Machine and Deep Learning in the Evaluation of Selected Qualitative Characteristics of Sweet Potatoes Obtained under Different Convective Drying Conditions

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material

2.2. Moisture Content

2.3. Convective Drying Procedure

2.4. Color Measurement

2.5. Texture Measurement

2.6. Acquisition of Image of Sweet Potatoes

2.7. Architecture of Used Artificial Neural Networks

- an input layer, i.e., numerical data in the form of 6 texture coefficients such as contrast, dissimilarity, homogeneity, and correlation (indirectly extracted from digital images using the GLCM matrix).

- a hidden layer, for which a range of 5 to 25 neurons was set.

- a set activation function for the hidden layer: Exponential, Hyperbolic Tangent (Tanh), Logistic and output layer type Hyperbolic Tangent (Tanh), Softmax, and Linear.

- an output layer, i.e., numerical data of classes 1–4 on the different drying temperatures.

- a Broyden–Fletcher–Goldfarb–Shanno (BFGS) learning algorithm was set up [41].

3. Results

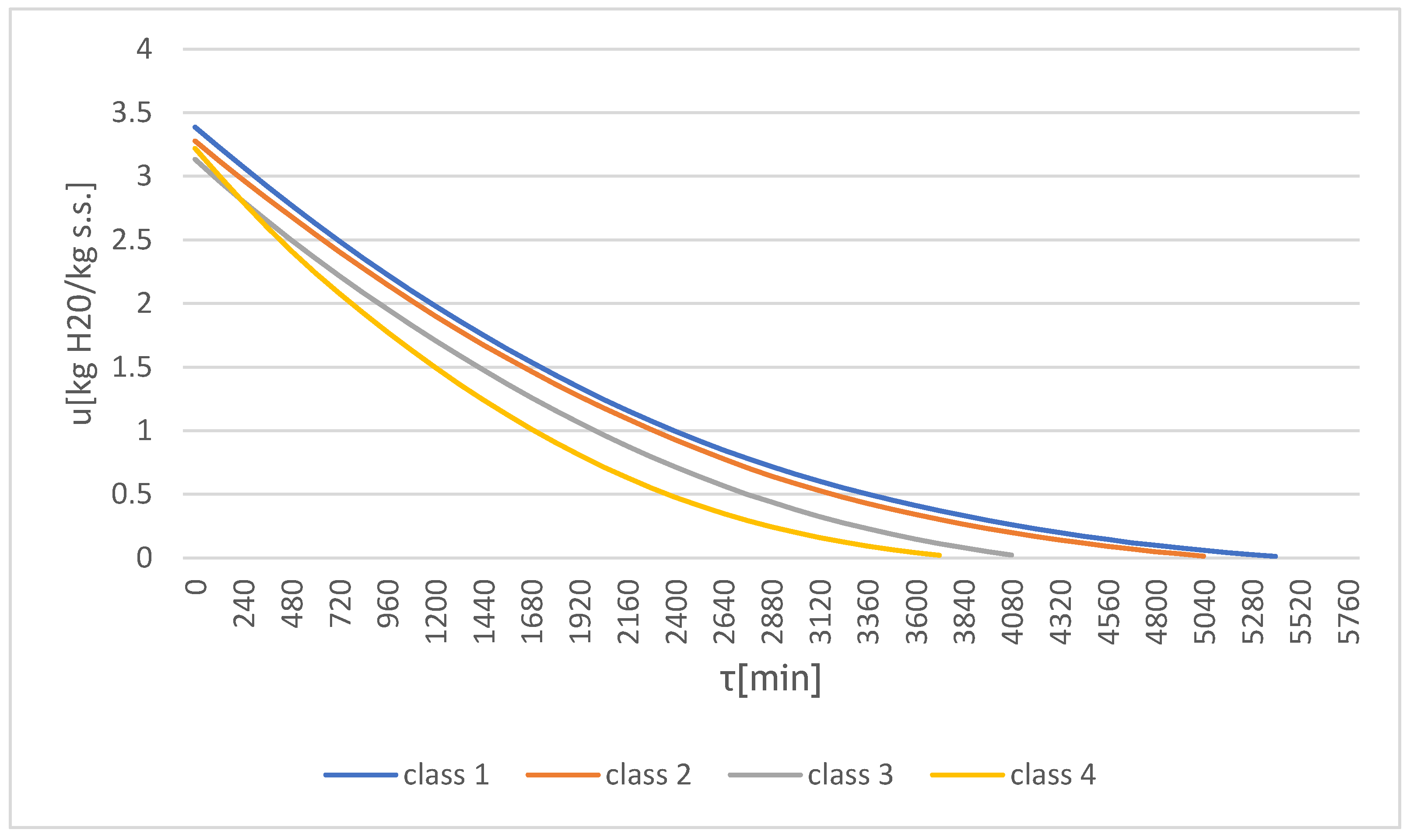

3.1. Dynamics of Convective Drying Process Applied to Collected Samples

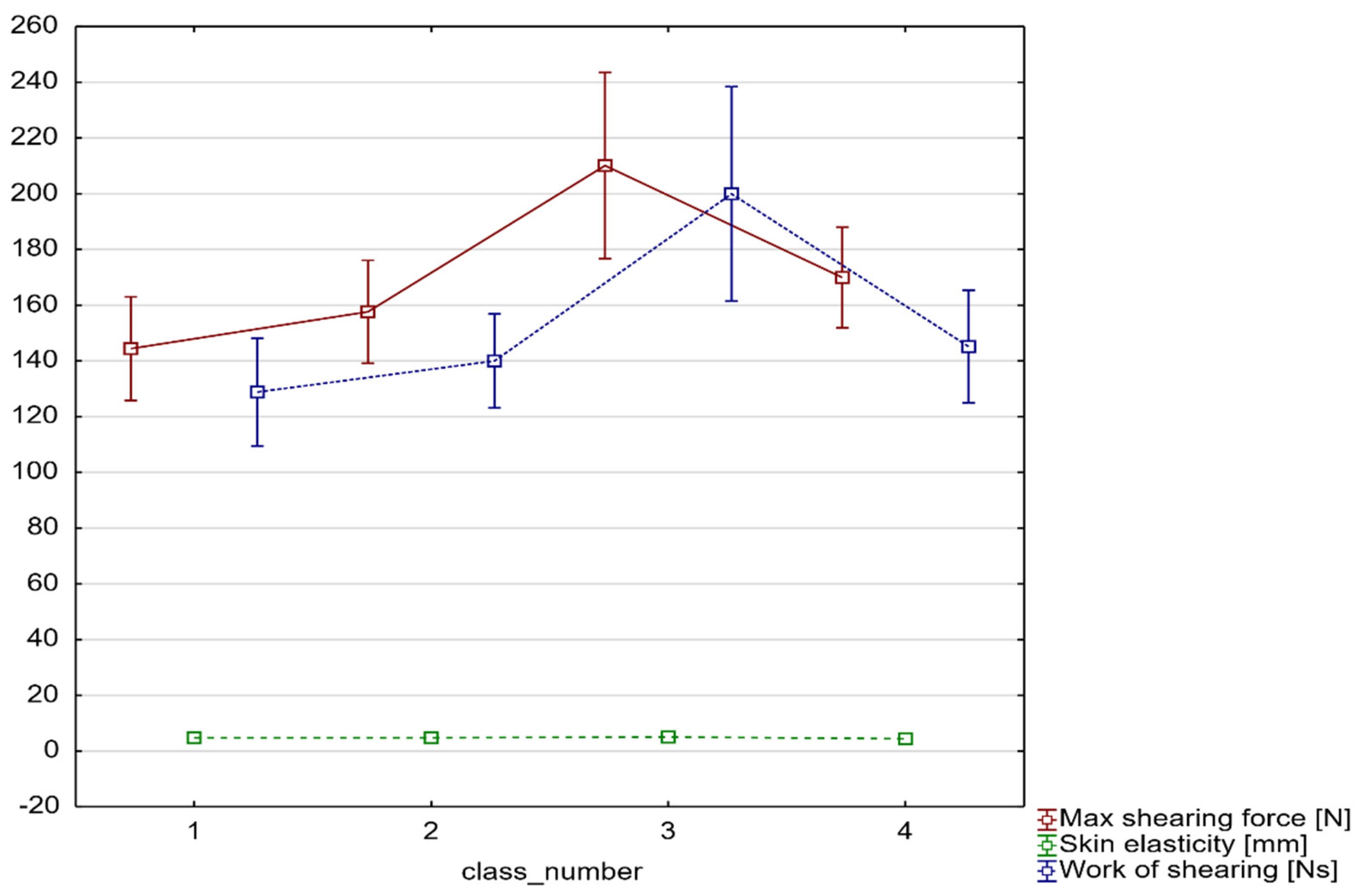

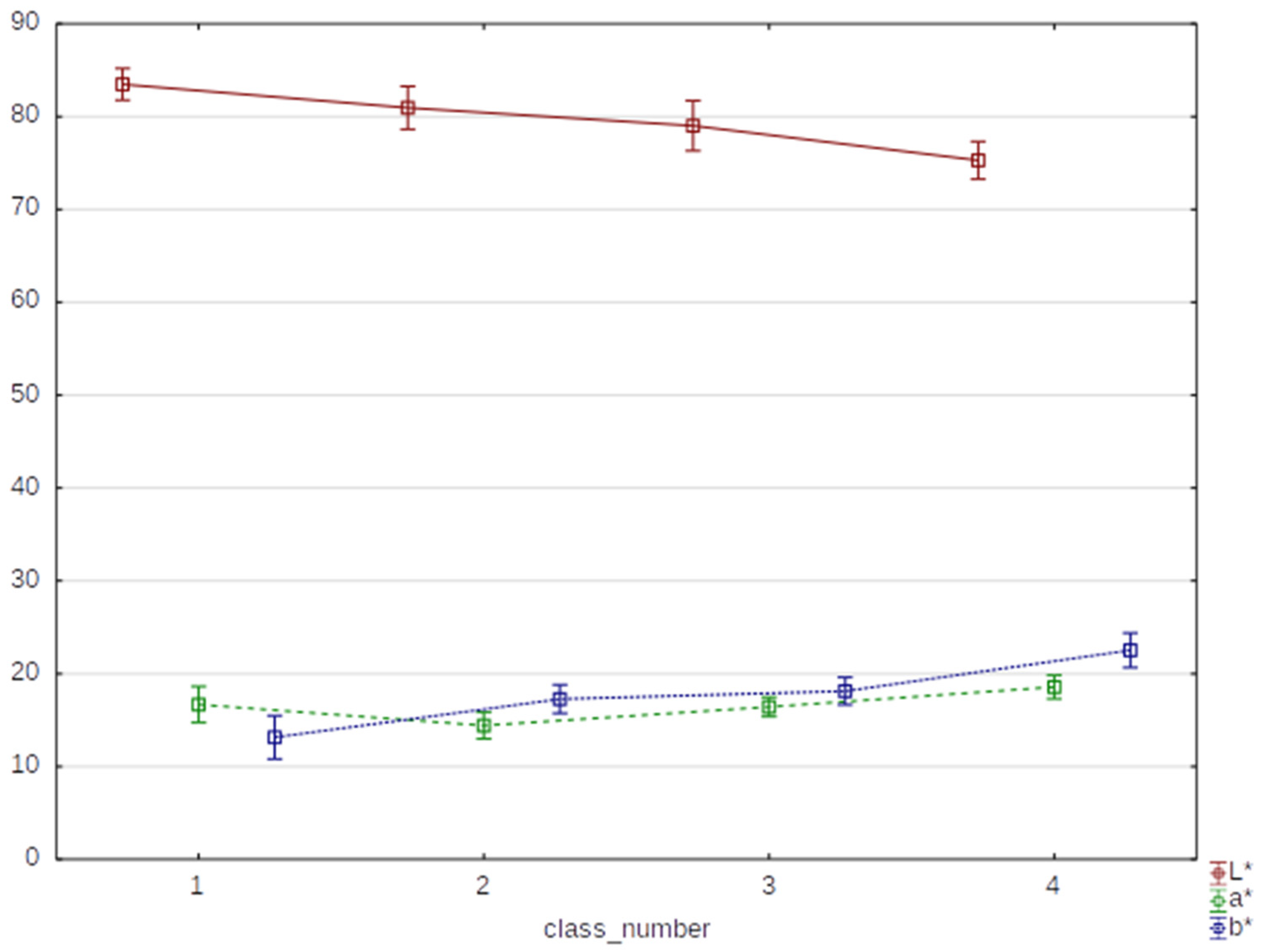

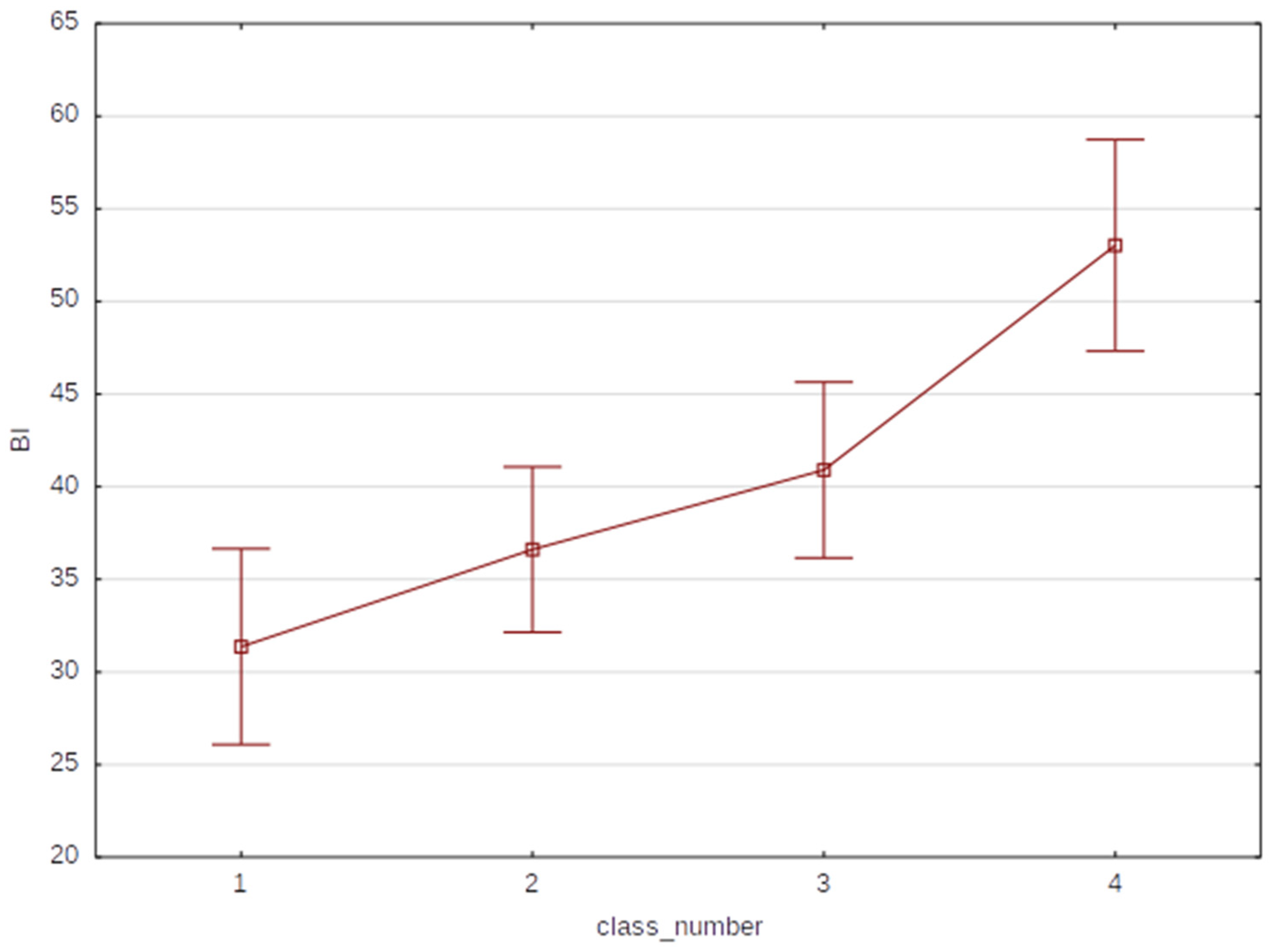

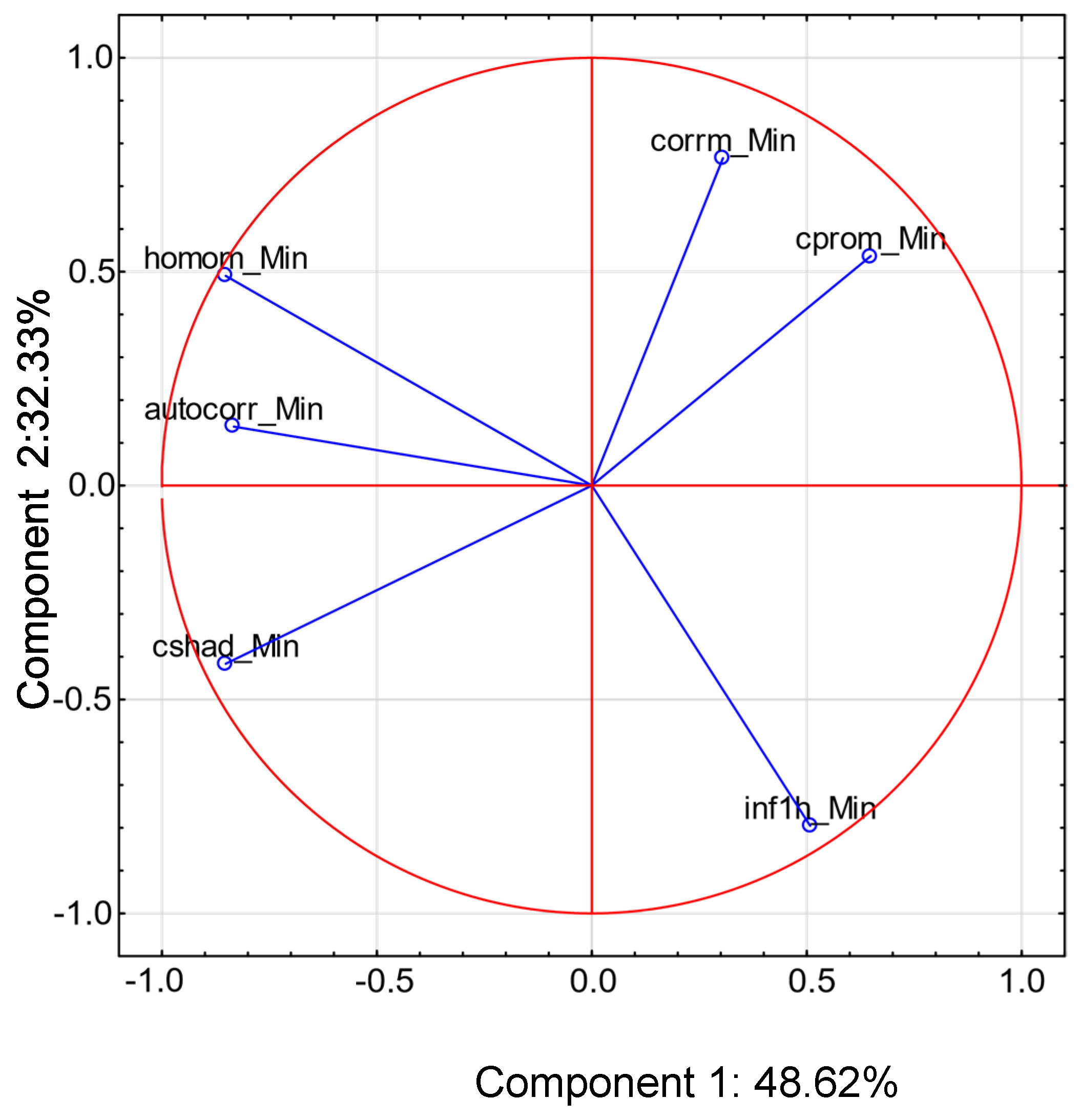

3.2. Statistical Analysis by Mechanical Texture, Color RGB, Color Lab, Texture GLCM

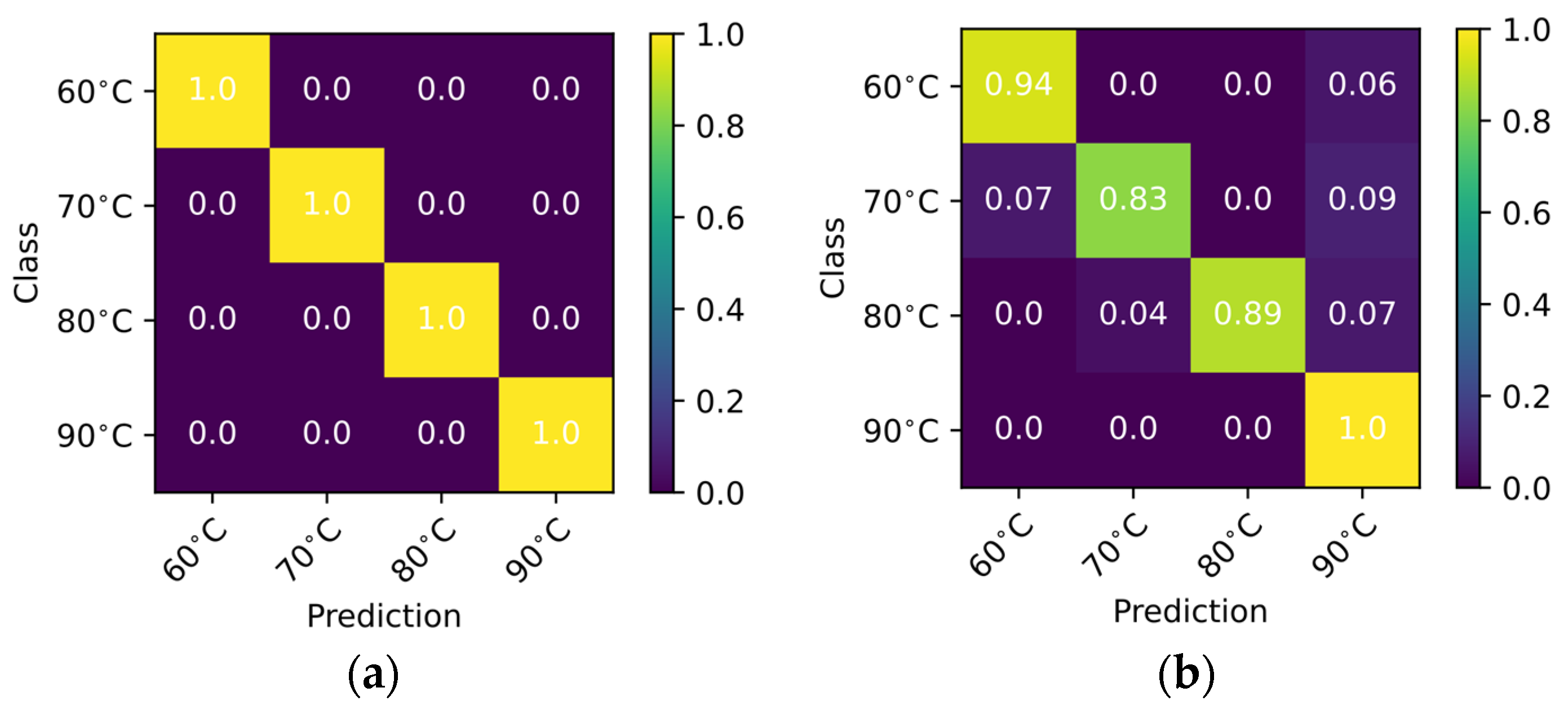

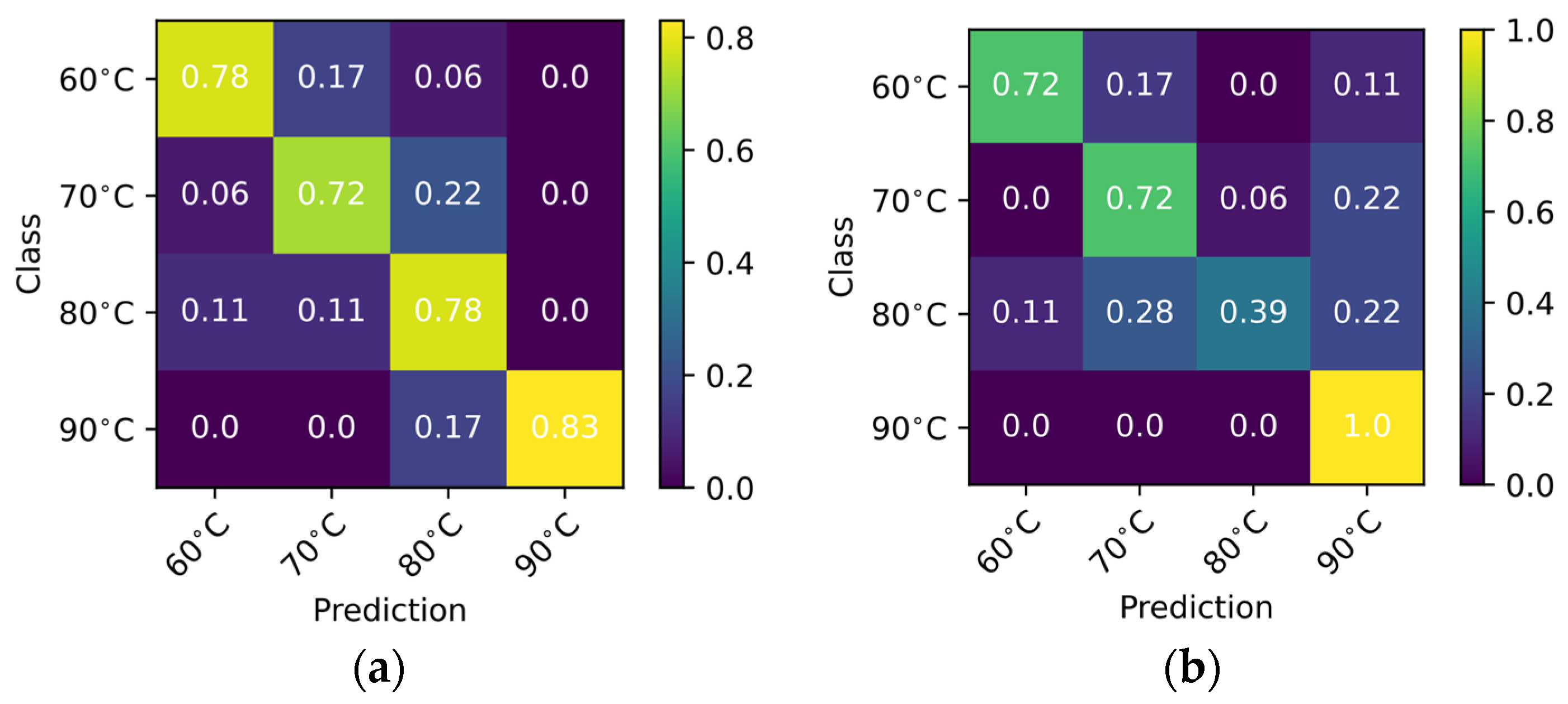

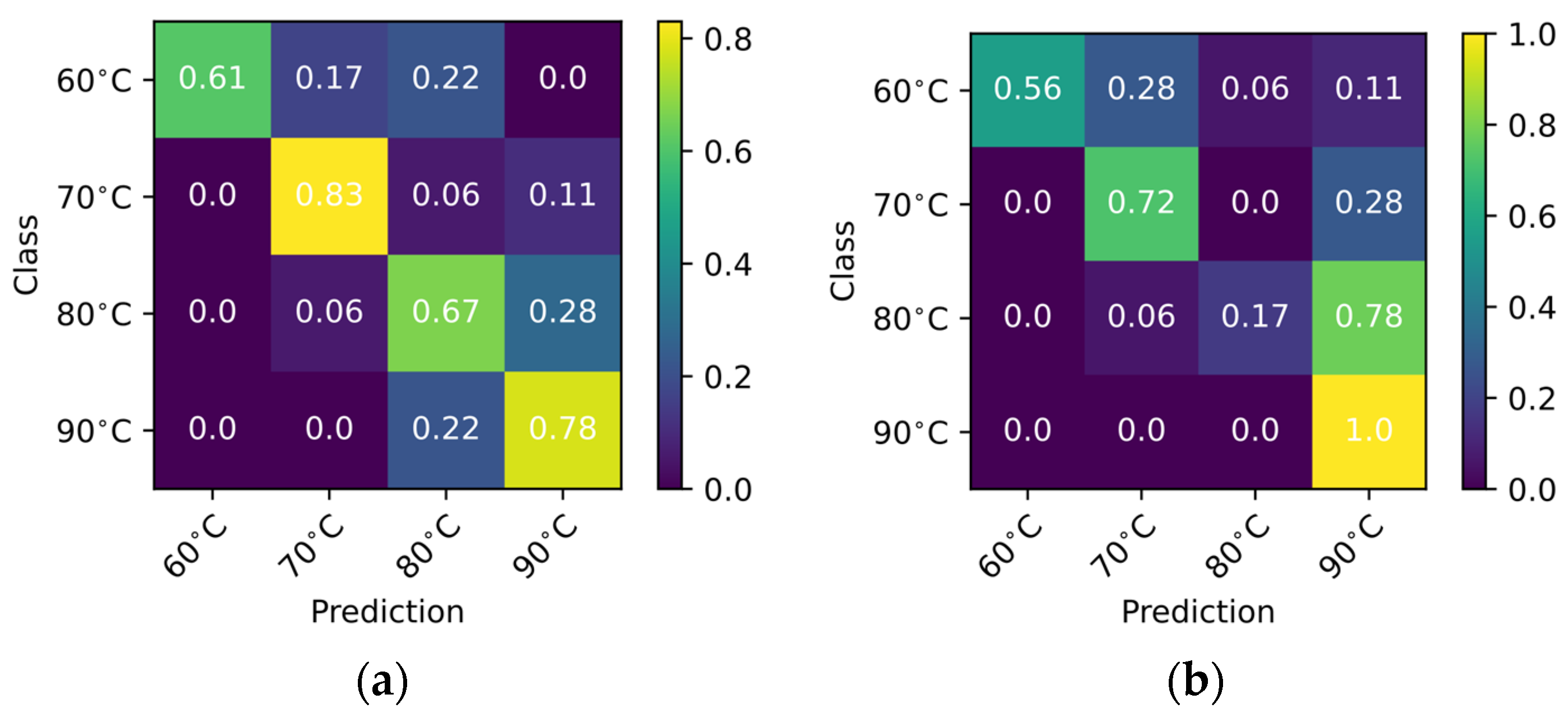

3.3. Classification of Samples Using Artificial Neural Networks

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kim, S.Y.; Wi, H.-R.; Choi, S.; Ha, T.J.; Lee, B.W.; Lee, M. Inhibitory effect of anthocyanin-rich black soybean testa (Glycine max (L.) Merr.) on the inflammation-induced adipogenesis in a DIO mouse model. J. Funct. Foods 2015, 14, 623–633. [Google Scholar] [CrossRef]

- Jiao, Q.; Lin, B.; Mao, Y.; Jiang, H.; Guan, X.; Li, R.; Wang, S. Effects of combined radio frequency heating with oven baking on product quality of sweet potato. Food Control 2022, 139, 109097. [Google Scholar] [CrossRef]

- Suárez, M.H.; Hernández, A.I.M.; Galdón, B.R.; Rodríguez, L.H.; Cabrera, C.E.M.; Mesa, D.R.; Rodríguez-Rodríguez, E.M.; Romero, C.D. Application of multidimensional scaling technique to differentiate sweet potato (Ipomoea batatas (L.) Lam) cultivars according to their chemical composition. J. Food Compos. Anal. 2016, 46, 43–49. [Google Scholar] [CrossRef]

- Alam, M.K.; Sams, S.; Rana, Z.H.; Akhtaruzzaman, M.; Islam, S.N. Minerals, vitamin C, and effect of thermal processing on carotenoids composition in nine varieties orange-fleshed sweet potato (Ipomoea batatas L.). J. Food Compos. Anal. 2020, 92, 103582. [Google Scholar] [CrossRef]

- Hossain, M.; Rahim, A.; Moutosi, H.N.; Das, L. Evaluation of the growth, storage root yield, proximate composition, and mineral content of colored sweet potato genotypes. J. Agric. Food Res. 2022, 8, 100289. [Google Scholar] [CrossRef]

- Mazza, G. Anthocyanins in Fruits, Vegetables, and Grains; Mazza, G., Miniati, E., Eds.; CRC Press: Boca Raton, FL, USA, 2018; ISBN 9781351069700. [Google Scholar]

- Jang, H.H.; Kim, H.W.; Kim, S.Y.; Kim, S.M.; Kim, J.B.; Lee, Y.M. In vitro and in vivo hypoglycemic effects of cyanidin 3-caffeoyl-p-hydroxybenzoylsophoroside-5 glucoside, an anthocyanin isolated from purple-fleshed sweet potato. Food Chem. 2019, 272, 688–693. [Google Scholar] [CrossRef]

- Amagloh, F.; Yada, B.; Tumuhimbise, G.; Amagloh, F.; Kaaya, A. The Potential of Sweetpotato as a Functional Food in Sub-Saharan Africa and Its Implications for Health: A Review. Molecules 2021, 26, 2971. [Google Scholar] [CrossRef]

- Wilson, C.D.; Pace, R.D.; Bromfield, E.; Jones, G.; Lu, J.Y. Consumer acceptance of vegetarian sweet potato products intended for space missions. Life Support Biosph. Sci. 1998, 5, 339–346. [Google Scholar]

- Salinas, J.G.; Alvarado, J.A.; Bergenståhl, B.; Tornberg, E. The influence of convection drying on the physicochemical properties of yacón (Smallanthus sonchifolius). Heat Mass Transf. 2018, 54, 2951–2961. [Google Scholar] [CrossRef] [Green Version]

- Campos, D.; Aguilar-Galvez, A.; Pedreschi, R. Stability of fructooligosaccharides, sugars and colour of yacon (Smallanthus sonchifolius) roots during blanching and drying. Int. J. Food Sci. Technol. 2016, 51, 1177–1185. [Google Scholar] [CrossRef]

- Oke, M.O.; Workneh, T.S. Convective Hot Air Drying of Different Varieties of Blanched Sweet Potato Slices. Int. J. Agric. Biosyst. Eng. 2014, 8, 12. [Google Scholar] [CrossRef]

- Pawlak, T.; Pilarska, A.A.; Przybył, K.; Stangierski, J.; Ryniecki, A.; Cais-Sokolińska, D.; Pilarski, K.; Peplińska, B. Application of Machine Learning Using Color and Texture Analysis to Recognize Microwave Vacuum Puffed Pork Snacks. Appl. Sci. 2022, 12, 5071. [Google Scholar] [CrossRef]

- Sebatjane, M. The impact of preservation technology investments on lot-sizing and shipment strategies in a three-echelon food supply chain involving growing and deteriorating items. Oper. Res. Perspect. 2022, 9, 100241. [Google Scholar] [CrossRef]

- Przybył, K.; Gawałek, J.; Koszela, K.; Wawrzyniak, J.; Gierz, L. Artificial neural networks and electron microscopy to evaluate the quality of fruit and vegetable spray-dried powders. Case study: Strawberry powder. Comput. Electron. Agric. 2018, 155, 314–323. [Google Scholar] [CrossRef]

- Saldaña, E.; Siche, R.; Castro, W.; Huamán, R.; Quevedo, R. Measurement parameter of color on yacon (Smallanthus sonchifolius) slices using a computer vision system. LWT Food Sci. Technol. 2014, 59, 1220–1226. [Google Scholar] [CrossRef]

- Hameed, K.; Chai, D.; Rassau, A. A comprehensive review of fruit and vegetable classification techniques. Image Vis. Comput. 2018, 80, 24–44. [Google Scholar] [CrossRef]

- Przybył, K.; Masewicz, Ł.; Koszela, K.; Duda, A.; Szychta, M.; Gierz, Ł. An MLP Artificial Neural Network for Detection of the Degree of Saccharification of Arabic Gum Used as a Carrier Agent of Raspberry Powders. In Proceedings of the Thirteenth International on Digital Image Processing (ICDIP 2021), Bellingham, WA, USA, 30 June 2021; Jiang, X., Fujita, H., Eds.; SPIE: Bellingham, WA, USA, 2021; Volume 11878, p. 93. [Google Scholar]

- Zhang, Y.; Wang, S.; Ji, G.; Phillips, P. Fruit classification using computer vision and feedforward neural network. J. Food Eng. 2014, 143, 167–177. [Google Scholar] [CrossRef]

- Cheng, X.; Yan, X.; Hu, M. The effect of storage pressure on the mechanical properties of paddy grains. J. Stored Prod. Res. 2016, 68, 19–24. [Google Scholar] [CrossRef]

- Przybył, K.; Samborska, K.; Koszela, K.; Masewicz, L.; Pawlak, T. Artificial neural networks in the evaluation of the influence of the type and content of carrier on selected quality parameters of spray dried raspberry powders. Measurement 2021, 186, 110014. [Google Scholar] [CrossRef]

- Soltani, M.; Omid, M.; Alimardani, R. Egg volume prediction using machine vision technique based on pappus theorem and artificial neural network. J. Food Sci. Technol. 2015, 52, 3065–3071. [Google Scholar] [CrossRef] [Green Version]

- Rad, M.R.N.; Koohkan, S.; Fanaei, H.R.; Rad, M.R.P. Application of Artificial Neural Networks to predict the final fruit weight and random forest to select important variables in native population of melon (Cucumis melo L.). Sci. Hortic. 2015, 181, 108–112. [Google Scholar] [CrossRef]

- Agarwal, M.; Singh, M.K.; Srivastava, R.; Gautam, R.K. Microstructural measurement and artificial neural network analysis for adhesion of tribolayer during sliding wear of powder-chip reinforcement based composites. Measurement 2021, 168, 108417. [Google Scholar] [CrossRef]

- Lu, C.; Shi, J. Relative density prediction of additively manufactured Inconel 718: A study on genetic algorithm optimized neural network models. Rapid Prototyp. J. 2022, 28, 1425–1436. [Google Scholar] [CrossRef]

- Rashed, K.; Kafi, A.; Simons, R.; Bateman, S. Fused filament fabrication of nylon 6/66 copolymer: Parametric study comparing full factorial and Taguchi design of experiments. Rapid Prototyp. J. 2022, 28, 1111–1128. [Google Scholar] [CrossRef]

- Agrawal, R. Sustainable design guidelines for additive manufacturing applications. Rapid Prototyp. J. 2022, 28, 1221–1240. [Google Scholar] [CrossRef]

- Krohn, J.; Beyleveld, G.; Bassens, A. Deep Learning Illustrated: A Visual, Interactive Guide to Artificial Intelligence; Addison-Wesley Professional: Boston, MA, USA, 2020. [Google Scholar]

- Boniecki, P.; Nowakowski, K.; Tomczak, R.J. Neural Networks Type MLP in the Process of Identification Chosen Varieties of Maize. In Proceedings of the 3rd International Conference on Digital Image Processing (ICDIP 2011), Chengdu, China, 8 July 2011; Volume 8009, pp. 11–13. [Google Scholar] [CrossRef]

- Kwon, S.J. Artificial Neural Networks; Nova Science Publishers, Inc.: London, UK, 2011; ISBN 9781617615535. [Google Scholar]

- Marwala, T. Multi-Layer Perceptron. In Handbook of Machine Learning; World Scientific: Singapore, 2018. [Google Scholar]

- Przybył, K.; Koszela, K.; Adamski, F.; Samborska, K.; Walkowiak, K.; Polarczyk, M. Deep and Machine Learning Using SEM, FTIR, and Texture Analysis to Detect Polysaccharide in Raspberry Powders. Sensors 2021, 21, 5823. [Google Scholar] [CrossRef] [PubMed]

- Kulapichitr, F.; Borompichaichartkul, C.; Fang, M.; Suppavorasatit, I.; Cadwallader, K.R. Effect of post-harvest drying process on chlorogenic acids, antioxidant activities and CIE-Lab color of Thai Arabica green coffee beans. Food Chem. 2022, 366, 130504. [Google Scholar] [CrossRef]

- Azetsu, T.; Suetake, N. Chroma Enhancement in CIELAB Color Space Using a Lookup Table. Designs 2021, 5, 32. [Google Scholar] [CrossRef]

- Pathare, P.; Opara, U.L.; Al-Said, F.A.-J. Colour Measurement and Analysis in Fresh and Processed Foods: A Review. Food Bioprocess Technol. 2013, 6, 36–60. [Google Scholar] [CrossRef]

- Pawlak, T.; Gawałek, J.; Ryniecki, A.; Stangierski, J.; Siatkowski, I.; Peplińska, B.; Pospiech, E. Microwave vacuum drying and puffing of the meat tissue—Process analysis. Dry. Technol. 2018, 37, 156–163. [Google Scholar] [CrossRef]

- Przybył, K.; Ryniecki, A.; Niedbała, G.; Mueller, W.; Boniecki, P.; Zaborowicz, M.; Koszela, K.; Kujawa, S.; Kozłowski, R.J. Software supporting definition and extraction of the quality parameters of potatoes by using image analysis. In Proceedings of the Eighth International Conference on Digital Image Processing, Chengu, China, 20–22 May 2016; p. 100332L. [Google Scholar] [CrossRef]

- Chollet, F. Deep Learning. Praca z Językiem Python i Biblioteką Keras; HELION SA: Gliwice, Poland, 2019; ISBN 978-83-283-4778-6. [Google Scholar]

- Haralick, R.M.; Shanmugam, K.; Dinstein, I.H. Textural Features for Image Classification. IEEE Trans. Syst. Man Cybern. 1973, 6, 610–621. [Google Scholar] [CrossRef] [Green Version]

- Unser, M. Texture classification and segmentation using wavelet frames. IEEE Trans. Image Process. 1995, 4, 1549–1560. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Atsamnia, D.; Hamadache, M.; Hanini, S.; Benkortbi, O.; Oukrif, D. Prediction of the antibacterial activity of garlic extract on E. coli, S. aureus and B. subtilis by determining the diameter of the inhibition zones using artificial neural networks. LWT Food Sci. Technol. 2017, 82, 287–295. [Google Scholar] [CrossRef]

- Chen, H.-Y.; Su, C.-Y. An Enhanced Hybrid MobileNet. In Proceedings of the 2018 9th International Conference on Awareness Science and Technology (iCAST), Fukuoka, Japan, 19–21 September 2018; pp. 308–312. [Google Scholar] [CrossRef] [Green Version]

- Manickavasagan, A.; Al-Mezeini, N.; Al-Shekaili, H. RGB color imaging technique for grading of dates. Sci. Hortic. 2014, 175, 87–94. [Google Scholar] [CrossRef]

- Howard, A.G.; Zhu, M.; Chen, B.; Kalenichenko, D.; Wang, W.; Weyand, T.; Andreetto, M.; Adam, H. MobileNets: Efficient Convolutional Neural Networks for Mobile Vision Applications. arXiv 2017, arXiv:1704.04861. [Google Scholar]

- Nelli, F. Deep Learning with TensorFlow. In Python Data Analytics; Apress: Berkeley, CA, USA, 2018. [Google Scholar]

- Gamboa-Santos, J.; Soria, A.C.; Fornari, T.; Villamiel, M.; Montilla, A. Optimisation of convective drying of carrots using selected processing and quality indicators. Int. J. Food Sci. Technol. 2013, 48, 1998–2006. [Google Scholar] [CrossRef] [Green Version]

- Chen, P.; Cheng, F.; Wei, L.; Wang, S.; Zhang, Z.; Hang, F.; Li, K.; Xie, C. Effect of Maillard reaction browning factors on color of membrane clarification non-centrifugal cane sugar during storage. Food Sci. Technol. 2022, 42. [Google Scholar] [CrossRef]

- Martins, S.I.F.S.; Jongen, W.M.F.; van Boekel, M.A.J.S. A review of Maillard reaction in food and implications to kinetic modelling. Trends Food Sci. Technol. 2011, 11, 364–373. [Google Scholar] [CrossRef]

- Lim, W.Y.; Cheun, C.F.; Wong, C.W. Inhibition of enzymatic browning in sweet potato (Ipomoea batatas (L.)) with chemical and natural anti-browning agents. J. Food Process. Preserv. 2019, 43, 11. [Google Scholar] [CrossRef]

- Raj, M.P.; Swaminarayan, P.R. Applications of Image Processing for Grading Agriculture products. Int. J. Recent Innov. Trends Comput. Commun. 2015, 3, 1194–1201. [Google Scholar]

- Przybył, K.; Wawrzyniak, J.; Koszela, K.; Adamski, F.; Gawrysiak-Witulska, M. Application of Deep and Machine Learning Using Image Analysis to Detect Fungal Contamination of Rapeseed. Sensors 2020, 20, 7305. [Google Scholar] [CrossRef] [PubMed]

- Naik, S.; Patel, B. Machine Vision based Fruit Classification and Grading—A Review. Int. J. Comput. Appl. 2017, 170, 9. [Google Scholar] [CrossRef]

| Name of ANN | MLP 4-3-4 | MLP 4-10-4 | MLP 4-3-4 | MLP 4-6-4 | MLP 4-7-4 |

|---|---|---|---|---|---|

| Quality of learning | 40.476 | 43.651 | 34.127 | 27.778 | 43.651 |

| Quality of testing | 48.148 | 55.556 | 51.852 | 51.852 | 55.556 |

| Quality of validation | 55.556 | 51.852 | 51.852 | 51.852 | 51.852 |

| Algorithm of training | BFGS 21 | BFGS 52 | BFGS 35 | BFGS 9 | BFGS 28 |

| Error function | Entropy | SOS | Entropy | Entropy | SOS |

| Hidden activation | Exponential | Exponential | Tanh | Tanh | Logistic |

| Output activation | Softmax | Linear | Softmax | Softmax | Tanh |

| Name of ANN | MLP 6-11-4 | MLP 6-11-4 | MLP 6-10-4 | MLP 6-10-4 | MLP 6-8-4 |

|---|---|---|---|---|---|

| Quality of learning | 66.67 | 32.54 | 34.92 | 37.3 | 36.51 |

| Quality of testing | 55.56 | 40.74 | 40.74 | 44.44 | 40.74 |

| Quality of validation | 44.44 | 48.15 | 51.85 | 48.15 | 48.15 |

| Algorithm of training | BFGS 60 | BFGS 7 | BFGS 4 | BFGS 9 | BFGS 6 |

| Error function | Entropy | SOS | Entropy | SOS | Entropy |

| Hidden activation | Tanh | Logistic | Linear | Logistic | Linear |

| Output activation | Softmax | Logistic | Softmax | Exponential | Softmax |

| Name of ANN | MobileNet-Color | MobileNet-Gray |

|---|---|---|

| Quality of learning | 100.00 | 100.00 |

| Quality of testing | 0.7083 | 0.7778 |

| Quality of validation | 0.6111 | 0.7222 |

| Algorithm of training | Adam | Adam |

| Error function | Entropy | Entropy |

| Hidden activation function | ReLu | ReLu |

| Output activation function | Softmax | Softmax |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Przybył, K.; Adamski, F.; Wawrzyniak, J.; Gawrysiak-Witulska, M.; Stangierski, J.; Kmiecik, D. Machine and Deep Learning in the Evaluation of Selected Qualitative Characteristics of Sweet Potatoes Obtained under Different Convective Drying Conditions. Appl. Sci. 2022, 12, 7840. https://doi.org/10.3390/app12157840

Przybył K, Adamski F, Wawrzyniak J, Gawrysiak-Witulska M, Stangierski J, Kmiecik D. Machine and Deep Learning in the Evaluation of Selected Qualitative Characteristics of Sweet Potatoes Obtained under Different Convective Drying Conditions. Applied Sciences. 2022; 12(15):7840. https://doi.org/10.3390/app12157840

Chicago/Turabian StylePrzybył, Krzysztof, Franciszek Adamski, Jolanta Wawrzyniak, Marzena Gawrysiak-Witulska, Jerzy Stangierski, and Dominik Kmiecik. 2022. "Machine and Deep Learning in the Evaluation of Selected Qualitative Characteristics of Sweet Potatoes Obtained under Different Convective Drying Conditions" Applied Sciences 12, no. 15: 7840. https://doi.org/10.3390/app12157840

APA StylePrzybył, K., Adamski, F., Wawrzyniak, J., Gawrysiak-Witulska, M., Stangierski, J., & Kmiecik, D. (2022). Machine and Deep Learning in the Evaluation of Selected Qualitative Characteristics of Sweet Potatoes Obtained under Different Convective Drying Conditions. Applied Sciences, 12(15), 7840. https://doi.org/10.3390/app12157840