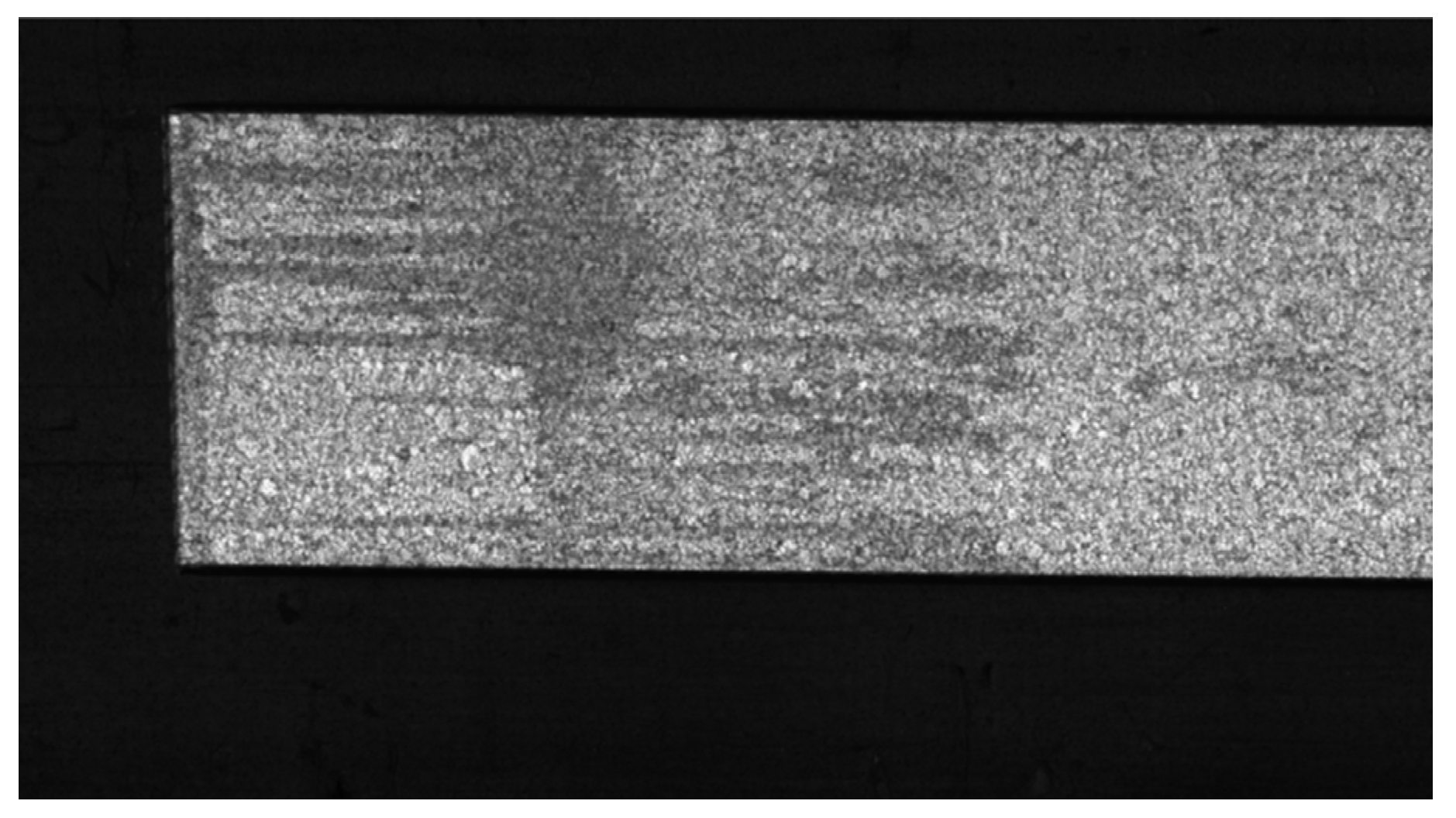

Visual Scratch Defect Detection System of Aluminum Flat Tube Based on Cubic Bezier Curve Fitting Using Linear Scan Camera

Abstract

:1. Introduction

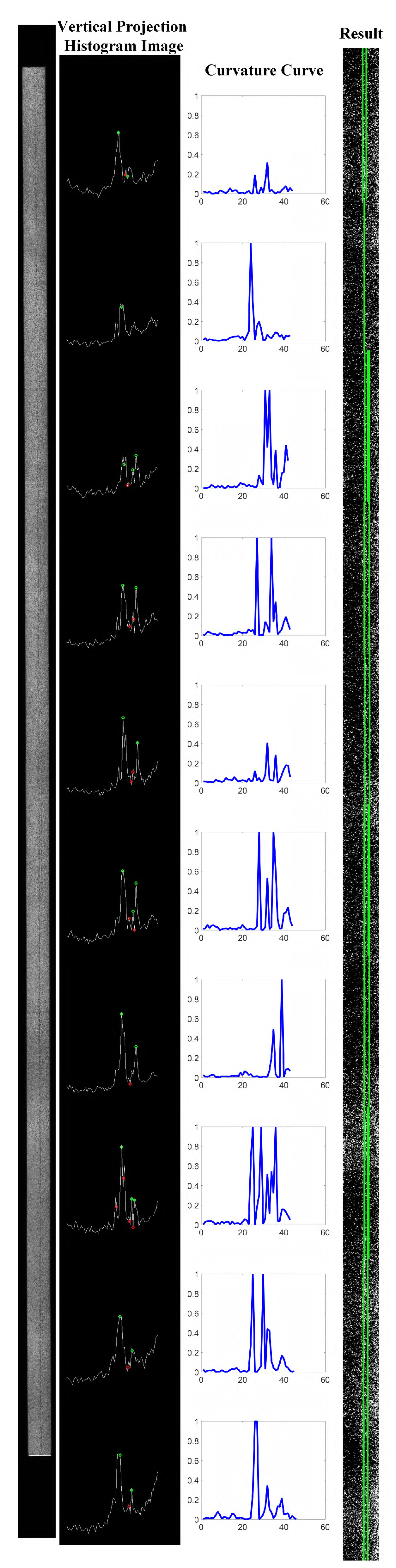

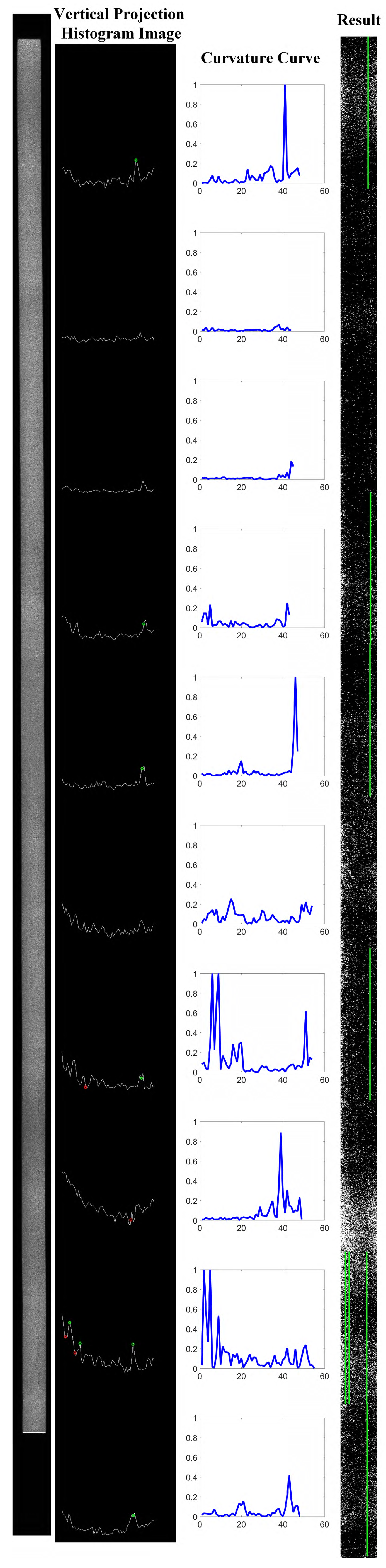

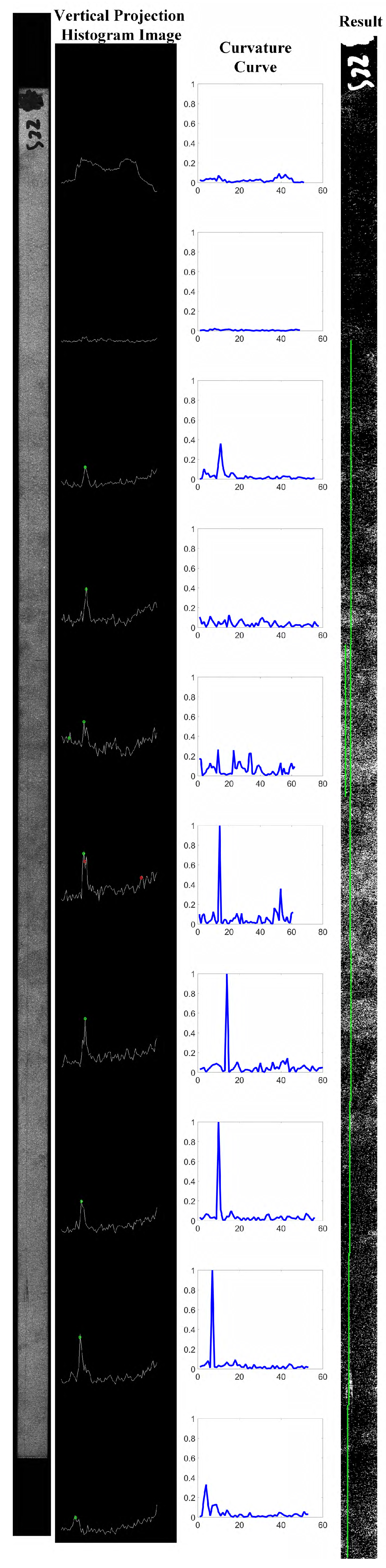

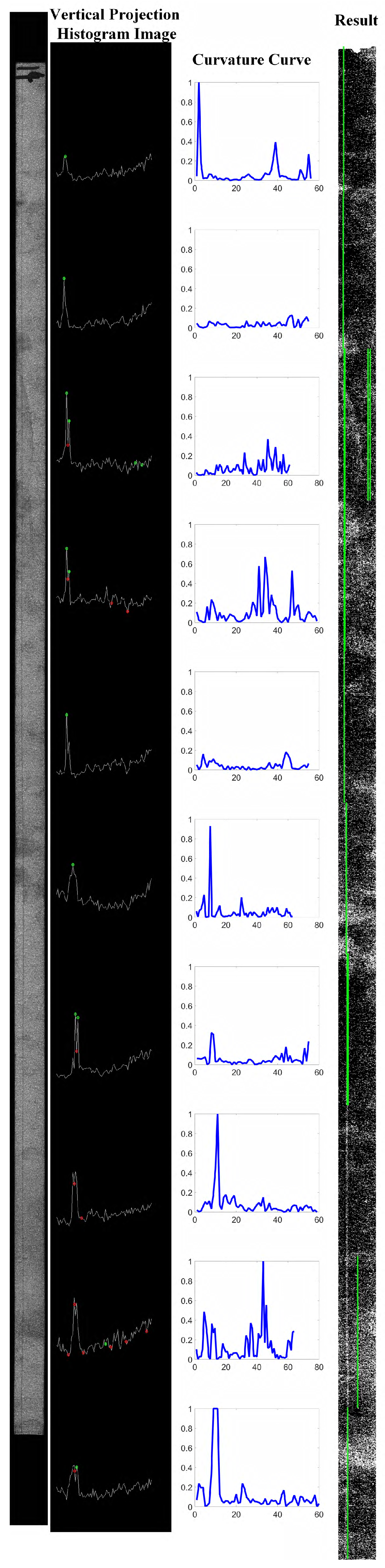

- A new scratch detection and location system was proposed to find local maximums based on Bezier curvature calculation and curve fitting. By using this technique, the stability and accuracy of curvature peak localization in the complex clutter background was improved significantly.

- Monte Carlo sampling was used to find the optimal four control points location of the Bezier curves. By using the Monte Carlo scheme, the optimal control points can be found in a less time-consuming way, which is important in real-time application.

- The scratch detection using the proposed method, achieved in real-time processing, based on a linear scan camera.

2. The Proposed Method

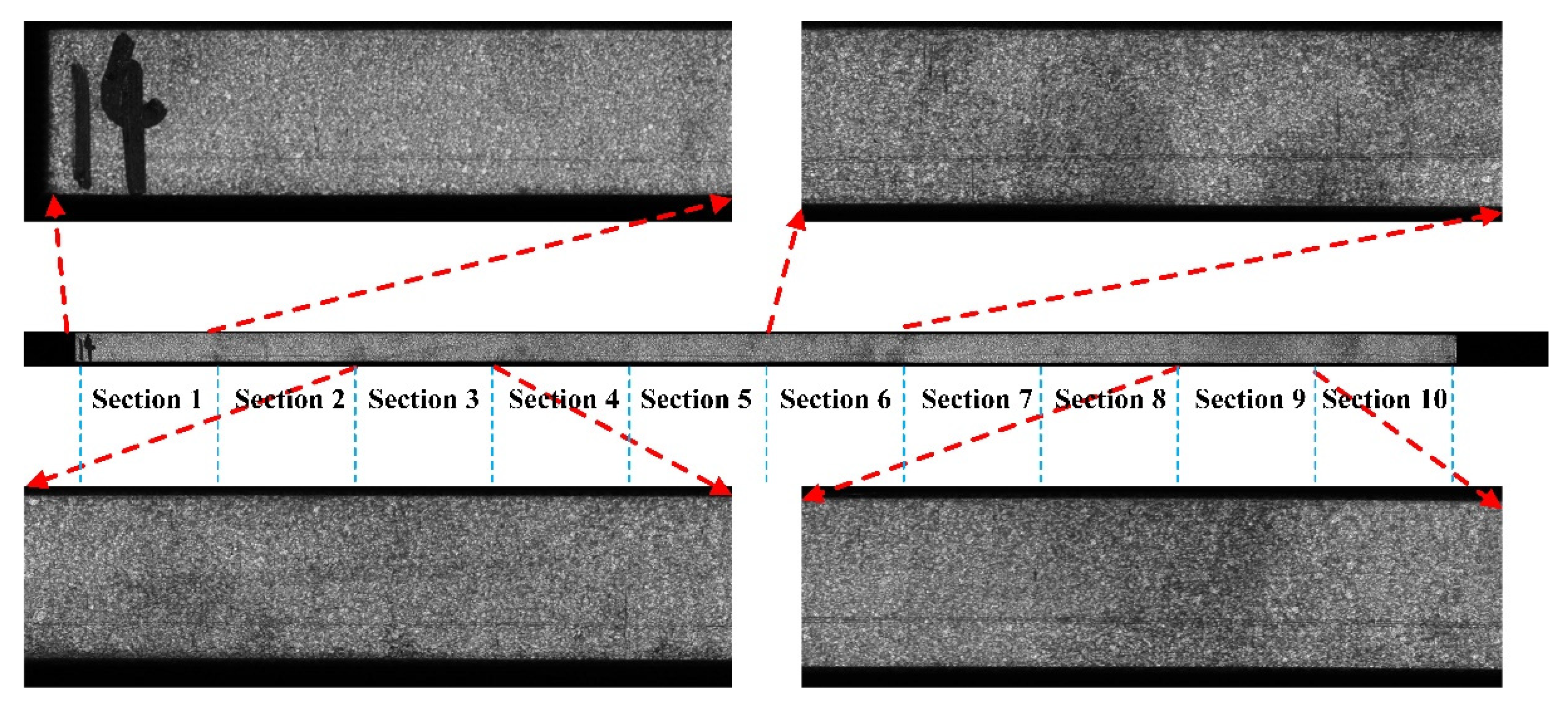

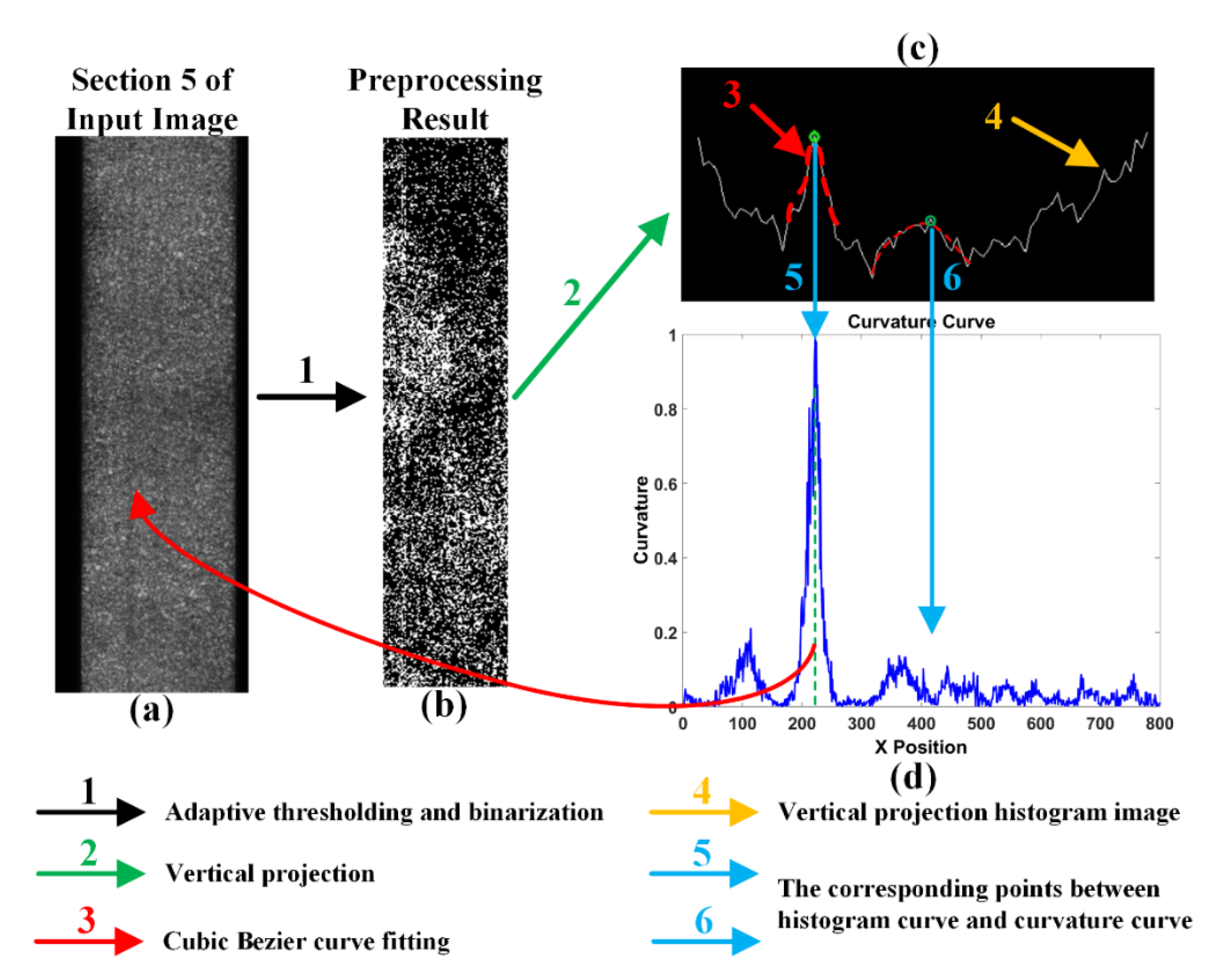

2.1. Overview of the Proposed Method and Image Preprocessing

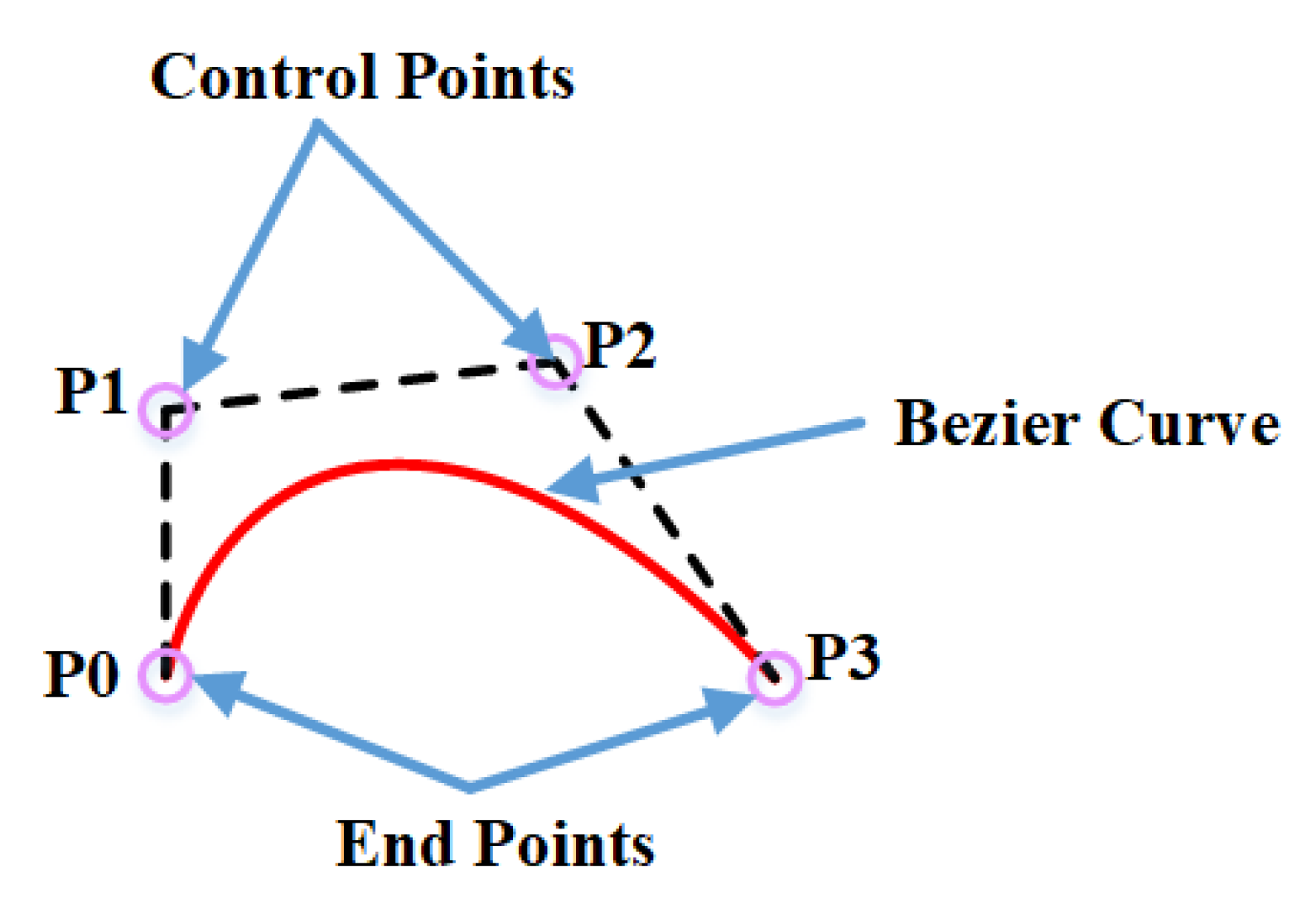

2.2. Bezier Curve

2.3. Monte Carlo Sampling

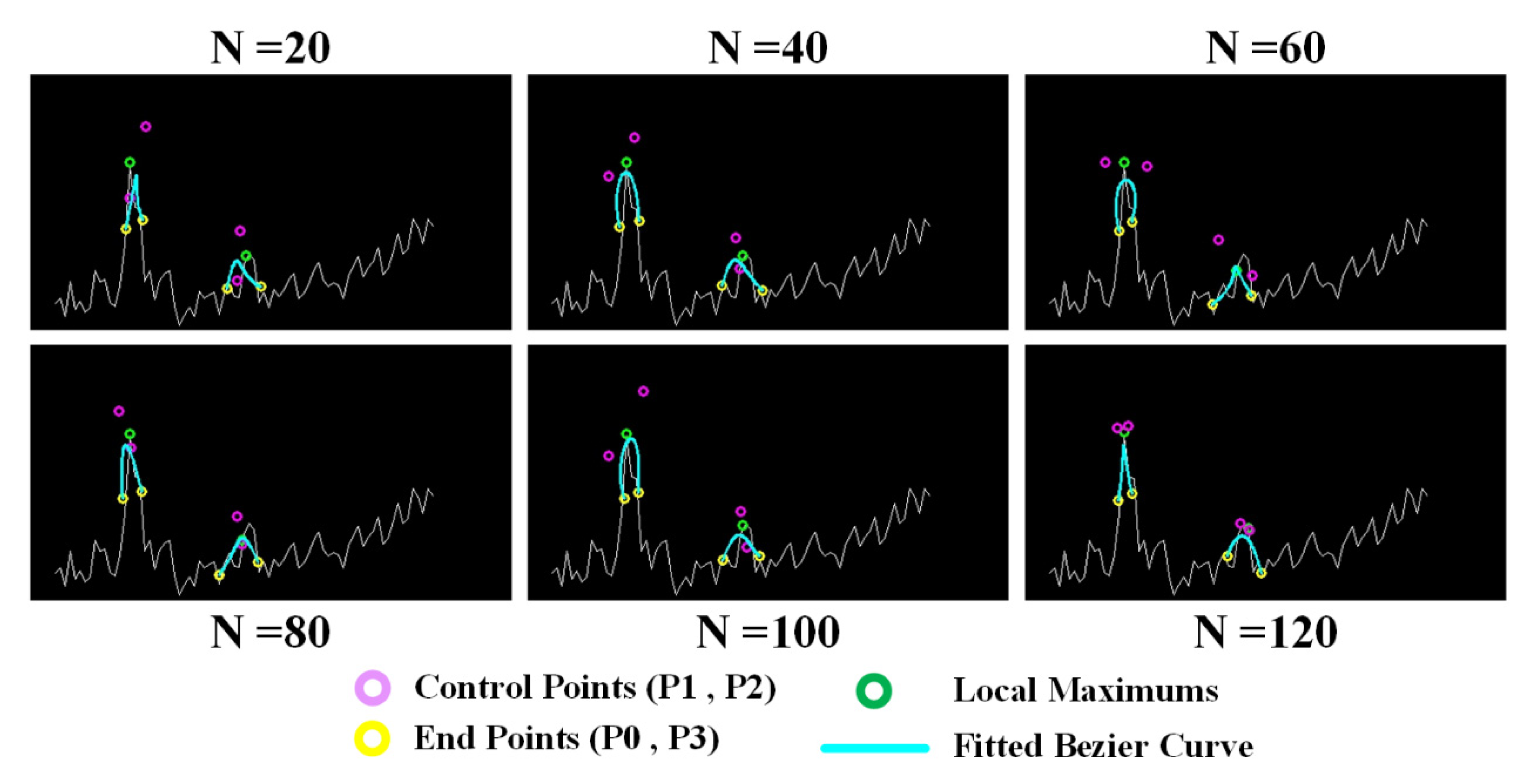

2.4. Minimum Sampling Number

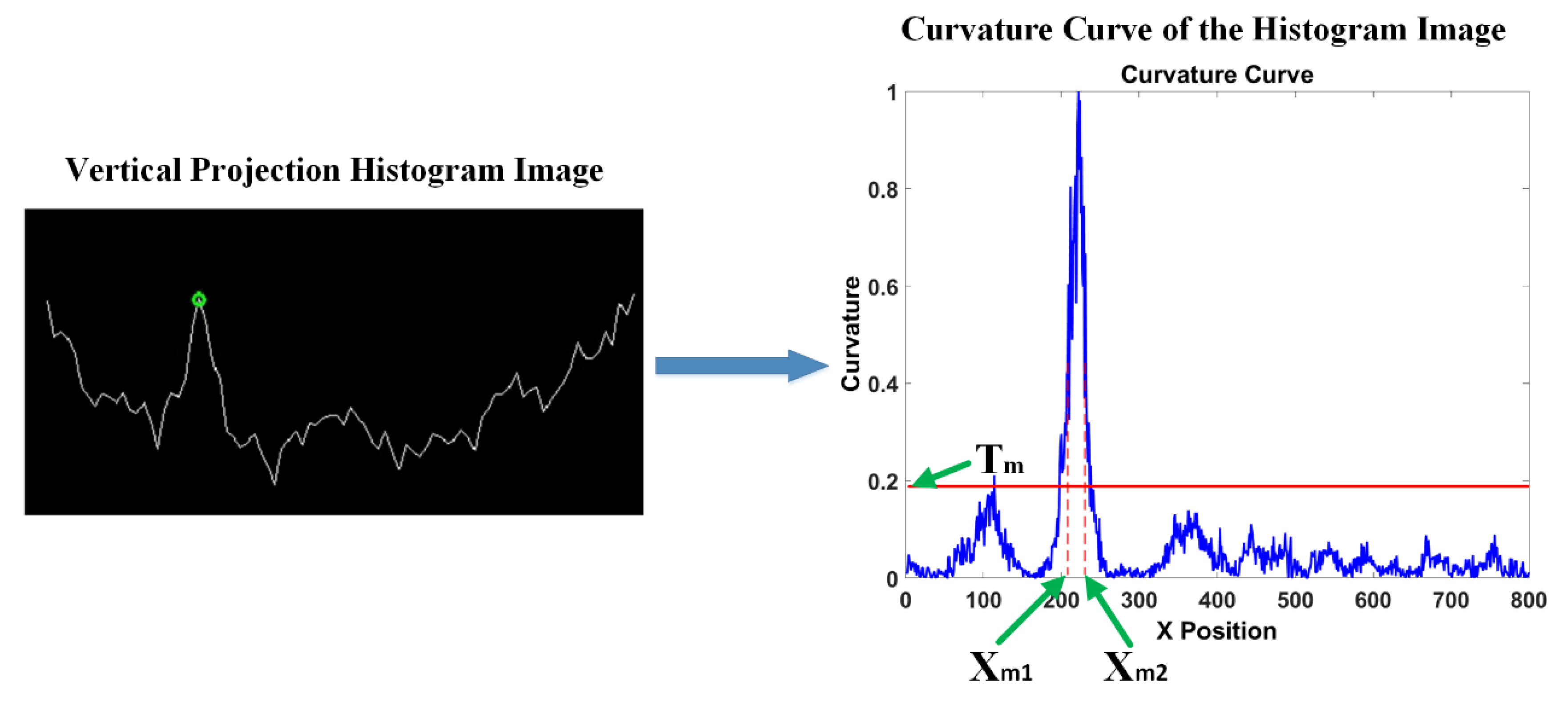

2.5. Bezier Curvature Calculation and Peak Location

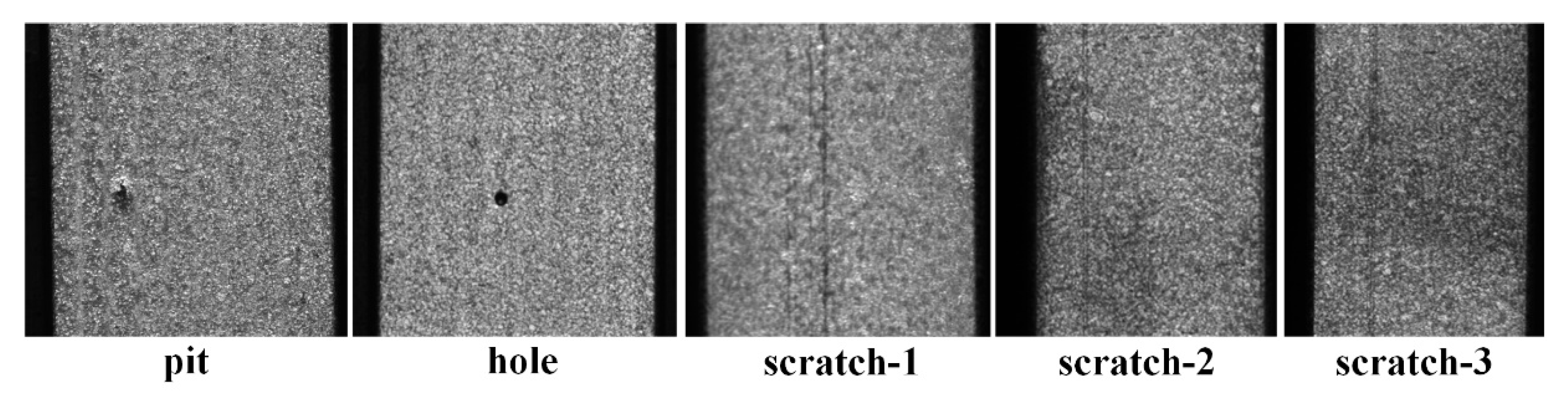

3. Experiments and Discussion

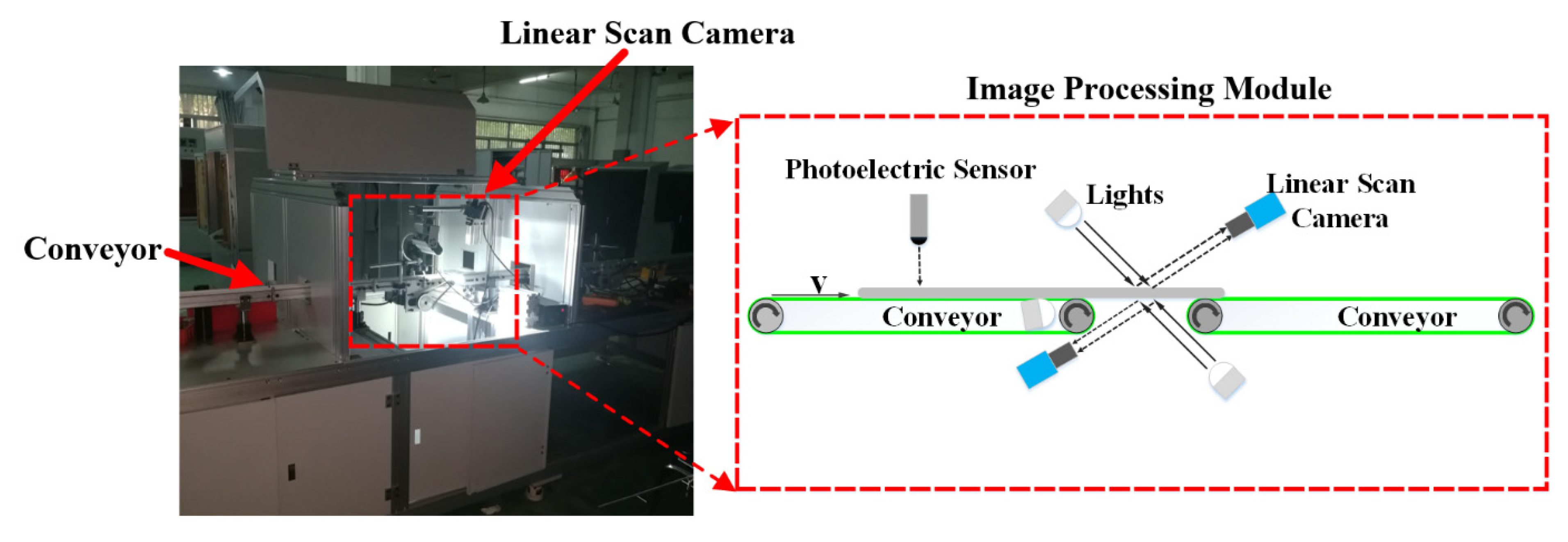

3.1. Experimental System

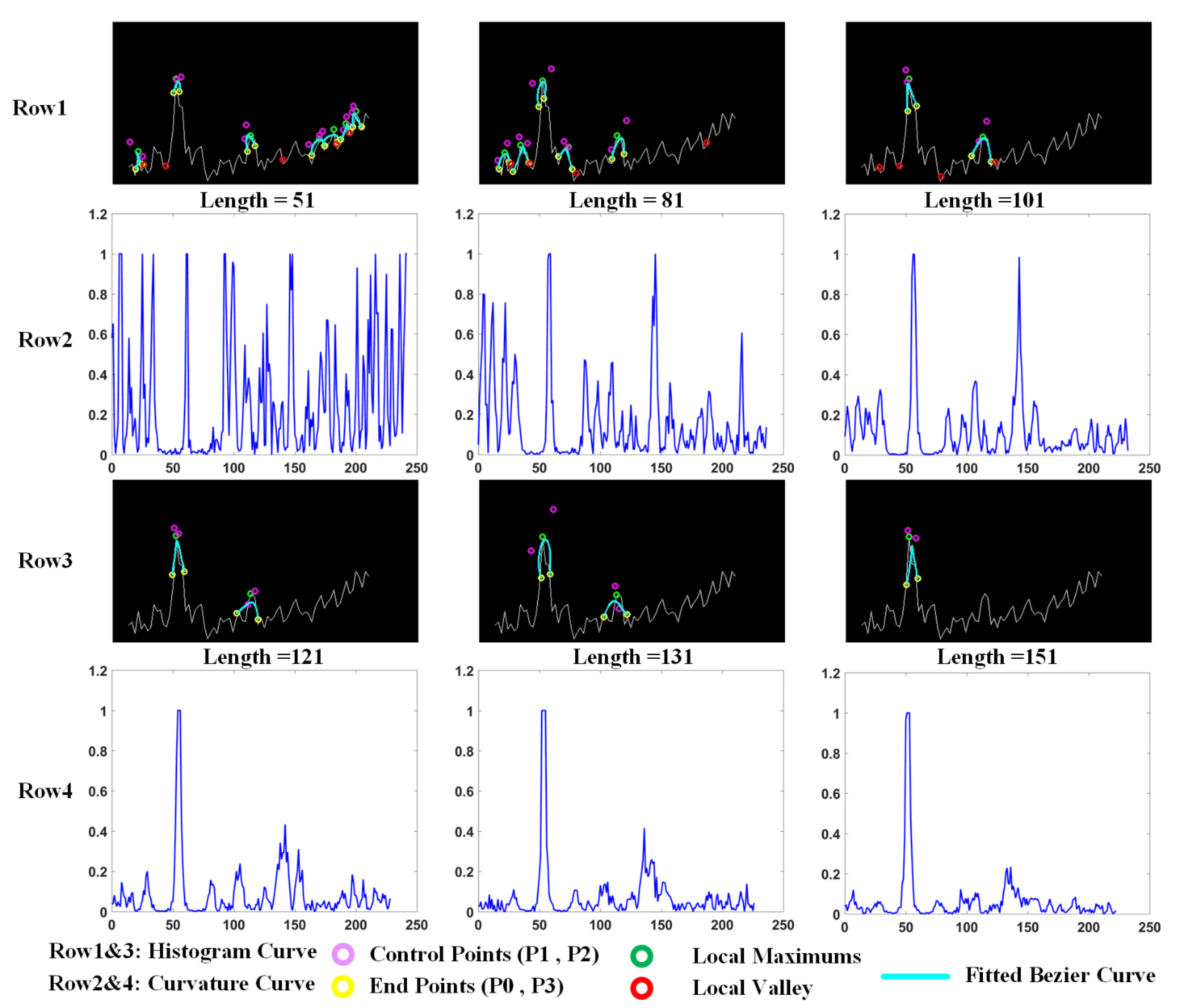

3.2. Parameters Setting

3.3. Experimental Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chodankar, V.A.V.L.; Seetharamu, K.N. Improved effectiveness of a cryogenic counter-current parallel flow—Three fluid heat exchanger with three thermal communication due to Joule Thomson pressure drop. Int. J. Therm. Sci. 2022, 172, 107267. [Google Scholar] [CrossRef]

- Yu, C.; Wang, Y.; Zhang, H.; Zeng, M.; Gao, B.; Fang, Z. Numerical investigation on turbulent thermal performance of parallel flow heat exchanger with a novel polyhedral longitudinal vortex generator in shell side. Int. J. Therm. Sci. 2021, 166, 106962. [Google Scholar] [CrossRef]

- Abu-Hamdeh, N.H.; Salilih, E.M. Numerical modelling of a parallel flow heat exchanger with two-phase heat transfer process. Int. Commun. Heat Mass Transf. 2021, 120, 105005. [Google Scholar] [CrossRef]

- Wang, Y.W.; Ni, Y.Q.; Wang, X. Real-time defect detection of high-speed train wheels by using Bayesian forecasting and dynamic model. Mech. Syst. Signal Process. 2020, 139, 106654. [Google Scholar] [CrossRef]

- Horan, P.; Underhill, P.R.; Krause, T.W. Pulsed eddy current detection of cracks in F/A-18 inner wing spar without wing skin removal using Modified Principal Component Analysis. NDT E Int. 2013, 55, 21–27. [Google Scholar] [CrossRef]

- Arjun, V.; Sasi, B.; Rao, B.P.C.; Mukhopadhyay, C.K.; Jayakumar, T. Optimisation of pulsed eddy current probe for detection of sub-surface defects in stainless steel plates. Sens. Actuators A Phys. 2015, 226, 69–75. [Google Scholar] [CrossRef]

- Peng, J.; Tian, G.Y.; Wang, L.; Zhang, Y.; Li, K.; Gao, X. Investigation into eddy current pulsed thermography for rolling contact fatigue detection and characterization. NDT E Int. 2015, 74, 72–80. [Google Scholar] [CrossRef]

- Huang, D.; Li, K.; Tian, G.Y.; Sunny, A.I.; Chen, X.; Tang, C.; Wu, J.; Zhang, H.; Zhao, A. Thermal pattern reconstruction of surface condition on freeform-surface using eddy current pulsed thermography. Sens. Actuators A Phys. 2016, 251, 248–257. [Google Scholar] [CrossRef]

- Sunny, A.I.; Tian, G.Y.; Zhang, J.; Pal, M. Low frequency (LF) RFID sensors and selective transient feature extraction for corrosion characterisation. Sens. Actuators A Phys. 2016, 241, 34–43. [Google Scholar] [CrossRef] [Green Version]

- Tehranchi, M.M.; Ranjbaran, M.; Eftekhari, H. Double core giant magneto-impedance sensors for the inspection of magnetic flux leakage from metal surface cracks. Sens. Actuators A Phys. 2011, 170, 55–61. [Google Scholar] [CrossRef]

- Baek, I.; Cho, B.K.; Gadsden, S.A.; Eggleton, C.; Oh, M.; Mo, C.; Kim, M.S. A novel hyperspectral line-scan imaging method for whole surfaces of round shaped agricultural products. Biosyst. Eng. 2019, 188, 57–66. [Google Scholar] [CrossRef]

- Zhang, X.-W.; Ding, Y.-Q.; Lv, Y.-Y.; Shi, A.-Y.; Liang, R.-Y. A vision inspection system for the surface defects of strongly reflected metal based on multi-class SVM. Expert Syst. Appl. 2011, 38, 5930–5939. [Google Scholar]

- Song, K.; Yan, Y. A noise robust method based on completed local binary patterns for hot-rolled steel strip surface defects. Appl. Surf. Sci. 2013, 285, 858–864. [Google Scholar] [CrossRef]

- Liu, X.; Xu, K.; Zhou, P.; Zhou, D.; Zhou, Y. Surface defect identification of aluminium strips with non-subsampled shearlet transform. Opt. Lasers Eng. 2020, 127, 105986. [Google Scholar] [CrossRef]

- Li, J.; Su, Z.; Geng, J.; Yin, Y. Real-time Detection of Steel Strip Surface Defects Based on Improved YOLO Detection Network. IFAC-PapersOnLine 2018, 51, 76–81. [Google Scholar] [CrossRef]

- He, Y.; Song, K.; Meng, Q.; Yan, Y. An End-to-End Steel Surface Defect Detection Approach via Fusing Multiple Hierarchical Features. IEEE Trans. Instrum. Meas. 2020, 69, 1493–1504. [Google Scholar] [CrossRef]

- Huang, D.; Liao, S.; Sunny, A.I.; Yu, S. A novel automatic surface scratch defect detection for fluid-conveying tube of Coriolis mass flow-meter based on 2D-direction filter. Measurement 2018, 126, 332–341. [Google Scholar] [CrossRef]

- Di, H.; Xu, K.; Zhou, P.; Zhou, D. Surface defect classification of steels with a new semi-supervised learning method. Opt. Lasers Eng. 2019, 117, 40–48. [Google Scholar] [CrossRef]

- Zhang, D.; Song, K.; Xu, J.; He, Y.; Yan, Y. Unified detection method of aluminium profile surface defects: Common and rare defect categories. Opt. Lasers Eng. 2020, 126, 105936. [Google Scholar] [CrossRef]

- Otsu, N. A Threshold Selection Method from Gray-Level Histograms. IEEE Trans. Syst. Man Cybern. 1979, 9, 62–66. [Google Scholar] [CrossRef] [Green Version]

- Saleem, N.; Agwu, I.K.; Ishtiaq, U.; Radenović, S. Strong Convergence Theorems for a Finite Family of Enriched Strictly Pseudocontractive Mappings and Φ T-Enriched Lipschitizian Mappings Using a New Modified Mixed-Type Ishikawa Iteration Scheme with Error. Symmetry 2022, 14, 1032. [Google Scholar] [CrossRef]

- Saleem, N.; Isık, H.; Khaleeq, S.; Park, C. Interpolative Ciric-Reich-Rus-type best proximity point results with applications. AIMS Math. 2022, 7, 9731–9747. [Google Scholar] [CrossRef]

| Parameters | Type A | Type B |

|---|---|---|

| Length | 800 mm | 200 mm |

| Width | 50 mm | 10 mm |

| Height | 2 mm | 1 mm |

| Speed of Conveyor | 2 m/s | 2 m/s |

| Interval Time | 500 ms | 333 ms |

| Results | Type A | Type B | ||

|---|---|---|---|---|

| No Defects | With Defects | No Defects | With Defects | |

| Total sample number | 100 | 100 | 100 | 100 |

| 93 | 2 | 95 | 1 | |

| 7 | 98 | 5 | 99 | |

| Time consuming/ms | 459.32 | 478.24 | 87.65 | 98.31 |

| FN/% | 1% | 0.5% | ||

| FP/% | 3.5% | 2.5% | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, J.; Cao, S.; Chen, J.; Song, T.; Xu, Z.; Zhou, Q.; Jiang, Q. Visual Scratch Defect Detection System of Aluminum Flat Tube Based on Cubic Bezier Curve Fitting Using Linear Scan Camera. Appl. Sci. 2022, 12, 6049. https://doi.org/10.3390/app12126049

Tang J, Cao S, Chen J, Song T, Xu Z, Zhou Q, Jiang Q. Visual Scratch Defect Detection System of Aluminum Flat Tube Based on Cubic Bezier Curve Fitting Using Linear Scan Camera. Applied Sciences. 2022; 12(12):6049. https://doi.org/10.3390/app12126049

Chicago/Turabian StyleTang, Jianbin, Songxiao Cao, Jiaze Chen, Tao Song, Zhipeng Xu, Qiaojun Zhou, and Qing Jiang. 2022. "Visual Scratch Defect Detection System of Aluminum Flat Tube Based on Cubic Bezier Curve Fitting Using Linear Scan Camera" Applied Sciences 12, no. 12: 6049. https://doi.org/10.3390/app12126049

APA StyleTang, J., Cao, S., Chen, J., Song, T., Xu, Z., Zhou, Q., & Jiang, Q. (2022). Visual Scratch Defect Detection System of Aluminum Flat Tube Based on Cubic Bezier Curve Fitting Using Linear Scan Camera. Applied Sciences, 12(12), 6049. https://doi.org/10.3390/app12126049