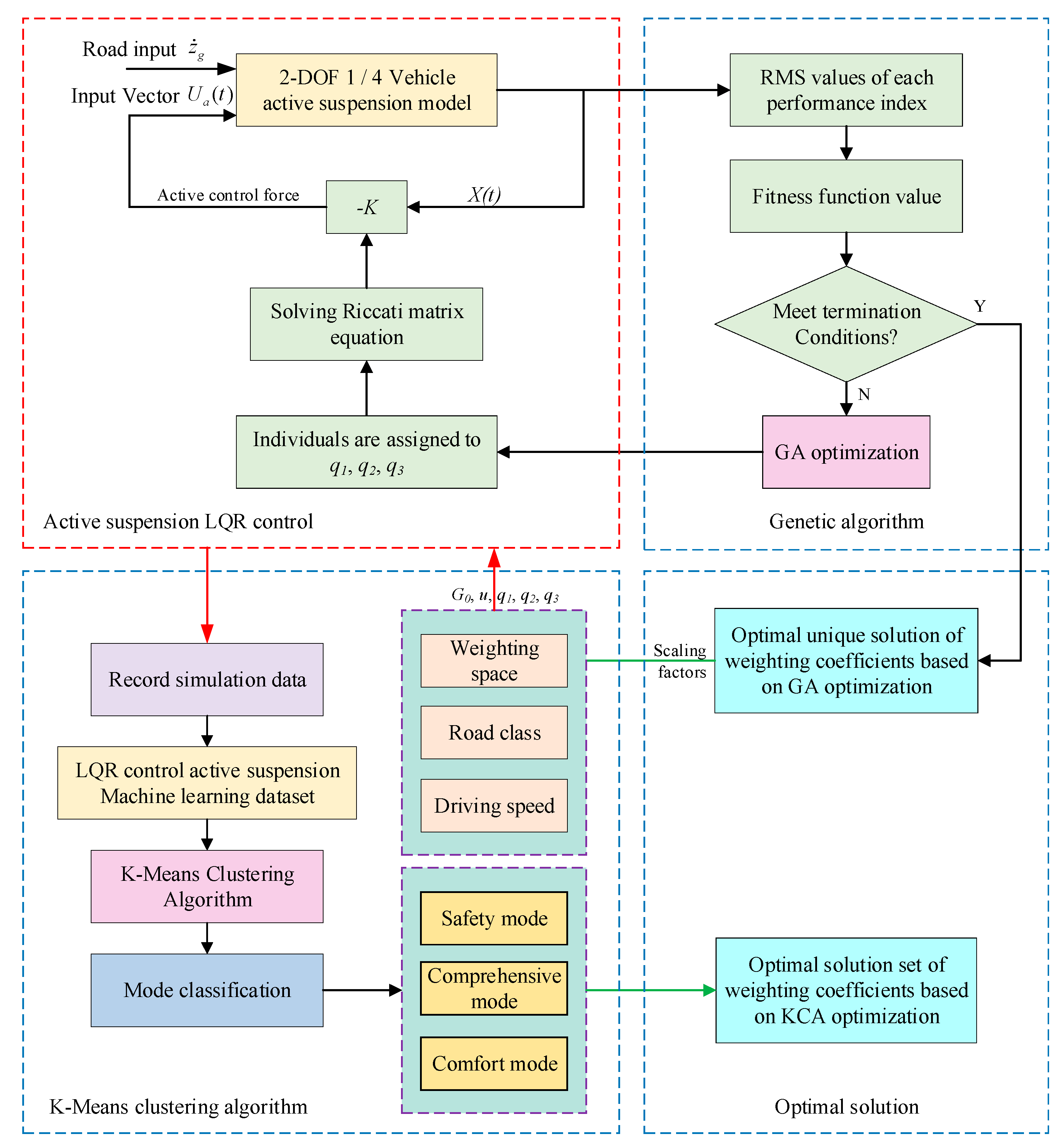

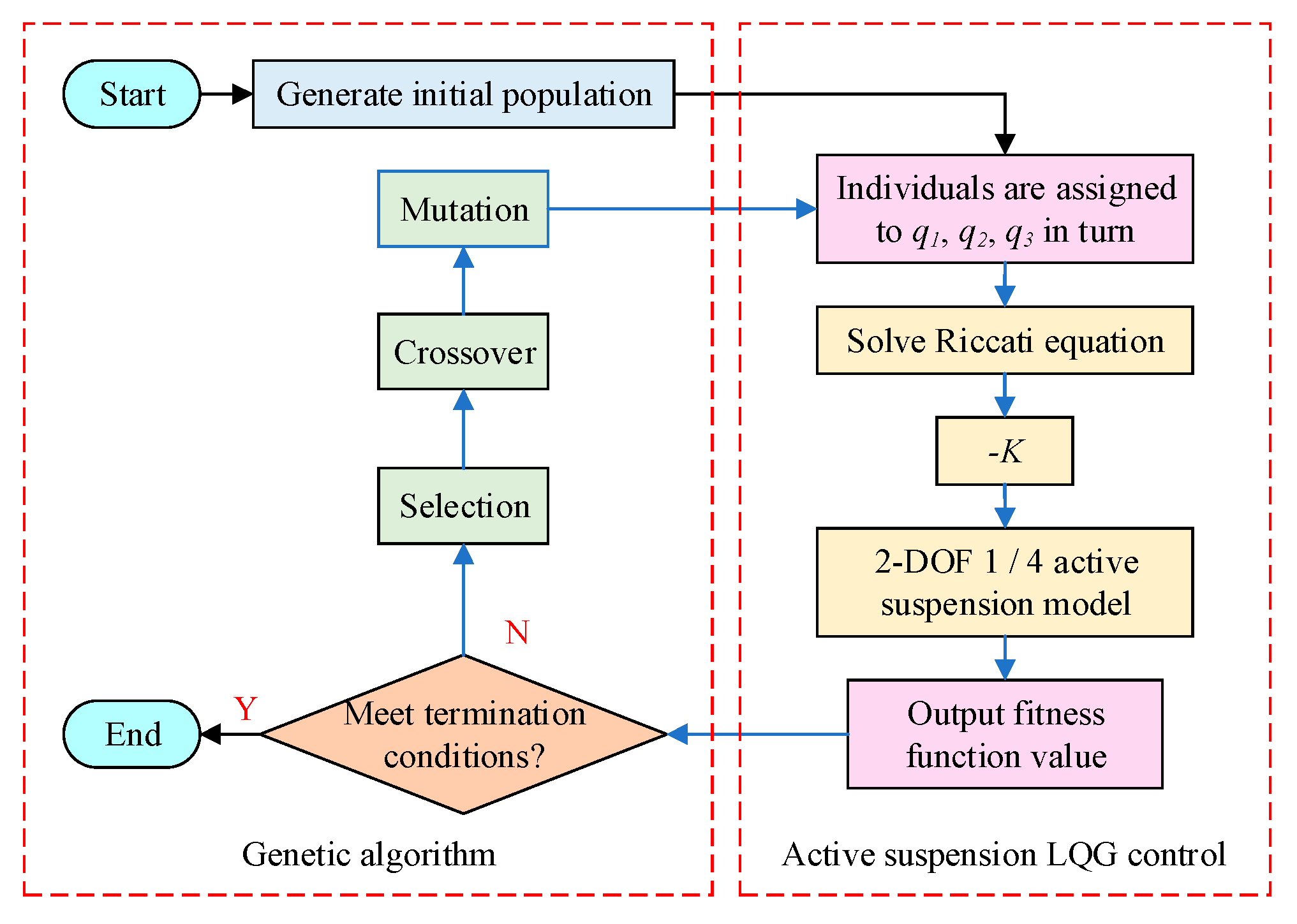

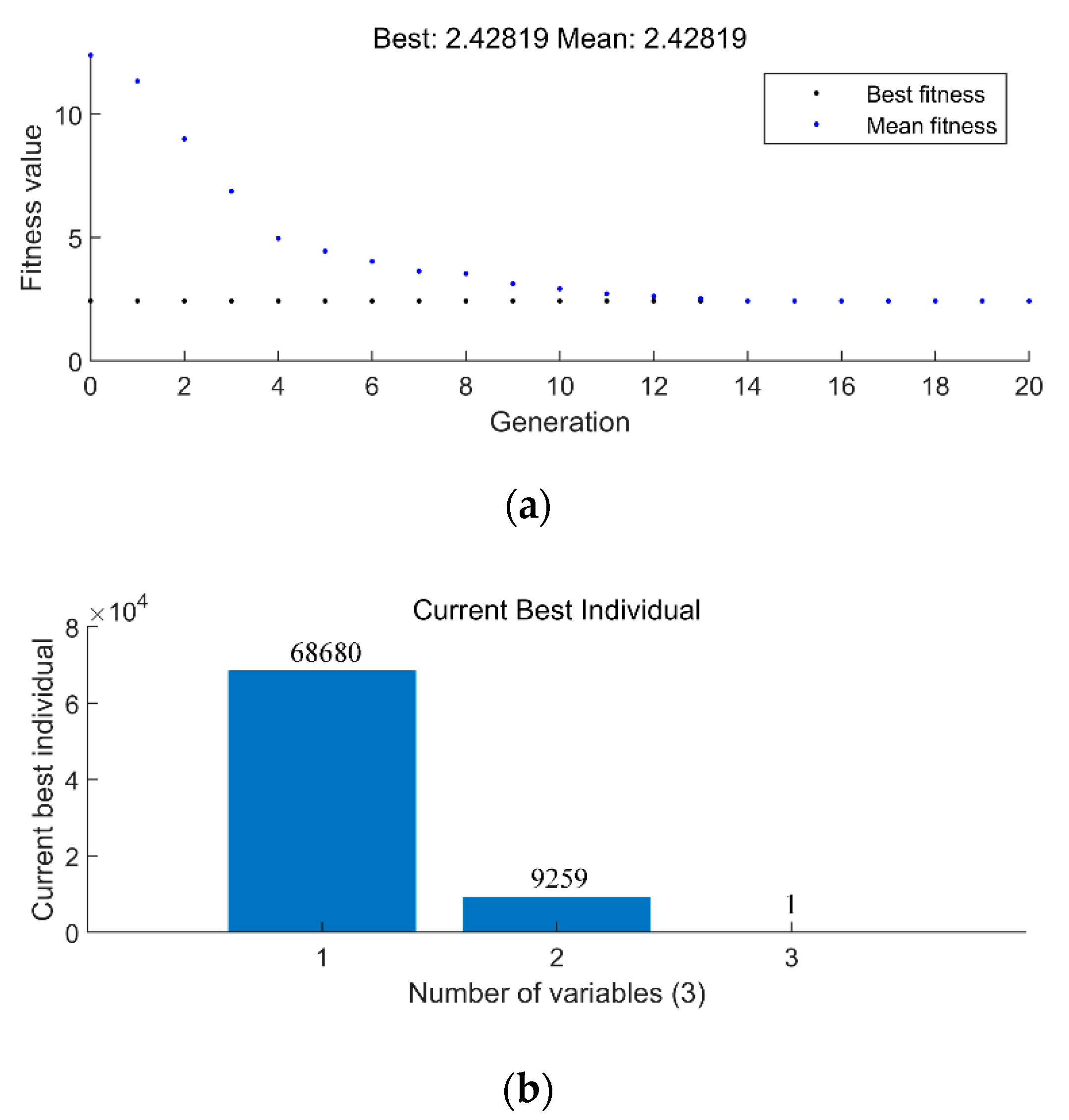

The GA mentioned in the previous section can only obtain one optimal solution for the LQR controller. The adaptability to variable working conditions is poor. It cannot meet the different requirements of different drivers for vehicle performance either. Therefore, in this paper, we introduce a machine learning approach to solve these problems.

4.1. Active Suspension Machine Learning Dataset

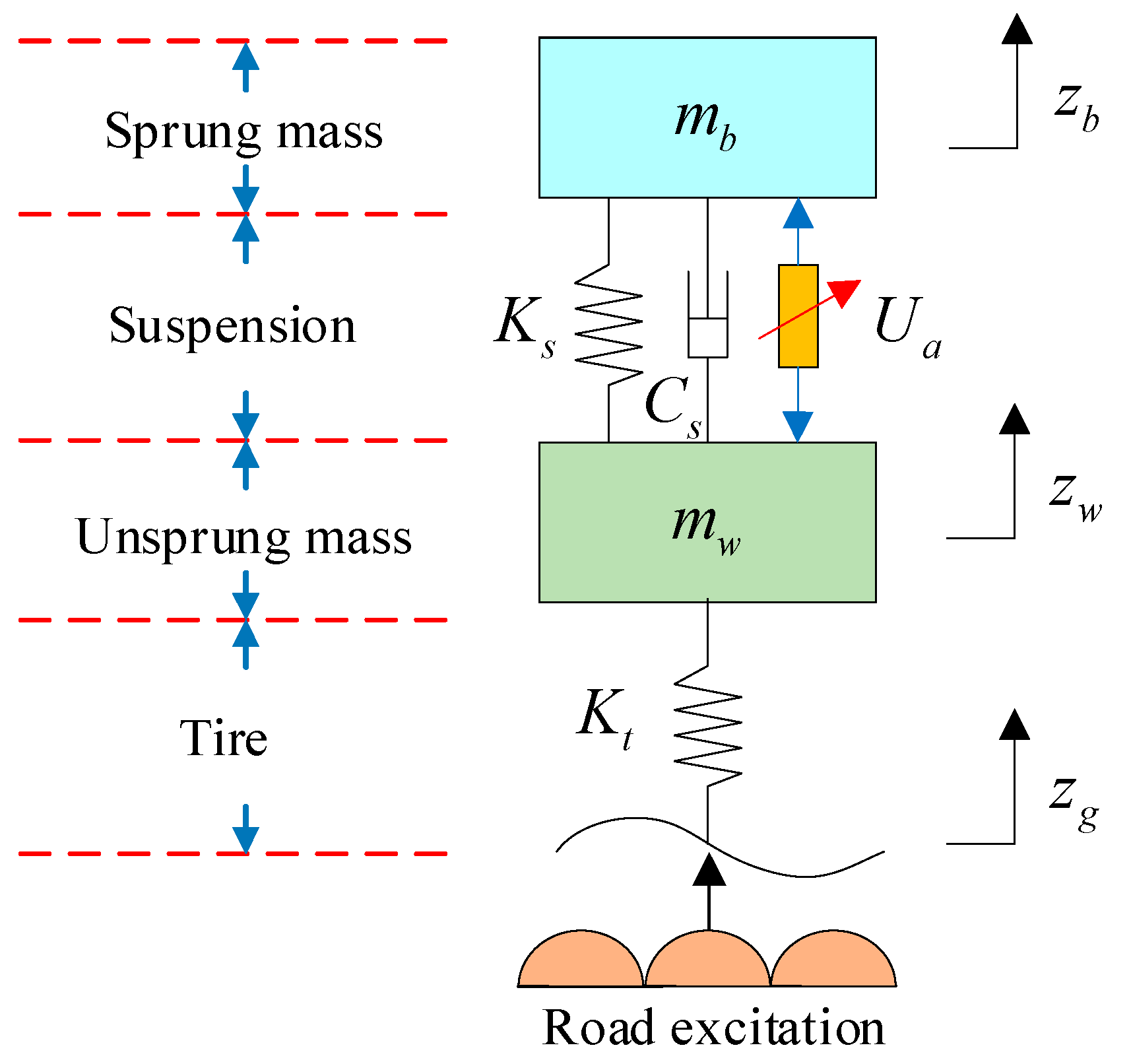

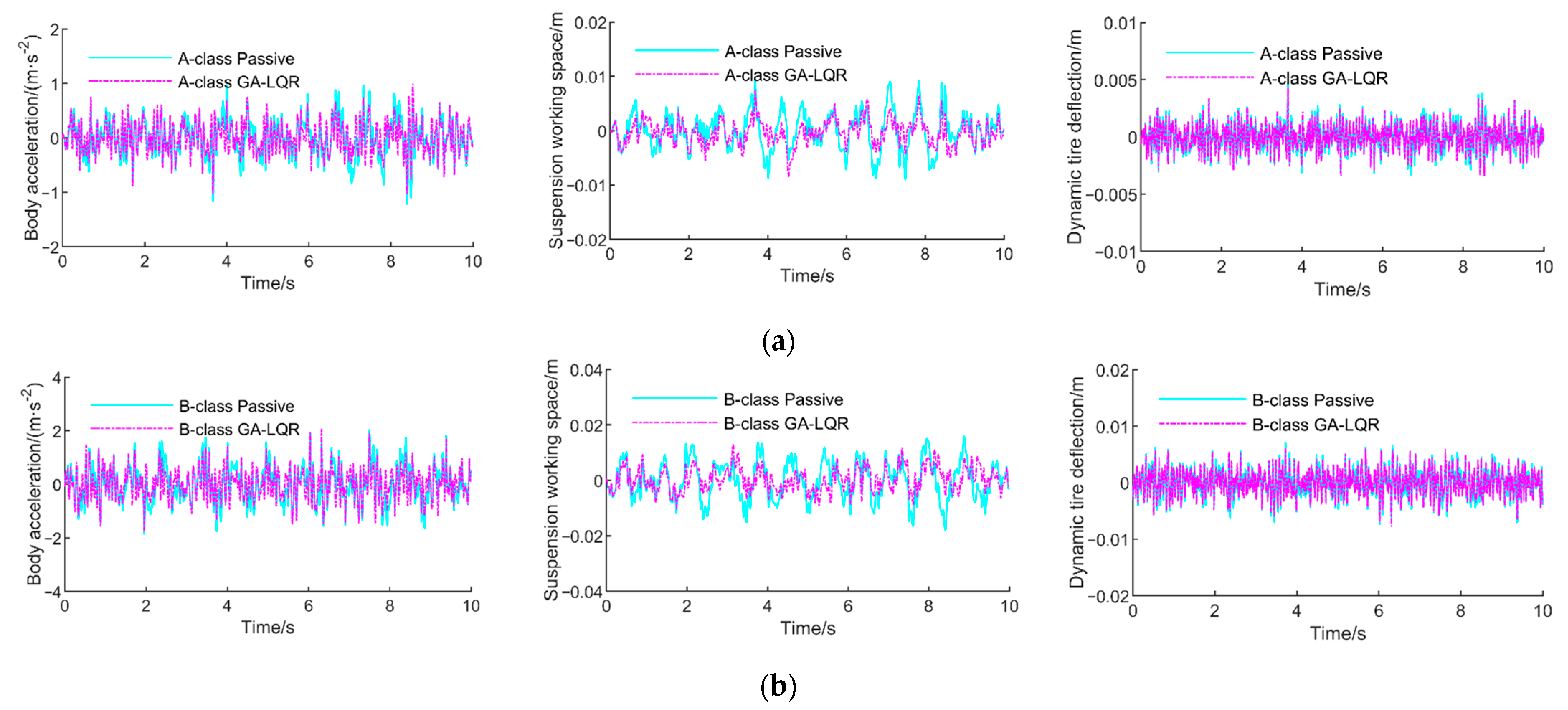

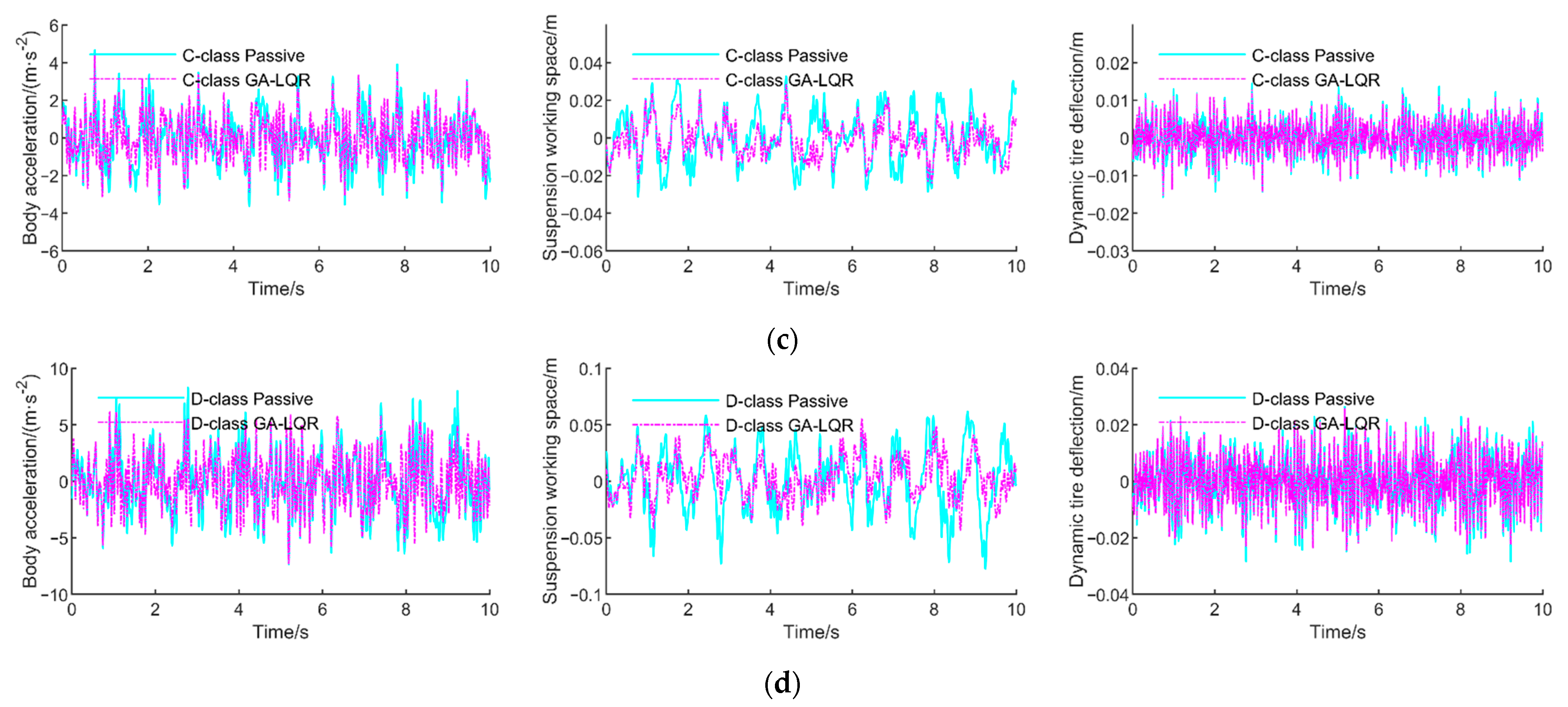

The performance of vehicle suspension is affected by many factors, which can be divided into internal and external factors. In terms of the internal factors, according to the LQR control principle, the selection of weighting coefficients has a great influence on the control effect. In terms of the external factors, the performance of suspension is affected by road roughness and vehicle motion state. Therefore, we take these two kinds of factors into account together. We selected five factors, including road class, vehicle speed , DTD weighting coefficient , SWS weighting coefficient , and BA weighting coefficient as independent variables to carry out simulations and build the machine learning dataset of LQR control active suspension.

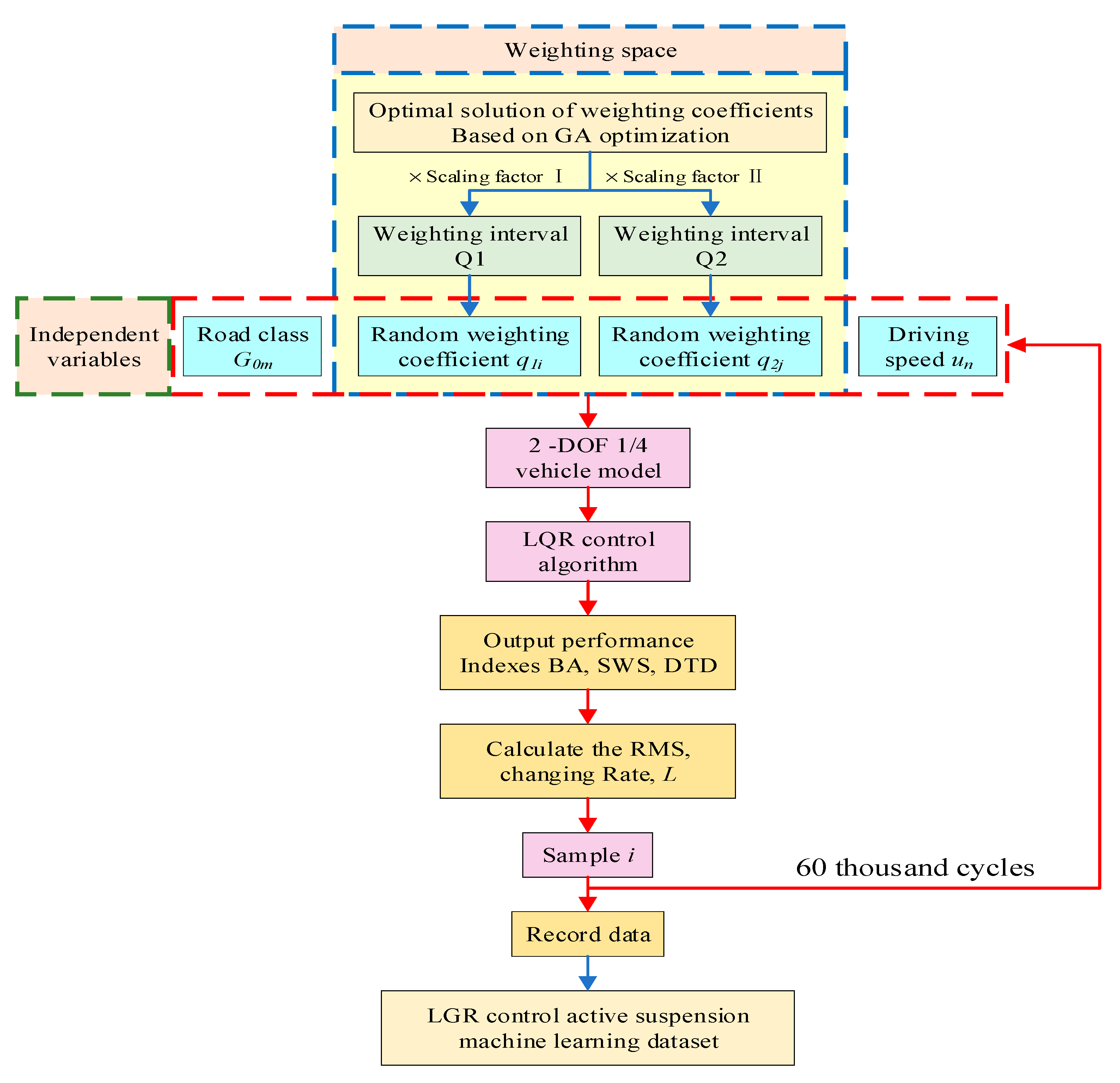

In the sample simulation, the BA weighting coefficient

is set as 1 for simplification, and the other four factors are selected as independent variables. The construction process of the machine learning dataset is shown in

Figure 7.

A possible weighting space is constructed based on the optimal solution optimized by GA. Two scaling factors, 1.75 and 1.1 in this case, are used to limit the range of weighting coefficients and , that is , . Then, 50 random numbers are generated in their respective intervals to form 2500 combinations of the weights. The random numbers are generated with the Linear congruential method as follows.

Generate random numbers:

where

A,

B, and

M are integer constants,

MOD is the remainder operation.

The generated Two-dimensional random data points,

in this case, are listed in

Table 4;

- 2.

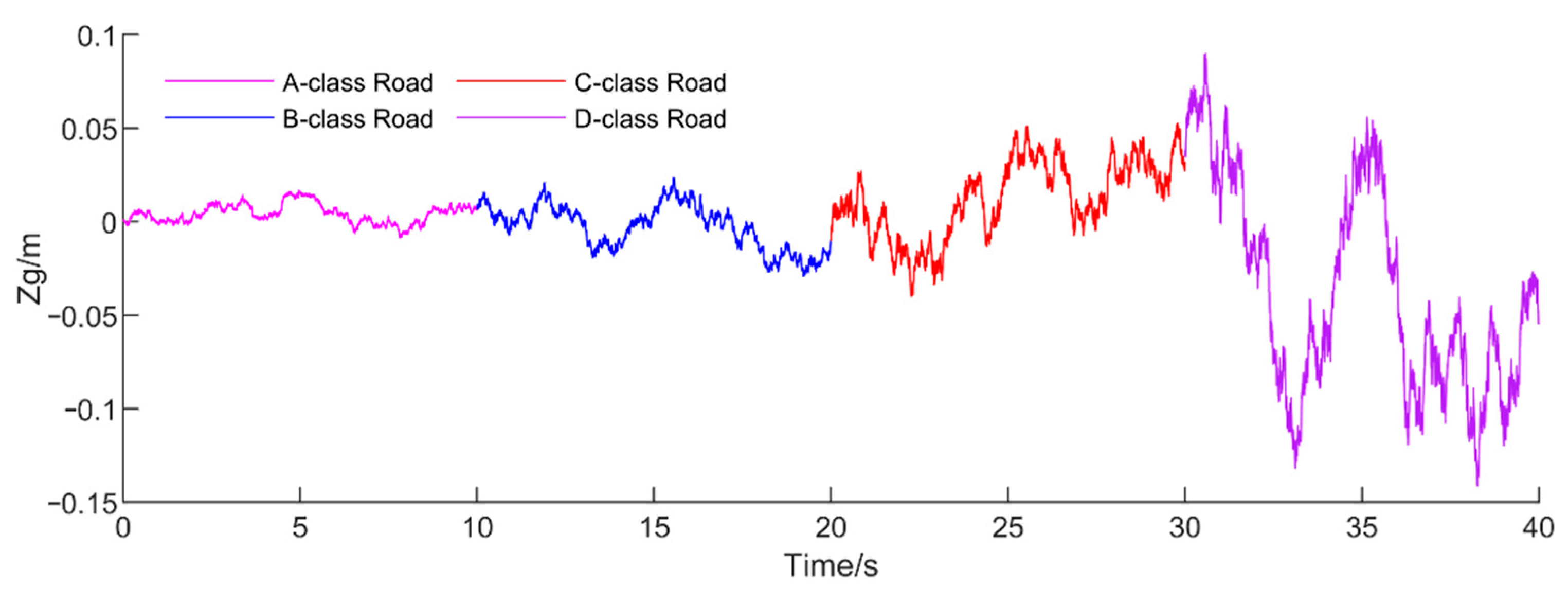

Select road class

According to the ride comfort test standards of passenger cars (ISO2631-1), the road roughness coefficient of four road classes (A, B, C, and D) is selected in turn;

- 3.

Select driving speed

Select six driving speeds (5, 10, 15, 20, 25, and 30 m/s) in turn;

- 4.

Select the weighting coefficients of performance indexes

Select the weights and of DTD and SWS in turn;

- 5.

Model simulation

After all independent variables have been selected, the 1/4 vehicle model is run for simulation;

- 6.

Construct the machine learning dataset of LQR active suspension

The results of each simulation are output and saved in the form of a matrix to construct the machine learning dataset of LQR active suspension (4 × 6 × 50 × 50 = 60,000 samples in total).

Each machine learning sample point contains 15 elements, including road roughness coefficient , driving speed , three weighting coefficients of performance indexes, three performance RMS values for active control and three for passive suspension, three changing rates of the performances, and the suspension integral control effect index .

The sample vector

is as follows:

The changing rate of three performance indexes are as follows:

where

,

,

are the changing rate of BA, SWS, DTD.

The suspension integral control effect index

is as follows:

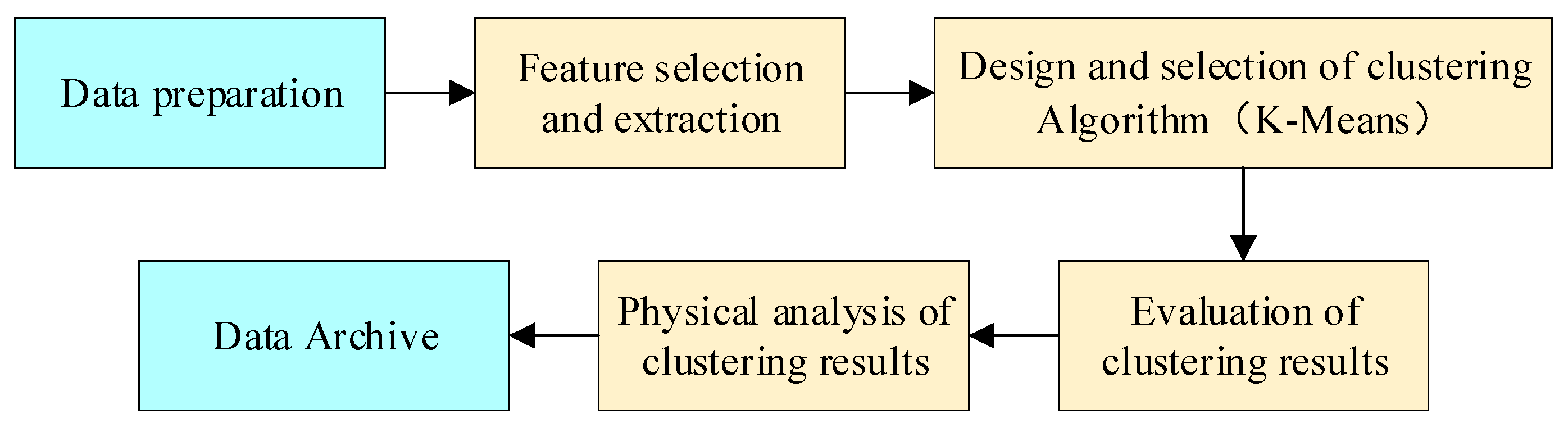

4.2. Data Analysis Based on K-means Clustering Algorithm

Clustering analysis is one of the popular algorithms in machine learning algorithms; it has the advantages of simplicity, practicality, and efficiency. Therefore, we chose a cluster analysis to analyze the data of the machine learning dataset constructed in the previous section. The cluster analysis process is shown in

Figure 8, which mainly includes feature selection, clustering algorithm selection, clustering results evaluation, and physical analysis of clustering results.

4.2.1. Selection of Feature and Clustering Algorithm

Feature selection refers to the selection of several effective features from all the original features in the dataset to optimize the specific indexes of the system. Through a good feature selection, we can reduce the dimensions of the dataset and improve the efficiency of the machine learning algorithm. In this case, the RMS values of the three performance indexes of active suspension are chosen as the effective characteristics for clustering analysis.

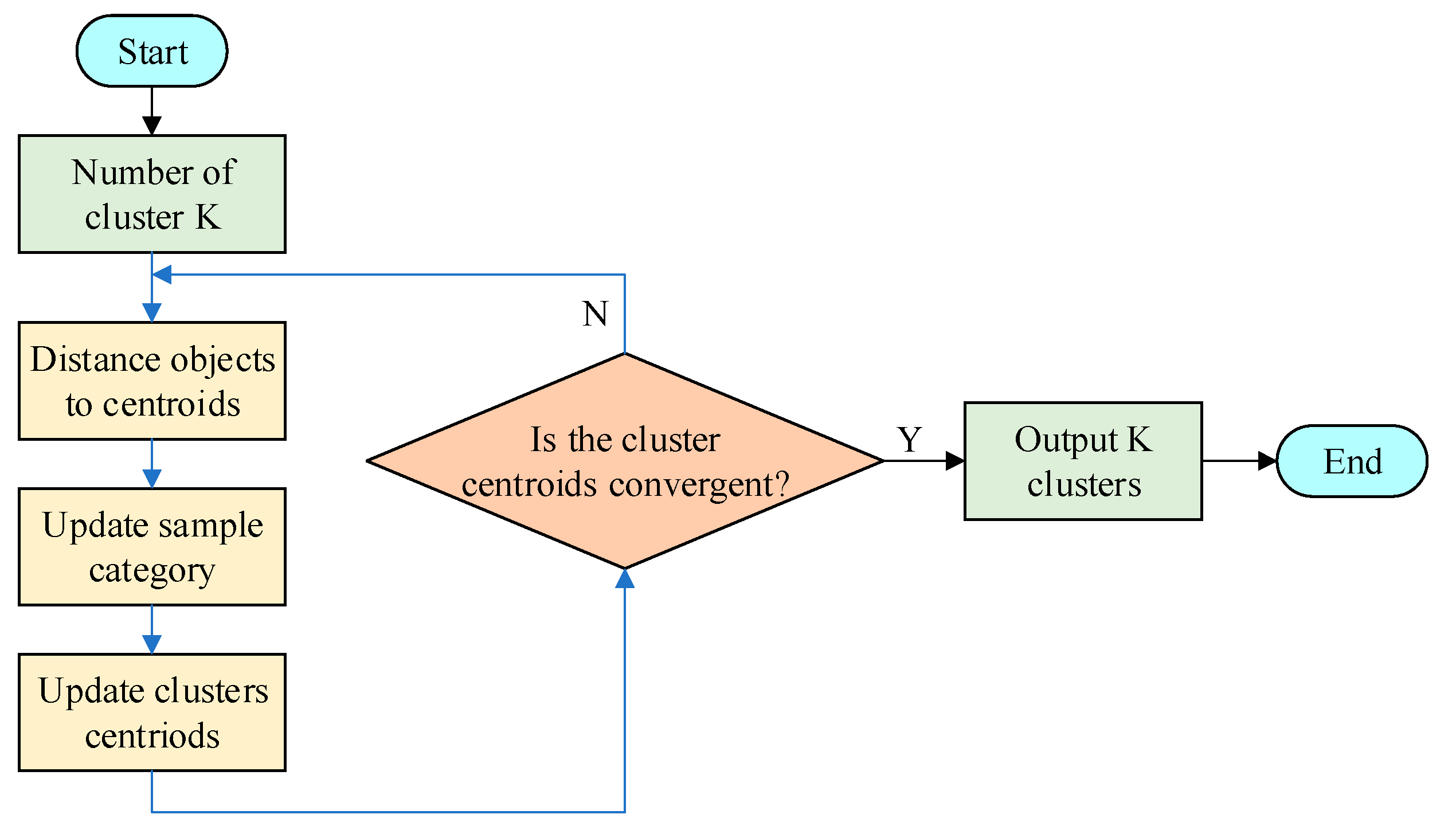

K-means clustering algorithm [

25] is subordinate to the partition clustering algorithm, which generally uses European distance as an index to measure the similarity between data objects. It has the advantages of simple process, fast operation speed, and good clustering effect. Therefore, we use the K-means clustering algorithm to analyze the machine learning dataset.

The process of the K-means clustering algorithm is shown in

Figure 9:

K objects are randomly selected as the initial cluster centers;

- 2.

Set iteration termination conditions

The maximum number of cycles

N or the sum of the squares of errors of the cluster center

SSE are usually set as the termination conditions. The calculation formula of

SSE is:

where,

is the data object,

is ith cluster center,

is the number of clusters;

- 3.

Update the cluster of the sample object

where

is the dimension of the data object,

and

are the jth attribute values of

and

.

The Euclidean distance of each data object to the cluster center is calculated by Equation (23), and the data object is allocated to the cluster close to the according to the distance criterion;

- 4.

Update the center of the cluster

where

is the new cluster center.

The new cluster center is recalculated for all sample points in by formula (24);

- 5.

Repeat steps 3 to 4 until the termination conditions in step 2 are met. Then, the iteration is stopped, and the clustering is completed.

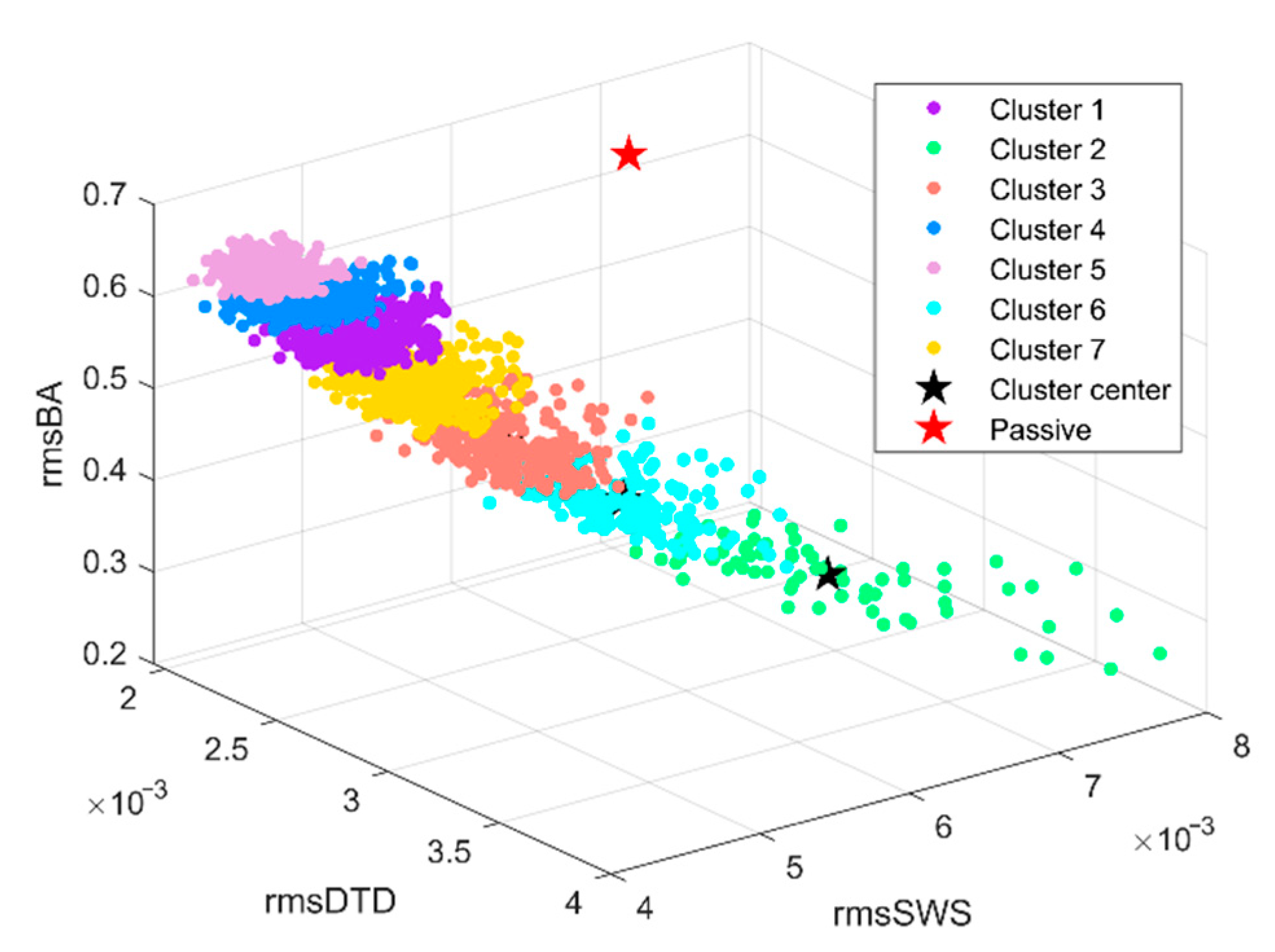

4.2.2. Evaluation of Clustering Results

The active suspension LQR controller studied in this paper changes 4 kinds of road classes, 6 kinds of speed, 50 weighting coefficients of DTD, and 50 weighting coefficients of SWS. The sample data of the machine learning dataset constructed after the simulation are so large that the clustering analysis cannot be carried out directly. Thus, keeping the road class and driving speed unchanged, a control variable method is used to divide the dataset into 24 subsets (i.e., 24 working conditions).

In this paper, the subset of B-class road under 20 m/s (B-20 subset for short) is taken as an example for cluster analysis, which is used to explore the rule information between the weighting coefficients and LQR control effect. The other subsets have the same analysis steps and similar clustering characteristics, which will not be repeated here. A K-means clustering program is written and run to cluster the sample data of the B-20 subset. This subset is divided into seven clusters according to the similarity of the three performance indexes. The clustering results are shown in

Figure 10:

As can be seen from

Figure 10, the sample data of the B-20 subset are divided into seven clusters, but there is lacking accurate data information to evaluate and analyze the results. Therefore, to accurately describe the clustering effect, the averages of each variable in each cluster are calculated, and all data are processed in ascending order according to the value of the suspension integral performance index

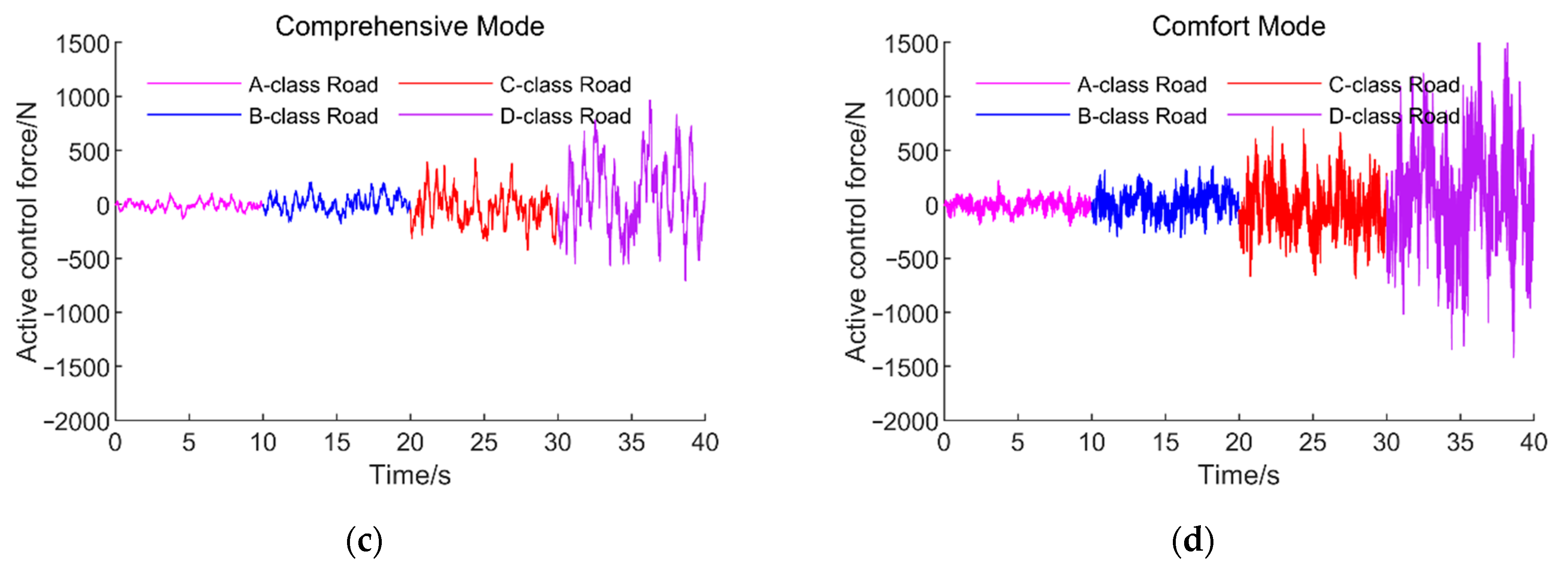

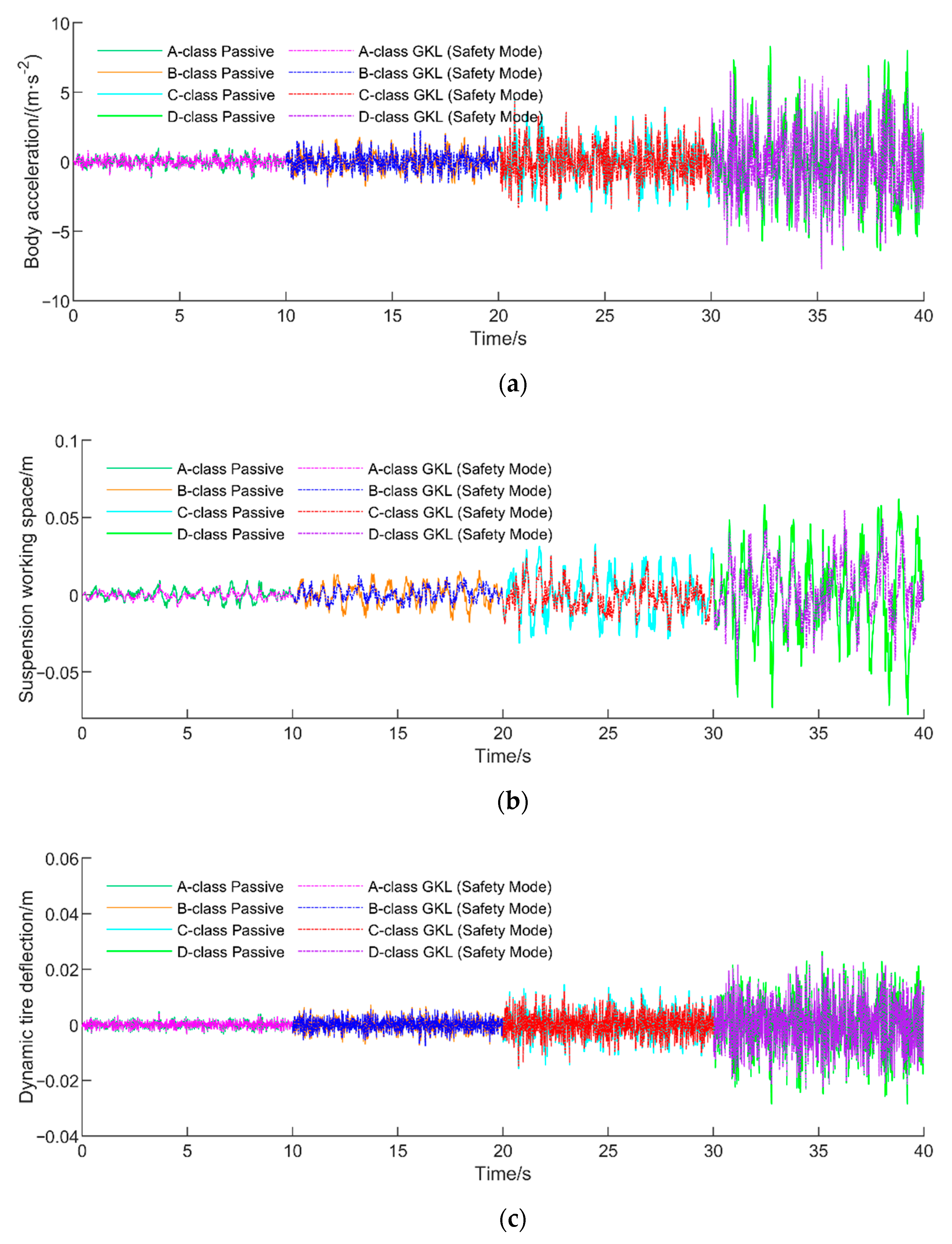

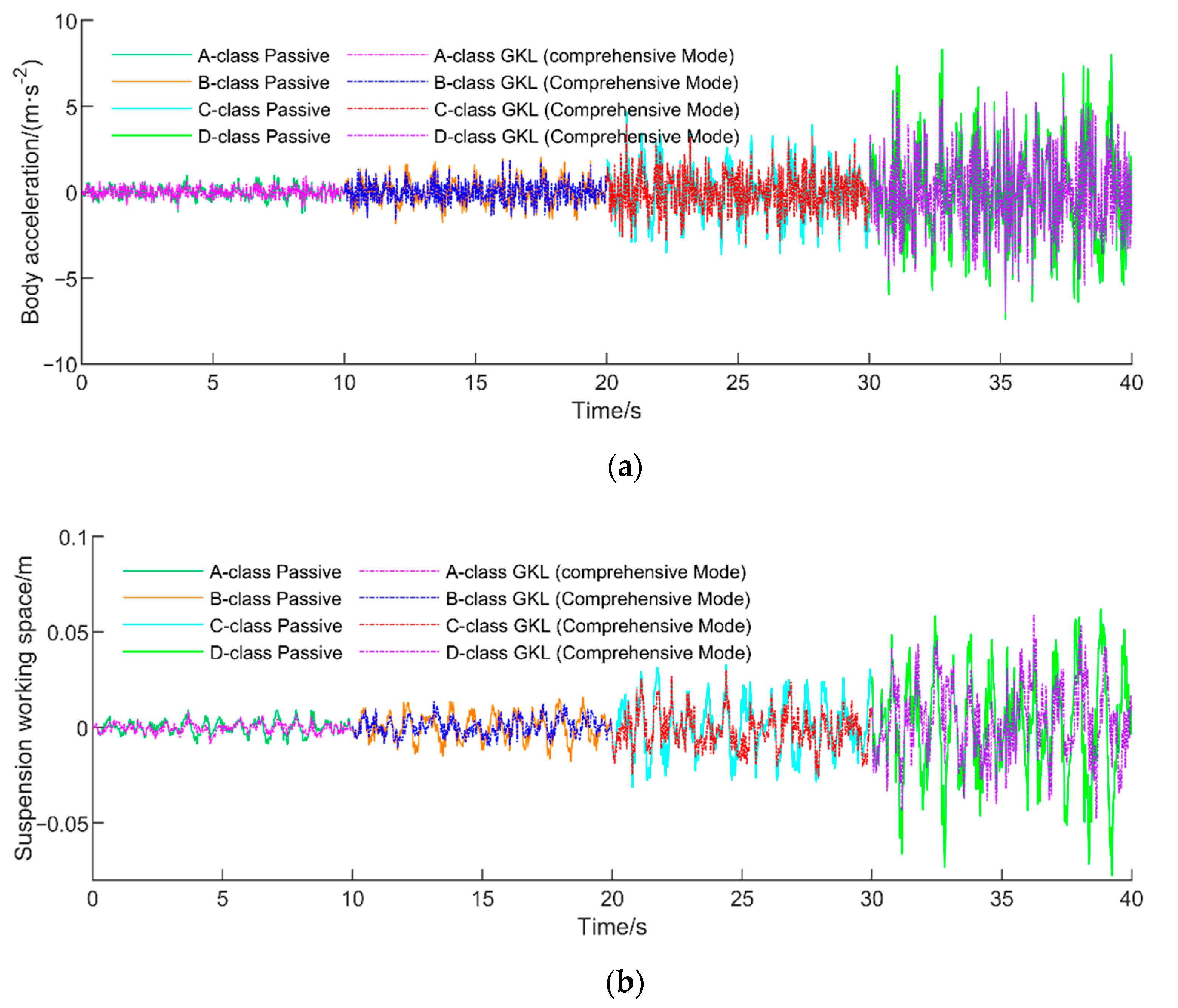

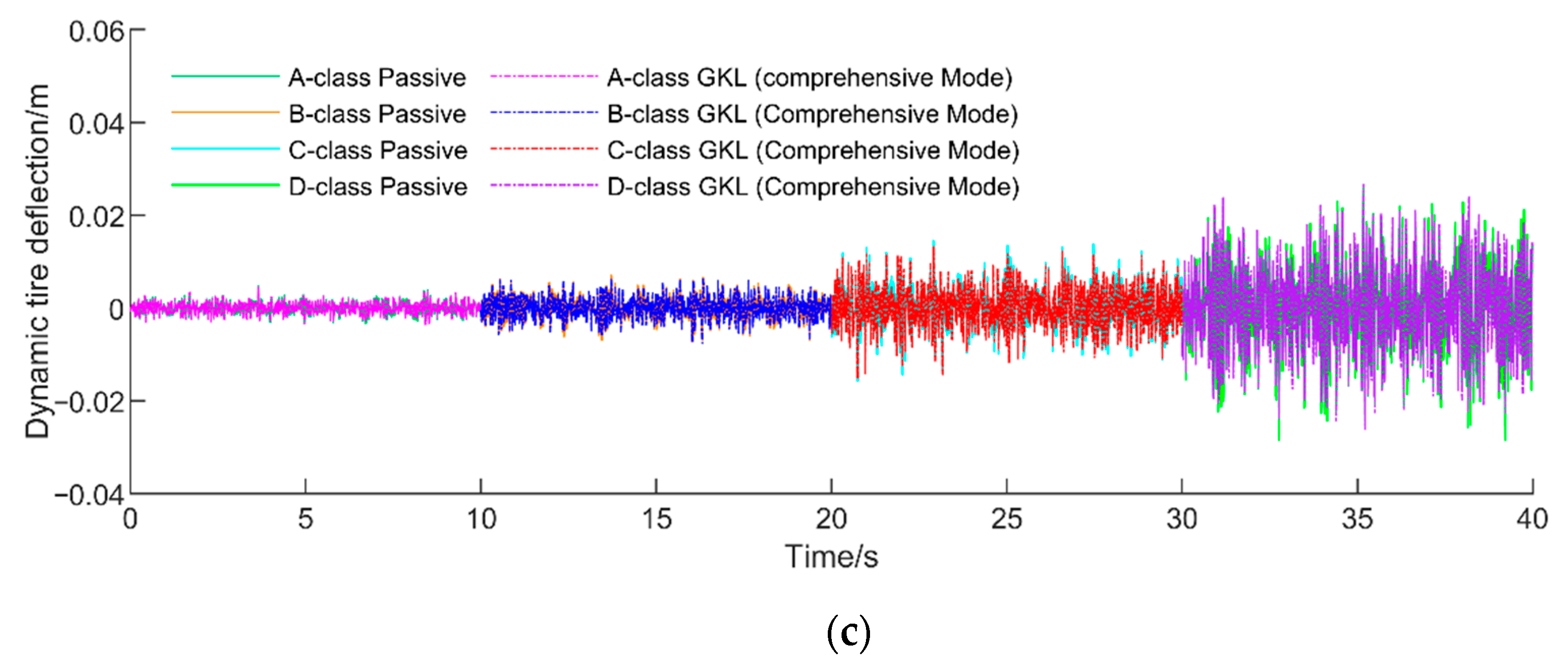

. Finally, all the control results are classified into three different suspension requirement modes, which are safety mode, comprehensive mode, and comfort mode. The optimal solutions for the weighting coefficients of each mode are computed. The clustering results are shown in

Table 5.

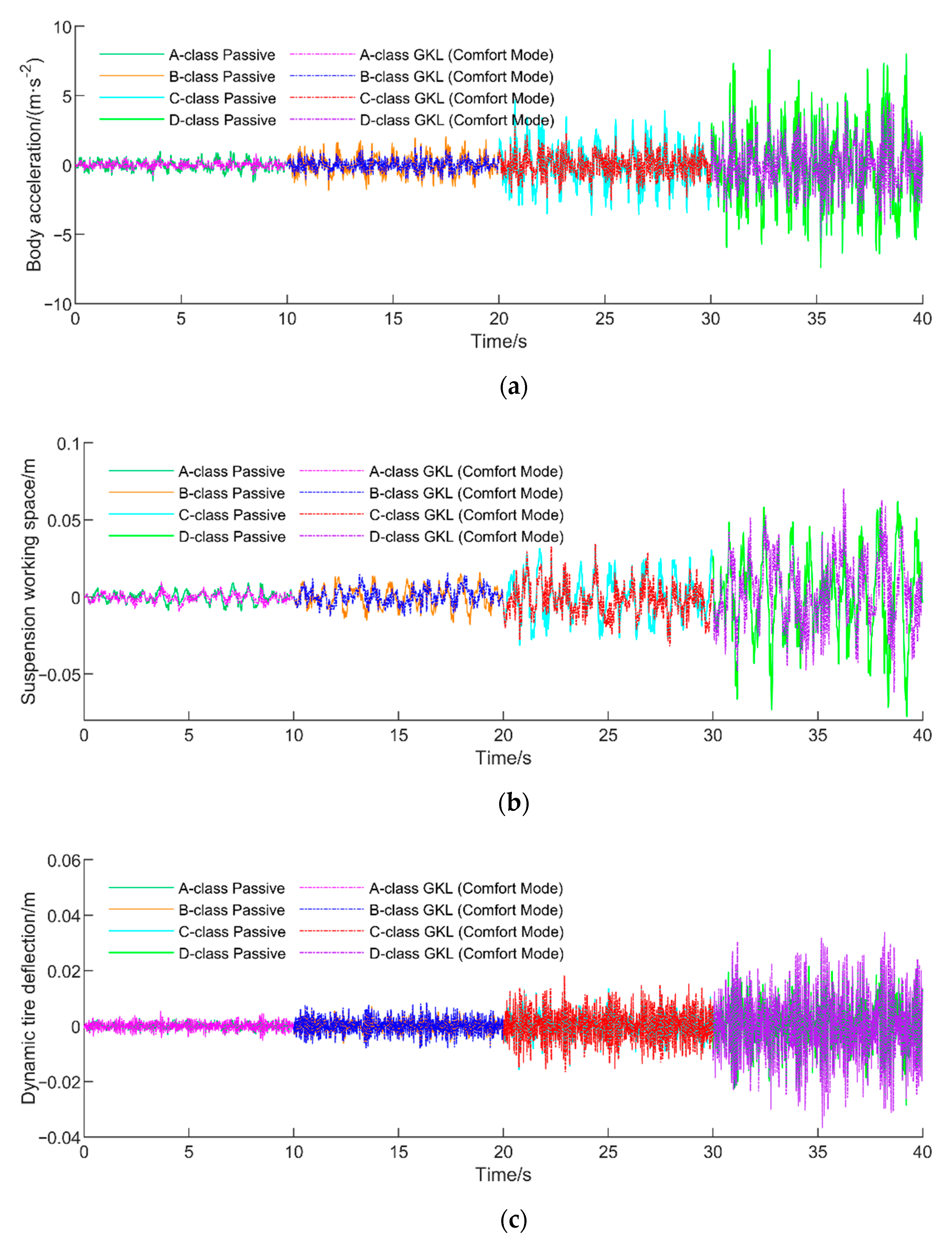

Compared with the RMS values of passive suspension, the optimization effect of BA in Cluster 2 is very good, and the optimization rate is as high as 48.23%. However, the DTD deteriorates significantly, and the deterioration rate is as high as 47.01%. Therefore, Cluster 2 should be deleted. For Cluster 5 and Cluster 4, the optimization effect of DTD is the best, which could be classified as safety mode. For Cluster 1 and Cluster 7, the optimization effect of each performance is good, which could be classified as comprehensive mode. For Cluster 3 and Cluster 2, the optimization effect of BA is the most prominent, which is classified as comfort mode.

The clustering results of the remaining 23 kinds of working conditions and the optimal weights of three performance modes can be obtained by the same clustering steps.

Table 6,

Table 7 and

Table 8 are the optimal solution and simulation results of safety mode, comprehensive mode, and comfort mode under B-class road, respectively.

Table 9 is the optimal solution and simulation results of comfort mode under C-class road. The others are not listed for simplification.

In

Table 6,

Table 7 and

Table 8, the six different rows represent the changes in driving speed. For each row, we performed 2500 simulations with random weighting coefficients. The listed

and

are the weight’s mean values after mode clustering. Then three performances, BA, SWS, and DTD, are calculated using these

and

. Therefore, the weights would change a lot in different modes, that is to say, the same row’s

and

are much different among the three tables. However, for the same mode (table), each weight matrix at a different speed may have close values. The analysis on the road changing is similar, comparing

Table 8 with

Table 9.

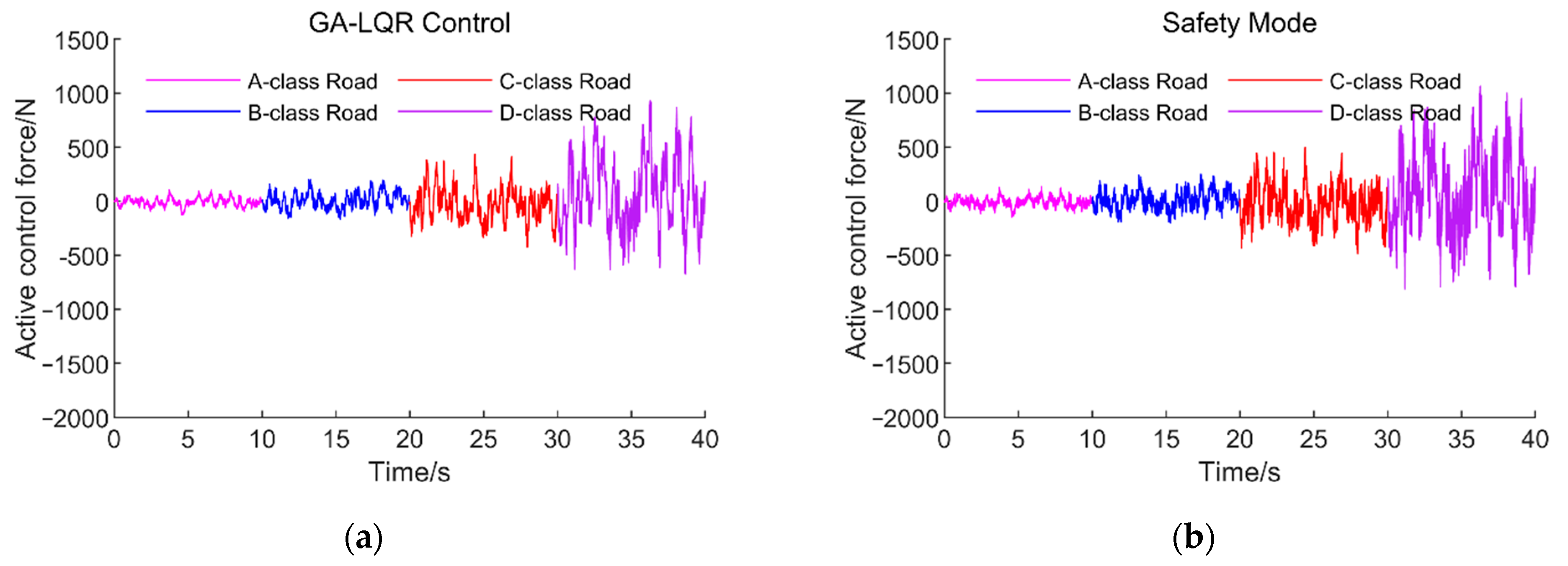

Comparing the data in

Table 6,

Table 7 and

Table 8, different modes have different changing rates of dBA, dSWS, and dDTD. The vehicle speed has less influence on the changing rate. There are diverse control effects of different modes. Comparing the data in

Table 7 and

Table 8, it can be known that the three changing rates change very little with road conditions and driving velocities. It may prove that our classification with the GKL algorithm could guarantee a stable control effect. Therefore, we could assume that the average values of weight

and

can be used securely. This assumption also shows good adaptability for the new GKL control. The final values of the optimal weighting coefficients for the three performance modes are shown in

Table 10.