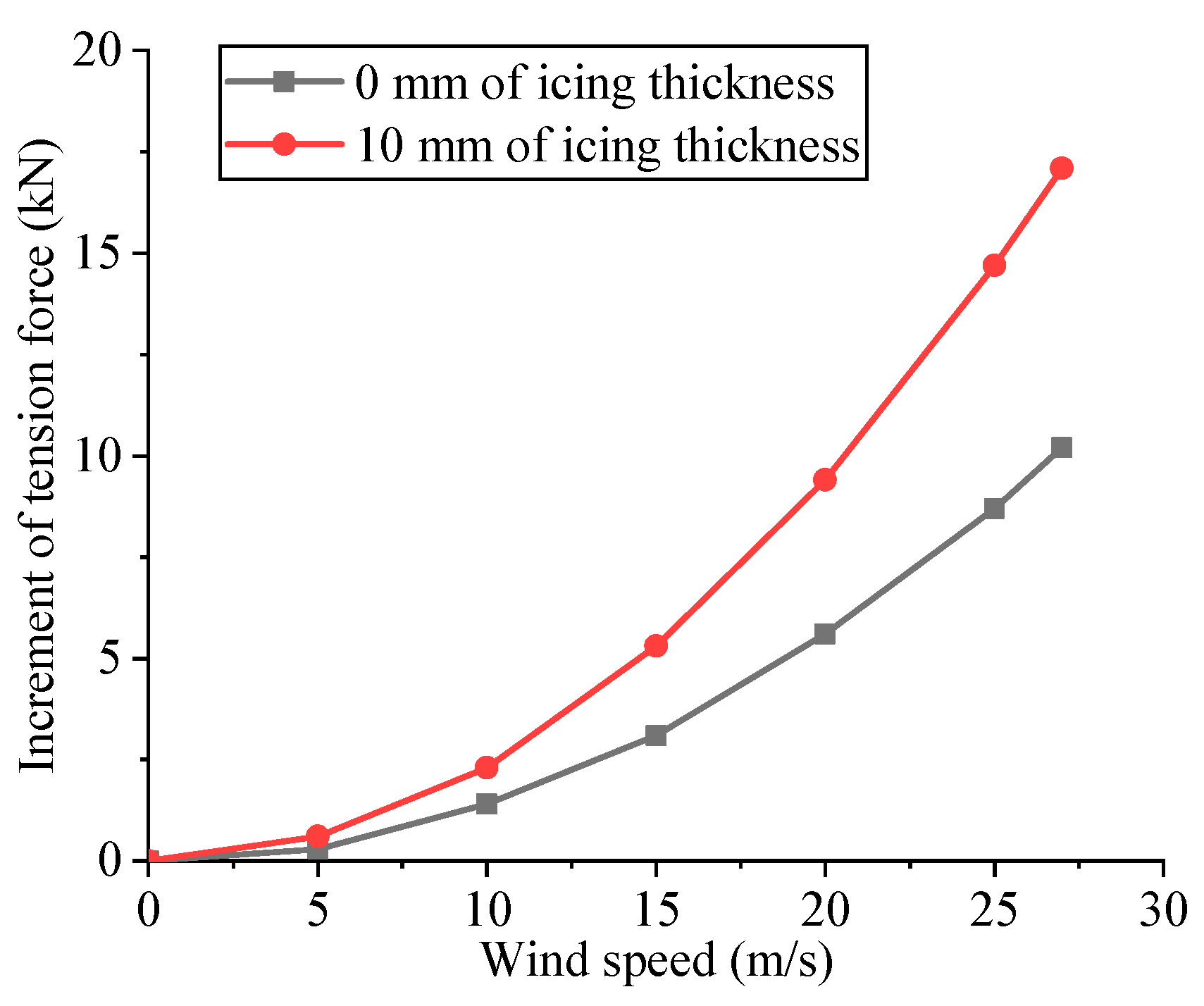

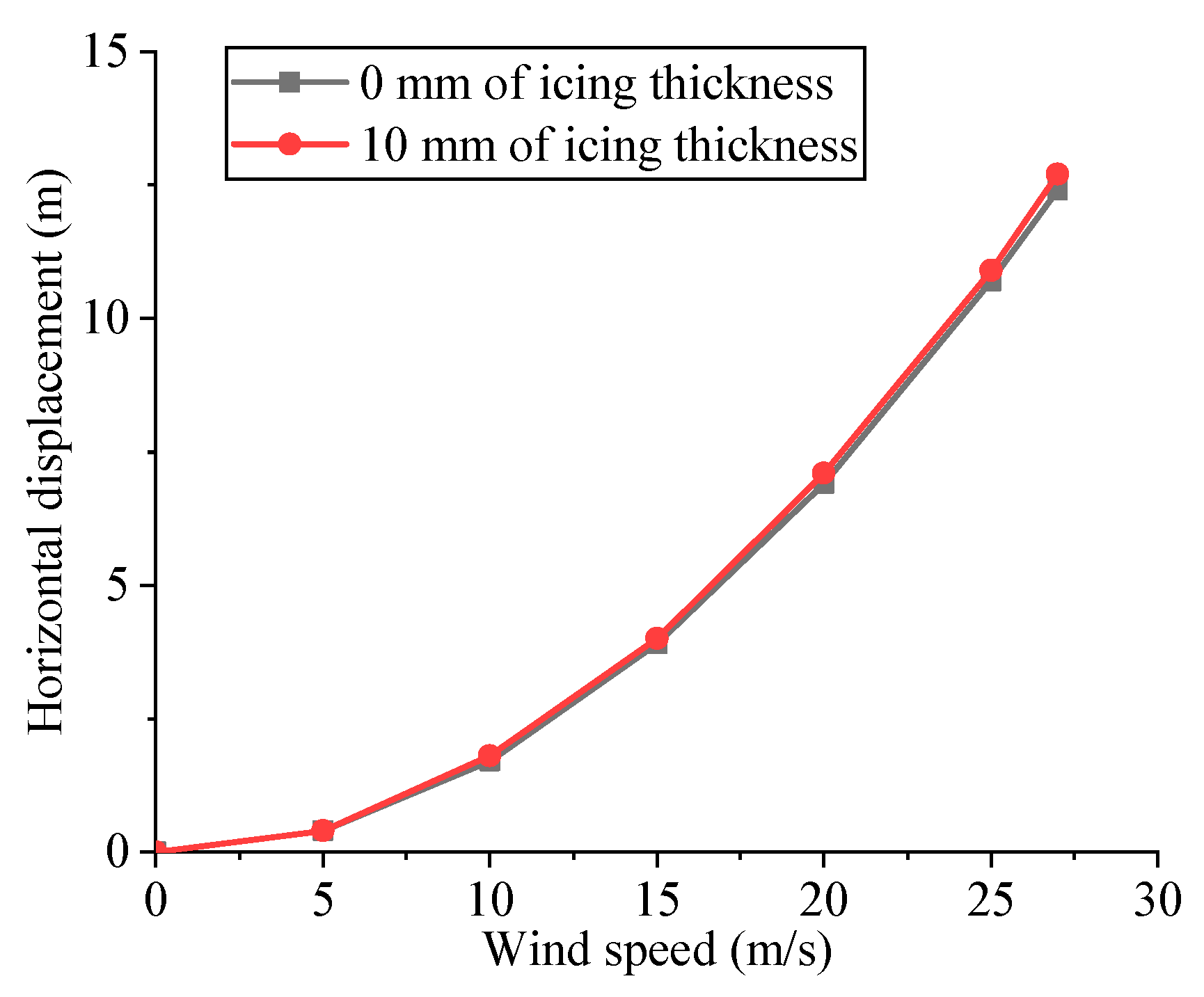

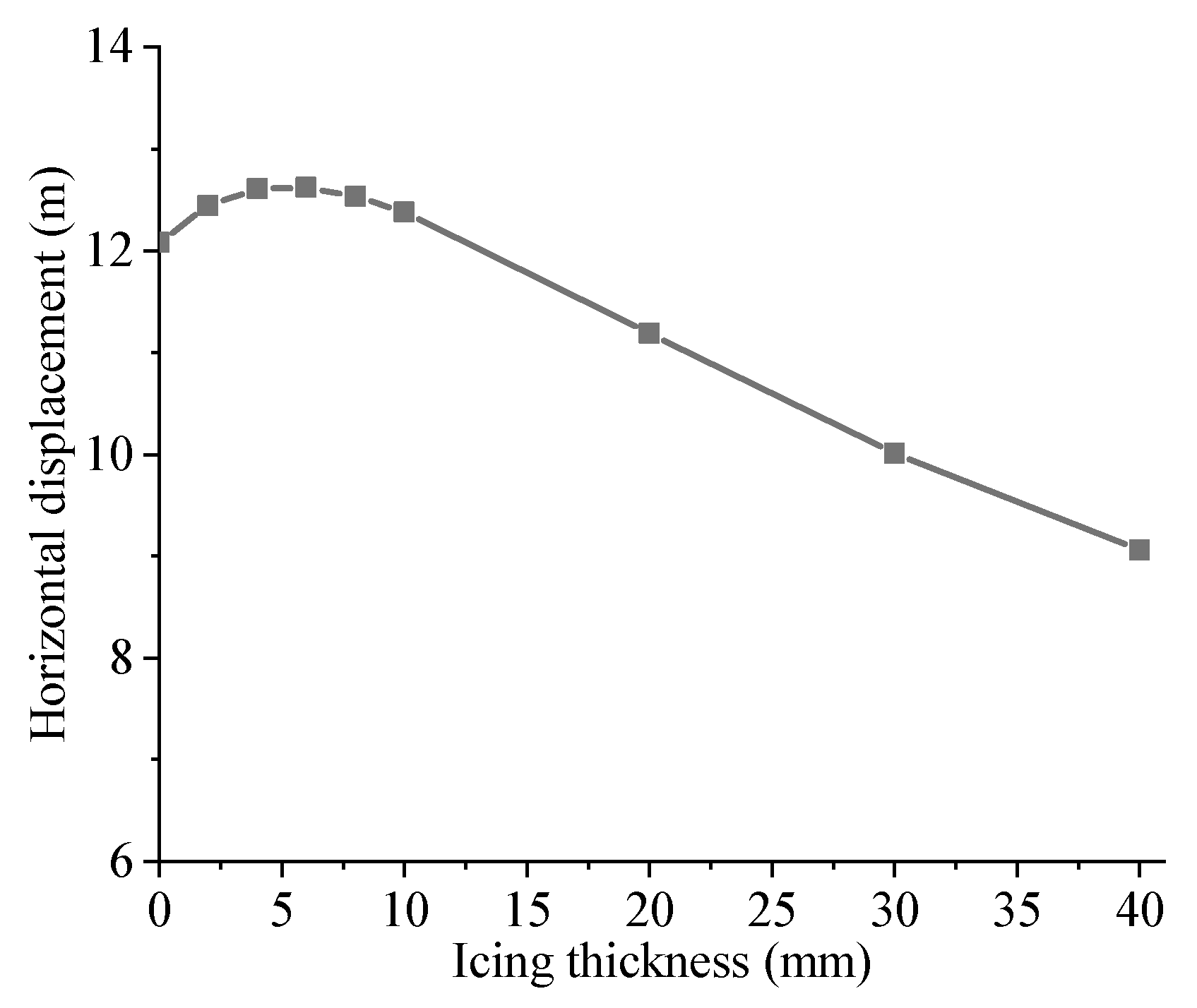

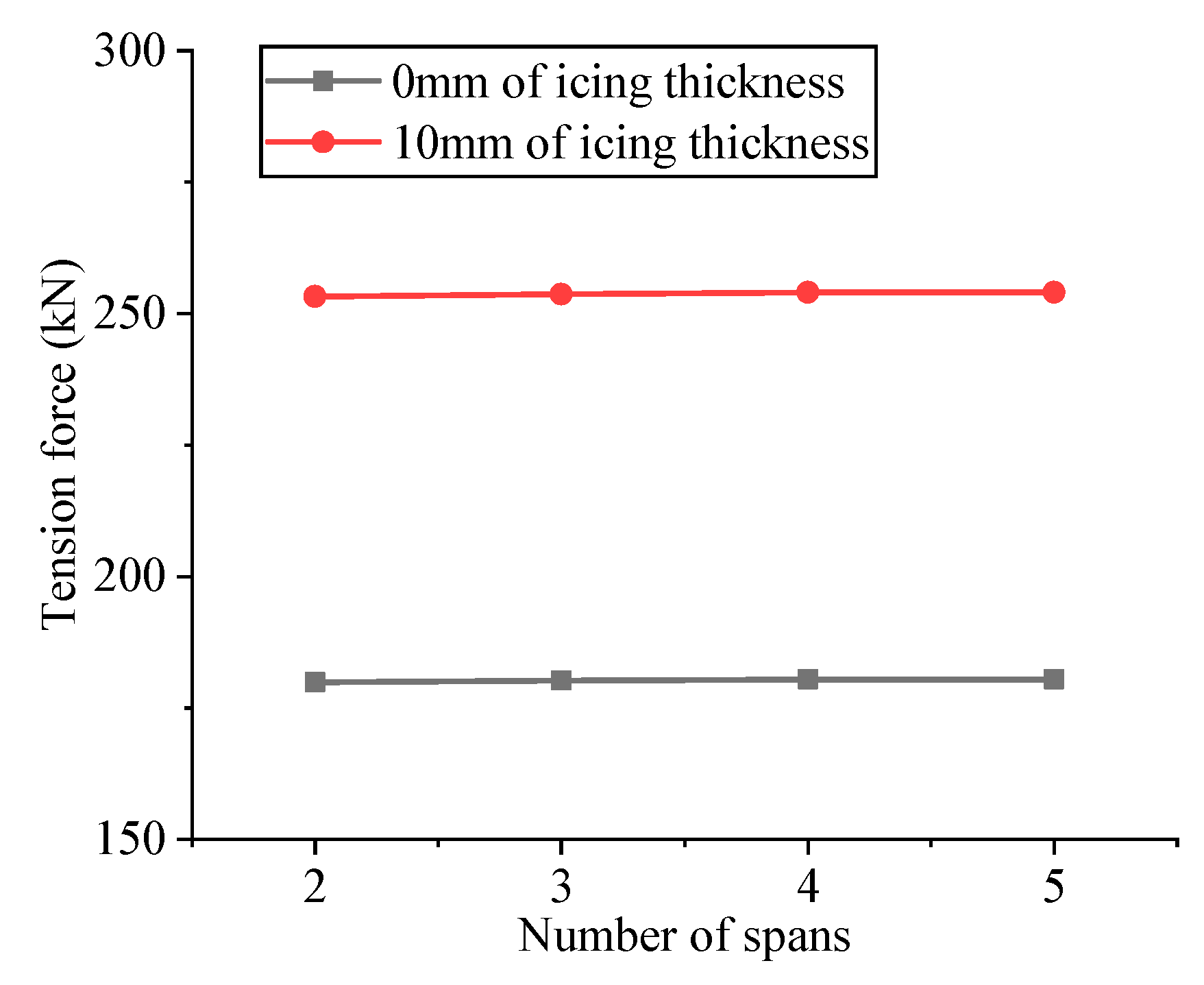

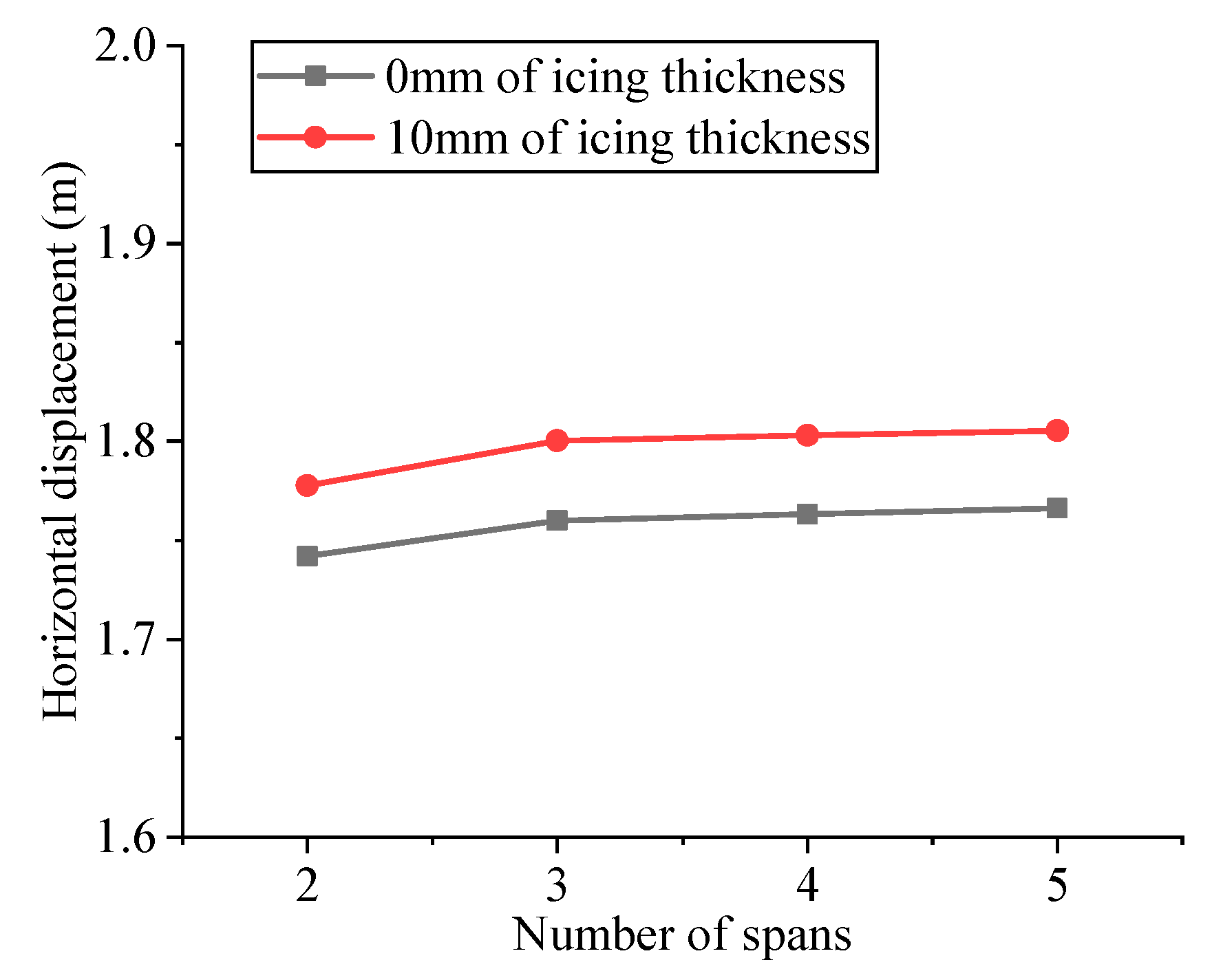

4.3. Result

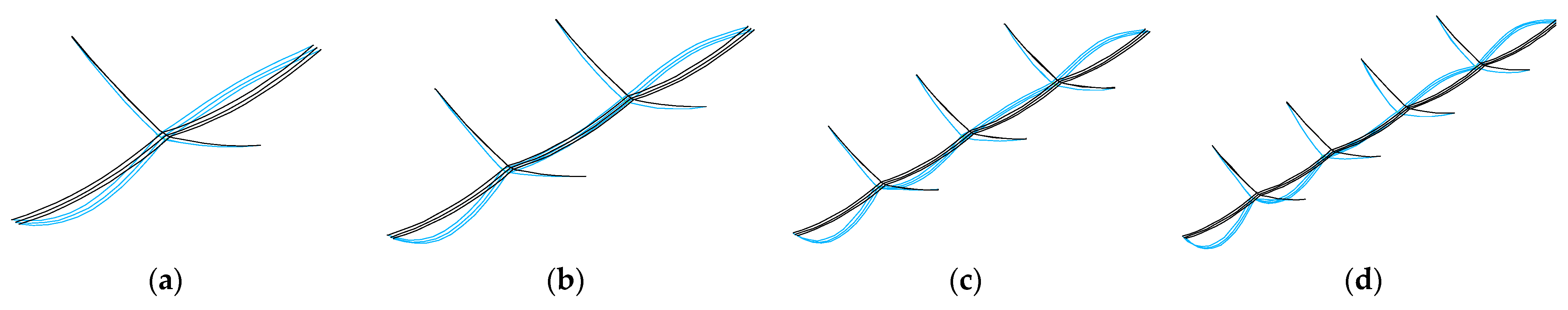

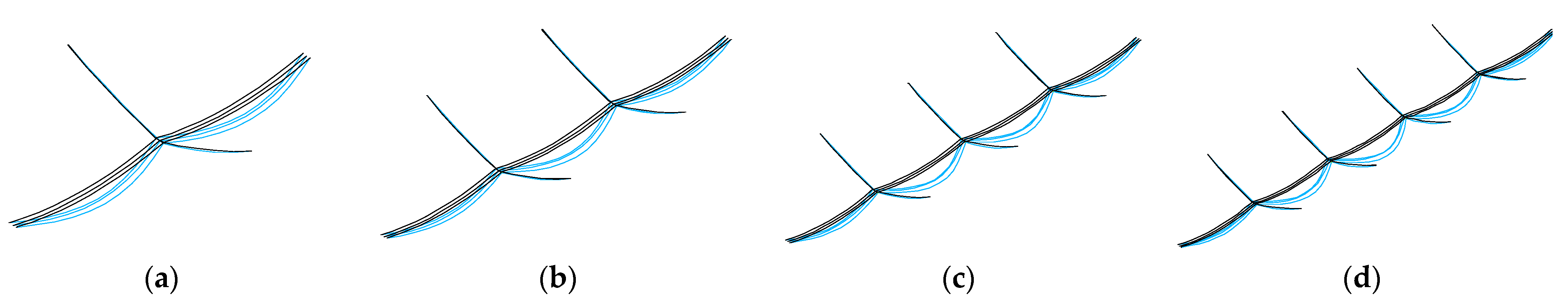

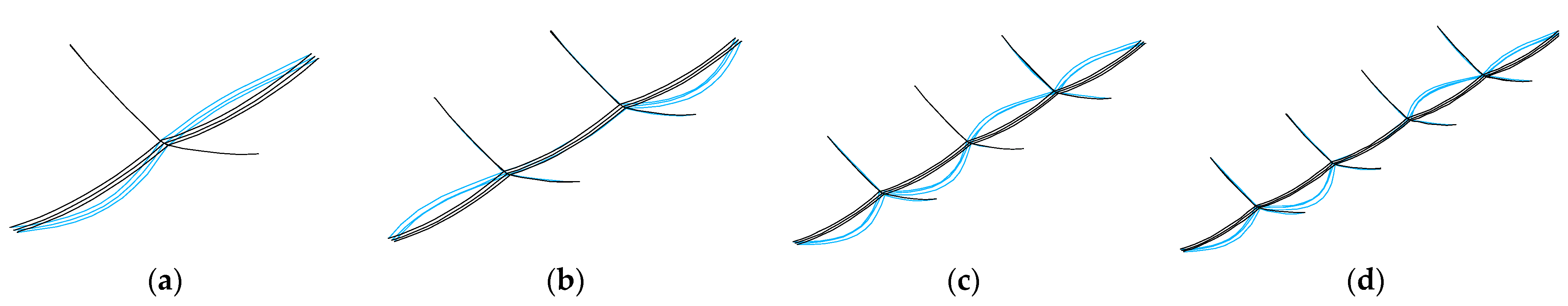

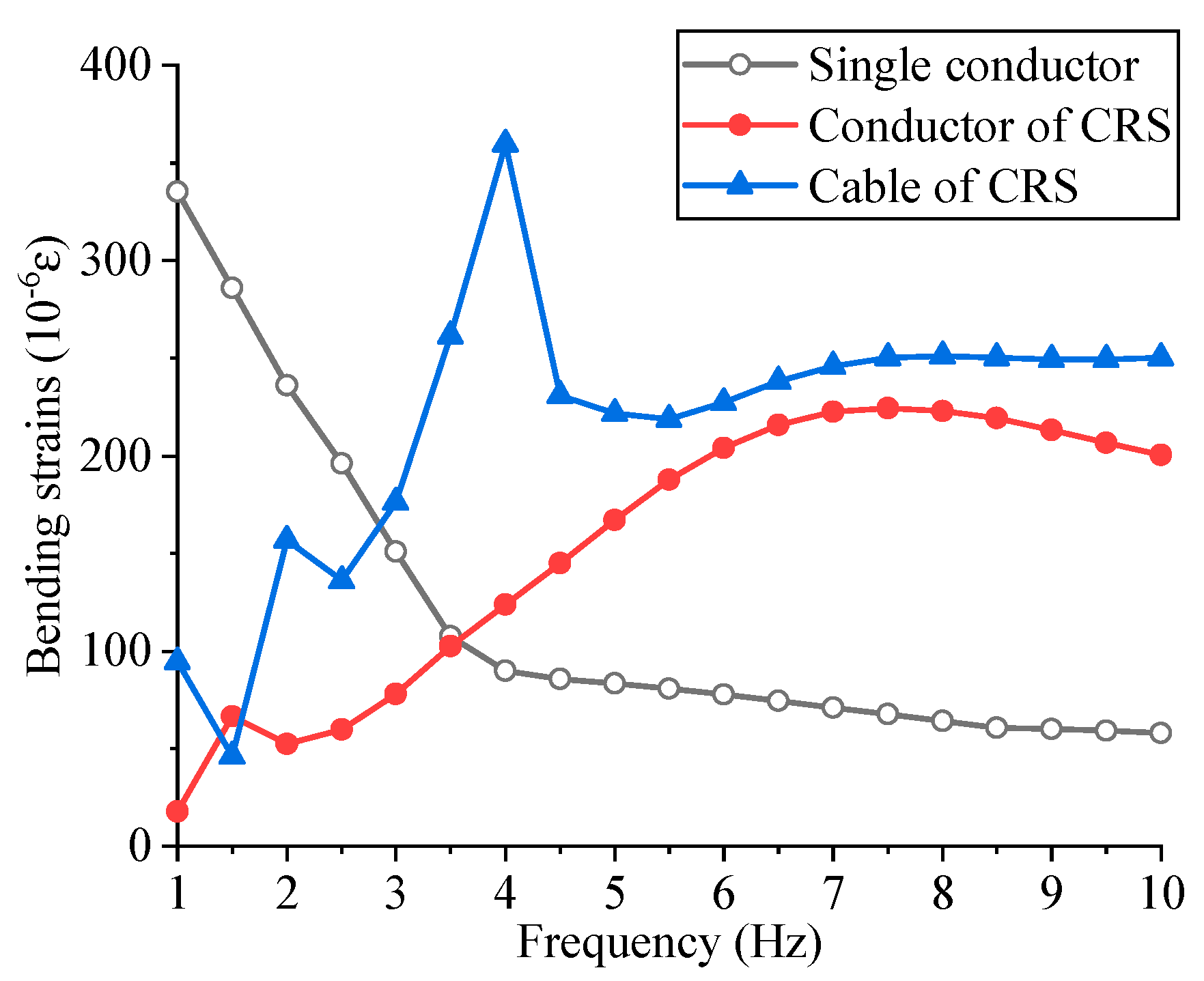

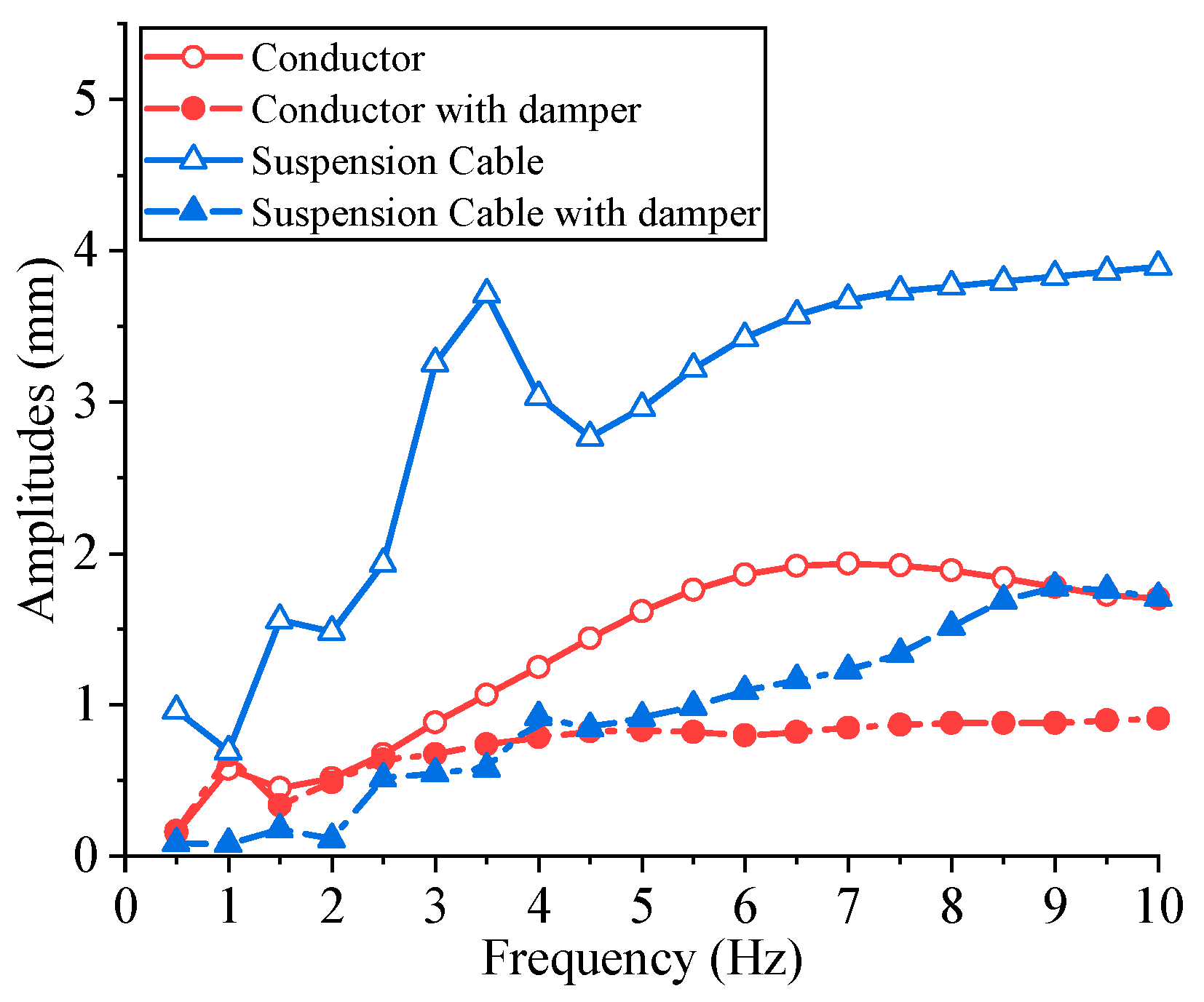

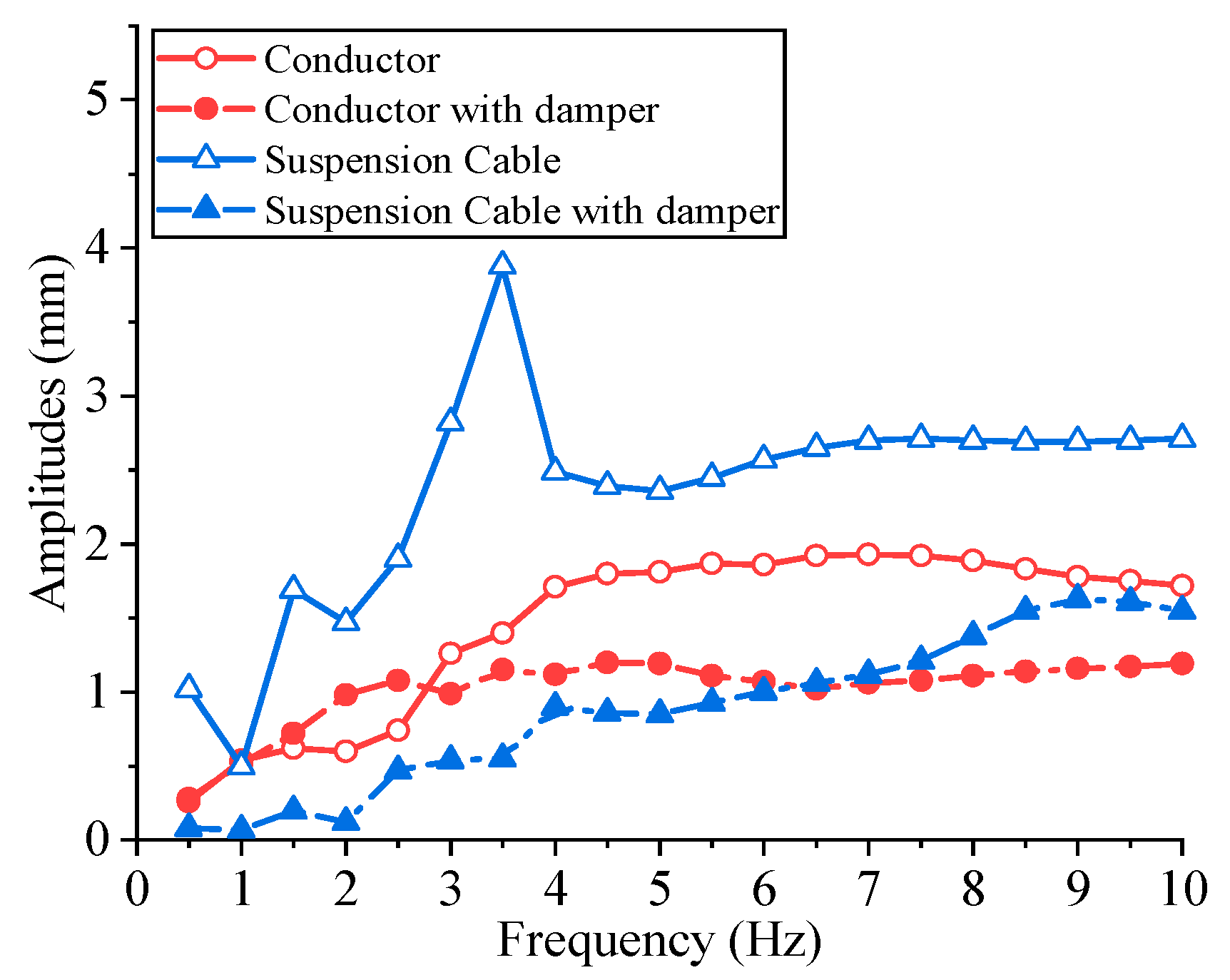

5. Aeolian Vibration and Its Controlling

5.1. Equivalent Lift Force of Vortex-Induced Vibration

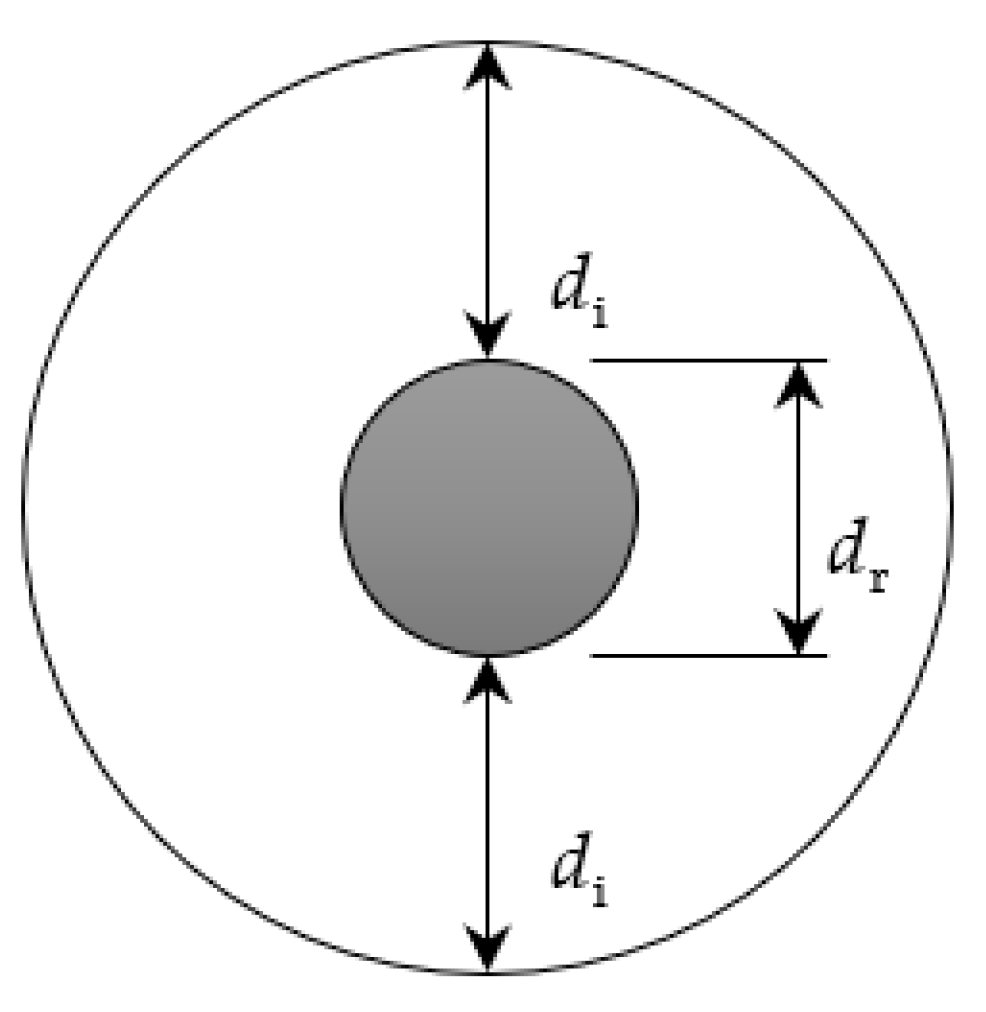

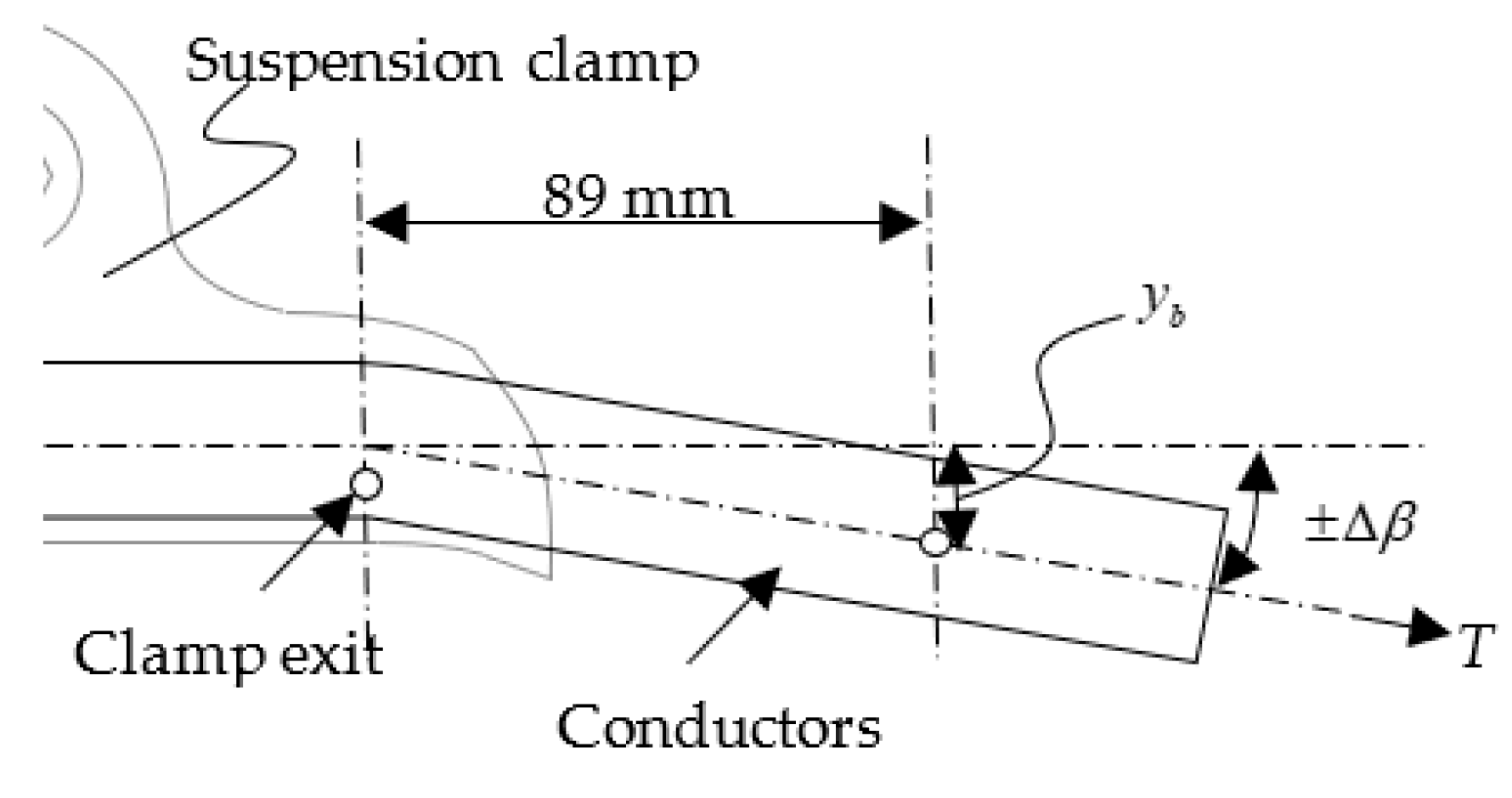

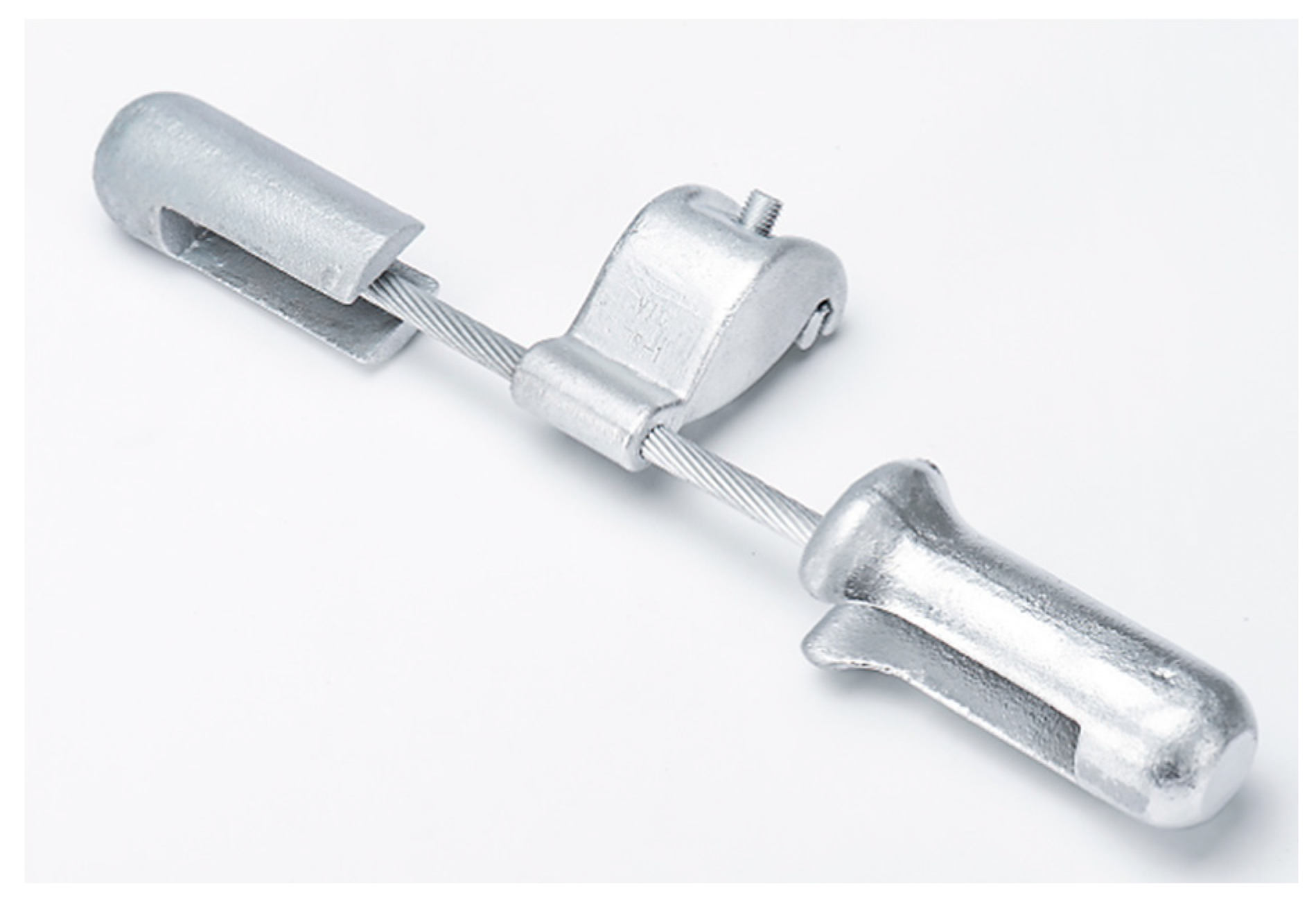

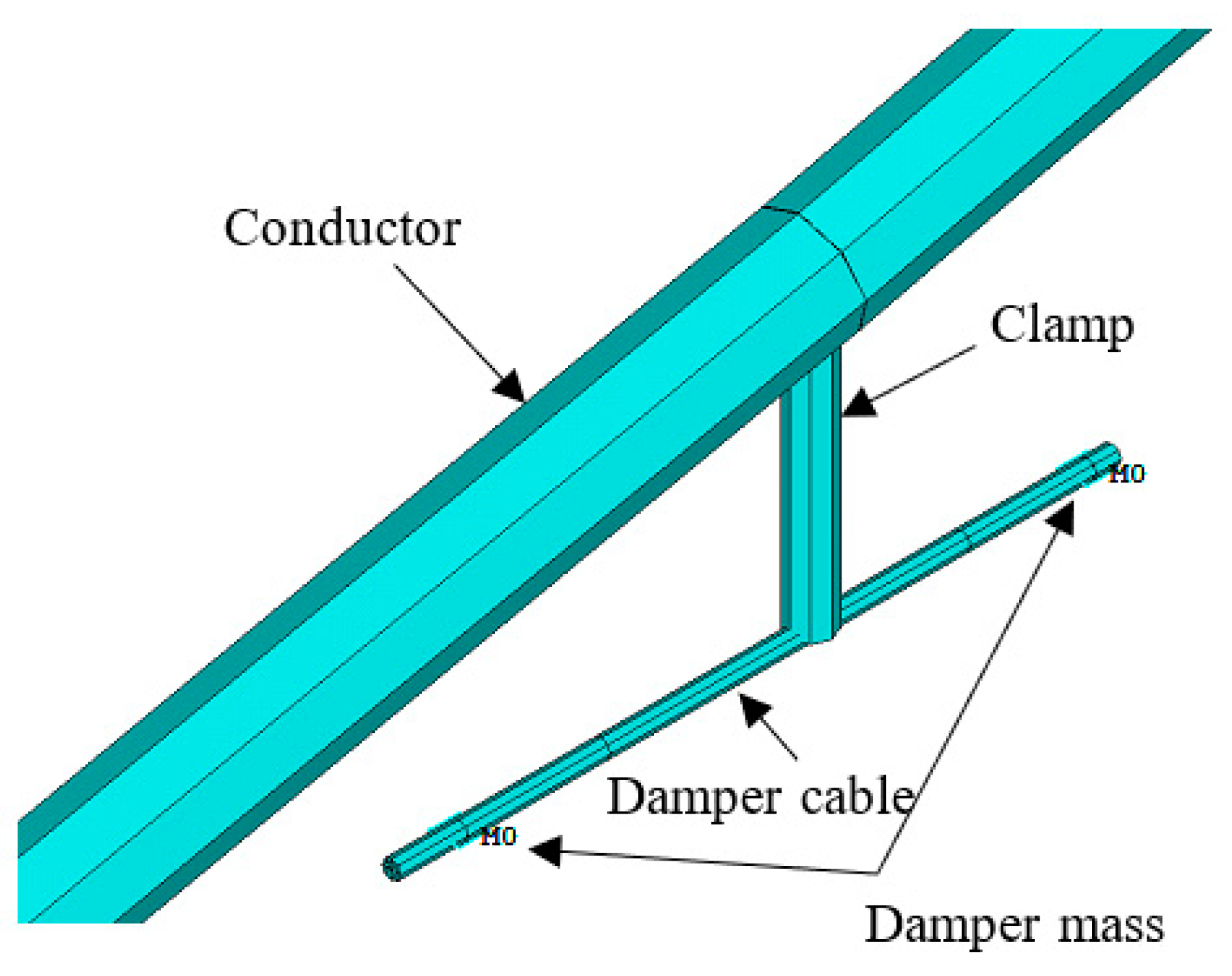

5.2. FE Model of Damper

5.3. Result

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Brian White, H. Guyed structures for transmission lines. Eng. Struct. 1993, 15, 289–302. [Google Scholar] [CrossRef]

- Burger, A.; Serrano, J.D.; Marais, P.; Jacobs, B. Construction of overhead lines in environmentally sensitive areas. Transm. Distrib. 2011, 7, 36–43. [Google Scholar]

- Behncke, R.H.; White, H.B. The Cross Rope Suspension Structure. In Electrical Transmission in a New Age; American Society of Civil Engineers: Reston, VA, USA, 2002; pp. 259–267. [Google Scholar] [CrossRef]

- Toklu, Y.C.; Bekdaş, G.; Temur, R. Analysis of cable structures through energy minimization. Struct. Eng. Mech. 2017, 62, 749–758. [Google Scholar] [CrossRef]

- Jia, Y.; Liu, R. Form-Finding System for Overhead Transmission Line Based on ANSYS. Energy Procedia 2012, 17, 975–982. [Google Scholar] [CrossRef][Green Version]

- Keyhan, H.; McClure, G.; Habashi, W.G. Dynamic analysis of an overhead transmission line subject to gusty wind loading predicted by wind–conductor interaction. Comput. Struct. 2013, 122, 135–144. [Google Scholar] [CrossRef]

- Krishnasamy, S.S.G.; Tabatabai, M. Wind loads on bare and ice-covered overhead conductors. J. Wind Eng. Ind. Aerodyn. 1990, 36, 171–180. [Google Scholar] [CrossRef]

- Lalonde, S.; Guilbault, R.; Langlois, S. Modeling multilayered wire strands, a strategy based on 3D finite element beam-to-beam contacts–Part II: Application to wind-induced vibration and fatigue analysis of overhead conductors. Int. J. Mech. Sci. 2017, 126, 297–307. [Google Scholar] [CrossRef]

- Song, Y.; Zhang, M.; Øiseth, O.; Rønnquist, A. Wind deflection analysis of railway catenary under crosswind based on nonlinear finite element model and wind tunnel test. Mech. Mach. Theory 2022, 168, 104608. [Google Scholar] [CrossRef]

- Chen, T.; Huang, Y.-C.; Xu, Z.-W.; Chen, J.C.Y. Wind vibration control of stay cables using an evolutionary algorithm. Wind Struct. 2021, 32, 71–80. [Google Scholar] [CrossRef]

- Vecchiarelli, J.; Currie, I.G.; Havard, D.G. Computational Analysis of Aeolian Conductor Vibration with a Stockbridge-Type DAMPER. J. Fluids Struct. 2000, 14, 489–509. [Google Scholar] [CrossRef]

- Nie, X.; Yan, Z.; Shi, J.; You, Y. The Refined Simulation and Model Analysis of the Suspension Cable Guyed Tower. J. Shanghai Jiaotong Univ. 2019, 53, 1066–1073. [Google Scholar] [CrossRef]

- Tian, L.; Zhou, M.Y.; Qiu, C.X.; Pan, H.Y.; Rong, K.J. Seismic response control of transmission tower-line system using SMA-based TMD. Struct. Eng. Mech. 2020, 74, 129–143. [Google Scholar] [CrossRef]

- Vaja, N.K.; Barry, O.R.; Tanbour, E.Y. On the modeling and analysis of a vibration absorber for overhead powerlines with multiple resonant frequencies. Eng. Struct. 2018, 175, 711–720. [Google Scholar] [CrossRef]

- Foti, F.; Martinelli, L. A unified analytical model for the self-damping of stranded cables under aeolian vibrations. J. Wind Eng. Ind. Aerodyn. 2018, 176, 225–238. [Google Scholar] [CrossRef]

- Foti, F.; Martinelli, L. An enhanced unified model for the self-damping of stranded cables under aeolian vibrations. J. Wind Eng. Ind. Aerodyn. 2018, 182, 72–86. [Google Scholar] [CrossRef]

- Fadel, A.A.; Rosa, D.; Murça, L.B.; Fereira, J.L.A.; Araújo, J.A. Effect of high mean tensile stress on the fretting fatigue life of an Ibis steel reinforced aluminium conductor. Int. J. Fatigue 2012, 42, 24–34. [Google Scholar] [CrossRef]

- Zhang, M.; Xu, F. Tuned mass damper for self-excited vibration control: Optimization involving nonlinear aeroelastic effect. J. Wind Eng. Ind. Aerodyn. 2022, 220, 104836. [Google Scholar] [CrossRef]

- Fujino, Y.; Abé, M. Design formulas for tuned mass dampers based on A perturbation technique. Earthq. Eng. Struct. Dyn. 1993, 22, 833–854. [Google Scholar] [CrossRef]

- Tu, X.; Wu, Y.; Li, Z.; Wang, Z. Vortex induced vibration and its controlling of long span Cross-Rope Suspension transmission line with tension insulator. Struct. Eng. Mech. 2021, 78, 87. [Google Scholar]

- Yan, Z.; Li, Z.; Savory, E.; Lin, W.E. Galloping of a single iced conductor based on curved-beam theory. J. Wind Eng. Ind. Aerodyn. 2013, 123, 77–87. [Google Scholar] [CrossRef]

- Gabbai, R.D.; Benaroya, H. An overview of modeling and experiments of vortex-induced vibration of circular cylinders. J. Sound Vib. 2005, 282, 575–616. [Google Scholar] [CrossRef]

- Zhang, M.; Xu, F.; Øiseth, O. Aerodynamic damping models for vortex-induced vibration of a rectangular 4:1 cylinder: Comparison of modeling schemes. J. Wind Eng. Ind. Aerodyn. 2020, 205, 104321. [Google Scholar] [CrossRef]

- Norberg, C. Fluctuating lift on a circular cylinder: Review and new measurements. J. Fluids Struct. 2003, 17, 57–96. [Google Scholar] [CrossRef]

- Peng, H.; Wang, B.; He, Q.; Zhen, Y.; Wang, Y.; Wen, S. Multi-parametric optimizations for power dissipation characteristics of Stockbridge dampers based on probability distribution of wind speed. Appl. Math. Model. 2019, 69, 533–551. [Google Scholar] [CrossRef]

- Kong, D.; Li, L.; Long, X.; Liang, Z. Analysis of aeolian vibration of UHV transmission conductor by finite element method. J. Vib. Shock 2007, 26, 64–67. (In Chinese) [Google Scholar]

- Poffenberger, J.C.; Swart, R.L. Differential Displacement and Dynamic Conductor Strain. IEEE Trans. Power Appar. Syst. 1965, 84, 281–289. [Google Scholar] [CrossRef]

- Dutkiewicz, M.; Machado, M. Spectral element method in the analysis of vibrations of overhead transmission line in damping environment. Struct. Eng. Mech. 2019, 71, 291–303. [Google Scholar] [CrossRef]

- Luo, X.Y.; Zhang, Y.S.; Xie, S.H.; Li, X.C.; Xu, Z.L.; Liu, L.J. Nonlinear impedance tests for a vibration damper and its parametric identification. Zhendong Yu Chongji/J. Vib. Shock 2013, 32, 182–185. [Google Scholar] [CrossRef]

| Design Parameters | Rope for Conductor | Quad-Bundle Conductor | Tension Insulator |

|---|---|---|---|

| Span (m) | 1000 | 800 | 10 in total |

| Total cross section area (mm2) | 766.50 | 425.24 | 125,600 |

| External diameter (mm) | 36 | 26.82 | 400 |

| Weight per length (kg/m) | 59.52 | 1.35 | 100 |

| Elastic modulus (N/mm2) | 180,000 | 65,000 | 190,000 |

| Substructures | Big Damper Mass | Small Damper Mass |

|---|---|---|

| Mass of damper (kg) | 2.557 | 1.842 |

| Length of damper cable (m) | 0.202 | 0.145 |

| Center of mass to the junction (m) | 3.25 × 10−2 | 1.21 × 10−2 |

| Rotary inertia (kg·m2) | 6.51 × 10−3 | 3.30 × 10−3 |

| Flexural rigidity of damper cable (N·m2) | 22.41 | 22.41 |

| Damping ratio of the system [29] | 0.16 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Hu, Y.; Tu, X. Wind-Induced Response and Its Controlling of Long-Span Cross-Rope Suspension Transmission Line. Appl. Sci. 2022, 12, 1488. https://doi.org/10.3390/app12031488

Li Z, Hu Y, Tu X. Wind-Induced Response and Its Controlling of Long-Span Cross-Rope Suspension Transmission Line. Applied Sciences. 2022; 12(3):1488. https://doi.org/10.3390/app12031488

Chicago/Turabian StyleLi, Zhengliang, Yujing Hu, and Xi Tu. 2022. "Wind-Induced Response and Its Controlling of Long-Span Cross-Rope Suspension Transmission Line" Applied Sciences 12, no. 3: 1488. https://doi.org/10.3390/app12031488

APA StyleLi, Z., Hu, Y., & Tu, X. (2022). Wind-Induced Response and Its Controlling of Long-Span Cross-Rope Suspension Transmission Line. Applied Sciences, 12(3), 1488. https://doi.org/10.3390/app12031488