Abstract

Maintaining probiotic effectiveness represents the most important task for the development of functional foods. Gastrointestinal stability and intestinal adhesion properties comprise one criterion for probiotic selection. Here, we investigated the benefits of milk fermented with Lactobacillus casei HY2782 at different fermentation times. The probiotic strain used was L. casei HY2782 and the reference strain was L. casei ATCC393 for comparisons. The samples were fermented for 7 days at 30 °C. We determined the pH, CFU/mL, survival rate during simulated gastrointestinal digestion, adhesion ability to HT-29 cells, and gene expression of tight-junction proteins known to regulate intestinal permeability in Caco-2 cells. L. casei HY2782 exhibited significantly higher survival rates in simulated gastrointestinal digestion during long-term fermentation than L. casei ATCC393. The adhesion ability to HT-29 cells was significantly increased with L. casei HY2782 (3.3% to 8.7%) after 7 days of fermentation; however, only a slight increase was observed for L. casei ATCC393 (3.1% to 4.7%). In addition, L. casei HY2782 can significantly increase the expression of genes encoding tight-junction proteins during long-term fermentation of milk. In conclusion, we confirmed that long-term fermentation could be a novel manufacturing process for fermented milk containing L. casei HY2782 and showed the beneficial effects.

1. Introduction

According to the International Scientific Association on Probiotics, microorganisms involved in fermented foods are defined as “live” strains that have beneficial effects on the host [1]. To provide health benefits, microorganisms must survive in sufficient numbers through the gastrointestinal tract, persist in the gut, remain biologically active and metabolically stable, and interact with the colonic epithelial cells [2]. As many varieties of fermented food-related microorganisms have probiotic properties [3], the interaction between colonic epithelial cells and administered bacteria is of interest to market players along with researchers in other fields [4]. Lactobacillus species constitute the microbiota of humans and animals and they colonize the gastrointestinal tract (GIT) and the female genital tract [5]. Lactobacillus casei is found in a variety of vegetables and fruits [6] and fermented foods [7,8,9]. L. casei has been extensively studied as a fermentation starter culture [10] and as a probiotic [11]. In particular, L. casei is a generally recognized as safe (GRAS) organism. To be useful as a probiotic strain, it can adhere to the intestinal mucosa and is able to colonize the gut [12,13]. Thus, the ability of a probiotic organism to attach to the host gastrointestinal (GI) mucosa is one of the criteria used to select probiotic microbes and is a prerequisite for temporary host colonization. High efficiency of gut colonization has been accepted as an attractive feature to prolong the intestinal retention time and the microbial beneficial effects on the host by promoting interactions with the host epithelium and immune cells [14,15]. Many studies have suggested yogurt as the most efficient product to deliver probiotics or lactobacilli to the small and large intestines without resulting in a significant loss of activity [16]. Fermented milk is a suitable carrier for probiotics and its consumption might be beneficial for improving health. In the development of probiotic-fermented milk, probiotic viability during fermentation and storage time and the interaction with the starter culture of the product and its impact on the sensory properties of the product should be considered. Yakult is prepared by adding glucose to skimmed milk and then inoculating the mixture with the lactobacillus and incubating it for 6 to 7 days at 37 °C [17]. L. casei HY2782 is used as a starter strain for Korean Yakult fermented milk products. Previous studies have shown that L. casei HY2782 has various functions such as increasing the expression of interleukin 12 in dendritic cells [18] and preventing the toxic effect induced by particulate matter [19,20]. Previous studies found that growth and metabolism mostly cease after 24 h of incubation. However, some Lactobacillus strains’ metabolism and growth can be unconnected. It is important to adjust the fermentation time since probiotic strains produce different amounts of metabolic products throughout that time [21]. Previous studies have shown that lactic acid bacteria exposed to an acidic environment for a certain period of time increase their adaptability to acids and bile [22,23]. In addition, it has been suggested that acidic stress can improve the ability of lactobacilli to adhere to intestinal cells [24]. According to a previous study, the products of secondary metabolism and peptide components produced by lactic acid bacteria during the fermentation process can increase the expression of tight-junction proteins [25].

In this study, we aimed to improve the functional properties of fermented milk with L. casei HY2782 using long-term fermentation. We measured the growth characteristics, decreasing pH, titratable acidity (TA), and viable cells in fermented milk at different fermentation times in comparison to those with L. casei ATCC393. We also confirmed the gastrointestinal tolerance, intestinal cell adhesion ability, and tight-junction protein-related gene expression in intestinal cells.

2. Materials and Methods

2.1. Probiotic Strains

L. casei HY2782 was obtained from the Korea Yakult Probiotics Library (Yongin, Republic of Korea) and L. casei ATCC393 was purchased from the American Type Culture Collection (ATCC, Rockville, MD, USA).

2.2. Preparation of the Inoculum

L. casei strains were anaerobically cultured in de Man, Rogosa and Sharpe (MRS) media (BD Difco, Sparks, MD, USA) at 37 °C for 24 h. One milliliter of an overnight culture was transferred to tubes of reconstituted skim milk (RSM; Oxoid, Basingstoke, UK) and incubated at 37 °C for 24 h. The inoculum concentration was determined on MRS agar at 37 °C for 72 h.

2.3. Preparation of Fermented Milk

To prepare 2 L of RSM for each of the two probiotic strains, 3% glucose and 10% skim milk powder were added to water and heated at 90 °C for 60 min while stirring. The milk was cooled rapidly to 30 °C and a 1% inoculum (v/v; approximately 5 × 106 CFU/mL) of each strain in aseptic RSM was inoculated aseptically and incubated at 37 °C for 7 days. Samples were taken on days 0, 1, 2, 3, 4, 5, 6, and 7 of incubation and changes in pH and TA were measured at each time point. The cell concentration of both probiotic strains was determined by counting colony-forming units (CFU) on MRS agar cultured at 37 °C for 72 h.

2.4. pH Determination

The pH of the samples was measured at 25 °C using a standard pH meter (Mettler Toledo, Zurich, Switzerland).

2.5. Titratable Acidity

The percentage TA was determined by titrating 9 g of each sample with 0.1 N NaOH using 0.5% phenolphthalein as an indicator. Results were expressed as g of lactic acid/100 g [26].

2.6. Microbial Viability

One milliliter of fermented milk with L. casei HY2782 or L. casei ATCC393 was diluted in 9 mL of sterile peptone water (Oxoid), and appropriate dilutions were plated on MRS agar (Difco BD, Sparks, MD, USA) and incubated at 37 °C for 72 h [27].

2.7. Viability of Probiotic Bacteria during In Vitro Digestion

In vitro digestion was carried out according to a previously described method [28]. Simulated salivary fluid (SSF), simulated gastric fluid (SGF), and simulated intestinal fluid (SIF) were prepared. The liquid was heated to 37 °C prior to in vitro digestion. Then, 5 mL of fermented milk with L. casei HY2782 or L. casei ATCC393 was weighed in a 50-mL conical tube. The oral phase was performed by adding 26 μL of 0.3 M CaCl2 × 2, 976 μL of distilled water, and 4 mL of 6.55 mg/mL α-amylase solution in SSF. Then, the pH was raised to 7 by adding 1 M NaOH, and the mixture was incubated at 37 °C for 2 min with constant shaking. In the aforementioned step, the gastric phase was performed by adding 6 μL of 0.3 mol/L CaCl2 × 2H2O, 694 μL of distilled water and solution, and 9.1 mL of 0.07 mg/mL pepsin in SGF. The pH was adjusted to 3 by adding 1 M HCl, and the mixture was incubated at 37 °C for 2 h with constant shaking. In the aforementioned step, the chime was held at 37 °C with shaking for 2 h. Finally, the gastric chime was mixed with 40 μL of 0.3 M CaCl2 × 2H2O, 1.31 mL of distilled water, 2.5 mL of 160 mM bile extract, and 16 mL of 22.15 mg/mL pancreatic solution in SIF. The pH was raised to 7 by adding 1 M NaOH, and the mixture was incubated at 37 °C for 2 h with constant shaking. At the end of each step, aliquots were collected and placed on ice. The survival rates of L. casei HY2782 and L. casei ATCC393 in fermented milk were compared with those of control samples, measured as described, before digestion and at the end of each step.

2.8. Propagation and Maintenance of Cell Lines

In this study, the human colon adenocarcinoma cell lines HT-29 and Caco-2 were used. Both cell lines were purchased from ATCC. These two cell lines were cultured in Dulbecco’s Modified Eagle Medium (Gibco, Billings, MT, USA) with 10% (v/v) fetal bovine serum (FBS; Gibco, Billings, MT, USA) and 1% (v/v) penicillin and streptomycin at 37 °C and 5% CO2.

2.9. Adhesion Assay

To measure the adhesion rate of fermented milk with L. casei HY2782 or L. casei ATCC393 to HT-29 cells, a previously described method was followed [29]. The cells were dispensed into a 6-well plate at 1.0 × 104 cells/well and each sample was diluted in phosphate-buffered saline (PBS) to 1.0 × 108 CFU/mL, inoculated into each well, and incubated for 2 h at 37 °C with 5% CO2 for attachment to HT-29 cells. After the culture was completed, the cells were washed three times with PBS and treated with 0.05% trypsin-EDTA for 10 min to separate cells. The separated cells were diluted step-by-step with sterile peptone water and inoculated on an MRS agar plate. The plates were incubated at 37 °C for 72 h to count colonies (A1, CFU/mL). Fermented milk samples with L. casei HY2782 or L. casei ATCC393 cells added first to each well of the plate were also assayed (A0, CFU/mL). The adhesion rate was calculated as follows.

% adhesion ability = (A1/A0) × 100

2.10. mRNA Expression Analyses

Caco-2 cells were seeded in the wells of 6-well tissue culture plates at a density of 3 × 105 cells/well. The medium was then refreshed every 1–2 days. The Caco-2 monolayer was incubated for 21 days to differentiate. Fermented milk containing L. casei HY2782 or L. casei ATCC393 was diluted to 1.0 × 108 CFU/mL in PBS and inoculated into 6 wells. After 10 h exposure (37 °C, 5% CO2), the solution was removed and the monolayer was washed with PBS. Total RNA was extracted from the Caco-2 cells purified using the RNeasy Mini Kit (QI-AGEN, San Diego, CA, USA) with DNAse treatment according to the manufacturer’s instructions. The RNA concentration and purity were measured using a NanoDrop ND-1000 UV/Vis spectrophotometer according to the manufacturer’s instructions (NanoDrop Technologies Inc., Wilmington, DE, USA). The RNA integrity was evaluated using the Bioanalyzer 2100 system (Agilent Technologies, Santa Clara, CA, USA), and only the samples with RNA integrity number ≥ 8 were used for mRNA experiments. Total RNA was reverse-transcribed using the High-Capacity cDNA Reverse Transcription kit (Applied Biosystems, Foster City, CA, USA). Real-time polymerase chain reaction (RT-PCR) analysis was performed on a Quant Studio 6 Real-Time PCR system (Thermo Fisher 150 Scientific, Waltham, MA, USA) using the TaqMan Gene Expression Mastermix (Life Technologies, Austin, TX, USA). The thermal cycling condition was as follows: heat activation at 50 °C for 1 min and denaturation at 95 °C for 10 min, followed by 40 cycles at 95 °C for 15 s and 60 °C for 1 min. TaqMan probes (Applied Biosystems, Foster City, CA, USA) were used to measure the following genes: glyceraldehyde-3-phosphate dehydrogenase (GAPDH, Hs02786624_g1), used as an internal standard, and tight-junction protein 1 (ZO-1, Hs01551871_m1), occludin (OCLN, Hs05465837_g1), claudin 1 (CLDN1, Hs00221623_m1), and claudin 3 (CLDN3, Hs00265816_s1). The 2−∆∆Ct method was employed to calculate the relative expression of each target gene. This study was conducted according to the Minimum Information for Publication of Quantitative Real-Time PCR experiments (MIQE) guidelines [30].

2.11. Statistical Analyses

All data were collected in MS Excel (version 2016; Microsoft, Redmond, WA, USA). Data are representative results of the means ± SD of three independent experiments. The differences in the relative levels were evaluated by unpaired Student’s t-tests in SPSS software (version 26; IBM, Somers, NY, USA), and those with p-values < 0.05 (*) or < 0.01 (**) were considered statistically significant.

3. Results

3.1. Acidification Capability and Growth Performance

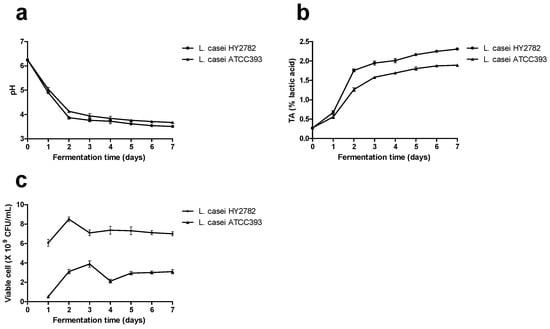

Changes in pH and TA occurred throughout the fermentation process of L. casei HY2782 and L. casei ATCC393 due to microbial activity. Depending on the probiotic strain used, the pH of RSM decreased from 6.7 to 3.51–3.67 after 7 days of fermentation (Figure 1a). The TA of fermented milk with L. casei HY2782 or L. casei ATCC393 increased from the initial value of 0.27 to 1.89–2.31 after 7 days of fermentation (Figure 1b). Changes in the viable counts of L. casei HY2782 and L. casei ATCC393 in fermented milk were determined throughout the fermentation process. L. casei HY2782 showed the highest growth rate as well as the highest viable cell count, specifically 8.50 × 109 CFU/mL on day 2, and slightly decreased thereafter from 7.10 × 109 on day 3 of fermentation to 7.00 × 109 CFU/mL after 7 days of fermentation. For L. casei ATCC393, the highest viable cell count, 3.88 × 109 CFU/mL, was observed on day 3, which decreased slightly thereafter, from 2.13 × 109 CFU/mL after 4 days of fermentation to 3.09 × 109 CFU/mL for fermentation on day 7 (Figure 1c). Both probiotic strains did not exhibit a significantly decreased viable count with low pH and high TA during long-term fermentation.

Figure 1.

Physiochemical characteristics of fermented milk with Lactobacillus casei HY2782 or L. casei ATCC393. (a) pH, (b) titratable acidity (TA), and (c) total number of viable cells versus fermentation time throughout milk fermentation with L. casei HY2782 or L. casei ATCC393. Results are expressed as the mean ± SD of three independent experiments (n = 3).

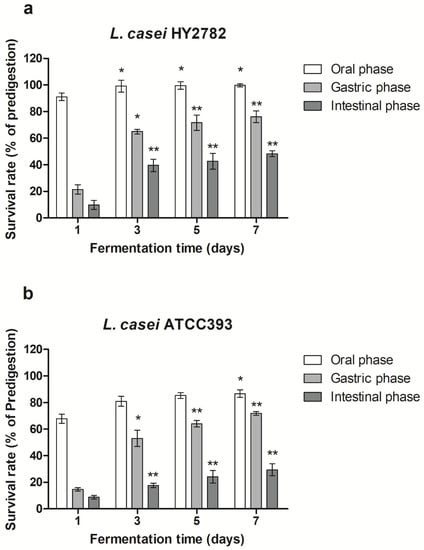

3.2. Bacterial Survival Rate under Simulated Gastrointestinal Digestion

Fermented milk containing L. casei HY2782 or L. casei ATCC393 for various culture times was evaluated based on the simulated oral, gastric, and intestinal phases, and survival at pre-digestion was used as a control. In the oral phase, survival rates were slightly increased in L. casei HY2782 (91.2% to 99.7%) and significantly increased for L. casei ATCC393 (67.8% to 86.6%) after 7 days of fermentation compared with the survival rate at the initial phase. In the gastric phase, survival rates were significantly increased for L. casei HY2782 (27.8% to 76.1%) and L. casei ATCC393 (14.6% to 71.8%) after 7 days of fermentation compared with the survival rate at the initial phase. In the intestinal phase, survival rates were significantly increased for L. casei HY2782 (9.8% to 48.3%) and L. casei ATCC393 (8.8% to 29.4%) after 7 days of fermentation compared with the survival rate at the initial phase. L. casei HY2782 exhibited significantly higher survival rates during simulated gastrointestinal digestion and long-term fermentation (Figure 2a) in comparison to those of L. casei ATCC393 (Figure 2b). Based on these results, long-term fermentation improved the survival rate during simulated gastrointestinal digestion.

Figure 2.

Survival rate during simulated gastrointestinal digestion of fermented milk with Lactobacillus casei HY2782 (a) or L. casei ATCC393 (b). Different letters above the bars indicate statistically significant differences from each stage on day 1 of fermentation (* p < 0.05, ** p < 0.01).

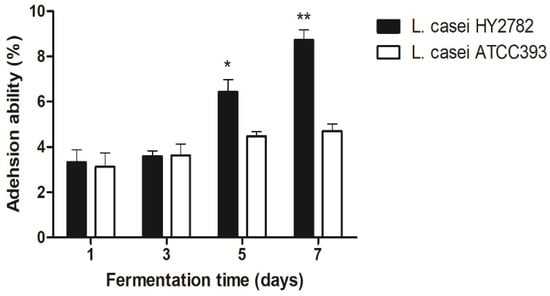

3.3. Intestinal Adhesion Ability on HT-29 Cells

The ability of L. casei HY2782 and L. casei ATCC393 to adhere to intestinal epithelial cells is one of the main criteria for the selection of probiotic strains. Prolonged mucosal adhesion time of probiotics might affect the gastrointestinal immune system and the host flora. Therefore, the ability to adhere to the intestine is consistent with the efficiency of the probiotic strain. As shown in Figure 3, the adhesion ability on HT-29 cells was significantly increased for L. casei HY2782 (3.3% to 8.7%) after 7 days of fermentation, whereas the adhesion ability was slightly increased for L. casei ATCC393 (3.1% to 4.7%) after 7 days of fermentation. Based on this result, we concluded that L. casei HY2782 might improve intestinal adhesion ability through long-term fermentation (Figure 3).

Figure 3.

Intestinal adhesion ability of fermented milk with Lactobacillus casei HY2782 and L. casei ATCC393 on HT-29 cells. Different letters above the bars indicate statistically significant differences from each sample on day 1 of fermentation (* p < 0.05, ** p < 0.01).

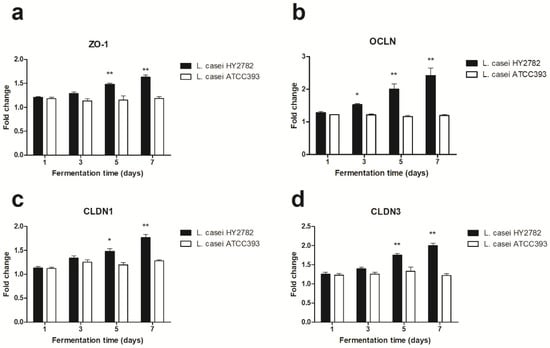

3.4. Tight-Junction-Related mRNA Expression

To investigate the molecular mechanisms underlying the effect of fermented milk with L. casei HY2782 or L. casei ATCC393 on Caco-2 cells at various fermentation times, the expression levels of genes encoding the tight-junction proteins TJP1 (ZO-1), occludin (OCLN), claudin 1 (CLDN1), and claudin 3 (CLDN3) were determined through qRT-PCR (Figure 4). The results confirmed the advantages of long-term fermentation. Increased gene expression of tight-junction proteins in Caco-2 monolayers is important for the regulation of paracellular permeability. Caco-2 cells treated with fermented milk with L. casei HY2782 or L. casei ATCC393 showed higher expression of ZO-1 (Figure 4a), OCLN (Figure 4b), CLDN1 (Figure 4c), and CLDN3 (Figure 4d) compared to that in the untreated control. The expression of ZO-1, OCLN, CLDN1, and CLDN3 showed a significant increase; specifically, ZO-1 (fold-change, 1.21 to 1.63), OCLN (fold-change, 1.29 to 2.42), CLDN1 (fold-change, 1.13 to 1.77), and CLDN3 (fold-change, 1.26 to 2.0) significantly increased with L. casei HY2782 after 7 days of fermentation. However, the same increase did not occur with L. casei ATCC393 for ZO-1 (fold-change, 1.18 to 1.19), OCLN (fold-change, 1.22 to 1.19), CLDN1 (fold-change, 1.12 to 1.28), and CLDN3 (fold-change, 1.23 to 1.22). This result showed that L. casei HY2782 increases the expression of tight-junction-related mRNA expression throughout long-term fermentation. Therefore, L. casei HY2782 might improve the intestinal barrier function.

Figure 4.

Relative mRNA levels of genes encoding the tight-junction proteins tight-junction protein 1 (ZO-1) (a), occludin (OCLN) (b), claudin 1 (CLDN1) (c), and CLDN3 (d) in Caco-2 cells after 10 h exposure to fermented milk with Lactobacillus casei HY2782 or L. casei ATCC393 versus fermentation time. Different letters above the bars indicate statistically significant differences from each sample on day 1 of fermentation (* p < 0.05, ** p < 0.01).

4. Discussion

In general, each probiotic strain might have different characteristics; therefore, probiotics are used for a selection of products by comprehensively considering strain characteristics such as safety, functionality, and technical aspects [31]. For lactic acid bacteria to be characterized as probiotics, they must pass through the stomach and duodenum, reach the final target site (the intestine), and attach to the intestinal epithelial cells to function [32,33]. Probiotics can contribute to the improvement of the intestinal mucosal barrier function and have been reported to affect the formation of proteins that help the physiological barrier function of the tight-junction structure by modulating various signaling systems of intestinal epithelial cells [34,35]. For probiotics to exhibit health-promoting effects through positive interactions with the intestinal environment and intestinal epithelial cells, the ability to colonize the intestine is essential [36]. It has been reported that bifidobacteria, a representative commercial probiotic, have lost the functions necessary to colonize the human intestinal environment [37]. Therefore, when probiotics are taken orally, it is necessary to investigate their ability to survive and reach the intestine and colonize the intestinal environment. Our results suggested that L. casei HY2782 has beneficial effects such as an increased survival rate in the digestive tract, better adhesion to intestinal cells, strengthening the intestinal barrier, and protecting the mucous membrane through long-term fermentation. Previous studies have shown that when lactic acid bacteria are exposed to an acidic environment for a certain period of time, their adaptability to acid and bile increases [22,23]. It has also been suggested that acidic stress can improve the ability of lactobacilli to adhere to intestinal cells [24]. Previous studies showed that L. casei ATCC 393 possesses significant adherence capacity in vitro [38], and thus, we used it as a reference strain for comparisons, but it did not result in an increase in the intestinal cell adhesion rate and tight-junction genes with long-term fermentation. L. casei produces a large amount of exopolysaccharide (EPS) during growth [39,40]. Research has shown that EPS components protect lactic acid bacteria from being killed in the human digestive system [41]. With low temperatures and the application of glucose as the carbohydrate source, the highest amounts of EPS and the highest specific EPS production are achieved [42]. L. casei can increase the expression of adhesion junction proteins [43,44] and might increase the expression of mucin proteins [45]. A previous study showed that the products of secondary metabolism and peptide components produced by lactic acid bacteria during the fermentation process can increase the expression of the tight junction protein and the expression of mucin proteins [25]. In particular, a condition in which the intestinal permeability increases due to the loosening of the tight junction is called intestinal leakage syndrome, which causes diseases such as abdominal bloating, diarrhea, abdominal pain, and irritable bowel syndrome [46,47,48]. The long-term fermentation of L. casei HY2782 can prevent intestinal diseases by increasing the expression of genes encoding tight-junction proteins.

Recently, coating materials or encapsulation technologies for probiotics have been studied to increase the survival rate during the digestion process [49]. We hope that this study will contribute to the selection of probiotics in the functional food fields related to health. Studies have been recently conducted to identify the health benefits of probiotics and metabolomics [50]. Our findings showed the importance of controlling the fermentation time, since the L. casei HY2782 strain showed improved viability and resistance to simulated gastrointestinal digestion and intestinal adhesion ability, with enhanced expression of genes involved in tight junctions depending on the fermentation time. L. casei HY2782 produces a large amount of EPS and the adaptability to acid and bile increases strongly due to long-term fermentation. Further studies are needed to understand the production of different amounts of metabolites at various fermentation times. Moreover, additional experiments are required to elucidate the mechanisms responsible for the beneficial effects of long-term fermented milk products on human health.

5. Conclusions

Long-term fermentation processes have been reviewed to discover the efficacy of fermented milk containing L. casei HY2782. We suggest that L. casei HY2782 has beneficial properties such as improved viability, resistance to simulated gastrointestinal digestion, intestinal adhesion ability, and enhancing effects on the expression of genes involved in tight junctions with long-term fermentation periods. We believe that our study makes a significant contribution to the research on dairy products because the use of probiotics is of interest since these organisms provide health benefits and many people are presently more concerned about making healthy life choices. We hope that further studies will be conducted on the identification of metabolites and functional ingredients according to the fermentation period in order to discover various reasons why fermented milk products are beneficial to health.

Author Contributions

Conceptualization, S.H.J., D.K.H., S.-J.B., J.-J.S. and J.-L.L.; methodology, S.H.J.; software, S.H.J.; validation, S.H.J.; formal analysis, S.H.J.; investigation, S.H.J., D.K.H. and S.-J.B.; writing—original draft preparation, S.H.J.; writing—review and editing, K.H.; visualization, S.H.J. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available in the article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Hill, C.; Guarner, F.; Reid, G.; Gibson, G.R.; Merenstein, D.J.; Pot, B.; Morelli, L.; Canani, R.B.; Flint, H.J.; Salminen, S.; et al. Expert Consensus Document. The International Scientific Association for Probiotics and Prebiotics Consensus Statement on the Scope and Appropriate Use of the Term Probiotic. Nat. Rev. Gastroenterol. Hepatol. 2014, 11, 506–514. [Google Scholar] [CrossRef] [PubMed]

- David, L.A.; Maurice, C.F.; Carmody, R.N.; Gootenberg, D.B.; Button, J.E.; Wolfe, B.E.; Ling, A.V.; Devlin, A.S.; Varma, Y.; Fischbach, M.A.; et al. Diet Rapidly and Reproducibly Alters the Human Gut Microbiome. Nature 2014, 505, 559–563. [Google Scholar] [CrossRef]

- Derrien, M.; van Hylckama Vlieg, J.E. Fate, Activity, and Impact of Ingested Bacteria within the Human Gut Microbiota. Trends Microbiol. 2015, 23, 354–366. [Google Scholar] [CrossRef]

- Ungaro, F.; Rubbino, F.; Danese, S.; D’Alessio, S. Actors and Factors in the Resolution of Intestinal Inflammation: Lipid Mediators as a New Approach to Therapy in Inflammatory Bowel Diseases. Front. Immunol. 2017, 8, 1331. [Google Scholar] [CrossRef]

- Parolin, C.; Marangoni, A.; Laghi, L.; Foschi, C.; Ñahui Palomino, R.A.; Calonghi, N.; Cevenini, R.; Vitali, B. Isolation of Vaginal Lactobacilli and Characterization of Anti-Candida Activity. PLoS ONE 2015, 10, e0131220. [Google Scholar] [CrossRef] [PubMed]

- Chang, S.-M.; Tsai, C.-L.; Wee, W.-C.; Yan, T.-R. Isolation and functional study of potentially probiotic. Afr. J. Microbiol. Res. 2013, 7, 683–691. [Google Scholar]

- Akabanda, F.; Owusu-Kwarteng, J.; Tano-Debrah, K.; Parkouda, C.; Jespersen, L. The Use of Lactic Acid Bacteria Starter Culture in the Production of Nunu, a Spontaneously Fermented Milk Product in Ghana. Int. J. Food Sci. 2014, 2014, 721067. [Google Scholar] [CrossRef] [PubMed]

- Ao, X.; Zhang, X.; Zhang, X.; Shi, L.; Zhao, K.; Yu, J.; Dong, L.; Cao, Y.; Cai, Y. Identification of Lactic Acid Bacteria in Traditional Fermented Yak Milk and Evaluation of Their Application in Fermented Milk Products. J. Dairy Sci. 2012, 95, 1073–1084. [Google Scholar] [CrossRef]

- Bao, Q.; Song, Y.; Xu, H.; Yu, J.; Zhang, W.; Menghe, B.; Zhang, H.; Sun, Z. Multilocus Sequence Typing of Lactobacillus casei Isolates from Naturally Fermented Foods in China and Mongolia. J. Dairy Sci. 2016, 99, 5202–5213. [Google Scholar] [CrossRef]

- Aryana, K.J.; Olson, D.W. A 100-Year Review: Yogurt and Other Cultured Dairy Products. J. Dairy Sci. 2017, 100, 9987–10013. [Google Scholar] [CrossRef] [PubMed]

- Ryan, P.M.; Ross, R.P.; Fitzgerald, G.F.; Caplice, N.M.; Stanton, C. Sugar-Coated: Exopolysaccharide Producing Lactic Acid Bacteria for Food and Human Health Applications. Food Funct. 2015, 6, 679–693. [Google Scholar] [CrossRef]

- Ouwehand, A.C.; Kirjavainen, P.V.; Shortt, C.; Salminen, S. Probiotics: Mechanisms and Established Effects. Int. Dairy J. 1999, 9, 43–52. [Google Scholar] [CrossRef]

- Macfarlane, G.T.; Cummings, J.H. Probiotics, Infection and Immunity. Curr. Opin. Infect. Dis. 2002, 15, 501–506. [Google Scholar] [CrossRef] [PubMed]

- Lebeer, S.; Vanderleyden, J.; De Keersmaecker, S.C. Genes and Molecules of Lactobacilli Supporting Probiotic Action. Microbiol. Mol. Biol. Rev. 2008, 72, 728–764. [Google Scholar] [CrossRef] [PubMed]

- Karczewski, J.; Troost, F.J.; Konings, I.; Dekker, J.; Kleerebezem, M.; Brummer, R.J.; Wells, J.M. Regulation of Human Epithelial Tight Junction Proteins by Lactobacillus plantarum In Vivo and Protective Effects on the Epithelial Barrier. Am. J. Physiol. Gastrointest. Liver Physiol. 2010, 298, G851–G859. [Google Scholar] [CrossRef] [PubMed]

- Lourens-Hattingh, A.; Viljoen, B.C. Yogurt as Probiotic Carrier Food. Int. Dairy J. 2001, 11, 1–17. [Google Scholar] [CrossRef]

- Jost, R. Milk and dariy products. In Ullmann’s Encyclopedia of Industrial Chemistry; Wiley-VCH Verlag GmbH & Co. KgaA: Weinheim, Germany, 2007; p. 300. [Google Scholar]

- Park, I.J.; Lee, J.H.; Kye, B.H.; Oh, H.K.; Cho, Y.B.; Kim, Y.T.; Kim, J.Y.; Sung, N.Y.; Kang, S.B.; Seo, J.M.; et al. Effects of Probiotics on the Symptoms and Surgical ouTComes after Anterior REsection of Colon Cancer (POSTCARE): A Randomized, Double-Blind, Placebo-Controlled Trial. J. Clin. Med. 2020, 9, 2181. [Google Scholar] [CrossRef]

- Kim, J.Y.; Lee, S.Y.; Jung, S.H.; Kim, M.R.; Choi, I.D.; Lee, J.L.; Sim, J.H.; Pan, C.H.; Kang, K. Protective Effect of Lactobacillus casei HY2782 against Particulate Matter Toxicity in Human Intestinal CCD-18Co Cells and Caenorhabditis elegans. Biotechnol. Lett. 2020, 42, 519–528. [Google Scholar] [CrossRef]

- Nam, W.; Kim, H.; Bae, C.; Kim, J.; Nam, B.; Lee, Y.; Kim, J.; Park, S.; Lee, J.; Sim, J. Lactobacillus HY2782 and Bifidobacterium HY8002 Decrease Airway Hyperresponsiveness Induced by Chronic PM2.5 Inhalation in Mice. J. Med. Food 2020, 23, 575–583. [Google Scholar]

- Østlie, H.M.; Helland, M.H.; Narvhus, J.A. Growth and Metabolism of Selected Strains of Probiotic Bacteria in Milk. Int. J. Food Microbiol. 2003, 87, 17–27. [Google Scholar] [CrossRef]

- Jung, S.; Lee, J.H. Characterization of Transcriptional Response of Lactobacillus plantarum under Acidic Conditions Provides Insight into Bacterial Adaptation in Fermentative Environments. Sci. Rep. 2020, 10, 19203. [Google Scholar] [CrossRef]

- Hill, D.; Sugrue, I.; Tobin, C.; Hill, C.; Stanton, C.; Ross, R.P. The Lactobacillus casei Group: History and Health Related Applications. Front. Microbiol. 2018, 9, 2107. [Google Scholar] [CrossRef] [PubMed]

- Bang, M.; Yong, C.C.; Ko, H.J.; Choi, I.G.; Oh, S. Transcriptional Response and Enhanced Intestinal Adhesion Ability of Lactobacillus rhamnosus GG after Acid Stress. J. Microbiol. Biotechnol. 2018, 28, 1604–1613. [Google Scholar] [CrossRef] [PubMed]

- Sánchez, B.; Bressollier, P.; Urdaci, M.C. Exported Proteins in Probiotic Bacteria: Adhesion to Intestinal Surfaces, Host Immunomodulation and Molecular Cross-Talking with the Host. FEMS. Immunol. Med. Microbiol. 2008, 54, 1–17. [Google Scholar] [CrossRef] [PubMed]

- Michael, M.; Phebus, R.K.; Schmidt, K.A. Impact of a Plant Extract on the Viability of Lactobacillus delbrueckii ssp. bulgaricus and Streptococcus thermophilus in Nonfat Yogurt. Int. Dairy J. 2010, 20, 665–672. [Google Scholar]

- Panda, S.H.; Ray, R.C. Lactic Acid Fermentation of Beta-Carotene Rich Sweet Potato (Ipomoea batatas L.) into Lacto-Juice. Plant Foods Hum. Nutr. 2007, 62, 65–70. [Google Scholar] [CrossRef] [PubMed]

- Minekus, M.; Alminger, M.; Alvito, P.; Ballance, S.; Bohn, T.; Bourlieu, C.; Carrière, F.; Boutrou, R.; Corredig, M.; Dupont, D.; et al. A Standardised Static In Vitro Digestion Method Suitable for Food—An International Consensus. Food Funct. 2014, 5, 1113–1124. [Google Scholar] [CrossRef] [PubMed]

- Jacobsen, C.N.; Rosenfeldt Nielsen, V.; Hayford, A.E.; Møller, P.L.; Michaelsen, K.F.; Paerregaard, A.; Sandström, B.; Tvede, M.; Jakobsen, M. Screening of Probiotic Activities of Forty-Seven Strains of Lactobacillus spp. by In Vitro Techniques and Evaluation of the Colonization Ability of Five Selected Strains in Humans. Appl. Environ. Microbiol. 1999, 65, 4949–4956. [Google Scholar] [CrossRef]

- Bustin, S.A.; Benes, V.; Garson, J.A.; Hellemans, J.; Huggett, J.; Kubista, M.; Mueller, R.; Nolan, T.; Pfaffl, M.W.; Shipley, G.L.; et al. The MIQE guidelines: Minimum information for publication of quantitative real-time PCR experiments. Clin. Chem. 2009, 55, 611–622. [Google Scholar] [CrossRef]

- Saarela, M.; Mogensen, G.; Fondén, R.; Mättö, J.; Mattila-Sandholm, T. Probiotic Bacteria: Safety, Functional and Technological Properties. J. Biotechnol. 2000, 84, 197–215. [Google Scholar] [CrossRef]

- Colum Dunne, L.O.; Mahony, L.M.; Thornton, G.; Morrissey, D.; O’Halloran, S.; Feeney, M.; Flynn, G.F.S.; Daly, C.; Kiely, B.; O’Gerald, C.; et al. In Vitro Selection Criteria for Probiotic Bacteria of Human Origin Correlation with In Vivo Findings. Am. J. Clin. Nutr. 2001, 73, 386S–392S. [Google Scholar] [CrossRef]

- Faghfoori, Z.; Pourghassem Gargari, B.; Saber Gharamaleki, A.; Bagherpour, H.; Yari Khosroushahi, A. Cellular and Molecular Mechanisms of Probiotics Effects on Colorectal Cancer. J. Funct. Foods 2015, 18, 463–472. [Google Scholar] [CrossRef]

- Stanton, C.; Ross, R.P.; Fitzgerald, G.F.; Van Sinderen, D. Fermented Functional Foods Based on Probiotics and Their Biogenic Metabolites. Curr. Opin. Biotechnol. 2005, 16, 198–203. [Google Scholar] [CrossRef] [PubMed]

- Ewaschuk, J.B.; Diaz, H.; Meddings, L.; Diederichs, B.; Dmytrash, A.; Backer, J.; Looijer-van Langen, M.; Madsen, K.L. Secreted Bioactive Factors from Bifidobacterium infantis Enhance Epithelial Cell Barrier Function. Am. J. Physiol. Gastrointest. Liver Physiol. 2008, 295, G1025–G1034. [Google Scholar] [CrossRef]

- Ruas-Madiedo, P.; Hugenholtz, J.; Zoon, P. An Overview of the Functionality of Exopolysaccharides Produced by Lactic Acid Bacteria. Int. Dairy J. 2002, 12, 163–171. [Google Scholar] [CrossRef]

- Lee, J.H.; O’Sullivan, D.J. Genomic Insights into Bifidobacteria. Microbiol. Mol. Biol. Rev. 2010, 74, 378–416. [Google Scholar] [CrossRef] [PubMed]

- Sidira, M.; Kourkoutas, Y.; Kanellaki, M.; Charalampopoulos, D. In vitro study on the cell adhesion ability of immobilized lactobacilli on natural supports. Food Res. Int. 2015, 76, 532–539. [Google Scholar] [CrossRef] [PubMed]

- Ren, Q.; Tang, Y.; Zhang, L.; Xu, Y.; Liu, N.; Ren, H. Exopolysaccharide Produced by Lactobacillus casei Promotes the Differentiation of CD4(+) T Cells into Th17 Cells in BALB/C Mouse Peyer’s Patches In Vivo and In Vitro. J. Agric. Food Chem. 2020, 68, 2664–2672. [Google Scholar] [CrossRef]

- Mozzi, F.; de Giori, G.S.; Oliver, G.; de Valdez, G.F. Exopolysaccharide Production by Lactobacillus Casei under Controlled pH. Biotechnol. Lett. 1996, 18, 435–439. [Google Scholar] [CrossRef]

- Mozzi, F.; Gerbino, E.; Font de Valdez, G.; Torino, M.I. Functionality of Exopolysaccharides Produced by Lactic Acid Bacteria in an In Vitro Gastric System. J. Appl. Microbiol. 2009, 107, 56–64. [Google Scholar] [CrossRef]

- Degeest, B.; Janssens, B.; De Vuyst, L. Exopolysaccharide (EPS) biosynthesis by Lactobacillus sakei 0-1: Production kinetics, enzyme activities and EPS yields. J. Appl. Microbiol. 2001, 91, 470–477. [Google Scholar] [CrossRef]

- Eun, C.S.; Kim, Y.S.; Han, D.S.; Choi, J.H.; Lee, A.R.; Park, Y.K. Lactobacillus casei Prevents Impaired Barrier Function in Intestinal Epithelial Cells. APMIS 2011, 119, 49–56. [Google Scholar] [CrossRef]

- Putt, K.K.; Pei, R.; White, H.M.; Bolling, B.W. Yogurt Inhibits Intestinal Barrier Dysfunction in Caco-2 Cells by Increasing Tight Junctions. Food Funct. 2017, 8, 406–414. [Google Scholar] [CrossRef]

- Tang, C.; Lu, Z. Health Promoting Activities of Probiotics. J. Food Biochem. 2019, 43, e12944. [Google Scholar] [CrossRef] [PubMed]

- Thompson, W.; Longstreth, G.; Drossman, D.; Heaton, K.; Irvine, E.; Müller-Lissner, S. Functional Bowel Disorders and Functional Abdominal Pain. Gut 1999, 45, 43–47. [Google Scholar] [CrossRef]

- Camilleri, M.; Lasch, K.; Zhou, W. Irritable Bowel Syndrome: Methods, Mechanisms, and Pathophysiology. The Confluence of Increased Permeability, Inflammation, and Pain in Irritable Bowel Syndrome. Am. J. Physiol. Gastrointest. Liver Physiol. 2012, 303, G775–G785. [Google Scholar]

- Gecse, K.; Róka, R.; Séra, T.; Rosztóczy, A.; Annaházi, A.; Izbéki, F.; Nagy, F.; Molnár, T.; Szepes, Z.; Pávics, L.; et al. Leaky Gut in Patients with Diarrhea-Predominant Irritable Bowel Syndrome and Inactive Ulcerative Colitis. Digestion 2012, 85, 40–46. [Google Scholar] [CrossRef] [PubMed]

- Lee, Y.; Ji, Y.R.; Lee, S.; Choi, M.J.; Cho, Y. Microencapsulation of Probiotic Lactobacillus acidophilus KBL409 by Extrusion Technology to Enhance Survival under Simulated Intestinal and Freeze-Drying Conditions. J. Microbiol. Biotechnol. 2019, 29, 721–730. [Google Scholar] [CrossRef] [PubMed]

- Aguilar-Toalá, J.E.; Garcia-Varela, R.; Garcia, H.S.; Mata-Haro, V.; González-Córdova, A.F.; Vallejo-Cordoba, B.; Hernández-Mendoza, A. Postbiotics: An Evolving Term within the Functional Foods Field. Trends Food Sci. Technol. 2018, 75, 105–114. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).