Recent Progress Trend on Abrasive Waterjet Cutting of Metallic Materials: A Review

Abstract

1. Introduction

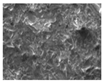

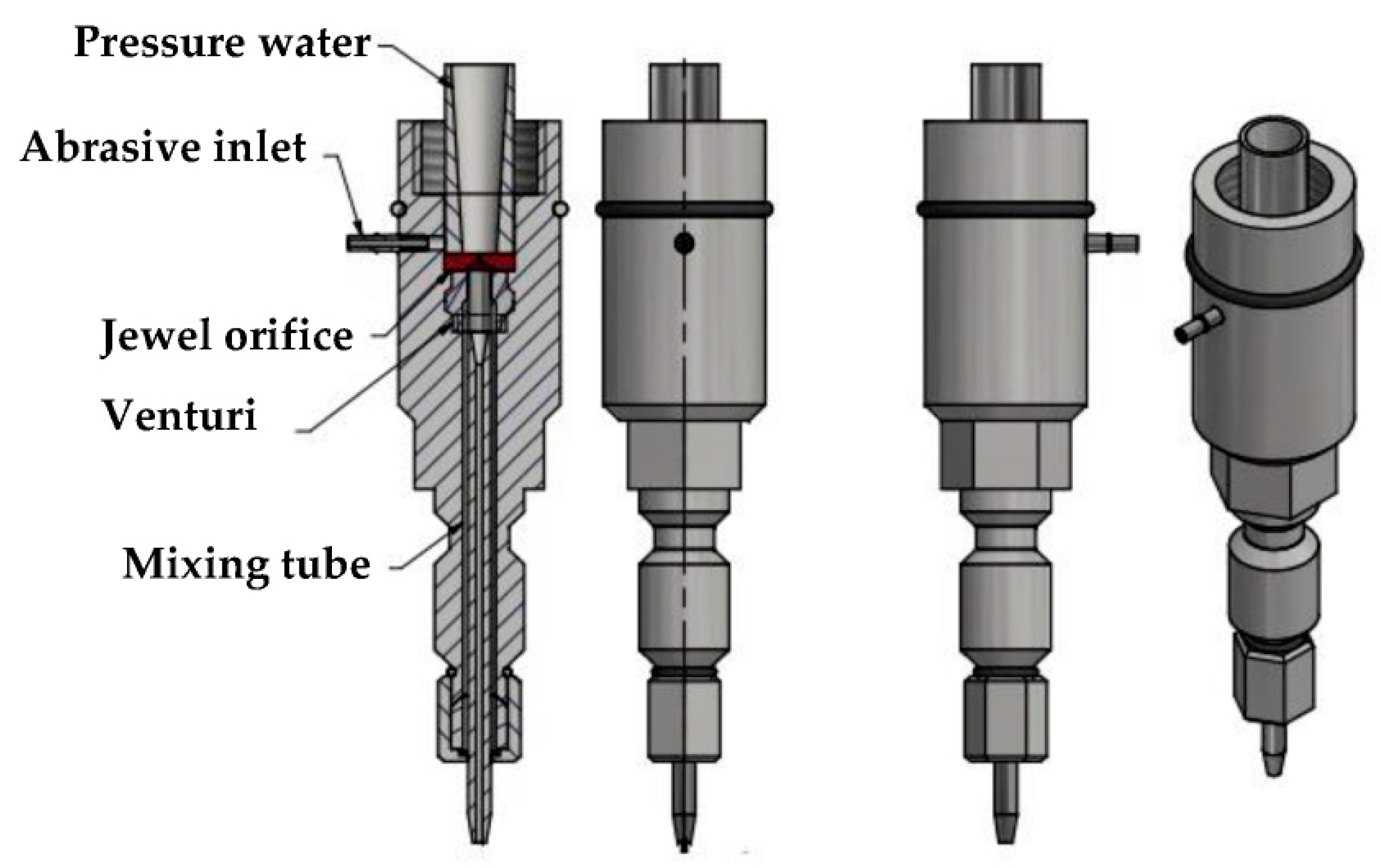

1.1. Abrasive Waterjet Machining System

1.2. Abrasive Waterjet Erosion Mechanism

1.3. AWJM Process and Advantages

1.4. Abrasive Waterjet Machining Application

2. Abrasive Waterjet Cutting Application Limitations and Challenges

| Defects | Material | Images | Key Findings and References |

|---|---|---|---|

| Cutting residue, striation and roughness | AISI 304 |  | Miao et al. [76] have found quality defects such as cutting residue, kerf taper and striation in cutting AISI 304 using abrasive waterjet machine. These defects are caused by the decreasing energy of the jet. |

| Kerf taper angle | AISI 1090 |  | Mohamad et.al. [62] have identified the kerf taper angle as an intrinsic characteristic of AWJ cutting of AISI 1090 mild steel. They determined that variation in the kerf top width wider and kerf bottom geometries resulted in a higher kerf taper angle. |

| Surface Roughness | Ti-6Al-4V |  | Gnanavelbabu et al. [77] applied AWJ cutting of Ti-6Al-4V and observed roughness and striations marks in cut surfaces. They discovered that the cut surface finish differs depending in the depth from surface entry of the abrasive jet. |

| Material removal rate, Kerf taper angle | Inconel 600 |  | Uthayakumar et al. [78] have known quality defects, such as kerf geometric inaccuracy and a low material removal rate in cutting super nickel alloy using abrasive waterjet machine. They established a high occurrence of inaccurate kerf geometries using a high level of water pressure and increasing the traverse speed. |

| Depth of Cut | SS304 |  | Supriya et al. [15] have determined that one of the challenges faced with cutting stainless steel is achieving a high depth of cut due to its low machinability. They concluded that using abrasive waterjet machine with a high level of pressure settings have increased the depth of cut. |

| Year & Author | Metallic Material | Thickness | Defects |

|---|---|---|---|

| Gnanavelbabu et al. 2018 [77] | Ti6Al4V | 5 mm | KTA, MRR, Ra |

| Wang et al. 2019 [61] | AA 6061-T6 | 5, 10, 25, 50 mm | KTA |

| Yuvaraj et al. 2017 [80] | AISI D2 Steel | 60 mm | Ra |

| Akkurt et al. 2018 [18] | SS 304 | 20 mm | Ra |

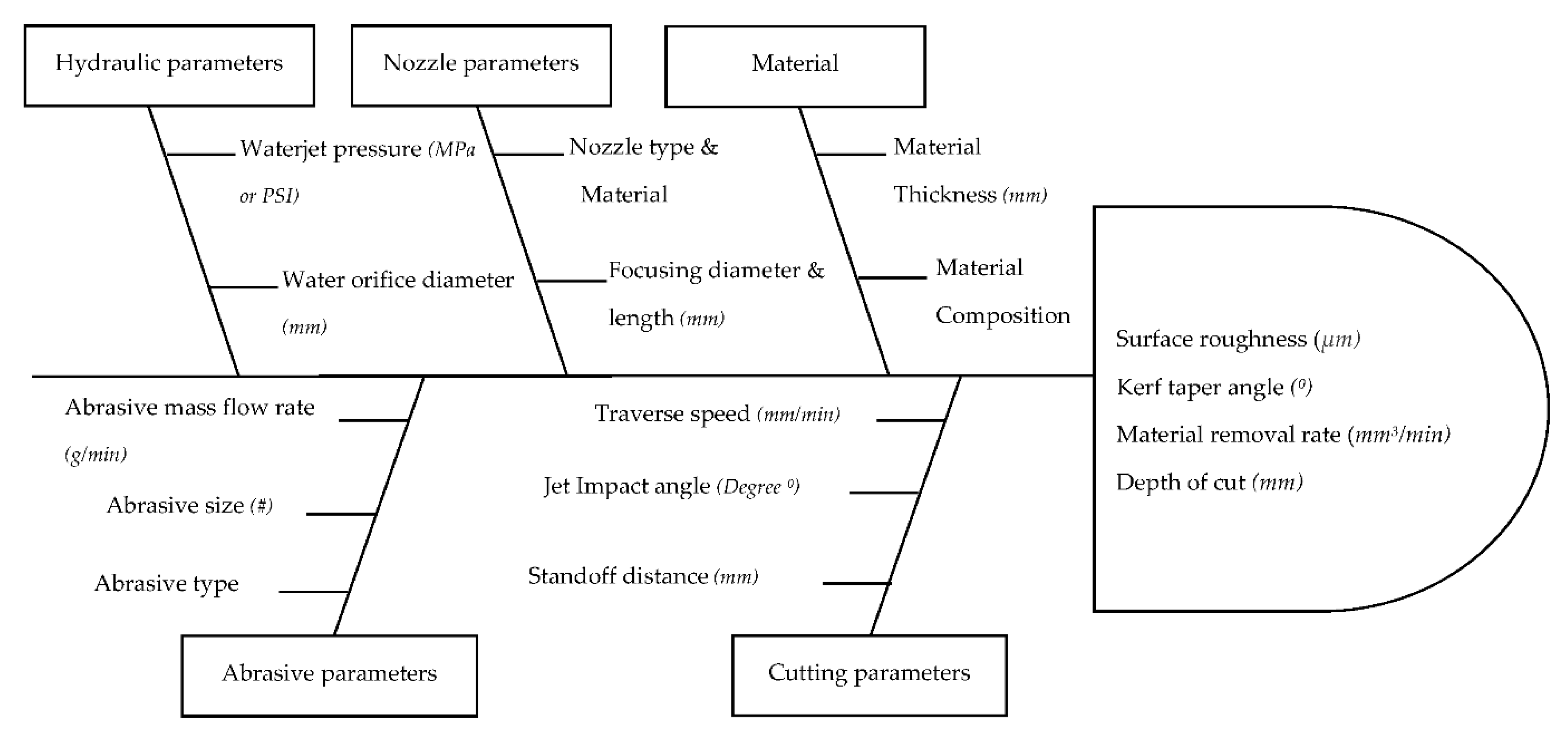

3. Abrasive Waterjet Cutting Process Parameters and Influences

3.1. Abrasive Waterjet Cutting Input Process Parameters Functions and Influences

3.1.1. Hydraulic System

3.1.2. Abrasive System

3.1.3. Nozzle System

3.1.4. Cutting System

3.2. Abrasive Waterjet Cutting Output Process Parameters

4. Abrasive Waterjet Cutting Process Parameters Improvements and Optimization

4.1. AWJ Cutting Process Parameters Improvements

4.2. AWJ Cutting Process Parameters Optimisation

5. Conclusions and Potential Future Scope of Study

5.1. Conclusions

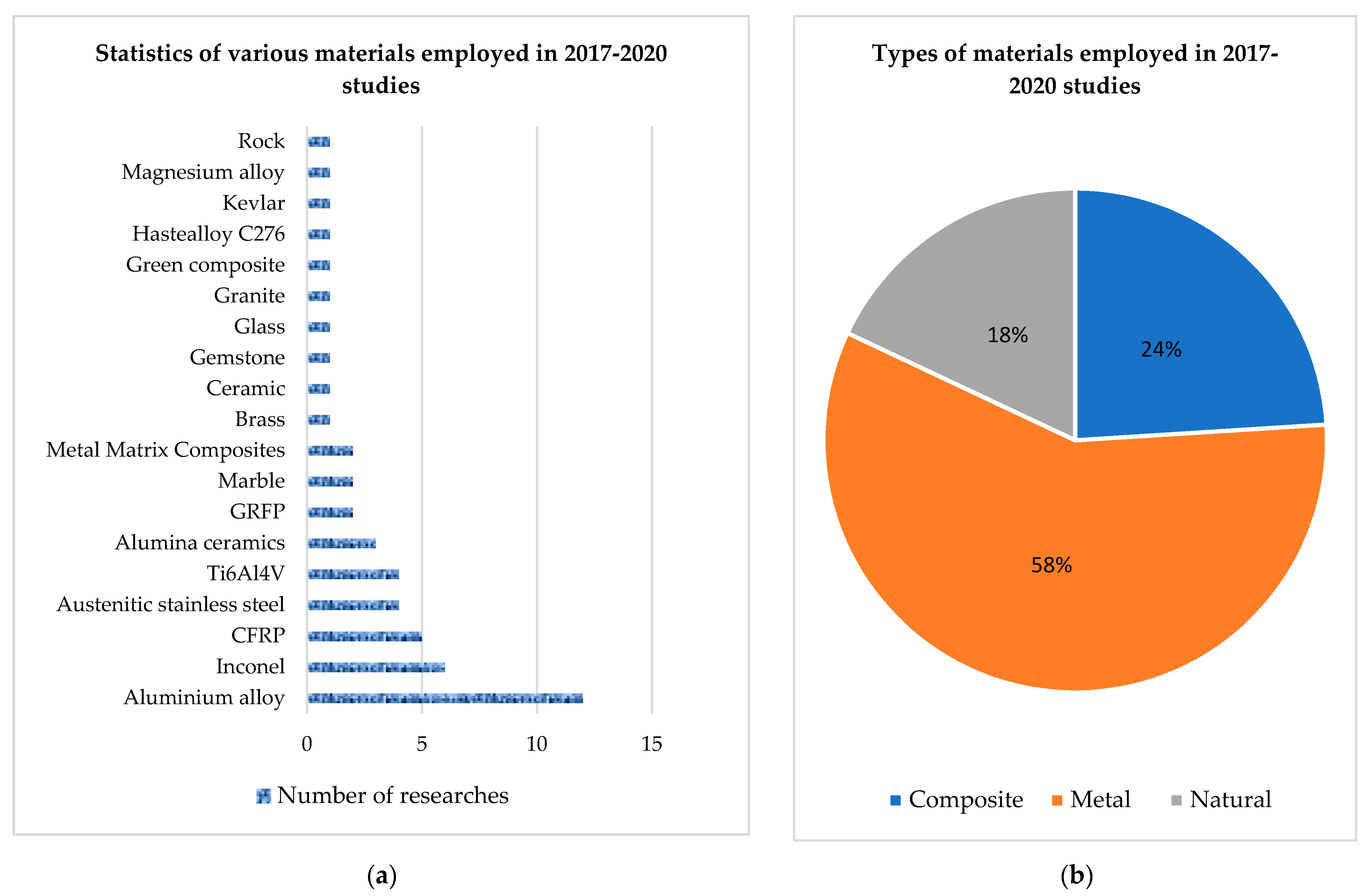

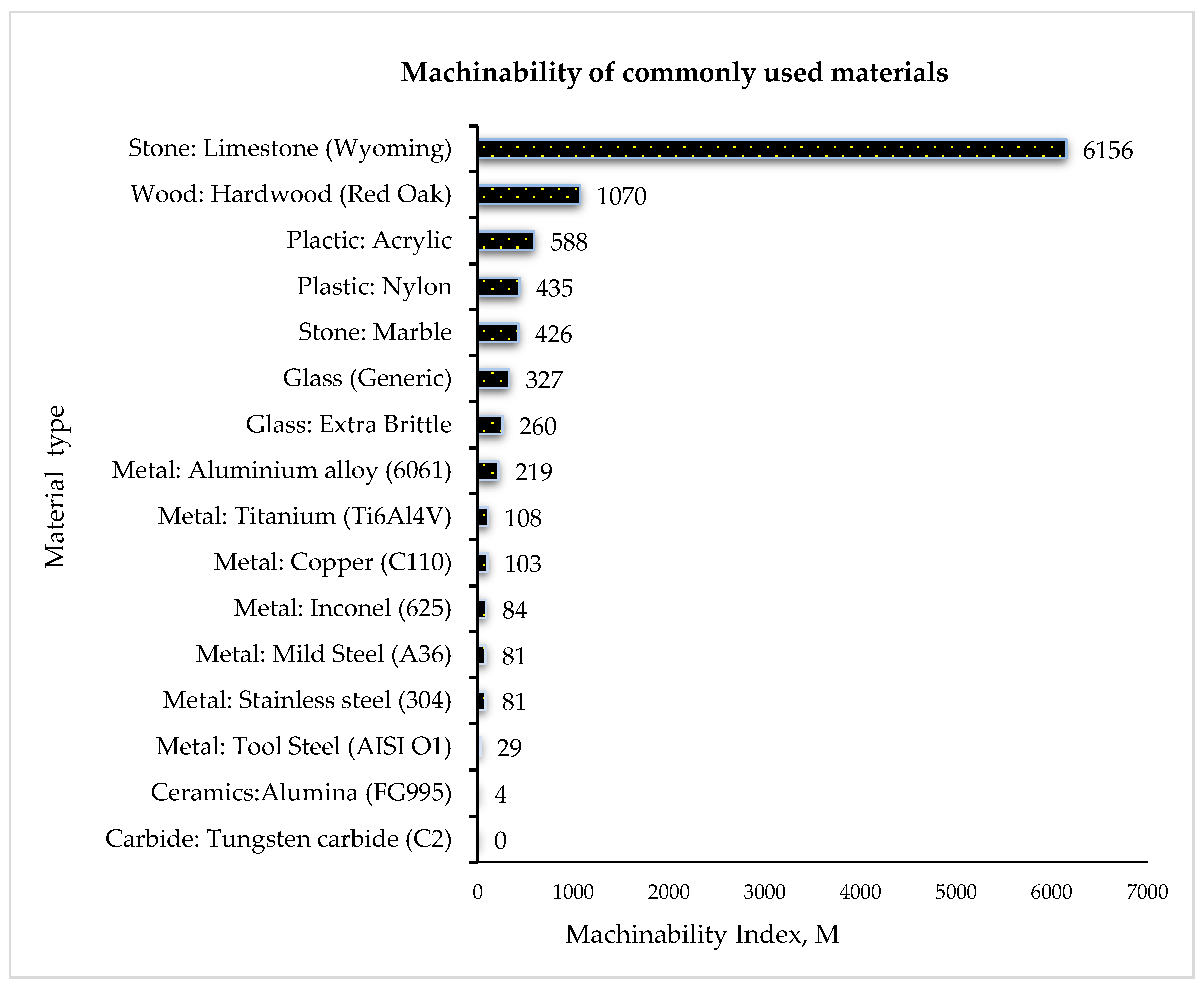

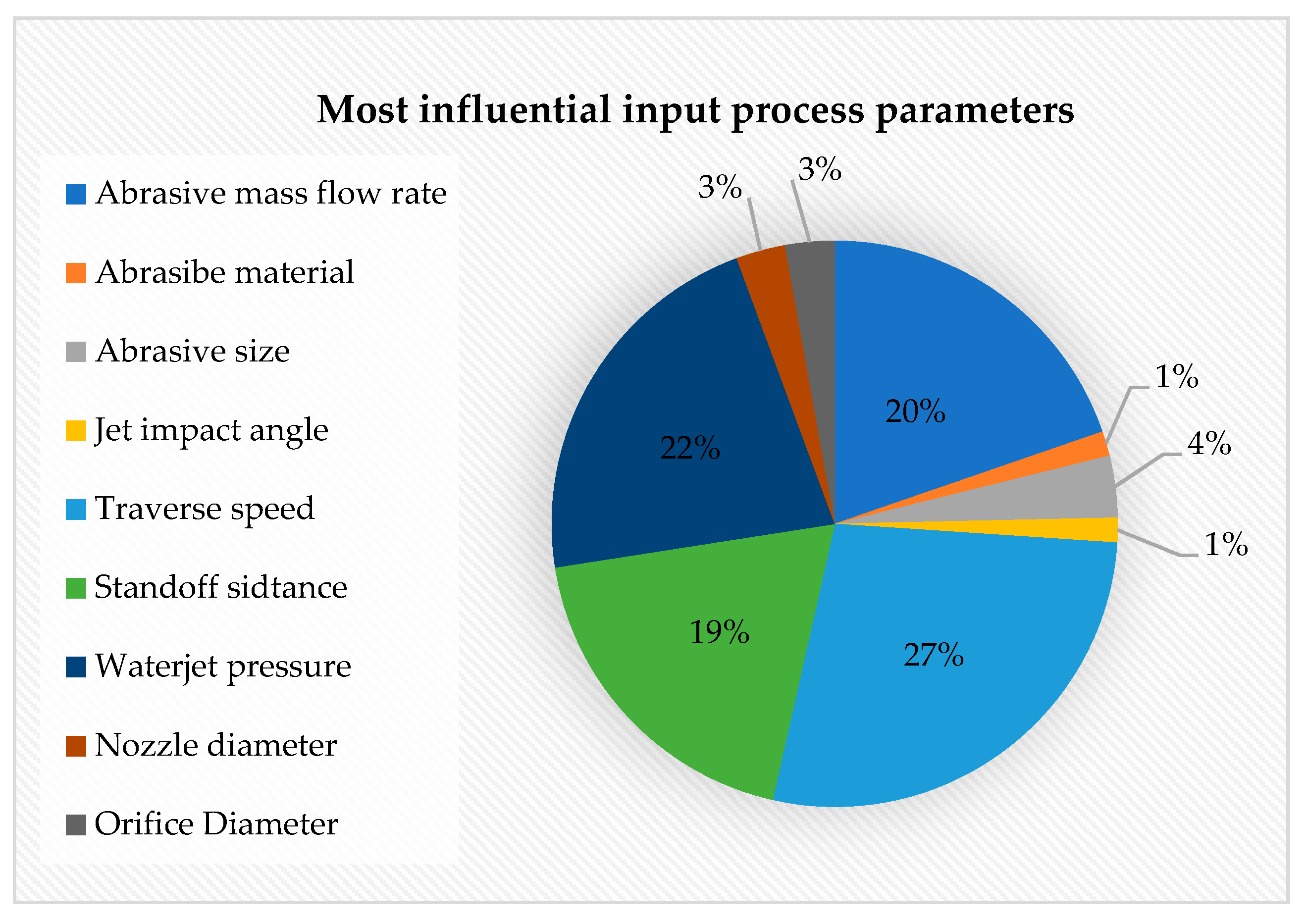

- The intensive review of the trend of recently published research studies has revealed that aluminium and other metal workpieces gained 53% of the attention in exploring AWJM application improvements. A total of 27% of recent studies have proved that traverse speed greatly impacts abrasive waterjet (AWJ) cutting performance, followed by abrasive mass flow rate and waterjet pressure with statistics of 22% and 20%, respectively. Garnet with a hardness scale of MOHS 7–8 and a mesh size of #80 at 180 µm gained 90% utilisation in AWJM applications due to its better performance and competitive price.

- AWJ cutting of hard-to-cut workpieces such as metallic materials including tungsten carbide, tool steel, and Inconel alloys have demonstrated distinct characteristics such as the fast speed at a rate of 2 to 3 mm3/s, versatility in cutting with thickness ranging from ≤304.8 mm, the ability to machine complicated shapes, and environmentally sustainable qualities. These characteristics explain their wide range of current applications across various industries.

- Cutting metallic materials with low machinability, i.e., stainless steel, Inconel and titanium, can attain lower surface roughness, higher depth of cut and material removal rate at a waterjet pressure ranging from 201 to 300 MPa. A traverse speed ranging from 60 to 90 mm/min, abrasive mass flow rate of 401 to 500 g/min, and stand-off distance ranging from 1.0 to 3.0 mm were established to achieve a lower surface roughness, lower kerf taper angle, and higher material removal rate applicable to various metals. Different optimisation techniques such as weighted principal components analysis (WPCA), surface and Box–Behnken methodology (RSM-BBD) and grey wolf optimiser (GWO) were employed and proved to be notably efficient in defining the optimum values of process parameters.

5.2. Potential Further Study

- AWJ cutting has acquired high interest in improving process performance at specific input parameter conditions. Hence, limited studies considered other parameters such as the jet impact angle, abrasive, and nozzle sizes. A further study on the impacts of these mentioned input parameters in AWJ cutting of various materials with different thicknesses can be considered for future improvements.

- Based on a review of past literature, numerous research studies and experiments have been conducted to evaluate the difference between the straight-slit and linear cutting process of AWJMs. Nonetheless, limited reports present AWJM performance in contour cutting. Thus, the cuttings of complex and complicated geometries are more regularly applied in manufacturing industries rather than straight-slit or linear cutting. Undertaking an empirical and analytical study of the effects of the process parameters in AWJ contour cutting would be important to various manufacturing processes in the fabrication industry.

- A prolific number of works have been fulfilled in predicting and monitoring AWJ cutting performance and responses in terms of quality and productivity. Its effectiveness in machining cost and intelligent process controlling are two areas that can be studied further to determine future developments.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| DOC | Depth of cut |

| ECDM | Electro chemical discharge machine |

| EDM | Electro discharge machine |

| HAZ | Heat affected zone |

| JIA | Jet impact angle |

| KBW | Kerf bottom width |

| KTA | Kerf taper angle |

| KTW | Kerf top width |

| KW | Kerf width |

| MRR | Material removal rate |

| LBM | Laser beam machine |

| MMC | Metal matrix composite |

| ND | Nozzle diameter |

| OD | Orifice diameter |

| P | Waterjet pressure |

| SOD | Standoff distance |

| Ti6AL-4V | Titanium alloy |

| TS | Traverse speed |

| Thickness of the material | |

| inclined length of workpiece | |

| Depth of cut | |

| Traverse speed | |

| profile height in a defined point | |

| Kerf width | |

| Kerf top width | |

| Kerf bottom width. | |

| Thickness of the material | |

| profile height in a defined point | |

| AA | Aluminum alloy |

| AFR | Abrasive mass flow rate |

| AL | Aluminum |

| AM | Abrasive material type |

| AS | Abrasive size |

| AWJ | Abrasive waterjet |

| AWJM | Abrasive waterjet machining |

References

- Alsoufi, M.S. State-of-the-Art in Abrasive Water Jet Cutting Technology and the Promise for Micro-and Nano-Machining. Int. J. Mech. Eng. Appl. 2017, 5, 1–14. [Google Scholar] [CrossRef]

- Gupta, K. Introduction to Abrasive Water Jet Machining. In Abrasive Water Jet Machining of Engineering Materials; Springer: Berlin/Heidelberg, Germany, 2020; pp. 1–11. [Google Scholar]

- Liu, X.; Liang, Z.; Wen, G.; Yuan, X. Waterjet machining and research developments: A review. Int. J. Adv. Manuf. Technol. 2019, 102, 1257–1335. [Google Scholar] [CrossRef]

- Natarajan, Y.; Murugesan, P.K.; Mohan, M.; Khan, S.A.L.A. Abrasive Water Jet Machining process: A state of art of review. J. Manuf. Process. 2020, 49, 271–322. [Google Scholar] [CrossRef]

- Liu, H. “7M” Advantage of Abrasive Waterjet for Machining Advanced Materials. J. Manuf. Mater. Process. 2017, 1, 11. [Google Scholar] [CrossRef]

- Saravanan, S.; Vijayan, V.; Suthahar, S.T.J.; Balan, A.V.; Sankar, S.; Ravichandran, M. A review on recent progresses in machining methods based on abrasive water jet machining. Mater. Today Proc. 2020, 21, 116–122. [Google Scholar] [CrossRef]

- Liu, H.; Schubert, E. Micro abrasive-waterjet technology. In Micromachining Techniques for Fabrication of Micro and Nano Structures; InTechOpen: London, UK, 2012; pp. 205–233. [Google Scholar]

- Singh, P.; Pramanik, A.; Basak, A.; Prakash, C.; Mishra, V. Developments of non-conventional drilling methods—A review. Int. J. Adv. Manuf. Technol. 2020, 106, 2133–2166. [Google Scholar] [CrossRef]

- Sureban, R.; Kulkarni, V.N.; Gaitonde, V. Modern Optimization Techniques for Advanced Machining Processes—A Review. Mater. Today Proc. 2019, 18, 3034–3042. [Google Scholar] [CrossRef]

- Nguyen, T.; Wang, J. A review on the erosion mechanisms in abrasive waterjet micromachining of brittle materials. Int. J. Extrem. Manuf. 2019, 1, 012006. [Google Scholar] [CrossRef]

- Mieszala, M.; Torrubia, P.L.; Axinte, D.A.; Schwiedrzik, J.J.; Guo, Y.; Mischler, S.; Michler, J.; Philippe, L. Erosion mechanisms during abrasive waterjet machining: Model microstructures and single particle experiments. J. Mater. Process. Technol. 2017, 247, 92–102. [Google Scholar] [CrossRef]

- Hlaváčová, I.M.; Sadílek, M.; Váňová, P.; Szumilo, Š.; Tyč, M. Influence of steel structure on machinability by abrasive water jet. Materials 2020, 13, 4424. [Google Scholar] [CrossRef]

- Kowsari, K.; Nouraei, H.; James, D.; Spelt, J.; Papini, M. Abrasive slurry jet micro-machining of holes in brittle and ductile materials. J. Mater. Process. Technol. 2014, 214, 1909–1920. [Google Scholar] [CrossRef]

- Ruiz-Garcia, R.; Ares, P.F.M.; Vazquez-Martinez, J.M.; Gomez, J.S. Influence of Abrasive Waterjet Parameters on the Cutting and Drilling of CFRP/UNS A97075 and UNS A97075/CFRP Stacks. Materials 2019, 12, 107. [Google Scholar] [CrossRef] [PubMed]

- Supriya, S.; Srinivas, S. Machinability studies on stainless steel by abrasive water jet-Review. Mater. Today Proc. 2018, 5, 2871–2876. [Google Scholar] [CrossRef]

- Rajurkar, K.P.; Sundaram, M.M.; Malshe, A.P. Review of Electrochemical and Electrodischarge Machining. Procedia Cirp 2013, 6, 13–26. [Google Scholar] [CrossRef]

- Rajurkar, K.P.; Hadidi, H.; Pariti, J.; Reddy, G.C. Review of Sustainability Issues in Non-traditional Machining Processes. In Proceedings of the International Conference on Sustainable Materials Processing and Manufacturing (SMPM 2017), Kruger, South Africa, 23–25 January 2017; pp. 714–720. [Google Scholar] [CrossRef]

- Akkurt, A. Surface properties of the cut face obtained by different cutting methods from AISI 304 stainless steel materials. Indian J. Mater. Sci. 2009, 16, 373–384. [Google Scholar]

- Krajcarz, D. Comparison Metal Water Jet Cutting with Laser and Plasma Cutting. In Proceedings of the 24th Daaam International Symposium on Intelligent Manufacturing and Automation, Zadar, Croatia, 23–26 October 2013; Volume 69, pp. 838–843. [Google Scholar] [CrossRef]

- Chaturvedi, C.; Rao, P.S. Some Technical Issues and Critical Assessment of Abrasive Water Jet Machining (AWJM) Process. Int. J. Innov. Technol. Explor. Eng. 2020, 9, 39520. [Google Scholar] [CrossRef]

- Rakshit, R.; Das, A.K. A review on cutting of industrial ceramic materials. Precis. Eng. 2019, 59, 90–109. [Google Scholar] [CrossRef]

- Kovacevic, R.; Mohan, R.; Beardsley, H.E. Monitoring of Thermal Energy Distribution in Abrasive Waterjet Cutting Using Infrared Thermography. J. Manuf. Sci. Eng. 1996, 118, 555–563. [Google Scholar] [CrossRef]

- Babu, M.K.; Chetty, O.K. A study on recycling of abrasives in abrasive water jet machining. Wear 2003, 254, 763–773. [Google Scholar] [CrossRef]

- Schramm, A.; Morczinek, F.; Götze, U.; Putz, M. Technical-economic evaluation of abrasive recycling in the suspension fine jet process chain. Int. J. Adv. Manuf. Technol. 2020, 106, 981–992. [Google Scholar] [CrossRef]

- Maneiah, D.; Shunmugasundaram, M.; Reddy, A.R.; Begum, Z. Optimization of machining parameters for surface roughness during abrasive water jet machining of aluminium/magnesium hybrid metal matrix composites. Mater. Today Proc. 2020, 27, 1293–1298. [Google Scholar] [CrossRef]

- Tripathi, D.R.; Vachhani, K.H.; Kumari, S.; Abhishek, K. Experimental investigation on material removal rate during abrasive water jet machining of GFRP composites. Mater. Today Proc. 2020, 26, 1389–1392. [Google Scholar] [CrossRef]

- Mogul, Y.I.; Nasir, I.; Myler, P. Investigation and optimization for depth of cut and surface roughness for control depth milling in Titanium Ti6AL4V with abrasive water jet cutting. Mater. Today Proc. 2020, 28, 604–610. [Google Scholar] [CrossRef]

- Naik, M.B.; Srikanth, D.; Rao, M.S. Abrasive Jet Machining on Soda lime Glass-An experimental investigation. Int. J. Res. Publ. 2020, 44, 887. [Google Scholar]

- Jeykrishnan, J.; Ramnath, B.V.; Vignesh, S.S.; Sridharan, P.; Saravanan, B. Optimization of Process Parameters in Abrasive Water Jet Machining/Cutting (AWJM) of Nickel Alloy using Traditional Analysis to Minimize Kerf Taper Angle. Mater. Today Proc. 2019, 16, 392–397. [Google Scholar] [CrossRef]

- Marichamy, S.; Ravichandran, M.; Stalin, B.; Babu, S.B. Optimization of abrasive water jet machining parameters for α-β brass using Taguchi methodology. FME Trans. 2019, 47, 116–121. [Google Scholar] [CrossRef]

- Kumar, P.; Tank, B.; Kant, R. Experimental investigation on abrasive waterjet machining of fibre vinyl ester composite. J. Manuf. Eng. 2019, 14, 134–138. [Google Scholar] [CrossRef]

- Srikanth, D.V.; Rao, M.S. Application of Taguchi & Response surface methodology in Optimization for machining of ceramics with abrasive jet machining. Mater Today Proc. 2015, 2, 3308–3317. [Google Scholar] [CrossRef]

- Niranjan, C.; Srinivas, S.; Ramachandra, M. An experimental study on depth of cut of AZ91 Magnesium Alloy in abrasive water jet cutting. Mater. Today Proc. 2018, 5, 2884–2890. [Google Scholar] [CrossRef]

- Rajamanickam, S.; Manjunathan, R.; Mariyappan, K.; Aravindh, S. Comparative analysis of MRR on abrasive water jet machining parameters over aerospace alloys: Inconel 825 & Ti-6Al-4V. Int. J. Pure Appl. Math. 2018, 118, 727–733. [Google Scholar]

- Yuvaraj, N.; Kumar, M.P. Optimisation of abrasive water jet cutting process parameters for AA5083-H32 aluminium alloy using fuzzy TOPSIS method. Int. J. Mach. Mach. Mater. 2018, 20, 118–140. [Google Scholar]

- Kmec, J.; Gombár, M.; Harničárová, M.; Valíček, J.; Kušnerová, M.; Kříž, J.; Kadnár, M.; Karková, M.; Vagaská, A. The Predictive Model of Surface Texture Generated by Abrasive Water Jet for Austenitic Steels. Appl. Sci. 2020, 10, 3159. [Google Scholar] [CrossRef]

- Samson, R.M.; Rajak, S.; Kannan, T.D.B.; Sampreet, K. Optimization of Process Parameters in Abrasive Water Jet Machining of Inconel 718 Using VIKOR Method. J. Inst. Eng. 2020, 101, 579–585. [Google Scholar] [CrossRef]

- Senthilkumar, T.; Muralikannan, R.; Kumar, S.S. Surface morphology and parametric optimization of AWJM parameters using GRA on aluminum HMMC. Mater. Today Proc. 2020, 22, 410–415. [Google Scholar] [CrossRef]

- Madara, S.R.; Pillai, S.R. Modelling of surface roughness in abrasive waterjet cutting of Kevlar 49 composite using artificial neural network. Mater. Today Proc. 2020. [Google Scholar] [CrossRef]

- Jagadish; Bhowmik, S.; Ray, A. Prediction of surface roughness quality of green abrasive water jet machining: A soft computing approach. J. Intell. Manuf. 2019, 30, 2965–2979. [Google Scholar] [CrossRef]

- Brucely, Y.; Jai Aultrin, K.S.; Jaison, D. Using Genetic Algorithm Optimizing the Cutting Parameters of AWJM Process for Aluminium 6061 Alloy. Int. J. Recent Trends Eng. Res. 2019, 5, 48–56. [Google Scholar] [CrossRef]

- Kumar, A.; Singh, H.; Kumar, V. Study the parametric effect of abrasive water jet machining on surface roughness of Inconel 718 using RSM-BBD techniques. Mater. Manuf. Process. 2018, 33, 1483–1490. [Google Scholar] [CrossRef]

- Manoj, M.; Jinu, G.R.; Muthuramalingam, T. Multi Response Optimization of AWJM Process Parameters on Machining TiB2 Particles Reinforced Al7075 Composite Using Taguchi-DEAR Methodology. Silicon 2018, 10, 2287–2293. [Google Scholar] [CrossRef]

- Pawar, P.J.; Vidhate, U.S.; Khalkar, M.Y. Improving the quality characteristics of abrasive water jet machining of marble material using multi-objective artificial bee colony algorithm. J. Comput. Des. Eng. 2018, 5, 319–328. [Google Scholar] [CrossRef]

- Rao, R.V.; Rai, D.P.; Balic, J. Multi-objective optimization of abrasive waterjet machining process using Jaya algorithm and PROMETHEE Method. J. Intell. Manuf. 2019, 30, 2101–2127. [Google Scholar] [CrossRef]

- Nair, A.; Kumanan, S. Optimization of size and form characteristics using multi-objective grey analysis in abrasive water jet drilling of Inconel 617. J. Braz. Soc. Mech. Sci. 2018, 40, 121. [Google Scholar] [CrossRef]

- Chakraborty, S.; Mitra, A. Parametric optimization of abrasive water-jet machining processes using grey wolf optimizer. Mater. Manuf. Process. 2018, 33, 1471–1482. [Google Scholar] [CrossRef]

- Johari, N.F.; Zain, A.M.; Mustaffa, N.H.; Udin, A. Machining parameters optimization using hybrid firefly algorithm and particle swarm optimization. J. Phys. Conf. Ser. 2017, 892, 012005. [Google Scholar] [CrossRef]

- Liu, S.; Zhou, F.; Li, H.; Chen, Y.; Wang, F.; Guo, C. Experimental Investigation of Hard Rock Breaking Using a Conical Pick Assisted by Abrasive Water Jet. Rock Mech. Rock Eng. 2020, 53, 4221–4230. [Google Scholar] [CrossRef]

- Madara, S.R.; Selvan, C.P.; Sampath, S.; Pillai, S.R. Impact of process parameters on surface roughness of hastelloy using abrasive waterjet machining technology. Int. J. Recent Technol. Eng. 2019, 7, 419–425. [Google Scholar]

- Balamurugan, K.; Uthayakumar, M.; Sankar, S.; Hareesh, U.; Warrier, K. Effect of abrasive waterjet machining on LaPO4/Y2O3 ceramic matrix composite. J. Aust. Ceram. Soc. 2018, 54, 205–214. [Google Scholar] [CrossRef]

- Krajcarz, D.; Bańkowski, D.; Młynarczyk, P. The Effect of Traverse Speed on Kerf Width in AWJ Cutting of Ceramic Tiles. Procedia Eng. 2017, 192, 469–473. [Google Scholar] [CrossRef]

- Lima, C.E.d.A.; Lebrón, R.; de Souza, A.J.; Ferreira, N.F.; Neis, P.D. Study of influence of traverse speed and abrasive mass flowrate in abrasive water jet machining of gemstones. Int. J. Adv. Manuf. Technol. 2016, 83, 77–87. [Google Scholar] [CrossRef]

- Kumar, R.S.; Gajendran, S.; Kesavan, R. Evaluation of Optimum Machining Parameters by AWJM for Granite through Multi Response Methods. Mater. Today Proc. 2020, 22, 3056–3066. [Google Scholar] [CrossRef]

- Kalusuraman, G.; Kumaran, S.T.; Siva, I.; Kumar, S.A. Cutting performance of luffa cylindrica fiber–reinforced composite by abrasive water jet. J. Test. Eval. 2020, 48, 3417–3428. [Google Scholar] [CrossRef]

- Kumar, R.S.; Gajendran, S.; Kesavan, R. Estimation of Optimal Process Parameters for Abrasive Water Jet Machining Of Marble Using Multi Response Techniques. Mater. Today Proc. 2018, 5, 11208–11218. [Google Scholar] [CrossRef]

- Yu, Y.; Sun, T.X.; Yuan, Y.M.; Gao, H.; Wang, X.P. Experimental investigation into the effect of abrasive process parameters on the cutting performance for abrasive waterjet technology: A case study. Int. J. Adv. Manuf. Tech. 2020, 107, 2757–2765. [Google Scholar] [CrossRef]

- Shibin, R.; Anandakrishnan, V.; Sathish, S.; Sujana, V.M. Investigation on the abrasive water jet machinability of AA2014 using SiC as abrasive. Mater. Today Proc. 2020, 21, 519–522. [Google Scholar] [CrossRef]

- Yogeswaran, R.; Pitchipoo, P. Characterization and machining analysis of AA3003 honeycomb sandwich. Mater. Today Proc. 2020, 28, 4–7. [Google Scholar] [CrossRef]

- Shukla, R.; Singh, D. Experimentation investigation of abrasive water jet machining parameters using Taguchi and Evolutionary optimization techniques. Swarm Evol. Comput. 2017, 32, 167–183. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, S.; Wu, Y.; Yang, F. Exploring kerf cut by abrasive waterjet. Int. J. Adv. Manuf. Technol. 2017, 93, 2013–2020. [Google Scholar] [CrossRef]

- Mohamad, W.; Kasim, M.; Norazlina, M.; Hafiz, M.; Izamshah, R.; Mohamed, S. Effect of standoff distance on the kerf characteristic during abrasive water jet machining. Results Eng. 2020, 6, 100101. [Google Scholar] [CrossRef]

- El-Hofy, M.; Helmy, M.; Escobar-Palafox, G.; Kerrigan, K.; Scaife, R.; El-Hofy, H. Abrasive water jet machining of multidirectional CFRP laminates. Procedia CIRP 2018, 68, 535–540. [Google Scholar] [CrossRef]

- Perec, A. Experimental research into alternative abrasive material for the abrasive water-jet cutting of titanium. Int. J. Adv. Manuf. Technol. 2018, 97, 1529–1540. [Google Scholar] [CrossRef]

- Li, M.; Huang, M.; Chen, Y.; Kai, W.; Yang, X. Experimental study on hole characteristics and surface integrity following abrasive waterjet drilling of Ti6Al4V/CFRP hybrid stacks. Int. J. Adv. Manuf. Tech. 2019, 104, 4779–4789. [Google Scholar] [CrossRef]

- Tiwari, T.; Sourabh, S.; Nag, A.; Dixit, A.R.; Mandal, A.; Das, A.K.; Mandal, N.; Srivastava, A.K. Parametric investigation on abrasive waterjet machining of alumina ceramic using response surface methodology. IOP Conf. Ser. Mater. Sci. Eng. 2018, 377, 012005. [Google Scholar] [CrossRef]

- Kaladhar, M.; Subbaiah, K.V.; Rao, C.S. Machining of austenitic stainless steels–a review. Int. J. Mach. Mach. Mater. 2012, 12, 178–192. [Google Scholar] [CrossRef]

- Hashish, M. A Modeling Study of Metal Cutting With Abrasive Waterjets. J. Eng. Mater. Technol. 1984, 106, 88–100. [Google Scholar] [CrossRef]

- Liu, H.-T.P. Advanced waterjet technology for machining curved and layered structures. Curved Layer. Struct. 2019, 6, 41–56. [Google Scholar] [CrossRef]

- Saraçyakupoğlu, T. Abrasive Water Jet (AWJ) Applications in the Aviation Industry. Int. J. Mech. Prod. Eng. Res. Dev. (IJMPERD) 2019, 9, 347–356. [Google Scholar] [CrossRef]

- Aurich, J.C.; Kirsch, B.; Setti, D.; Axinte, D.; Beaucamp, A.; Butler-Smith, P.; Yamaguchi, H. Abrasive processes for micro parts and structures. CIRP Ann. 2019, 68, 653–676. [Google Scholar] [CrossRef]

- Selvan, M.C.P.; Midhunchakkaravarthy, D.; Senanayake, R.; Pillai, S.R.; Madara, S.R. A mathematical modelling of Abrasive Waterjet Machining on Ti-6Al-4V using Artificial Neural Network. Mater. Today Proc. 2020. [Google Scholar] [CrossRef]

- Pahuja, R.; Ramulu, M. Machinability of randomly chopped discontinuous fiber composites: A comparative assessment of conventional and abrasive waterjet. In Proceedings of the 23rd International Conference on Waterjetting, Seattle, WA, USA, 13 November 2016; pp. 127–148. [Google Scholar]

- Chen, M.; Zhang, S.; Zeng, J.; Chen, B.; Xue, J.; Ji, L. Correcting shape error on external corners caused by the cut-in/cut-out process in abrasive water jet cutting. Int. J. Adv. Manuf. Technol. 2019, 103, 849–859. [Google Scholar] [CrossRef]

- Miao, X.; Qiang, Z.; Wu, M.; Song, L.; Ye, F. Research on quality improvement of the cross section cut by abrasive water jet based on secondary cutting. Int. J. Adv. Manuf. Technol. 2018, 97, 71–80. [Google Scholar] [CrossRef]

- Miao, X.; Ye, F.; Wu, M.; Song, L.; Qiang, Z. The method of 3D nozzle tilt cutting of abrasive water jet. Int. J. Adv. Manuf. Technol. 2019, 103, 3109–3114. [Google Scholar] [CrossRef]

- Gnanavelbabu, A.; Saravanan, P.; Rajkumar, K.; Karthikeyan, S. Experimental investigations on multiple responses in abrasive waterjet machining of Ti-6Al-4V alloy. Mater. Today Proc. 2018, 5, 13413–13421. [Google Scholar] [CrossRef]

- Uthayakumar, M.; Khan, M.A.; Kumaran, S.T.; Slota, A.; Zajac, J. Machinability of nickel-based superalloy by abrasive water jet machining. Mater. Manuf. Process. 2016, 31, 1733–1739. [Google Scholar] [CrossRef]

- Khan, M.A.; Gupta, K. Machinability Studies on Abrasive Water Jet Machining of Low Alloy Steel for Different Thickness. IOP Conf. Ser. Mater. Sci. Eng. 2020, 709, 044099. [Google Scholar] [CrossRef]

- Yuvaraj, N.; Kumar, M.P. Surface integrity studies on abrasive water jet cutting of AISI D2 steel. Mater. Manuf. Process. 2017, 32, 162–170. [Google Scholar] [CrossRef]

- Kechagias, J.; Petropoulos, G.; Vaxevanidis, N. Application of Taguchi design for quality characterization of abrasive water jet machining of TRIP sheet steels. Int. J. Adv. Manuf. Technol. 2012, 62, 635–643. [Google Scholar] [CrossRef]

- Naresh Babu, M.; Muthukrishnan, N. Investigation on surface roughness in abrasive water-jet machining by the response surface method. Mater. Manuf. Process. 2014, 29, 1422–1428. [Google Scholar] [CrossRef]

- Akkurt, A.; Kulekci, M.K.; Seker, U.; Ercan, F. Effect of feed rate on surface roughness in abrasive waterjet cutting applications. J. Mater. Process. Technol. 2004, 147, 389–396. [Google Scholar] [CrossRef]

- Liu, H.; Schubert, E.; McNiel, D.; Soo, K. Applications of abrasive-fluidjets for precision machining of composites. In Proceedings of the International SAMPE Symposium and Exhibition (Proceedings), Seattle, WA, USA, 17–20 May 2010; pp. 17–20. [Google Scholar]

- Pashmforoush, F.; Hassanpour Babajan, A.; Beyraghi Baranlou, R. Experimental Study of Geometric Tolerances and Surface Roughness in Abrasive Water Jet Machining Process of Hardox 400 Steel. Modares Mech. Eng. 2020, 20, 953–961. [Google Scholar]

- Perec, A.; Pude, F.; Grigoryev, A.; Kaufeld, M.; Wegener, K. A study of wear on focusing tubes exposed to corundum-based abrasives in the waterjet cutting process. Int. J. Adv. Manuf. Tech. 2019, 104, 2415–2427. [Google Scholar] [CrossRef]

- Liu, H.-T. Waterjet technology for machining fine features pertaining to micromachining. J. Manuf. Process 2010, 12, 8–18. [Google Scholar] [CrossRef]

- Dong, Y.Z.; Liu, W.W.; Zhang, H.; Zhang, H.C. On-line recycling of abrasives in abrasive water jet cleaning. CIRP Conf. Life Cycle Eng. 2014, 15, 278–282. [Google Scholar] [CrossRef]

- Hlavacova, I.; Geryk, V. Abrasives for water-jet cutting of high-strength and thick hard materials. Int. J. Adv. Manuf. Technol. 2017, 90, 1217–1224. [Google Scholar] [CrossRef]

- Perec, A.; Pude, F.; Stirnimann, J.; Wegener, K. Feasibility Study on the Use of Fractal Analysis for Evaluating the Surface Quality Generated by Waterjet. Teh. Vjesn. 2015, 22, 879–883. [Google Scholar] [CrossRef]

- Melentiev, R.; Fang, F. Recent advances and challenges of abrasive jet machining. CIRP J. Manuf. Sci. Technol. 2018, 22, 1–20. [Google Scholar] [CrossRef]

- Hashish, M. Optimization Factors in Abrasive-Waterjet Machining. J. Eng. Ind. 1991, 113, 29–37. [Google Scholar] [CrossRef]

- Thamizhvalavan, P.; Arivazhagan, S.; Yuvaraj, N.; Ramesh, B. Machinability study of abrasive aqua jet parameters on hybrid metal matrix composite. Mater. Manuf. Process. 2019, 34, 321–344. [Google Scholar] [CrossRef]

- Babu, M.N.; Muthukrishnan, N. Exploration on Kerf-angle and surface roughness in abrasive waterjet machining using response surface method. J. Inst. Eng. 2018, 99, 645–656. [Google Scholar] [CrossRef]

- Hashish, M. A Model for Abrasive-Waterjet (AWJ) Machining. J. Eng. Mater. Technol. 1989, 111, 154–162. [Google Scholar] [CrossRef]

- Radovanovic, M. Multi-Objective Optimization of Abrasive Water Jet Cutting Using MOGA. Procedia Manuf. 2020, 47, 781–787. [Google Scholar] [CrossRef]

- Nandakumar, N.; Sasikumar, K.; Sambathkumar, M.; Saravanan, N. Investigations on AWJ cutting process of hybrid aluminium 7075 metal matrix composites using nozzle oscillation technique. Mater. Today Proc. 2020, 33, 2798–2802. [Google Scholar] [CrossRef]

- Sasikumar, K.; Arulshri, K.; Ponappa, K.; Uthayakumar, M. A study on kerf characteristics of hybrid aluminium 7075 metal matrix composites machined using abrasive water jet machining technology. J. Eng. Manuf. 2018, 232, 690–704. [Google Scholar] [CrossRef]

- Ishfaq, K.; Ahmad Mufti, N.; Ahmed, N.; Pervaiz, S. Abrasive waterjet cutting of cladded material: Kerf taper and MRR analysis. Mater. Manuf. Process. 2019, 34, 544–553. [Google Scholar] [CrossRef]

- Karmiris-Obratański, P.; Karkalos, N.E.; Kudelski, R.; Papazoglou, E.L.; Markopoulos, A.P. On the Effect of Multiple Passes on Kerf Characteristics and Efficiency of Abrasive Waterjet Cutting. Metals 2021, 11, 74. [Google Scholar] [CrossRef]

- Yuvaraj, N.; Kumar, M.P. Cutting of aluminium alloy with abrasive water jet and cryogenic assisted abrasive water jet: A comparative study of the surface integrity approach. Wear 2016, 362, 18–32. [Google Scholar] [CrossRef]

- Mardi, K.B.; Dixit, A.; Mallick, A. Studies on non-traditional machining of metal matrix composites. Mater. Today Proc. 2017, 4, 8226–8239. [Google Scholar] [CrossRef]

- Srinivas, S.; Babu, N.R. Penetration Ability of Abrasive Waterjets in Cutting of Aluminum-Silicon Carbide Particulate Metal Matrix Composites. Mach. Sci. Technol. 2012, 16, 337–354. [Google Scholar] [CrossRef]

- Gostimirovic, M.; Pucovsky, V.; Sekulic, M.; Rodic, D.; Pejic, V. Evolutionary optimization of jet lag in the abrasive water jet machining. Int. J. Adv. Manuf. Technol. 2019, 101, 3131–3141. [Google Scholar] [CrossRef]

- Hanif, M.I.; Aamir, M.; Ahmed, N.; Maqsood, S.; Muhammad, R.; Akhtar, R.; Hussain, I. Optimization of facing process by indigenously developed force dynamometer. Int. J. Adv. Manuf. Technol. 2019, 100, 1893–1905. [Google Scholar] [CrossRef]

- Kumar, P.; Kant, R. Development of a predictive model for kerf taper angle in AWJM of Kevlar epoxy composite. Mater. Today Proc. 2020, 28, 1164–1169. [Google Scholar] [CrossRef]

- Otto, K.N.; Antonsson, E.K. Extensions to the Taguchi Method of Product Design. J. Mech. Des. 1993, 115, 5–13. [Google Scholar] [CrossRef]

- Aamir, M.; Tu, S.S.; Tolouei-Rad, M.; Giasin, K.; Vafadar, A. Optimization and Modeling of Process Parameters in Multi-Hole Simultaneous Drilling Using Taguchi Method and Fuzzy Logic Approach. Materials 2020, 13, 680. [Google Scholar] [CrossRef] [PubMed]

- Rao, R.V.; Rai, D.P.; Balic, J. Optimization of Abrasive Waterjet Machining Process using Multi-objective Jaya Algorithm. Mater. Today Proc. 2018, 5, 4930–4938. [Google Scholar] [CrossRef]

- Nair, A.; Kumanan, S. Multi-performance optimization of abrasive water jet machining of Inconel 617 using WPCA. Mater. Manuf. Process. 2017, 32, 693–699. [Google Scholar] [CrossRef]

- Opricovic, S.; Tzeng, G.H. Extended VIKOR method in comparison with outranking methods. Eur. J. Oper. Res. 2007, 178, 514–529. [Google Scholar] [CrossRef]

- Rao, R. Jaya: A simple and new optimization algorithm for solving constrained and unconstrained optimization problems. Int. J. Ind. Eng. Comp. 2016, 7, 19–34. [Google Scholar]

- Fan, Z.; Liu, E.; Xu, B. Weighted principal component analysis. In International Conference on Artificial Intelligence and Computational Intelligence; Springer: Berlin/Heidelberg, Germany, 2011; pp. 569–574. [Google Scholar]

| Cutting Activity | AWJM | LBM | EDM | ECDM |

|---|---|---|---|---|

| Heated affected zone (HAZ) | No | Yes | Yes | Yes |

| Material Distortion | No | Yes | No | Yes |

| Tool Wear | No | No | Yes | Yes |

| Material Removal Rate (mm3/s) | Medium-slow (approx. ≤ 2) | Fast (approx. 2–3) for non-reflective materials only | Medium (approx.1–2) | Medium (approx.1–2) |

| Type of material | metals, composites, natural, electrically, non-conductive, non-reflective | metals, composites, natural, electrically, non-conductive, non-reflective surface | Only electrically conductive such as metals and composites | Only electrically conductive such as metals and composites |

| Material thickness (mm) | Ranging ≤ 304.8 | Ranging ≤ 20 | Ranging ≤ 304.8 | Ranging ≤ 304.8 |

| Type of shapes | Complex and complicated shapes | Complex and complicated shapes | Simple | Simple |

| Burr formation | Minimal | High | High | Minimal |

| Hazardous vapour | None | fumes, gases | CO & CH4 | NaOH/NaNO3 |

| Materials | Industrial Application | |

|---|---|---|

| Type | Workpiece | |

| Natural | Concrete, cement, ceramics, graphite, stone or rock. | Mining, manufacturing and processing of ceramics and graphite, building, construction, housing, and tile industry. |

| Metals | Titanium, aluminium, stainless steel, and alloys. | Automotive, marine, aerospace, architecture and civil, medical, food industry, automotive, electronics industry. |

| Composites | Wire glass, laminated glass, optic glass, composites, and magnetic materials. | Aerospace, automotive, electronics industry, Glass, decorations, promotional, optical fiber, and the medical industry. |

| Category Details | A. Glass | B. Natural | ||

|---|---|---|---|---|

| Abrasive types |  |  |  |  |

| Glass beads | Garnet | Ceramic beads | Black corundum | |

| Hardness | MOHS 5–6 | MOHS 7–8 | MOHS 9 | |

| Shape | Round | Irregular sharp—edged | ||

| Application | Grinding, polishing, drilling, cutting, tumbling media, sharpening, and metal cleaning | |||

| Industrial use | Automotive, metal fabrication, machinery, electronic, construction, metallurgy, petrochemical | |||

| Category Details | C. Zirconia Alumina | |||

| Abrasive types |  |  |  |  |

| Black Silicon carbide | Green Silicon carbide | White fused alumina | Brown fused alumina | |

| Hardness | MOHS 9 | |||

| Shape | Round | Irregular sharp—edged | ||

| Application | Drilling, lapping, grinding, or polishing | |||

| Industrial use | Automotive, metal fabrication, optics, household applications, construction, metallurgy | |||

| Category Details | D. Steel Grit, Shot, Cut Wire and Copper Slag | |||

| Abrasive types |  |  |  |  |

| Steel grit | Steel shot | SS Cut wire | Copper slag | |

| Hardness | MOHS 7–9 or HRC (Hardness Rockwell C) 40–60 | |||

| Shape | Irregular rounded | |||

| Application | Cleaning, surface preparation, stone cutting, shot peening | |||

| Industrial use | Automotive, construction, metallurgy, petrochemical industry | |||

| Mesh Number # | Mesh in Microns µm | Grade |

|---|---|---|

| 40–60 | 250–400 | Coarse |

| 80–100 | 180–210 | Medium coarse |

| 120–150 | 90–105 | Medium fine |

| 180–220 | 70–88 | Fine |

| 240 upwards | ≤60 | Very fine |

| Output Process Parameter | Analytic Equations | Unit of Measurement | Equation Number and Reference | |

|---|---|---|---|---|

| Depth of cut (ht) | inclined length of workpiece | mm | Equation (1) [103] | |

| Material removal rate (MRR) | is depth of cut, is traverse speed, is kerf width () | mm3/min | Equation (2) [77] | |

| Kerf taper angle (KTA) | is top kerf width and is bottom kerf width, is thickness of material | Degree (°) | Equation (3) [77] | |

| Surface roughness (Ra) | is sampling length, is profile height in a defined point of -axis | µm | Equation (4) [104] | |

| Output Parameters and Materials | Input Parameters | Key Findings and References | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Water Pressure, MPa | Traverse Speed, mm/min | Stand of Distance, mm | Abrasive Mass Flow Rate, g/min | |||||||||||

| Range | ||||||||||||||

| 100–200 | 201–300 | 301–400 | 60–90 | 91–120 | 121–150 | 1–3 | 4–6 | 7–9 | 100–250 | 251–400 | 401–550 | |||

| DOC | AA2014 | ✓ | ✓ | ✓ | ✓ | They obtained a high value of DOC at 29.70 mm by increasing the value of p, which is recognised as the most influencing factor in AWJ cutting [58]. | ||||||||

| AZ91 | ✓ | ✓ | They found that increasing water pressure and decreasing traverse speed values can achieve a maximum value of 12.57 mm DOC in AWJ cutting of magnesium alloy [33] | |||||||||||

| MRR | Ti-6Al-4V | ✓ | ✓ | ✓ | They determined that high-level of AFR at 340 g/min, TS at 120 mm/min and moderate P at 275 MPa obtained a maximum MRR with a value 345.8 mm3/min in abrasive waterjet machining [77]. | |||||||||

| Inconel 600 | ✓ | ✓ | They achieved a maximum value 350 mm3/min of MRR by utilizing a moderate value of parameters i.e., P at 280 MPa and TS at 40–60 mm/min [78]. | |||||||||||

| MRR | Inconel 617 | ✓ | ✓ | ✓ | ✓ | They discovered that a lower or near SOD with an increasing value of AFR and TR was favourable in achieving a maximum value of MRR [107]. | ||||||||

| Brass | ✓ | ✓ | ✓ | They concluded that P provides the utmost impact in minimizing Ra. A low rate of P at 200 MPa with a medium rate of TS at 100 mm/min obtained a minimum Ra; value of 1.45 um [30]. | ||||||||||

| KTA | AISI 1018 | ✓ | ✓ | ✓ | ✓ | They attained a minimum value of KTA by decreasing feed rate and it has been identified to be the most significant parameter controlling the AWJ cutting responses [94]. | ||||||||

| Material | Input Parameter | Output Parameter | Key Findings and References |

|---|---|---|---|

| Metal Matrix Composites | SOD, TS, AFR | Ra | Maneiah et al. [25] used Taguchi-L9 orthogonal array in their experimental investigations. The results showed that the essential parameters in reducing Ra were TS and AFR. |

| Ti6AL4V | P, TS, AFR, ND, OD | Ra, DOC | Mogul et al. [27] worked in the prediction of cutting depth by using the Taguchi method. It was proven that TS was the most influencing parameter for a higher depth of cut. |

| Inconel 625 | P, AFR, SOD | KTA | Jeykrishnan et al. [29] employed Taguchi’s technique in this study, and it was observed that P played a significant role in lower kerf taper angle. |

| Brass | P, TS, AFR | Ra, MRR | By utilizing Taguchi’s L9 orthogonal array, Marichamy et al. [30] proved the feasibility of utilising an abrasive waterjet machine in cutting brass material. They concluded that increasing P, TS, and AFR can minimise Ra; and maximise MRR. |

| AZ91 Magnesium alloy | P, TS | DOC | Niranjan et al. [33] examined influence of process parameters in the depth of cut through the Taguchi experimental design of the L9 orthogonal array. The result showed that a higher DOC could be obtained with high P and low TS. |

| Ti-6Al-4V and Inconel 825 | P, SOD, AFR | Ra | Rajamanickam et al. [34] achieved a higher MRR for Ti-6Al-4V at a value of 3.132 gm/min and 3.246 gm/min for Inconel 825 by utilising an experimental Taguchi approach. |

| Material | Input Parameter | Output Parameter | Optimisation Techniques | Key Findings and References |

|---|---|---|---|---|

| AA5083-H32 | P, JIA, AS | Ra, KTA, KTW, KBW | Fuzzy TOPSIS method | Yuvaraj et al. [35] employed an optimisation technique to select optimal values of input parameters, specifically, P of 150 MPa, AS of #80, and JIA of 70°. They concluded that oblique JIA improved the cutting performance of abrasive waterjet machine. |

| Inconel 718 | P, SOD, AFR | Ra, MRR, KTA | VlseKriterijumska Optimizacija I Kompromisno Resenje in Serbian (VIKOR) method | Samson et al. [37] distinguished the optimised parameter combinations of 180 MPa P, 0.42 kg/min of AFR and 2 mm SOD. They concluded that the lower standoff distance was favourable, as it increased the material removal rate. |

| Inconel 718 | P, TS, AFR, AM | Ra | Response surface methodology—Box Behnken Method (RSM-BBM) | Kumar et al. [42] obtained a surface roughness within the range of 2.75 to 4.94 µm with the optimal level of P at 40,757 psi, AFR at 1.25 lb/min, SOD at 0.6 mm and TS at 20 mm/min. They discovered that TS and AFR were the most important parameters in the machining of Inconel 718. |

| Al7075/TiB2 | P, TS, AFR, AS, SOD, OD | Ra, MRR, KTA | Taguchi DEAR (Data Envelopment Analysis Based Ranking) Methodology | Manoj et al. [43] discovered that waterjet pressure has the highest influence in AWJ cutting responses such as MRR, Ra and KTA. The optimal process parameters combination achieved are P of (280 MPa), TS of 345 mm/min and SOD of 4 mm. |

| AA631-T6 | TS, SOD, AFR | Ra, MRR, KTA | Jaya algorithm (JA) | Rao et al. [110] utilised single-objective (SAO) and multi-objective (MOJA) to achieve better cutting performance. The maximum value of MRR obtained by the MO-Jaya algorithm was 6769.6 µm3/µs, and the minimum value of Ra obtained by the MO-Jaya algorithm was 2.7002 µm. |

| Inconel 617 | SOD, P, TS, AFR | MRR, Geometric accuracy | Weighted principal components analysis (WPCA) | Nair et al. [107] studied MRR and geometric accuracy considering SOD, P, TS, AFR as input parameters. They determined optimal factors and observed that waterjet pressure was a less significant factor as the minimum setting was adequate enough to execute the machining process. |

| AA 6061 | P, TS, AFR, SOD, ND | Ra, MRR, KTA | Grey wolf optimizer (GWO) | Chakraborty et al. [47] attained the optimum parametric settings, which were P of 310 MPa, TS of 0.05 mm/s, AFR of 11.5 g/s, and nozzle tilted in 115°, by using the GWO method. This combination resulted in an MRR of 6769.597 µm3/μs. |

| Ti-6Al-4V | P, TS, SOD, AFR | DOC | Artificial Neural Network (ANN) | Selvan et al. [72] concluded that SOD and TS are inversely proportional to DOC. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Llanto, J.M.; Tolouei-Rad, M.; Vafadar, A.; Aamir, M. Recent Progress Trend on Abrasive Waterjet Cutting of Metallic Materials: A Review. Appl. Sci. 2021, 11, 3344. https://doi.org/10.3390/app11083344

Llanto JM, Tolouei-Rad M, Vafadar A, Aamir M. Recent Progress Trend on Abrasive Waterjet Cutting of Metallic Materials: A Review. Applied Sciences. 2021; 11(8):3344. https://doi.org/10.3390/app11083344

Chicago/Turabian StyleLlanto, Jennifer Milaor, Majid Tolouei-Rad, Ana Vafadar, and Muhammad Aamir. 2021. "Recent Progress Trend on Abrasive Waterjet Cutting of Metallic Materials: A Review" Applied Sciences 11, no. 8: 3344. https://doi.org/10.3390/app11083344

APA StyleLlanto, J. M., Tolouei-Rad, M., Vafadar, A., & Aamir, M. (2021). Recent Progress Trend on Abrasive Waterjet Cutting of Metallic Materials: A Review. Applied Sciences, 11(8), 3344. https://doi.org/10.3390/app11083344