Research on Key Factors of Sealing Performance of Combined Sealing Ring

Abstract

:1. Introduction

2. Structure Drawing, Material, and Simulation Method of the Combined Sealing Ring

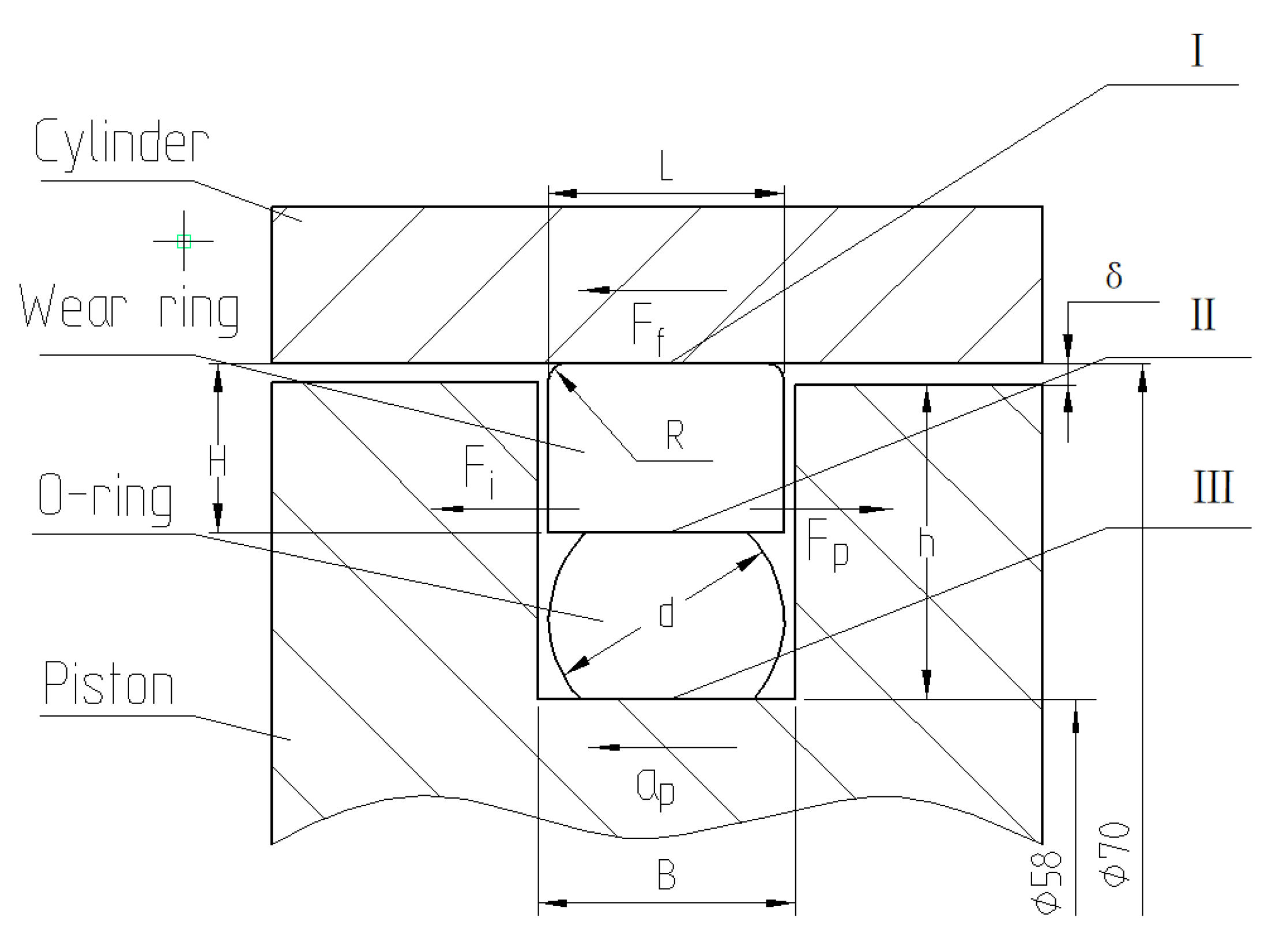

2.1. Assembly Structure Diagram of Combination Seal Ring

2.2. Material Table of Hydraulic Cylinder and Combined Sealing Ring

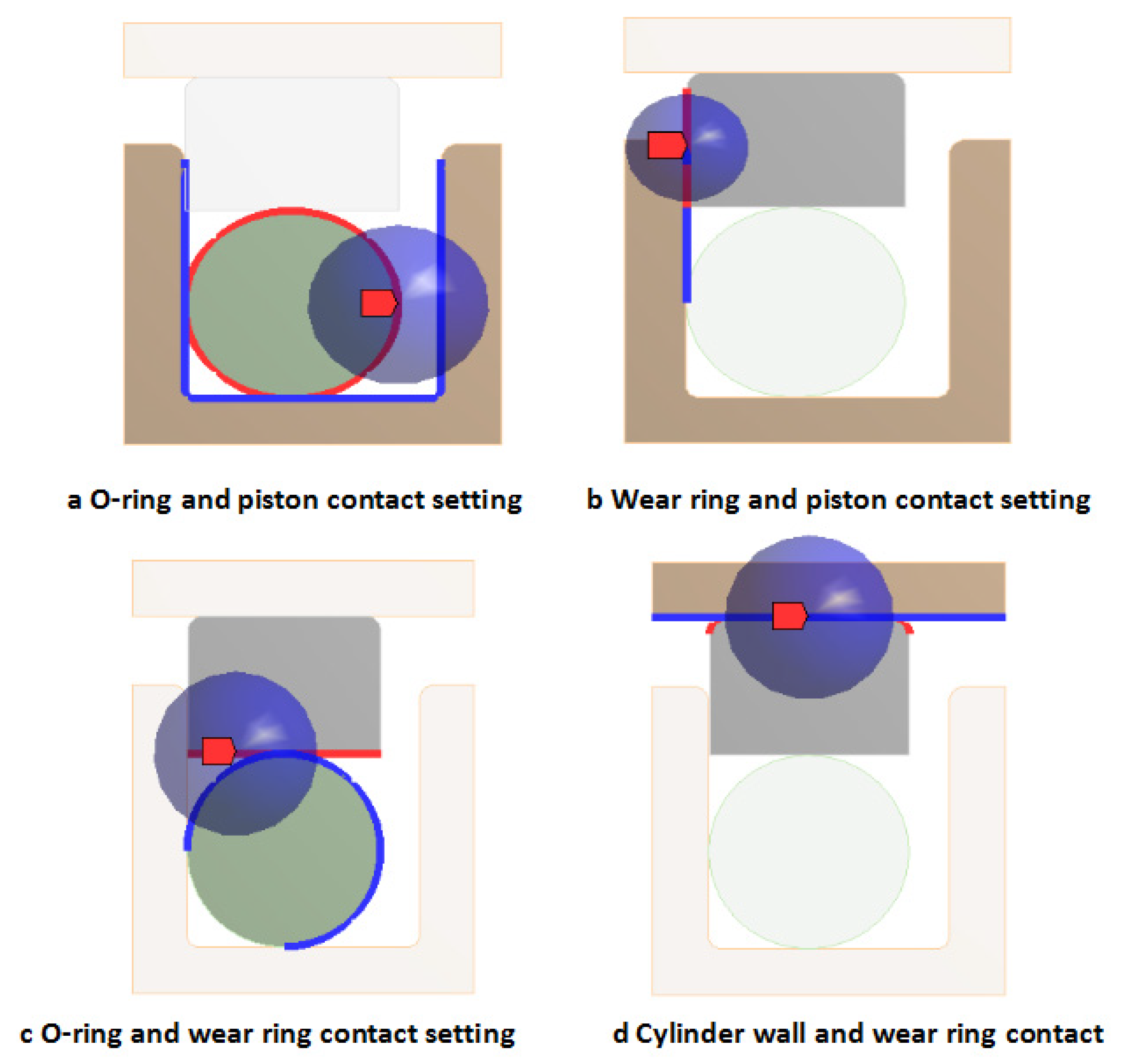

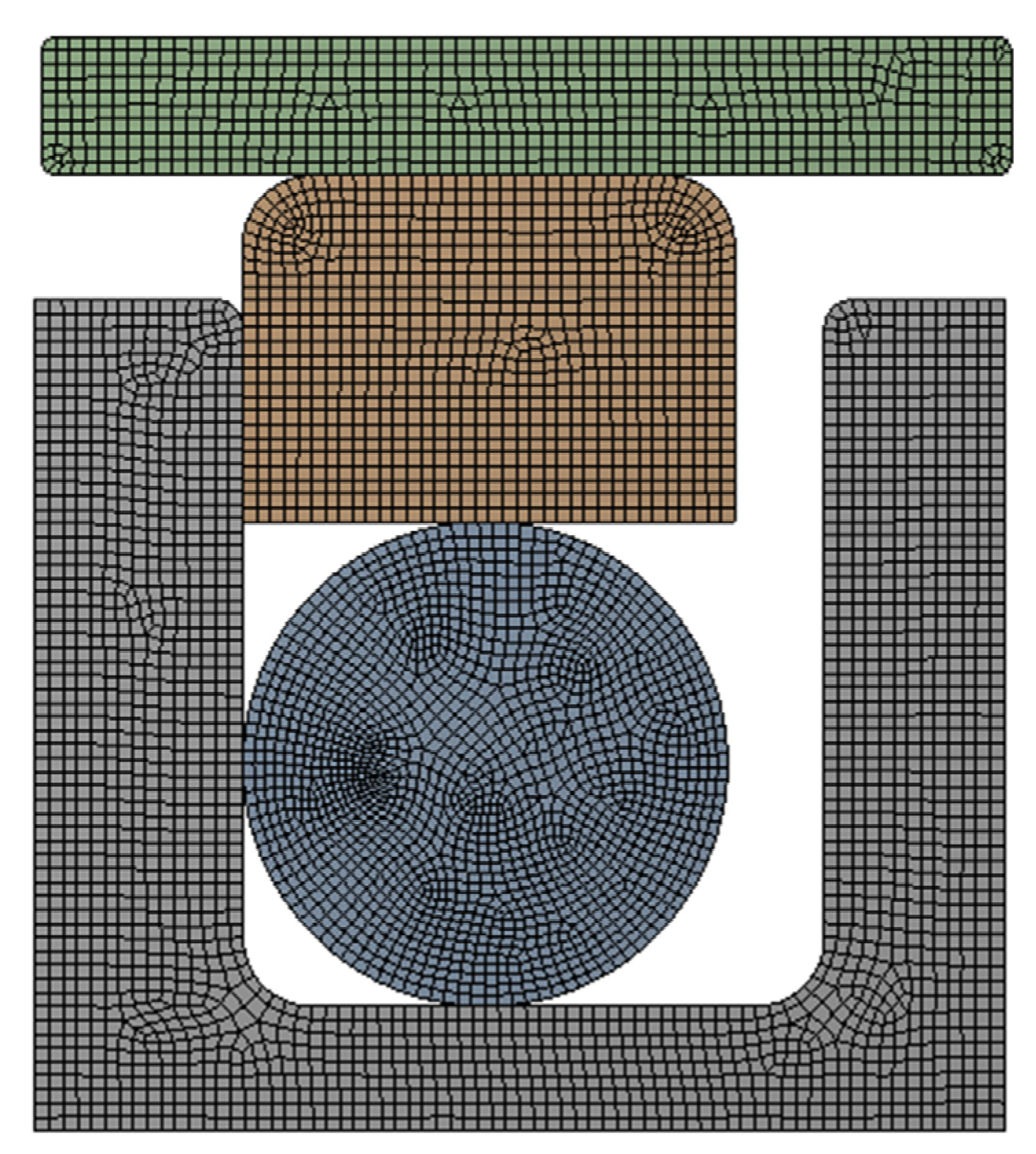

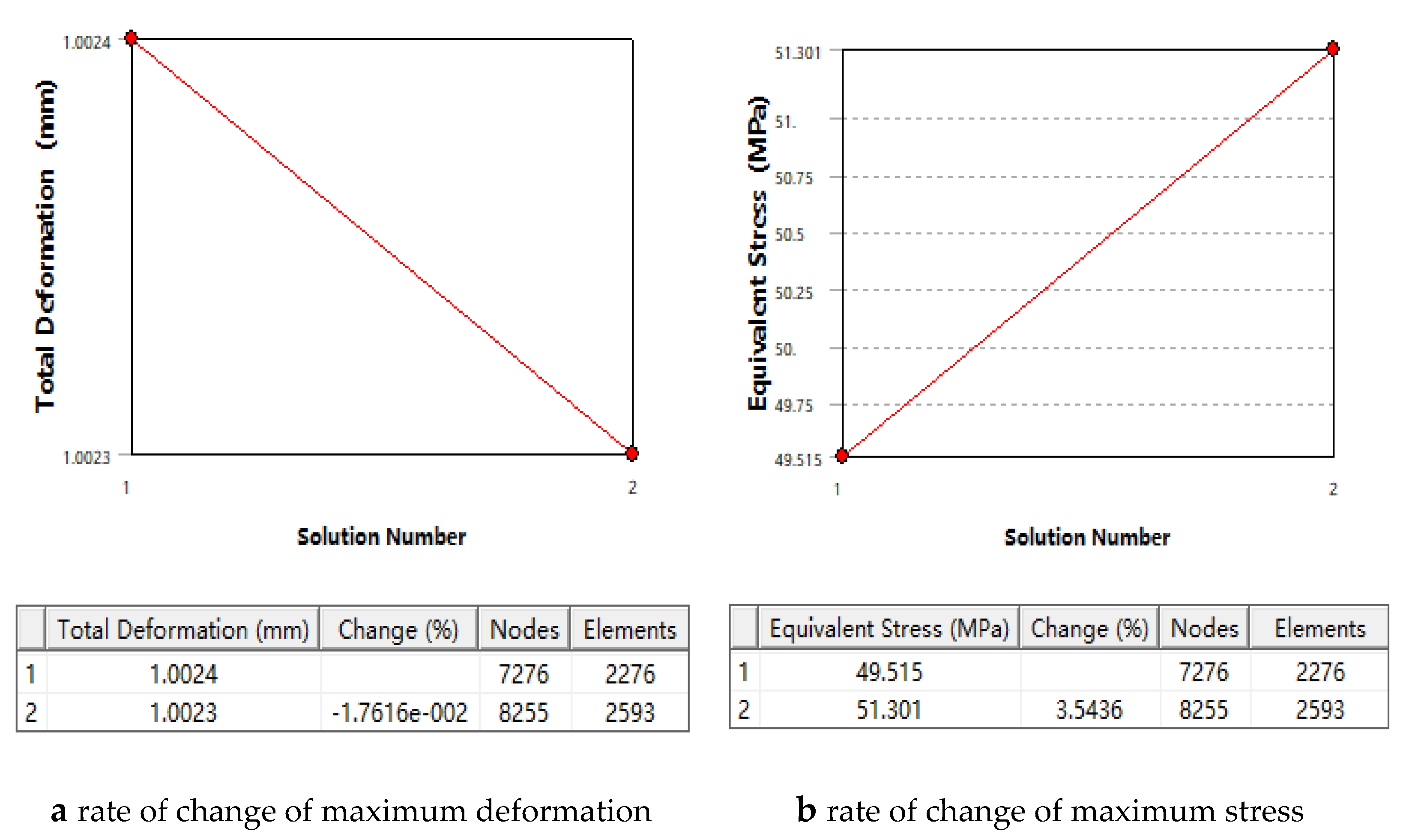

2.3. Define Contact and Meshing

2.4. Boundary Condition Setting and Simulation Method for Combined Sealing Ring

3. Analysis and Results

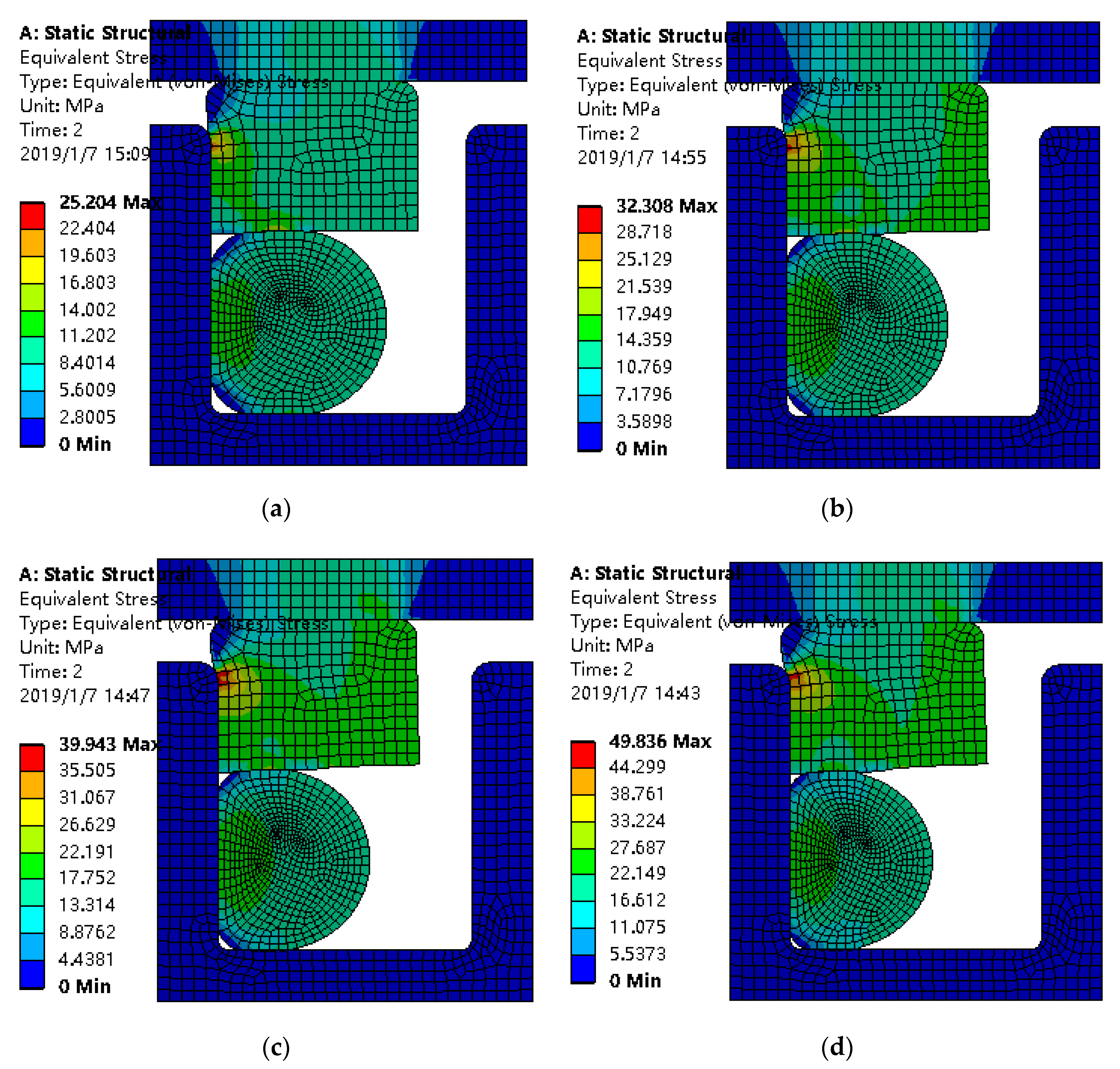

3.1. Effect of Operating Conditions on Sealing Performance

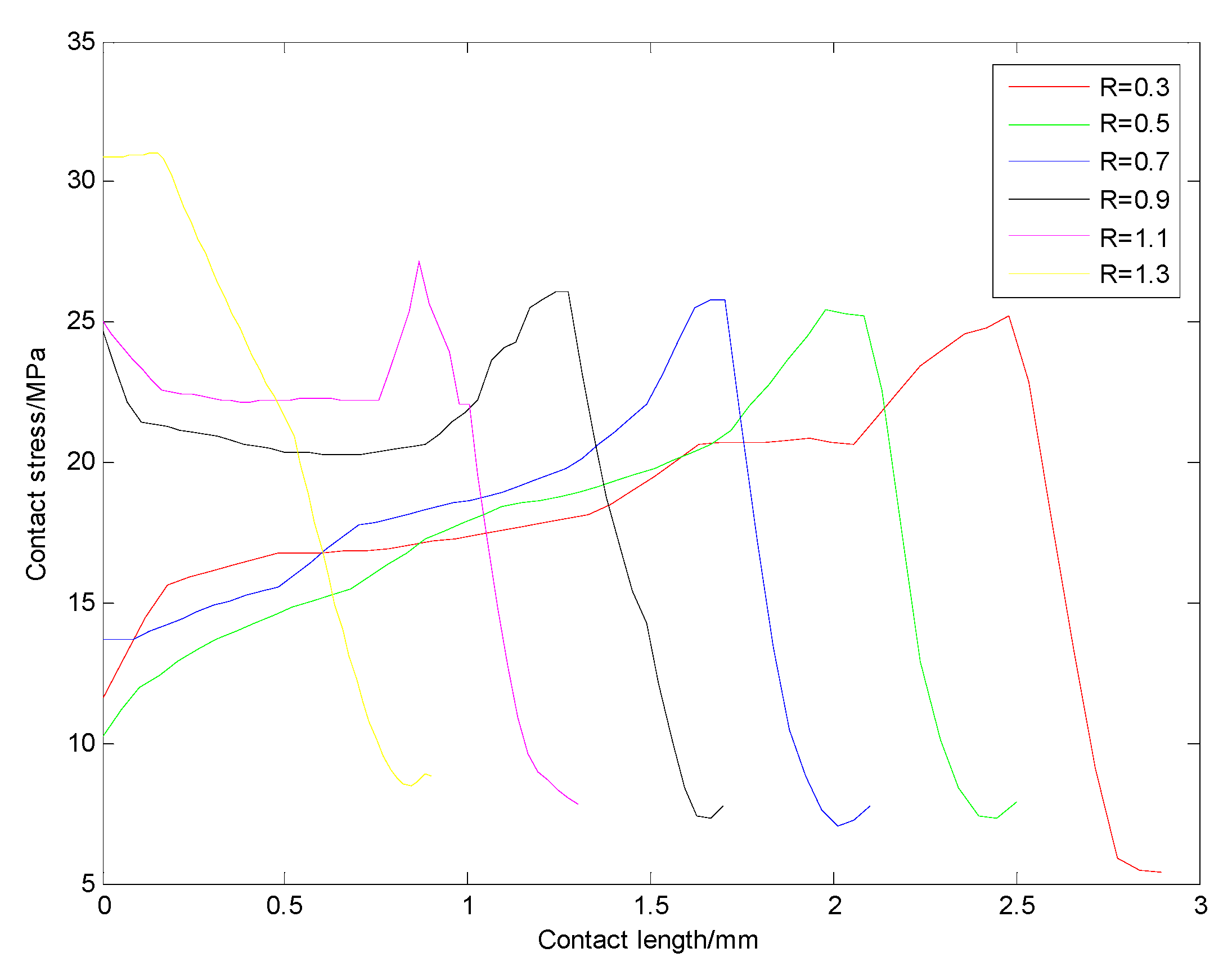

3.2. Effect of O-Ring Pre-Compression (Compression Ratio) on Sealing Performance

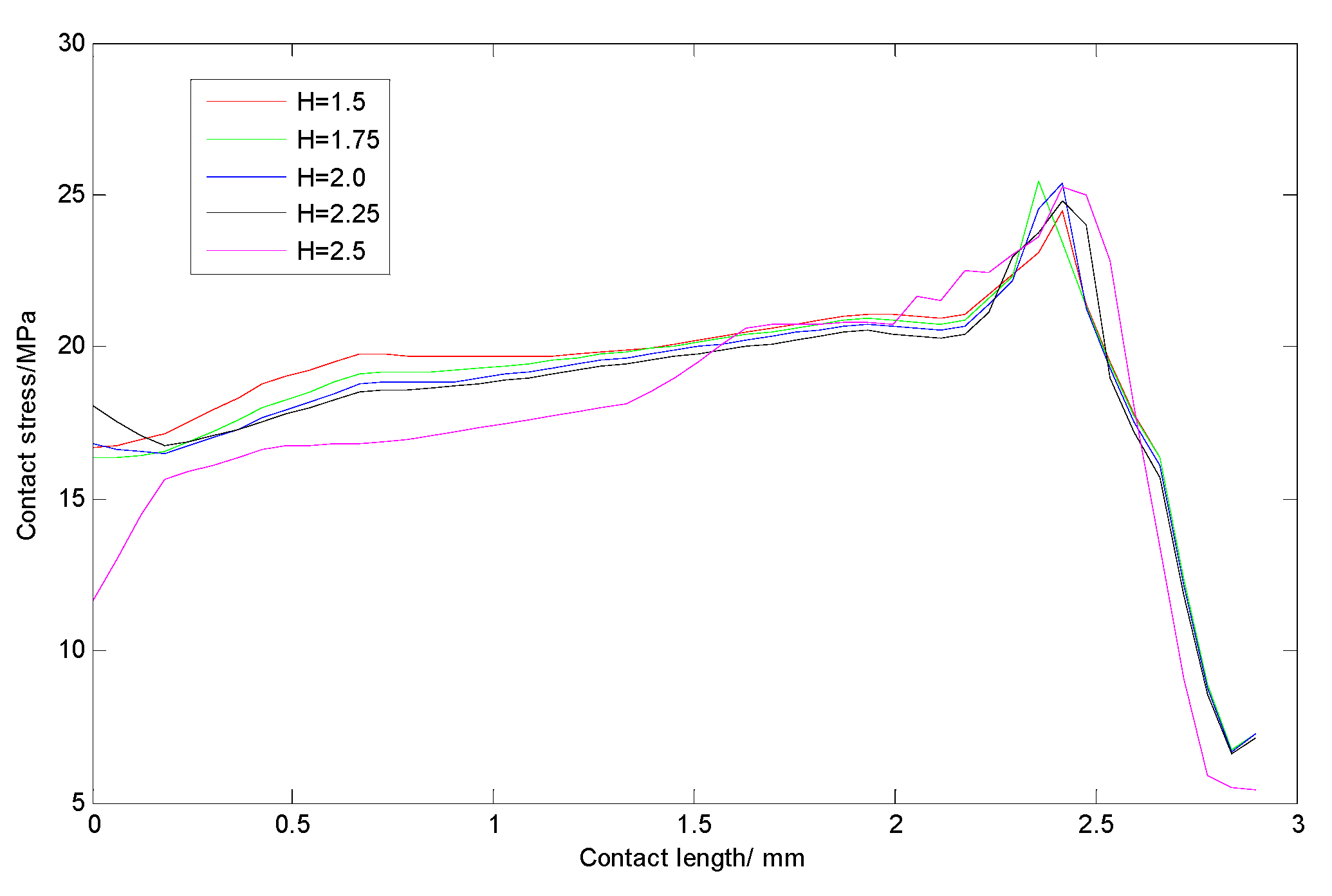

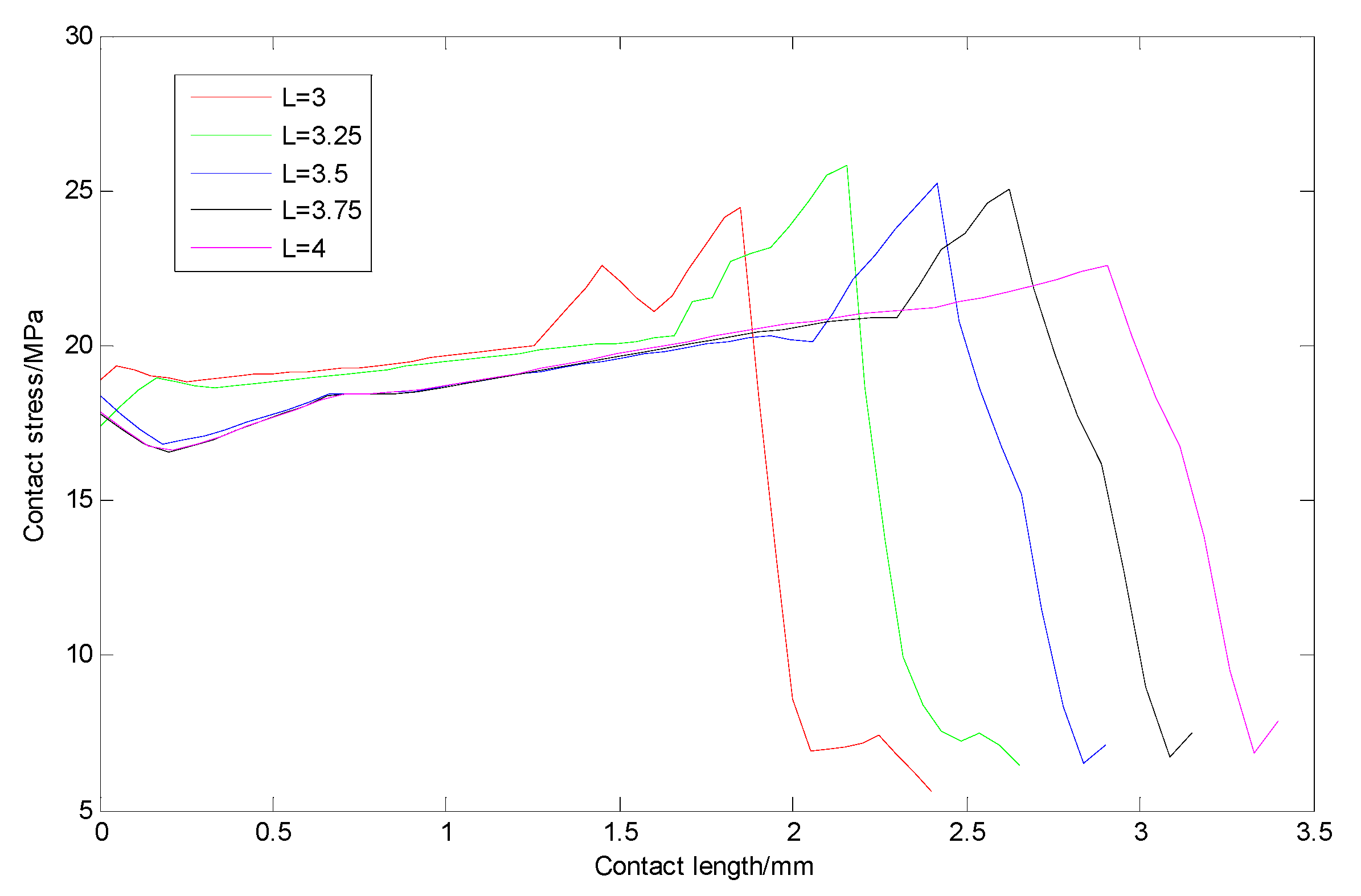

3.3. Effect of Wear Ring Structure Size on Sealing Performance

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hongbao, L. Research on the key technology of metal ring self-adaptive sealing. Hydraul. Pneum. 2014, 7, 31–33. [Google Scholar]

- Heipl, O.; Murrenhoff, H. Friction of hydraulic rod seals at high velocities. Tribol. Int. 2015, 85, 66–73. [Google Scholar] [CrossRef]

- Jun, J.; Yuan, G.; Liangcai, Z.; Congchang, Z.; Shuguang, F. Simulation analysis of the leakage of the gap seal hydraulic cylinder. Lubr. Seal. 2013, 38, 75–79. [Google Scholar]

- Yu-Ming, P.X.D.W.; Kun, H.X.L. State-of-the-Art and future development of sealing technology. Hydraul. Pneum. Seals 2009, 4, 4–11. [Google Scholar]

- Guibin, T. Advances in tribology onelastomer sealing and its future trends for the huge machinery. Tribology 2016, 36, 559–566. [Google Scholar]

- Ping, Y.T.; Sheng, Z.Y.; Hiatao, B. Sealingprinciple of new type combined seal and its application. Mach. Tool Hydraul. 2003, 1, 244–245. [Google Scholar]

- Bingqing, W.; Xudong, P.; Xiankai, M. Analysis of sealing performance of a hydraulic glyd-ring seal based on soft ehl model. Tribology 2018, 1, 75–83. [Google Scholar]

- Ylinen, A.; Marjamaki, H.; Makinen, J. A hydraulic cylinder model for multibody simulations. Comput. Struct. 2014, 138, 62–72. [Google Scholar] [CrossRef]

- He, Q.; Huang, W.; Liu, Y.; Liu, X.; Li, Y.; Wang, Y. Contact status between seal ring and its support: Crucial factor in hydrostatic mechanical face seal. Ind. Lubr. Tribol. 2019, 71, 885–892. [Google Scholar] [CrossRef]

- Mezghani, S.; Demirci, I.; Zahouani, H. The effect of groove texture pattems on piston-ring pack friction. Precis. Eng. 2012, 36, 210–217. [Google Scholar] [CrossRef] [Green Version]

- Johansson, S.; Nilsson, P.; Ohlsson, R. Experimmental friction evaluation of cylinder liner/piston ring contact. Wear 2011, 271, 625–633. [Google Scholar] [CrossRef]

- Kapsiz, M.; Durat, M.; Ficici, F. Friction and wear studies between cylinder liner and piston ring pair using Taguchi design method. Adv. Eng. Softw. 2011, 42, 595–603. [Google Scholar] [CrossRef]

- Grabon, W.; Koszela, W.; Pawlus, P. Improving teibological behaviour of piston ring-cylinder liner frictional pair by liner surface texturing. Tribol. Int. 2013, 61, 102–108. [Google Scholar] [CrossRef]

- Tran, X.B.; Hafizah, N.; Yanada, H. Modeling of dynamic frition behaviors of hydraulic cylinders. Mechatronics 2012, 22, 65–75. [Google Scholar] [CrossRef]

- Yang, C.Z.; Guo, Z.; Xu, C. Effect of grooved cylinder liner depths on the tribological performances of cylinder liner-piston ring. Ind. Lubr. Tribol. 2019, 72, 465–471. [Google Scholar] [CrossRef]

- Hingawe, N.D.; Bhore, S.P. Tribological performance of a surface textured meso scale air bearing. Ind. Lubr. Tribol. 2019, 72, 599–609. [Google Scholar] [CrossRef]

- Quan, S.; Guo, Y.; Liu, X.; Chen, Z.; Liu, Y. Analysis of lubrication and sealing performance on textured piston pair with multi-factor coupling. Ind. Lubr. Tribol. 2021; ahead-of-print. [Google Scholar] [CrossRef]

- Shen, C.; Khonsari, M.M. Tribological and Sealing Performance of Laser Pocketed Piston Rings in a Diesel Engine. Tribol. Lett. 2016, 64, 26. [Google Scholar] [CrossRef]

- Guo, Z.; Yuan, C.; Liu, P.; Peng, Z.; Yan, X. Study on Influence of Cylinder Liner Surface Texture on Lubrication Performance for Cylinder Liner–Piston Ring Components. Tribol. Lett. 2013, 51, 9–23. [Google Scholar] [CrossRef]

- Yan, C.; Jia, X.; Jiang, B.; Gao, L.; Guo, F. Influence of oil temperature on the lip seal’s performance. Tribol. Trans. 2019, 1, 739–746. [Google Scholar] [CrossRef]

- Jian, Z.; Qinghui, X.; Hong, J. Parametric modeling and sealing performance analysis of Glyy ring based on Abaqus/CAE. Hydropneumatics Seal. 2017, 37, 35–38. [Google Scholar]

- Bingqing, W.; Sancheng, Y.; Xiangkai, M. Sealing performance analysis of high-pressure star-shaped sealing ring. Fluid Mach. 2017, 8, 37–42. [Google Scholar]

- Brando, H.C.; Daniel, M.C.; Carlos, P.G.; Marlen, D.S.; Jhon, P.L. Influence of compression rings on the dynamic characteristics and sealing capacity of the combustion chamber in diesel engines. Lubricants 2021, 9, 25. [Google Scholar] [CrossRef]

- Foko, F.F.; Heimes, J.; Magyar, B.; Sauer, B. Friction Energy-Based Wear Simulation for Radial Shaft Sealing Ring. Lubricants 2020, 8, 15. [Google Scholar] [CrossRef] [Green Version]

- Kurt, M. Testing elastomers for hyperelastic material models in finite element analysis. Rubber Technol. Int. 1999, 88, 36–42. [Google Scholar]

- Dolce, M.; Cardone, D.; Croatto, F. Frictional Behavior of Steel-PTFE Interfaces for Seismic Isolation. Bull. Earthq. Eng. 2005, 3, 75–99. [Google Scholar] [CrossRef]

- Kong, J.; Liang, Z.; Zhu, T. Structural analysis and improvement measures of rubber track. Constr. Mach. Equip. 2002, 6, 27–30. [Google Scholar]

| Name | Material | Elastic Modulus | Poisson’s Ratio |

|---|---|---|---|

| Piston | ASTM (1.1191/C45E): 1045 (HRC55) | 210 GPa | 0.3 |

| Cylinder | ASTM (1.1191/C45E): 1045 (HRC55) | 210 GPa | 0.3 |

| Wear ring | PTFE (polytetrafluoroethylene) | 280 MPa | 0.4 |

| O-ring | nitrile-butadiene rubber | 7.8 MPa | 0.499 |

| Compression Ratio | 15% | 17.5% | 20% | 22.5% | 25% |

|---|---|---|---|---|---|

| Von-mises stress (MPa) | 28.991 | 23.562 | 25.373 | 19.367 | 20.633 |

| Contact stress at I (MPa) | 10.941 | 10.679 | 11.239 | 11.972 | 13.292 |

| Contact stress at II (MPa) | 16.53 | 17.426 | 18.575 | 19.067 | 19.731 |

| Contact stress at III (MPa) | 12.779 | 13.707 | 14.563 | 15.416 | 16.251 |

| Compression Ratio | 15% | 17.5% | 20% | 22.5% | 25% |

|---|---|---|---|---|---|

| Von-mises stress (MPa) | 36.633 | 36.05 | 38.527 | 35.73 | 31.777 |

| Contact stress at I (MPa) | 15.688 | 15.331 | 15.107 | 15.079 | 15.729 |

| Contact stress at II (MPa) | 21.127 | 21.936 | 22.247 | 23.848 | 24.533 |

| Contact stress at III (MPa) | 15.263 | 16.399 | 17.281 | 18.135 | 19.022 |

| Compression Ratio | 15% | 17.5% | 20% | 22.5% | 25% |

|---|---|---|---|---|---|

| Von-mises stress (Mpa) | 43.288 | 47.978 | 47.066 | 36.262 | 42.782 |

| Contact stress at I (Mpa) | 21.501 | 20.929 | 20.612 | 20.574 | 20.004 |

| Contact stress at II (Mpa) | 25.752 | 26.685 | 26.929 | 27.543 | 28.008 |

| Contact stress at III (Mpa) | 17.974 | 19.5 | 20.184 | 20.77 | 21.716 |

| Compression Ratio | 15% | 17.5% | 20% | 22.5% | 25% |

|---|---|---|---|---|---|

| Von-mises stress (Mpa) | 49.588 | 60.605 | 53.036 | 45.418 | 53.243 |

| Contact stress at I (Mpa) | 26.807 | 25.924 | 25.977 | 25.226 | 24.979 |

| Contact stress at II (Mpa) | 29.916 | 31.082 | 31.54 | 32.27 | 32.97 |

| Contact stress at III (Mpa) | 20.716 | 22.174 | 24.841 | 25.236 | 26.339 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, H.; Chen, X.; Chen, X.; Liu, H. Research on Key Factors of Sealing Performance of Combined Sealing Ring. Appl. Sci. 2022, 12, 714. https://doi.org/10.3390/app12020714

Cheng H, Chen X, Chen X, Liu H. Research on Key Factors of Sealing Performance of Combined Sealing Ring. Applied Sciences. 2022; 12(2):714. https://doi.org/10.3390/app12020714

Chicago/Turabian StyleCheng, Heming, Xinyuan Chen, Xiaolan Chen, and Hucheng Liu. 2022. "Research on Key Factors of Sealing Performance of Combined Sealing Ring" Applied Sciences 12, no. 2: 714. https://doi.org/10.3390/app12020714

APA StyleCheng, H., Chen, X., Chen, X., & Liu, H. (2022). Research on Key Factors of Sealing Performance of Combined Sealing Ring. Applied Sciences, 12(2), 714. https://doi.org/10.3390/app12020714