Study on the Influence of Ultrasound Homogenisation on the Physical Properties of Vegan Ice Cream Mixes

Abstract

:1. Introduction

2. Materials and Methods

2.1. The Preparation of the Hydrolysates of Iota Carrageenan

2.2. The Preparation of Ice Cream Mixes

2.2.1. The Materials for the Recipe for Ice Cream Mixes

2.2.2. The Production of Ice Cream Mixes

2.2.3. Ultrasound Homogenisation

2.3. The Ice Cream Mixes’ Physical Analysis

2.3.1. Stability Analysis of Ice Cream Mixes

2.3.2. The Analysis of Particle Size Distribution

2.3.3. The Morphology of the Ice Cream Mix

2.3.4. The Rheological Analysis of the Ice Cream Mix

2.4. Statistical Analysis

3. Results

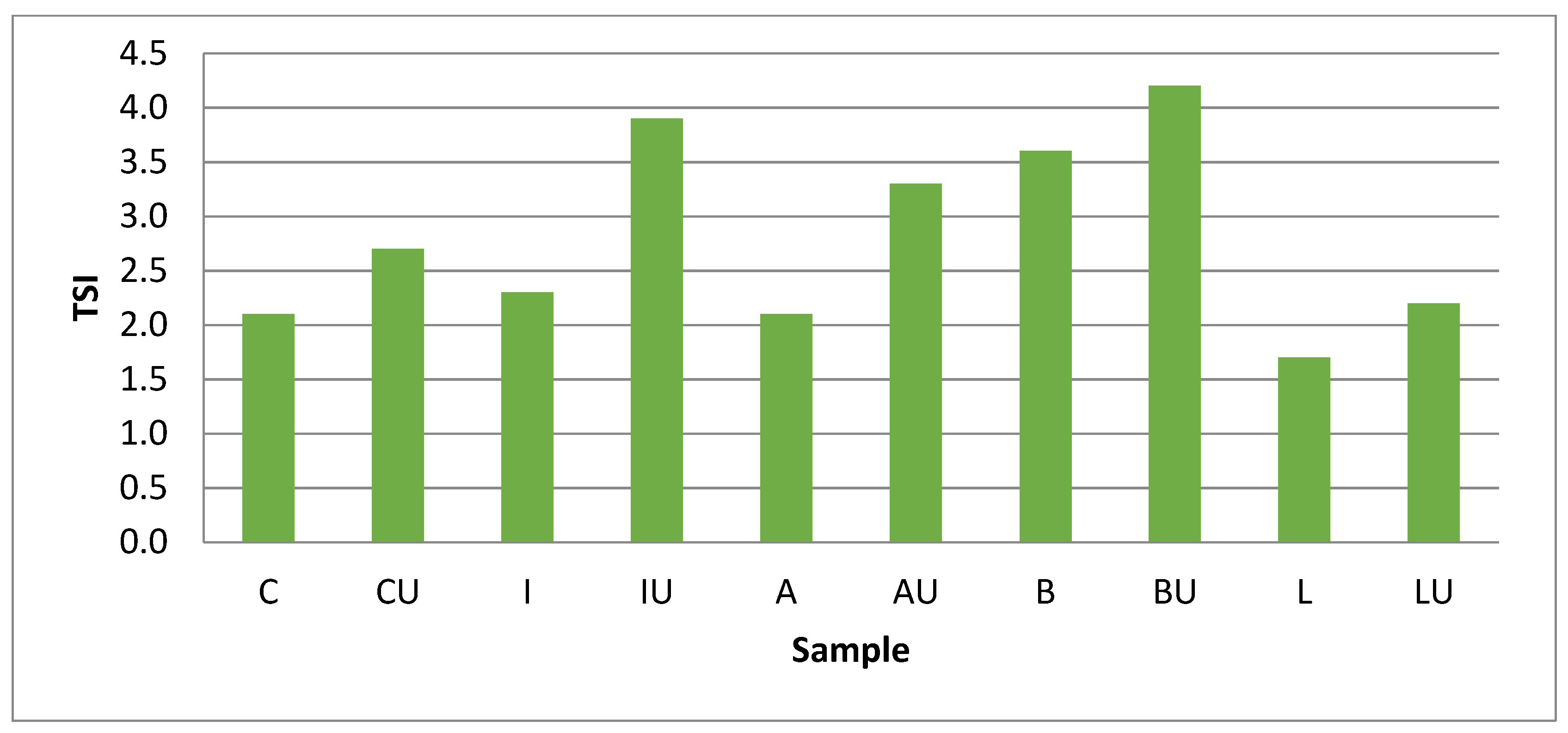

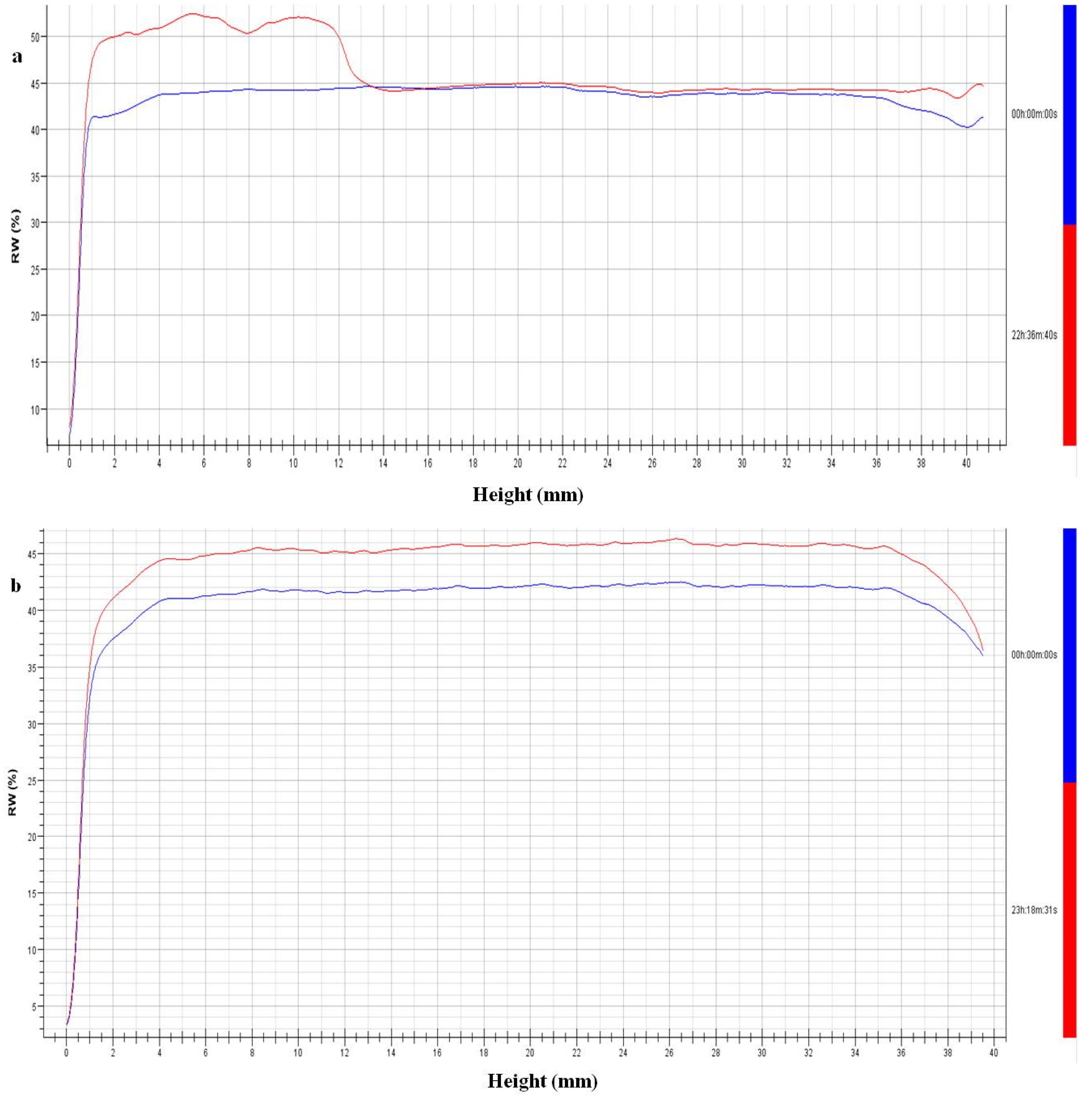

3.1. The Analysis of the Stability of Ice Cream Mixes

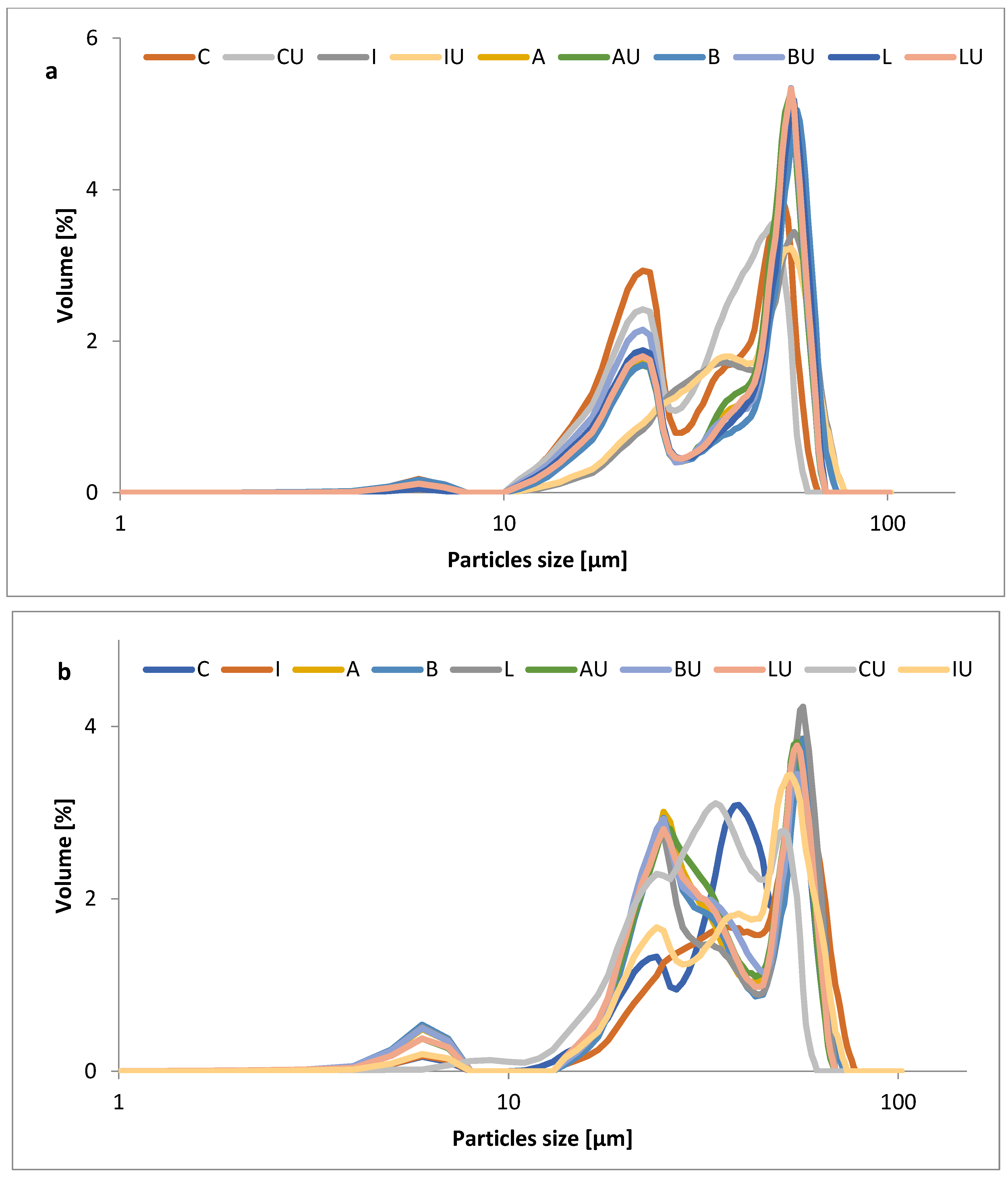

3.2. Analysis of Particle Sizes of Ice Cream Mixes

3.3. Analysis of Rheological Properties of Ice Cream Mixes

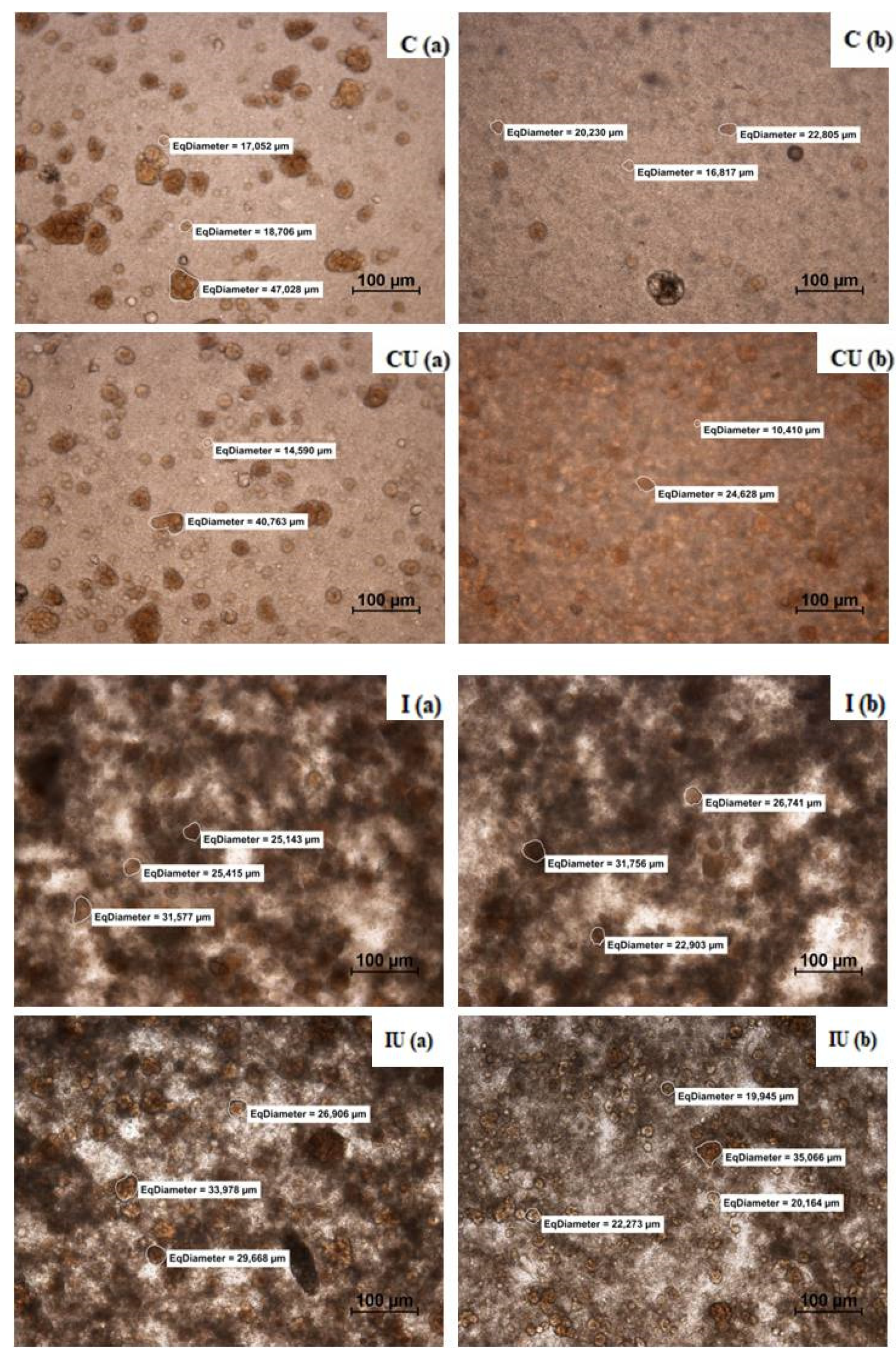

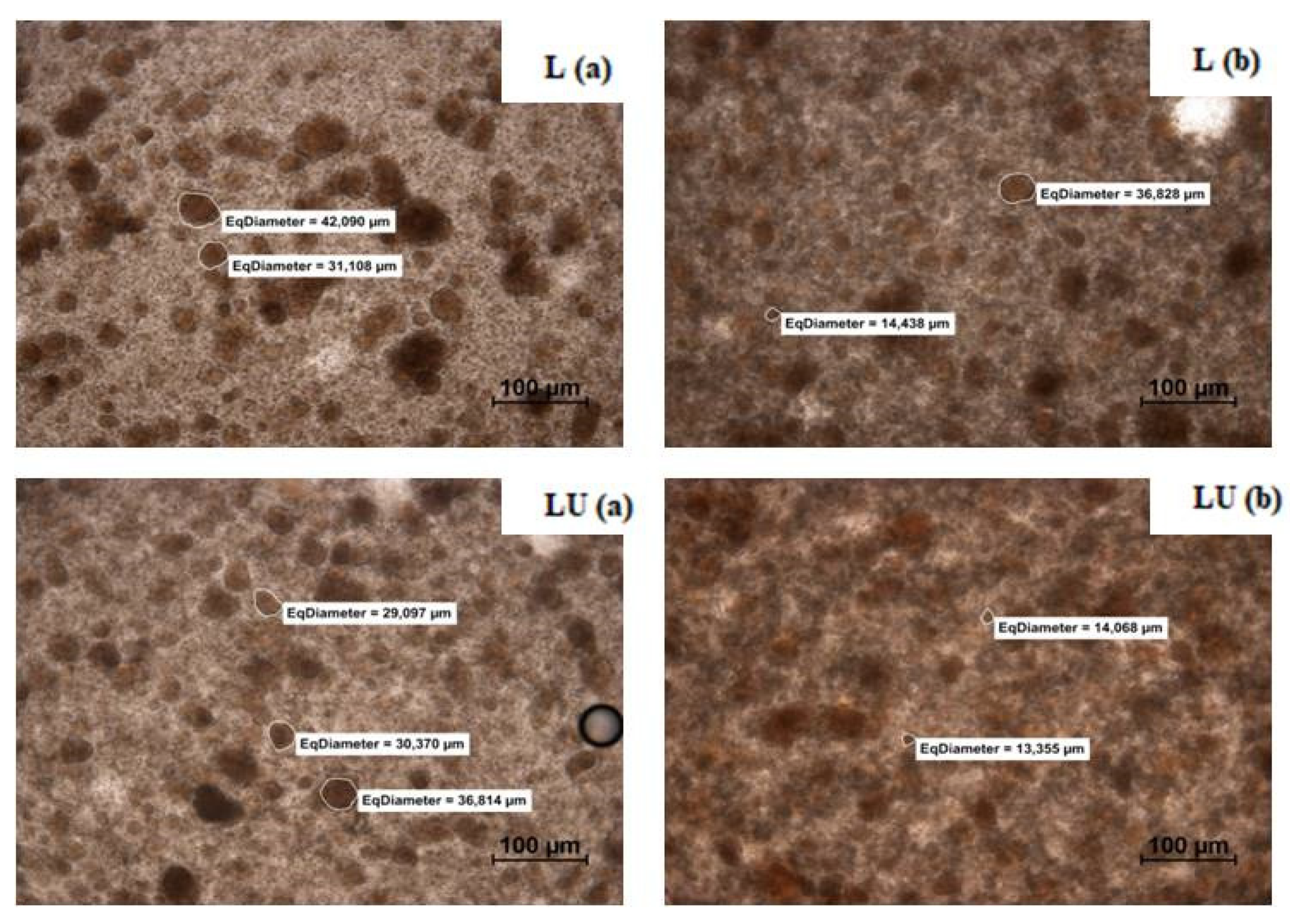

3.4. The Microstructure of Ice Cream Mixes

4. Discussion

4.1. Analysis of the Stability of Ice Cream Mixes

4.2. An Analysis of Particle Sizes of Ice Cream Mixes

4.3. An Analysis of Rheological Properties of Ice Cream Mixes

4.4. The Microstructure of Ice Cream Mixes

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fiol, C.; Prado, D.; Romero, C.; Laburu, N.; Mora, M.; Alava, I.J. Introduction of a new family of ice creams. Int. J. Gastron. Food Sci. 2017, 7, 5–10. [Google Scholar] [CrossRef]

- Biasutti, M.; Venir, E.; Marino, M.; Maifreni, M.; Innocente, N. Effects of high pressure homogenisation of ice cream mix on the physical and structural properties of ice cream. Int. Dairy J. 2013, 32, 40–45. [Google Scholar] [CrossRef]

- Lomolino, G.; Zannoni, S.; Zabara, A.; Da Lio, M.; De Iseppi, A. Ice recrystallization and melting in ice cream with different proteins levels and subjected to thermal fluctuation. Int. Dairy. J. 2020, 100, 104557. [Google Scholar] [CrossRef]

- Goff, H.D. Colloidal aspects of ice cream. A review. Int. Dairy J. 1997, 7, 363–373. [Google Scholar] [CrossRef]

- Mesa, J.; Hinestroza-Córdoba, L.I.; Barrera, C.; Seguí, L.; Betoret, E.; Betoret, N. High homogenization pressures to improve food quality, functionality and sustainability. Molecules 2020, 25, 3305. [Google Scholar] [CrossRef]

- Carrillo-Lopez, L.M.; Garcia-Galicia, I.A.; Tirado-Gallegos, J.M.; Sanchez-Vega, R.; Huerta-Jimenez, M.; Ashokkumar, M.; Alarcon-Rojo, A.D. Recent advances in the application of ultrasound in dairy products: Effect on functional, physical, chemical, microbiological and sensory properties. Ultrason. Sonochem. 2021, 73, 105467. [Google Scholar] [CrossRef]

- Laborde, J.-L.; Bouyer, C.; Caltagirone, J.-P.; Gerard, A. Acoustic bubble cavitation at low frequencies. Ultrasonics 1998, 36, 589–594. [Google Scholar] [CrossRef]

- Chemat, F.; Zill-e-Huma; Khan, K.M. Application of ultrasound in food technology: Processing, preservation and extraction. Ultrason. Sonochem. 2011, 18, 813–835. [Google Scholar] [CrossRef]

- Akdeniz, V.; Akalin Sibel, A. New approach for yoghurt and ice cream production: High-intensity ultrasound. Trends Food Sci. Technol. 2019, 86, 392–398. [Google Scholar] [CrossRef]

- Gallo, M.; Ferrara, L.; Naviglio, D. Application of Ultrasound in Food Science and Technology: A perspective. Foods 2018, 7, 164. [Google Scholar] [CrossRef] [Green Version]

- Arzeni, C.; Martinez, K.; Zema, P.; Arias, A.; Perez, O.E.; Pilsof, A.M.R. Comparative study of high intensity of ultrasound effects on food proteins functionality. J. Food Eng. 2012, 108, 463–472. [Google Scholar] [CrossRef]

- Bhargava, N.; Mor, R.S.; Kumar, K.; Sharanagat, V.S. Advances in application of ultrasound in food processing: A review. Ultrason. Sonochem. 2021, 70, 105293. [Google Scholar] [CrossRef]

- Hii, C.L.; Ong, S.P.; Yap, J.Y.; Putranto, A.; Mangindaan, D. Hybrid drying of food and bioproducts: A review. Dry. Technol. 2021, 39, 1554–1576. [Google Scholar] [CrossRef]

- Firouz, M.S. Application of high-intensity ultrasound in food processing for improvement of food quality. In Design and Optimization of Innovative Food Processing Techniques Assisted by Ultrasound. Developing Healthier and Sustainable Food Products; Barba, F., Cravotto, G., Chemat, F., Lorenzo Rodriguez, J.M., Sichetti Munekata, P.E., Eds.; Elsevier Inc.: Amsterdam, The Netherlands, 2021; pp. 155–159. [Google Scholar] [CrossRef]

- Firouz, M.S.; Farahmandi, A.; Hosseinpour, S. Recent advances in ultrasound application as a novel technique in analysis, processing and quality control of fruits, juices and dairy products industries: A review. Ultrason. Sonochem. 2019, 57, 73–88. [Google Scholar] [CrossRef]

- Aslan, D.; Dogan, M. The influence of ultrasound on the stability of dairy-based, emulsifier-free emulsions: Rheological and morphological aspect. Eur. Food Res. Technol. 2017, 244, 409–421. [Google Scholar] [CrossRef]

- Kot, A.; Kamińska-Dwórznicka, A.; Galus, S.; Jakubczyk, E. Effects of different ingredients and stabilisers on properties of mixes based on almond drink for vegan ice cream production. Sustainability 2021, 13, 12113. [Google Scholar] [CrossRef]

- O’Sullivan, J.; Beevers, J.; Park, M.; Greenwood, R.; Norton, I. Comparative assessment of the effect of ultrasound treatment on protein functionality pre- and post-emulsification. Colloids Surf. A Physicochem. Eng. Asp. 2015, 484, 89–98. [Google Scholar] [CrossRef]

- Mengual, O.; Meunier, G.; Cayre, I.; Puech, K.; Snabre, P. Characterisation of instability of concentrated dispersion by a new optical analyser: The TURBISCAN MA 1000. Colloids Surf. A Physicochem. Eng. Asp. 1999, 152, 111–123. [Google Scholar] [CrossRef]

- Voronin, G.L.; Roberts, R.; Felix, T.L.; Coupland, J.N.; Harte, F.M. Effect of high-pressure-jest processing on the physicochemical properties of low-fat ice cream mix. J. Dairy Sci. 2020, 103, 6003–6014. [Google Scholar] [CrossRef]

- O’Sullivan, J.; Murray, B.; Flynn, C.R.; Norton, I. The effect of ultrasound on the structural, physical and emulsifying properties of animal and vegetable proteins. Food Hydrocoll. 2016, 53, 141–154. [Google Scholar] [CrossRef]

- Sert, D.; Mercan, E. High-pressure homogenisation of sheep milk ice cream mix: Physicochemical and microbiological characterization. LWT 2021, 151, 1124148. [Google Scholar] [CrossRef]

- Zhang, R.; Luo, L.; Yang, Z.; Ashokkumar, M.; Hemar, Y. Formation by high ultrasound of aggregated emulsions stabilised with milk protein concentrate (MPC70). Ultrason. Sonochem. 2021, 81, 105852. [Google Scholar] [CrossRef]

- Warren, M.M.; Hartel, R.W. Effects of emulsifier, overrun and dasher speed on ice cream microstructure and melting properties. J. Food Sci. 2018, 83, 639–647. [Google Scholar] [CrossRef]

- Huppertz, T.; Smiddy, M.A.; Goff, H.D.; Kelly, A.L. Effects of high pressure treatment of mix on ice cream manufacture. Intern. Dairy J. 2011, 21, 718–726. [Google Scholar] [CrossRef]

- Innocente, N.; Biasutti, M.; Venir, E.; Spaziani, M.; Marchesini, G. Effect of high-pressure homogenization on droplet size distribution and rheological properties of ice cream mixes. J. Dairy Sci. 2009, 92, 1864–1875. [Google Scholar] [CrossRef]

- Rao, M.A. Rheology of Fluid And Semisolid Foods: Principles and Applications; Springer Science & Business Media: New York, NY, USA, 2007. [Google Scholar] [CrossRef]

- Mostafavi, F.S.; Tehrani, M.M.; Mohebbi, M. Rheological and sensory properties of fat reduced vanilla ice creams containing milk protein concentrate (MPC). J. Food Meas. Charact. 2017, 11, 567–575. [Google Scholar] [CrossRef]

- Ahn, N.; Park, J.; Chai, C.; Imm, J. The interaction of milk sphingomyelin and proteins on stability and microstructure of dairy emulsions. J. Dairy Sci. 2022, 105, 3832–3845. [Google Scholar] [CrossRef]

- Kamińska-Dwórznicka, A.; Łaba, S.; Jakubczyk, E. The effects of selected stabilizers addition on physical properties and changes in crystal structure of whey ice cream. LWT 2022, 154, 112841. [Google Scholar] [CrossRef]

- Kot, A.; Kamińska-Dwórznicka, A.; Antczak, A.; Jakubczyk, E.; Matwijczuk, A. Effect of ι-carrageenan and its acidic and enzymatic hydrolysates on ice crystal structure changes in model sucrose solution. Colloids Surf. A Physicochem. Eng. Asp. 2022, 643, 128744. [Google Scholar] [CrossRef]

| Sample | Description |

|---|---|

| C | The control sample |

| CU | The control sample after ultrasound homogenisation |

| I | The sample with stabilisers (the combination of iota carrageenan, LBG and xanthan gum) |

| IU | The sample with stabilisers (the combination of iota carrageenan, LBG and xanthan gum) after ultrasound homogenisation |

| A | The sample with stabilisers (the combination of acid hydrolysates of iota carrageenan, LBG and xanthan gum) |

| AU | The sample with stabilisers (the combination of acid hydrolysates of iota carrageenan, LBG and xanthan gum) after ultrasound homogenisation |

| B | The sample with stabilisers (the combination of enzymatic β-galactosidase hydrolysates of iota carrageenan, LBG and xanthan gum) |

| BU | The sample with stabilisers (the combination of enzymatic β-galactosidase hydrolysates of iota carrageenan, LBG and xanthan gum) after ultrasound homogenisation |

| L | The sample with stabilisers (the combination of enzymatic commercial lactase hydrolysates of iota carrageenan, LBG and xanthan gum) |

| LU | The sample with stabilisers (the combination of enzymatic commercial lactase hydrolysates of iota carrageenan, LBG and xanthan gum) after ultrasound homogenisation |

| Sample | D50 before Maturation | D50 after Maturation |

|---|---|---|

| C | 15.65 ± 0.62 a | 17.23 ± 0.49 c |

| CU | 14.68 ± 0.17 a | 9.97 ± 0.23 a |

| I | 30.40 ± 0,44 e | 28.50 ± 0.43 e |

| IU | 28.70 ± 0.16 d | 23.73 ± 0.62 d |

| A | 38.36 ± 0.49 c | 11.41 ± 0.97 ab |

| AU | 35.70 ± 0.50 b | 11.24 ± 1.41 a |

| B | 42.15 ± 0.19 g | 11.29 ± 0.53 ab |

| BU | 34.29 ± 0.14 f | 9.76 ± 0.36 a |

| L | 38.31 ± 0.66 c | 13.20 ± 0.45 b |

| LU | 36.92 ± 0.56 b | 10.59 ± 0.09 a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kot, A.; Kamińska-Dwórznicka, A.; Jakubczyk, E. Study on the Influence of Ultrasound Homogenisation on the Physical Properties of Vegan Ice Cream Mixes. Appl. Sci. 2022, 12, 8492. https://doi.org/10.3390/app12178492

Kot A, Kamińska-Dwórznicka A, Jakubczyk E. Study on the Influence of Ultrasound Homogenisation on the Physical Properties of Vegan Ice Cream Mixes. Applied Sciences. 2022; 12(17):8492. https://doi.org/10.3390/app12178492

Chicago/Turabian StyleKot, Anna, Anna Kamińska-Dwórznicka, and Ewa Jakubczyk. 2022. "Study on the Influence of Ultrasound Homogenisation on the Physical Properties of Vegan Ice Cream Mixes" Applied Sciences 12, no. 17: 8492. https://doi.org/10.3390/app12178492

APA StyleKot, A., Kamińska-Dwórznicka, A., & Jakubczyk, E. (2022). Study on the Influence of Ultrasound Homogenisation on the Physical Properties of Vegan Ice Cream Mixes. Applied Sciences, 12(17), 8492. https://doi.org/10.3390/app12178492