Investigation into Dynamic Behaviors of High-Temperature Sandstone under Cyclic Impact Loading Using DIC Technology

Abstract

:1. Introduction

2. Specimen Preparation and Test Equipment

2.1. Specimen Preparation

2.2. Impact Test Device

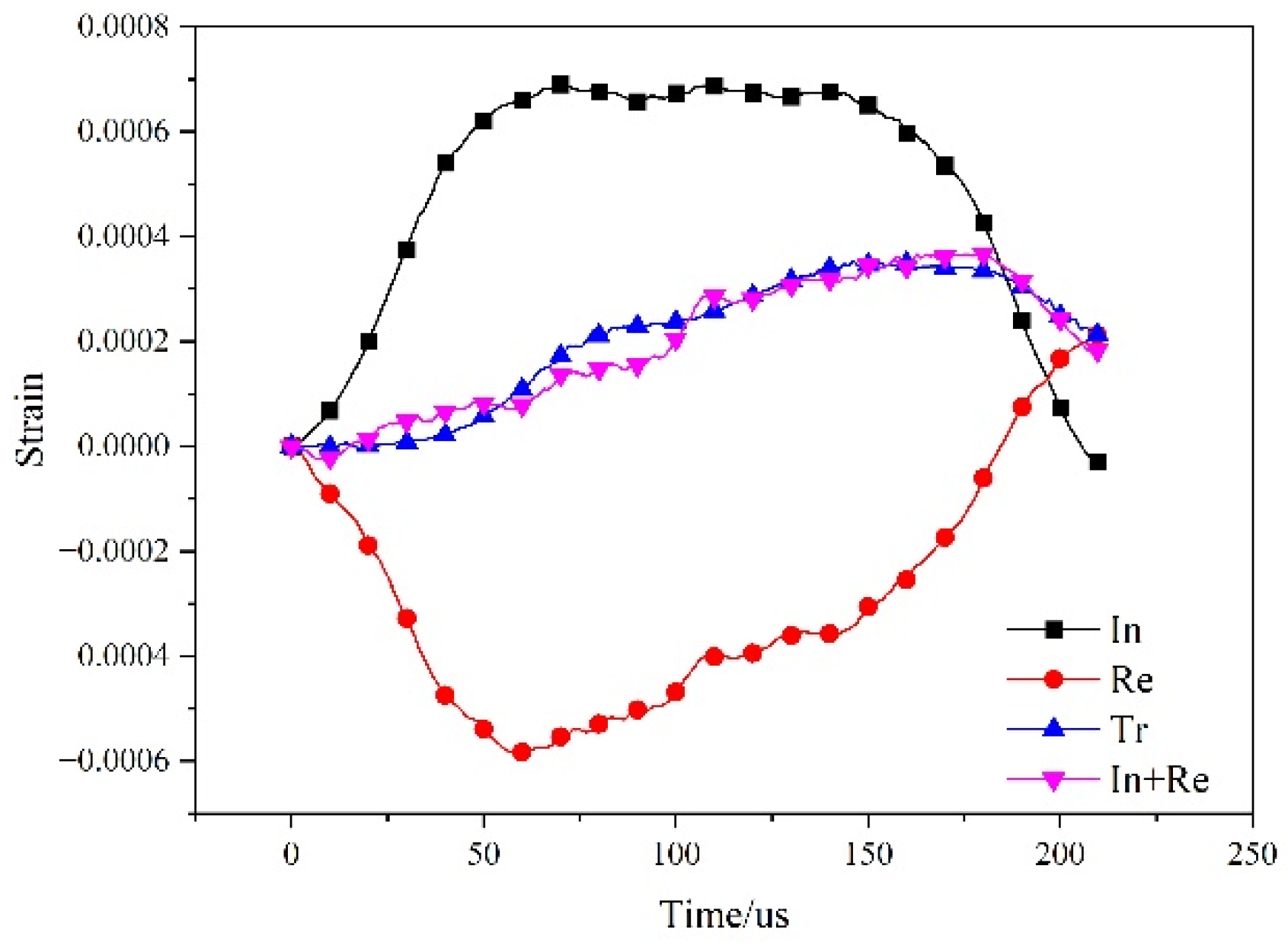

3. Analysis of Dynamic Performance and Energy Consumption

3.1. Mineral Composition Analysis at Different Temperatures

3.2. Analysis of Dynamic Mechanical Properties in the First Impact

3.3. Analysis of Cyclic Impact STRESS and Strain

3.4. Analysis of Cyclic Impact Energy

4. Analysis of DIC Results at the First Impact

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, T.; Pei, X.; Wang, D.; Huang, R.; Tang, H. Nonlinear behavior and damage model for fractured rock under cyclic loading based on energy dissipation principle. Eng. Fract. Mech. 2019, 206, 330–341. [Google Scholar] [CrossRef]

- Sheng, L.; Xiaohe, W.; Chaojun, F.; Haohao, Z.; Zheng, L.; Kun, Y. Experimental study on evolution characteristics of coal pores under impact loadings. China Saf. Sci. J. 2019, 29, 91–97. [Google Scholar] [CrossRef]

- Jing, L.; Stephansson, O.; Nordlund, E. Study of rock joints under cyclic loading conditions. Rock Mech. Rock Eng. 1993, 26, 215–232. [Google Scholar] [CrossRef]

- Song, H.; Zhang, H.; Kang, Y.; Huang, G.; Fu, D.; Qu, C. Damage evolution study of sandstone by cyclic uniaxial test and digital image correlation. Tectonophysics 2013, 608, 1343–1348. [Google Scholar] [CrossRef]

- Millon, O.; Ruiz-Ripoll, M.L.; Hoerth, T. Analysis of the Behavior of Sedimentary Rocks under Impact Loading. Rock Mech. Rock Eng. 2016, 49, 4257–4272. [Google Scholar] [CrossRef]

- Mishra, S.; Zaid, M.; Rao, K.S.; Gupta, N.K. FEA of Urban Rock Tunnels under Impact Loading at Targeted Velocity. Geotech. Geol. Eng. 2021, 40, 1693–1711. [Google Scholar] [CrossRef]

- Aziznejad, S.; Esmaieli, K.; Hadjigeorgiou, J.; Labrie, D. Responses of jointed rock masses subjected to impact loading. J. Rock Mech. Geotech. Eng. 2018, 10, 624–634. [Google Scholar] [CrossRef]

- Zhang, Z.; Qian, Q.; Wang, H.; Huang, Y.; Wang, J.; Liu, H. Study on the Dynamic Mechanical Properties of Metamorphic Limestone under Impact Loading. Lithosphere 2021, 2021, 8403502. [Google Scholar] [CrossRef]

- Li, X.; Wu, Y.; He, L.; Zhang, X.; Wang, J. Research on Dynamic Properties of Deep Marble Influenced by High Temperature. Mathematics 2022, 10, 2603. [Google Scholar] [CrossRef]

- Wang, J.; Zuo, T.; Li, X.; Tao, Z.; Ma, J. Study on the Fractal Characteristics of the Pomegranate Biotite Schist under Impact Loading. Geofluids 2021, 2021, 1570160. [Google Scholar] [CrossRef]

- Demirdag, S.; Tufekci, K.; Kayacan, R.; Yavuz, H.; Altindag, R. Dynamic mechanical behavior of some carbonate rocks. Int. J. Rock Mech. Min. Sci. 2010, 47, 307–312. [Google Scholar] [CrossRef]

- Li, X.B.; Lok, T.S.; Zhao, J. Dynamic Characteristics of Granite Subjected to Intermediate Loading Rate. Rock Mech. Rock Eng. 2004, 38, 21–39. [Google Scholar] [CrossRef]

- Jin, J. Study on Rock Dynamic Mechanical Properties of under Coupled Static-Cyclic Impact Loading. Ph.D. Thesis, Central South University, Changsha, China, 2012. (In Chinese) [Google Scholar] [CrossRef]

- Jin, J.; Li, X.; Chang, J.; Tao, W.; Qiu, C. Stress-strain curve and stress wave characteristics of rock subjected to cyclic impact loadings. Explos. Shock. Waves 2013, 33, 613–619. [Google Scholar] [CrossRef]

- Jin, J.; Li, X.; Qiu, C.; Tao, W.; Zhou, X. Evolution model for damage accumulation of rock under cyclic impact loadings and effect of static loads on damage evolution. Chin. J. Rock Mech. Eng. 2014, 33, 1662–1671. [Google Scholar] [CrossRef]

- Wang, M.; Wang, H.; Zong, Q. Experimental study on energy dissipation of mudstone in coal mine under impact loading. J. China Coal Soc. 2019, 44, 1716–1725. [Google Scholar] [CrossRef]

- Mishra, S.; Chakraborty, T.; Matsagar, V.; Loukus, J.; Bekkala, B. High Strain-Rate Characterization of Deccan Trap Rocks Using SHPB Device. J. Mater. Civ. Eng. 2018, 30, 04018059. [Google Scholar] [CrossRef]

- Yu, Y.; Zhang, W.; Fan, L.; Gong, J.; Yang, M.; Sun, L. Strain rate effect and energy dissipation characteristics of sandstone in coal measures under impact loading. J. China Coal Soc. 2021, 46, 2281–2293. [Google Scholar] [CrossRef]

- Bagde, M.N.; Petroš, V. Fatigue and dynamic energy behaviour of rock subjected to cyclical loading. Int. J. Rock Mech. Min. Sci. 2009, 46, 200–209. [Google Scholar] [CrossRef]

- Bagde, M.; Petroš, V. Fatigue properties of intact sandstone samples subjected to dynamic uniaxial cyclical loading. Int. J. Rock Mech. Min. Sci. 2004, 42, 237–250. [Google Scholar] [CrossRef]

- Wang, P.; Yin, T.; Li, X.; Zhang, S.; Bai, L. Dynamic Properties of Thermally Treated Granite Subjected to Cyclic Impact Loading. Rock Mech. Rock Eng. 2018, 52, 991–1010. [Google Scholar] [CrossRef]

- Shu, R.-H.; Yin, T.-B.; Li, X.-B.; Yin, Z.-Q.; Tang, L.-Z. Effect of thermal treatment on energy dissipation of granite under cyclic impact loading. Trans. Nonferrous Met. Soc. China 2019, 29, 385–396. [Google Scholar] [CrossRef]

- Hassanzadegan, A.; Blöcher, G.; Milsch, H.; Urpi, L.; Zimmermann, G. The Effects of Temperature and Pressure on the Porosity Evolution of Flechtinger Sandstone. Rock Mech. Rock Eng. 2013, 47, 421–434. [Google Scholar] [CrossRef]

- Pathiranagei, S.V.; Gratchev, I. Coupled thermo-mechanical constitutive damage model for sandstone. J. Rock Mech. Geotech. Eng. 2022. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, G.; Wang, X.; Chen, Z.; Li, Z.; Wang, R. Microfabric characteristics of tight sandstone of Xujiahe formation in western Sichuan after high temperature and the effect on mechanical properties. Chin. J. Rock Mech. Eng. 2021, 40, 2249–2259. [Google Scholar] [CrossRef]

- Liang, S.; Fang, S.; Wei, G.; Zhu, X.; Li, W.; Ma, J. Experiments on Mechanical Properties of Siliceous Sandstone after High Temperature. J. Zhengzhou Univ. (Eng. Sci.) 2021, 42, 87–92. [Google Scholar] [CrossRef]

- Qi, F.; Zhang, K.; Xie, J. Fracturing mechanism of rock-like specimens with different joint densities based on DIC technology. Rock Soil Mech. 2021, 42, 1669–1680. [Google Scholar] [CrossRef]

- Munoz, H.; Taheri, A.; Chanda, E.K. Pre-Peak and Post-Peak Rock Strain Characteristics during Uniaxial Compression by 3D Digital Image Correlation. Rock Mech. Rock Eng. 2016, 49, 2541–2554. [Google Scholar] [CrossRef]

- Xu, L.; Deng, J.; Wang, L. Study on the single crack propagation and damage evolution characteristics of rock materials based on DIC. J. Guizhou Univ. (Nat. Sci.) 2018, 35, 110–115. [Google Scholar] [CrossRef]

- Fan, J.; Zhu, X.; Hu, J.; Tang, Y.; He, C. Experimental study on crack propagation and damage monitoring of sandstone using three-dimensional digital image correlation technology. Rock Soil Mech. 2022, 43, 1009–1019. [Google Scholar] [CrossRef]

- Seisuke, O.; Tang, Y.; Xu, J.; Peng, S.; Chen, C.; Yan, Z. Application of 3D-DIC system in rock mechanic test. Rock Soil Mech. 2019, 40, 3263–3273. [Google Scholar] [CrossRef]

- Fourmeau, M.; Gomon, D.; Vacher, R.; Hokka, M.; Kane, A.; Kuokkala, V.-T. Application of DIC Technique for Studies of Kuru Granite Rock under Static and Dynamic Loading. Procedia Mater. Sci. 2014, 3, 691–697. [Google Scholar] [CrossRef]

- Gao, G.; Huang, S.; Xia, K.; Li, Z. Application of Digital Image Correlation (DIC) in Dynamic Notched Semi-Circular Bend (NSCB) Tests. Exp. Mech. 2014, 55, 95–104. [Google Scholar] [CrossRef]

- Gao, G.; Yao, W.; Xia, K.; Li, Z. Investigation of the rate dependence of fracture propagation in rocks using digital image correlation (DIC) method. Eng. Fract. Mech. 2015, 138, 146–155. [Google Scholar] [CrossRef]

- Yang, R.; Li, W.; Fang, S.; Zhu, Y.; Li, Y. Experimental study on impact dynamic characteristics of layered composite rocks. Chin. J. Rock Mech. Eng. 2019, 38, 1747–1757. [Google Scholar] [CrossRef]

- Subsidiary for Mining Design and Research, General Institute of Coal Science and Research. Methods for Determining Physical and Mechanical Properties of Coal and Rock Part 4: Methods for Calculating Porosity of Coal and Rock. Standard, General Administration of State Quality Supervision, Inspection and Quarantine of the People’s Republic of China; China National Standardization Management Committee: Beijing, China, 2009. [Google Scholar]

- Ping, Q.; Zhang, C.; Sun, H. Experimental study on dynamic characteristics of sandstone after different high temperature cyclings. J. Min. Saf. Eng. 2021, 38, 1015–1024. [Google Scholar] [CrossRef]

- Lee, O.; Kim, M. Dynamic material property characterization by using split Hopkinson pressure bar (SHPB) technique. Nucl. Eng. Des. 2003, 226, 119–125. [Google Scholar] [CrossRef]

| Specimen No. | Temperature/°C | Diameter/mm | Length/mm | Initial Mass/g | Porosity/% | Density/kg·m−3 | VP/m·s−1 |

|---|---|---|---|---|---|---|---|

| 7-1 | 25 | 67.16 | 66.6 | 562.85 | 2.94 | 2385.65 | 2579 |

| 8-5 | 200 | 66.86 | 66.68 | 546.79 | 3.11 | 2335.62 | 2551 |

| 6-3 | 400 | 67.5 | 66.7 | 539.01 | 2.74 | 2258.25 | 2310 |

| 17-2 | 600 | 68.5 | 67 | 562.44 | 3.13 | 2277.87 | 2392 |

| 23-2 | 800 | 67.4 | 67 | 550.24 | 3.21 | 2301.80 | 2554 |

| 4-4 | 1000 | 67.66 | 67.2 | 545.71 | 3.16 | 2258.59 | 2429 |

| Specimen No. | Temperature/°C | Impact No. | Impact Velocity/m·s−1 | Peak Stress/MPa | Peak Strain | Average Strain Rate/s−1 |

|---|---|---|---|---|---|---|

| 7-1 | 25 | 1 | 7.81 | 56.86 | 0.00635 | 45.64 |

| 2 | 8.23 | 57.53 | 0.00486 | 50.97 | ||

| 3 | 8.05 | 41.63 | 0.00545 | 47.57 | ||

| 8-5 | 200 | 1 | 7.90 | 35.45 | 0.00335 | 70.95 |

| 2 | 7.84 | 38.98 | 0.00497 | 60.93 | ||

| 3 | 7.58 | 37.21 | 0.00684 | 58.19 | ||

| 6-3 | 400 | 1 | 7.78 | 34.24 | 0.00648 | 51.23 |

| 2 | 7.99 | 29.29 | 0.00178 | 53.29 | ||

| 3 | 7.87 | 20.17 | 0.00018 | 57.37 | ||

| 17-2 | 600 | 1 | 8.23 | 29.76 | 0.00733 | 67.31 |

| 2 | 7.90 | 27.90 | 0.00129 | 67.42 | ||

| 23-2 | 800 | 1 | 8.47 | 14.92 | 0.00055 | 30.95 |

| 2 | 8.08 | 10.89 | 0.00291 | 59.73 | ||

| 4-4 | 1000 | 1 | 7.84 | 8.66 | 0.00080 | 38.24 |

| 2 | 8.05 | 6.56 | 0.00024 | 22.74 |

| Specimen No. | T/°C | Impact No. | Peak Stress/MPa | Impact Velocity/m·s−1 | WI/J | WR/J | WT/J | WL/J | ζ/% |

|---|---|---|---|---|---|---|---|---|---|

| 7-1 | 25 | 1 | 56.86 | 7.81 | 307 | 132 | 36 | 139 | 45.3 |

| 2 | 57.53 | 8.23 | 357 | 246 | 40 | 71 | 19.9 | ||

| 3 | 41.63 | 8.05 | 342 | 136 | 26 | 180 | 52.6 | ||

| 8-5 | 200 | 1 | 35.45 | 7.90 | 318 | 215 | 16 | 87 | 27.4 |

| 2 | 38.98 | 7.84 | 318 | 257 | 19 | 42 | 13.2 | ||

| 3 | 37.21 | 7.58 | 322 | 149 | 16 | 157 | 48.7 | ||

| 6-3 | 400 | 1 | 34.24 | 7.78 | 332 | 164 | 23 | 145 | 43.7 |

| 2 | 29.29 | 7.99 | 333 | 248 | 12 | 73 | 21.9 | ||

| 3 | 20.17 | 7.87 | 313 | 235 | 5 | 73 | 23.3 | ||

| 17-2 | 600 | 1 | 29.76 | 8.23 | 375 | 217 | 15 | 143 | 38.2 |

| 2 | 27.90 | 7.90 | 353 | 287 | 8 | 58 | 16.4 | ||

| 23-2 | 800 | 1 | 14.92 | 8.47 | 489 | 423 | 16 | 50 | 10.2 |

| 2 | 10.89 | 8.08 | 351 | 218 | 0.4 | 132.6 | 37.8 | ||

| 4-4 | 1000 | 1 | 8.66 | 7.84 | 346 | 313 | 0.6 | 32.4 | 9.4 |

| 2 | 6.56 | 8.05 | 356 | 320 | 0.3 | 35.7 | 10.02 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, H.; Chen, Q.; Ma, X. Investigation into Dynamic Behaviors of High-Temperature Sandstone under Cyclic Impact Loading Using DIC Technology. Appl. Sci. 2022, 12, 9247. https://doi.org/10.3390/app12189247

Lu H, Chen Q, Ma X. Investigation into Dynamic Behaviors of High-Temperature Sandstone under Cyclic Impact Loading Using DIC Technology. Applied Sciences. 2022; 12(18):9247. https://doi.org/10.3390/app12189247

Chicago/Turabian StyleLu, Hua, Qiaoli Chen, and Xiaotong Ma. 2022. "Investigation into Dynamic Behaviors of High-Temperature Sandstone under Cyclic Impact Loading Using DIC Technology" Applied Sciences 12, no. 18: 9247. https://doi.org/10.3390/app12189247

APA StyleLu, H., Chen, Q., & Ma, X. (2022). Investigation into Dynamic Behaviors of High-Temperature Sandstone under Cyclic Impact Loading Using DIC Technology. Applied Sciences, 12(18), 9247. https://doi.org/10.3390/app12189247