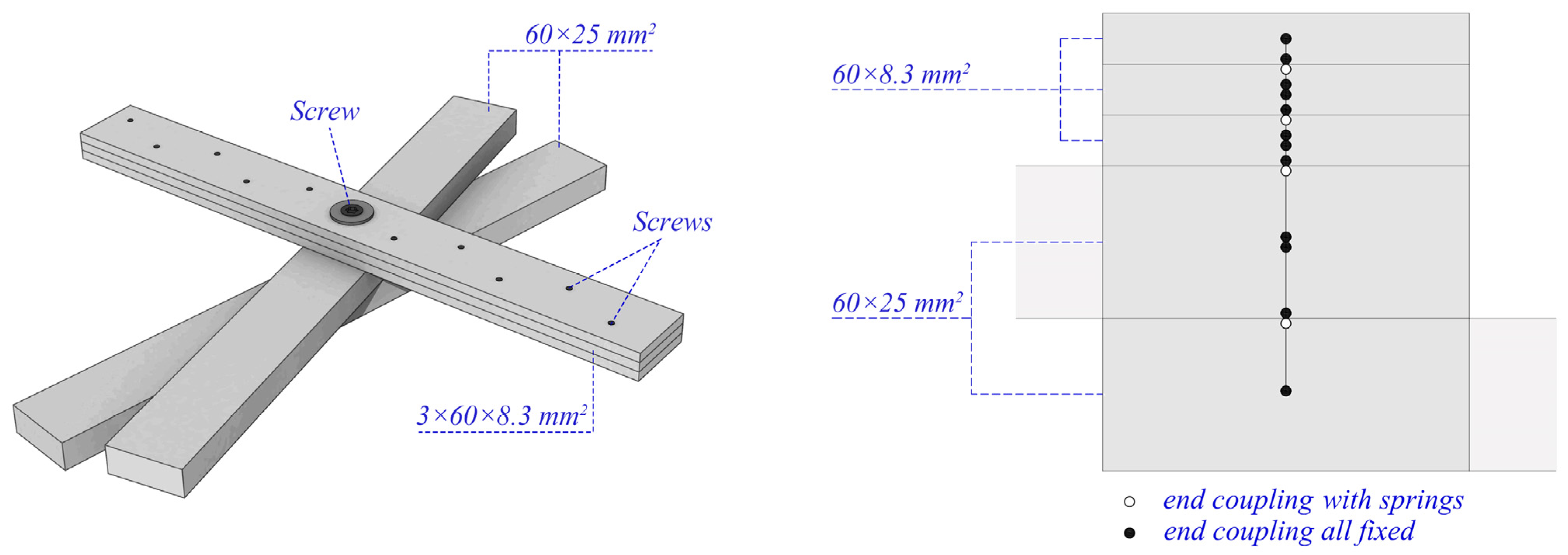

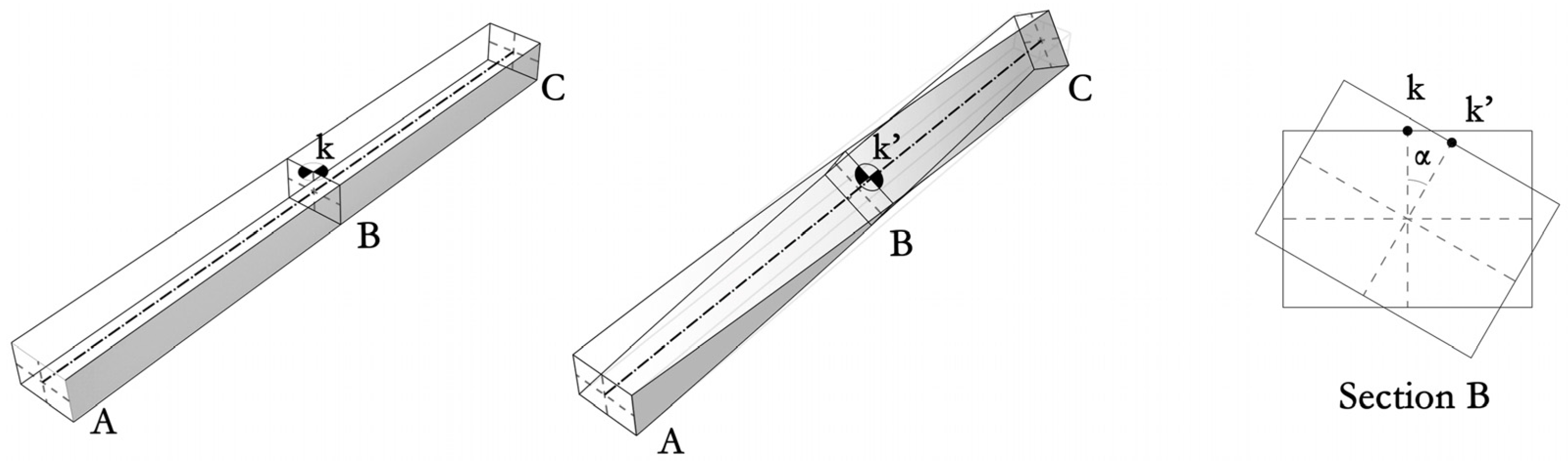

This section presents a computational finite element model (FEM) for the structural analysis of TEL-gridshells, with a focus on the stiffness calibration of the model. In addition, stresses due to external loads are analysed. The model consists of including the actual eccentricity of the joints and the existing interlayer slips. For this purpose, a system of couplings aligned in the actual position of each connection is implemented, which include springs in all shear planes. The results of the full-scale test described in the previous section are used to validate the proposed model and to analyse the most influential aspects in its stiffness.

4.3. Geometry, Materials and General Aspects

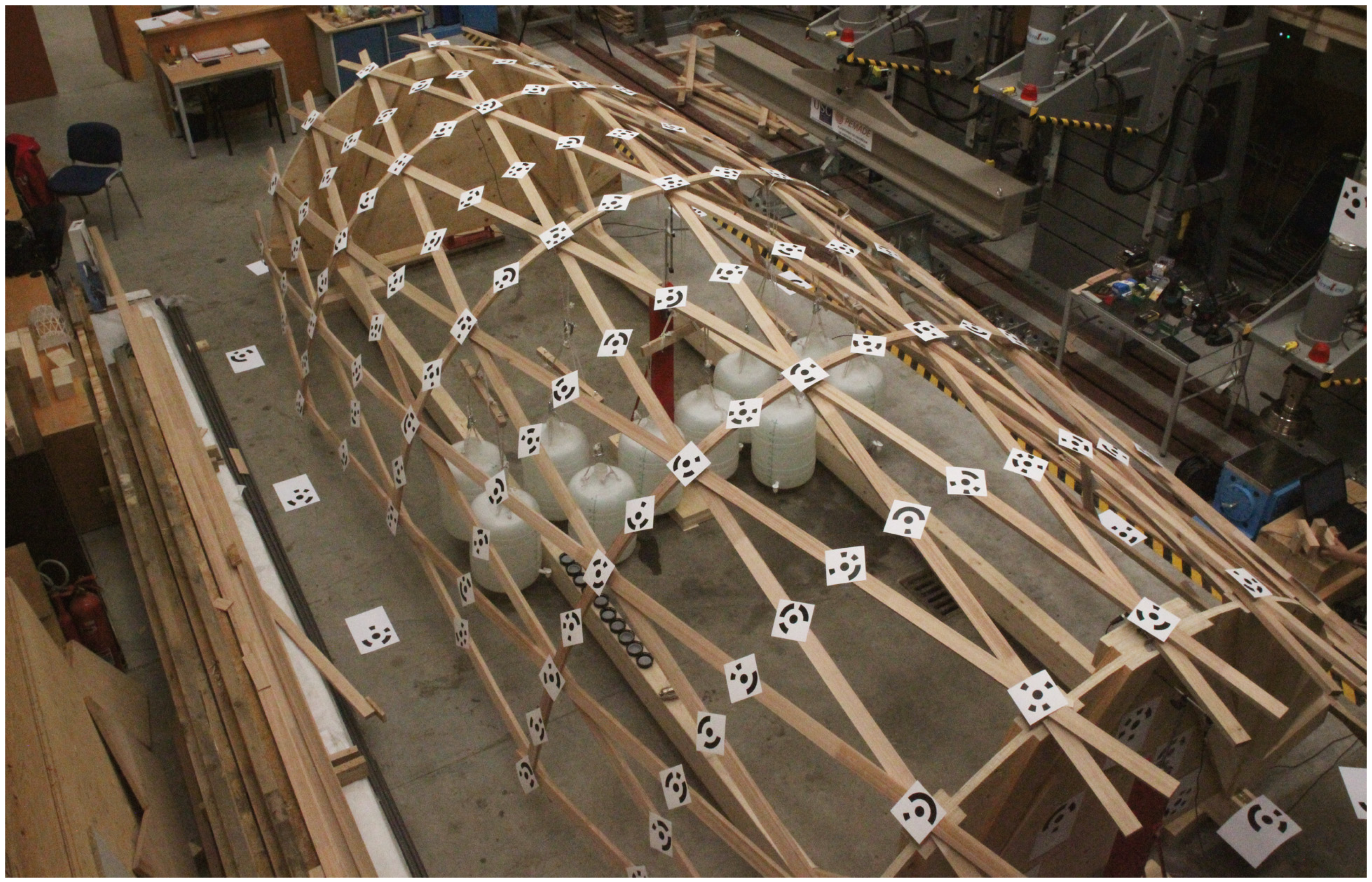

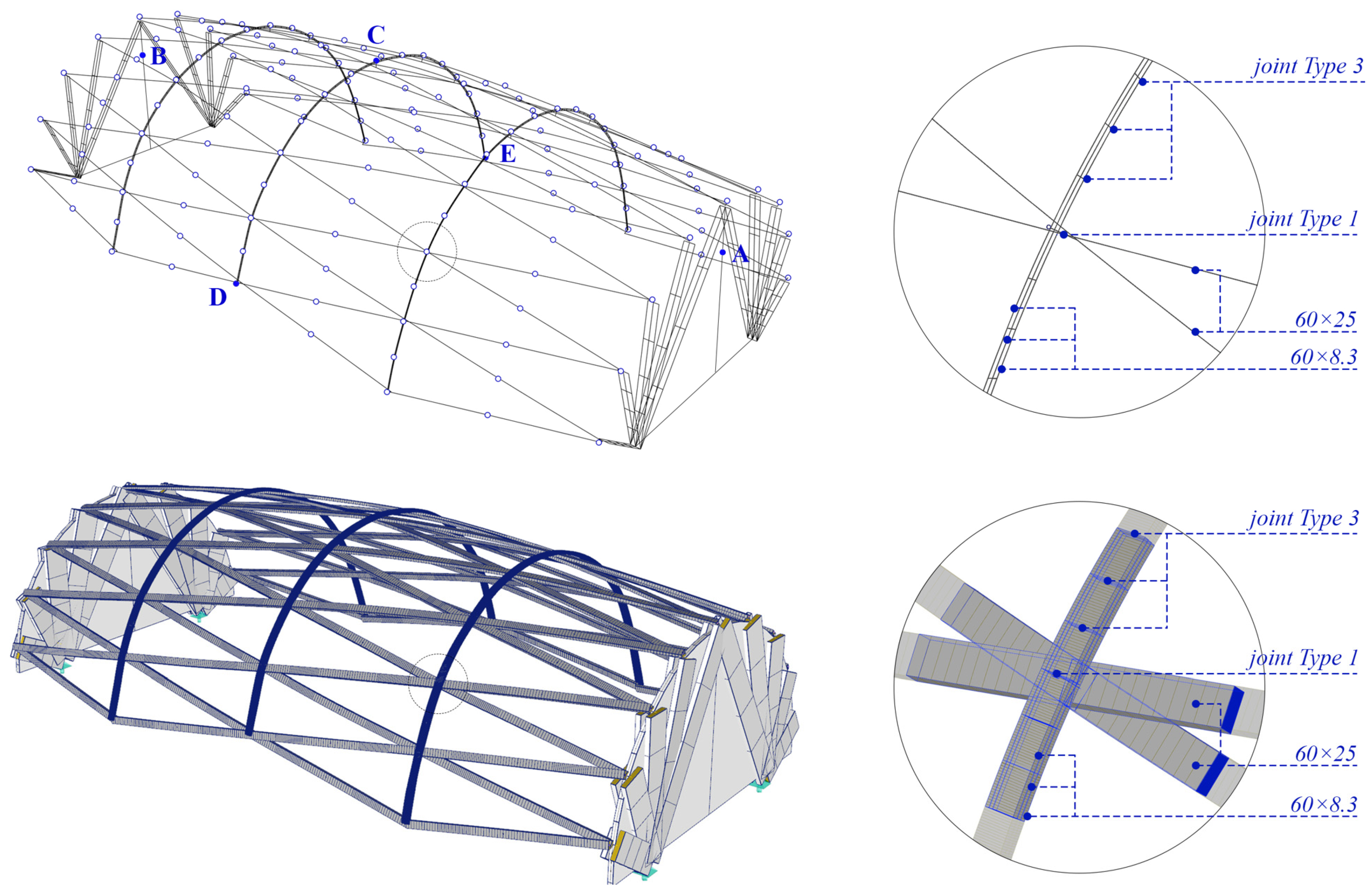

The geometry was modelled in Rhino and Grasshopper [

45] reconstructed from the coordinates of the target points measured by photogrammetry, and not from the original design model. This takes into account construction imperfections and the small movements of the structure due to elastic recovery, minimising uncertainties arising from geometrical differences between the computational model and the tested prototype.

The main family of laths was discretised into six segments in each span between nodes. Rotation around the weak axis of the cross-section was allowed at the end nodes of each of the 18 laths. The transverse laths were discretised into segments of 60 mm in length, corresponding to the screw spacing of the Type 3 joint. The cross-section of each member segment was oriented so that the weak axis coincided with the vector normal to the surface at the centre point of each segment.

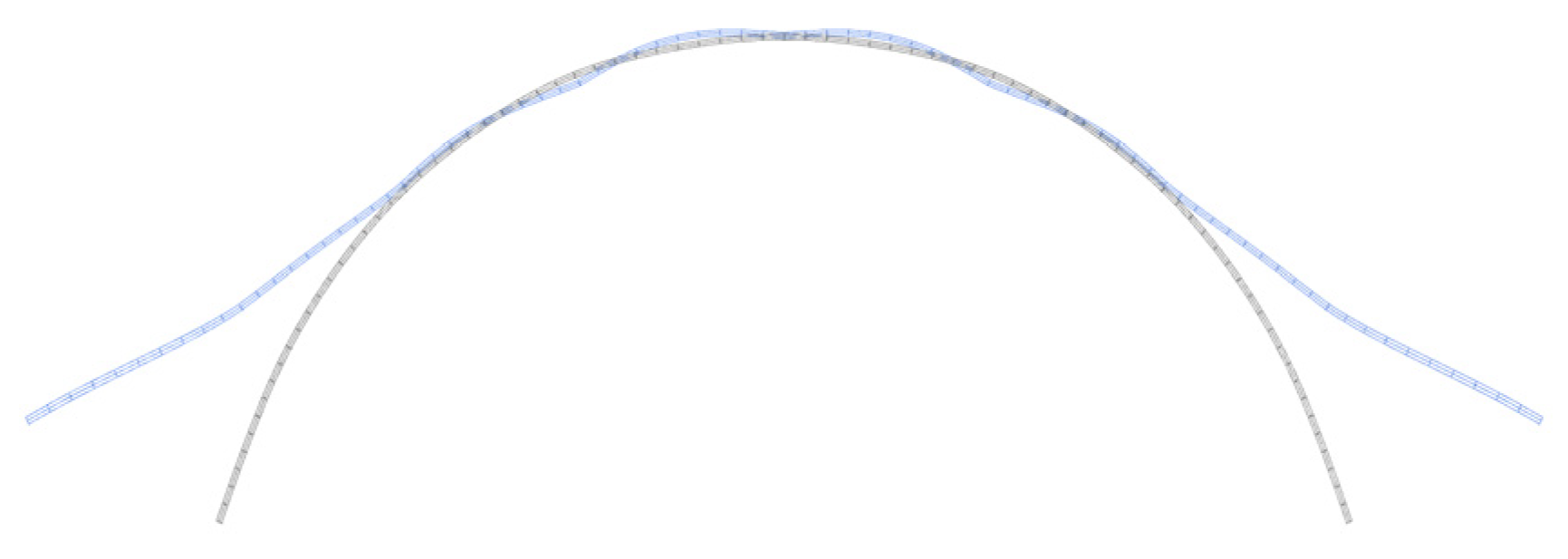

The points corresponding to each target (deformation control points) were implemented in the numerical model using small beam members that perpendicularly join the lath axis with the point corresponding to the centre of each target. In this way, a total correspondence was achieved between the coordinates of the targets in the numerical model and those obtained from the photogrammetry. This strategy also made it possible to detect the rotation by torsion of the members even if their ends do not move (

Figure 9).

After completion of the geometrical model in Rhino, it was exported to RFEM (Dlubal Software GmbH, Tiefenbach, Germany) [

46], where all necessary structural information was added. The timber laths were modelled as beam elements (with axial, shear, bending and torsional stiffness), to which the actual cross-section and average elastic properties were assigned.

The LVL supports were modelled as shell elements of 40 mm thickness. The shells were meshed so that one of their nodes coincided with the position of the LVDTs (control points A and B). The meshing of these elements was performed automatically in RFEM allowing triangular and quadrangular elements with a maximum side length of 0.5 m. No mesh refinement was applied. The reinforcement pieces were modelled as beams in their actual position, which were connected to the shell using small couplings. The general appearance of the developed geometrical and FEM models of the TEL-gridshell, including the location of control points A, B, C, D and E, and the detail of a nodal joint can be seen in

Figure 10.

Linear and elastic material behaviour was assumed. The material properties of the beams are summarised in

Table 4. For the shells, 2D orthotropic elastic material was taken. The average values of the mechanical properties of eucalyptus have been obtained from tests carried out by the authors (see

Section 3.2), while those of pine LVL have been taken from data provided by the manufacturer (Metsä Wood, Espoo, Finland) [

47]. The external loads were applied as point loads at the upper nodes of the corresponding joints. These were applied incrementally in eight steps until the experimental test load was reached. Geometrically non-linear large deformation analysis was performed.

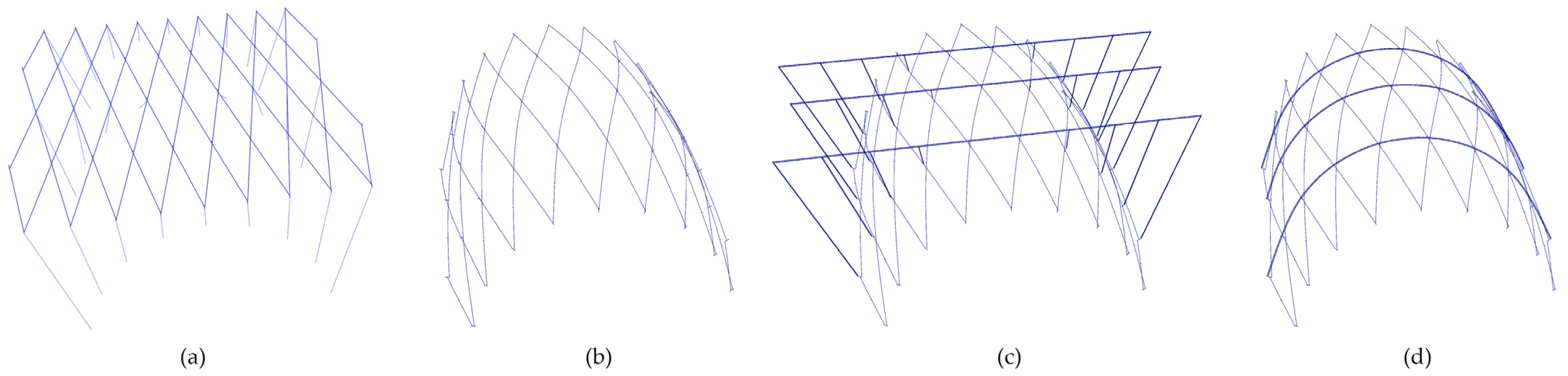

To better understand the behaviour of the structure, the influence of the LVL supports and the stiffness of the joints on the overall stiffness of the gridshell was analysed. For this purpose, several numerical models (with and without LVL supports, and with and without slip) were developed for the three types of joints defined. The models considered are compiled in

Table 5. Non-slip joints modelled without springs are defined as “Rigid”.

4.4. Experimental Results and Comparison with Numerical Analysis

The experimental displacements of the gridshell prototype points where the targets were placed were easily calculated from the coordinates of these points before and after loading. The average displacement of all nodes was 10.22 mm. The displacement vectors of the target points in the different numerical models were also obtained. Comparison of the experimental and numerical displacement values for the 145 measured points is shown in

Table 6. The first row shows the sum of the displacements in absolute value for all nodes, Σ|U|. It provides an overview of the deformability of the structure. The second row presents the ratio of the above parameter for each numerical model in relation to the experimental one, Σ|U|

num/Σ|U|

exp. The third row gives the value of the mean displacement at each point, |U|

mean. The following five rows show the displacements corresponding to the control points A–E presented in

Table 2. The last rows show the deviation of the numerical results with respect to the experimental ones, providing the absolute difference between the experimental and numerical displacement vectors, |U

exp − U

num|, and the angle (in absolute value) formed by their directions.

As can be observed from

Table 6, the C5 model, which incorporates the LVL supports and semi-rigidity in all joints, gives the best results. For this model, the calculated gridshell deformation shows reasonable agreement with the experimental values. The mean displacements are in the same range as the actual ones with a mean error of 1.85 mm and a standard deviation of 1.6 mm. This numerical error is very close to the mean error of the experimental measurement (1.63 mm, see

Section 3.6), so better fittings of the numerical model are difficult to quantify.

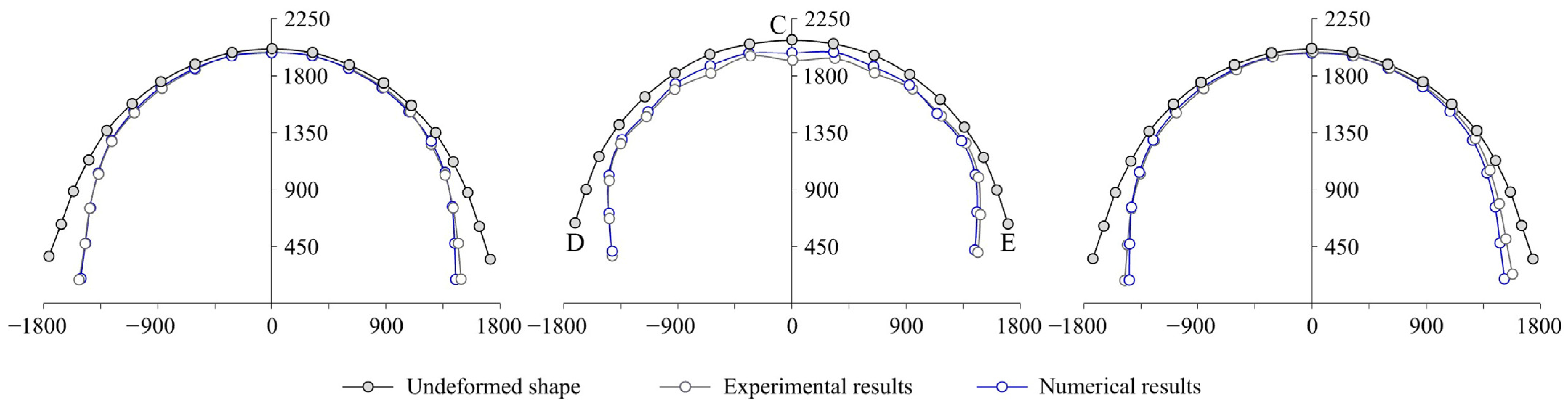

Figure 11 shows the final global deformations of the C5 model. For easier comparison with the experimental results, the three transverse laths of this model are presented in

Figure 12.

As can be seen, the deformations at the load application points resulted greater in the experimental test than in the numerical model. Although the maximum experimental displacement in this area was 13.8 mm (14.6 mm from LVDT measurement), which is below the maximum value corresponding to SLS (L/300 = 21.7 mm), the stress in the joints may exceed their service range due to the application of heavy concentred loads. This could lead to local effects not considered in the model, such as non-linearity phenomena in the slip of the joints. To improve the model fitting in this respect, experimental studies of the joints would be necessary to determine their stiffness over the entire load range and to implement non-linear laws for the behaviour of the springs.

It should be noted that the greatest displacements of the structure do not occur in the load application points, but in the lower part of the transverse laths, which close inwards when the vertical loads are applied.

This behaviour highlights the lack of stiffness of the structure in this area, and points to the need for design modifications. Numerical simulations carried out by the authors have shown that an increase in the cross-sections of the longitudinal laths had practically no influence in this respect [

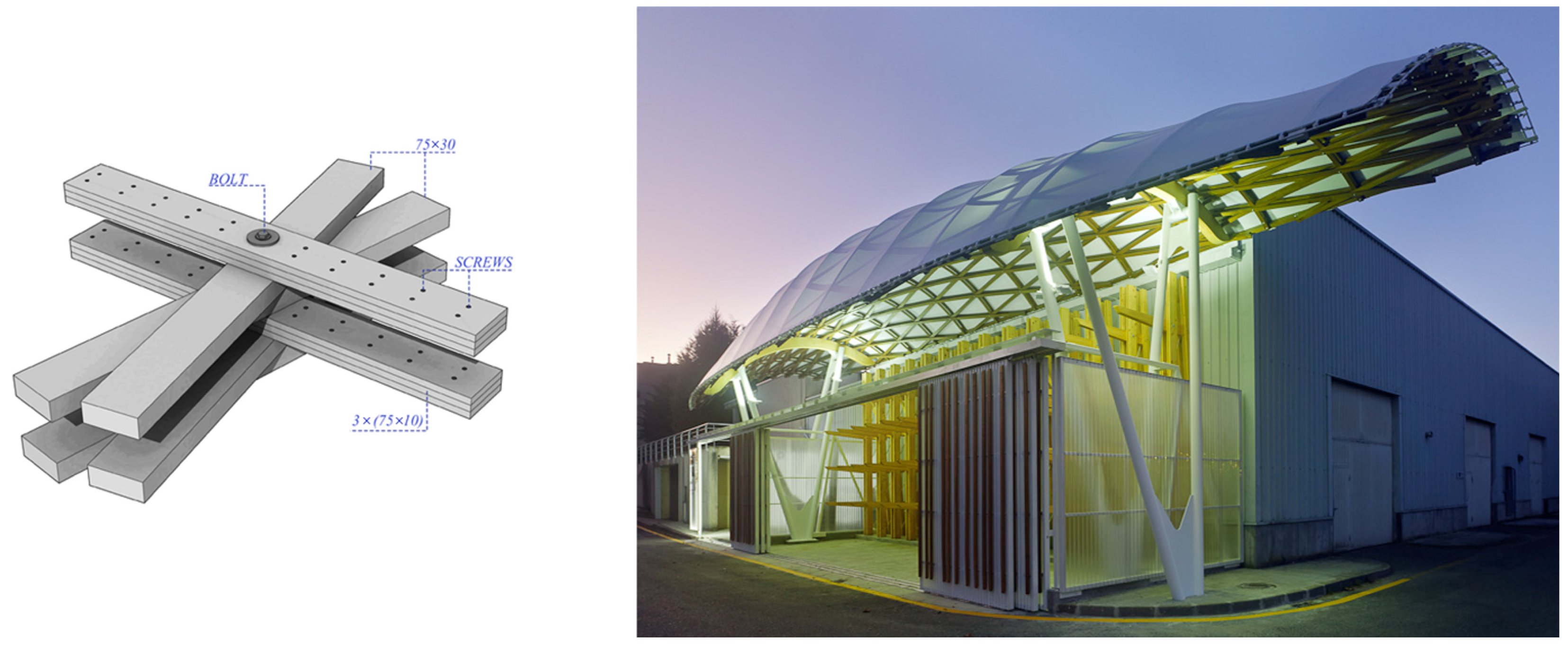

11]. To increase the gridshell stiffness in that area, it is necessary to have an edge beam of large cross-section or to increase the moment of inertia of the transverse laths. The latter solution was used in a first permanent TEL-gridshell structure designed by the authors, in which double transverse laths were arranged (

Figure 2 and

Figure 13).

Analysing each of the different aspects involved in stiffness separately, it is observed that the addition of the LVL supports in the model is the most important to properly simulate the stiffness of the structure. The S5 model, without LVL supports but with slip at all joints, showed an average displacement much lower than that of any other model including LVL supports, even lower than that of the C1 model with all rigid joints. In particular, when comparing the S5 model with its counterpart C5 with supports, the mean displacement of the latter was more than three times higher than that of the former.

Likewise, the assumption of semi-rigidity at the nodal joints and supports in the model is of relevant importance to adjust the stiffness of the structure. As can be seen in

Table 6, the gridshell with LVL supports and semirigid

Type 1 and

Type 2 joints (C4 model) had a 40% higher |U|

mean than the same structure with all rigid joints (C1 model).

In short, similar to what happens in arches where their behaviour is strongly dependent on the stiffness of their supports, the gridshell under study requires the most accurate modelling possible of both the supporting structural elements and the connections of the laths resting on them. From a design point of view, it is a priority to provide the lateral supports and their connections with the maximum possible stiffness in order to minimise the deformations of the structure.

The relative influence of considering the stiffness of the mechanical laminate joints in the transverse laths (joint Type 3) can be analysed by comparing models C1, C2 and C3. As can be observed, the semi-rigidity of the nodal joints (C2) increases the displacement values more significantly than the consideration of semi-rigidity in the transverse laths (C3). The latter is the least influential variable on the overall stiffness of the prototype. Similar conclusions from a qualitative point of view are obtained by analysing models without the LVL supports, which are ultimately equivalent to structures with rigid supports. A parameterised study of all geometric and stiffness variables would be necessary to generalise these statements for TEL-gridshells.

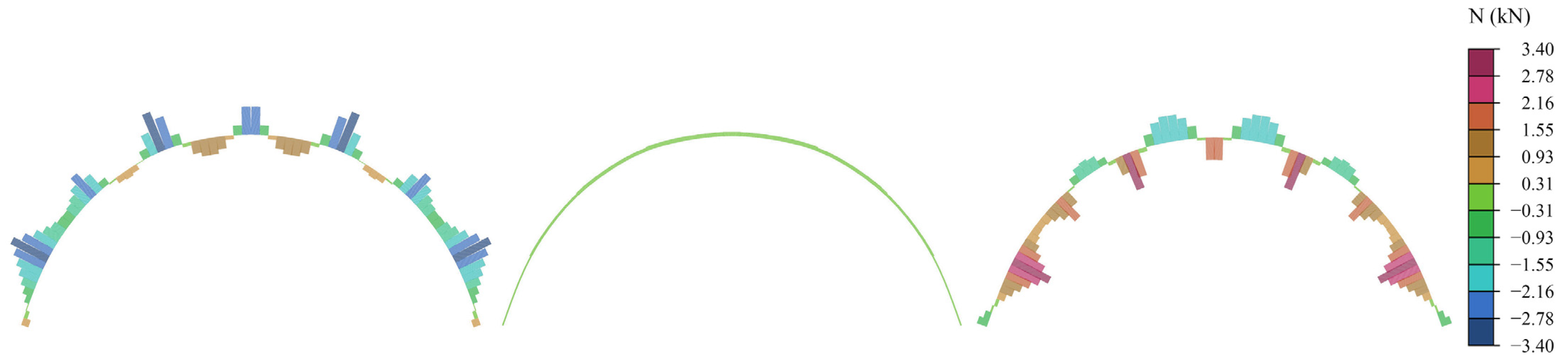

In order to have an approximation of the stress level reached in the prototype members due to the external load alone, the stresses obtained numerically are also analysed. The stresses have not been verified with any experimental procedure, but since the deformation obtained with model C5 provides a reasonable agreement with the experimental deformation, it is reasonable to think that the stresses obtained with this model also offer an adequate approximation.

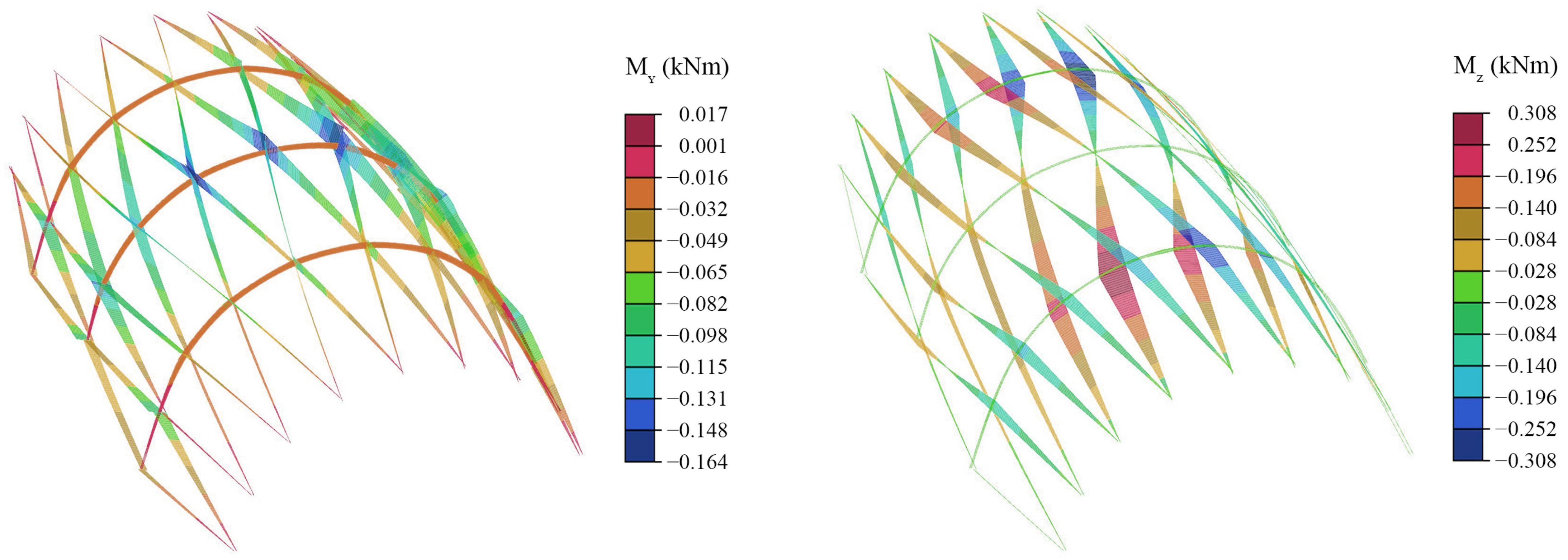

Table 7 summarises the maximum values of axial forces (N), weak/strong axis bending moment (M

y and M

z, respectively), torsion moment (M

t), and weak/strong axis shear force (V

y and V

z) obtained with model C5. The results using model C1 (with all rigid connections) are also shown to better understand the influence of the joint stiffness on the stresses of the members.

As can be seen, in the model without slip at the joints (C1), the bending stresses due to My and Mz are 90% and 65% of the model with slip (C5), respectively. In contrast, the axial stresses are approximately 13% higher. Higher axial stresses and lower bending stresses are always desirable in the design of gridshell structures, as they lead to a better behaviour of the structure as a membrane and, consequently, to greater material savings. From a design point of view, this consideration is crucial and points out the importance of reflecting on the type of connection to be used, looking for high stiffness solutions.

In general, the stresses in the structure are small, with maximum values in the zone of application of the point loads. Focusing on the results of model C5, the maximum values of combined normal stresses produced by the simultaneous action of axial and bending stresses (N, M

y and M

z) resulted in 11.5 N/mm

2 for the longitudinal grid laths and 20.0 N/mm

2 for the laths of the transverse laths. These are located in both cases in the kidney area of the central transverse lath, where the deformation due to curvature in the weak axis is more pronounced (see

Figure 12). In fact, normal stresses due to M

y are responsible for more than 70% of the maximum combined normal stress in the case of longitudinal laths and 85% in the case of transverse laths.

The maximum shear stresses due to Vy and Vz are also small. The maximum value of 0.39 N/mm2 occurs in the transverse laths, in the same area as the maximum combined normal stress. The tangential stress due to Mt is very low and does not exceed 0.20 N/mm2 at any point.

In relation to the stresses in the joints,

Table 8 shows the maximum shear V

j obtained in each type, calculated as (V

y2 + V

z2)

0.5. As expected, shear values are higher in the model without slip than with slip. It should be noted that the maximum value of V

j in the nodal joints (

Type 1 and

Type 2) is only between 5% (

Type 1) and 22% (

Type 2-Spring 2B) higher in model C1 than in model C5, while it is more than twice as high in the case of the screws of the mechanical laminate of the transverse laths (

Type 3 joint).

The results presented in this section do not take into account the stresses generated by the construction process. These are discussed in the next section.