Gases Emissions during Composting Process of Agri-Food Industry Waste

Abstract

:1. Introduction

- running the experiments with composting of selected organic waste under laboratory conditions,

- comparison of the composting process occurring in three chosen compost mixtures,

- defining the parameters changes of the obtained composts in comparison with initial material.

2. Materials and Methods

2.1. Time and Research Place, Experiment System

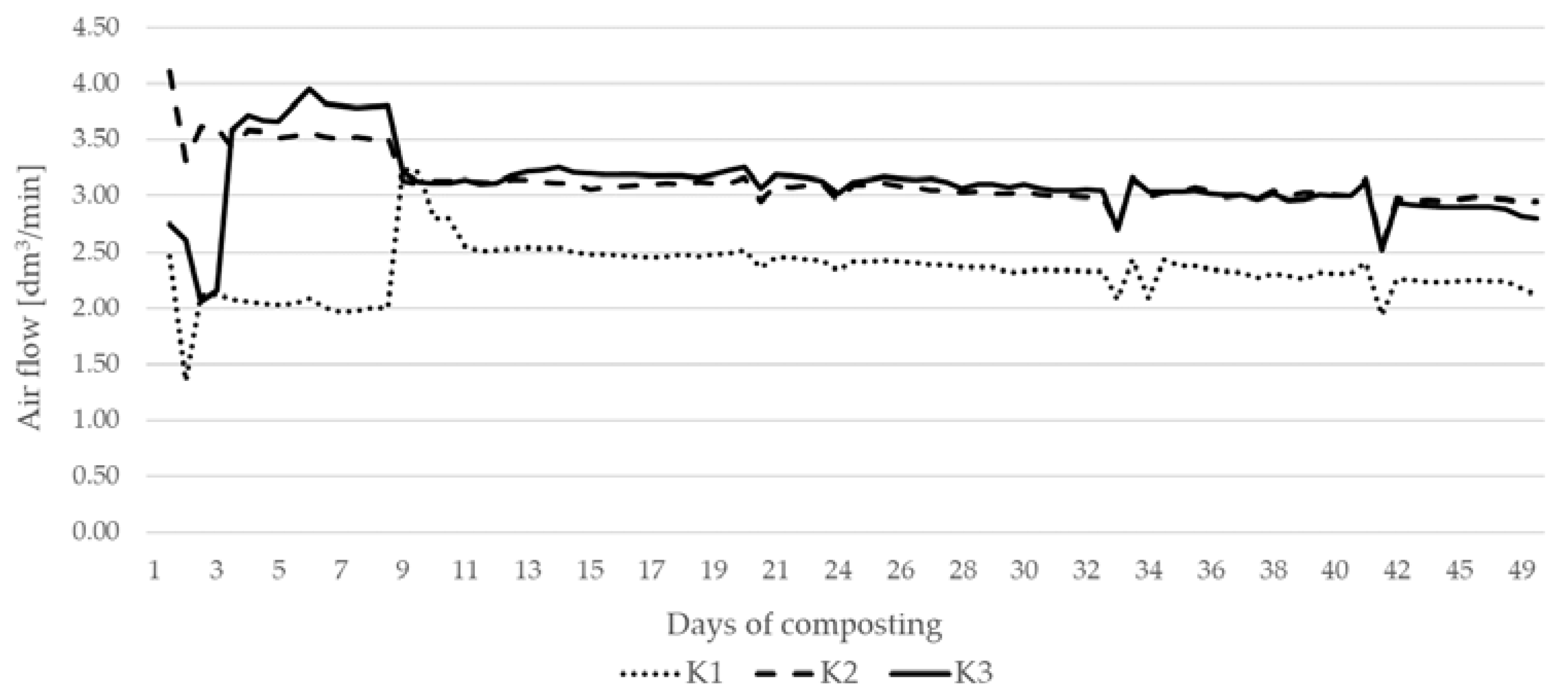

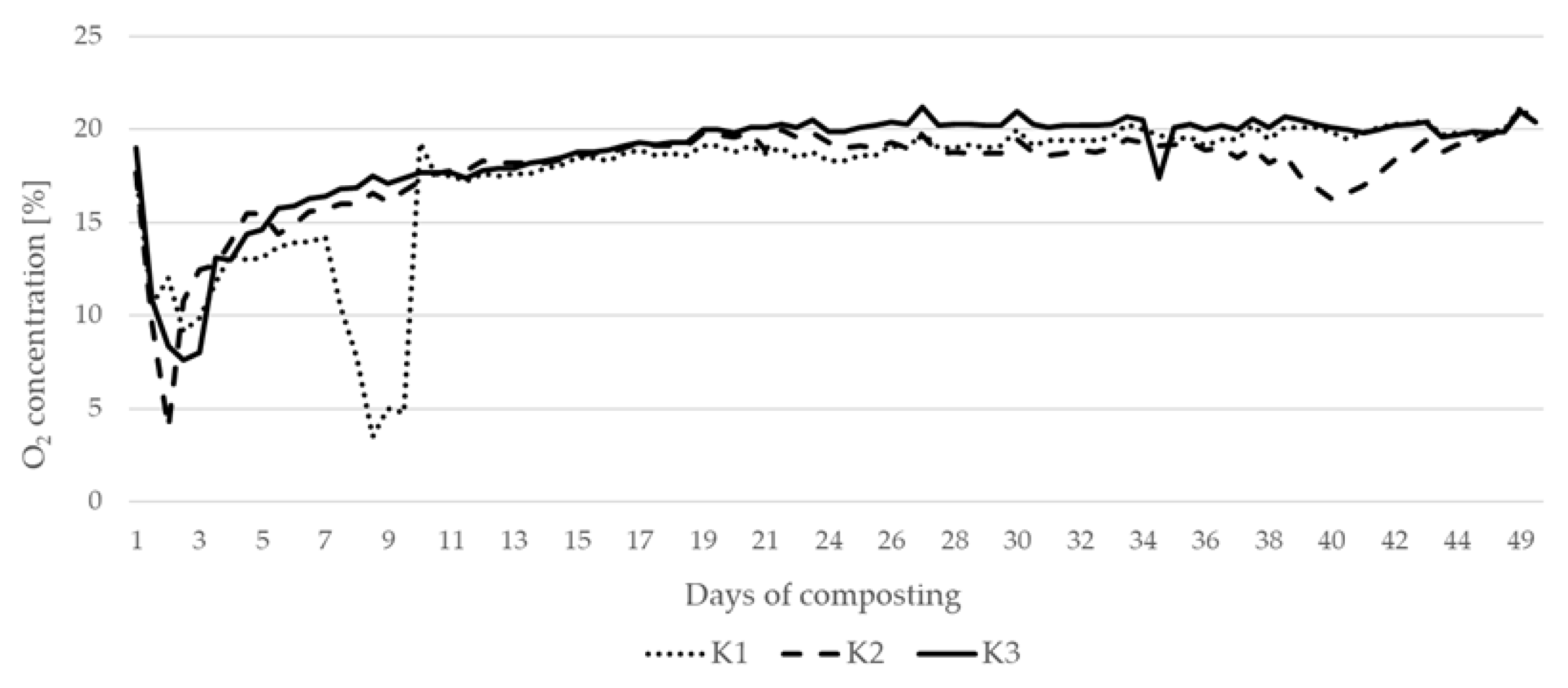

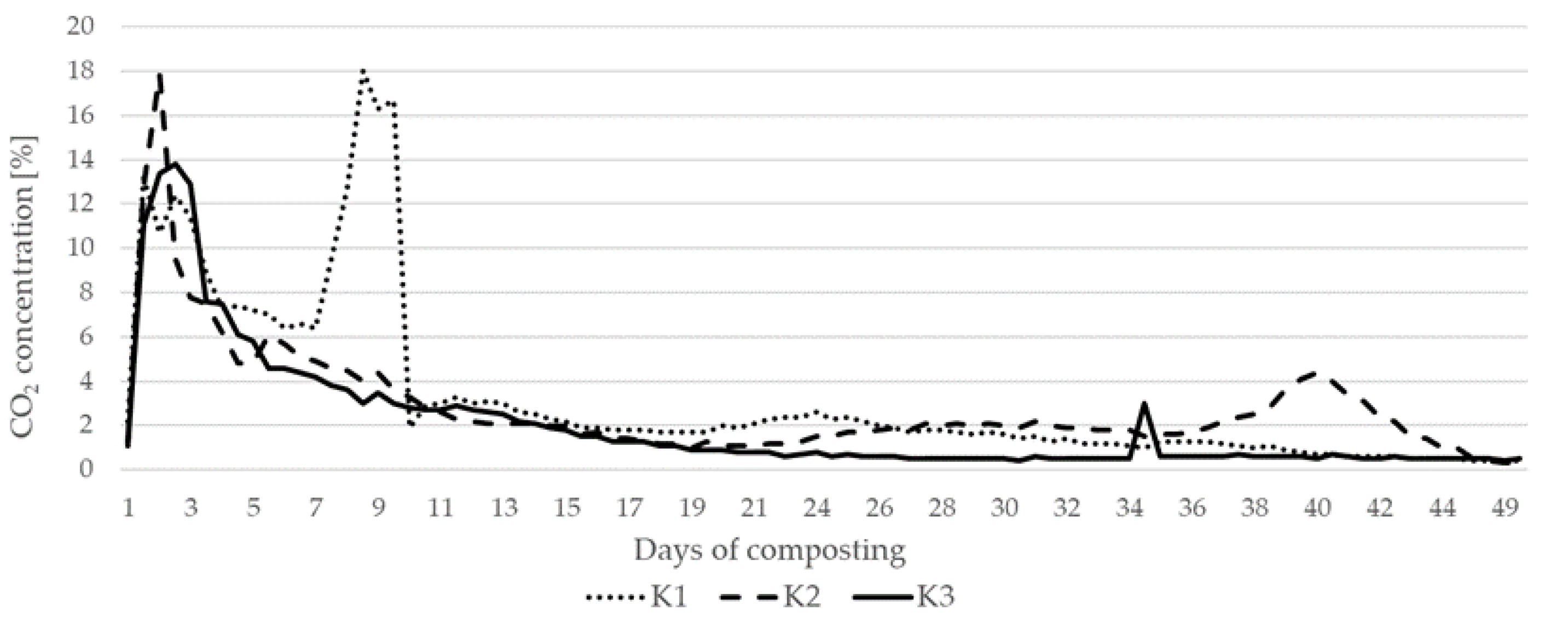

2.2. Air Flow and Gases Measurements

2.3. The Measurement and Analysis of the Other Process Parameters

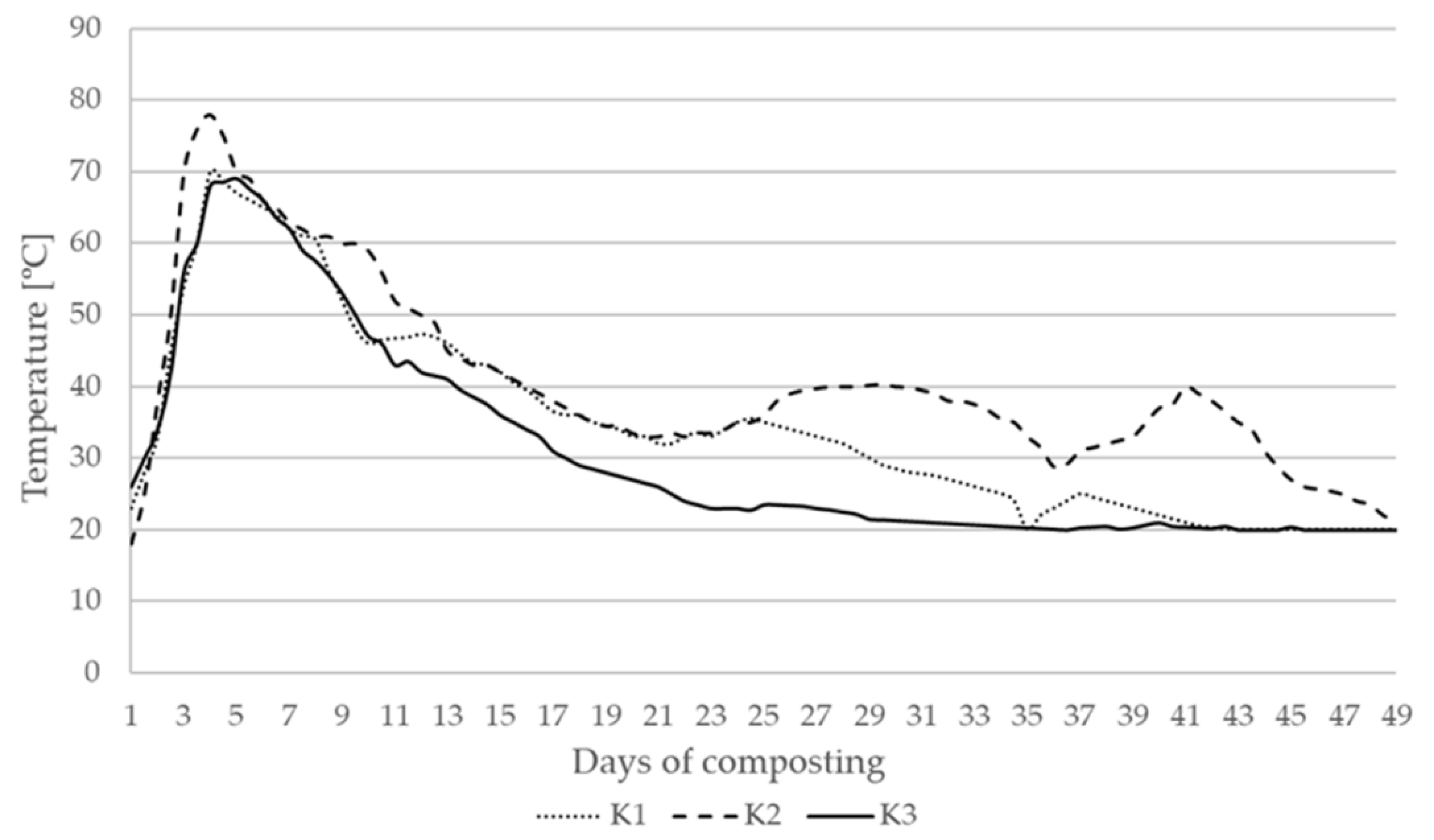

- Temperature measurements in the composted material

- Sampling and analysis

- pH and conductivity measurements

- Defining the content of dry mass and dry organic mass

- Mass and bulk density measurements

3. Results and Discussion

3.1. Temperature Changes

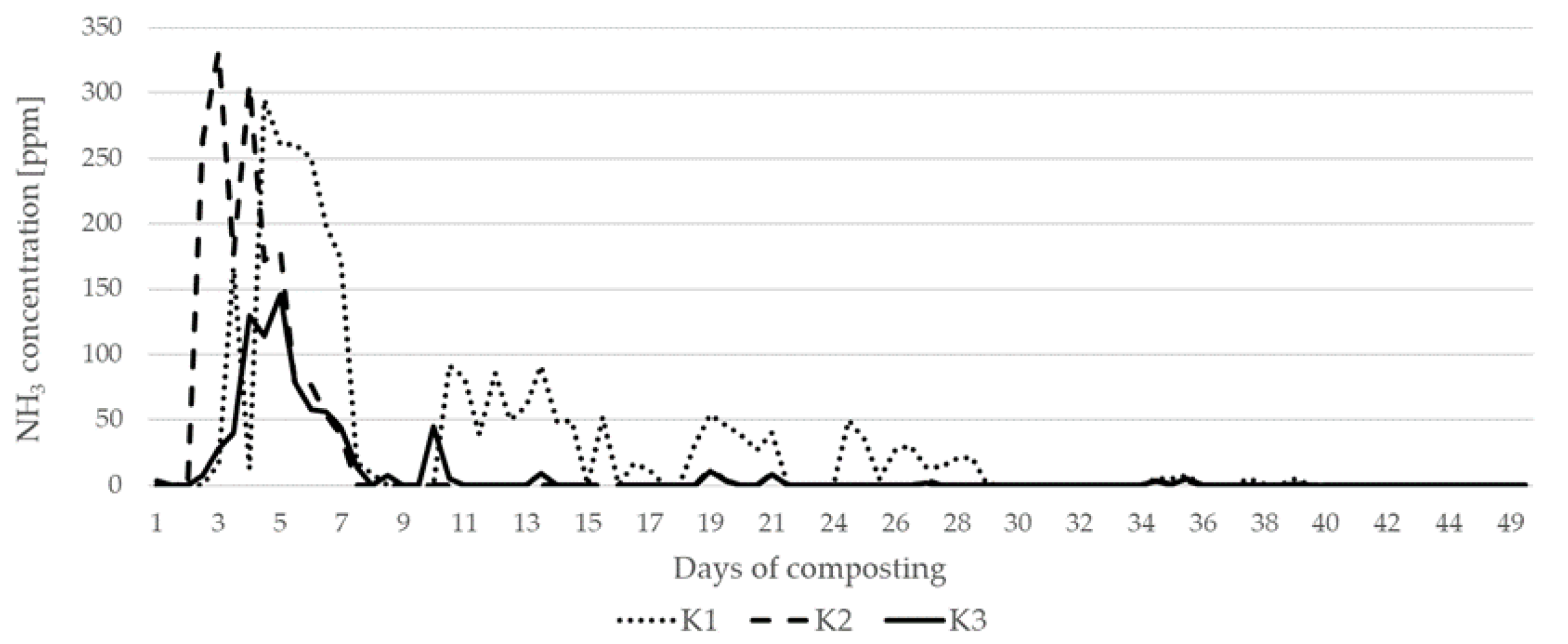

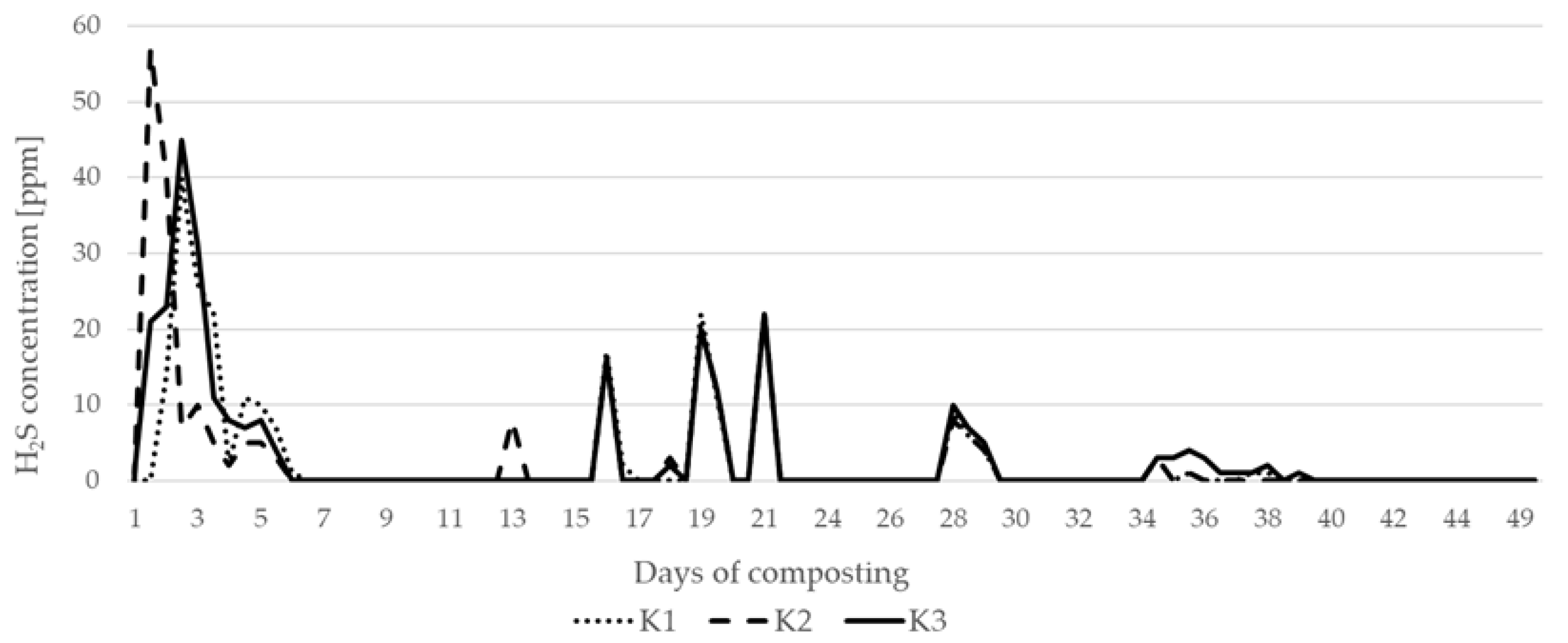

3.2. Changes of Gases Emissions

3.3. Changes of the Other Parameters

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- United Nations Department of Economic and Social Affairs, Population Division. Global Population Growth and Sustainable Development. UN DE-SA/POP/2021/TR/NO. 2. 2021. Available online: https://www.un.org/development/desa/pd/sites/www.un.org.development.desa.pd/files/undesa_pd_2022_global_population_growth.pdf (accessed on 22 July 2022).

- Scaffidi, F. Regional Implications of the Circular Economy and Food Greentech Companies. Sustainability 2022, 14, 9004. [Google Scholar] [CrossRef]

- European Commission, 2021, Agriculture and Rural Development in Poland. Available online: https://agriculture.ec.europa.eu/common-agricultural-policy/market-measures/school-fruit-vegetables-and-milk-scheme/country/poland_en (accessed on 23 July 2022).

- Kumar, H.; Bhardwaj, K.; Sharma, R.; Nepovimova, E.; Kuča, K.; Dhanjal, D.S.; Verma, R.; Bhardwaj, P.; Sharma, S.; Kumar, D. Fruit and Vegetable Peels: Utilization of High Value Horticultural Waste in Novel Industrial Applications. Molecules 2020, 25, 2812. [Google Scholar] [CrossRef] [PubMed]

- Kelley, A.J.; Campbell, D.N.; Wilkie, A.C.; Maltais-Landry, G.; Kelley, A.J.; Campbell, D.N.; Wilkie, A.C.; Maltais-Landry, G. Compost Composition and Application Rate Have a Greater Impact on Spinach Yield and Soil Fertility Benefits Than Feedstock Origin. Horticulturae 2022, 8, 688. [Google Scholar] [CrossRef]

- Sharma, B.; Vaish, B.; Monika; Singh, U.K.; Singh, P.; Singh, P.R. Recycling of Organic Wastes in Agriculture: An Environmental Perspective. Int. J. Environ. Res. 2019, 13, 409–429. [Google Scholar] [CrossRef]

- Janczak, D.; Lewicki, P.; Mazur, R.; Boniecki, P.; Dach, J.; Przybył, J.; Pawlak, M.; Pilarski, K.; Czekała, W. The selected examples of the application of computer image analysis in the assessment of environmental quality. In Proceedings of the SPIE-The International Society for Optical Engineering, 5th International Conference on Digital Image Processing, ICDIP 2013, Beijing, China, 21–22 April 2013; Volume 8878. [Google Scholar] [CrossRef]

- Duque-Acevedo, M.; Belmonte-Ureña, L.J.; Terán-Yépez, E.; Camacho-Ferre, F. Sustainability and circularity in fruit and vegetable production. Perceptions and practices of reduction and valorization of agricultural waste biomass in south-eastern Spain. J. Environ. Manag. 2022, 316, 115270. [Google Scholar] [CrossRef]

- Morales-Polo, C.; del Mar Cledera-Castro, M.; Yolanda Moratilla Soria, B. Reviewing the Anaerobic Digestion of Food Waste: From Waste Generation and Anaerobic Process to Its Perspectives. Appl. Sci. 2018, 8, 1804. [Google Scholar] [CrossRef]

- Giwa, A.S.; Xu, H.; Chang, F.; Zhang, X.; Ali, N.; Yuan, J.; Wang, K. Pyrolysis coupled anaerobic digestion process for food waste and recalcitrant residues: Fundamentals, challenges, and considerations. Energy Sci. Eng. 2019, 7, 2250–2264. [Google Scholar] [CrossRef]

- Psomopoulos, C.S.; Kiskira, K.; Kalkanis, K.; Leligou, H.C.; Themelis, N.J. The role of energy recovery from wastes in the decarbonization efforts of the EU power sector. IET Renew. Power Gener. 2022, 16, 48–64. [Google Scholar] [CrossRef]

- Vershinina, K.; Nyashina, G.; Strizhak, P. Combustion, Pyrolysis, and Gasification of Waste-Derived Fuel Slurries, Low-Grade Liquids, and High-Moisture Waste: Review. Appl. Sci. 2022, 12, 1039. [Google Scholar] [CrossRef]

- Sun, Y.; Qin, Z.; Tang, Y.; Huang, T.; Ding, S.; Ma, X. Techno-environmental-economic evaluation on municipal solid waste (MSW) to power/fuel by gasification-based and incineration-based routes. J. Environ. Chem. Eng. 2021, 9, 106108. [Google Scholar] [CrossRef]

- Hu, M.; Ye, Z.; Zhang, H.; Chen, B.; Pan, Z.; Wang, J. Thermochemical conversion of sewage sludge for energy and resource recovery: Technical challenges and prospects. Environ. Pollut. Bioavailab. 2021, 33, 145–163. [Google Scholar] [CrossRef]

- Kozłowski, K.; Pietrzykowski, M.; Czekała, W.; Dach, J.; Kowalczyk-Juśko, A.; Jóźwiakowski, K.; Brzoski, M. Energetic and economic analysis of biogas plant with using the dairy industry waste. Energy 2019, 183, 1023–1031. [Google Scholar] [CrossRef]

- Bi, S.; Westerholm, M.; Qiao, W.; Mahdy, A.; Xiong, L.; Yin, D.; Fan, R.; Dach, J.; Dong, R. Enhanced methanogenic performance and metabolic pathway of high solid anaerobic digestion of chicken manure by Fe2+ and Ni2+ supplementation. Waste Manag. 2019, 94, 10–17. [Google Scholar] [CrossRef] [PubMed]

- Pochwatka, P.; Kowalczyk-Juśko, A.; Sołowiej, P.; Wawrzyniak, A.; Dach, J. Biogas Plant Exploitation in a Middle-Sized Dairy Farm in Poland: Energetic and Economic Aspects. Energies 2020, 13, 6058. [Google Scholar] [CrossRef]

- Mahapatra, S.; Kumar, D.; Singh, B.; Sachan, P.K. Biofuels and their sources of production: A review on cleaner sustainable alternative against conventional fuel, in the framework of the food and energy nexus. Energy Nexus 2021, 4, 100036. [Google Scholar] [CrossRef]

- Nevzorova, T.; Kutcherov, V. Barriers to the wider implementation of biogas as a source of energy: A state-of-the-art review. Energy Strat. Rev. 2019, 26, 100414. [Google Scholar] [CrossRef]

- Pérez-Murcia, M.D.; Bustamante, M.Á.; Orden, L.; Rubio, R.; Agulló, E.; Carbonell-Barrachina, Á.A.; Moral, R. Use of Agri-Food Composts in Almond Organic Production: Effects on Soil and Fruit Quality. Agronomy 2021, 11, 536. [Google Scholar] [CrossRef]

- Dach, J.; Mazurkiewicz, J.; Janczak, D.; Pulka, J.; Pochwatka, P.; Kowalczyk-Jusko, A. Cow Manure Anaerobic Digestion or Composting-Energetic and Economic Analysis. In Proceedings of the 2020 4th International Conference on Green Energy and Applications, ICGEA, Singapore, 7–9 March 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 143–147. [Google Scholar] [CrossRef]

- Jain, M.S.; Daga, M.; Kalamdhad, A.S. Composting physics: A science behind bio-degradation of lignocellulose aquatic waste amended with inoculum and bulking agent. Process Saf. Environ. Prot. 2018, 116, 424–432. [Google Scholar] [CrossRef]

- Bai, M.; Impraim, R.; Coates, T.; Flesch, T.; Trouvé, R.; van Grinsven, H.; Cao, Y.; Hill, J.; Chen, D. Lignite effects on NH3, N2O, CO2 and CH4 emissions during composting of manure. J. Environ. Manag. 2020, 271, 110960. [Google Scholar] [CrossRef]

- Sołowiej, P.; Pochwatka, P.; Wawrzyniak, A.; Łapiński, K.; Lewicki, A.; Dach, J. The Effect of Heat Removal during Thermophilic Phase on Energetic Aspects of Biowaste Composting Process. Energies 2021, 14, 1183. [Google Scholar] [CrossRef]

- Marks, S.; Dach, J.; Morales, F.J.F.; Mazurkiewicz, J.; Pochwatka, P.; Gierz, Ł. New Trends in Substrates and Biogas Systems in Poland. J. Ecol. Eng. 2020, 21, 19–25. [Google Scholar] [CrossRef]

- Mazurkiewicz, J.; Marczuk, A.; Pochwatka, P.; Kujawa, S. Maize Straw as a Valuable Energetic Material for Biogas Plant Feeding. Materials 2019, 12, 3848. [Google Scholar] [CrossRef]

- Pochwatka, P.; Kowalczyk-Juśko, A.; Mazur, A.; Janczak, D.; Pulka, J.; Dach, J.; Mazurkiewicz, J. Energetic and economic aspects of biogas plants feed with agriculture biomass. In Proceedings of the 2020 4th International Conference on Green Energy and Applications, ICGEA, Singapore, 7–9 March 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 130–133. [Google Scholar]

- Junne, S.; Neubauer, P. How scalable and suitable are single-use bioreactors? Curr. Opin. Biotechnol. 2018, 53, 240–247. [Google Scholar] [CrossRef] [PubMed]

- Kujawa, S.; Janczak, D.; Mazur, A. Image Analysis of Sewage Sludge and Barley Straw as Biological Materials Composted under Different Conditions. Materials 2019, 12, 3644. [Google Scholar] [CrossRef] [PubMed]

- Lewicki, A.; Dach, J.; Boniecki, P.; Czekała, W.; Witaszek, K. The Control of Air Humidity and Temperature in Relationship with a Biowaste Composting Process. Adv. Mater. Res. 2014, 909, 455–462. [Google Scholar] [CrossRef]

- Wolna-Maruwka, A.; Dach, J. Effect of type and proportion of different structure-creating additions on the inactivation rate of pathogenic bacteria in sewage sludge composting in a cybernetic bioreactor. Arch. Environ. Prot. 2009, 35, 87–100. [Google Scholar]

- Luo, W.H.; Yuan, J.; Luo, Y.M.; Li, G.X.; Nghiem, L.D.; Price, W.E. Effects of mixing and covering with mature compost on gaseous emissions during composting. Chemosphere 2014, 117, 14–19. [Google Scholar] [CrossRef]

- Miyatake, F.; Iwabuchi, K. Effect of high compost temperature on enzymatic activity and species diversity of culturable bacteria in cattle manure compost. Bioresour. Technol. 2005, 96, 1821–1825. [Google Scholar] [CrossRef]

- Macias-Corral, M.A.; Cueto-Wong, J.A.; Morán-Martínez, J.; Reynoso-Cuevas, L. Effect of different initial C/N ratio of cow manure and straw on microbial quality of compost. Int. J. Recycl. Org. Waste Agric. 2019, 8, 357–365. [Google Scholar] [CrossRef] [Green Version]

- Sayara, T.; Sánchez, A. Gaseous Emissions from the Composting Process: Controlling Parameters and Strategies of Mitigation. Processes 2021, 9, 1844. [Google Scholar] [CrossRef]

- Stegenta-Dąbrowska, S.; Randerson, P.F.; Białowiec, A. Aerobic Biostabilization of the Organic Fraction of Municipal Solid Waste—Monitoring Hot and Cold Spots in the Reactor as a Novel Tool for Process Optimization. Materials 2022, 15, 3300. [Google Scholar] [CrossRef] [PubMed]

- Xu, S.; Reuter, T.; Gilroyed, B.H.; Tymensen, L.; Hao, Y.; Hao, X.; Belosevic, M.; Leonard, J.J.; McAllister, T.A. Microbial communities and greenhouse gas emissions associated with the biodegradation of specified risk material in compost. Waste Manag. 2013, 33, 1372–1380. [Google Scholar] [CrossRef] [PubMed]

- Hwang, H.Y.; Kim, S.H.; Shim, J.; Park, S.J. Composting Process and Gas Emissions during Food Waste Composting under the Effect of Different Additives. Sustainability 2020, 12, 7811. [Google Scholar] [CrossRef]

- Fuertes-Mendizábal, T.; Hirel, B.; Ariz, I.; Gu, J.; Martins-Loução, M.A.; Dias, T.; Cruz, C. Integrating Ecological Principles for Addressing Plant Production Security and Move beyond the Dichotomy ‘Good or Bad’ for Nitrogen Inputs Choice. Agronomy 2022, 12, 1632. [Google Scholar] [CrossRef]

- Oyetunji, O.; Bolan, N.; Hancock, G. A comprehensive review on enhancing nutrient use efficiency and productivity of broadacre (arable) crops with the combined utilization of compost and fertilizers. J. Environ. Manag. 2022, 317, 115395. [Google Scholar] [CrossRef]

- Mazurkiewicz, J. Energy and Economic Balance between Manure Stored and Used as a Substrate for Biogas Production. Energies 2022, 15, 413. [Google Scholar] [CrossRef]

- Lindborg, A. The properties of ammonia. Frigoscandia Proc. 9–17 November 1997. [Google Scholar]

- Sokač, T.; Valinger, D.; Benković, M.; Jurina, T.; Kljusurić, J.G.; Redovniković, I.R.; Tušek, A.J. Application of Optimization and Modeling for the Composting Process Enhancement. Processes 2022, 10, 229. [Google Scholar] [CrossRef]

- Zheng, G.; Wang, Y.; Wang, X.; Yang, J.; Chen, T. Oxygen Monitoring Equipment for Sewage-Sludge Composting and Its Application to Aeration Optimization. Sensors 2018, 18, 4017. [Google Scholar] [CrossRef]

- Boniecki, P.; Dach, J.; Nowakowski, K.; Jakubek, A. Neural image analysis of maturity stage during composting of sewage sludge. In Proceedings of the International Conference on Digital Image Processing, Bangkok, Thailand, 7–9 March 2009; Volume 2009, pp. 200–203. [Google Scholar] [CrossRef]

- Chavez-Rico, V.S.; Bodelier, P.L.E.; van Eekert, M.; Sechi, V.; Veeken, A.; Buisman, C. Producing organic amendments: Physicochemical changes in biowaste used in anaerobic digestion, composting, and fermentation. Waste Manag. 2022, 149, 177–185. [Google Scholar] [CrossRef]

- Jiang-Ming, Z. Effect of turning frequency on co-composting pig manure and fungus residue. J. Air Waste Manag. Assoc. 2016, 67, 313–321. [Google Scholar] [CrossRef]

- Rastogi, M.; Nandal, M.; Khosla, B. Microbes as vital additives for solid waste composting. Heliyon 2020, 6, e03343. [Google Scholar] [CrossRef] [PubMed]

- Piotrowska-Cyplik, A.; Chrzanowski, Ł.; Cyplik, P.; Dach, J.; Olejnik, A.; Staninska, J.; Czarny, J.; Lewicki, A.; Marecik, R.; Powierska-Czarny, J. Composting of oiled bleaching earth: Fatty acids degradation, phytotoxicity and mutagenicity changes. Int. Biodeterior. Biodegrad. 2013, 78, 49–57. [Google Scholar] [CrossRef]

- Tortosa, G.; Fernández-González, A.J.; Lasa, A.V.; Aranda, E.; Torralbo, F.; González-Murua, C.; Fernández-López, M.; Benítez, E.; Bedmar, E.J. Involvement of the metabolically active bacteria in the organic matter degradation during olive mill waste composting. Sci. Total Environ. 2021, 789, 147975. [Google Scholar] [CrossRef]

| Initial Parameters of the Substrates * | Share in the Mixtures [kg F.M.] | |||||||

|---|---|---|---|---|---|---|---|---|

| C:N | D.M. [%] | O.D.M. [%] | pH | Cond [mS·cm−1] | K1 | K2 | K3 | |

| cabbage leaves | 20.1 | 11.3 | 90.3 | 5.94 | 0.12 | 20 | 20 | 20 |

| tomato dry leaves | 29.2 | 76.8 | 70 | 6.35 | 11.9 | 10 | - | - |

| solid fraction from biogas plant | 26.7 | 32.5 | 92.9 | 9.07 | 1.29 | - | 20 | - |

| onion husk | 42,0 | 20.9 | 72.8 | 8.49 | 1.03 | - | - | 20 |

| cattle manure | 22.1 | 15.2 | 70.3 | 8.37 | 2.19 | 3 | 3 | - |

| cattle slurry | 17.4 | 1.7 | 40.7 | 8.5 | 18.22 | 3 | - | - |

| straw | 88.0 | 85.6 | 96.1 | 7.7 | 0.69 | - | 1.5 | 2 |

| Reactor | Time | F.M. [kg] | D.M. [%] | O.D.M. [%] | ρ * [kg·m−3] | pH [-] | Cond [mS·cm−1] |

|---|---|---|---|---|---|---|---|

| K1 | Start | 35 | 29.8 | 74.81 | 275 | 6.63 | 5.16 |

| Aeration ** | 23 | 26.44 | 55.25 | 484 | 8.36 | 6.77 | |

| End | 21.6 | 26.6 | 52.86 | 515 | 8.02 | 7.14 | |

| K2 | Start | 44.5 | 23.6 | 92.41 | 349 | 8.36 | 0.53 |

| Aeration | 31.2 | 17.75 | 81.17 | 444 | 9.08 | 9.39 | |

| End | 27 | 17.78 | 78.93 | 483 | 8.74 | 1.68 | |

| K3 | Start | 42 | 19.4 | 82.29 | 336 | 7.75 | 0.65 |

| Aeration | 28.8 | 17.57 | 56.22 | 720 | 9.07 | 1.03 | |

| End | 25.1 | 18.87 | 53.47 | 743 | 9.42 | 1.52 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Czekała, W.; Janczak, D.; Pochwatka, P.; Nowak, M.; Dach, J. Gases Emissions during Composting Process of Agri-Food Industry Waste. Appl. Sci. 2022, 12, 9245. https://doi.org/10.3390/app12189245

Czekała W, Janczak D, Pochwatka P, Nowak M, Dach J. Gases Emissions during Composting Process of Agri-Food Industry Waste. Applied Sciences. 2022; 12(18):9245. https://doi.org/10.3390/app12189245

Chicago/Turabian StyleCzekała, Wojciech, Damian Janczak, Patrycja Pochwatka, Mateusz Nowak, and Jacek Dach. 2022. "Gases Emissions during Composting Process of Agri-Food Industry Waste" Applied Sciences 12, no. 18: 9245. https://doi.org/10.3390/app12189245

APA StyleCzekała, W., Janczak, D., Pochwatka, P., Nowak, M., & Dach, J. (2022). Gases Emissions during Composting Process of Agri-Food Industry Waste. Applied Sciences, 12(18), 9245. https://doi.org/10.3390/app12189245