Property Analysis of Double-Sided Composite Waterproofing Sheet for Simultaneous Application on Asphalt Concrete and Latex-Modified Concrete Pavements for Bridge Decks

Abstract

:1. Introduction

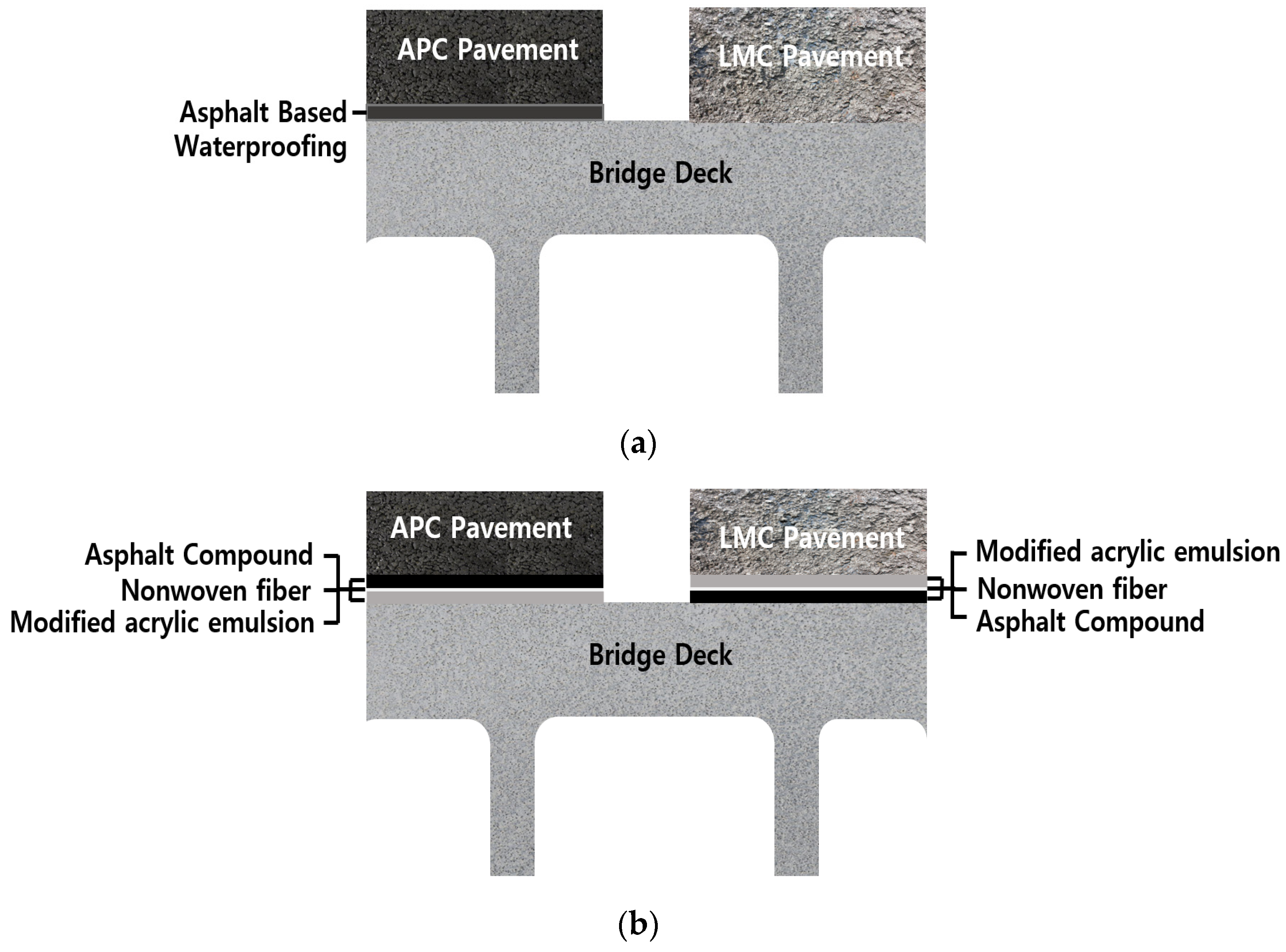

2. Properties and Test Methods of Newly Proposed Waterproofing Sheet and Layer

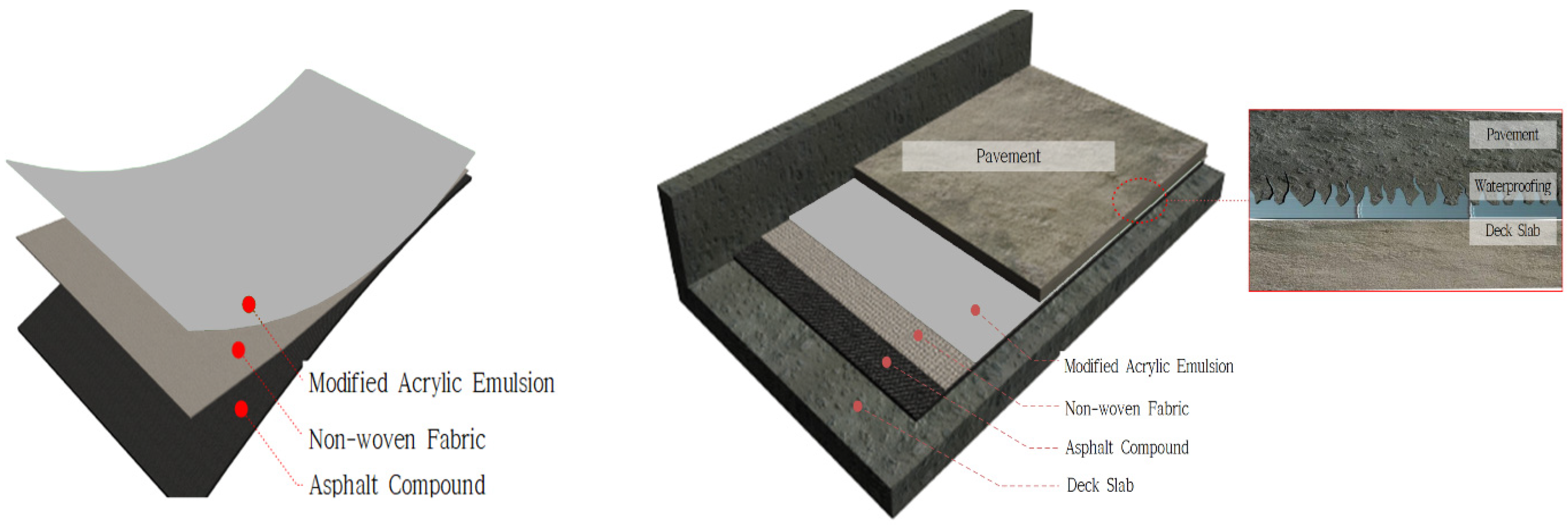

2.1. Properties of Newly Proposed Composite Waterproofing Sheet

2.1.1. A Double-Side Bonding Waterproofing Sheet

2.1.2. Properties of Modified Latex Acrylic Emulsion

2.1.3. Required Physical Properties and Evaluation Items of Waterproofing Sheet

2.2. Preparation of Pavement and Deck Concrete Materials

2.3. Test Methods for Performance Evaluation of Waterproofing Layer Applied to Pavement Layer

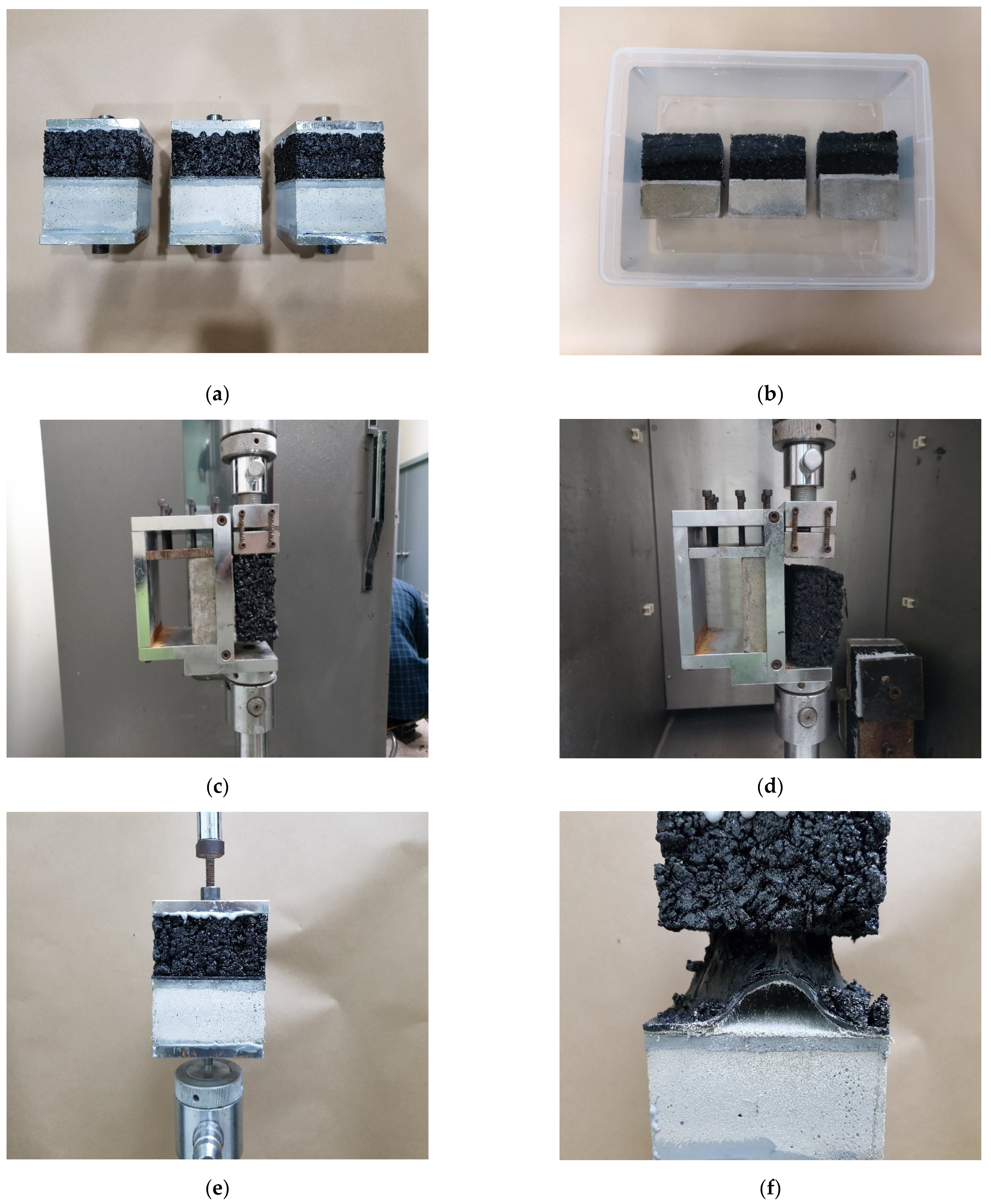

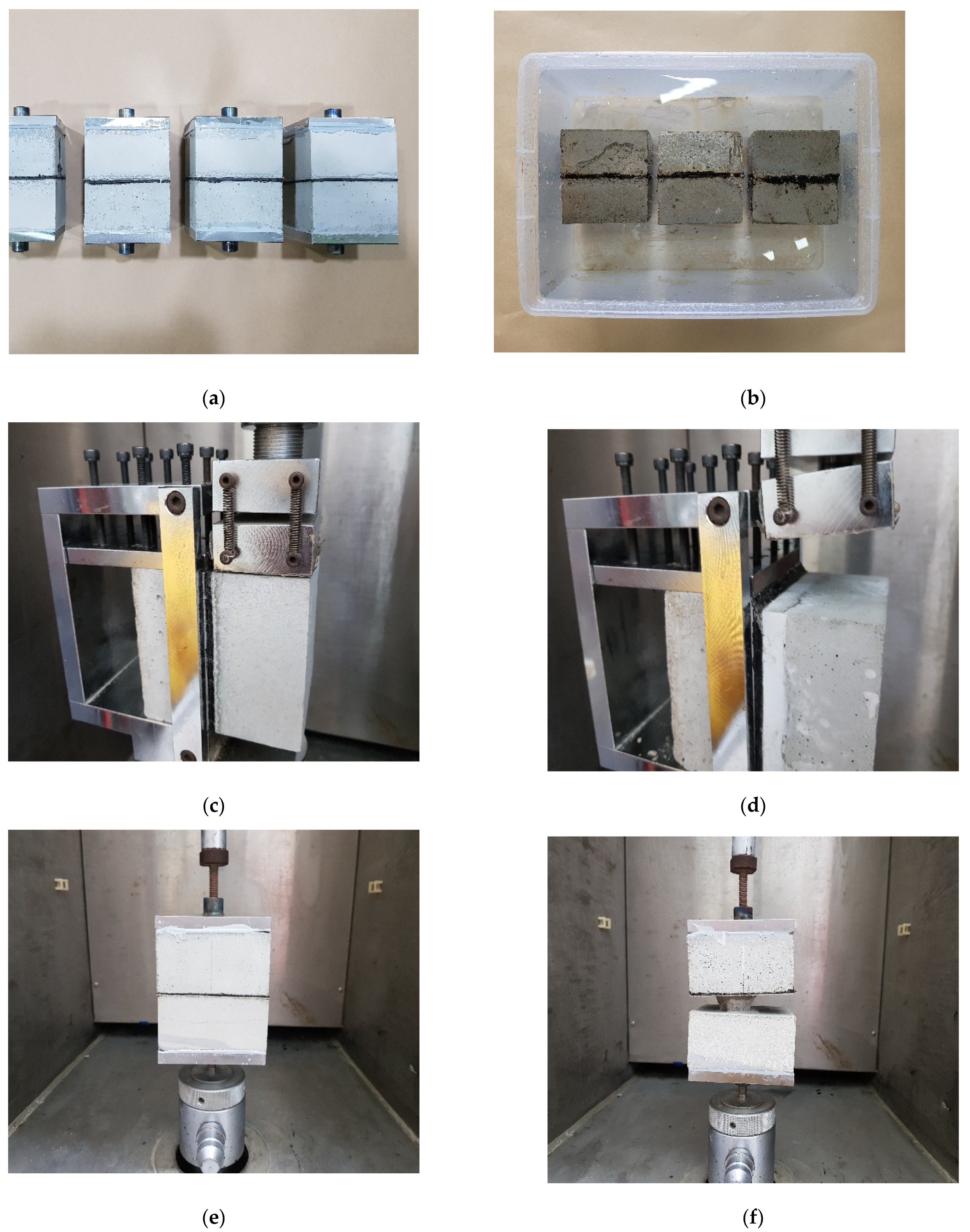

2.3.1. Specimen Preparation and Test Methods of Waterproofing Sheet

- (1)

- Specimen fabrication

- (2)

- Test method

2.3.2. Performance Evaluation Items and Quality Standard of Waterproofing Layer between Pavement and Bridge Deck Concrete

3. Evaluation Results and Considerations

3.1. Performance of Double-Sided Bonding Waterproofing Sheet

3.1.1. Basic Property Test Results

3.1.2. Consideration

3.2. Performance Properties of Waterproofing Sheet after Construction of APC or LMC Pavement Layer

3.2.1. Effect of APC Pavement Layer

- (1)

- Test results

- (2)

- Consideration

3.2.2. Effect of LMC Pavement Layer

- (1)

- Test results

- (2)

- Consideration

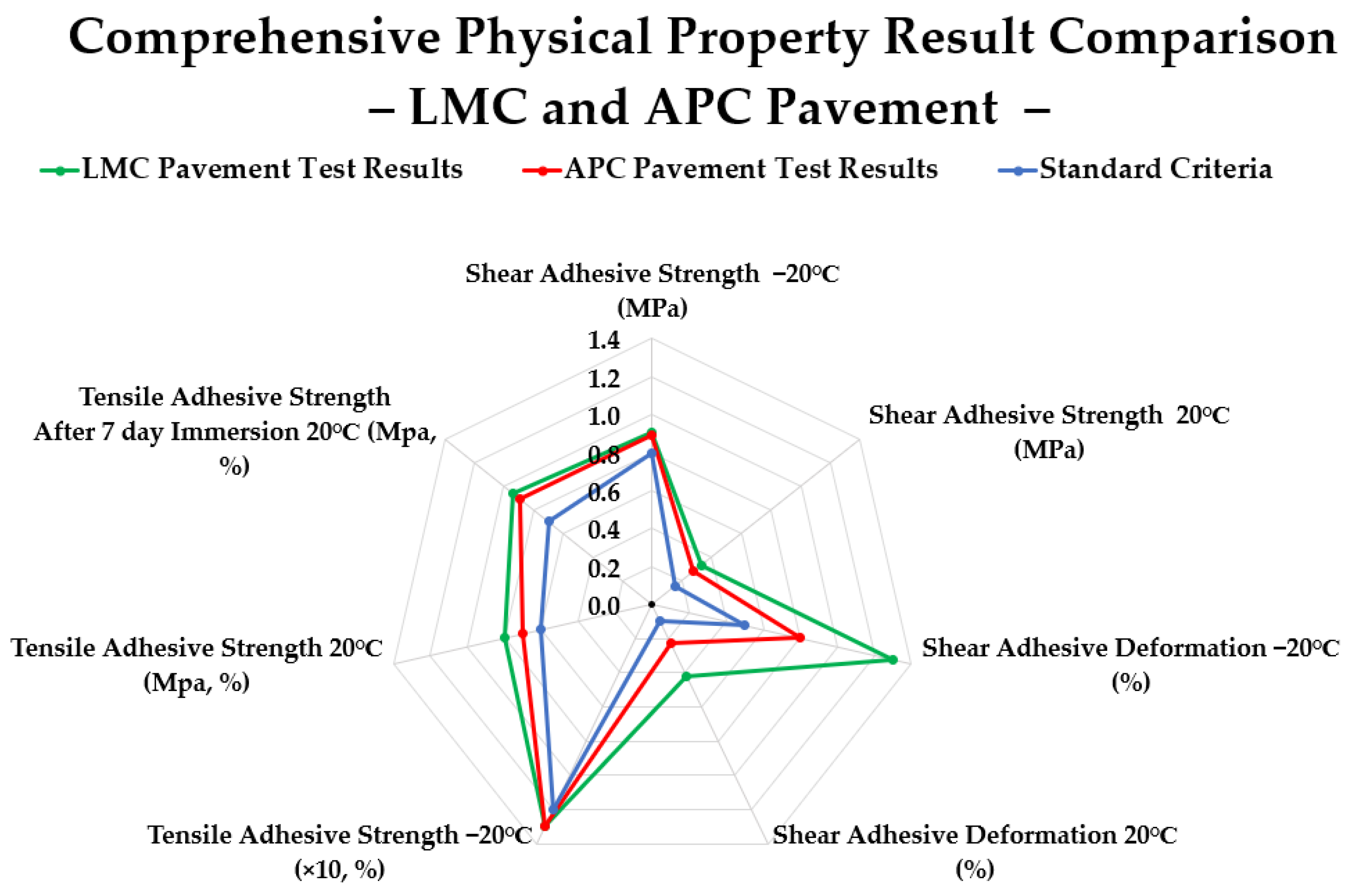

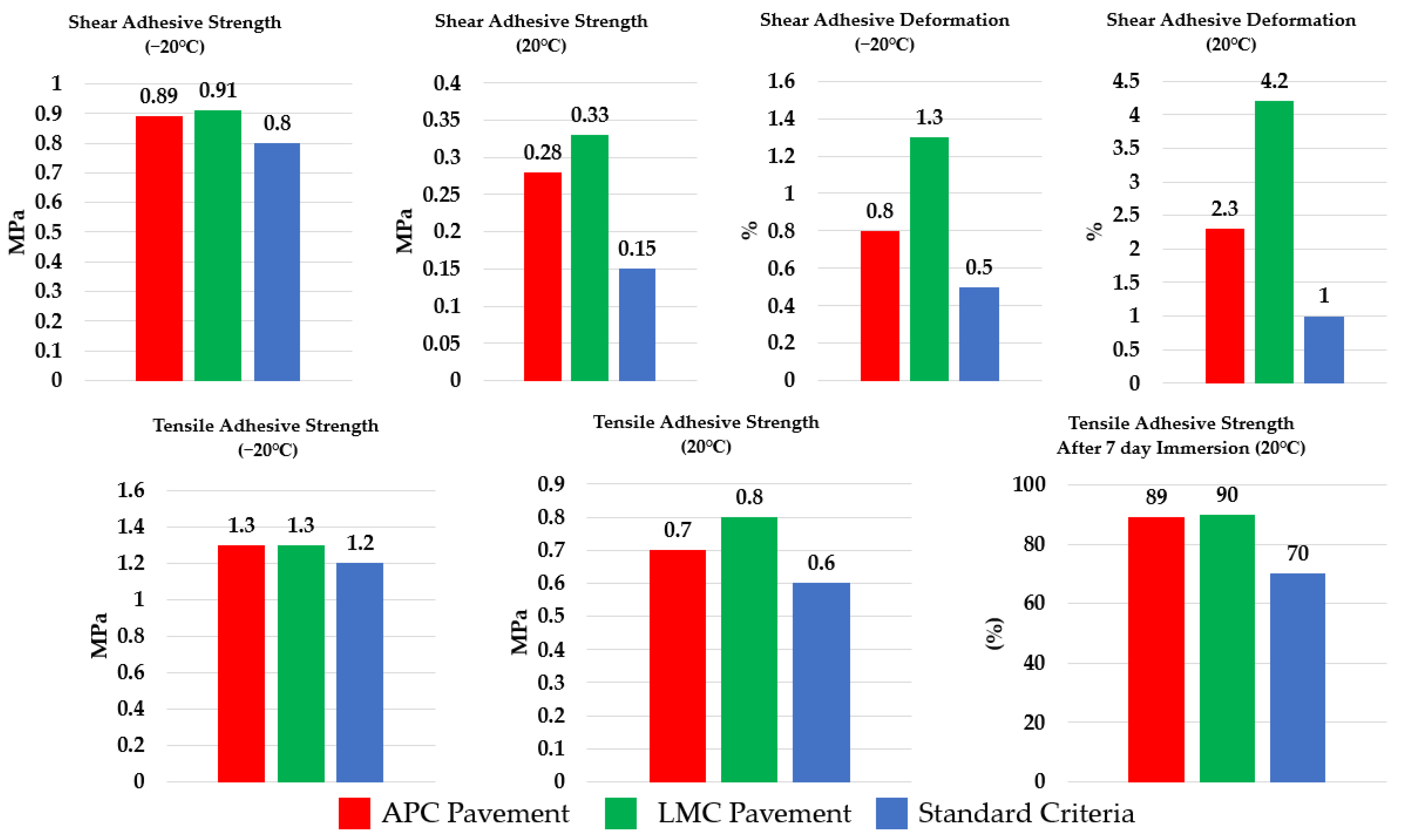

3.2.3. Comparison of the Performance of the Waterproofing Layer in the APC and LMC Pavement

4. Conclusions

- (1)

- For the purpose of preventing water leakage to ensure long-term durability of concrete bridges, a double-sided composite waterproofing sheet manufactured by laminating an asphalt compound layer and a modified acrylic emulsion layer on both sides with a non-woven fabric as the central material was proposed as a new bridge surface waterproofing material. As a result of measuring the resistance performance of deterioration factors such as temperature change, chemical influence, crack behavior, and water pressure for the newly proposed waterproofing sheet, according to the KS test method related to the waterproofing material for bridges, it is confirmed that the performance exceeds the KS quality standard;

- (2)

- As a result of evaluating the applicability of this waterproofing sheet when used with the APC pavement, it is confirmed that the material exceeds the performance requirement outlined in the KS standard by at least 8% and at most 130% in various performance items. Therefore, the waterproofing sheet proposed in this study is expected to exhibit stable waterproof performance even when applied to the APC pavement. In the case of LMC pavement, it is verified that the material exceeds the performance requirements outlined in the KS standard, at most, by about 320% in various performance items;

- (3)

- Comparing the results of using this waterproofing sheet for APC and LMC pavements, the performance is shown to be relatively higher with the LMC pavement, and it is predicted that this result is due to the difference in the waterproofing layer adhesion caused by the difference in the properties of the waterproofing sheet material and the pavement material.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| LMC | Latex-modified concrete |

| APC | Asphalt concrete |

| KS | Korean standard |

References

- Haynes, M.A.; Coleri, E.; Obaid, I. Performance of Waterproofing Membranes to Protect Concrete Bridge Decks. Transp. Res. Rec. J. Transp. Res. Board 2021, 2675, 1693–1706. [Google Scholar] [CrossRef]

- Liu, X.; Scarpas, A.; Li, J.; Tzimiris, G. Study of the Performance of Membrane Material between the Asphalt Concrete Surfacing Layers and the Decks of Steel Bridges. In Airfield and Highway Pavement 2013: Sustainable and Efficient Pavements; American Society of Civil Engineers: Los Angeles, CA, USA, 2013; pp. 1434–1444. [Google Scholar] [CrossRef]

- Transport Infrastructure of Ireland. In Waterproofing and Surfacing of Concrete Bridge Decks; Transport Infrastructure Ireland (TII) Publications: Dublin, Ireland, 2000; pp. 1–44.

- Korean Standard. KS F 4931; Sheet Waterproofing Materials for Concrete Bridges, 2017. Korean Agency for Technology and Standard. KATS: Seoul, Korea, 2017.

- Russell, H. Waterproofing Membranes for Concrete Bridge Decks; 35 Transportation Research Board: Washington, WA, USA, 2012. [Google Scholar] [CrossRef]

- Frosch, R.; Kreger, M.; Strandquist, B. Implementation of Performance-Based Bridge Deck Protective Systems; Indiana Department of Transportation: Indianapolis, IN, USA, 2013. [Google Scholar]

- Park, H.-M.; Choi, J.-Y.; Kim, S.-W. Characteristics of Waterproofing System on Concrete Bridge Deck. J. Korean Concr. Inst. 2006, 18, 20–25. [Google Scholar]

- Lee, B.; Ahn, T. Causes and Improvements of Deterioration of Waterproofing Systems in Concrete Bridge Decks. J. Korean Concr. Inst. 2006, 18, 42–50. [Google Scholar]

- Kim, Y. Performance of Waterproofing System of Concrete Bridge Deck. J. Korean Concr. Inst. 2006, 18, 10–13. [Google Scholar] [CrossRef]

- Oh, S.K.; Lee, J.Y.; Choi, S.M. An Experimental Study on the Highly Adhesive Composite Waterproofing Sheet using Reclaimed Rubber. J. Archit. Inst. Korea 2014, 16, 279–284. [Google Scholar]

- Ahn, D.S. A Study on the Physical Properties Change of Synthetic Rubber Polymer Gel by Using Stirring crew Mixer. Master’s Thesis, Seoul National University of Science and Technology, Seoul, Korea, 2015. [Google Scholar]

- Lee, B.-D.; Park, S.-K.; Kim, K.-W. Effect of Asphalt Pavement Conditions on Tensile Adhesive Strength of Waterproofing System on Concrete Bridge Deck. Int. J. Highw. Eng. 2003, 5, 299–304. [Google Scholar]

- Park, H.; Won, J. Bridge Deck Overlay Technology Using High Performance Concrete. In Proceedings of the 2008 Spring Conference of the Korean Concrete Institute, Seoul, Korea, 31 March 2008; pp. 1113–1116. [Google Scholar]

- Kim, K.-I.; Shim, S.-H.; Lee, H. Development of SBS Modified Asphalt for High Durable Bridge Deck Pavements. J. Korean Soc. Road Eng. 2006, 10, 137–144. [Google Scholar]

- An, K.; Kang, H.; Oh, S. Hardening State and Basic Properties Changes According to the Mixture Ratio of MMA Resin Used as a Waterproofing Coating Material in Concrete Bridges. J. Korean Recycl. Constr. Resour. Inst. 2019, 7, 224–234. [Google Scholar]

- An, K.; Kim, C.; Oh, S. Tensile Bond Strength Westing When Changing Adhesion Method of Double-sided Waterproof Sheet Used on Surface Layer of Bridge-deck. Proc. Korea Inst. Build. Constr. 2019, 19, 217–218. [Google Scholar]

- An, K.; Kang, H.; Oh, S. Overlap Tensile Strength testing of Waterproofing Sheet used in Concrete Bridges. Proc. Korea Inst. Build. Constr. 2018, 17, 335–336. [Google Scholar]

- Korean Standard. KS F 4934; Self Adhesive Rubberized Asphalt Sheet, 2018. Korean Agency for Technology and Standard. KATS: Seoul, Korea, 2018.

- Haynes, M.; Coleri, E.; Sreedhar, S.; Obaid, I. Bridge Deck Asphalt Concrete Pavement Armoring; Dept. of Transportation, Research Section: Oregon City, OR, USA, 2020. [Google Scholar]

- Haynes, M.; Coleri, E.; Sreedhar, S. Impermeable Asphalt Concrete Layer to Protect and Seal Concrete Bridge Decks. Transp. Res. Rec. J. Transp. Res. Board 2019, 2673, 355–367. [Google Scholar] [CrossRef]

| Mixture Ratio Based on Weight Percentage (%) | |||||

|---|---|---|---|---|---|

| Components | Ratio 1 | Ratio 2 | Ratio 3 | Ratio 4 | Ratio 5 |

| Functional cement | 10 | 15 | 18 | 23 | 25 |

| Silica fine powder | 25 | 38 | 32 | 35 | 48 |

| New synthetic resin | 85 | 41 | 38 | 55 | 46 |

| Tackifier | 4 | 5 | 3 | 0.5 | 1.0 |

| Color pigment | 10 | 6 | 6 | 10 | 5 |

| Antifoam and additives | 3 | 4 | 2.5 | 10 | 12 |

| Adhesive performance confirmation (N/mm2) | 0 (no adhesion) | 24 | 7.5 | 8.6 | 0 (no adhesion) |

| Item | Criteria | Quality Standard | |

|---|---|---|---|

| Tensile performance | Tensile strength (N/mm) | Untreated | More than 13.0 |

| Alkali-treated | |||

| Temperature-variation-treated | |||

| Elongation (%) | Untreated | More than 33 | |

| Alkali-treated | |||

| Temperature-variation-treated | |||

| Permeability | Should not leak | ||

| Chloride ion penetration resistance (Coulombs) | Less than 100 | ||

| Impact resistance | Holes should not form | ||

| Heat resistance stability (%) | 150 °C, 30 min | Within ± 2.0 deformation | |

| Low temperature flexibility | −20 °C | No cracks should form | |

| Overlap section strength (N/mm) | More than 5.0 | ||

| Fatigue resistance | No cracks, tears, or breakage should form | ||

| Crack resistance | −20 °C | No cracks, tears, or breakage should form | |

| Composition | Asphalt | Coarse Aggregate | Fine Aggregate | Filler (Limestone Powder) | Others |

|---|---|---|---|---|---|

| Mixture ratio based on weight percentage (%) | 4~5 | 65~80 | 14~26 | 1~2 | 2~4 |

| Composition | Cement Binder | Fine Aggregate | Coarse Aggregate | Water | Latex | Others |

|---|---|---|---|---|---|---|

| Mixture ratio based on weight percentage (%) | 15~20 | 40~45 | 30~35 | 5~10 | 1~3 | 1~2 |

| Mixture Ratio Based on Weight Percentage | ||||||

|---|---|---|---|---|---|---|

| Water/Cement Ratio (%) | Unit water (kg/m3) | Small Aggregate (%) | Air Content (%) | Cement (kg/m3) | Sand (kg/m3) | Gravel (kg/m3) |

| 50 | 82.5 | 43 | 4.1 | 165 | 646 | 895 |

| Items | Quality Standards | ||

|---|---|---|---|

| Shear adhesive performance | Shear adhesive strength (MPa) | −20 °C | >0.80 |

| 20 °C | >0.15 | ||

| Shear adhesive deformation (%) | −20 °C | >0.5 | |

| 20 °C | >1.0 | ||

| Tensile adhesive strength (MPa) | −20 °C | >1.2 | |

| 20 °C | >0.6 | ||

| Tensile adhesive strength after 7 days of water immersion (%) | 20 °C | 70% or more before water immersion | |

| Evaluation Items | Test Results | Quality Standard | |||

|---|---|---|---|---|---|

| Tensile performance | Tensile strength (N/mm) | Untreated | Length | 23.7 (182.31% ↑) | >13.0 |

| Width | 19.3 (148.46% ↑) | ||||

| Alkali-treated | Length | 24.2 (186.15% ↑) | |||

| Width | 19.8 (152.31% ↑) | ||||

| Temperature-variation-treated | Length | 21.1 (162.30% ↑) | |||

| Width | 16.8 (129.23% ↑) | ||||

| Elongation (%) | Untreated | Length | 59 (178.78% ↑) | >33 | |

| Width | 73 (221.21% ↑) | ||||

| Alkali-treated | Length | 118 (357.57% ↑) | |||

| Width | 102 (309.09% ↑) | ||||

| Temperature-variation-treated | Length | 107 (324.24% ↑) | |||

| Width | 98 (296.96% ↑) | ||||

| Permeability | No leakage | Should not leak | |||

| Chloride ion penetration resistance (Coulombs) | 86 (14% ↑) | <100 | |||

| Impact resistance | No holes formed | Holes should not form | |||

| Heat resistance stability (%) | 150 °C, 30 min | Length | 1.1 (45% ↑) | Within ±2.0 deformation | |

| Width | 0.9 (55% ↑) | ||||

| Low temperature flexibility | −20 °C | No cracks | |||

| Overlap section strength (N/mm) | 8.5 (170% ↑) | >5.0 | |||

| Fatigue resistance | No cracks, tears, or breakage | No cracks, tears, or breakage should form | |||

| Crack resistance | −20 °C | No cracks, tears, or breakage | No cracks, tears, or breakage should form | ||

| Evaluation Items | Test Results | Quality Standard | ||

|---|---|---|---|---|

| Shear adhesive performance | Shear adhesive strength (MPa) | −20 °C | 0.89 (11.25% ↑) | More than 0.80 |

| 20 °C | 0.28 (86.67% ↑) | More than 0.15 | ||

| Shear adhesive deformation (%) | −20 °C | 0.8 (60% ↑) | More than 0.5 | |

| 20 °C | 2.3 (130% ↑) | More than 1.0 | ||

| Tensile adhesive strength (MPa) | −20 °C | 1.3 (8.33% ↑) | More than 1.2 | |

| 20 °C | 0.7 (16.67% ↑) | More than 0.6 | ||

| Tensile adhesive strength after 7 days of water immersion (%) | 20 °C | 89% (27.14%↑) | 70% or more before water immersion | |

| Criteria | Test Results | Quality Standard | ||

|---|---|---|---|---|

| Shear adhesive performance | Shear adhesive strength (MPa) | −20 °C | 0.91 (13.75% ↑) | More than 0.80 |

| 20 °C | 0.33 (120% ↑) | More than 0.15 | ||

| Shear adhesive deformation (%) | −20 °C | 1.3 (160% ↑) | More than 0.5 | |

| 20 °C | 4.2 (320% ↑) | More than 1.0 | ||

| Tensile adhesive strength (MPa) | −20 °C | 1.3 (8.33% ↑) | More than 1.2 | |

| 20 °C | 0.8 (33.33% ↑) | More than 0.6 | ||

| Tensile adhesive strength after 7 days of water immersion (%) | 20 °C | 94% (28.57% ↑) | 70% or more before water immersion | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kang, H.; Oh, K.; Ahn, K.; Jiang, B.; He, X.; Oh, S. Property Analysis of Double-Sided Composite Waterproofing Sheet for Simultaneous Application on Asphalt Concrete and Latex-Modified Concrete Pavements for Bridge Decks. Appl. Sci. 2022, 12, 9779. https://doi.org/10.3390/app12199779

Kang H, Oh K, Ahn K, Jiang B, He X, Oh S. Property Analysis of Double-Sided Composite Waterproofing Sheet for Simultaneous Application on Asphalt Concrete and Latex-Modified Concrete Pavements for Bridge Decks. Applied Sciences. 2022; 12(19):9779. https://doi.org/10.3390/app12199779

Chicago/Turabian StyleKang, Hyojin, Kyuhwan Oh, Kiwon Ahn, Bo Jiang, Xingyang He, and Sangkeun Oh. 2022. "Property Analysis of Double-Sided Composite Waterproofing Sheet for Simultaneous Application on Asphalt Concrete and Latex-Modified Concrete Pavements for Bridge Decks" Applied Sciences 12, no. 19: 9779. https://doi.org/10.3390/app12199779

APA StyleKang, H., Oh, K., Ahn, K., Jiang, B., He, X., & Oh, S. (2022). Property Analysis of Double-Sided Composite Waterproofing Sheet for Simultaneous Application on Asphalt Concrete and Latex-Modified Concrete Pavements for Bridge Decks. Applied Sciences, 12(19), 9779. https://doi.org/10.3390/app12199779