Mechanical and Thermomechanical Properties of Clay-Cowpea (Vigna Unguiculata Walp.) Husks Polyester Bio-Composite for Building Applications

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

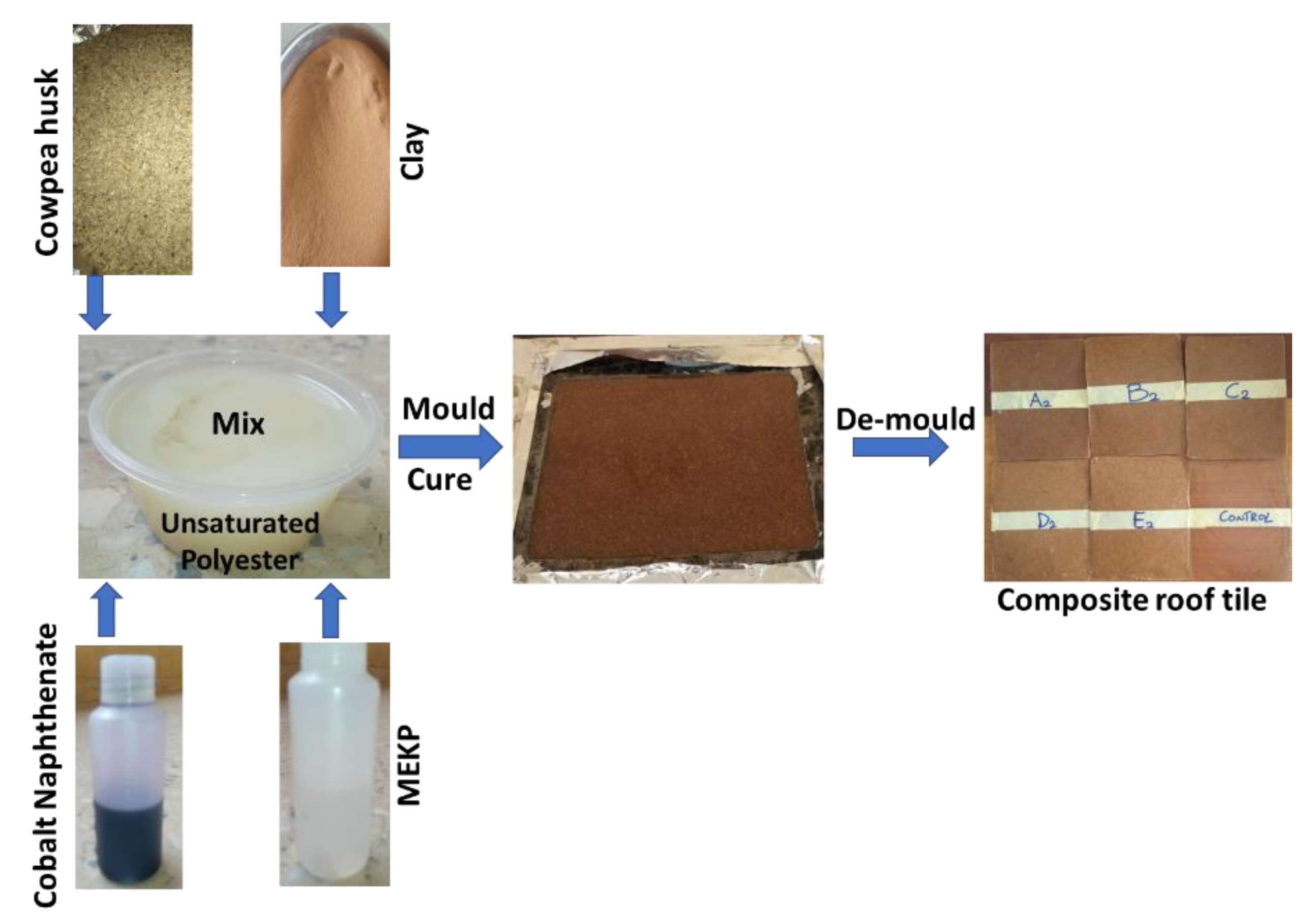

2.2. Composite Preparation and Experimental Design

2.3. Morphology and Mechanical Behaviour of the Composite

2.3.1. Morphological Examination

2.3.2. Tensile Test

2.3.3. Flexural Test

2.3.4. Hardness Test

2.3.5. Thermomechanical Analysis

2.3.6. Statistical Analysis of Responses

3. Results and Discussion

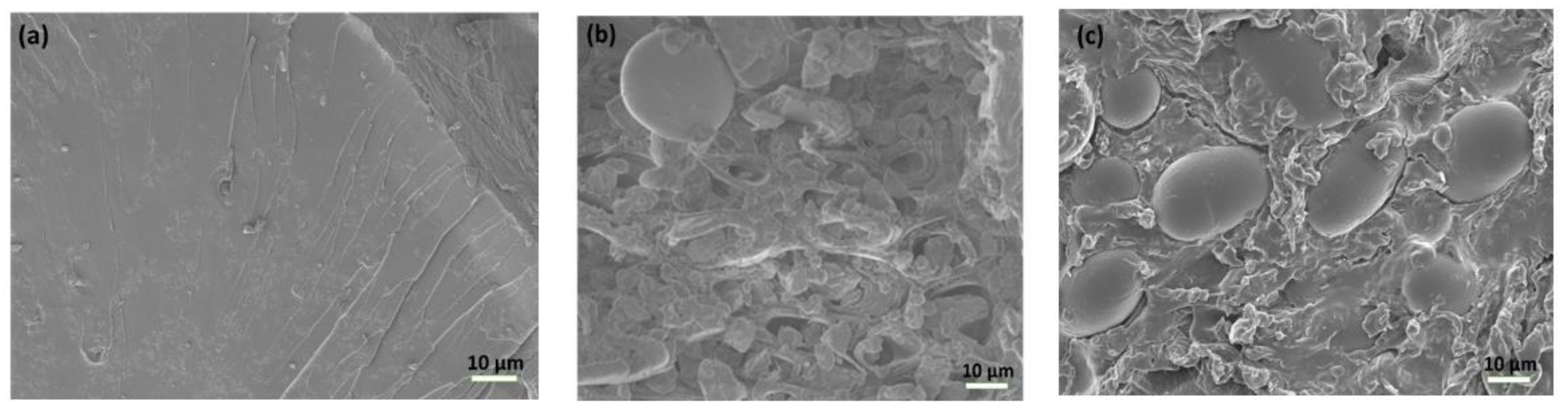

3.1. Morphological Analysis

3.2. Mechanical Properties

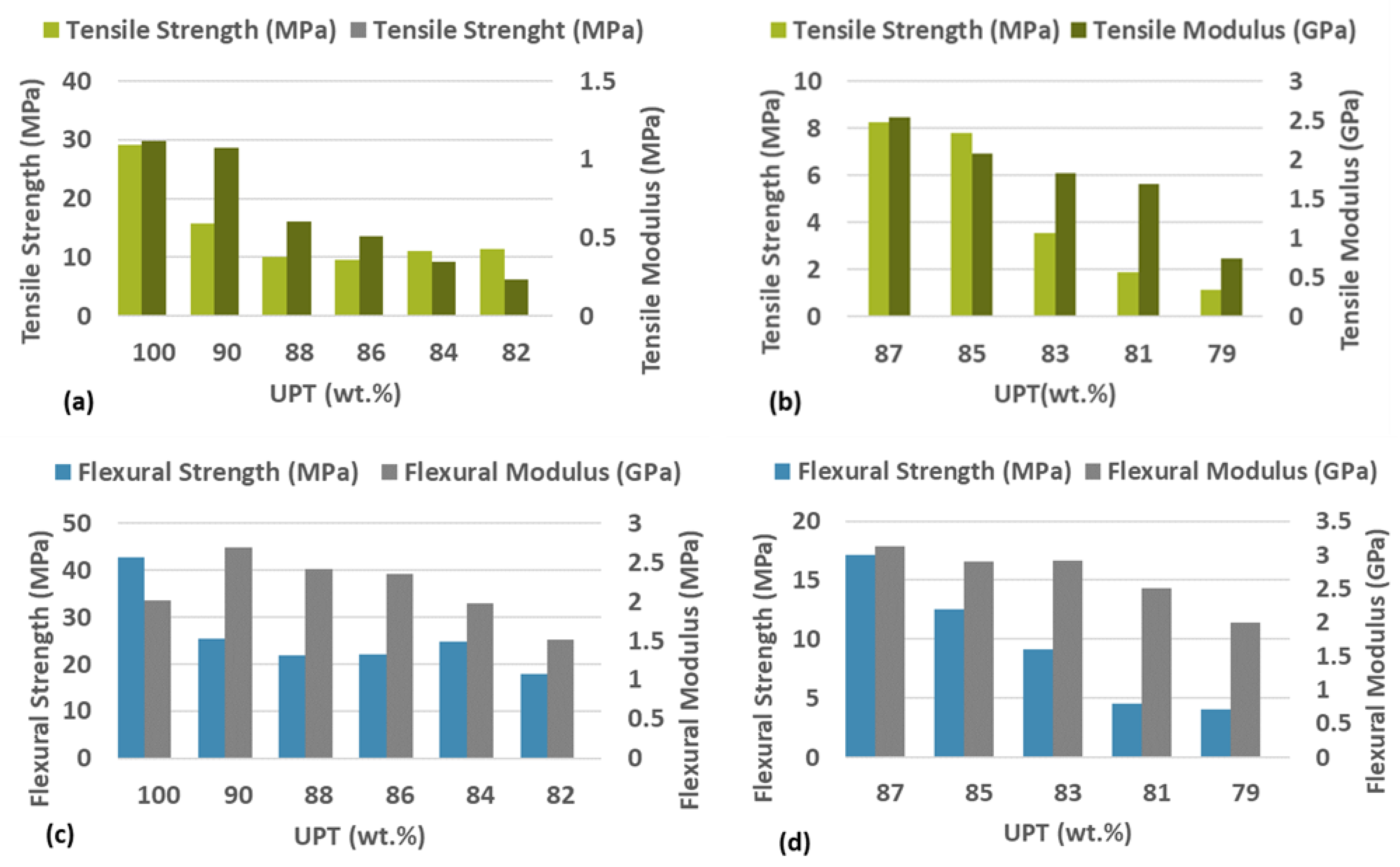

3.2.1. Tensile Properties

3.2.2. Flexural Properties

3.2.3. Hardness

3.3. Thermomechanical Properties

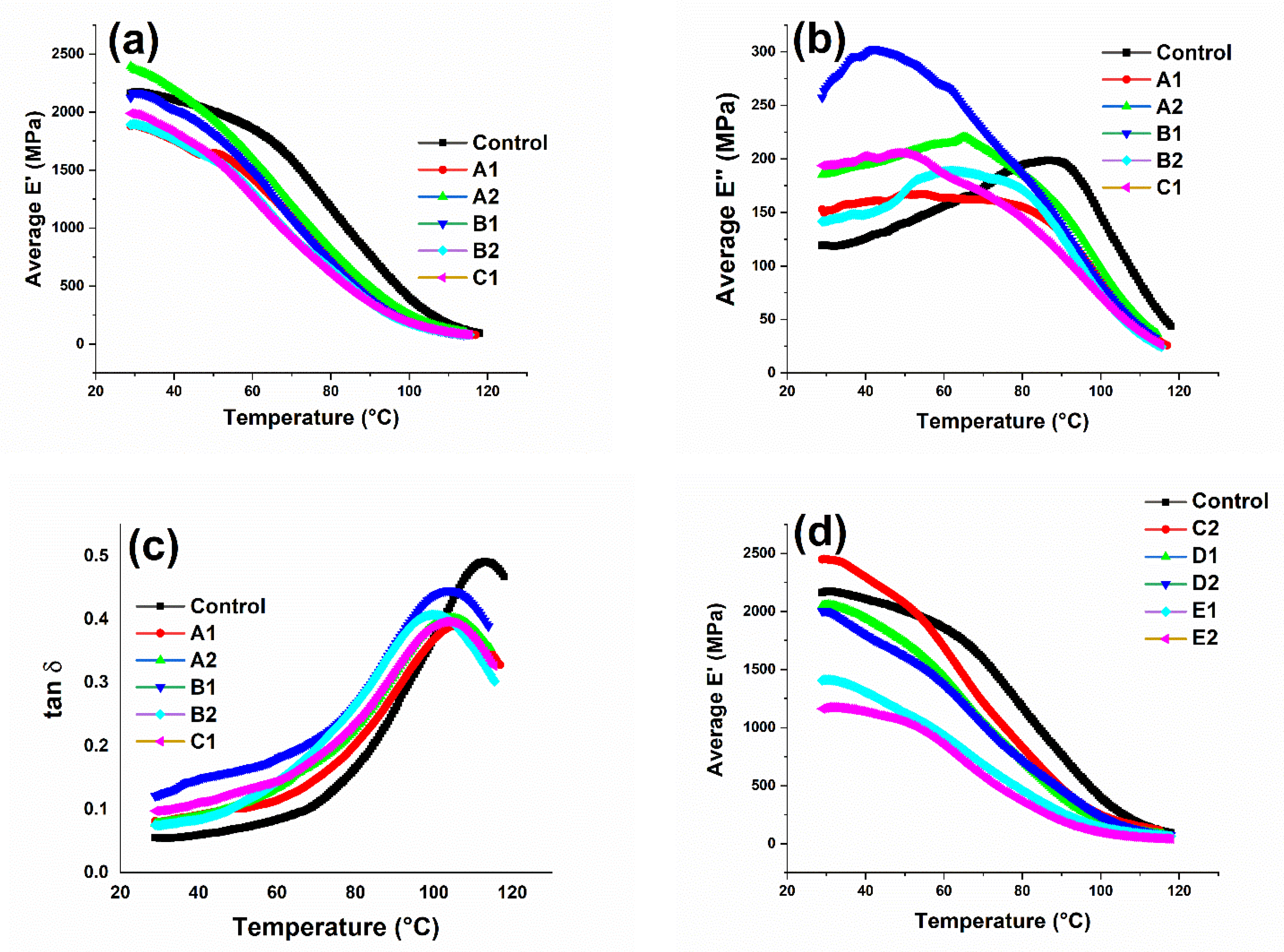

3.3.1. Storage Modulus (E’)

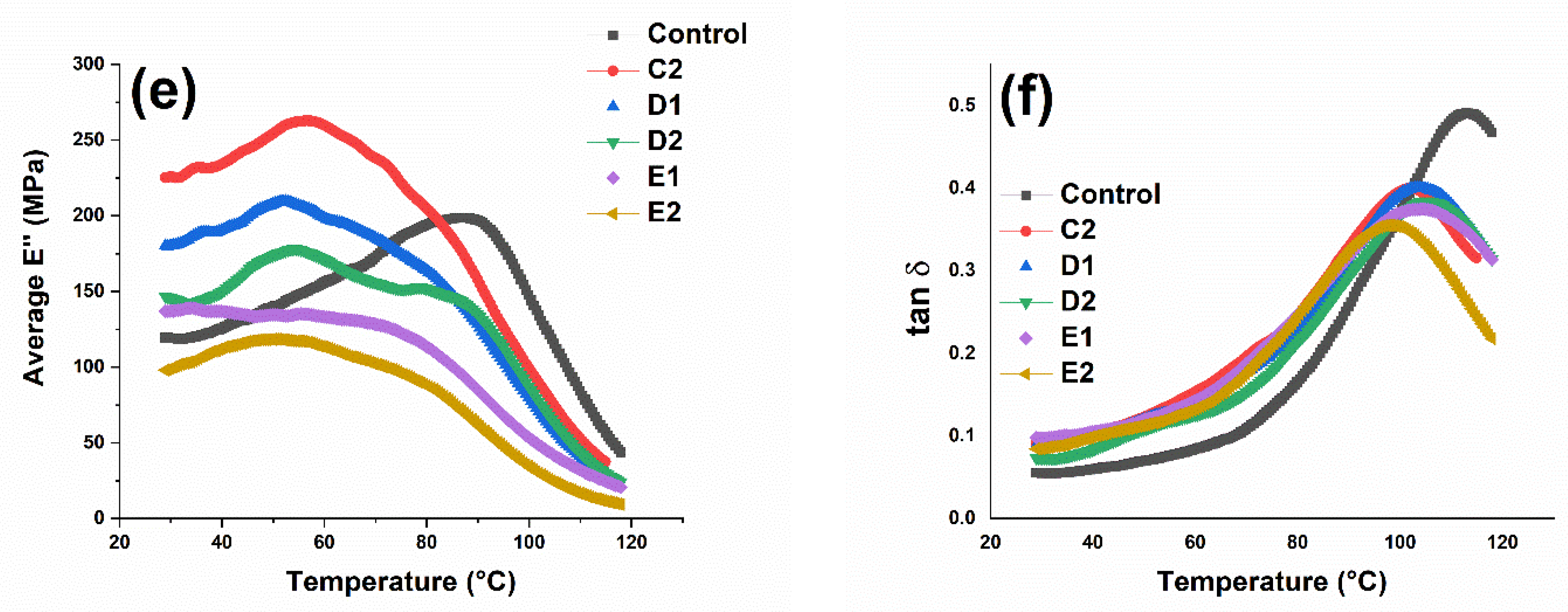

3.3.2. Loss Modulus (E”)

3.3.3. Damping Factor (tanδ)

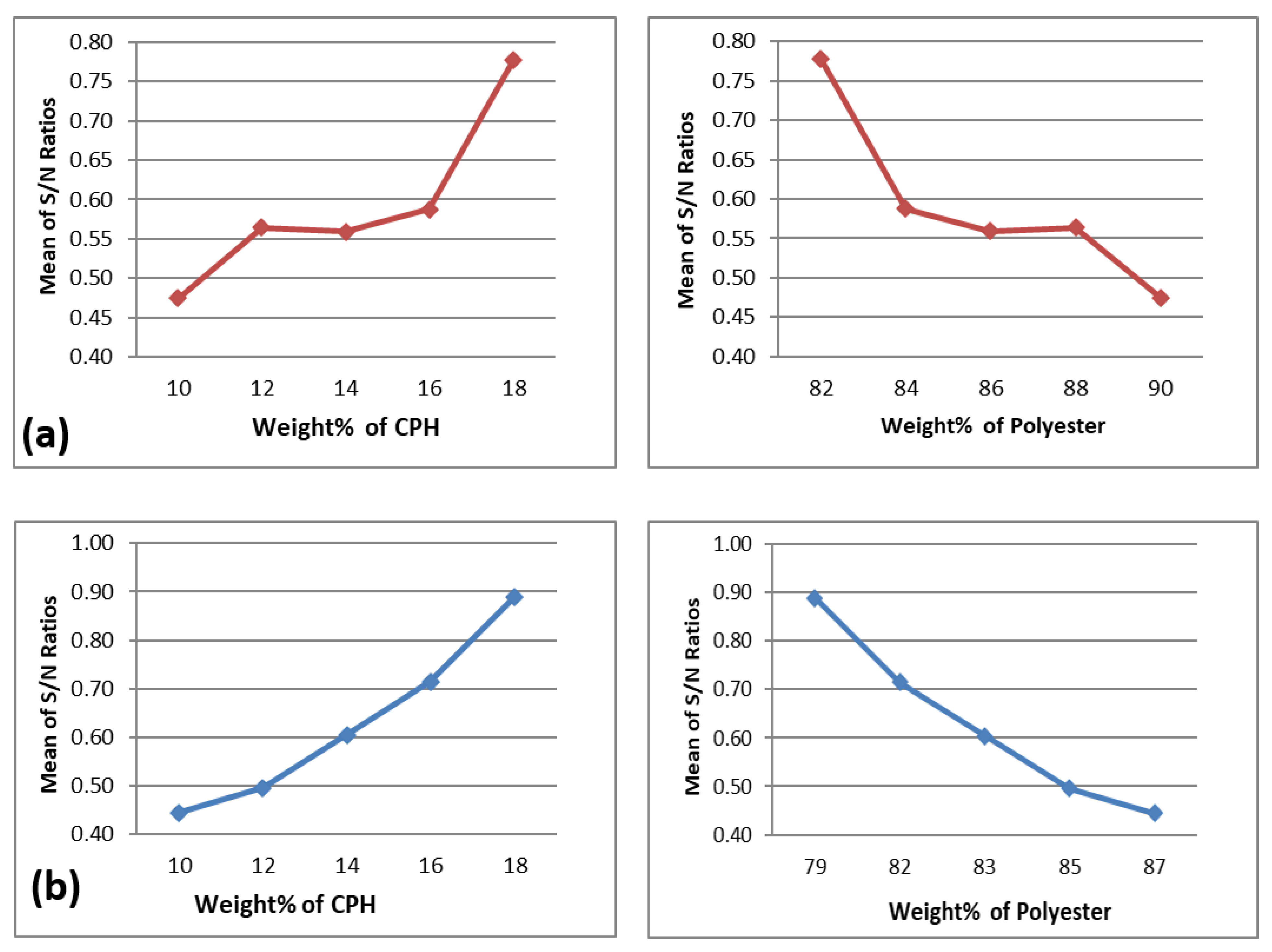

3.4. Statistical Optimization Results

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- World Health Organization. WHO Housing and Health Guidelines. 2018. Available online: http://www.who.int/phe%0Ahttp://apps.who.int/bookorders (accessed on 18 June 2021).

- Adenikinju, A.F. Bridging Housing Deficit in Nigeria: Lessons from Other Jurisdictions. Econ. Financ. Rev. 2019, 57, 17–36. [Google Scholar]

- Moorev, R.; Moore, E.A. Addressing Housing Deficit in Nigeria: Issues, Challenges and Prospects. CBN Econ. Financ. Rev. 2019, 57, 201–222. Available online: https://dc.cbn.gov.ng/efr/vol57/iss4/15/ (accessed on 18 June 2021).

- Reckford, T.M.J. 5 Ways to Tackle the Housing Crisis after COVID-19. 2020. Available online: https://www.weforum.org/agenda/2020/11/5-ways-to-tackle-the-housing-crisis-after-covid-19/ (accessed on 23 June 2021).

- Mcclelland, A.; Boyle, M.; Jarvis, S.; Arnold, T. Responding to COVID-19 in the Liverpool City Region: Introducing the Heseltine Institute’s COVID-19 Policy Briefs; University of Liverpool, Heseltine Institute for Public Policy, Practice and Place: Liverpool, UK, 2020; 8p. [Google Scholar] [CrossRef]

- Olugbenga, T.D.; Yusoff, N.; Aziz, N.A.; Baba, A.N. Unleashing the Potentials of Housing Sector in Nigeria as Perceived by Users. Int. J. Built Environ. Sustain. 2017, 4, 172–179. [Google Scholar] [CrossRef][Green Version]

- Ayedun, C.A.; Oluwatobi, A.O. Issues and Challenges Militating against the Sustainability of Affordable Housing Provision in Nigeria. Bus. Manag. Dyn. 2011, 1, 1–8. [Google Scholar]

- Mahamat, A.A.; Obianyo, I.I.; Ngayakamo, B.; Bih, N.L.; Ayeni, O.; Azeko, S.T.; Savastano, H. Alkali activation of compacted termite mound soil for eco-friendly construction materials. Heliyon 2021, 7, e06597. [Google Scholar] [CrossRef]

- Obianyo, I.I.; Mahamat, A.A.; Anosike-Francis, E.N.; Stanislas, T.T.; Geng, Y.; Onyelowe, K.C.; Odusanya, S.; Onwualu, A.P.; Soboyejo, A.B.O.; Obianyo, I. Performance of lateritic soil stabilized with combination of bone and palm bunch ash for sustainable building applications. Cogent Eng. 2011, 8, 1921673. [Google Scholar] [CrossRef]

- Ojo, E.B.; Mustapha, K.; Teixeira, R.S.; Savastano, H. Development of unfired earthen building materials using muscovite rich soils and alkali activators. Case Stud. Constr. Mater. 2019, 11, e00262. [Google Scholar] [CrossRef]

- Viel, M.; Collet, F.; Lanos, C. Chemical and multi-physical characterization of agro-resources’ by-product as a possible raw building material. Ind. Crops Prod. 2018, 120, 214–237. [Google Scholar] [CrossRef]

- Jannat, N.; Hussien, A.; Abdullah, B.; Cotgrave, A. Application of agro and non-agro waste materials for unfired earth blocks construction: A review. Constr. Build. Mater. 2020, 254, 119346. [Google Scholar] [CrossRef]

- Stanislas, T.T.; Komadja, G.C.; Ngasoh, O.F.; Obianyo, I.I.; Tendo, J.F.; Onwualu, P.A.; Junior, H.S. Performance and Durability of Cellulose Pulp-Reinforced Extruded Earth-based Composites. Arab. J. Sci. Eng. 2021, 46, 11153–11164. [Google Scholar] [CrossRef]

- Ngayakamo, B.H.; Bello, A.; Onwualu, A.P. Development of eco-friendly fired clay bricks incorporated with granite and eggshell wastes. Environ. Chall. 2020, 1, 100006. [Google Scholar] [CrossRef]

- Zhang, Y.; Pu, S.; Li, R.Y.M.; Zhang, J. Microscopic and mechanical properties of undistributed and remoulded red clay from Guiyang, China. Sci. Rep. 2020, 10, 18003. [Google Scholar] [CrossRef]

- Solis, M.; Silveira, S. Technologies for chemical recycling of household plastics—A technical review and TRL assessment. Waste Manag. 2020, 105, 128–138. [Google Scholar] [CrossRef]

- Economy, C. National Agreement on the Circular Economy. Government of The Netherlands; 2017. Available online: https://www.government.nl/documents/discussion-documents/2017/01/24/national-agreement-on-the-circular-economy (accessed on 2 July 2021).

- Azambuja, R.D.R.; de Castro, V.G.; Trianoski, R.; Iwakiri, S. Utilization of construction and demolition waste for particleboard production. J. Build. Eng. 2018, 20, 488–492. [Google Scholar] [CrossRef]

- Almeshal, I.; Tayeh, B.A.; Alyousef, R.; Alabduljabbar, H.; Mohamed, A.M.; Alaskar, A. Use of recycled plastic as fine aggregate in cementitious composites: A review. Constr. Build. Mater. 2020, 253, 119146. [Google Scholar] [CrossRef]

- Amziane, S. Overview on biobased building material made with plant aggregate. Sustain. Constr. Mater. Technol. 2016, 1, 31–38. [Google Scholar] [CrossRef]

- Olorunnisola, A.O. Development of Sustainable Building Materials from Agro-Industrial Wastes in Nigeria. Sustain. Constr. Build. Mater. 2019, 55–74. [Google Scholar] [CrossRef]

- Chen, J.; Li, C.; Ristovski, Z.; Milic, A.; Gu, Y.; Islam, M.S.; Wang, S.; Hao, J.; Zhang, H.; He, C.; et al. A review of biomass burning: Emissions and impacts on air quality, health and climate in China. Sci. Total Environ. 2017, 579, 1000–1034. [Google Scholar] [CrossRef] [PubMed]

- Kumar, P.; Joshi, L. Pollution Caused by Agricultural Waste Burning and Possible Alternate Uses of Crop Stubble: A Case Study of Punjab. Wasser Abfall 2019, 21, 51. [Google Scholar] [CrossRef]

- Yahaya, F. The Menace of Soot in Portharcourt. Indep. Newspapers Ltd. 2018. Available online: https://independent.ng/the-menace-of-soot-in-port-harcourt/ (accessed on 26 September 2021).

- Rees, N.; Wickham, A.; Choi, Y. Silent Suffocation in Africa: Air Pollution Is a Growing Menace, Affacting the Poorest Children the Most; United Nations Children’s Fund (UNICEF): New York, NY, USA, 2019; pp. 1–14. Available online: https://www.unicef.org/media/55081/file/Silent_suffocation_in_africa_air_pollution_2019.pdf (accessed on 26 September 2021).

- Guna, V.; Yadav, C.; Maithri, B.R.; Ilangovan, M.; Touchaleaume, F.; Saulnier, B.; Grohens, Y.; Reddy, N. Wool and coir fiber reinforced gypsum ceiling tiles with enhanced stability and acoustic and thermal resistance. J. Build. Eng. 2021, 41, 102433. [Google Scholar] [CrossRef]

- Akindapo, J.O.; Binni, U.A.; Sanusi, O.M. Development of Roofing Sheet Material Using Groundnut Shell Particles and Epoxy Resin as Composite Material. Am. J. Eng. Res. 2015, 4, 165–173. [Google Scholar]

- De Vecchi, A.; Valenza, A.; Colajanni, S.; Sanfilippo, E.; Fiore, V.; Volpe, A.L. Evaluation and application of opuntia ficus-indica panel. Acad. J. Civ. Eng. 2015, 33, 460–466. [Google Scholar] [CrossRef]

- Darsana, P.; Abraham, R.; Joseph, A.; Jasheela, A.; Binuraj, P.R.; Sarma, J. Development of Coir-fibre Cement Composite Roofing Tiles. Procedia Technol. 2016, 24, 169–178. [Google Scholar] [CrossRef]

- Pasilo, A.; Teeboonma, U. A Study of the Roofing Tiles Product Properties Manufactured from Agricultural Residues. In Proceedings of the 2018 International Conference and Utility Exhibition on Green Energy for Sustainable Development (ICUE), Phuket, Thailand, 24 October 2018; pp. 713–722. [Google Scholar] [CrossRef]

- Topacio, A.; Eng, M.; Arkuino, R.C.; Romano, K.V.; Jayvee, C. Development of Hydrophobic Composite Roof Tiles Utilizing Recycled Plastic Materials. Mater. Eng. Dev. 2018, 6, 1–3. [Google Scholar]

- Okafor, C.E.; Ihueze, C.C. Strength Analysis and Variation of Elastic Properties in Plantain Fiber/Polyester Composites for Structural Applications. In Composite and Nanocomposite Materials—From Knowledge to Industrial Applications; IntechOpen: London, UK, 2020; pp. 1–23. [Google Scholar] [CrossRef]

- Beaumont, P.W.; Soutis, C.; Hodzic, A. The Structural Integrity of Carbon Fiber Composites, 1st ed.; Springer: Cham, Switzerland, 2017. [Google Scholar] [CrossRef]

- Pei, X.; Han, W.; Ding, G.; Wang, M.; Tang, Y. Temperature effects on structural integrity of fiber-reinforced polymer matrix composites: A review. J. Appl. Polym. Sci. 2019, 136, 48206. [Google Scholar] [CrossRef]

- Atiqah, A.; Maleque, M.A.; Jawaid, M.; Iqbal, M. Development of kenaf-glass reinforced unsaturated polyester hybrid composite for structural applications. Compos. Part B Eng. 2014, 56, 68–73. [Google Scholar] [CrossRef]

- Saba, N.; Jawaid, M.; Alothman, O.Y.; Paridah, M.T. A review on dynamic mechanical properties of natural fibre reinforced polymer composites. Constr. Build. Mater. 2016, 106, 149–159. [Google Scholar] [CrossRef]

- Adeosun, S.O.; Akpan, E.I.; Akanegbu, H.A. Thermo-Mechanical Properties of Unsaturated Polyester Reinforced with Coconut and Snail Shells. Int. J. Compos. Mater. 2015, 5, 52–64. [Google Scholar] [CrossRef]

- Chee, S.S.; Jawaid, M.; Alothman, O.Y.; Fouad, H. Effects of nanoclay on mechanical and dynamic mechanical properties of bamboo/kenaf reinforced epoxy hybrid composites. Polymers 2021, 13, 395. [Google Scholar] [CrossRef]

- Hansen, B.; Borsoi, C.; Júnior, M.A.D.; Catto, A.L. Thermal and thermo-mechanical properties of polypropylene composites using yerba mate residues as reinforcing filler. Ind. Crops Prod. 2019, 140, 111696. [Google Scholar] [CrossRef]

- Lalit, R.; Mayank, P.; Ankur, K. Natural fibers and biopolymers characterization: A future potential composite material. J. Mech. Eng. 2018, 68, 33–50. [Google Scholar] [CrossRef]

- Yıldızhan, Ş.; Çalık, A.; Özcanlı, M.; Serin, H. Bio-composite materials: A short review of recent trends, mechanical and chemical properties, and applications. Eur. Mech. Sci. 2018, 2, 83–91. [Google Scholar] [CrossRef]

- Hills, C.D.; Tripathi, N.; Singh, R.S.; Carey, P.J.; Lowry, F. Valorisation of agricultural biomass-ash with CO2. Sci. Rep. 2020, 10, 13801. [Google Scholar] [CrossRef] [PubMed]

- Dhaliwal, J.S. “Natural Fibers: Applications.” Generation, Development and Modifications of Natural Fiber; Intech: Vienna, Austria, 2019; pp. 1–23. [Google Scholar] [CrossRef]

- Arulmurugan, S.; Venkateshwaran, N. Effect of nanoclay addition and chemical treatment on static and dynamic mechanical analysis of jute fibre composites. Polimeros 2019, 29, 4–11. [Google Scholar] [CrossRef]

- Hossen, M.F.; Hamdan, S.; Rahman, M.R.; Rahman, M.M.; Liew, F.K.; Lai, J.C. Effect of fiber treatment and nanoclay on the tensile properties of jute fiber reinforced polyethylene/clay nanocomposites. Fibers Polym. 2015, 16, 479–485. [Google Scholar] [CrossRef]

- Okonkwo, E.G.; Anabaraonye, C.N.; Egoigwe, S.V.; Okeke, P.E.; Whyte, F.G. Mechanical and thermomechanical properties of clay-Bambara nut shell polyester bio-composite. Int. J. Adv. Manuf. Technol. 2020, 108, 2483–2496. [Google Scholar] [CrossRef]

- Aderogba, K.A. Polymer Wastes and Management in Cities and Towns of Africa and Sustainable Environment: Nigeria and European Experiences. Soc. Sci. 2014, 3, 79. [Google Scholar] [CrossRef][Green Version]

- Gao, Y.; Romero, P.; Zhang, H.; Huang, M.; Lai, F. Unsaturated polyester resin concrete: A review. Constr. Build. Mater. 2019, 228, 116709. [Google Scholar] [CrossRef]

- ASTM D3039; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. ASTM International: West Conshohocken, PA, USA, 2017. [CrossRef]

- ASTM D790; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. American Society for Testing and Materials: Philadelphia, PA, USA, 2010.

- Saba, N.; Jawaid, M.; Sultan, M.T.H. An Overview of Mechanical and Physical Testing of Composite Materials; Woodhead Publishing: Cambridge, UK, 2018. [Google Scholar] [CrossRef]

- ASTM D5023-15; Standard Test Method for Plastics: Dynamic Mechanical Properties: In Flexure (Three-Point Bending). ASTM International: West Conshohocken, PA, USA, 2015. Available online: https://www.astm.org/ (accessed on 15 April 2021).

- Liu, S.; Lin, Y. Introduction to grey systems theory. J. Grey Syst. 1989, 1, 1–24. [Google Scholar] [CrossRef]

- Morán, J.; Granada, E.; Míguez, J.L.; Porteiro, J. Use of grey relational analysis to assess and optimize small biomass boilers. Fuel Process. Technol. 2006, 87, 123–127. [Google Scholar] [CrossRef]

- Kuo, Y.; Yang, T.; Huang, G.W. The use of a grey-based Taguchi method for optimizing multi-response simulation problems. Eng. Optim. 2008, 40, 517–528. [Google Scholar] [CrossRef]

- Abutu, J.; Lawal, S.A.; Ndaliman, M.B.; Lafia-Araga, R.A.; Adedipe, O.; Choudhury, I.A. Effects of process parameters on the properties of brake pad developed from seashell as reinforcement material using grey relational analysis. Eng. Sci. Technol. Int. J. 2018, 21, 787–797. [Google Scholar] [CrossRef]

- Mourad, A.H.I.; Abu-Jdayil, B.; Hassan, M. Mechanical behavior of Emirati red shale fillers/unsaturated polyester composite. SN Appl. Sci. 2020, 2, 497. [Google Scholar] [CrossRef]

- Halim, Z.A.A.; Yajid, M.A.M.; Idris, M.H.; Hamdan, H. Effects of silica aerogel particle sizes on the thermal–mechanical properties of silica aerogel–unsaturated polyester composites. Plast. Rubber Compos. 2017, 46, 184–192. [Google Scholar] [CrossRef]

- Adi, M.; Abu-jdayil, B.; al Ghaferi, F.; al Yahyaee, S.; al Jabri, M. Seawater-Neutralized Bauxite Residue–Polyester Composites as Insulating Construction Materials. Buildings 2021, 11, 20. [Google Scholar] [CrossRef]

- Abu-Jdayil, B.; Mourad, A.H.I.; Hussain, A. Investigation on the mechanical behavior of polyester-scrap tire composites. Constr. Build. Mater. 2016, 127, 896–903. [Google Scholar] [CrossRef]

- Abral, H.; Andriyanto, H.; Samera, R.; Sapuan, S.M.; Ishak, M.R. Mechanical Properties of Screw Pine (Pandanus Odoratissimus) Fibers-Unsaturated Polyester Composites. Polym.-Plast. Technol. Eng. 2012, 51, 500–506. [Google Scholar] [CrossRef]

- Reddy, K.O.; Shukla, M.; Maheswari, C.U.; Rajulu, A.V. Evaluation of mechanical behavior of chemically modified Borassus fruit short fiber/unsaturated polyester composites. J. Compos. Mater. 2012, 46, 2987–2998. [Google Scholar] [CrossRef]

- Fan, Y.; Lou, J.; Shinozaki, D.M. Microstructure dependent properties of polypropylene-clay nanocomposites. J. Appl. Polym. Sci. 2007, 103, 204–210. [Google Scholar] [CrossRef]

- Norizan, M.N.; Abdan, K.; Salit, M.S.; Mohamed, R. Physical, mechanical and thermal properties of sugar palm yarn fibre loading on reinforced unsaturated polyester composites. J. Phys. Sci. 2017, 28, 115–136. [Google Scholar] [CrossRef]

- del Pino, G.G.; Kieling, A.C.; Bezazi, A.; Boumediri, H.; de Souza, J.F.R.; Díaz, F.V.; Rivera, J.L.V.; Dehaini, J.; Panzera, T.H. Hybrid Polyester Composites Reinforced with Curauá Fibres and Nanoclays. Fibers Polym. 2020, 21, 399–406. [Google Scholar] [CrossRef]

- Shahroze, R.M.; Ishak, M.R.; Salit, M.S.; Leman, Z.; Asim, M.; Chandrasekar, M. Effect of organo-modified nanoclay on the mechanical properties of sugar palm fiber-reinforced polyester composites. BioResources 2018, 13, 7430–7444. [Google Scholar] [CrossRef]

- Reddy, T.R.K.; Kim, H.-J.; Park, J.-W. Renewable Biocomposite Properties and their Applications. In Composites from Renewable and Sustainable Materials; IntechOpen: London, UK, 2016; pp. 177–197. [Google Scholar] [CrossRef]

- Ali, M.F.; Hossain, M.S.; Moin, T.S.; Ahmed, S.; Chowdhury, A.M.S. Utilization of waste chicken feather for the preparation of eco-friendly and sustainable composite. Clean. Eng. Technol. 2021, 4, 100190. [Google Scholar] [CrossRef]

- Naveen, J.; Jawaid, M.; Zainudin, E.S.; Sultan, M.T.H.; Yahaya, R. Improved mechanical and moisture-resistant properties of woven hybrid epoxy composites by graphene nanoplatelets (GNP). Materials 2019, 12, 1249. [Google Scholar] [CrossRef]

- Medupin, R.O.; Abubakre, O.K.; Abdulkareem, A.S.; Muriana, R.A.; Kariim, I.; Bada, S.O. Thermal and physico-mechanical stability of recycled high density polyethylene reinforced with oil palm fibres. Eng. Sci. Technol. Int. J. 2017, 20, 1623–1631. [Google Scholar] [CrossRef]

- Kaymakci, A.; Ayrilmis, N. Composites: Part B Investigation of correlation between Brinell hardness and tensile strength of wood plastic composites. Compos. Part B 2014, 58, 582–585. [Google Scholar] [CrossRef]

- Kumar, S.S. Dataset on mechanical properties of natural fiber reinforced polyester composites for engineering applications. Data Br. 2020, 28, 105054. [Google Scholar] [CrossRef] [PubMed]

- Ala, E.S.W. Preparation of Polymeric Composites from Saturated Polyesters Glass Powder (Flourscent) and Study of its Mechanical Properties. Iraqi J. Mark. Res. Consum. Prot. 2021, 13, 131–139. [Google Scholar] [CrossRef]

- Kaymakci, A.; Ayrilmis, N.; Gulec, T. Surface properties and hardness of polypropylene composites filled with sunflower stalk flour. BioResources 2013, 8, 592–602. [Google Scholar] [CrossRef]

- Wypych, G. The Effect of Fillers on the Mechanical Properties of Filled Materials. In Handbook of Fillers, 4th ed.; Elsevier: Amsterdam, The Netherlands, 2016; pp. 467–531. [Google Scholar] [CrossRef]

- Kaundal, R. Utilization of Flyash as Filler Material in Hybrid Polyester Composites for Improved Thermo-Mechanical and Erosion Wear Behavior. Silicon 2018, 10, 2439–2452. [Google Scholar] [CrossRef]

- Palanivel, A.; Veerabathiran, A.; Duruvasalu, R.; Iyyanar, S.; Velumayil, R. Dynamic mechanical analysis and crystalline analysis of hemp fiber reinforced cellulose filled epoxy composite. Polimeros 2017, 27, 309–319. [Google Scholar] [CrossRef]

- Saba, N.; Safwan, A.; Sanyang, M.L.; Mohammad, F.; Pervaiz, M.; Jawaid, M.; Alothman, O.Y.; Sain, M. Thermal and dynamic mechanical properties of cellulose nanofibers reinforced epoxy composites. Int. J. Biol. Macromol. 2017, 102, 822–828. [Google Scholar] [CrossRef]

- Sreenivasan, V.S.; Rajini, N.; Alavudeen, A.; Arumugaprabu, V. Dynamic mechanical and thermo-gravimetric analysis of Sansevieria cylindrica/polyester composite: Effect of fiber length, fiber loading and chemical treatment. Compos. Part B Eng. 2015, 69, 76–86. [Google Scholar] [CrossRef]

- Pothan, L.A.; Thomas, S.; Groeninckx, G. The role of fibre/matrix interactions on the dynamic mechanical properties of chemically modified banana fibre/polyester composites. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1260–1269. [Google Scholar] [CrossRef]

- Binu, P.P.; George, K.E.; Vinodkumar, M.N. Effect of Nanoclay, Cloisite15A on the Mechanical Properties and Thermal Behavior of Glass Fiber Reinforced Polyester. Procedia Technol. 2016, 25, 846–853. [Google Scholar] [CrossRef]

- Jesuarockiam, N.; Jawaid, M.; Zainudin, E.S.; Sultan, M.T.H.; Yahaya, R. Enhanced thermal and dynamic mechanical properties of synthetic/natural hybrid composites with graphene nanoplateletes. Polymers 2019, 11, 1085. [Google Scholar] [CrossRef]

- Asim, M.; Jawaid, M.; Paridah, M.T.; Saba, N.; Nasir, M.; Shahroze, R.M. Dynamic and thermo-mechanical properties of hybridized kenaf/PALF reinforced phenolic composites. Polym. Compos. 2019, 40, 3814–3822. [Google Scholar] [CrossRef]

- Mallarino, S.; Chailan, J.F.; Vernet, J.L. Interphase study in cyanate/glass fibre composites using thermomechanical analysis and micro-thermal analysis. Compos. Sci. Technol. 2009, 69, 28–32. [Google Scholar] [CrossRef]

- Lazar, P.J.L.; Sengottuvelu, R.; Natarajan, E. Assessments of secondary reinforcement of epoxy matrix-glass fibre composite laminates through nanosilica (SiO2). Materials 2018, 11, 2186. [Google Scholar] [CrossRef] [PubMed]

| Samples | Designation | Composition (wt.%) | ||

|---|---|---|---|---|

| Polyester | Clay | CPH | ||

| 100% UPT | Control | 100 | 0 | 0 |

| 10% CPH | A1 | 90 | 0 | 10 |

| 12% CPH | A2 | 88 | 0 | 12 |

| 14% CPH | B1 | 86 | 0 | 14 |

| 16% CPH | B2 | 84 | 0 | 16 |

| 18% CPH | C1 | 82 | 0 | 18 |

| 10% CPH + 3% clay | C2 | 87 | 3 | 10 |

| 12% CPH + 3% clay | D1 | 85 | 3 | 12 |

| 14% CPH + 3% clay | D2 | 83 | 3 | 14 |

| 16% CPH + 3% clay | E1 | 81 | 3 | 16 |

| 18% CPH + 3% clay | E2 | 79 | 3 | 18 |

| Run | S/N for wt% UPT | S/N for Flexural Strength (MPa) | S/N for Flexural Modulus (GPa) | S/N for Tensile Strength (MPa) | S/N for Tensile Modulus (GPa) | S/N for Hardness (HV) |

|---|---|---|---|---|---|---|

| A1 | 39.0849 | 28.0830 | 8.5821 | 23.9373 | 0.6120 | 32.1491 |

| A2 | 38.8897 | 26.7612 | 7.6655 | 20.0563 | 4.1095 | 33.2797 |

| B1 | 38.6900 | 26.8957 | 7.4251 | 19.5224 | 3.5738 | 34.1292 |

| B2 | 38.4856 | 27.8820 | 5.9025 | 20.8279 | 2.5551 | 34.3866 |

| C1 | 38.2763 | 25.0861 | 3.5853 | 21.0884 | 1.8052 | 34.9436 |

| Run | S/N for wt% UPT | S/N for Flexural Strength (MPa) | S/N for Flexural Modulus (GPa) | S/N for Tensile Strength (MPa) | S/N for Tensile Modulus (GPa) | S/N for Hardness (HV) |

|---|---|---|---|---|---|---|

| C2 | 38.7904 | 18.3291 | 8.0864 | 24.6701 | 9.8914 | 32.1491 |

| D1 | 38.5884 | 17.8530 | 6.3613 | 21.9729 | 9.2510 | 33.2797 |

| D2 | 38.3816 | 10.9555 | 5.2490 | 19.1808 | 9.2838 | 34.1292 |

| E1 | 38.1697 | 5.4368 | 4.5577 | 13.0449 | 7.9588 | 34.3866 |

| E2 | 37.9525 | 1.0616 | −2.6154 | 12.1919 | 5.9771 | 34.9436 |

| Run Order | GRC for wt% UPT | GRC for Flexural Strength (MPa) | GRC for Flexural Modulus (GPa) | GRC for Tensile Strength (MPa) | GRC for Tensile Modulus (GPa) | GRC for Hardness (HV) | GRC for GR*grade |

|---|---|---|---|---|---|---|---|

| Xo | 1.0000 | 1.0000 | 1.0000 | 1.0000 | 1.0000 | 1.0000 | - |

| A1 | 1.000 | 1.000 | 1.000 | 1.000 | 0.333 | 0.333 | 0.778 |

| A2 | 0.674 | 0.531 | 0.732 | 0.363 | 0.771 | 0.456 | 0.588 |

| B1 | 0.506 | 0.558 | 0.683 | 0.333 | 0.642 | 0.632 | 0.559 |

| B2 | 0.403 | 0.882 | 0.483 | 0.415 | 0.487 | 0.715 | 0.564 |

| C1 | 0.333 | 0.333 | 0.333 | 0.437 | 0.413 | 1.000 | 0.475 |

| Run Order | GRC for wt% UPT | GRC for Flexural Strength (MPa) | GRC for Flexural Modulus (GPa) | GRC for Tensile Strength (MPa) | GRC for Tensile Modulus (GPa) | GRC for Hardness (HV) | GRC for GR*grade |

|---|---|---|---|---|---|---|---|

| Xo | 1.0000 | 1.0000 | 1.0000 | 1.0000 | 1.0000 | 1.0000 | - |

| C2 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 0.333 | 0.889 |

| D1 | 0.675 | 0.948 | 0.756 | 0.698 | 0.753 | 0.456 | 0.714 |

| D2 | 0.506 | 0.539 | 0.653 | 0.532 | 0.763 | 0.632 | 0.604 |

| E1 | 0.403 | 0.401 | 0.603 | 0.349 | 0.503 | 0.715 | 0.496 |

| E2 | 0.333 | 0.333 | 0.333 | 0.333 | 0.333 | 1.000 | 0.444 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Anosike-Francis, E.N.; Ubi, P.A.; Obianyo, I.I.; Kalu-Uka, G.M.; Bello, A.; Ofem, M.I.; Olorunnisola, A.O.; Onwualu, A.P. Mechanical and Thermomechanical Properties of Clay-Cowpea (Vigna Unguiculata Walp.) Husks Polyester Bio-Composite for Building Applications. Appl. Sci. 2022, 12, 713. https://doi.org/10.3390/app12020713

Anosike-Francis EN, Ubi PA, Obianyo II, Kalu-Uka GM, Bello A, Ofem MI, Olorunnisola AO, Onwualu AP. Mechanical and Thermomechanical Properties of Clay-Cowpea (Vigna Unguiculata Walp.) Husks Polyester Bio-Composite for Building Applications. Applied Sciences. 2022; 12(2):713. https://doi.org/10.3390/app12020713

Chicago/Turabian StyleAnosike-Francis, Esther Nneka, Paschal Ateb Ubi, Ifeyinwa Ijeoma Obianyo, Godwin Mong Kalu-Uka, Abdulhakeem Bello, Michael Ikpi Ofem, Abel Olajide Olorunnisola, and Azikiwe Peter Onwualu. 2022. "Mechanical and Thermomechanical Properties of Clay-Cowpea (Vigna Unguiculata Walp.) Husks Polyester Bio-Composite for Building Applications" Applied Sciences 12, no. 2: 713. https://doi.org/10.3390/app12020713

APA StyleAnosike-Francis, E. N., Ubi, P. A., Obianyo, I. I., Kalu-Uka, G. M., Bello, A., Ofem, M. I., Olorunnisola, A. O., & Onwualu, A. P. (2022). Mechanical and Thermomechanical Properties of Clay-Cowpea (Vigna Unguiculata Walp.) Husks Polyester Bio-Composite for Building Applications. Applied Sciences, 12(2), 713. https://doi.org/10.3390/app12020713