Experimental Study on Mechanical Properties of High Temperature Granite with Different Cooling Methods

Abstract

:Featured Application

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Processing

2.2. Test Schemes

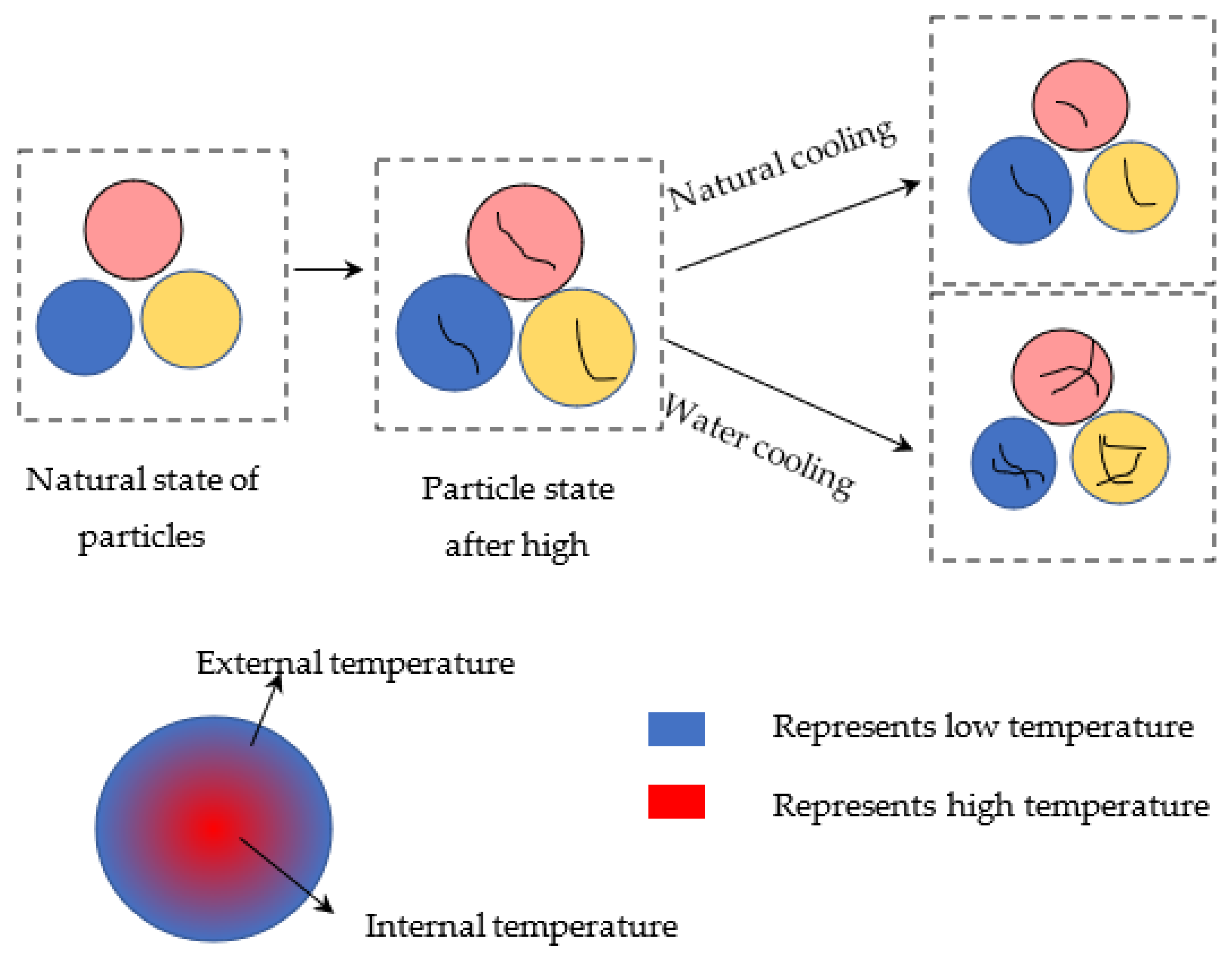

- The mass and size of the samples were measured. Then the granite samples in the natural state were treated with high temperature by being heated in a high temperature furnace. In order to avoid cracks caused by a too rapid heating rate, the heating rate was set to 5 °C/min. After heating to the target temperature, the sample was kept warm for two hours to ensure uniform heating. This paper picked three granite samples for each group to undergo the heating treatment and five groups of tests in total were carried out;

- After the heat preservation, half of the samples were taken out at room temperature for natural cooling. The other half were taken out for cooling in normal temperature water until they reached room temperature (sample immersed). The size and mass of samples were measured, which were treated by different cooling methods, and were then stored in a sealed bag waiting for testing;

- Samples treated by different cooling methods were used in uniaxial compression tests and they were loaded in the displacement control mode (0.06 mm/min rate) until the sample was damaged. The compressive strength and stress–strain curves of the samples were recorded during this process.

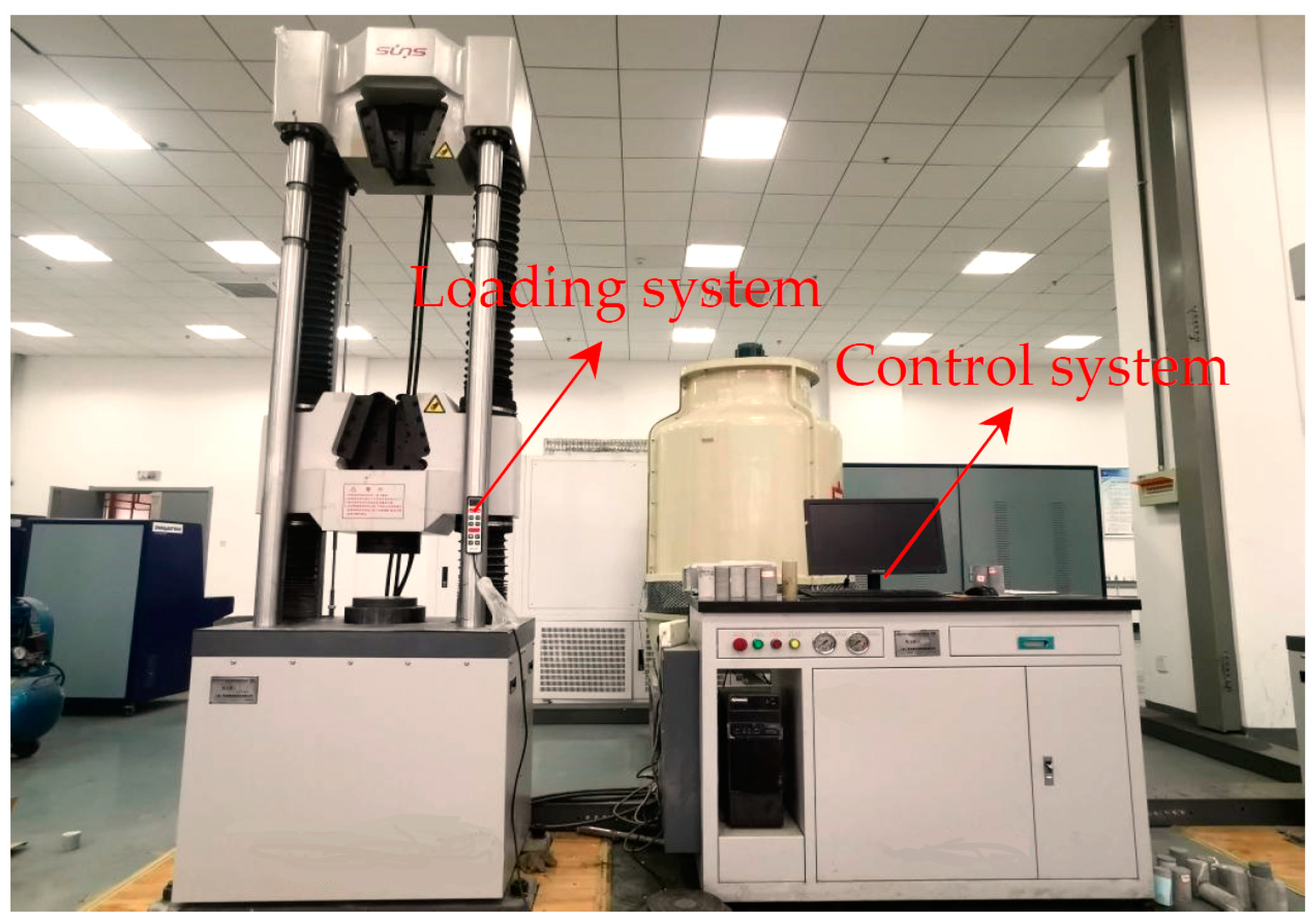

2.3. Test Equipment

3. Test Results and Analysis

3.1. Changes in Physical Properties

3.1.1. Surface Morphologic Change

3.1.2. Mass Changes

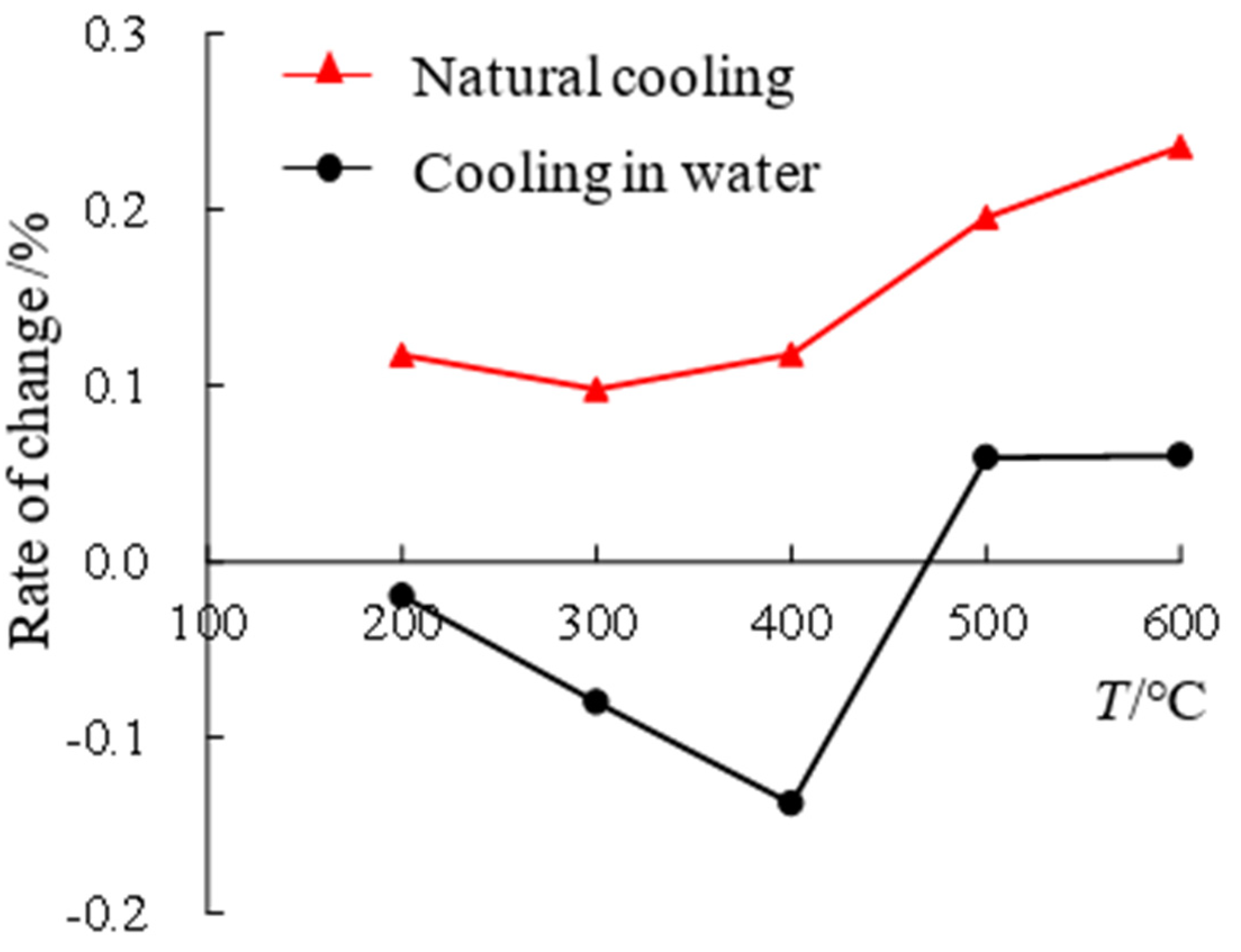

3.1.3. Volume Change

3.1.4. Density Change

3.2. Changes in Mechanical Properties

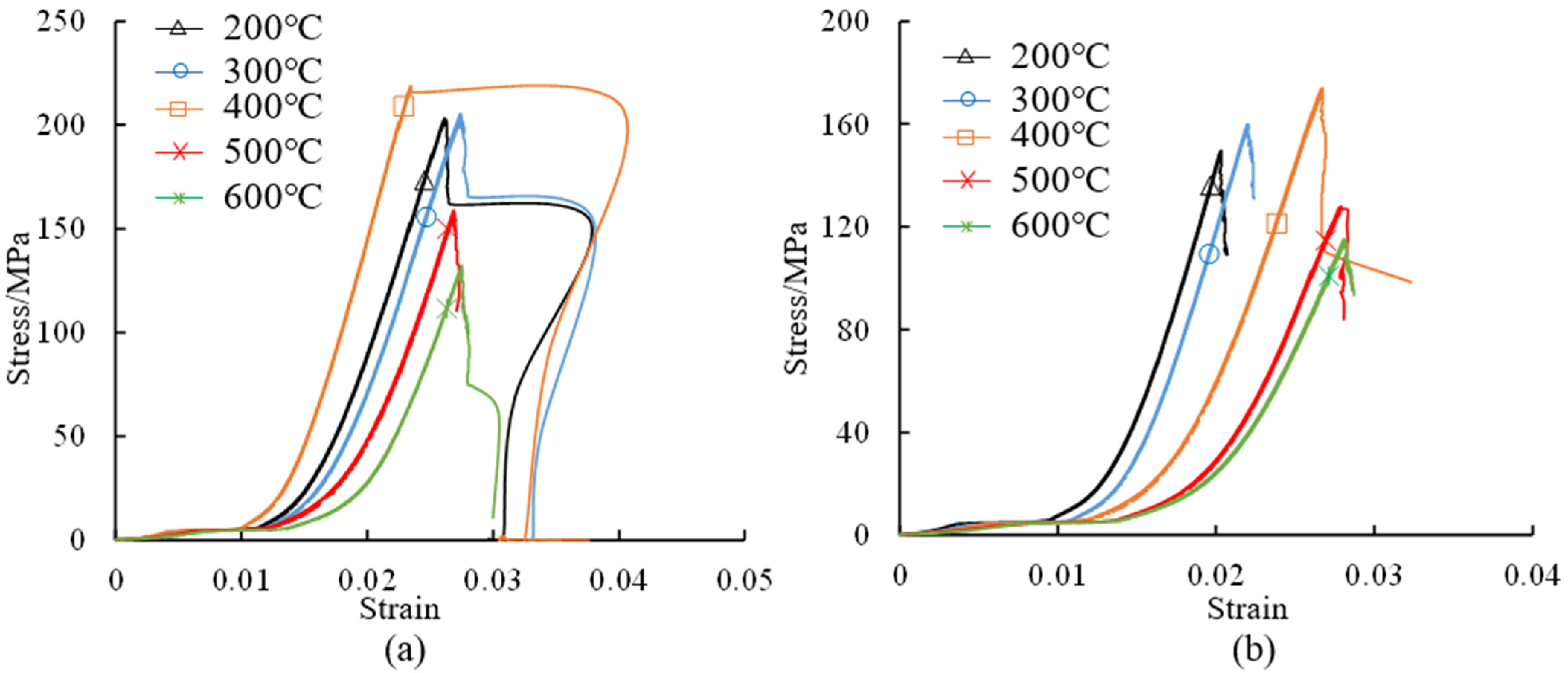

3.2.1. Stress–Strain Curve

3.2.2. Strength Characteristics

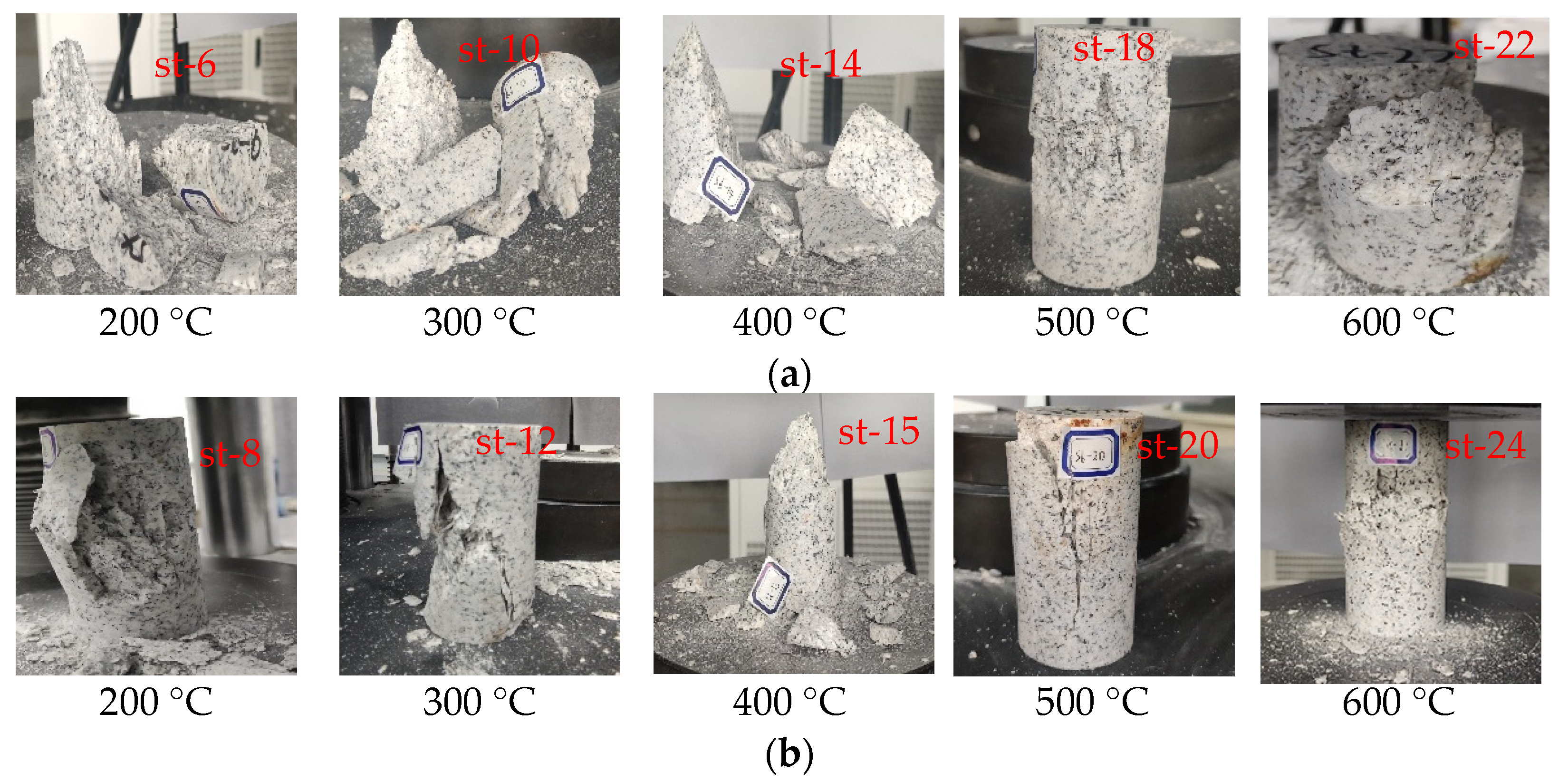

3.3. Failure Mode Analysis

4. Discussion

5. Conclusions

- Under different cooling methods, the samples show a deterioration trend little by little as the temperature goes up, and the deterioration degree is greater through water cooling. With the increase in temperature, the sample mass gradually goes down under the effect of natural cooling. However, under the effect of water cooling, it firstly goes up and then down, which is related to the water occurrence state and material change inside the rock. The volume and density of naturally cooled samples come with the phenomenon of increasing gradually, while the volume of water-cooled samples decreases first and then increases;

- The stress–strain curves of the samples after different cooling methods include four stages: crack compaction stage; elastic deformation stage; nonlinear deformation stage and failure stage;

- The peak strength of the samples after different cooling methods increases first and then decreases with the temperature rising. At different temperatures, the peak strength of samples under natural cooling is higher than that of water cooling. The elastic modulus of the sample first changed slightly but then became smaller little by little and the deformation modulus changes were less obvious with the temperature increasing;

- As the temperature rises, the failure degree of samples with different cooling methods has a hallmark trend of going up first and then down. The integrity of the sample is maintained under high temperature treatment. The damage degree of the natural cooling sample is higher, and for the water cooling is looser.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Clarkl, S.P. Handbook of Physical Constants; The Geological Society of America: Boulder, CO, USA, 1966. [Google Scholar]

- Fellner, M.; Supancic, P. Thermal Shock Failure of Brittle Materials. Key Eng. Mater. 2002, 223, 97–106. [Google Scholar] [CrossRef]

- Sun, Q.; Zhang, W.; Xue, L.; Zhu, S.Y. Thermal damage pattern and thresholds of granite. Environ. Earth Sci. 2015, 74, 2341–2349. [Google Scholar] [CrossRef]

- Sun, Q.; Zhang, Z.Z.; Xue, L.; Zhu, S.Y. High-temperature phase transformation of rocks and changes in physical and mechanical properties. Chin. J. Rock Mech. Eng. 2013, 32, 935–942. [Google Scholar]

- Zhu, Z.N. The Physical and Mechanical Characteristics of Wall Rock during Drilling and Mining of Dry-Hot Granite. Ph.D. Thesis, China University of Geosciences, Beijing, China, 2021. [Google Scholar]

- Zhao, Y.Y.; Wei, K.; Zhou, J.Q.; Li, X.; Chen, Y.F. Experimental study and mesomechanical analysis of thermal damage mechanical properties of three types of rock. Chin. J. Rock Mech. Eng. 2017, 36, 142–151. [Google Scholar]

- Somerton, W.H. Thermal Properties and Temperature-related Behavior of Rock/Fluid Systems; Elsevier: Amsterdam, The Netherlands, 1992; pp. 22–29. [Google Scholar]

- Glover, P.W.J.; Baud, P.; Darot, M. α/β phase transition in quartz monitored using acoustic emissions. Geophys. J. R. Astron. Soc. 2010, 120, 775–782. [Google Scholar] [CrossRef]

- Du, S.J.; Liu, H.; Du, H.T.; Chen, H.H. Experimental study on mechanical properties of granite after high temperature. Rock Mech. Eng. 2004, 14, 2359–2364. [Google Scholar]

- Yang, S.Q.; Ranjith, P.G.; Jing, H.W.; Tian, W.L.; Ju, Y. An experimental investigation on thermal damage and failure mechanical behavior of granite after exposure to different high temperature treatments. Geothermics 2017, 65, 180–197. [Google Scholar] [CrossRef]

- Zhang, F.; Zhao, J.J.; Hu, D.W.; Skoczylas, F.; Shao, J.F. Laboratory Investigation on Physical and Mechanical Properties of Granite After Heating and Water-Cooling Treatment. Rock Mech. Rock Eng. 2018, 51, 677–694. [Google Scholar] [CrossRef]

- Xu, X.L.; Gao, F.; Zhang, Z.Z. Effect of confining pressure on deformation and strength characteristics of granite after high temperature. Chin. J. Geotech. Eng. 2014, 36, 2246–2252. [Google Scholar]

- Liang, M.; Zhang, S.H.; Shu, B. Effects of different cooling methods on Brazilian splitting characteristics of high-temperature granite. J. Water Resour. Water Eng. 2018, 29, 186–193. [Google Scholar]

- Cui, H.B.; Tang, J.P.; Jiang, X.T. Experimental study on mechanical-acoustic characteristics of high temperature granite after natural cooling and water cooling. Chin. J. Solid Mech. 2019, 40, 571–582. [Google Scholar]

- Zhang, S.; Shu, B.; Liang, M.; Hu, Y.P. Mesoscopic damage quantification and mechanism analysis of high-temperature granite under different cooling methods. Coal Geol. Explor. 2022, 50, 106–114. [Google Scholar]

- Wang, Y.C.; Dou, B.; Yu, Y.; Zheng, J.; Tian, H.; Liu, H.J. Experimental study on Brazilian splitting and acoustic emission characteristics of high temperature granite under different cooling methods. Bull. Geol. Sci. Technol. 2022, 41, 200–207. [Google Scholar]

- Zhu, Q.; Zhang, J.R.; Zhou, Y.B. Overview of dry hot rock development and power generation technology application. Sino-Glob. Energy 2019, 24, 19–27. [Google Scholar]

- Bu, Y.S. Experimental Study on CO2 Permeability and Fatigue Mechanical Properties of Sandstone after High Temperature Damage. Master’s Thesis, China University of Mining and Technology, Xuzhou, China, 2021. [Google Scholar]

- Mahabadi, O.K.; Tatone, B.S.A.; Grasselli, G. Influence of microscale heterogeneity and microstructure on the tensile behavior of crystalline rocks. J. Geophys. Res. Solid Earth 2014, 119, 5324–5341. [Google Scholar] [CrossRef]

- Chen, B.; Zhang, S.C.; Shen, B.T.; Li, Y.Y.; Wang, C.G. Mechanical properties and failure characteristics of granite treated with a combined water–air cooling cycle. Case Stud. Therm. Eng. 2022, 34, 101964. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.-S.; Lu, Y.; Pang, J.-Y.; Bu, Y.-S. Experimental Study on Mechanical Properties of High Temperature Granite with Different Cooling Methods. Appl. Sci. 2022, 12, 5968. https://doi.org/10.3390/app12125968

Zhang J-S, Lu Y, Pang J-Y, Bu Y-S. Experimental Study on Mechanical Properties of High Temperature Granite with Different Cooling Methods. Applied Sciences. 2022; 12(12):5968. https://doi.org/10.3390/app12125968

Chicago/Turabian StyleZhang, Jin-Song, Yu Lu, Jian-Yong Pang, and Yi-Shun Bu. 2022. "Experimental Study on Mechanical Properties of High Temperature Granite with Different Cooling Methods" Applied Sciences 12, no. 12: 5968. https://doi.org/10.3390/app12125968

APA StyleZhang, J.-S., Lu, Y., Pang, J.-Y., & Bu, Y.-S. (2022). Experimental Study on Mechanical Properties of High Temperature Granite with Different Cooling Methods. Applied Sciences, 12(12), 5968. https://doi.org/10.3390/app12125968