Strength Characteristics and In Situ Stress Measurement of Rock Cores from a Large Section Underground Station: A Case Study

Abstract

:Featured Application

Abstract

1. Introduction

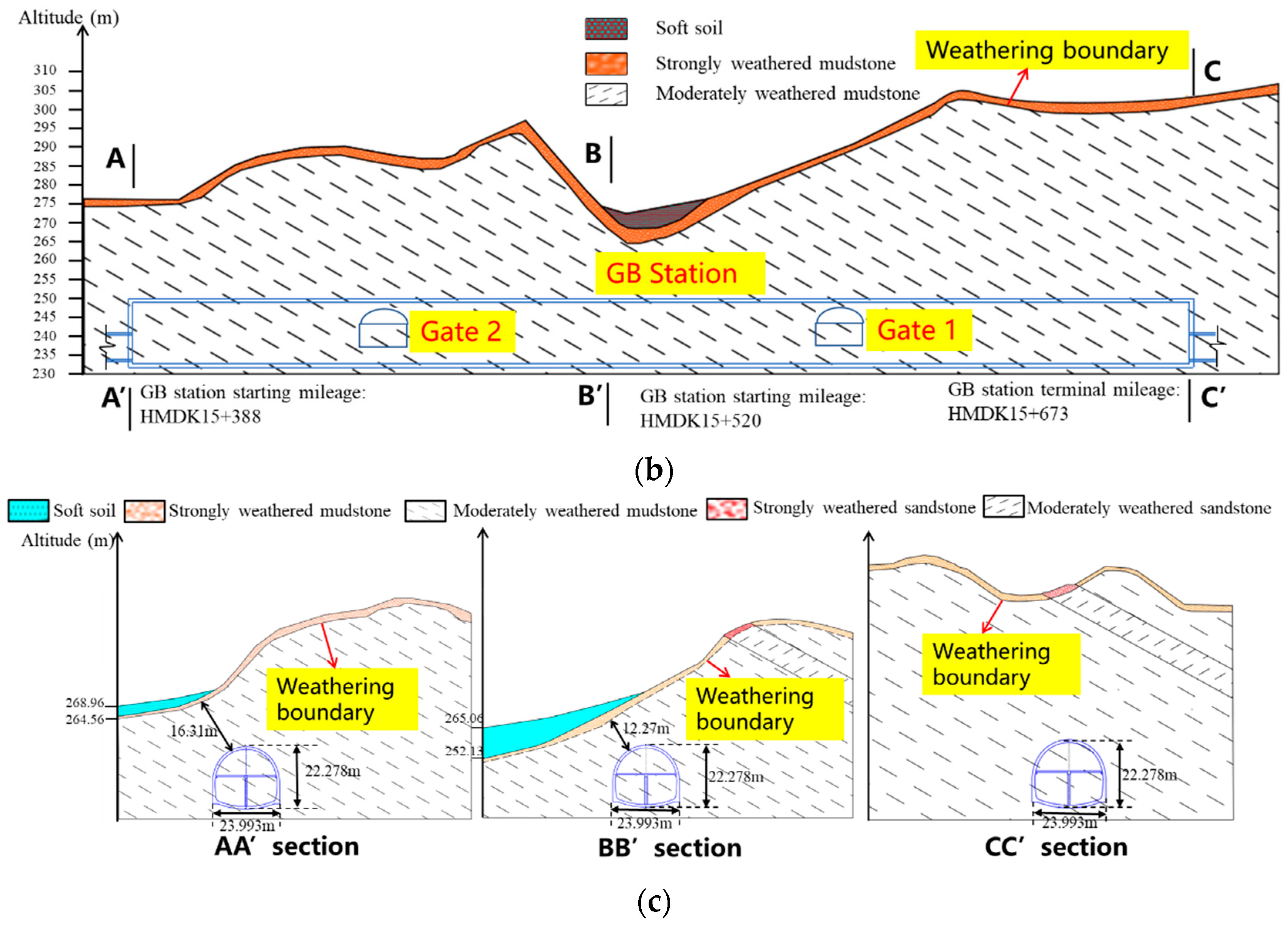

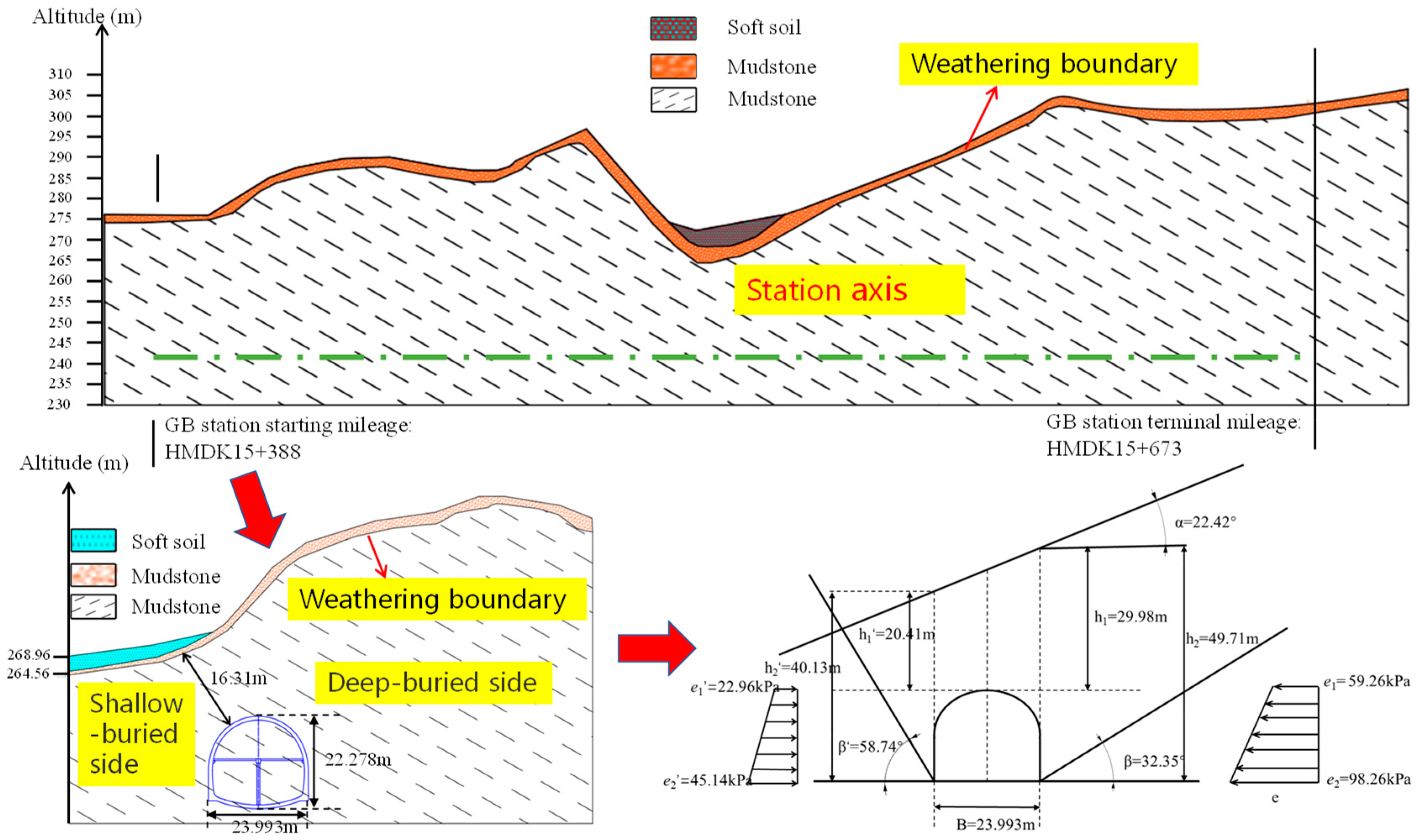

2. Project Overview and Geological Conditions of the Area

3. Test Methods

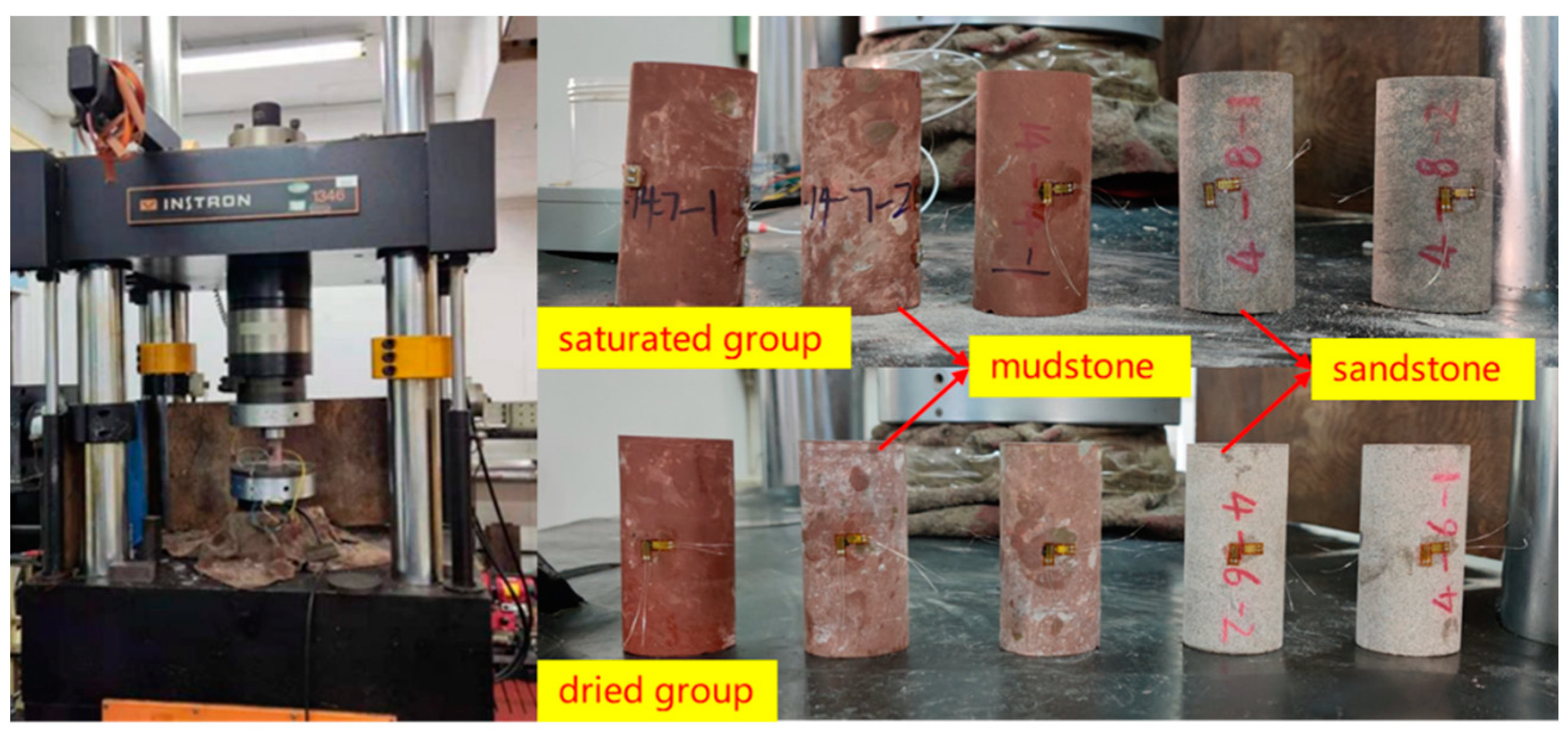

3.1. Sample Preparation

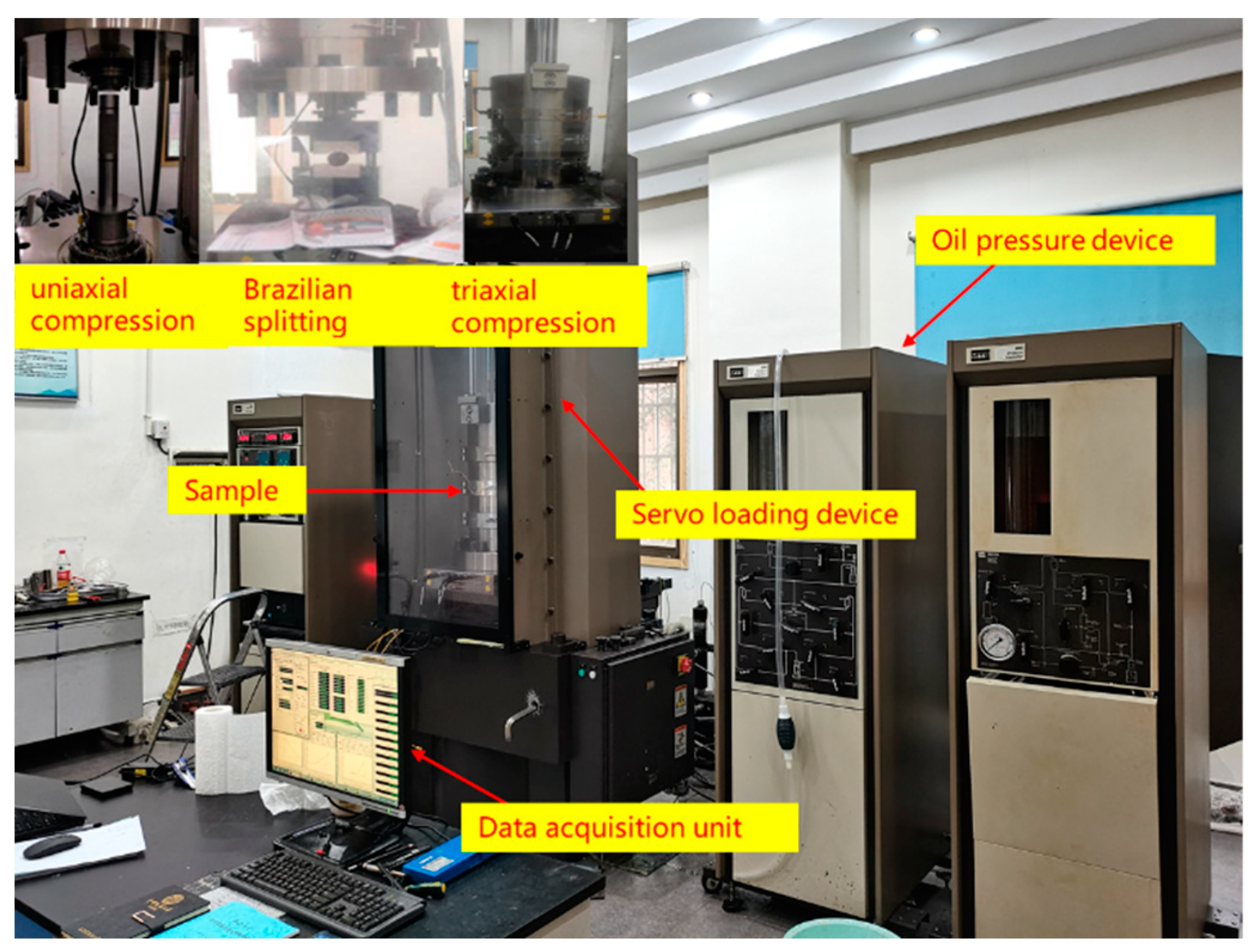

3.2. Test Equipment and Materials

4. Test Results and Analysis

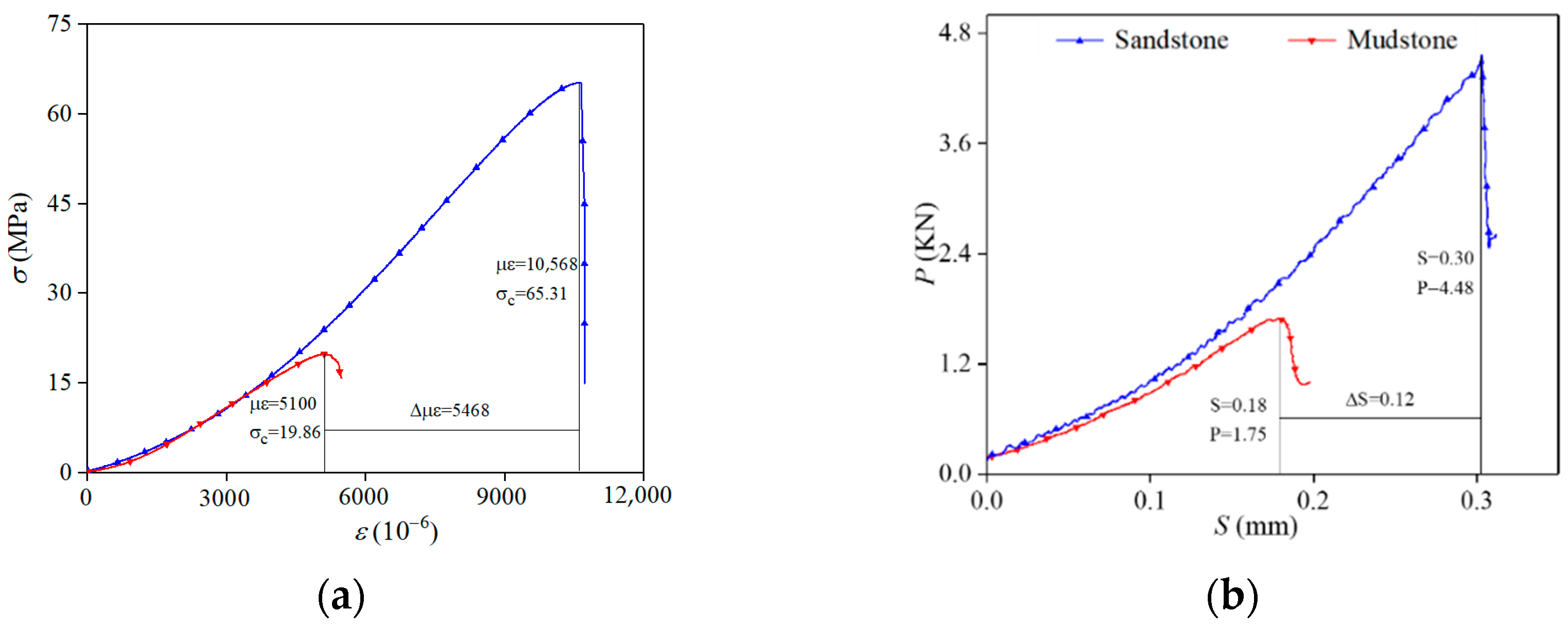

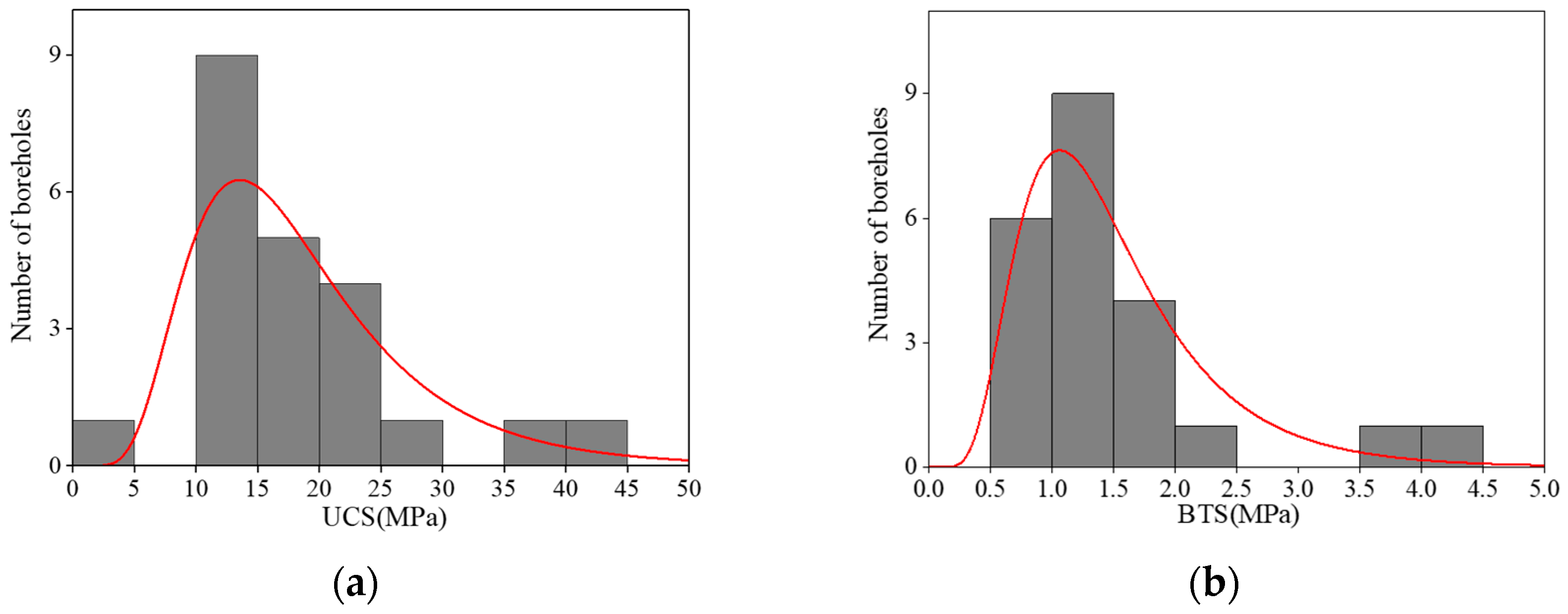

4.1. UCT and BST

4.2. TCT

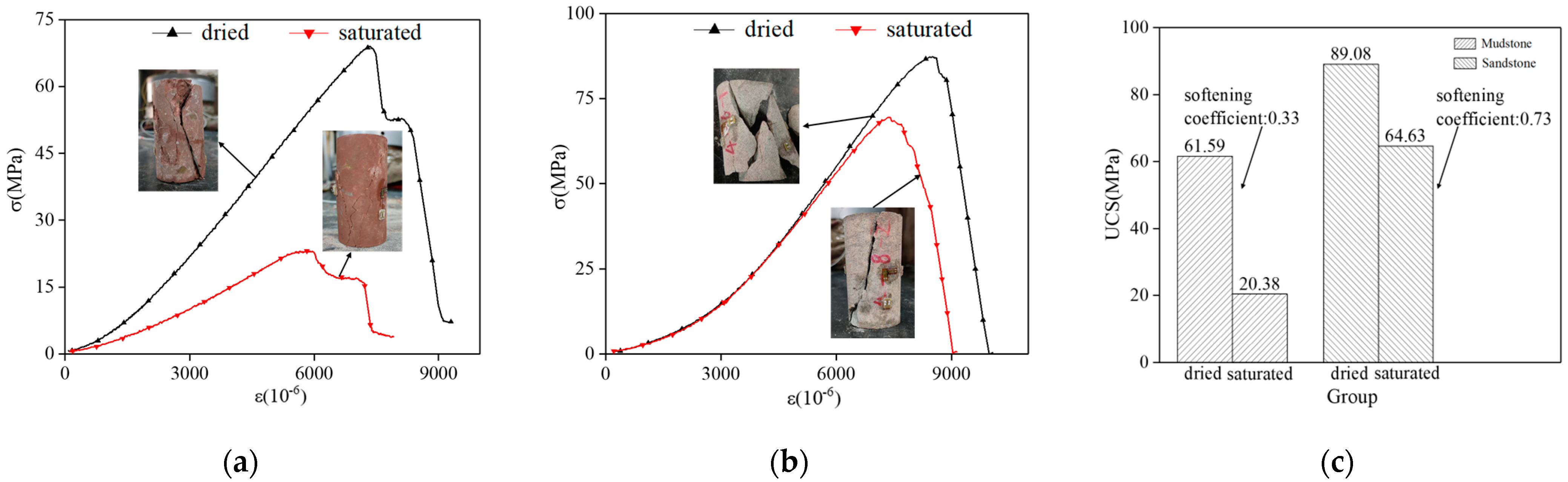

4.3. Softening Coefficient Test

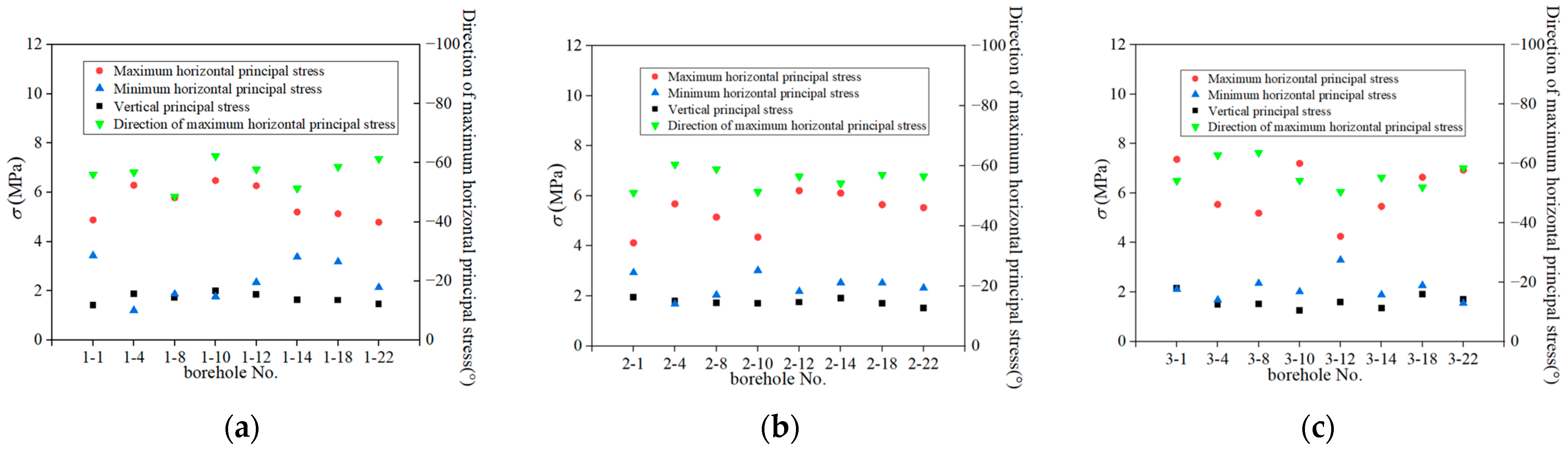

4.4. In Situ Stress Test

5. Discussion

5.1. Bias Pressures

5.2. High In Situ Stresses

5.3. Surrounding Rock Deterioration

6. Conclusions

- (1)

- The rock mass in the Guobo station project area is mainly mudstone, and sandstone is only found at borehole 4–4. The UCS of mudstone in the natural state is 4.43~42.43 MPa, with an average value of 18.60 MPa. The BTS is 0.66~4.30 MPa, and the average value is 1.51 MPa. The strength of the mudstone specimens differs greatly from different boreholes, but both the UCS and BTS obey lognormal distributions. The average UCS of sandstone in the natural state is 65.31 MPa, and the average BTS is 3.06 MPa.

- (2)

- The softening coefficients of mudstone and sandstone are 0.33 and 0.73, respectively, which indicates that the water content has an important impact on the strength of both mudstone and sandstone but has a greater effect on mudstone.

- (3)

- The in situ stress field in the project area is affected by horizontal tectonism. The relationship of the principal in situ stresses is: σH > σh > σV. In the area with a cover depth of approximately 60 m, the maximum horizontal principal stress ranges between 4.25~7.36 MPa. The azimuth is distributed between N45°W~65°N°W, and the lateral pressure coefficient is 2.11~5.71, with an average value of 3.39. A large lateral pressure coefficient may cause a tensile stress concentration on the side walls of the station after excavation.

- (4)

- The uniaxial compressive strength of the rock mass at Guobo station does not exceed 1 MPa. The strength–stress ratio of the surrounding rock is only 0.12~0.21 when the GSI is 50, which indicates that the tunnel is prone to large deformation during excavation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tomar, M.S.; Khurana, S. Impact of passive fire protection on heat release rates in road tunnel fire: A review. Tunn. Undergr. Space Technol. 2019, 85, 149–159. [Google Scholar] [CrossRef]

- Xiong, Z.; Guo, J.; Xia, Y.; Lu, H.; Wang, M.; Shi, S. A 3D Multi–scale geology modeling method for tunnel engineering risk assessment. Tunn. Undergr. Space Technol. 2018, 73, 71–81. [Google Scholar] [CrossRef]

- Wang, J.; Qiu, Z.; Deng, W. Shear Strength of a Crushed Sandstone–Mudstone Particle Mixture. Int. J. Archit. Eng. Technol. 2014, 1, 33–37. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhao, W.; Gao, Y.; Li, X.; Li, Y.; He, X. Experimental Study on the Mechanical Properties of Rock Slope Collapse. Fresenius Environ. Bull. 2017, 26, 8166–8175. [Google Scholar]

- Bian, K.; Liu, J.; Liu, Z.; Liu, S.; Ai, F.; Zheng, X.; Ni, S.; Zhang, W. Mechanisms of large deformation in soft rock tunnels: A case study of Huangjiazhai Tunnel. Bull. Eng. Geol. Environ. 2019, 78, 431–444. [Google Scholar] [CrossRef]

- Xue, Y.; Liu, H.; Bai, C.; Su, M.; Qiu, D.; Zhou, B.; Yu, Y.; Jiang, X. Extension prediction model of soft rock tunnel deformation grade based on entropy weight method and rough set. Environ. Earth Sci. 2022, 81, 1–13. [Google Scholar] [CrossRef]

- Wu, K.; Shao, Z.; Qin, S.; Wei, W.; Chu, Z. A critical review on the performance of yielding supports in squeezing tunnels. Tunn. Undergr. Space Technol. 2021, 115, 103815. [Google Scholar] [CrossRef]

- Hoek, E.; Guevara, R. Overcoming Squeezing in the Yacambú–Quibor Tunnel, Venezuela. Rock Mech. Rock Eng. 2009, 42, 389–418. [Google Scholar] [CrossRef]

- Steiner, W. Tunnelling in squeezing rocks: Case histories. Rock Mech. Rock Eng. 1996, 29, 211–246. [Google Scholar] [CrossRef]

- Li, D.; Li, X.; Li, C.C.; Huang, B.; Gong, F.; Zhang, W. Case studies of groundwater flow into tunnels and an innovative water–gathering system for water drainage. Tunn. Undergr. Space Technol. 2009, 24, 260–268. [Google Scholar] [CrossRef]

- Xue, Y.; Li, X.; Li, G.; Qiu, D.; Gong, H.; Kong, F. An Analytical Model for Assessing Soft Rock Tunnel Collapse Risk and its Engineering Application. Geomech. Eng. 2020, 23, 441–454. [Google Scholar]

- Bizjak, K.F.; Petkovšek, B. Displacement analysis of tunnel support in soft rock around a shallow highway tunnel at Golovec. Eng. Geol. 2004, 75, 89–106. [Google Scholar] [CrossRef]

- Zhong, Z.; Liu, X.; Wang, D.; Zheng, C.; Huang, M. Mechanism Analysis of Floor Heave in Taoshuya Tunnel and its Prevention Techniques. Chin. J. Geotech. Eng. 2012, 34, 471–476. [Google Scholar]

- Małkowski, P.; Ostrowski, Ł.; Bednarek, Ł. The Effect of Selected Factors on Floor Upheaval in Roadways—In Situ Testing. Energies 2020, 13, 5686. [Google Scholar] [CrossRef]

- Małkowski, P.; Ostrowski, Ł.; Stasica, J. Modeling of Floor Heave in Underground Roadways in Dry and Waterlogged Conditions. Energies 2022, 15, 4340. [Google Scholar] [CrossRef]

- Rehman, H.; Naji, A.M.; Nam, K.; Ahmad, S.; Muhammad, K.; Yoo, H.-K. Impact of Construction Method and Ground Composition on Headrace Tunnel Stability in the Neelum–Jhelum Hydroelectric Project: A Case Study Review from Pakistan. Appl. Sci. 2021, 11, 1655. [Google Scholar] [CrossRef]

- Li, D. Analysis of Coupling Effect of Stress Field and Seepage Field in Surrounding Rock of Expressway Multi Arch Tunnel. Master’s Thesis, Central South University, Changsha, China, 2006. [Google Scholar]

- He, W. Features and Formation Mechanism of the Eastern–Sichuan—Western–Hunan–Hubei Fold–Thrust Belt in South China. Ph.D. Thesis, China University Of Petroleum (Beijing), Beijing, China, 2018. [Google Scholar]

- Xie, G.; Jia, D.; Zhang, Q.; Wu, X.; Shen, L.; Lv, Y.; Zou, X. Physical Modeling of the Jura–Type Folds in Eastern Sichuan. Acta Geol. Sin. 2013, 87, 773–788. [Google Scholar]

- Pei, Y.; Sheng, S.; Miao, Z.; Mou, Y.; Su, N.; Guo, W.; Feng, B.; Wang, J.; Liang, H.; Xie, L. Sandbox physical modelling with multiple detachment layers and its implication on structural evolution of East Sichuan Fold Belt. J. China Univ. Pet. (Ed. Nat. Sci.) 2022, 46, 38–49. [Google Scholar]

- Yan, D.-P.; Zhou, M.-F.; Song, H.-L.; Wang, X.-W.; Malpas, J. Origin and tectonic significance of a Mesozoic multi–layer over–thrust system within the Yangtze Block (South China). Tectonophysics 2003, 361, 239–254. [Google Scholar] [CrossRef]

- Zhang, M.; Yin, Y.; Huang, B. Mechanisms of rainfall–induced landslides in gently inclined red beds in the eastern Sichuan Basin, SW China. Landslides 2015, 12, 973–983. [Google Scholar] [CrossRef]

- Xu, R.; Zhou, J. Red Bed and Dam; China University of Geosciences Press: Wuhan, China, 2010. [Google Scholar]

- GB/T 23561.10–2010; General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China; Standardization Administration of the People’s Republic of China. Methods for Determining the Physical and Mechanical Properties of Coal and Rock. Standards Press of China: Beijing, China, 2009.

- Li, X.; Chen, J.; Ma, C.; Huang, L.; Li, C.; Zhang, J.; Zhao, Y. A novel in–situ stress measurement method incorporating non–oriented core ground re–orientation and acoustic emission: A case study of a deep borehole. Int. J. Rock Mech. Min. Sci. 2022, 152, 105079. [Google Scholar] [CrossRef]

- Hoek, E.; Wood, D.; Shah, S. A Modified Hoek–Brown Failure Criterion for Jointed Rock Masses. In Proceedings of the Rock Characterization: ISRM Symposium, Eurock’92, Chester, UK, 14–17 September 1992; Thomas Telford: London, UK, 1992. [Google Scholar]

- Hoek, E.; Brown, E.T. Empirical Strength Criterion for Rock Masses. J. Geotech. Geoenviron. Eng. 1980, 106, 1013–1035. [Google Scholar] [CrossRef]

- Hoek, E.; Brown, E.T. The Hoek–Brown Failure Criterion and GSI–2018 Edition. J. Rock Mech. Geotech. Eng. 2018, 11, 445–463. [Google Scholar] [CrossRef]

- Marinos, P.; Hoek, E. GSI–A Geologically Friendly Tool for Rock Mass Strength Estimation. In Proceedings of the ISRM International Symposium, Melbourne, Australia, 19–24 November 2000; OnePetro: Salzburg, Austria, 2000. [Google Scholar]

- Wu, S. Rock Mechanics; Higher Education Press: Beijing, China, 2021; pp. 232–238. [Google Scholar]

- Zhao, G.; Yang, S. Analytical solutions for rock stress around square tunnels using complex variable theory. Int. J. Rock Mech. Min. Sci. 2015, 80, 302–307. [Google Scholar] [CrossRef]

- Zhang, N.; Fang, Q.; Li, Y.; Zhang, D. Mechanical Analysis of Secondary Lining of High–Speed Railway Tunnel. KSCE J. Civ. Eng. 2017, 22, 2384–2389. [Google Scholar] [CrossRef]

- State Railway Administration. Code for Design of Railway Tunnel; China Railway Press: Beijing, China, 2017. [Google Scholar]

- Lei, M.; Peng, L.; Shi, C. Model test to investigate the failure mechanisms and lining stress characteristics of shallow buried tunnels under unsymmetrical loading. Tunn. Undergr. Space Technol. 2015, 46, 64–75. [Google Scholar] [CrossRef]

- Wang, Y. Comparison and Selection of Advanced Supporting Methods and Asymmetric Optimization Analysis for Shallowly Buried Biased Tunnel. Railw. Constr. Technol. 2022, 5, 159–163. [Google Scholar]

- Lu, G.; Zhou, B.; Xu, F.; Shangguan, W.; Wang, G.; Zhang, S. Stability Analysis and Construction Mechanics of Shallow Buried Bias Tunnel Openings. J. Shangdong Univ. 2021, 51, 61–70. [Google Scholar]

- Chen, F.; He, C.; Deng, J. Concept of High Geostress and its Qualitative and Quantitative Definitions. Rock Soil Mech. 2015, 36, 971–980. [Google Scholar]

- Ma, D.; Sun, Y.; Wang, W.; Jin, L. Key Technologies for Controlling Large Deformation of Soft Rock Tunnels with High Geostress. Tunn. Constr. 2021, 41, 1634–1643. [Google Scholar]

- Lei, S.; Zhao, W. Study on Mechanism of Circumferential Yielding Support for Soft Rock Tunnel with Large Deformation. Rock Soil Mech. 2020, 41, 1039–1047. [Google Scholar]

- Wu, G.; Chen, W.; Tian, H.; Jia, S.; Yang, J.; Tan, X. Numerical evaluation of a yielding tunnel lining support system used in limiting large deformation in squeezing rock. Environ. Earth Sci. 2018, 77, 439. [Google Scholar] [CrossRef]

- Guo, Q.; Su, H.; Jing, H.; Zhu, W. Effect of Wetting–Drying Cycle on the Deformation and Seepage Behaviors of Rock Masses around a Tunnel. Geofluids 2020, 4237163. [Google Scholar] [CrossRef]

- Cui, T.; Du, S.; Zhang, W.; Yang, S. Cause Analysis of Longitudinal Cracks of Secondary Lining in railway Soft Rock Tunnel. Rainway Eng. 2018, 58, 74–77. [Google Scholar]

| Borehole No. | Test Content | Specimen No. | Number of Samples |

|---|---|---|---|

| 1–2,1–5,1–9,1–11,1–13, 1–17,1–21 | UCT and TCT (Sample size: φ50 × 100) | UCT: Drill core No.–A– number | 23 |

| 2–2,2–5,2–9,2–11,2–13, 2–17,2–21 | BST (Sample size: φ50 × 25) | BST: Drill core No.–B– number | 45 |

| 3–2,3–5,3–9,3–11,3–13, 3–17,3–21, 4–4,4–6 | TST: Drill core No.–C– σ3 | 6 | |

| 1–14,4–4 | Softening coefficient test | Dried group: Drill core No.–D– number | 5 |

| (Sample size: φ50 × 100) | Saturated group: Drill core No.–E– number | 5 | |

| 1–1,1–4,1–8,1–10,1–12, 1–14,1–18,1–22 | In situ stress test | Vertical group: Drill core No.–E– number | 72 |

| 2–1,2–4,2–8,2–10,2–12, 2–14,2–18,2–22 | (Sample size: φ50 × 100 for horizontal group and φ25 × 50 for vertical group) | Horizontal group1: Drill core No.–F– number | 96 |

| 3–1,3–4,3–8,3–10,3–12, 3–14,3–18,3–22 | Horizontal group2: Drill core No.–G– number | 96 | |

| Horizontal group3: Drill core No.–H– number | 96 |

| Borehole No. | Lithology | UCS (MPa) | BTS (MPa) | Young’s Modulus (GPa) |

|---|---|---|---|---|

| 1–2 | Mudstone | 4.43 | 1.47 | 1.3 |

| 1–5 | Mudstone | 11.66 | 1.23 | 2.4 |

| 1–9 | Mudstone | 14.88 | 1.13 | 2.4 |

| 1–11 | Mudstone | 16.48 | 1.60 | 2.7 |

| 1–13 | Mudstone | 23.02 | 2.03 | 2.5 |

| 1–17 | Mudstone | 15.30 | 3.59 | 2.2 |

| 1–21 | Mudstone | 19.86 | 0.93 | 4.9 |

| 2–2 | Mudstone | 19.84 | 0.85 | 1.9 |

| 2–5 | Mudstone | 15.23 | 1.08 | 1.7 |

| 2–9 | Mudstone | 21.38 | 1.34 | 2.9 |

| 2–11 | Mudstone | 10.60 | 1.36 | 2.3 |

| 2–13 | Mudstone | 22.27 | 0.85 | 3.6 |

| 2–17 | Mudstone | 13.36 | 0.85 | 1.7 |

| 2–21 | Mudstone | 35.89 | 1.98 | 4.3 |

| 3–2 | Mudstone | 14.10 | 0.66 | 1.7 |

| 3–5 | Mudstone | 12.72 | 1.97 | 2.1 |

| 3–9 | Mudstone | 19.48 | 1.47 | 2.6 |

| 3–11 | Mudstone | 27.80 | 1.91 | 3.3 |

| 3–13 | Mudstone | 14.24 | 1.02 | 3.2 |

| 3–17 | Mudstone | 42.43 | 4.30 | 5.2 |

| 3–21 | Mudstone | 21.45 | 1.01 | 2.1 |

| 4–6 | Mudstone | 12.68 | 0.70 | 1.2 |

| 4–4 | Sandstone | 65.31 | 3.06 | 8.5 |

| mi | α | GSI | mb | s | UCS (MPa) | Young’s Modulus (GPa) |

|---|---|---|---|---|---|---|

| 13.36 | 0.5 | 40 | 1.567 | 0.0013 | 0.481 | 0.42 |

| 42 | 1.683 | 0.0016 | 0.544 | 0.48 | ||

| 44 | 1.808 | 0.0020 | 0.614 | 0.55 | ||

| 46 | 1.942 | 0.0025 | 0.692 | 0.63 | ||

| 48 | 2.086 | 0.0031 | 0.779 | 0.72 | ||

| 50 | 2.240 | 0.0039 | 0.875 | 0.81 |

| Specimen No. | Lithology | UCS (MPa) | Group | Average Value (MPa) | Softening Coefficient |

|---|---|---|---|---|---|

| 1–14–D–1 | Mudstone | 54.12 | dried | 61.59 | 0.33 |

| 1–14–D–2 | Mudstone | 69.05 | dried | ||

| 1–14–D–3 | Mudstone | 17.90 | The specimen has cracks before test (excluded) | ||

| 1–14–E–1 | Mudstone | 17.64 | saturated | 20.38 | |

| 1–14–E–2 | Mudstone | 18.59 | The specimen has cracks before test(excluded) | ||

| 1–14–E–3 | Mudstone | 23.11 | saturated | ||

| 4–4–D–1 | Sandstone | 87.40 | dried | 89.08 | 0.73 |

| 4–4–D–2 | Sandstone | 90.76 | dried | ||

| 4–4–E–1 | Sandstone | 69.46 | Saturated | 64.63 | |

| 4–4–E–2 | Sandstone | 59.79 | Saturated |

| Borehole No. | Buried Depth of Measuring Point (m) | σV (MPa) | σg (MPa) | σH (MPa) | σh (MPa) | θ (°) |

|---|---|---|---|---|---|---|

| 1–1 | 58.00 | 1.42 | 1.57 | 4.88 | 3.43 | −56.08 |

| 1–4 | 58.50 | 1.88 | 1.58 | 6.29 | 1.21 | −56.82 |

| 1–8 | 57.20 | 1.73 | 1.54 | 5.78 | 1.87 | −48.61 |

| 1–10 | 60.00 | 1.99 | 1.62 | 6.48 | 1.77 | −62.30 |

| 1–12 | 48.50 | 1.86 | 1.31 | 6.27 | 2.35 | −57.83 |

| 1–14 | 64.53 | 1.64 | 1.74 | 5.20 | 3.38 | −51.33 |

| 1–18 | 65.26 | 1.62 | 1.76 | 5.13 | 3.18 | −58.61 |

| 1–22 | 61.30 | 1.47 | 1.66 | 4.79 | 2.14 | −61.34 |

| 2–1 | 60.00 | 1.95 | 1.62 | 4.12 | 2.93 | −51.03 |

| 2–4 | 60.49 | 1.79 | 1.63 | 5.68 | 1.68 | −60.46 |

| 2–8 | 58.82 | 1.73 | 1.59 | 5.15 | 2.04 | −58.90 |

| 2–10 | 60.00 | 1.70 | 1.62 | 4.35 | 3.02 | −51.33 |

| 2–12 | 58.30 | 1.75 | 1.57 | 6.21 | 2.18 | −56.47 |

| 2–14 | 64.10 | 1.91 | 1.73 | 6.11 | 2.53 | −54.12 |

| 2–18 | 63.30 | 1.71 | 1.71 | 5.65 | 2.52 | −57.01 |

| 2–22 | 68.00 | 1.51 | 1.84 | 5.53 | 2.32 | −56.48 |

| 3–1 | 64.00 | 2.16 | 1.73 | 7.36 | 2.11 | −54.15 |

| 3–4 | 64.00 | 1.49 | 1.73 | 5.54 | 1.68 | −62.75 |

| 3–8 | 60.45 | 1.52 | 1.63 | 5.19 | 2.35 | −63.64 |

| 3–10 | 60.00 | 1.26 | 1.62 | 7.20 | 2.01 | −54.25 |

| 3–12 | 58.00 | 1.59 | 1.57 | 4.25 | 3.29 | −50.42 |

| 3–14 | 65.50 | 1.35 | 1.77 | 5.46 | 1.89 | −55.23 |

| 3–18 | 58.80 | 1.91 | 1.59 | 6.64 | 2.27 | −51.94 |

| 3–22 | 68.00 | 1.70 | 1.84 | 6.93 | 1.55 | −58.38 |

| Section Mileage | Slope Angle α(°) | e1′(kPa) | e1(kPa) | e2′(kPa) | e2(kPa) |

|---|---|---|---|---|---|

| HMDK15 + 388 | 22.42 | 22.96 | 59.26 | 45.14 | 98.26 |

| HMDK15 + 520 | 12.70 | 19.65 | 32.86 | 43.33 | 64.43 |

| HMDK15 + 560 | 19.22 | 29.19 | 58.66 | 51.92 | 93.16 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, D.; Zhou, A.; Wang, L.; Chen, Y.; Ma, C. Strength Characteristics and In Situ Stress Measurement of Rock Cores from a Large Section Underground Station: A Case Study. Appl. Sci. 2022, 12, 10873. https://doi.org/10.3390/app122110873

Li D, Zhou A, Wang L, Chen Y, Ma C. Strength Characteristics and In Situ Stress Measurement of Rock Cores from a Large Section Underground Station: A Case Study. Applied Sciences. 2022; 12(21):10873. https://doi.org/10.3390/app122110873

Chicago/Turabian StyleLi, Diyuan, Aohui Zhou, Lichuan Wang, Yuda Chen, and Chunde Ma. 2022. "Strength Characteristics and In Situ Stress Measurement of Rock Cores from a Large Section Underground Station: A Case Study" Applied Sciences 12, no. 21: 10873. https://doi.org/10.3390/app122110873

APA StyleLi, D., Zhou, A., Wang, L., Chen, Y., & Ma, C. (2022). Strength Characteristics and In Situ Stress Measurement of Rock Cores from a Large Section Underground Station: A Case Study. Applied Sciences, 12(21), 10873. https://doi.org/10.3390/app122110873