Smart Patch for Structural Health Monitoring of Composite Repair

Abstract

1. Introduction

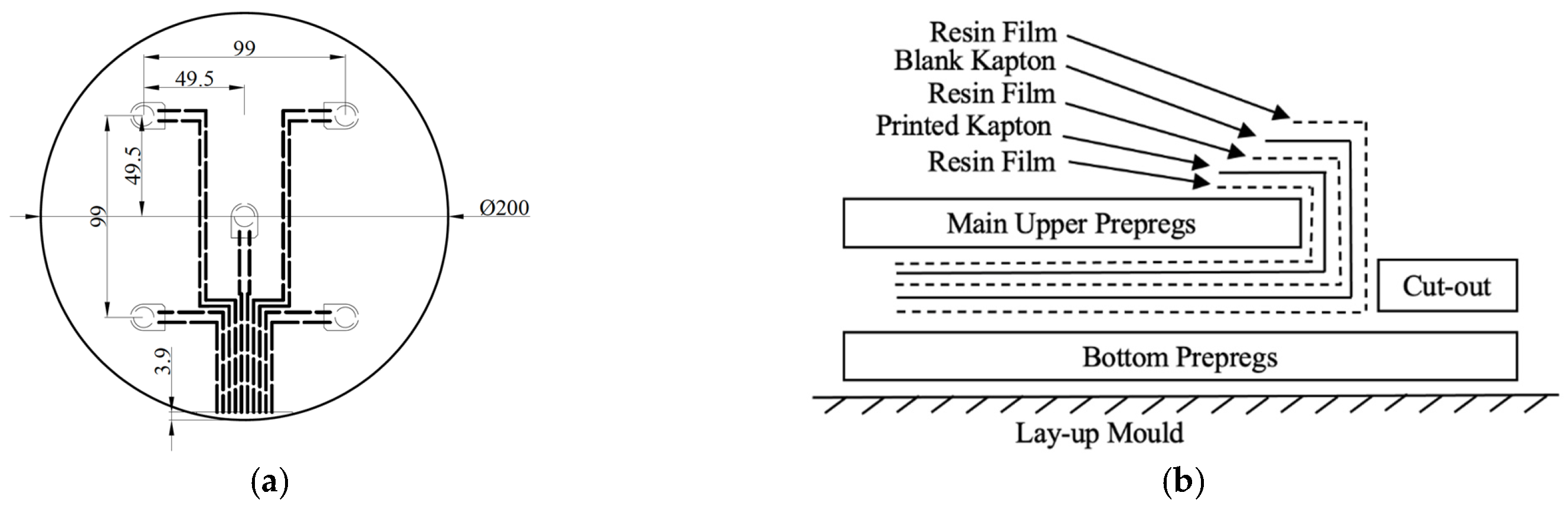

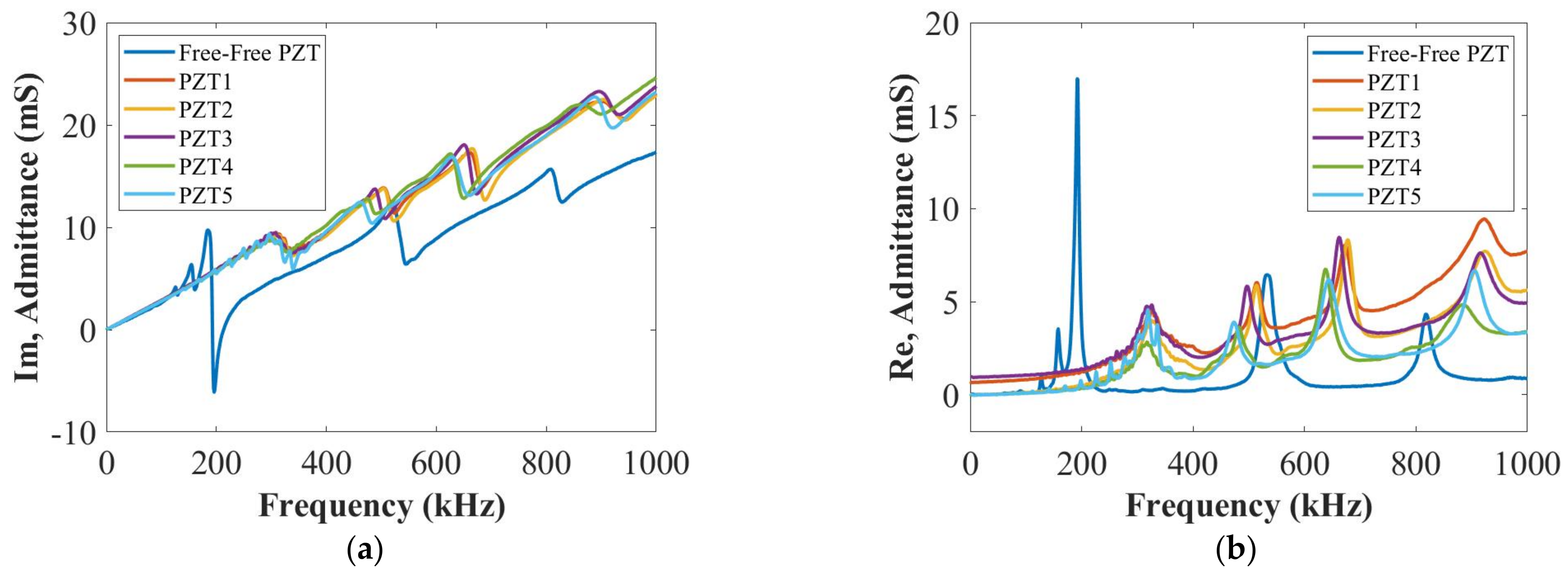

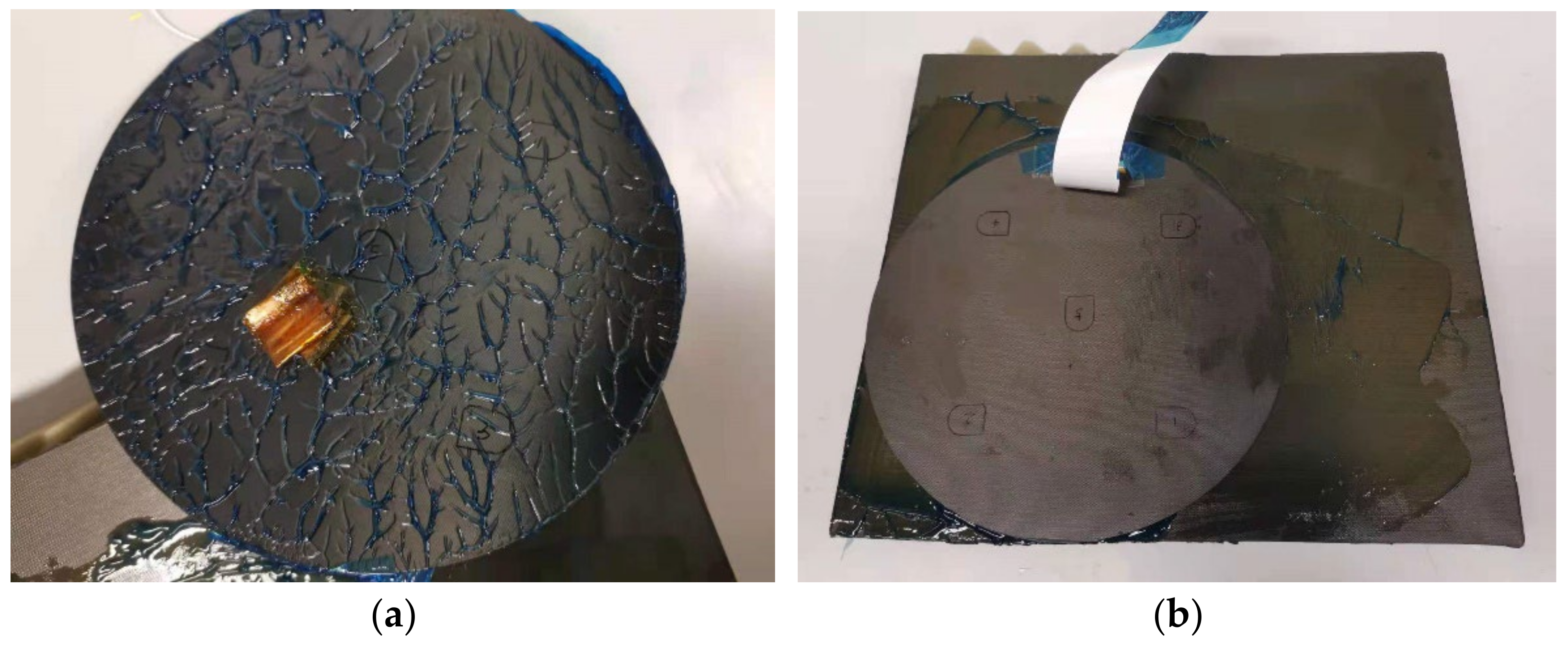

2. Experimental Setup

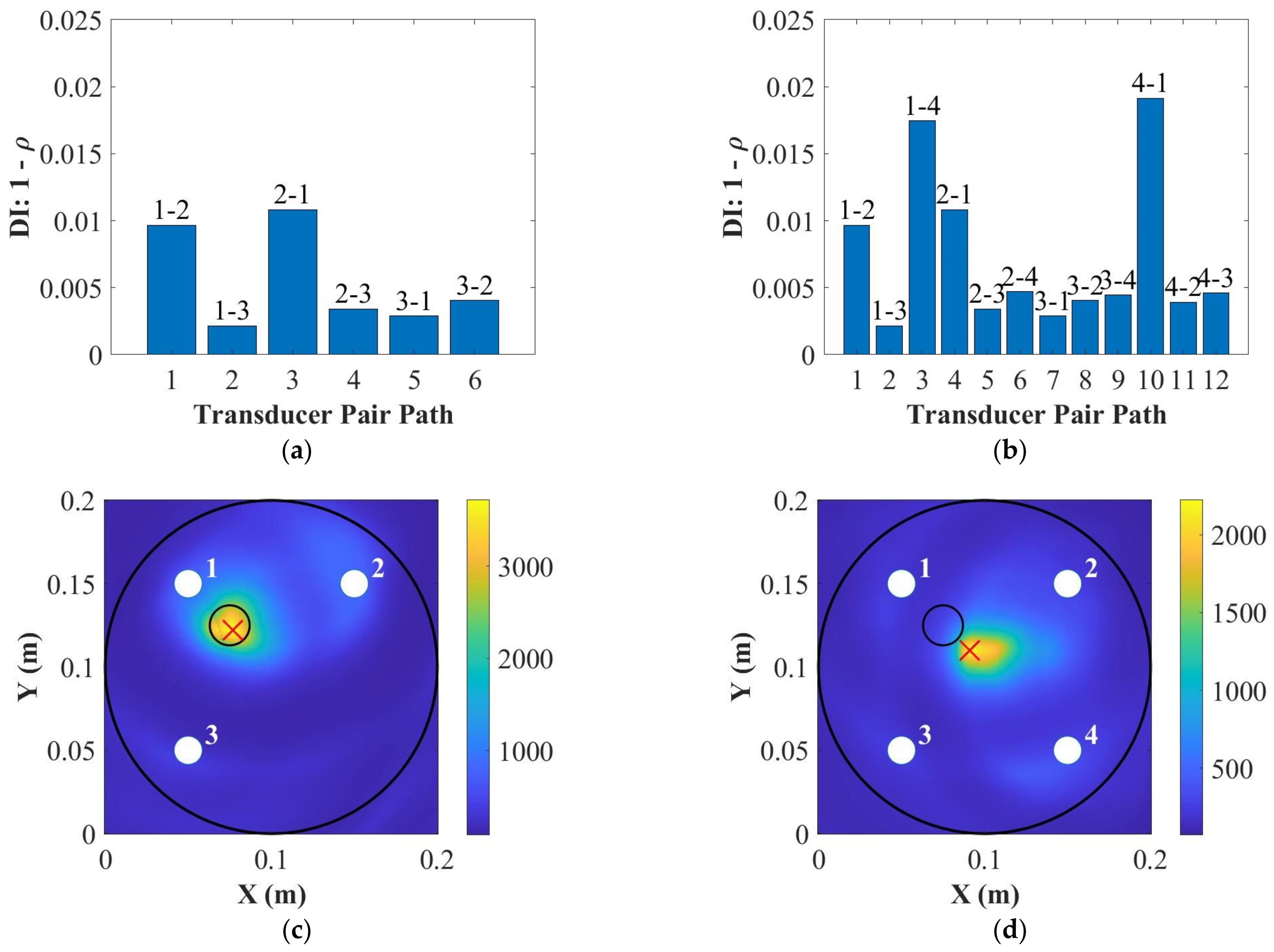

3. Damage Detection and Localization

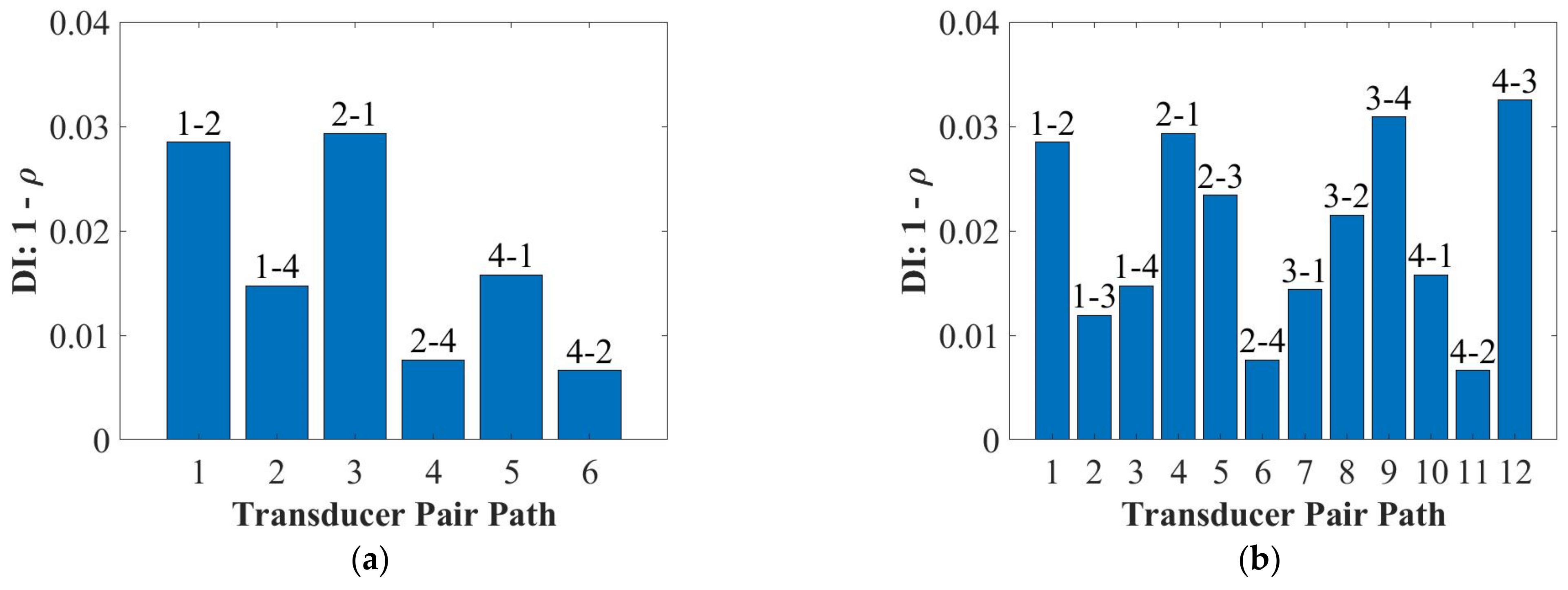

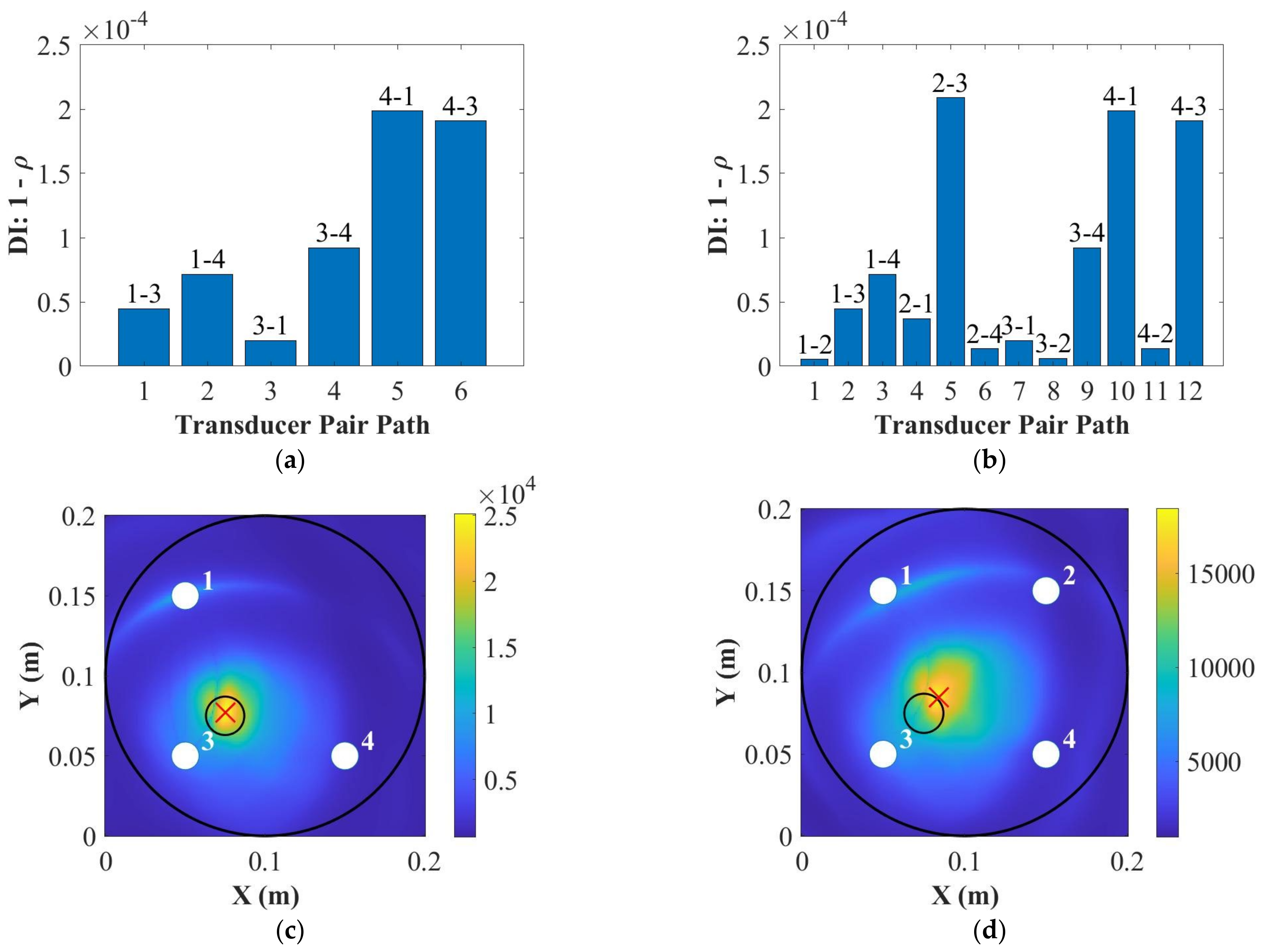

3.1. Delamination

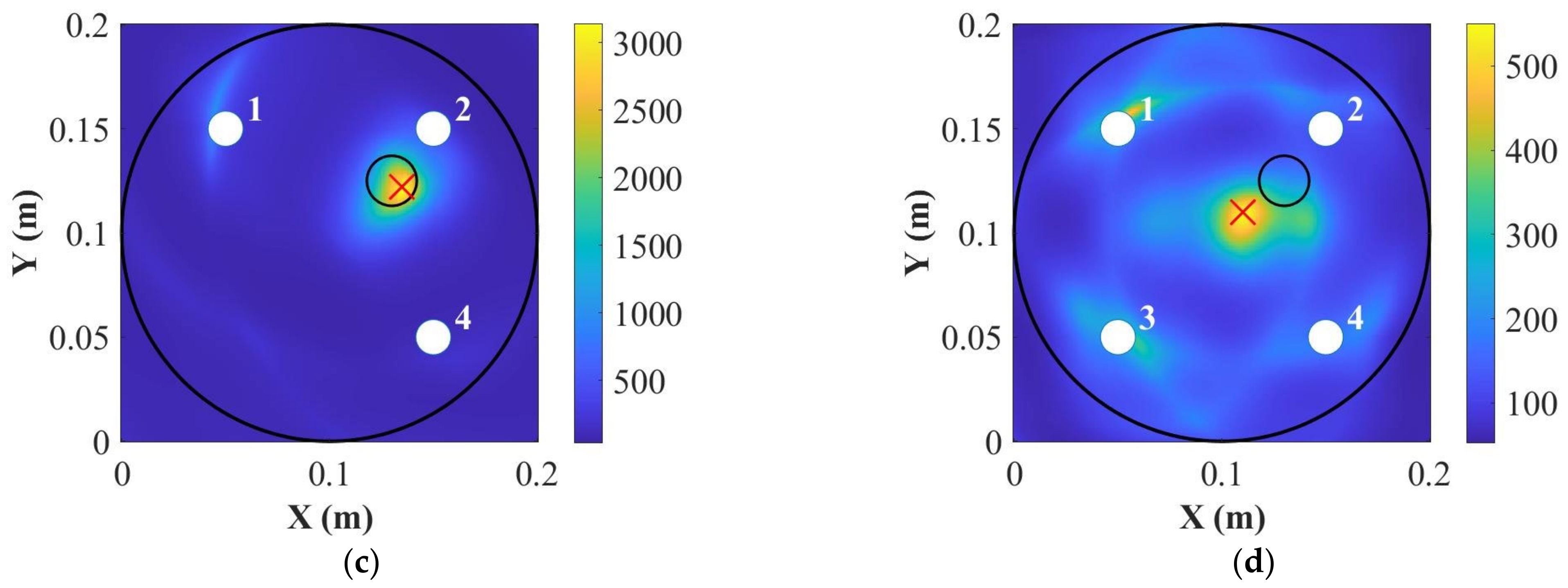

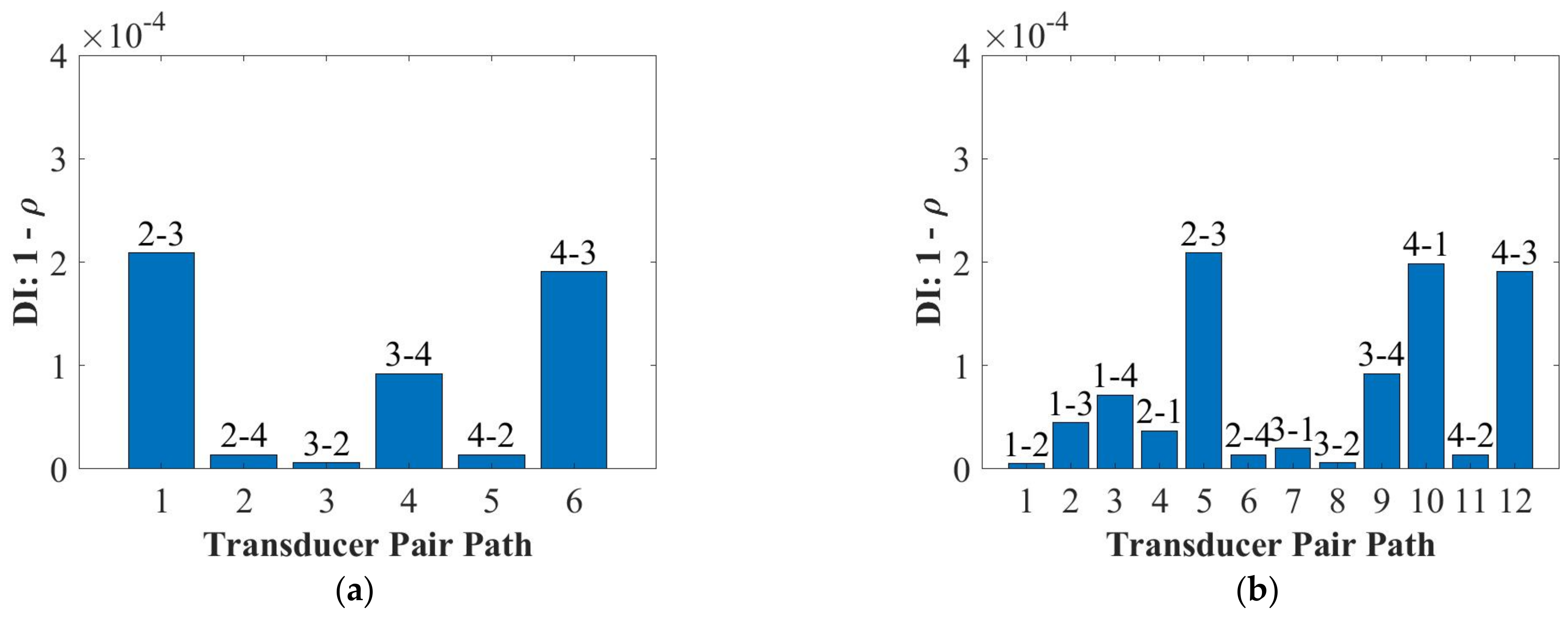

3.2. Surface-Mounted Artificial Damage—Surface of the Repair Patch

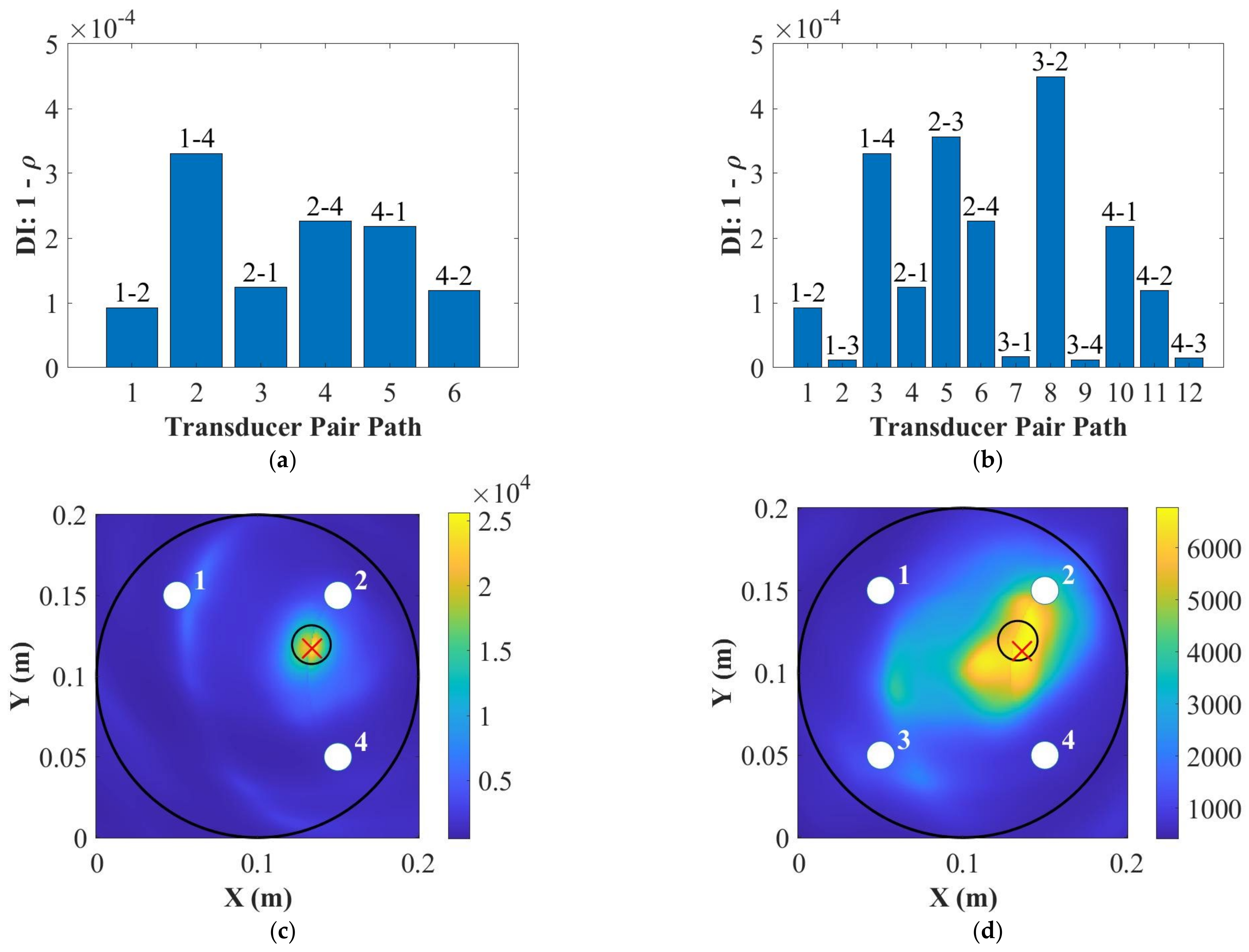

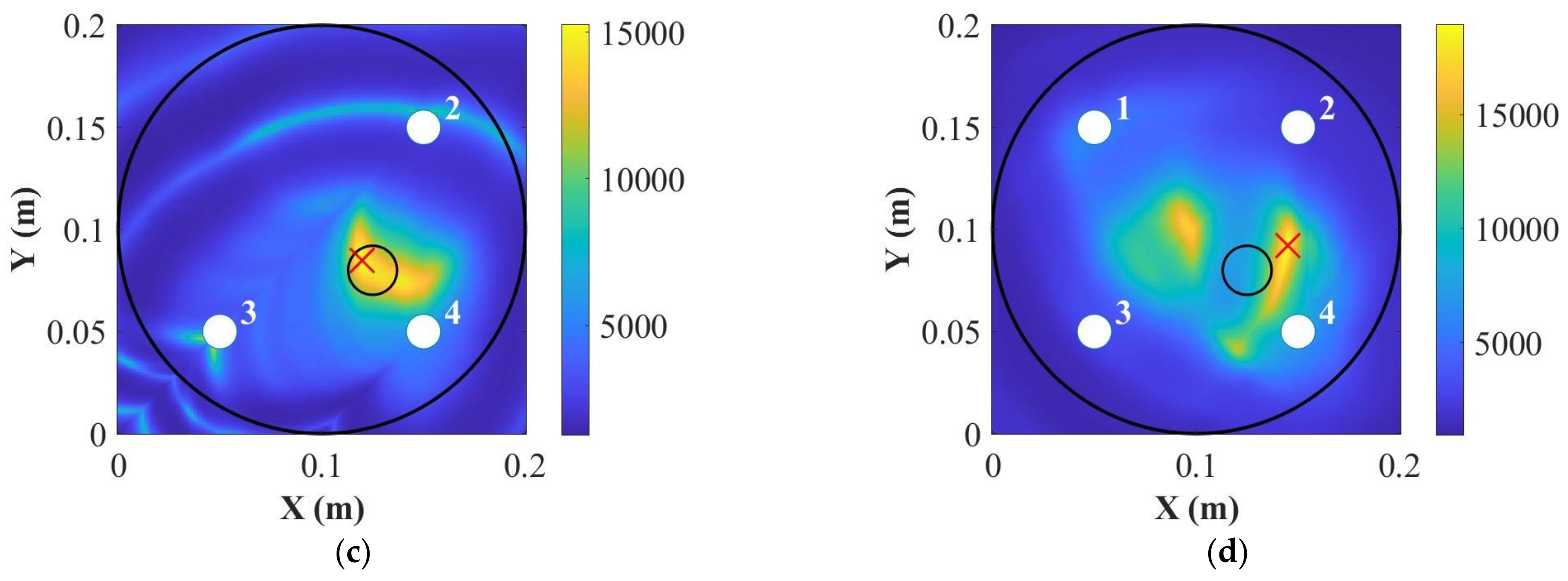

3.3. Surface-Mounted Artificial Damage—Bottom of the Host Structure

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Flor, F.R.; De Medeiros, R.; Tita, V. Numerical and Experimental Damage Identification in Metal-Composite Bonded Joint. J. Adhes. 2014, 91, 863–882. [Google Scholar] [CrossRef]

- Sikdar, S.; Fiborek, P.; Malinowski, P.; Ostachowicz, W. Ultrasonic guided wave propagation in a repaired stiffened composite panel. In Proceedings of the Health Monitoring of Structural and Biological Systems XIII, Denver, CO, USA, 3–7 March 2019. [Google Scholar]

- Lambinet, F.; Khodaei, Z.S. Damage detection & localization on composite patch repair under different environmental effects. Eng. Res. Express 2020, 2, 045032. [Google Scholar] [CrossRef]

- Katnam, K.B.; Comer, A.J.; Roy, D.; da Silva, L.; Young, T. Composite Repair in Wind Turbine Blades: An Overview. J. Adhes. 2015, 91, 113–139. [Google Scholar] [CrossRef]

- Spearing, S.M.; Lagace, P.A.; McManus, H.L.N. On the Role of Lengthscale in the Prediction of Failure of Composite Structures: Assessment and Needs. Appl. Compos. Mater. 1998, 5, 139–149. [Google Scholar] [CrossRef]

- Gryzagoridis, J.; Findeis, D. Benchmarking shearographic NDT for composites. Insight-Non-Destr. Test. Cond. Monit. 2008, 50, 249–252. [Google Scholar] [CrossRef][Green Version]

- Katnam, K.B.; Dhôte, J.X.; Young, T.M. Experimental analysis of the bondline stress concentrations to characterize the influence of adhesive ductility on the composite single lap joint strength. J. Adhes. 2013, 89, 486–506. [Google Scholar] [CrossRef]

- Gharib, H. Structural Health Monitoring of Adhesive Bond in Aircraft Repair Patches. Available online: https://www.researchgate.net/profile/Hossam-Gharib/publication/282121093_A_Review_on_Structural_Health_Monitoring_of_Adhesive_Bond_in_Aircraft_Repair_Patches/links/56036a9508ae596d2591e664/A-Review-on-Structural-Health-Monitoring-of-Adhesive-Bond-in-Aircraft-Repair-Patches.pdf (accessed on 20 March 2022).

- Sherwin, G.R. Non-autoclave processing of advanced composite repairs. Int. J. Adhes. Adhes. 1999, 19, 155–159. [Google Scholar] [CrossRef]

- Brostow, W.; Glass, N.M. Cure progress in epoxy systems: Dependence on temperature and time. Mater. Res. Innov. 2003, 7, 125–132. [Google Scholar] [CrossRef]

- Katnam, K.; Comer, A.; Stanley, W.; Buggy, M.; Ellingboe, A.; Young, T. Characterising pre-preg and non-crimp-fabric composite single lap bonded joints. Int. J. Adhes. Adhes. 2011, 31, 679–686. [Google Scholar] [CrossRef]

- Lambinet, F.; Khodaei, Z.S. Development of smart bonded composite patch repair solution. AIP Conf. Proc. 2020, 2309, 020009. [Google Scholar]

- Lambinet, F.; Khodaei, Z.S.; Aliabadi, F.M. Effectiveness of RAPID and SSM Algorithms on Composite Scarf Repair. Key Eng. Mater. 2018, 774, 535–540. [Google Scholar] [CrossRef]

- Zhu, J.; Wang, Y.; Qing, X. A real-time electromechanical impedance-based active monitoring for composite patch bonded repair structure. Compos. Struct. 2019, 212, 513–523. [Google Scholar] [CrossRef]

- Rocha, H.; Semprimoschnig, C.; Nunes, J.P. Sensors for process and structural health monitoring of aerospace composites: A review. Eng. Struct. 2021, 237, 112231. [Google Scholar] [CrossRef]

- Su, Z.; Ye, L. Identification of Damage Using Lamb Waves: From Fundamentals to Applications; Springer Science & Business Media: Berlin, Germany, 2009. [Google Scholar]

- Giurgiutiu, V.; Zagrai, A.; Bao, J.J. Piezoelectric Wafer Embedded Active Sensors for Aging Aircraft Structural Health Monitoring. Struct. Health Monit. 2002, 1, 41–61. [Google Scholar] [CrossRef]

- Kim, H.S.; Ghoshal, A.; Chattopadhyay, A.; Prosser, W.H. Development of Embedded Sensor Models in Composite Laminates for Structural Health Monitoring. J. Reinf. Plast. Compos. 2004, 23, 1207–1240. [Google Scholar] [CrossRef]

- Dib, G.; Koricho, E.G.; Karpenko, O.; Haq, M.; Udpa, L.; Udpa, S.S. Feasibility of PZT ceramics for impact damage detection in composite structures. AIP Conf. Proc. 2015, 1650, 1072–1080. [Google Scholar] [CrossRef]

- Qiu, Y.; Wang, Q.-B.; Zhao, H.-T.; Chen, J.-A.; Wang, Y.-Y. Review on composite structural health monitoring based on fiber Bragg grating sensing principle. J. Shanghai Jiaotong Univ. (Science) 2013, 18, 129–139. [Google Scholar] [CrossRef]

- Giurgiutiu, V. Structural Health Monitoring of Aerospace Composites; Academic Press: Cambridge, MA, USA, 2015. [Google Scholar]

- Güemes, A.; Fernández-López, A.; Díaz-Maroto, P.F.; Lozano, A.; Sierra-Perez, J. Structural health monitoring in composite structures by fiber-optic sensors. Sensors 2018, 18, 1094. [Google Scholar] [CrossRef]

- Jinachandran, S.; Rajan, G. Fibre Bragg Grating Based Acoustic Emission Measurement System for Structural Health Monitoring Applications. Materials 2021, 14, 897. [Google Scholar] [CrossRef]

- Zhao, X.; Gao, H.; Zhang, G.; Ayhan, B.; Yan, F.; Kwan, C.; Rose, J.L. Active health monitoring of an aircraft wing with embedded piezoelectric sensor/actuator network: I. Defect detection, localization and growth monitoring. Smart Mater. Struct. 2007, 16, 1208–1217. [Google Scholar] [CrossRef]

- Aliabadi, M.H.F.; Khodaei, Z.S. Structural Health Monitoring for Advanced Composite Structures; World Scientific Publishing Europe Ltd.: London, UK, 2017. [Google Scholar]

- Güemes, A.; Fernandez-Lopez, A.; Pozo, A.R.; Sierra-Pérez, J. Structural Health Monitoring for Advanced Composite Structures. J. Compos. Sci. 2020, 4, 13. [Google Scholar] [CrossRef]

- Michaels, J.E. Detection, localization and characterization of damage in plates with an in situ array of spatially distributed ultrasonic sensors. Smart Mater. Struct. 2008, 17, 035035. [Google Scholar] [CrossRef]

- Khodaei, Z.S.; Aliabadi, M.H. Assessment of delay-and-sum algorithms for damage detection in aluminium and composite plates. Smart Mater. Struct. 2014, 23, 075007. [Google Scholar] [CrossRef]

- Rito, R.; Crocombe, A.; Ogin, S. Health monitoring of composite patch repairs using CFBG sensors: Experimental study and numerical modelling. Compos. Part A Appl. Sci. Manuf. 2017, 100, 255–268. [Google Scholar] [CrossRef]

- Roth, W.; Giurgiutiu, V. Structural health monitoring of an adhesive disbond through electromechanical impedance spectroscopy. Int. J. Adhes. Adhes. 2017, 73, 109–117. [Google Scholar] [CrossRef]

- Qing, X.; Beard, S.J.; Kumar, A.; Hannum, R. A real-time active smart patch system for monitoring the integrity of bonded repair on an aircraft structure. Smart Mater. Struct. 2006, 15, N66–N73. [Google Scholar] [CrossRef]

- Bekas, D.G.; Sharif-Khodaei, Z.; Baltzis, D.; Aliabadi, M.F.; Paipetis, A.S. Quality assessment and damage detection in nanomodified adhesively-bonded composite joints using inkjet-printed interdigital sensors. Compos. Struct. 2019, 211, 557–563. [Google Scholar] [CrossRef]

- Sánchez-Romate, X.F.; García, C.; Rams, J.; Sánchez, M.; Ureña, A. Structural health monitoring of a CFRP structural bonded repair by using a carbon nanotube modified adhesive film. Compos. Struct. 2021, 270, 114091. [Google Scholar] [CrossRef]

- Bekas, D.G.; Sharif-Khodaei, Z.; Aliabadi, M.F. An Innovative Diagnostic Film for Structural Health Monitoring of Metallic and Composite Structures. Sensors 2018, 18, 2084. [Google Scholar] [CrossRef]

- Feng, T.; Bekas, D.; Aliabadi, M.H.F. Active Health Monitoring of Thick Composite Structures by Embedded and Surface-Mounted Piezo Diagnostic Layer. Sensors 2020, 20, 3410. [Google Scholar] [CrossRef]

- Lin, M.; Chang, F.-K. Composite structures with built-in diagnostics. Mater. Today 1999, 2, 18–22. [Google Scholar] [CrossRef]

- Feng, T.; Aliabadi, M.F. Structural Integrity Assessment of Composites Plates with Embedded PZT Transducers for Structural Health Monitoring. Materials 2021, 14, 6148. [Google Scholar] [CrossRef]

- Salmanpour, M.S.; Khodaei, Z.S.; Aliabadi, M.H. Airborne Transducer Integrity under Operational Environment for Structural Health Monitoring. Sensors 2016, 16, 2110. [Google Scholar] [CrossRef] [PubMed]

- Yue, N.; Khodaei, Z.S.; Aliabadi, M.H. Damage detection in large composite stiffened panels based on a novel SHM building block philosophy. Smart Mater. Struct. 2021, 30, 045004. [Google Scholar] [CrossRef]

- Xu, C.; Khodaei, Z.S. A Novel Fabry-Pérot Optical Sensor for Guided Wave Signal Acquisition. Sensors 2020, 20, 1728. [Google Scholar] [CrossRef] [PubMed]

- Park, G.; Farrar, C.R.; Di Scalea, F.L.; Coccia, S. Performance assessment and validation of piezoelectric active-sensors in structural health monitoring. Smart Mater. Struct. 2006, 15, 1673–1683. [Google Scholar] [CrossRef]

- Zou, F.; Benedetti, I.; Aliabadi, M.H. A boundary element model for structural health monitoring using piezoelectric transducers. Smart Mater. Struct. 2014, 23, 015022. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, T.; Aliabadi, M.H.F. Smart Patch for Structural Health Monitoring of Composite Repair. Appl. Sci. 2022, 12, 4916. https://doi.org/10.3390/app12104916

Feng T, Aliabadi MHF. Smart Patch for Structural Health Monitoring of Composite Repair. Applied Sciences. 2022; 12(10):4916. https://doi.org/10.3390/app12104916

Chicago/Turabian StyleFeng, Tianyi, and M. H. Ferri Aliabadi. 2022. "Smart Patch for Structural Health Monitoring of Composite Repair" Applied Sciences 12, no. 10: 4916. https://doi.org/10.3390/app12104916

APA StyleFeng, T., & Aliabadi, M. H. F. (2022). Smart Patch for Structural Health Monitoring of Composite Repair. Applied Sciences, 12(10), 4916. https://doi.org/10.3390/app12104916