Improving Thickness Uniformity of Amorphous Oxide Films Deposited on Large Substrates by Optical Flux Mapping

Abstract

:1. Introduction

2. Methods

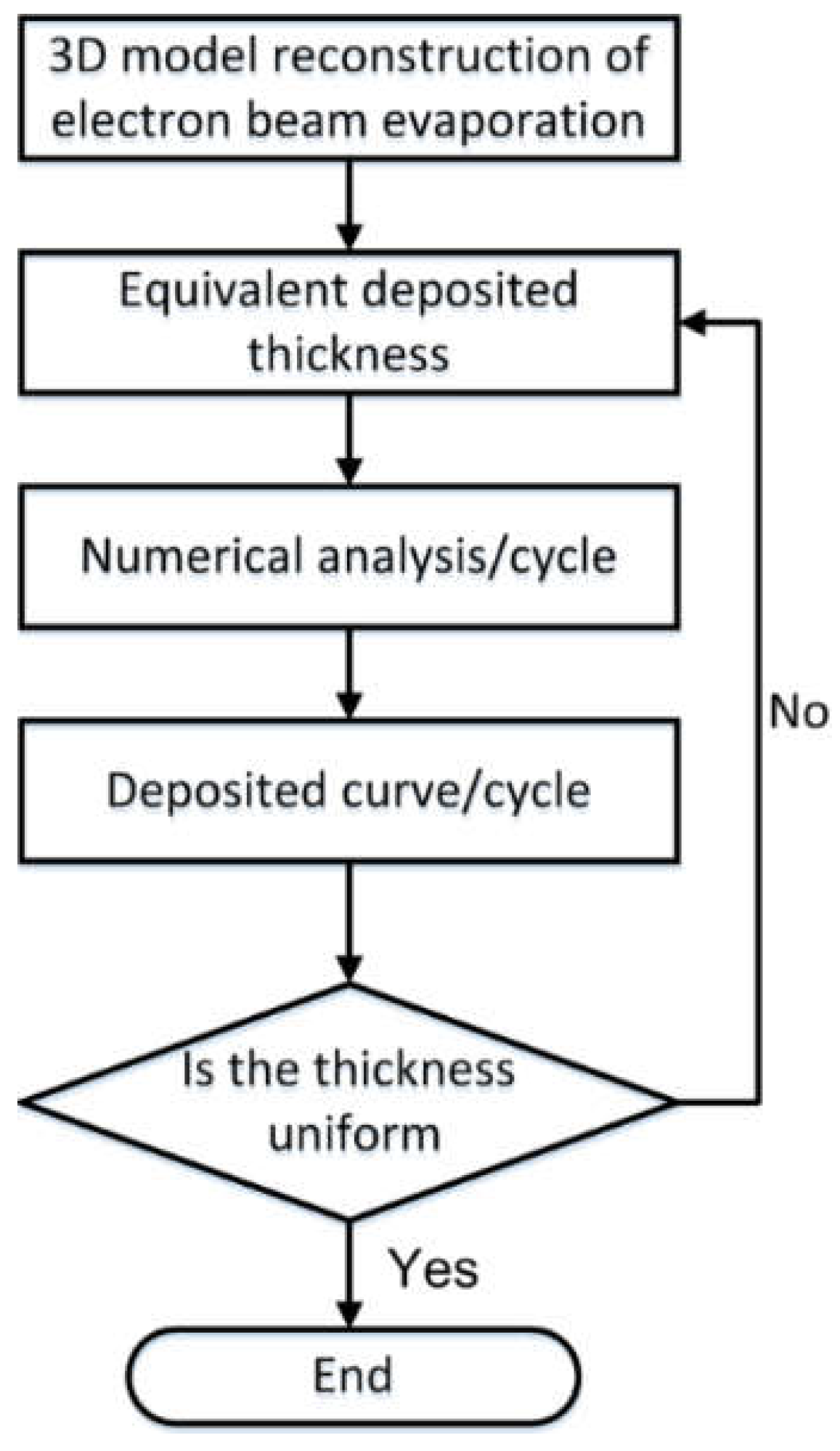

2.1. Thin Film Thickness Uniformity Simulation

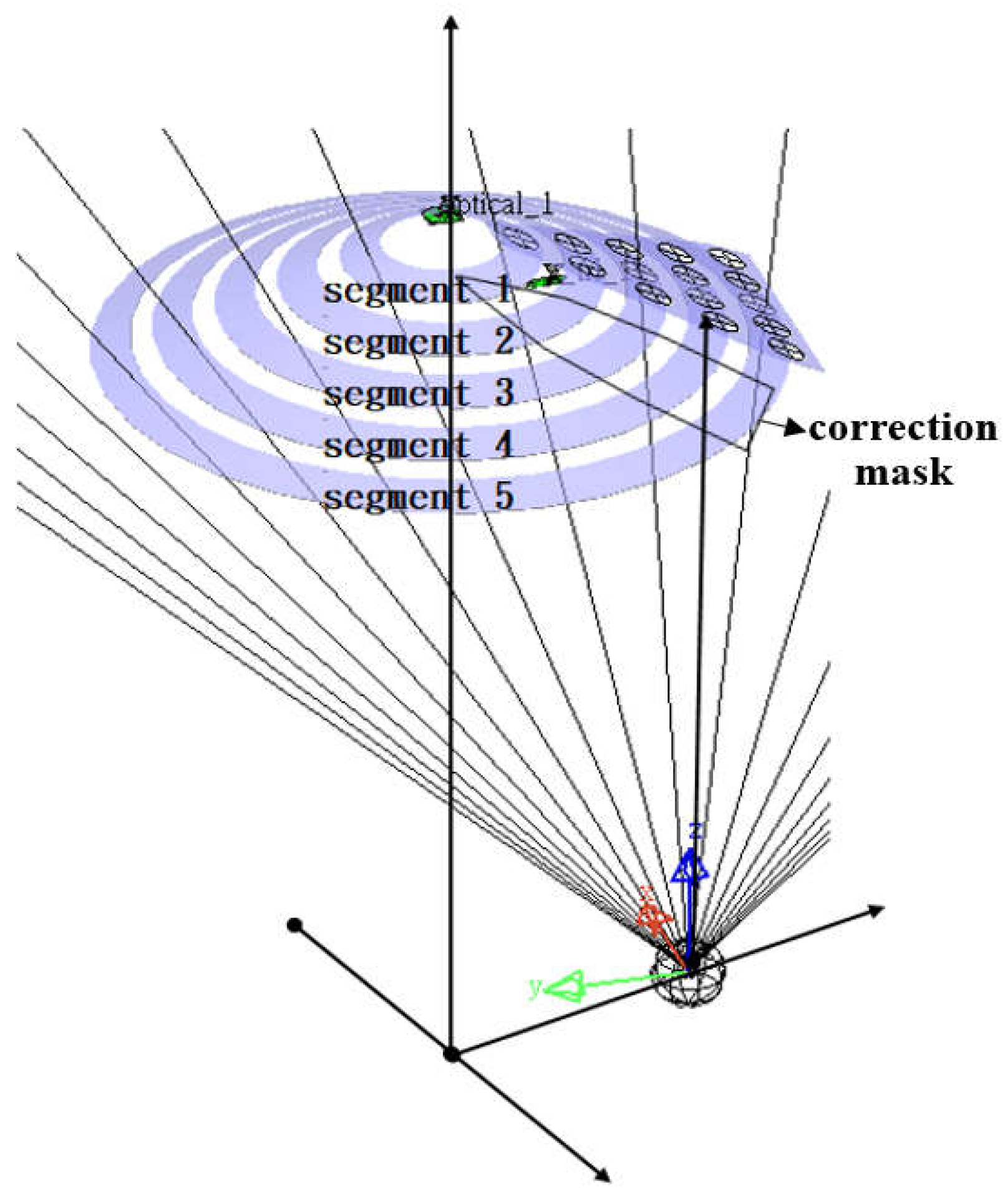

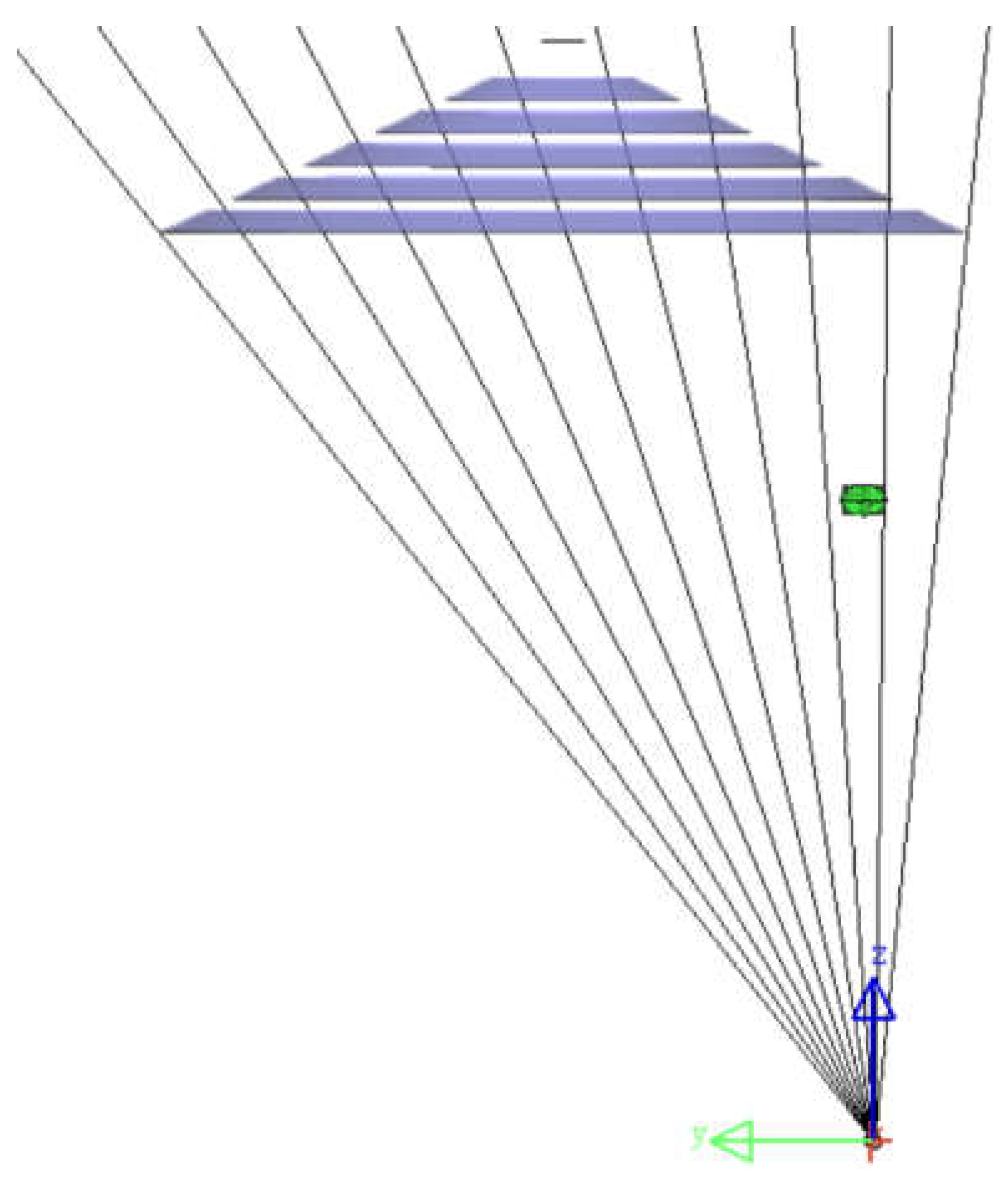

2.2. Three-Dimensional Model Construction of Electron Beam Evaporation

2.3. Flux Mapping Method

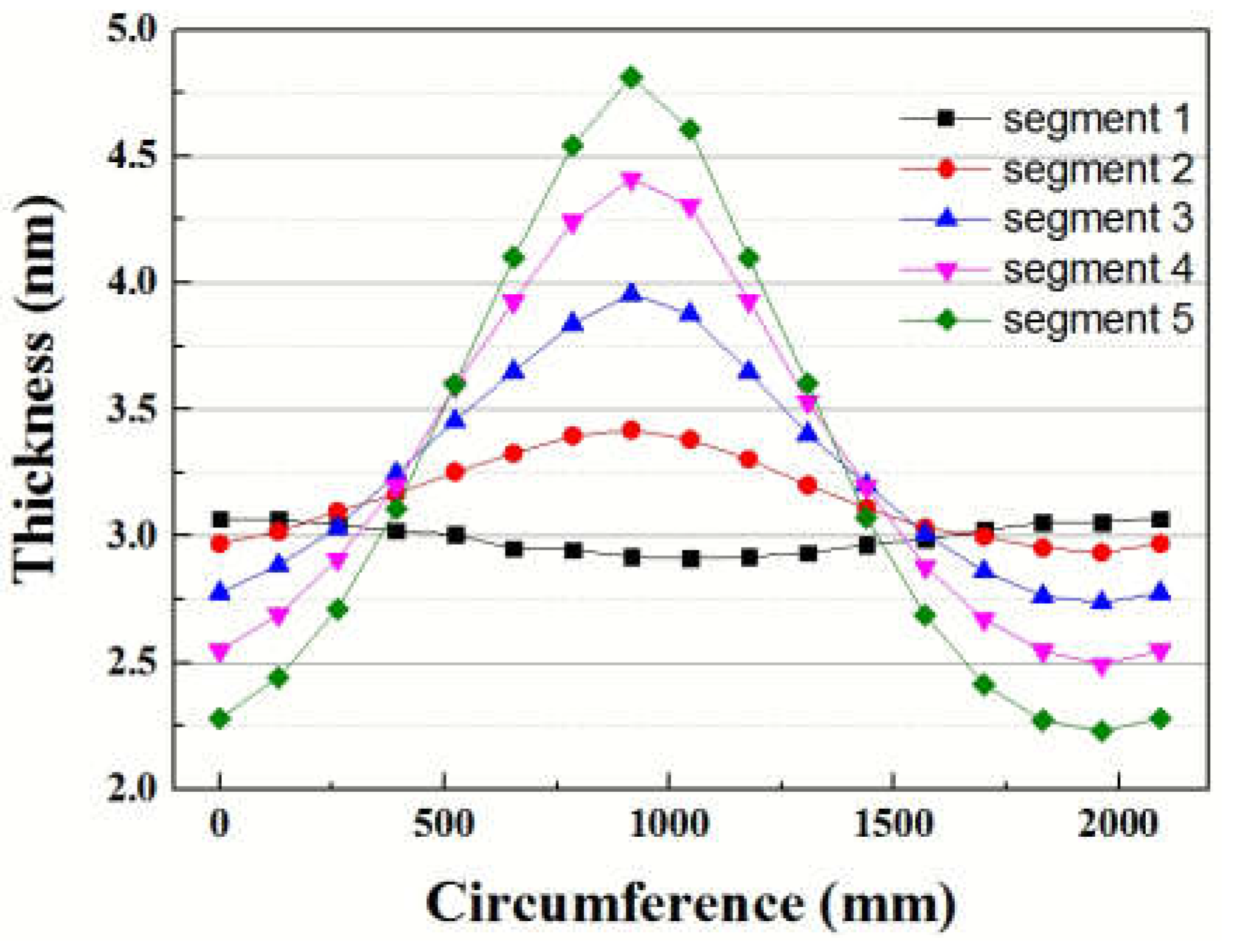

2.4. Numerical Analysis and Deposition Curve

2.5. Electron-Beam Evaporation

2.6. Optical Characteristics and Optical Constants

3. Result and Discussion

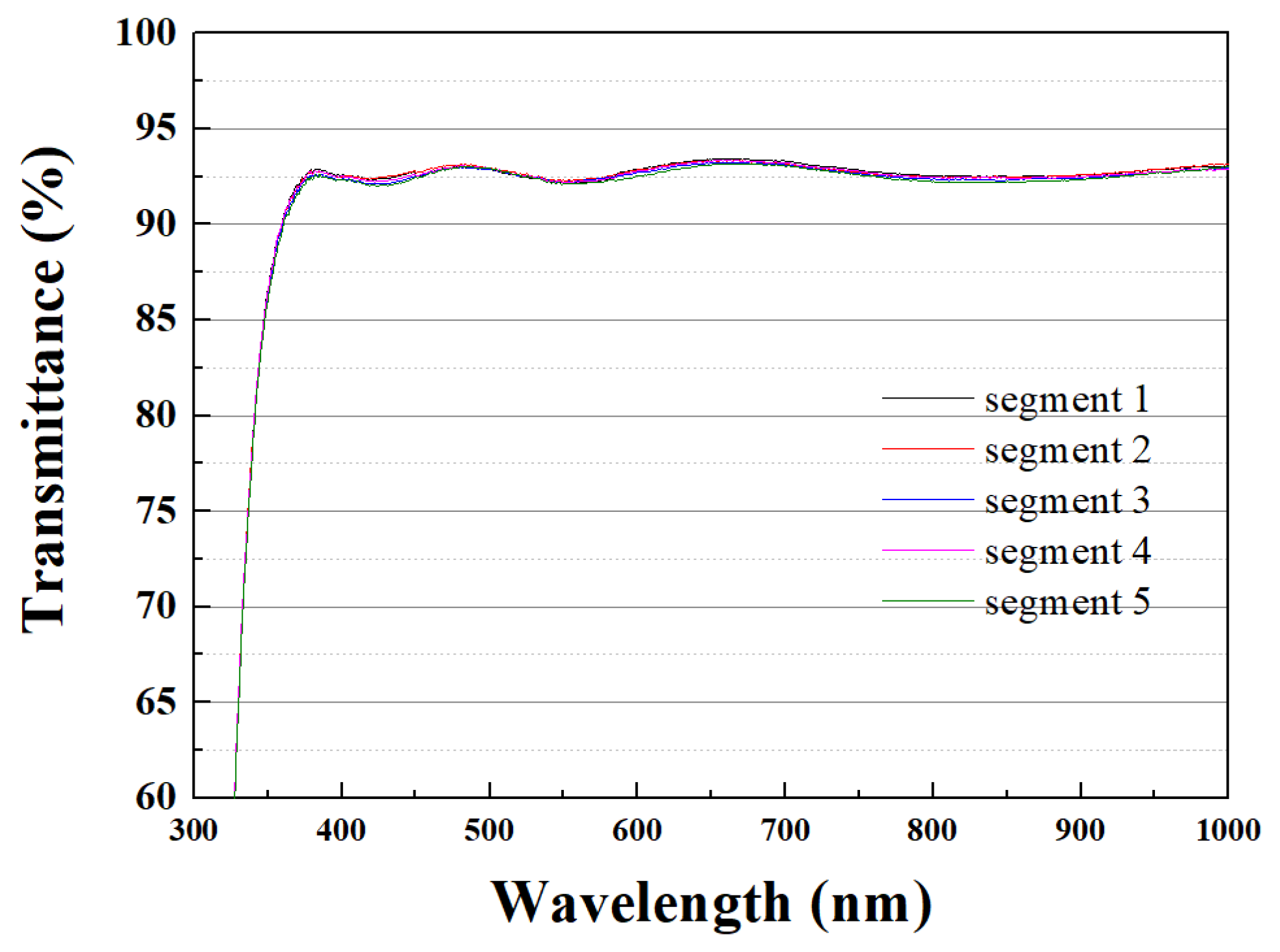

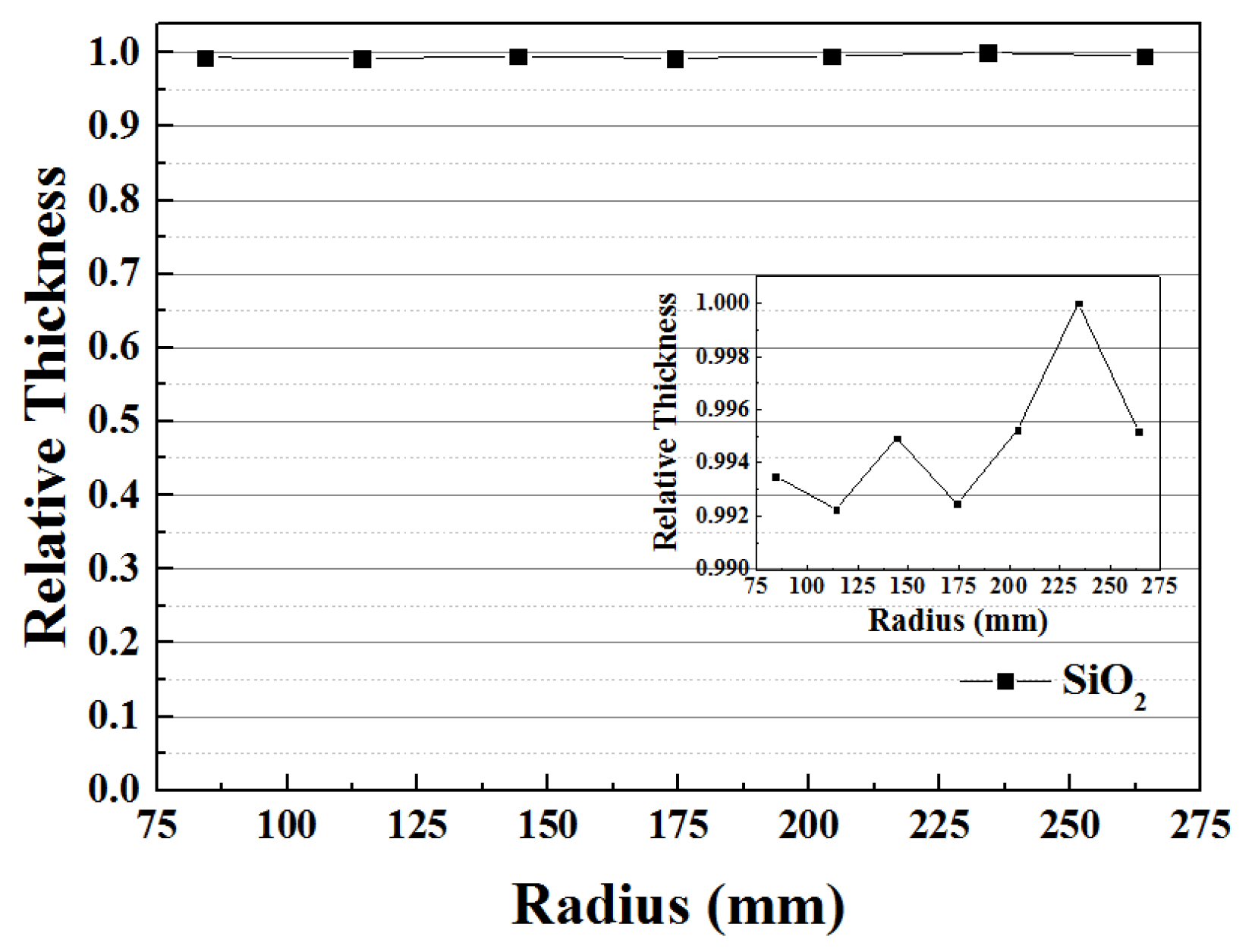

3.1. Optical Constant and Thickness Analysis of SiO2 Thin Film

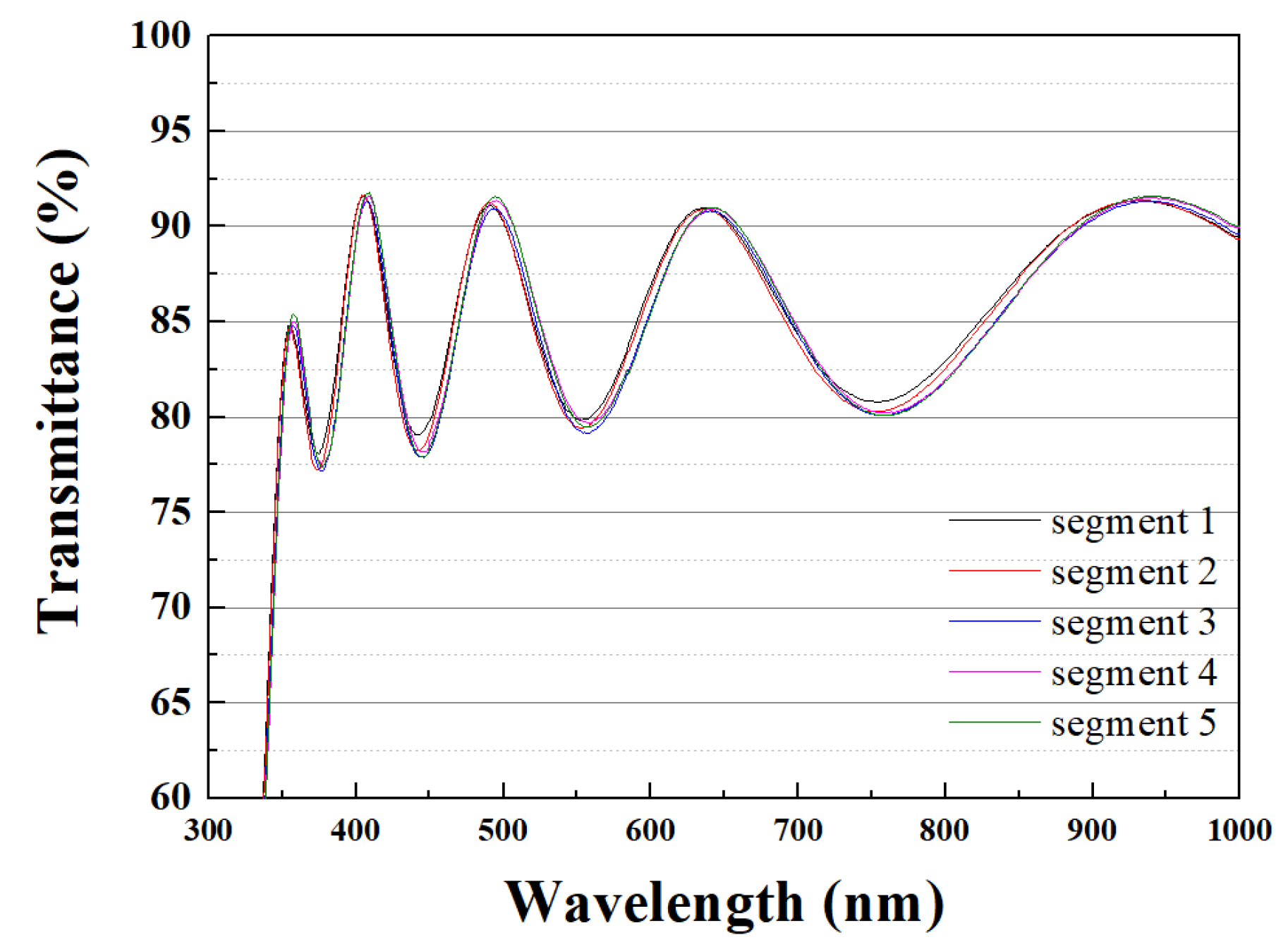

3.2. Optical Constant and Thickness Analysis of Ta2O5 Thin Film

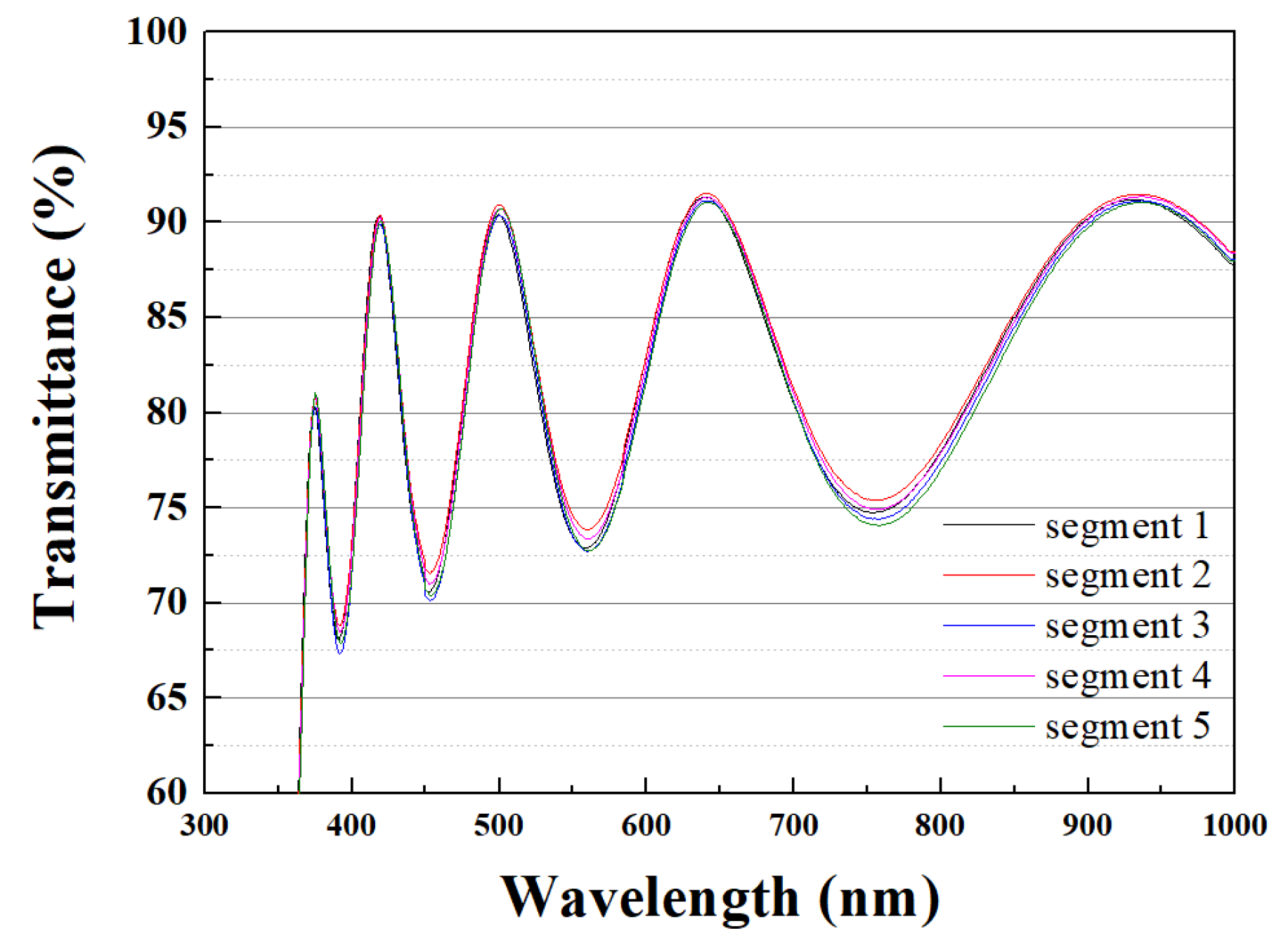

3.3. Optical Constant and Thickness Analysis of Nb2O5 Thin Film

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fancey, K.S. A coating thickness uniformity model for physical vapor-deposition systems: Overview. Surf. Coat. Technol. 1995, 71, 16–29. [Google Scholar] [CrossRef]

- Swann, S.; Collett, S.A.; Scarlett, I.R. Film thickness distribution control with off-axis circular magnetron sources onto rotating substrate holders: Comparison of computer simulation with practical results. J. Vac. Sci. Technol. A 1990, 8, 1299–1303. [Google Scholar] [CrossRef]

- Ho, C.Y.; Chen, B.C.; Xiong, C.W.; Fan, S.L.; Wan, S.F.; Li, L.G.; Shu, Y.F.; Yu, X.Q. A novel spatial-distribution-function of electron beam-induced vapor plume for analyzing EBPVD thickness. AIP Adv. 2018, 8, 085108. [Google Scholar] [CrossRef] [Green Version]

- Villa, F.; Martínez, A.; Regalado, L.E. Correction masks for thickness uniformity in large-area thin films. Appl. Opt. 2000, 39, 1602–1610. [Google Scholar] [CrossRef]

- Wang, B.; Fu, X.; Song, S.; Chu, H.O.; Gibson, D.; Li, C.; Shi, Y.; Wu, Z. Simulation and Optimization of Film Thickness Uniformity in Physical Vapor Deposition. Coatings 2018, 8, 325. [Google Scholar] [CrossRef] [Green Version]

- Savale, P.A. Physical vapor deposition (PVD) methods for synthesis of thin films: A comparative study. Arch. Appl. Sci. Res. 2016, 8, 1–8. [Google Scholar]

- Pinard, L.; Michel, C.; Sassolas, B.; Balzarini, L.; Degallaix, J.; Dolique, V.; Flaminio, R.; Forest, D.; Granata, M.; Lagrange, B.; et al. The mirrors used in the LIGO interferometers for the first-time detection of gravitational waves. Appl. Opt. 2017, 56, C11–C15. [Google Scholar] [CrossRef] [Green Version]

- Raut, H.K.; Ganesh, V.A.; Nair, A.S.; Ramakrishna, S. Anti-reflective coatings: A critical, in-depth review. Energy Environ. Sci. 2011, 4, 3779–3804. [Google Scholar] [CrossRef]

- Lee, C.C. Thin Film Optics and Coating Technology; Yi Hsien Publishing Co., Ltd.: Taipei, China, 2019. [Google Scholar]

- Gross, M.; Dligatch, S.; Chtanov, A. Optimization of coating uniformity in an ion beam sputtering system using a modified planetary rotation method. Appl. Opt. 2011, 50, C316–C320. [Google Scholar] [CrossRef]

- Kozlovskiy, A.L.; Zdorovets, M.V. Synthesis, structural, strength and corrosion properties of thin films of the type CuX (X = Bi, Mg, Ni). J. Mater. Sci. Mater. Electron. 2019, 30, 11819–11832. [Google Scholar] [CrossRef]

- Zubar, T.I.; Usovich, T.I.; Tishkevich, D.I.; Kanafyev, O.D.; Fedkin, V.A.; Kotelnikova, A.N.; Panasyuk, M.I.; Kurochka, A.S.; Nuriev, A.V.; Idris, A.M.; et al. Features of Galvanostatic Electrodeposition of NiFe Films with Composition Gradient: Influence of Substrate Characteristics. Nanomaterials 2022, 12, 2926. [Google Scholar] [CrossRef]

- Kadyrzhanov, K.K.; Shlimas, D.I.; Kozlovskiy, A.L.; Zdorovets, M.V. Research of the shielding effect and radiation resistance of composite CuBi2O4 films as well as their practical applications. J. Mater. Sci. Mater. Electron. 2020, 31, 11729–11740. [Google Scholar] [CrossRef]

- Trukhanov, A.V.; Grabchikov, S.S.; Solobai, A.A.; Tishkevich, D.I.; Trukhanov, S.V.; Trukhanova, E.L. AC and DC-shielding properties for the Ni80Fe20/Cu film structures. J. Magn. Magn. Mater. 2017, 443, 142–148. [Google Scholar] [CrossRef]

- Trukhanov, S.V.; Trukhanov, A.V.; Vasiliev, A.N.; Szymczak, H. Frustrated exchange interactions formation at low temperatures and high hydrostatic pressures in La0.70Sr0.30MnO2.85. J. Exp. Theor. Phys. 2010, 111, 209–214. [Google Scholar] [CrossRef]

- Zhumatayeva, I.Z.; Kenzhina, I.E.; Kozlovskiy, A.L.; Zdorovets, M.V. The study of the prospects for the use of Li0.15Sr0.85TiO3 ceramics. J. Mater. Sci. Mater. Electron. 2020, 31, 6764–6772. [Google Scholar] [CrossRef]

- Ghiyasiyan-Arani, M.; Salavati-Niasari, M. New nanocomposites based on Li-Fe-Mn double spinel and carbon self-doped graphitic carbon nitrides with synergistic effect for electrochemical hydrogen storage application. Ind. Eng. Chem. Res. 2019, 58, 23057–23067. [Google Scholar] [CrossRef]

- Ghiyasiyan-Arani, M.; Salavati-Niasari, M.; Zonouz, A.F. Effect of operational synthesis parameters on the morphology and the electrochemical properties of 3D hierarchical AlV3O9 architectures for Li-Ion batteries. J. Electrochem. Soc. 2020, 167, 020544. [Google Scholar] [CrossRef]

- Ghiyasiyan-Arani, M.; Masoud Salavati-Niasari, M. Strategic design and electrochemical behaviors of Li-ion battery cathode nanocomposite materials based on AlV3O9 with carbon nanostructures. Compos. Part B 2020, 183, 107734. [Google Scholar] [CrossRef]

- Kim, M.G.; Pahk, H.J. Simulation of thin film thickness distribution for thermal evaporation process using a scanning linear source. J. SID 2017, 25, 249–257. [Google Scholar] [CrossRef]

- Burkhard, D.G.; Shealy, D.L. Flux density for ray propagation in geometrical optics. J. Opt. Soc. Am. 1973, 63, 299–304. [Google Scholar] [CrossRef]

- Mao, X.; Li, H.; Han, Y.; Luo, Y. Polar-grids based source-target mapping construction method for designing freeform illumination system for a lighting target with arbitrary shape. Opt. Express 2015, 23, 4313–4328. [Google Scholar] [CrossRef]

- Tang, C.J.; Chang, R.S.; Han, C.Y. Using imaging ellipsometry to determine angular distribution of ellipsometric parameters without scanning mechanism. Opt. Lasers Eng. 2016, 77, 39–43. [Google Scholar] [CrossRef]

- Vuye, G.; López-Ríos, T. Precision in the ellipsometric determination of the optical constants of very thin films. Appl. Opt. 1982, 21, 2968–2971. [Google Scholar] [CrossRef]

| Segment | Refractive Index | Extinction Coefficient | Film Thickness (nm) |

|---|---|---|---|

| One | 1.429 | 0.0007 | 566.76 nm |

| Two | 1.437 | 0.0007 | 567.58 nm |

| Three | 1.443 | 0.0004 | 566.17 nm |

| Four | 1.438 | 0.0005 | 567.76 nm |

| Five | 1.449 | 0.0006 | 570.47 nm |

| Segment | Refractive Index | Extinction Coefficient | Film Thickness (nm) |

|---|---|---|---|

| One | 2.023 | 0.004 | 480.38 nm |

| Two | 2.039 | 0.007 | 480.82 nm |

| Three | 2.045 | 0.007 | 482.23 nm |

| Four | 2.026 | 0.004 | 483.86 nm |

| Five | 2.031 | 0.003 | 483.53 nm |

| Segment | Refractive Index | Extinction Coefficient | Film Thickness (nm) |

|---|---|---|---|

| One | 2.281 | 0.007 | 420.86 nm |

| Two | 2.261 | 0.009 | 421.82 nm |

| Three | 2.284 | 0.008 | 421.41 nm |

| Four | 2.272 | 0.008 | 421.93 nm |

| Five | 2.275 | 0.006 | 422.17 nm |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tien, C.-L.; Cheng, K.-S. Improving Thickness Uniformity of Amorphous Oxide Films Deposited on Large Substrates by Optical Flux Mapping. Appl. Sci. 2022, 12, 11878. https://doi.org/10.3390/app122311878

Tien C-L, Cheng K-S. Improving Thickness Uniformity of Amorphous Oxide Films Deposited on Large Substrates by Optical Flux Mapping. Applied Sciences. 2022; 12(23):11878. https://doi.org/10.3390/app122311878

Chicago/Turabian StyleTien, Chuen-Lin, and Kuan-Sheng Cheng. 2022. "Improving Thickness Uniformity of Amorphous Oxide Films Deposited on Large Substrates by Optical Flux Mapping" Applied Sciences 12, no. 23: 11878. https://doi.org/10.3390/app122311878

APA StyleTien, C.-L., & Cheng, K.-S. (2022). Improving Thickness Uniformity of Amorphous Oxide Films Deposited on Large Substrates by Optical Flux Mapping. Applied Sciences, 12(23), 11878. https://doi.org/10.3390/app122311878