2.1. Gridshells

Gridshells, like other shell structures, are inherently material-efficient structures. Recent development in digital design tools has made gridshells more accessible amongst architects and engineers, with architects as drivers for interesting shapes and architectural concepts. Engineers are developing new methods for form-finding and analyses of gridshells.

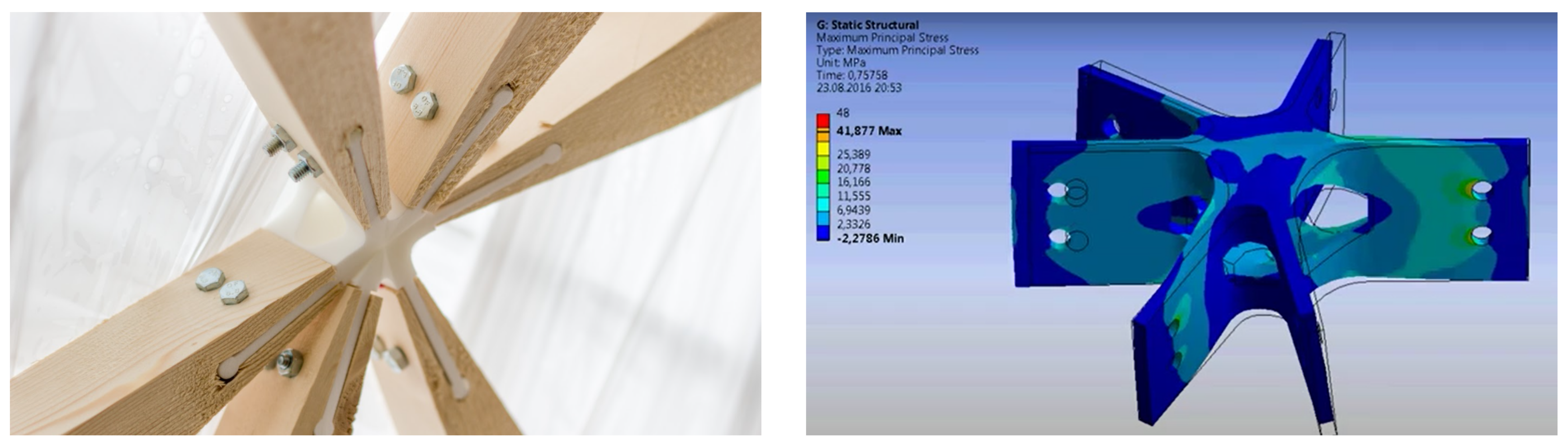

In recent years, the Conceptual Structural Design Group at NTNU (CSDG) has been investigating conceptual design in the collaboration between architects and structural engineers, focusing on gridshells, resulting in both built prototypes and new design tools. In 2016 a temporary pavilion called Printshell was realised for a local festival in Trondheim. It had a footprint of 6 × 6 m and a height of 3 m. It was built from members of 48 × 48 mm of C24 spruce with standardised cuts at the ends and unique lengths. The ends of members were produced in the workshop with saw tables and were connected to 51 unique nodes produced with 3D-printing, hence the name Printshell. The nodes should distribute the forces between the members. As the nodes would be highly visible in the structure, it was essential to be able to visualise the geometries as precise as possible. Manufacture and analysis of the nodes was the key issue and focus of the project.

A parametric model was used to define the geometries for the nodes. The design workflow also included a connection between global and local modelling of the gridshell. The global model evaluated the overall structural performance, representing the gridshell members (beams) as the lines and nodes as the points. The global model enables the designer to preview the volumetric representation of the model. The local model included detailed node geometries. The global model and local geometry generation were done in a parametric environment using Rhinoceros

® and Grasshopper 3D

® [

1], with the global structural analysis made in Karamba3D

® [

2]. The local analysis on behavior of the nodes was made in ANSYS

® [

3]. The design of relatively small elements cannot be done on the global model with readily available one- and two-dimensional finite elements. Therefore a Finite element analysis (FEA) with volumetric finite elements was deemed necessary for the analysis. However, the volumetric analysis was a computationally heavy and slow procedure, demanding changes between software and geometry conversion. The most crucial nodes were exported to ANSYS from Rhinoceros and analysed individually, with little options for automation.

Figure 1 shows one of the prindshell nodes, manufactured with 3D-printing, and an example of a node analysis in ANSYS.

2.2. Gridshell Nodes

Gridshell nodes have three main functions. First, they ensure structural integrity by transferring forces between the members; second, they play a key role in the assembly and prefabrication of a gridshell; lastly, they accommodate the small geometry changes between the connecting members. In addition, they can serve as visible objects that enhance the architectural concept.

Gridshells, like other shells, transfer forces primarily through in-plane membrane forces, which in gridshells are subjected to the members as axial forces. Although this enables efficient material usage, the slenderness makes shell structures subjected to compression forces prone to buckling and stability issues. In gridshells, the nodes are an integral part of the structural system. An assumption that these are rigidly connected to all the adjoining members is both an unrealistic and unconservative estimate. Rigid connections imply a complete transmission of bending moments between members and nodes, which causes the analytical model to be significantly stiffer than the actual system. Rigid connections are only possible in practice if all members are welded to the node. In addition, small gaps and imperfections from production allow for small node movements.

Modelling connections as either pinned or rigid is common in almost all practical finite element analyses. After extracting the forces in the node, a connection with the appropriate number of fasteners to withstand the internal forces is selected. By using a more realistic node stiffness based on the actual properties of the connector, the global behaviour of the system will be altered. For larger buildings and structures, the cost of the extra analysis done by the engineer is unfeasible compared to the price of some additional bolts and welds. However, for gridshells, where the form follows the forces, the advantage of accurate accounting for node rigidity is significant. A recent study by Lara-Bocanegra et al. demonstrates this importance on an elastic timber gridshell by comparing the deflections of a full-scale model to those of a numerical analysis [

4]. Without considering the joints’ rigidity, the analytical model underestimates the deflections and fails to capture the gridshell’s physical behaviour. Therefore, joint rigidity is an important factor when evaluating gridshells as using pinned joints in the evaluation often leads to unstable structures, and rigid joints could result in too unconservative estimates. Several studies report this, including [

5,

6,

7].

Nodes are also often reported as the most expensive parts in realising gridshells [

8,

9,

10]. Nodes are thus both crucial for the structural integrity and the final cost of a gridshell; however, recent studies by the authors have shown that gridshell nodes are not a pronounced priority in recent research on gridshells [

11]. When selecting nodes for a steel and aluminium gridshell, manufacturing companies can provide a set of pre-accepted solutions. For timber gridshells, the nodes are typically developed for each project. Analyses of gridshell nodes are typically done using solid elements as seen in the recent studies by Castriotto et al. [

12] and Seifi et al. [

7]. Like in the Printshell project presented in

Section 2.1, the analyses require exporting to separate tools for performing the meshing and analyses. Structural or mechanical engineers often drive the design of nodes. Harris et al. describe [

13] how timber engineers designed the nodes for The Pods sports academy B&K Structures with Westmucket and Hawkes (structural consultants) as sub-contractors for the detailing of the nodes.

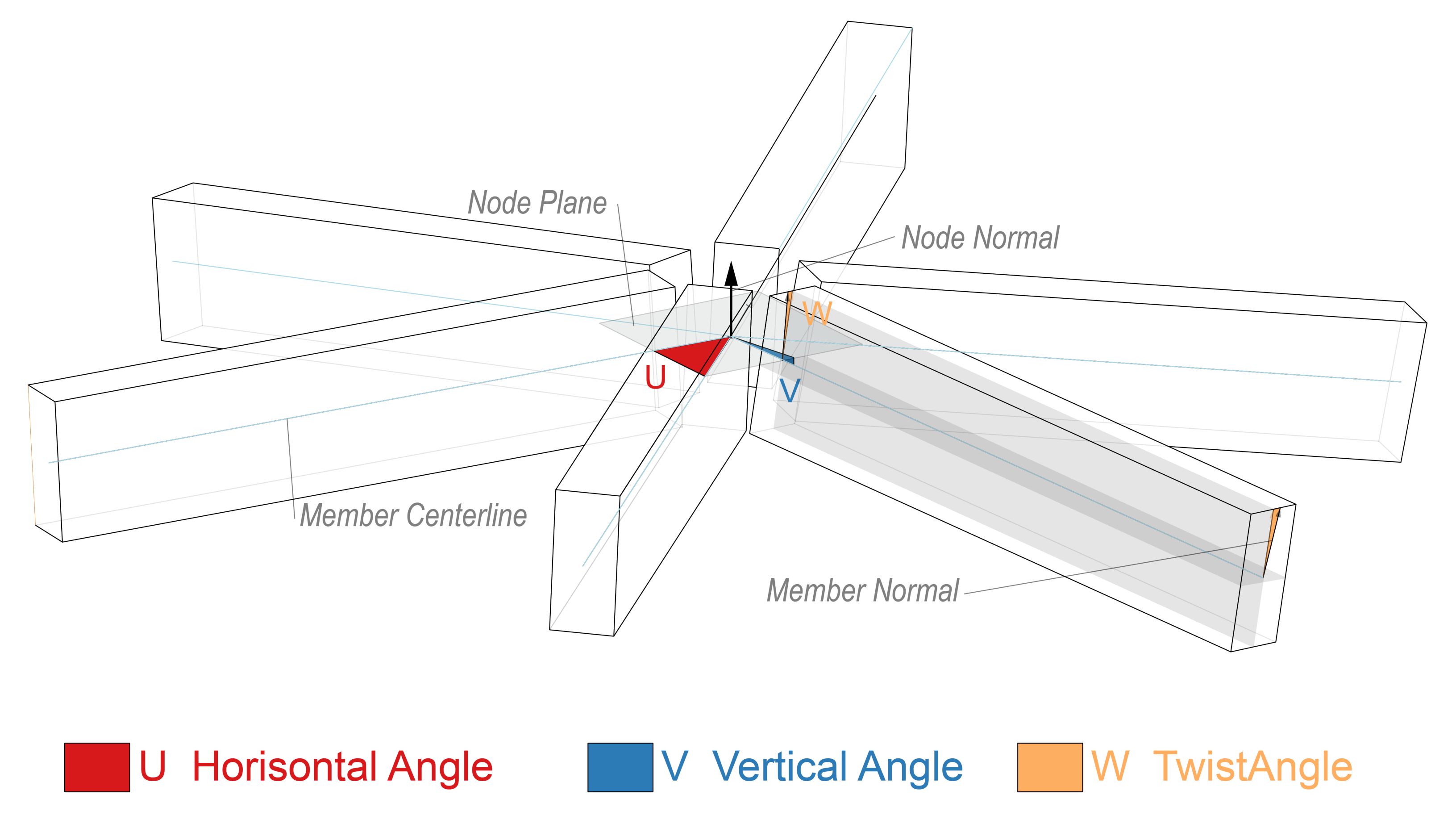

The geometry deviations between the members’- and the node’s plane can be described with three angles, often referred to as the U-, V-, and W-angles [

14].

Figure 2 illustrates these three angles. The U-angle represents the horizontal angle, meaning the angle between two members in the node plane, the vertical angle, V, represents the vertical kink between the normal direction of two nodes at each end of a member, and the twist angle, W, represents the twist between the same normal directions. In general, the nodes need high precision in manufacturing to accommodate these angles.

To summarise, gridshell nodes are crucial for both the structural performance and costs of a gridshell, especially in timber gridshells. The main challenge in designing gridshell nodes is the need for analyses with inefficient software changes and geometry conversions. One way to solve this challenge is to include volumetric analyses within the same environment used for the architectural design of the gridshell. With the evaluation of node geometries within the same design environment, the designers, architects and engineers could more easily understand the implications of specific node designs at the global scale and include the design of the nodes as visible objects in the design concept.

2.3. Architectural versus Analytical Models

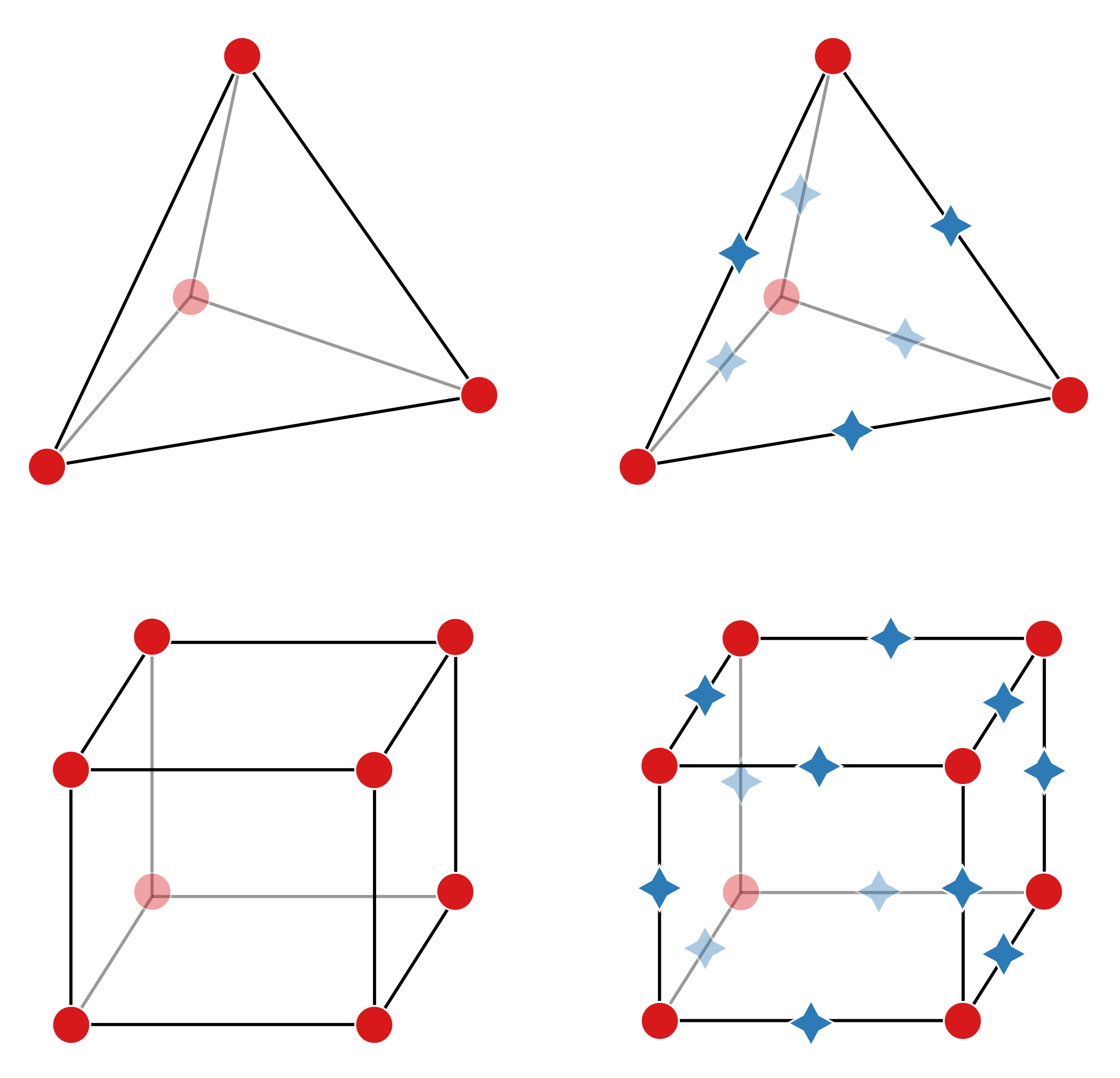

A critical aspect when facilitating close collaboration between architects and engineers is the consideration of model types. The primary purpose of an architectural model is to represent space. On the other side, a structural engineer aims to analyse the strength and stability of the under-laying structure. In an architectural model, all elements such as beams, columns, walls, and roofs generally have a three-dimensional boundary. It is not straightforward to convert these physical elements into elements compatible with an analytical model for finite element analysis. Depending on the problem, different element types may represent the physical situation. Real-world objects are broken down into smaller parts for the analysis, a process known as discretisation. The beam in

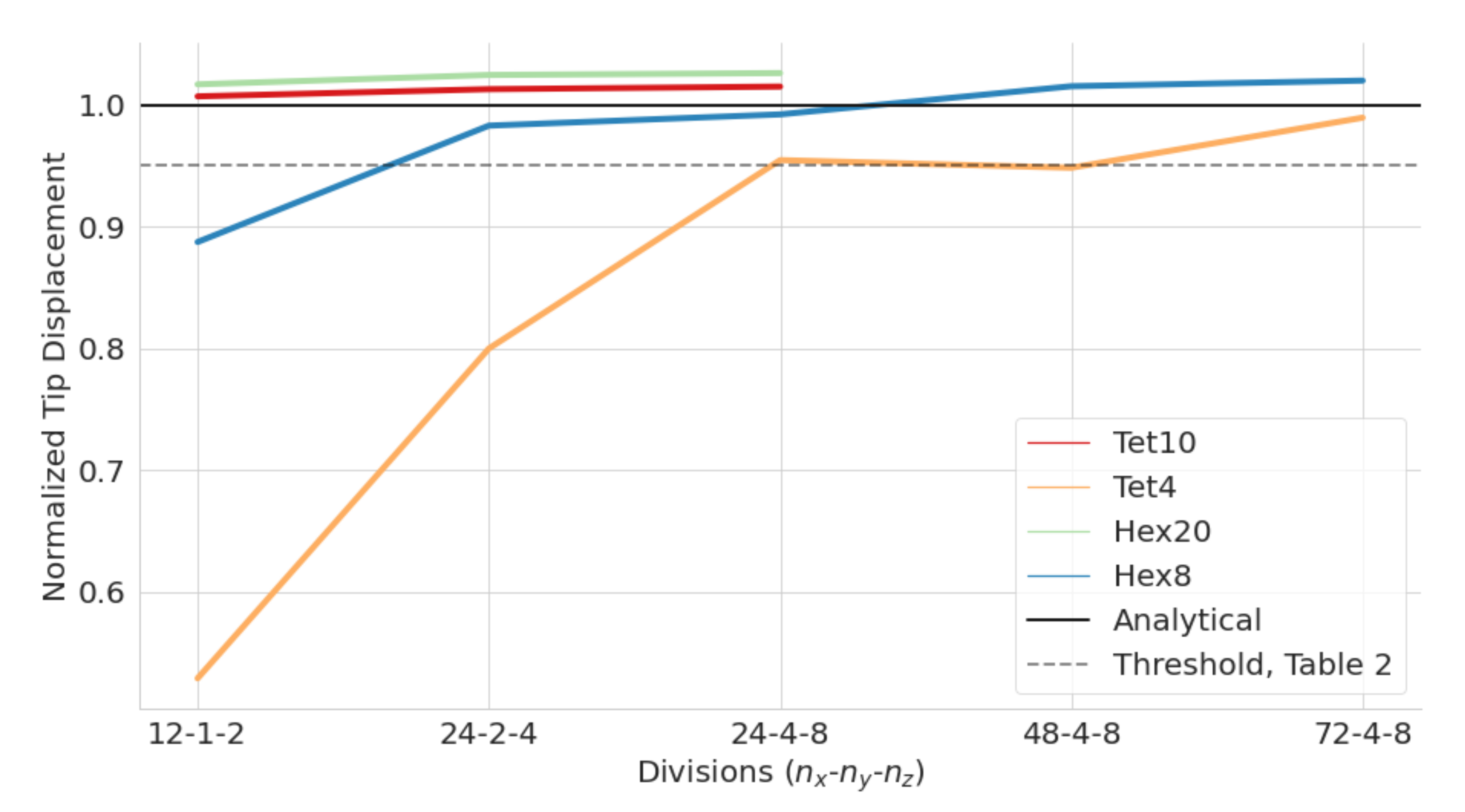

Figure 3 use used as an example; the architectural beam has a width, depth, and length. Depending on the information sought and expected behaviour, the engineer may use a one-dimensional element such as a beam and bar element consisting of two end nodes connecting a straight line; each end node has degrees of freedom relevant to the problem. In other cases, a two-dimensional model may be more apt. Here the engineer discretises the beam into shell or plate elements. Apart from the type of element selected, the number of elements used will affect the accuracy of the solution. Finally, solid three-dimensional elements can be used as well. Here, all three dimensions represent the physical beam by “populating” it with discrete elements.

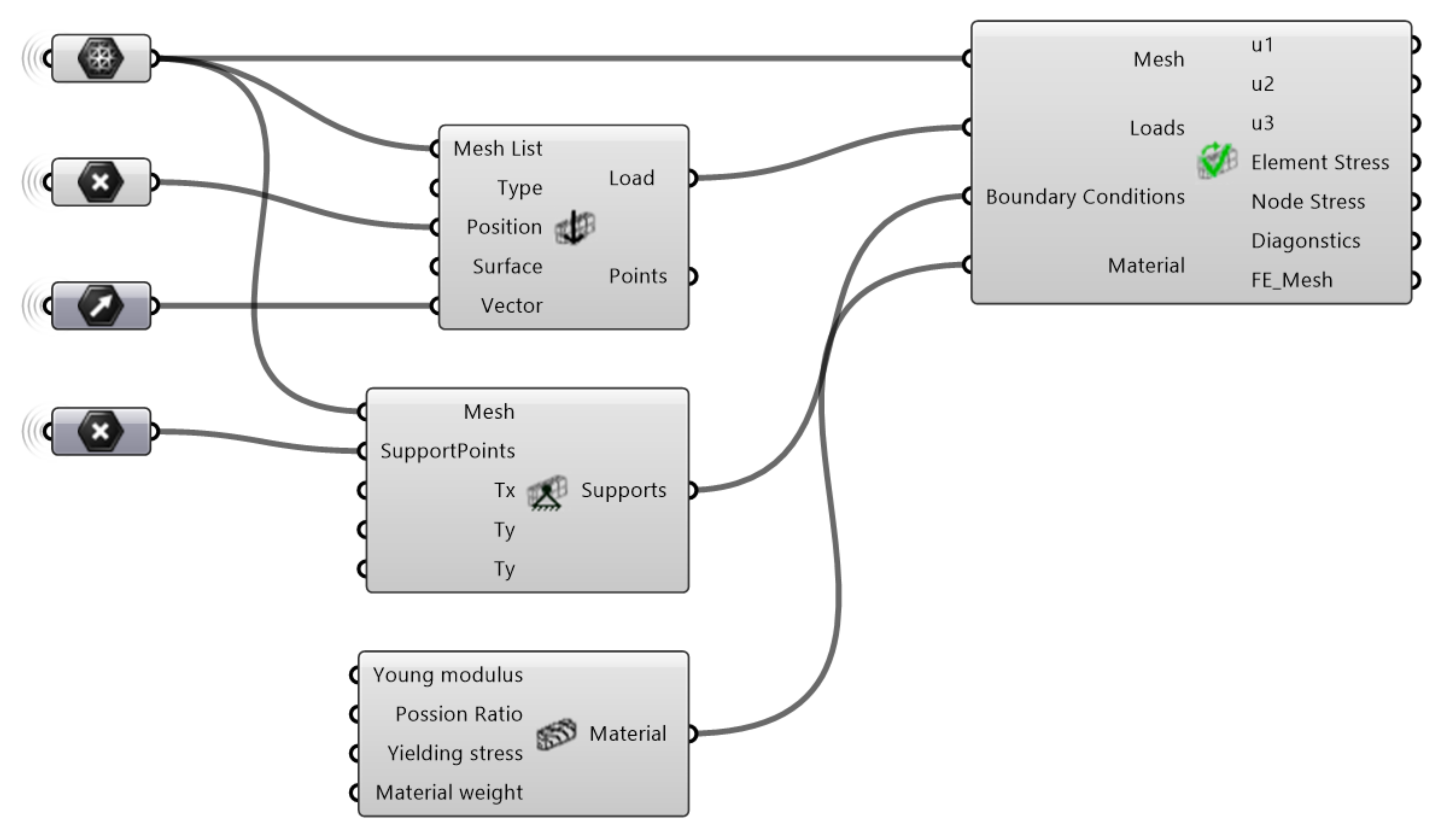

In most engineering problems related to architecture, one- and two-dimensional elements are sufficiently accurate and computationally effective. In Grasshopper 3D, there are also plugins for FEA internally or connecting to external FEA software such as Karamba3D, Sofistik® and FEM-Design®, respectively. These plugins take line- and surface geometries together with information about cross-sections and material as input for creating structural elements for the analytical model. However, in cases such as the one in this paper where small physical elements, the gridshell nodes, are subjected to sizeable forces, the assumptions necessary for the one- and two-dimensional elements to be valid are no longer applicable. For example, the premise of small deflection and plane sections remaining plane after deformation might not apply in a gridshell node. For these cases, a FEA using solid elements is necessary to evaluate the geometry accurately.

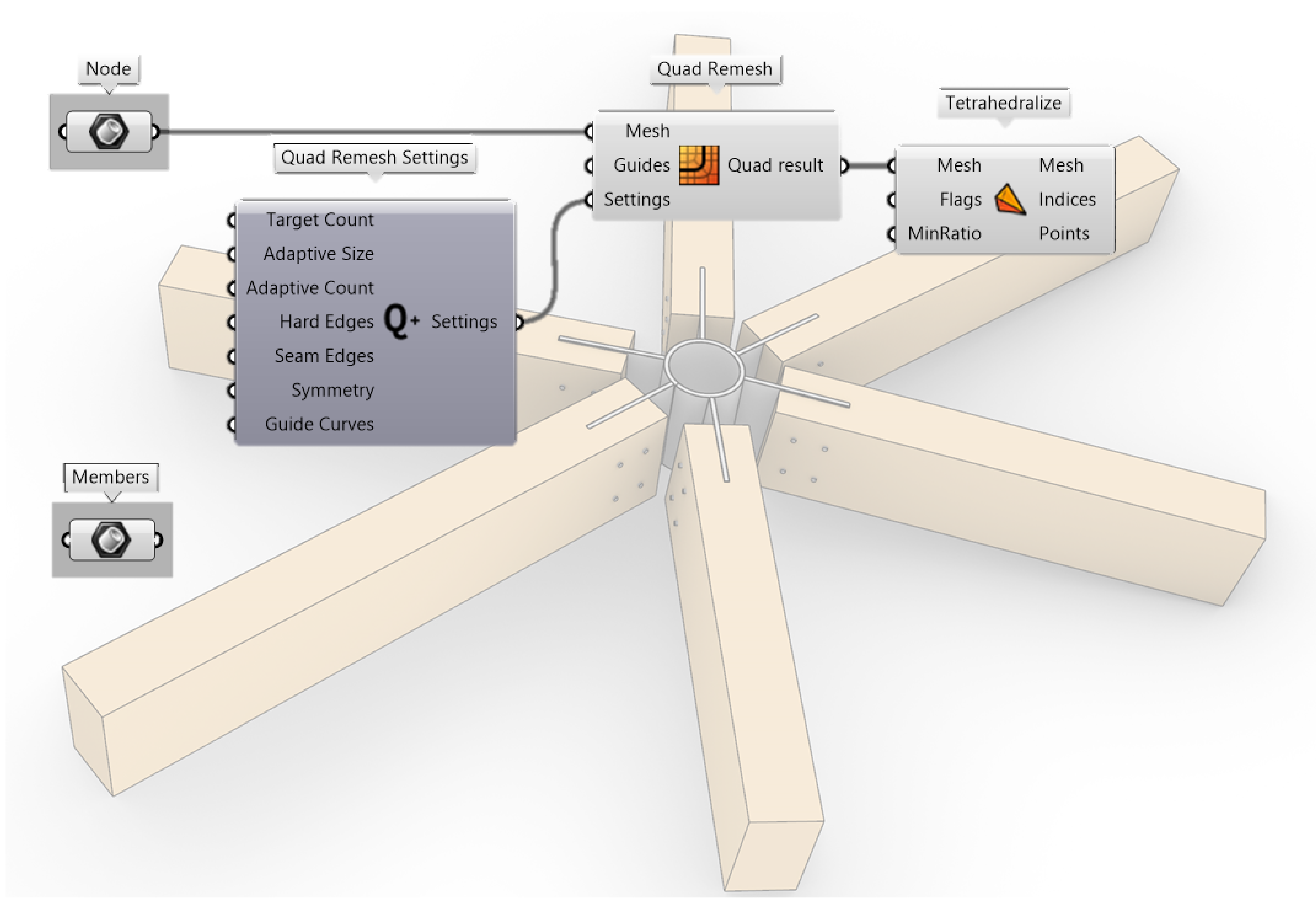

This raises the question of how to discretise a volumetric architectural element into small solid finite elements while working in the same software as the architect to maintain close collaboration. Most computer-aided design (CAD) software can easily discretise curves into a series of straight elements or a surface into a mesh of triangular or quad faces. Dividing a volumetric element into a solid mesh element is significantly more complicated. Normally, one would export the object and use different specialised software. As seen for Printshell discussed in

Section 2.1, this is a timely procedure which impedes the creativity necessary in a conceptual design phase. Luckily, one of Grasshopper 3D’s greatest strengths is the possibility for third-party developers to create their own plugins within the program. The website food4Rhino.com [

15] is a marketplace where these are distributed among users, often free of charge for non-commercial purposes. Here, the plugin Tetrino can be found [

16]. This is a plugin working as a wrapper for the TetGen algorithm [

17] that allows for the meshing of solid elements directly in Grasshopper 3D. Thus, a change in the architectural model can be automatically updated within Grasshopper 3D for the analytical model of the engineer. Despite the necessary geometric information and different possibilities for generating meshes for an FEA, there exists, to the authors’ knowledge, no tool that performs a complete FEA using solid elements within Grasshopper 3D today. Consequently, this paper presents the work to implement such a tool.

In order to test the efficiency and functionality of the plugin, a series of gridshell node geometries have been examined with the tool. A more thorough description of the methodology for developing gridshell nodes will be presented in another article by the authors. The selected nodes and the results from the case studies are presented in

Section 4. The current version of this tool only supports linear analysis using isotropic material such as metal. Implementation of orthotropic material, nonlinearities and contacts are expected to be included in further versions. Due to these limitations, the case studies in this paper only consider the metal part of the nodes without any interaction between fasteners and timber beams.