Abstract

Monitoring the progress on a construction site during the construction phase is crucial. An inadequate understanding of the project status can lead to mistakes and inappropriate actions, causing delays and increased costs. Monitoring and controlling projects via digital tools would reduce the risk of error and enable timely corrective actions. Although there is currently a wide range of technologies for these purposes, these technologies and interoperability between them are still limited. Because of this, it is important to know the possibilities of integration and interoperability regarding their implementation. This article presents a bibliographic synthesis and interpretation of 30 nonconventional digital tools for monitoring progress in terms of field data capture technologies (FDCT) and communication and collaborative technologies (CT) that are responsible for information processing and management. This research aims to perform an integration and interoperability analysis of technologies to demonstrate their potential for monitoring and controlling construction projects during the execution phase. A network analysis was conducted, and the results suggest that the triad formed by building information modeling (BIM), unmanned aerial vehicles (UAVs) and photogrammetry is an effective tool; the use of this set extends not only to monitoring and control, but also to all phases of a project.

1. Introduction

The construction industry is an important and dynamic economic activity that is characterized by one of the economy’s reactivating mechanisms and by its contribution to the generation of employment; however, it has also been characterized by its low productivity [1,2]. Currently, the world economy is experiencing a major crisis caused by the COVID-19 pandemic. This public health emergency has presented a change in paradigms and challenges due to the lack of workers in the whole supply chain, extended closing of businesses in other areas of the economy and interruptions due to social distancing measures in existing projects [3]. These changes imply challenges for the reactivation of the economy, where strategies focus on digitalization and sustainability [4].

With the arrival of the Fourth Industrial Revolution, Industry 4.0 is a new paradigm that proposes to encourage the use of cyber physical systems; that is, technologies that enable the merging of virtual and physical worlds to create a real networked environment in which intelligent objects communicate and interact with each other [5]. In this context, the concept of Construction 4.0 has been proposed as a response to Industry 4.0 in the Architecture, Engineering, Construction and Operation (AECO) industry, which seeks to upgrade digitalization to improve the efficiency of production processes, business models and value chains. This transformation is possible due to the convergence of existing and emerging technologies, which promise to reformulate the way of designing and building the assets of the built environment [6,7].

Integration and interoperability are two key factors in Construction 4.0 [7]. Interoperability is the ability of two systems to understand each other and use the functionality of the other, which represents the ability of two systems to exchange data and share information and knowledge. Integration of information systems achieves seamless cooperation between organizations and industries [8]. The traditional method, which involves manual tracking of construction progress, still dominates the AECO industry [9]. Current monitoring practices during the execution of a construction project require multiple inspections, which are time intensive and may, by their nature, include mistakes. Therefore, a reliable monitoring system that can provide early detection and notification of project problems, whether actual or potential, is necessary [10]. In this context, the application of several technologies has great potential to improve management practices in the construction industry [11]. The advances in digital technologies that have been established in many productive sectors are permeating the AECO industry [8] at less accelerated rates [12].

The goal of this research is to perform an interoperability analysis of digital tools for monitoring and controlling construction projects during the execution phase. For this purpose, innovative technologies that are classified according to their use, in this case, field data capture technologies (FDCT) and communication and collaboration technologies (CT), which are responsible for the processing and management of information, are revised. Although these technologies have unique advantages, they often offer integration with other technologies, allowing for the formation of more powerful hybrid systems with more than a single intelligence dimension.

2. Background

Management methods are the set of actions framed in a prototype that allow for directing the activities of a public or private organization; their purpose may have one or more objectives that are aimed at achieving greater productivity in all human activities [13]. Methodologies are generally approached in different ways, many of them known and common among a high number of engineering and construction companies, with the same guidelines for decades, which have become examples to follow and/or apply [14]. Multiple problems affect the performance of projects in the construction industry, including lower labor productivity, inadequate identification of design requirements and lack of standardized construction management. Therefore, the integration of projects is essential for success, and the collaboration of different specialties in the supply chain allows for effective interaction, keeping the budget and schedule in the expected parameters [15].

The planning and control of a construction project is the process of defining, coordinating and determining the order in which activities should be carried out. The objective is to execute the most efficient and economical use of available equipment, elements and resources. For this purpose, a work plan, which must be controlled throughout the project to evaluate its compliance, is established and defined. Two actions that must be carried out in this recursive process are to carry out pertinent revisions or modifications and to eliminate unnecessary diversification of efforts. Both actions are framed in the final objective set since the beginning of a project [16]. Currently, as a result of technological advancements, new techniques that allow for remote and automated management have been incorporated to obtain information from the digitalization of the construction [8].

2.1. Traditional Construction Monitoring and Control System

The planning and control of a project is one of the key processes for the adequate development of the project and the success of each of its phases during its life cycle. Appropriate planning allows for the explicit definition of the work to be done, risk identification, consideration of different scenarios and the attainment of solutions. Adequate control offers the possibility of detecting deviations, informing on time the anomalies, allowing for their correction and ensuring the quality of a project [14]. Establishing a system to ensure the correct execution of the work is fundamental and must be adapted to the nature of each project and its environment. For this reason, there are different methodologies to carry out project management, that is, the application of knowledge, skills, tools and techniques to the activities of a project to comply with its requirements [17].

According to some studies, control tasks using traditional methods generate difficulties for information management caused by imprecise manual documentation and deferred data collection, which leads to delays in decision making [18]. It is common that a lack of opportune information about the actual state causes problems to remain unresolved and prevents field engineering staff from solving them in an opportune amount of time. An incorrect understanding of the current situation can cause errors and inappropriate adjustments by the management team, which could result in further delays and increased costs [19].

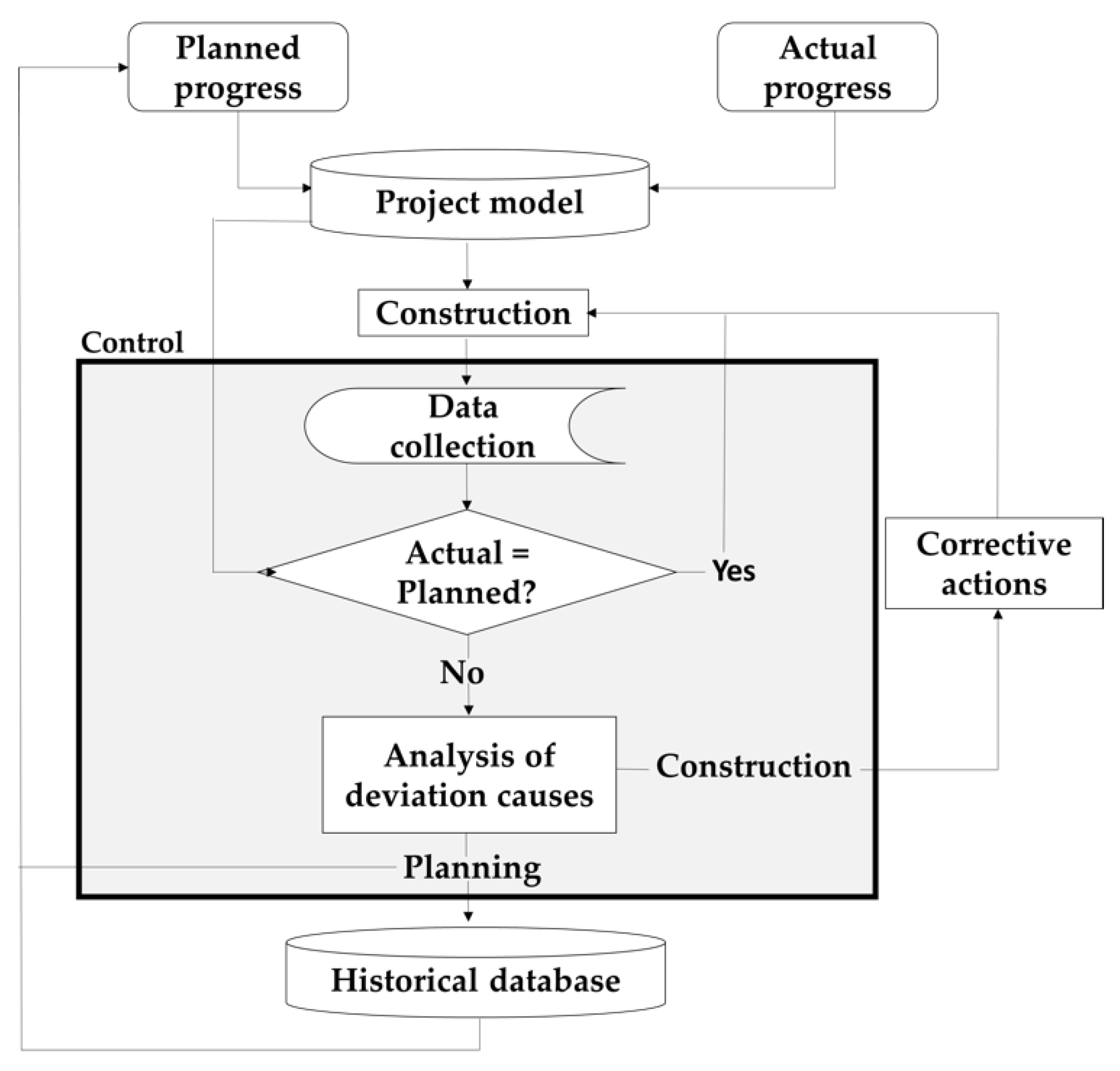

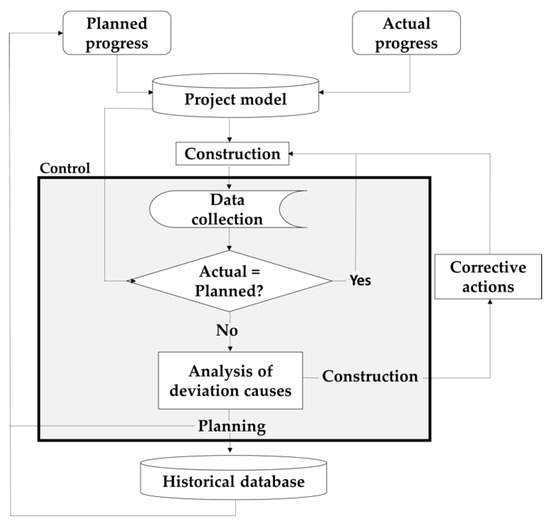

The set of monitoring and control activities consists of the processes required to monitor, analyze and regulate the progress and performance of a project, to identify areas where the plan requires changes and to make the corresponding modifications [20]. In this sense, because of the dynamism in a project, maintaining daily control can have a considerable impact, providing greater precision around the schedule and costs to comply with the scope defined in the project [21]. To carry out progress control, it is fundamental to have a work program to know when, with what and how the works will be executed. During the construction phase, it is relevant to know if the work is being performed according to the established schedule. An accurate evaluation of progress allows project managers to make adjustments to minimize costs that lead to program deviations [10] (Figure 1).

Figure 1.

Schematic of model for real-time closed loop control. Adapted from [22].

Figure 1 shows a schematic of a model for real-time closed loop control. In this model, it is necessary to establish a control system that can regularly keep project managers informed of the progress made in each activity. In the case of delay or deficiency in any activity, this system enables time-sensitive corrections, either by increasing the number of workers, changing the equipment or correcting the work program. If it is verified in an opportune way that there was a planning mistake, and it is possible, although with modifications, to maintain the original program, then it will be possible to fulfill the delivery terms. If these corrections are not made on time, it is difficult to continue with the initial project schedule, and a new plan will have to be constructed, whose application will certainly mean disorders and greater project costs [23]. Therefore, the objective of monitoring is to ensure compliance with the objectives and goals proposed by the plan during its implementation, alerting any difficulties and relieving pending or delayed tasks, and allowing visualization of complementary actions by making the necessary adjustments. It is worth noting that for the monitoring of a plan, it is necessary to establish methodologically how information about projects and management measures will be obtained to understand the plan’s progress and facilitate its control. This approach allows for the comparison between the baseline of the plan and its actual execution, consequently identifying the gap between what was proposed and what was achieved and defining corrective and preventive actions that minimize these gaps [17].

The practice of monitoring and control in the tracking of work, based on traditional techniques, has become indispensable for any construction project. It is common that the activities that include the management of information are based on collecting the information in the field, which is documented manually for its subsequent digitalization. The employees in charge of creating reports using this process devote between 28% and 41% of their daily time to doing so. Because information is scattered among multiple documents, which may exclude data, the traditional approach is slow and inefficient. Similarly, the construction industry makes little use of technical resources, making it difficult to track building projects due to the lack of automated processes [18].

2.2. Digitized Construction Monitoring

The current requirements presented by the AECO industry demand the application of modern monitoring and control methods and tools by companies in order to meet regulatory requirements and improve the competitiveness of companies in the construction market [24]. In this respect, increasing productivity implies the improvement in various processes by the use of new technologies and construction procedures [25]. Successful construction management requires the integration of processes, technologies and people to achieve its objectives [26], where information on the progress of a project offers a continuous diagnosis of it, allowing the different members of a team to make appropriate decisions about any measure to save the project and ensure its completion [27]. Technology is slowly paving the way for technologically supported project management practices in construction, for transforming and allowing the establishment of new tools for remote monitoring and for allowing for automation of the supervision of construction progress, improvement in data acquisition and, consequently, improvements in decision-making in project management to meet objectives and ensure productivity [28].

The continuous development of technology has made it possible to effectively solve practical problems associated with the AECO industry. [29]. Therefore, the development of digitized construction monitoring has the main purpose of developing the connection between traditional or existing methods and new technological systems. The basic theory for developing such a model is to extend the traditional approach so that construction operations become dynamic and simultaneous [30]. The World Economic Forum (2016) developed a transformational framework for the construction industry that lists 30 best practice measures. The three most important components of the transformation of its traditional approach are the following: (i) being open to innovation to take advantage of the opportunities offered by new technologies, materials and tools to reduce production costs; (ii) considering the adoption of mechanized and automated production systems with offsite construction techniques to accelerate the construction process and improve the timely completion of projects in a collaborative environment; and (iii) the role of project management and cost control in the design and planning stages [31].

It has been mentioned that the construction industry has been criticized for its slow adoption of emerging technologies. However, in recent years this trend has changed. The rapid growth of the availability and power of technologies, with their continuously decreasing cost, has allowed them to be adopted and considered an effective tool for the analysis of massive data for the purpose of monitoring and controlling the progress of projects [32]. During recent decades, research efforts have been made towards advanced 4D planning models by integrating three-dimensional (3D) models with the time parameter [30].

There is an evident need to develop an integrated model to automate the current practice, since monitoring and manual control have not produced the expected results. Efficient management can be obstructed by lost time in information recovery, poor structuring and delayed communications [33]. Manual monitoring is labor intensive and often requires a choice between monitoring based on rough estimates or spending a lot of time collecting and processing data. [34].

Introducing digitized construction monitoring in the construction phase would allow project managers and site engineers to more effectively and accurately monitor project progress. Therefore, this system will improve the decision-making process and productivity and reduce claims for delays [30]. Each team member needs to know, in a timely and accurate manner, the progress of the project and the current status to contrast such information with the originally established plans [35].

Some research has shown that monitoring of work and comparison with the project baseline can be used to assess work in progress, providing an accuracy error of less than 20% [22]. Studies in the literature indicate that greater standardization of work will make the application of automated procedures less complex [36]. For this reason, the means to represent possible discrepancies between planned progress and constructed progress is an important factor in facilitating decisions on corrective measures [10].

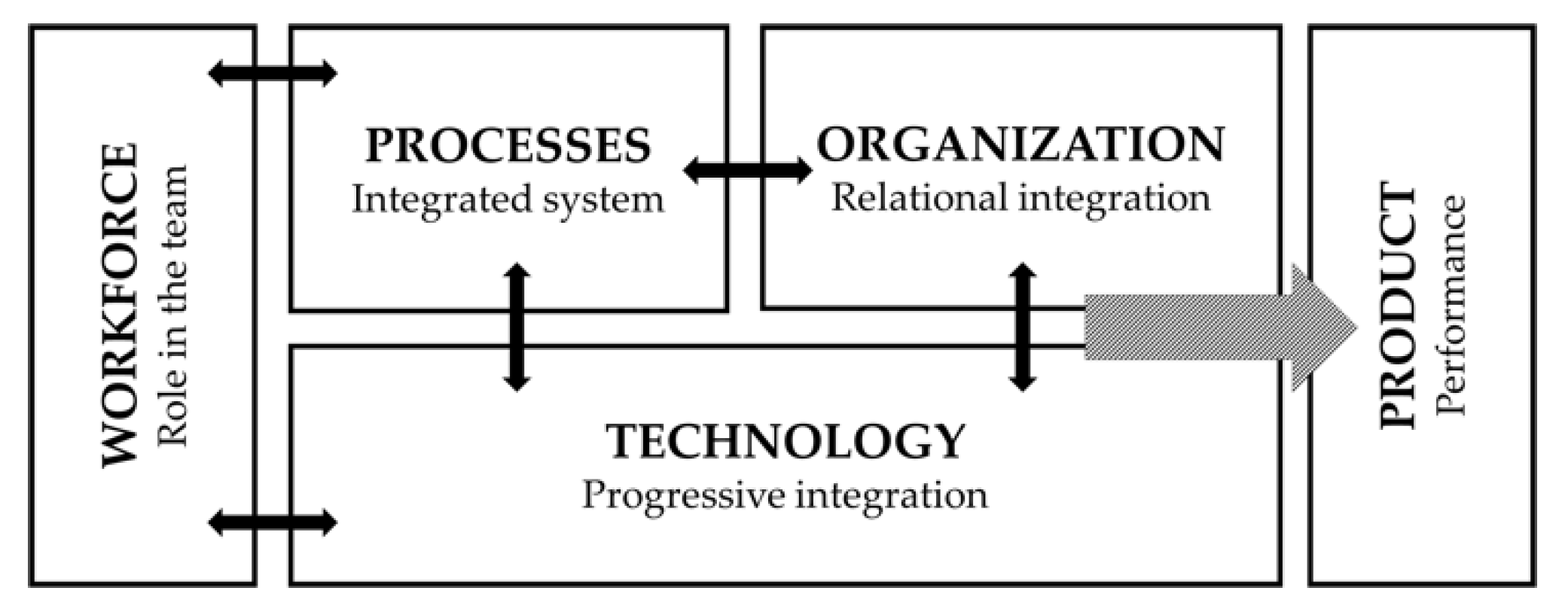

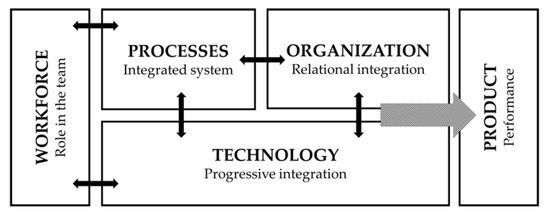

The results of the adoption of digital approaches in construction are increasingly showing positive results; for example, projects that would otherwise present a high risk of cost overruns are being delivered on time and within budget. The implementation of digital tools allows for the integration of teams, processes and organizations, reducing the problem of fragmentation present in traditional methods [31] (Figure 2).

Figure 2.

Integrated construction environment. Adapted from [31].

In the last few years, with the increasing level of competition in the AECO industry, research efforts have focused on the application of information technology as a way to improve the process of integration of construction supply chain management [37]. This collaboration has emerged as computer-assisted collaborative learning, facilitating interactions between two or more individuals who may be geographically and/or temporally separated [31]. As a result, there is a need to adapt technology to improve design and planning processes in a common and secure data environment (CDE). This type of environment allows for the integrated collaboration of project participants and their interaction via accessible information that supports decision making [38]. This concept could be achieved by using different technologies that provide a richness of varied and complementary information, facilitating the joint work of the teams via collaborative work and problem solving without considering the geographical distance. These technologies could also work both synchronously and asynchronously, allowing for the sharing of documents not only anywhere, but also at all times. In this way, the provided tools help communication and collaboration and provide a means of solving problems in the early stages of the project [31].

3. Materials and Methods

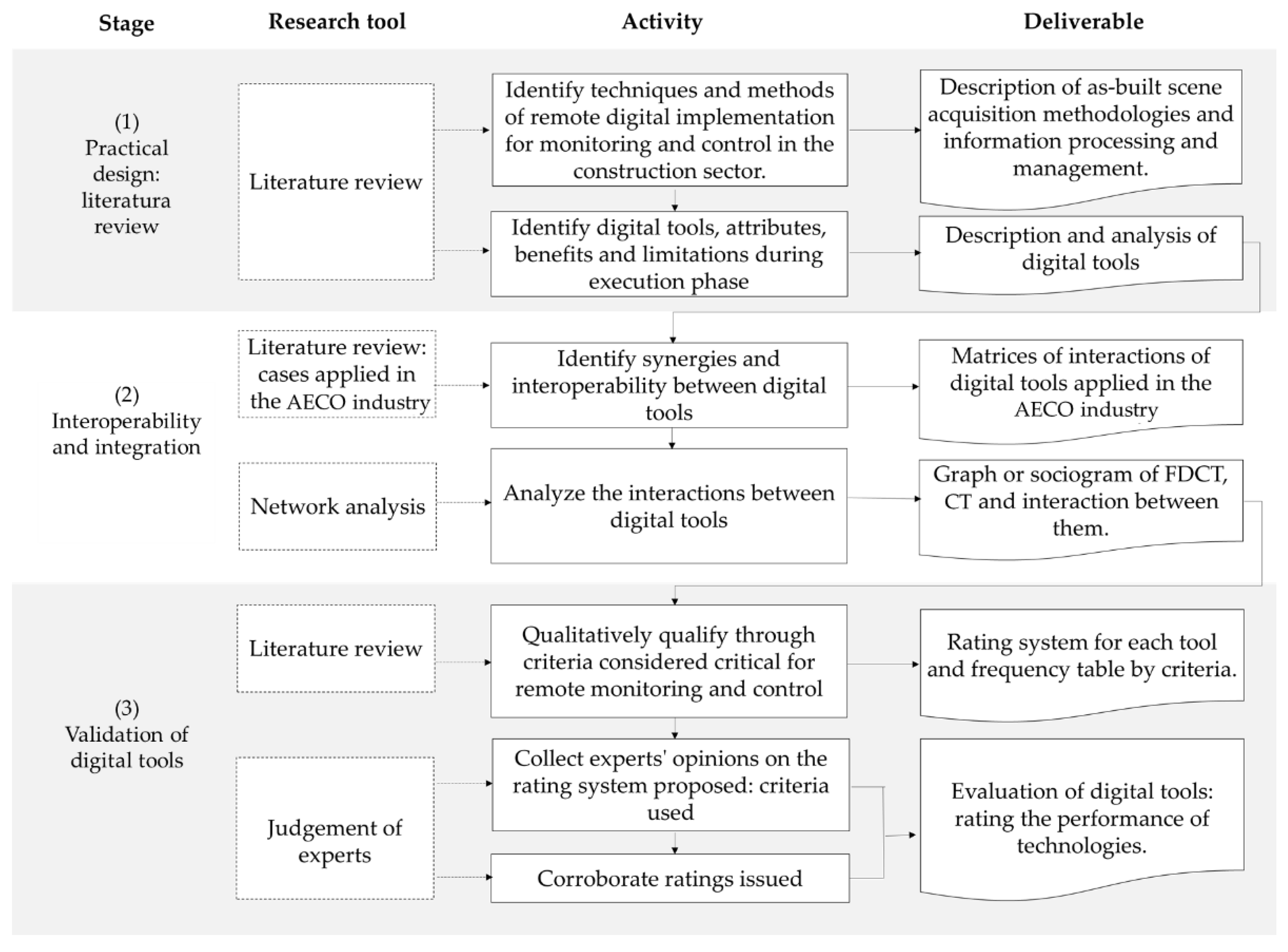

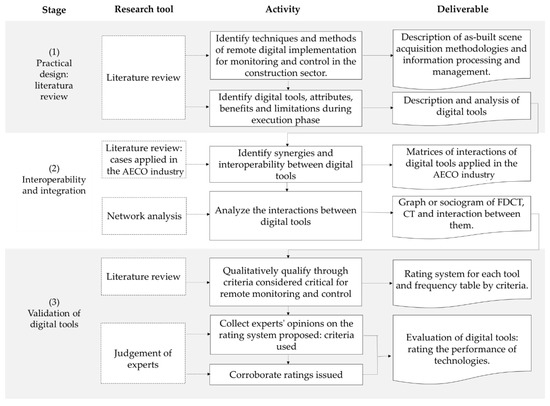

To achieve the objective of this study, the research was divided into three stages: (1) the design of remote monitoring and control practices—the literature review; (2) interoperability and integration; and (3) the validation of digital tools. Figure 3 shows the research tools used to perform each activity and their respective deliverables.

Figure 3.

Three stages of the research method.

In the first stage, we identified and selected the techniques and methods that have a potential use for monitoring and control during the construction or execution phase of projects. These are presented with a brief description of their benefits, limitations and application in the AECO industry. In the second stage, the synergies and interoperability shared by different digital tools are identified, performing an exhaustive analysis of the interactions presented. In the third stage, the main researcher qualified the tools based on criteria considered critical to achieve satisfactory performance based on the deliverables of stages 1 and 2. Five experts were invited to validate these tools by means of corrections, suggestions and comments about the proposed evaluation.

3.1. Stage 1: Practice Design—Literature Review

A literature review of journals specialized in engineering and construction project management and of the proceedings of the main conferences held between 2012 and 2020 was conducted. The search was carried out in the following libraries: Google Scholar, ResearchGate, Engineering Village, Web of Science and Scopus. The search topics were automated progress monitoring, monitoring system, progress monitoring, as-built as-planned comparison, construction method into automated progress monitoring techniques, management model for construction monitoring and control, digitalizing construction monitoring, constructions phases, construction management, construction progress, interoperability, real-time monitoring and Industry 4.0.

The articles were selected by applying three inclusion/exclusion criteria: (1) innovation, (2) technology and (3) adoption of monitoring and control systems. For monitoring and information gathering, the distinction is made between (a) field data capture technologies (FDCT), which refers to sensing techniques used to capture as-built scenes, and (b) communication and collaboration technologies (CT), which are responsible for processing and managing as-built data information.

3.2. Stage 2: Interoperability and Integration

Seamless data exchange between FDCT and CT should be performed based on the search for the interoperability between them. In the search for relevant studies, technologies that have application support in the AECO industry were examined. A literature review was conducted in specialized journals in engineering and construction project management and of the proceedings of the main conferences, and a search was carried out in the following libraries: Google Scholar, ResearchGate and Scopus. The equations in the search process are presented in Table 1, where the keywords and respective Boolean operators are presented.

Table 1.

Keywords and Boolean operators used to identify relevant studies.

The articles were selected by applying three inclusion/exclusion criteria: (1) the case of monitoring and control during the execution stage; (2) being linked to one of the following areas—progress, machinery operation, intelligent construction or productivity; and (3) the most recent case of application. With the information obtained, three relationship matrices were elaborated with the possible combinations between the investigated tools for FDCT, CT and the integration between both.

All combinatorics without repetition between pairs of technologies were performed for the three search groups executed, according to Table 1. Table 2 identifies the total technologies per relationship matrix and the potential interoperability cases present in the AIC industry. The possible combinatorics are calculated according to Equation (1), where n is the total number of technologies to be chosen and r is the chosen technologies.

Table 2.

Details of combinatorics generated according to the relationship matrix.

The results are presented in three relationship matrices. In the case of intra-connections, they are represented by a square matrix of upper triangular type of dimension nxn, where n is the number of technologies identified, particularly 7 × 7 and 23 × 23. On the other hand, the interconnections are given by the dimensions between rows and columns, where the rows represent the CTs and the columns represent the FDCTs, with dimensions of 23 × 7. When there is a link between two technologies, the box contains the corresponding reference declaring the link. Otherwise, it is represented by an X.

For network analysis, the concepts of full inter- or intra-connections are employed, the former for connections between the same type of technology subcategory and the latter for cases of different subcategories, where only the interactions between FDCT and CT, and not the relationships between the same subcategories, are measured. To obtain global information, i.e., interactions between the inter-array connections of FDCT and CT and the intra-array connections, the concept of full is utilized.

In addition, a tool that allows for interconnecting the elements and facilitating the dissemination and understanding of the results is network analysis, which allows for visualizing the interconnected elements and thus performing an analysis of the existing relationships via graph theory; for this purpose, the free software Gephi 0.9.2 was employed. The metrics applied for network analysis are described in Table 3.

Table 3.

Description of metrics used in network analysis. Adapted from [39].

3.3. Stage 3: Validation of Digital Tools

Two rating systems were developed for criteria considered critical to enable the automation of a monitoring and control system, according to the previously mentioned subdivision according to their function, i.e., information capture and communication and collaboration. Scores are provided according to the qualification obtained, i.e., satisfactory performance, intermediate performance and poor performance, marked with white, gray and black, respectively. Likewise, a score was assigned with values of 2, 1 and 0. For each of the criteria, a brief explanation is presented, as shown in Table 4 and Table 5.

Table 4.

Criteria scoring system for FDCT. Adapted from [10].

Table 5.

Criteria scoring system for CT. Adapted from [9].

In the case of FDCT, six criteria are considered as follows: usability, time efficiency, accuracy, level of automation, training required and equipment [10]. On the other hand, for CTs, six criteria are considered as follows: interoperability, virtualization, decentralization, real-time capability, service orientation and flexibility [8].

The ratings were assigned based on the information obtained in the first and second stages of this research. Although each of the explored technologies has unique advantages and limitations, this rating is framed to the application for monitoring and control in the execution stage. It is worth mentioning that there are criteria that do not apply to certain technologies, in which case they are registered with the acronym NA.

Additionally, the ratings were grouped according to the frequency obtained for each of the criteria, so that the results have greater representativeness, thus avoiding the linearity of the criteria, since the choice of one technology over another depends on factors such as application, accuracy and the scale of the project. For this reason, the adopters determine which factor or factors they wish to prioritize.

These qualifications were then validated by means of an expert judgment made up of academics and researchers. The experts summoned had to meet the following criteria: (i) more than 10 years of experience in the field of monitoring and control of works and (ii) experience in the application or research in management models for monitoring and control of civil works via the remote adoption of digital tools. Thus, five experts were invited to participate in this research (Table 6).

Table 6.

Characterization of expert judgment.

4. Results and Discussion

4.1. Cyber-Physical Systems

A cyber-physical system is made up of layers and components specialized to processing, communication, sensing and control functions. Multiple devices, hardware components, computational resources and sensors are all connected by communication protocols. Actuators, machines, robots and devices all have computing resources that are responsible for local decision making and onboard control. On the other hand, more centralized systems acquire and process data from a variety of sources. Higher-level computational processes may be responsible for autonomous or semiautonomous decision making at the system level, whereas control algorithms may be utilized to maintain the process-specific parameters of a device or machine [8].

Additionally, 3D data structures are significant in the architecture and construction domains; they are used to record both design intents and the as-built condition. Multiple input and monitoring devices, such as user interfaces and displays, may be included in a cyber-physical system [8]. Deferred information and inefficient communication among project stakeholders limit the efficiency of construction monitoring. Therefore, it is necessary to inquire about collaborative work procedures, where the collection, analysis and dissemination of information are standardized [29].

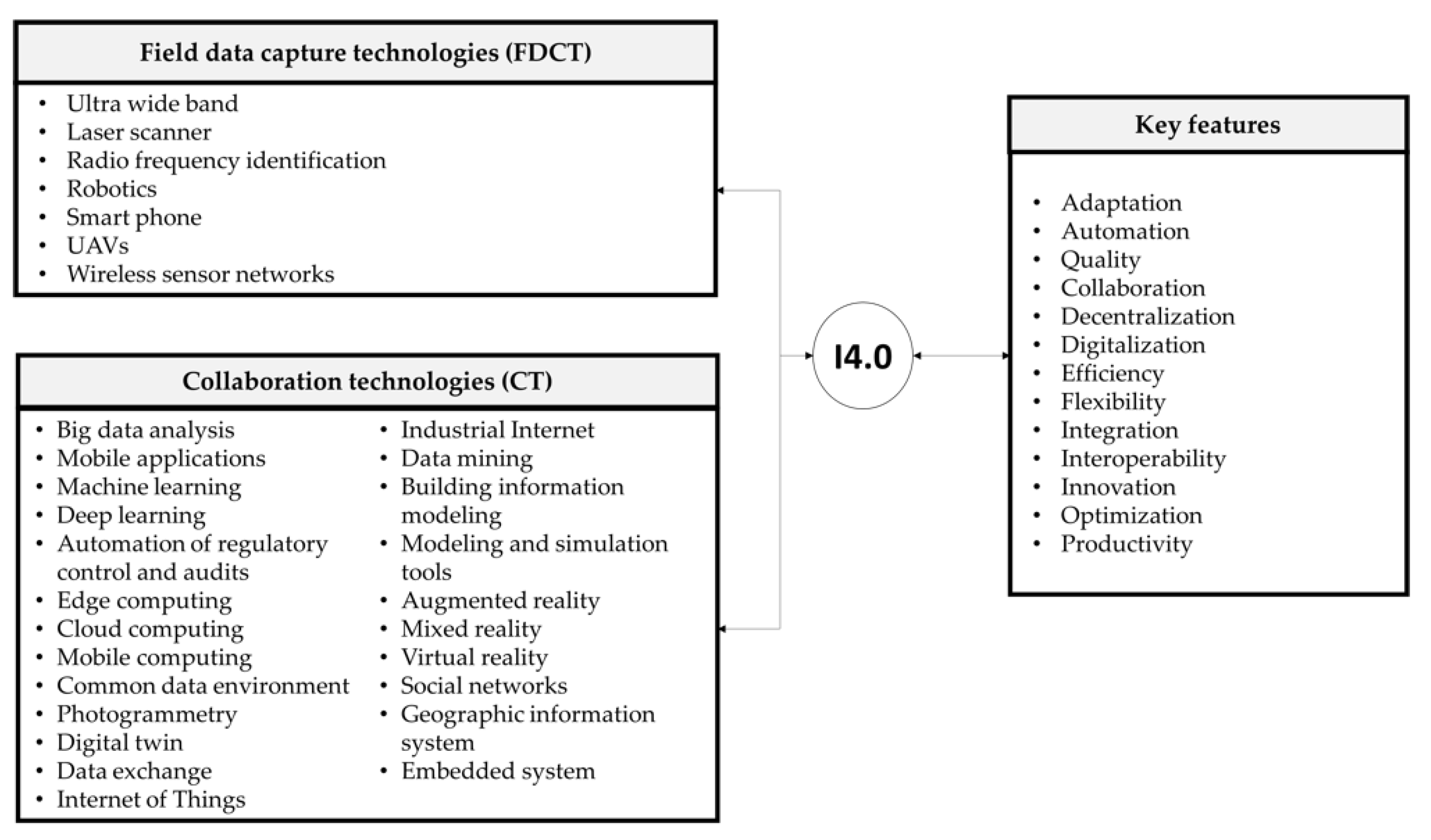

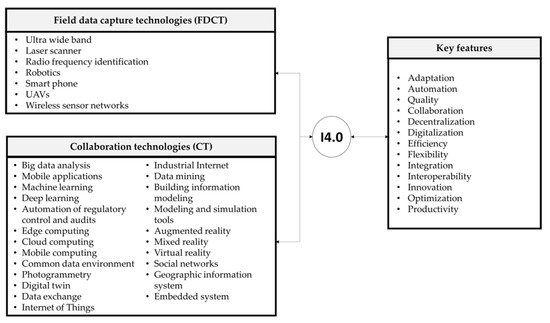

Based on these findings, the variation between the planned and executed schedule and budget of construction projects is due to the absence of a system that integrates the necessary tools to manage this type of project, from their planning and design to their execution, follow-up and control [40]. Emphasizing the last-mentioned stage, we examine the tools whose innovative use of technology allows for the monitoring of progress in projects, which are shown in Figure 4, classified according to their data capture (FDCT) or collaboration (CT) status, where the main key characteristics associated with Industry 4.0 can be distinguished.

Figure 4.

Key technologies and features of Industry 4.0. Adapted from [8].

4.1.1. Field Data Capture Technologies (FDCT)

Progress data have encouraged many researchers and practitioners to introduce various data acquisition technologies via digitization and an automated process of continuous and accurate monitoring of all activities. With these technologies, a better diagnosis and prognosis for the whole construction process is facilitated, with a direct impact on the improvement of production capacities [41]. Construction 4.0 proposes automating and digitizing design and construction processes, with a heavy focus on real-time data capture and technology integration in on-site construction. Some of these technologies have already been tried and used in construction, yielding some promising but limited outcomes; hence, Construction 4 is currently being implemented [41].

Technologies have proven their effectiveness in different functions, such as detection, counting, object identification, measurement of execution times and speeds, quality control, site conditions, location and tracking of elements [42]. To automate the tracking of construction progress, several methods can be used with different types of data acquisition; among the most used are imaging techniques and geospatial techniques [33].

These technologies are characterized according to their capture, visualization and/or geospatial pressure capabilities. Vision-based technologies, such as digital imaging, have enabled the development of civil engineering-related applications that aid in the design, construction and maintenance of construction projects [37]. Visual information from regions that are difficult to access can be easily collected; for example, daily photographs arranged in chronological order make it possible to track changes at a construction site. Therefore, there is the possibility to control the oldest state of the stored information, as all of them are collected in a database [43]. Studies using vision-based technologies for progress monitoring can be grouped into three categories: (i) studies on the generation of as-built 3D models integrated with BIM, (ii) studies using image processing and machine learning methods to monitor the construction progress and (iii) studies using unmanned aerial vehicles for autonomous data collection [44]. In recent years, the focus of researchers has been the use of unmanned aerial vehicles (UAVs) or drones that can be employed for photographic surveys to develop accurate three-dimensional models for intelligent monitoring of the construction progress of large-scale projects [45]. The use of unmanned aerial vehicles (UAVs) or drones has captured the attention of researchers and professionals [46]. UAVs can be employed in different uses depending on the types of sensors that are incorporated in the equipment [47]. Using UAVs with a camera sensor, UAVs allow for photographic surveys to develop accurate three-dimensional models for various applications, such as intelligent monitoring of the construction progress of large-scale projects [45,48], emergency assistance [49] and industrial operations safety monitoring [50,51,52].

It is common for several of these methods, such as laser scanning, photogrammetry and videogrammetry, to generate three-dimensional point clouds, which allow for the construction of as-built models that give the opportunity to identify the progress at a construction site from various angles and, thus, evaluate the current progress of a project. Among these methods, photogrammetry is the most economical and efficient technique for obtaining a 3D point cloud, which is necessary for progress documentation [53]. Additionally, data fusion using overlapping time frames or overlapping location information from multiple sources is possible by matching the same timestamps or locations. In this way, it is possible to validate the geometry of 3D models with geospatial techniques, such as GPS coordinates, and thus perform centimeter-level precision measurements, such as length, area, and volume measurements [43]. These accuracy measurements make it possible to evaluate the amount of work performed and efficiently and accurately identify construction deviations [19]. There are a considerable number of studies on outdoor progress monitoring; however, research on indoor progress monitoring is lacking. Researchers have used image processing methods or laser scanners but have not utilized photogrammetry [19]. Machine teams, robots and employees can collaborate on shared building activities thanks to device-to-device communication, which can connect many concurrent processes and enable new modalities of construction. These possibilities come with obstacles and necessitate the development of new enabling technologies, such as domain-specific hardware and software tools tailored to the needs and restrictions of the construction industry [54]. The use of the technologies could be conditioned to meteorological conditions [55]. In the case of the use of UAVs and image capture, recreational and semi-professional drones may not be prepared to withstand rain, for example. Additionally, light conditions on a sunny or cloudy day may affect the quality of the images, so it is necessary to consider weather conditions when planning flights [55,56,57].

4.1.2. Communication and Collaboration Technologies (CT)

Industry 4.0 generates a large amount of data. This information needs to be processed, analyzed and used efficiently, which demands solid technological management. By definition, this data management must occur in real time and needs human support. [58]. In this sense, the quality of the information generated, its efficiency, the format in which it is transferred, its applications and its subsequent uses are key elements for effective management [35] for correct processing to provide meaningful information [59]. The application of virtual collaboration in construction necessitates the use of various novel technologies and communications, collaboration software and visualization applications to create a better collaborative environment. The goal of planning and executing virtual collaboration is to provide a communication platform that has the potential to share essential visual information to support communication and knowledge sharing among planners, engineers and other team members [60].

It is widely accepted that to improve productivity and performance in construction, the industry requires an integrated collaborative approach to project execution. Collaborative environments provide tools that support the exchange of information among different applications, simultaneous access to data and the sharing of information sources across a network to enable collaboration among different users and support for all teams, addressing the challenges of fragmentation. The correct management of information is crucial to achieve these objectives [60]. Although there has been rapid growth in the development of collaborative tools and systems in recent years, especially in communication, visualization, information and knowledge management, the adoption and application of these tools has been slow and with mixed levels of success. Therefore, a well-defined methodology for collaborative work is needed [60].

A large amount of stored and processed data requires a robust storage system, which allows for access almost anywhere and by any stakeholder, inside or outside a network, enabling global data management, control and analysis. [61]. This system is particularly complex in an industry that is characterized by fragmentation and cascade planning of processes and performance stages of its disciplines and professionals. These barriers must be overcome, both inside and outside an organization, by actively involving suppliers in the logistics and innovation processes [62].

4.2. Interoperability: Integrated Use of FDCT and CT

The selection of a solution that works for each organization will depend on its role in CSCs and the investments being made. In choosing a particular solution, organizations should consider the compatibility among technologies [40] according to the actions carried out both individually and concurrently [63]. There are technologies with higher development; in this sense, Table 7 presents eight actions aligned with Construction 4.0 in relation to the monitoring and control of tasks during the construction phase. It is evident that the same technology can have several different actions, giving it a competitive advantage. Given the need to identify the unobstructed data exchange among different cyber-physical systems, a search for interoperability is carried out within the tools offered in the market. In this sense, Table 8 and Table 9 represent the intra-connections for the cases of FDCT and CT, respectively, and Table 10 identifies the interconnections, which represent the existing combination between the two subdivisions of concurrent technologies.

Table 7.

Actions associated with the technologies applied during the construction phase: monitoring and control. Construction 4.0. Adapted from [62].

Table 8.

Interoperability matrix among field data capture technologies—intra-FDCT.

Table 9.

Interoperability matrix among communication technologies and intra-CT collaboration.

Table 10.

Integration matrix between field data capture and communication and collaboration technologies—inter-FDCT and -CT.

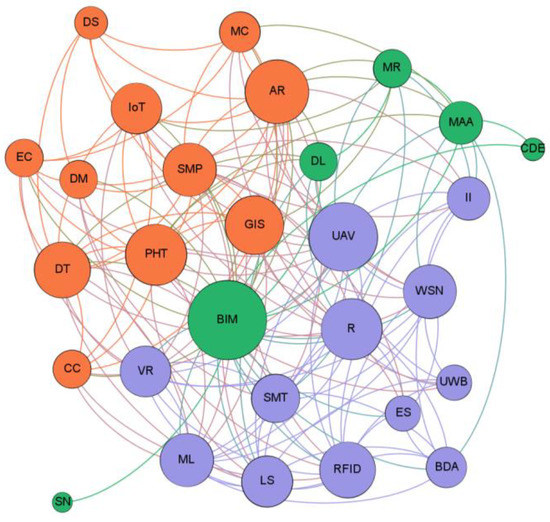

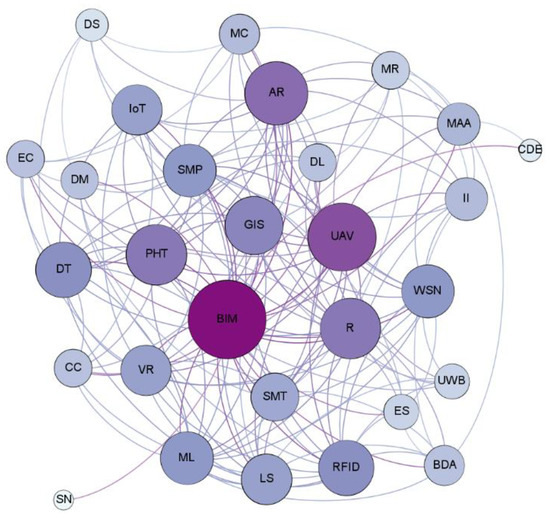

Based on the links identified in the matrices in Table 8, Table 9 and Table 10 of the previous chapter, a network analysis was performed. The results are represented by three types of connections: (1) inter-edge, (2) intra-edge and (3) full. Each node represents the different technologies, either FDCT or CT. The connections, which are represented by edges, symbolize the existing interoperability. It is worth mentioning that the nodes that do not have edges are those that do not manage to connect with other technologies, such as the automation of regulatory control and audits (ARCA), for which there is no reported evidence that this technology is linked with other technologies, which is inferred because it is a recent technology. Although it has the potential to be utilized for monitoring and control, it still fails to integrate with existing technologies, at least in the AECO industry. Table 11 shows the metrics analyzed with a description of their interpretation and how they are graphically represented in the diagrams generated.

Table 11.

Interpretation and graphical representation of network analysis.

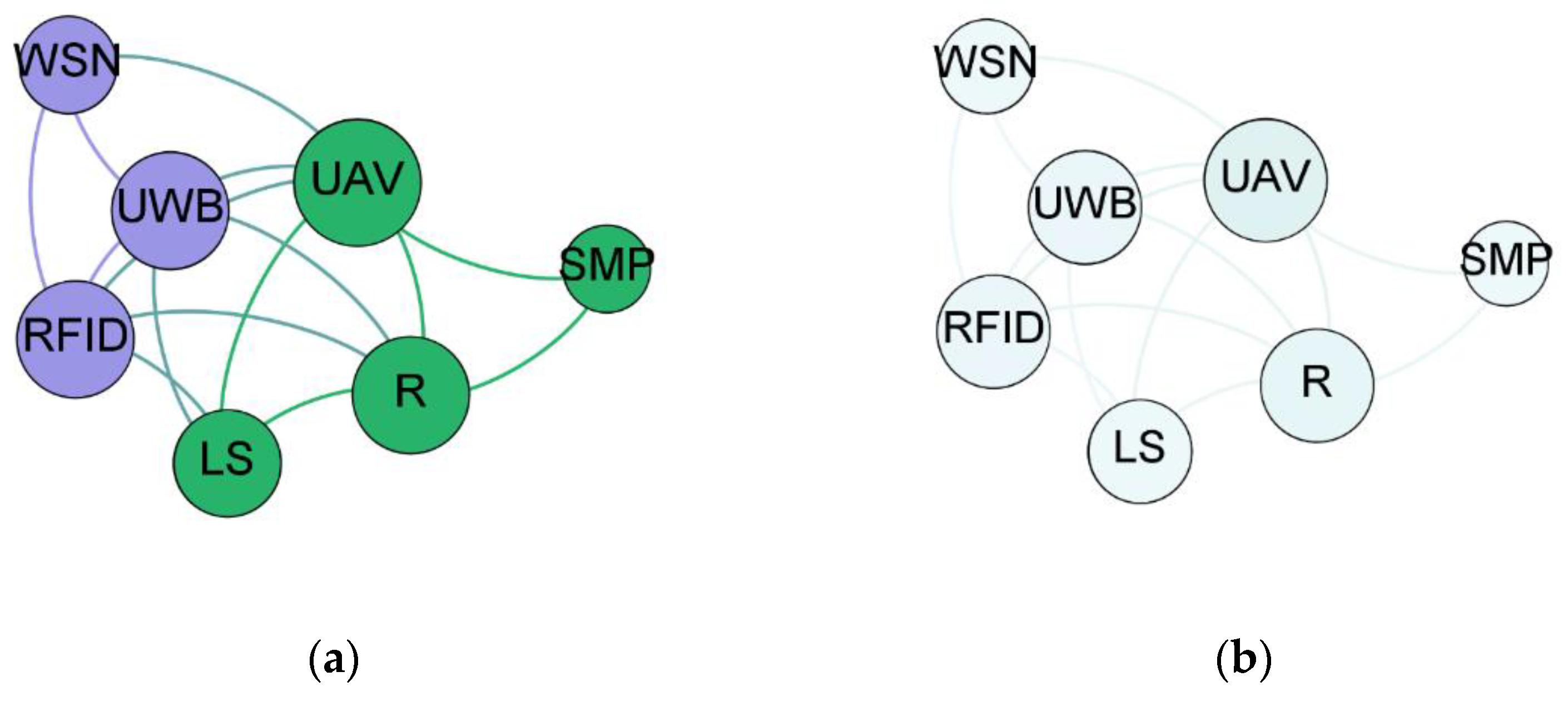

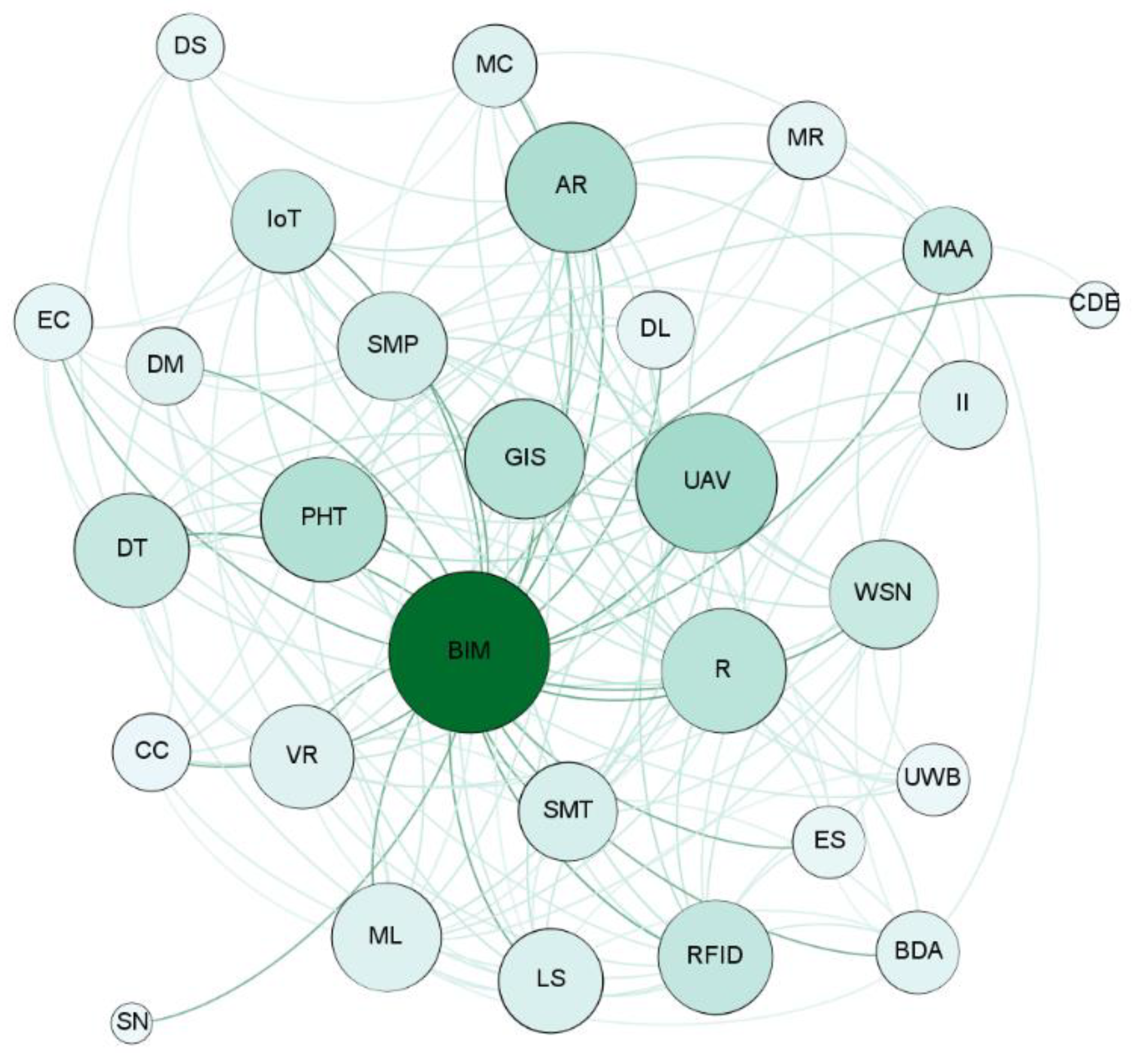

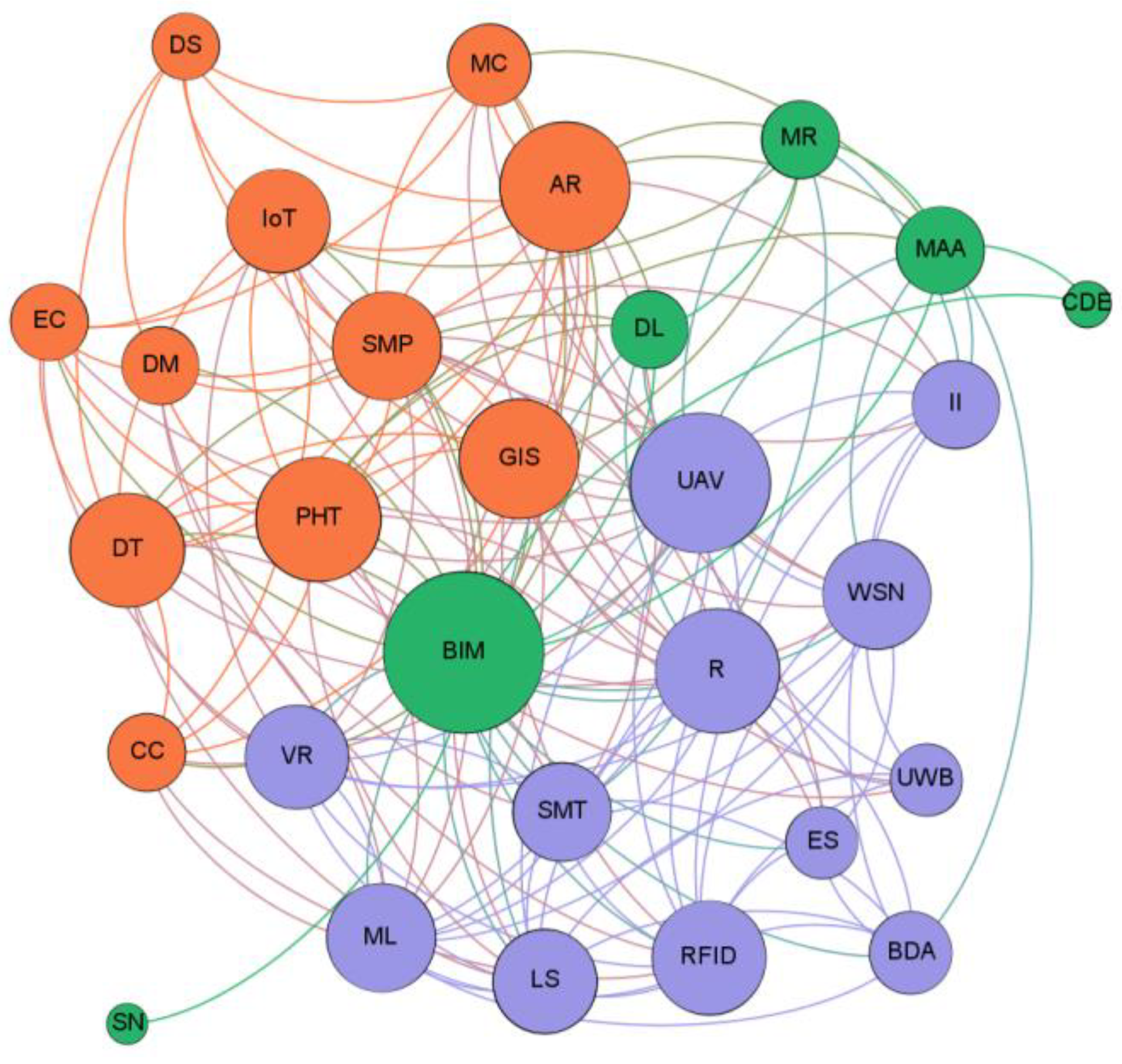

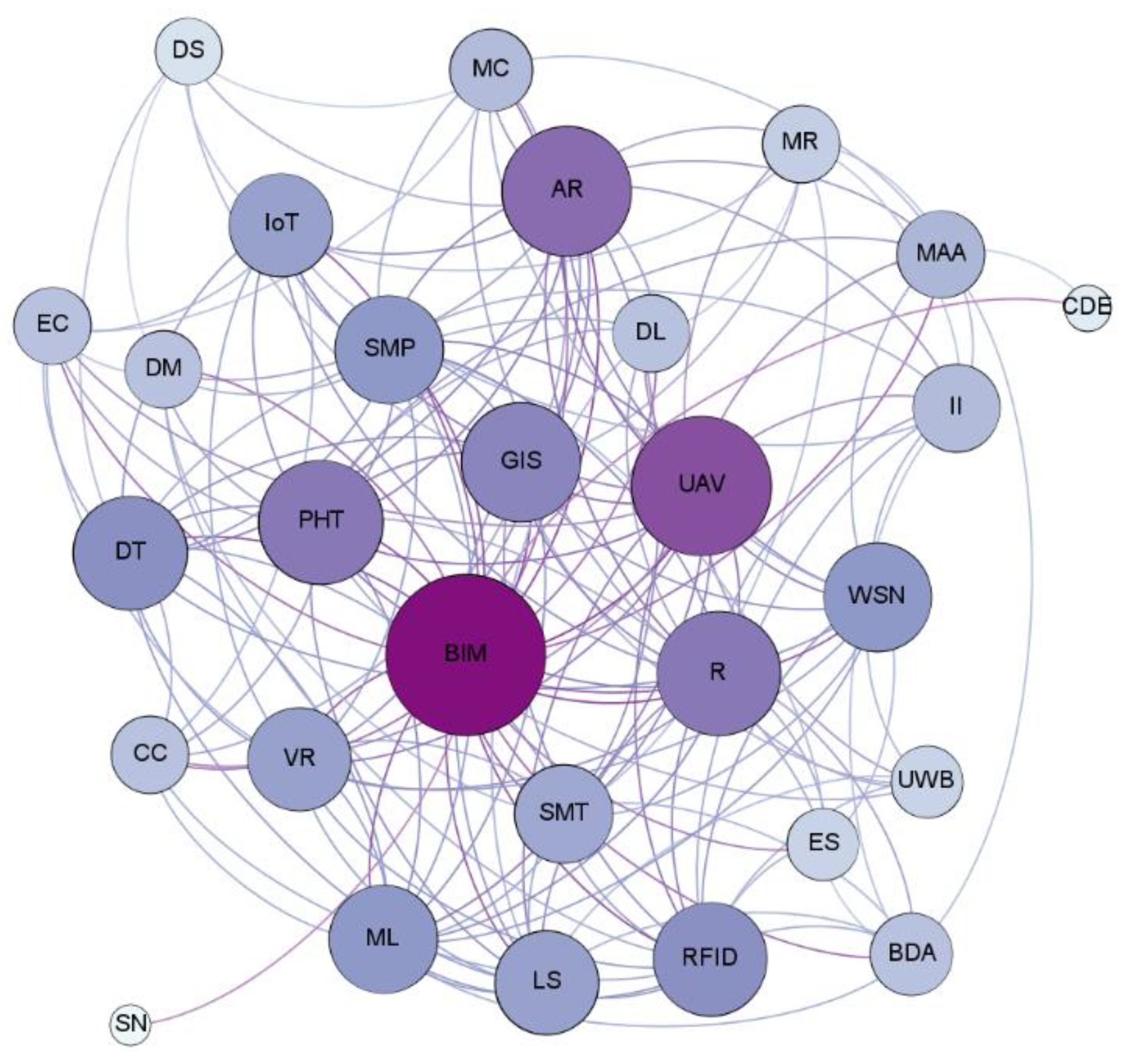

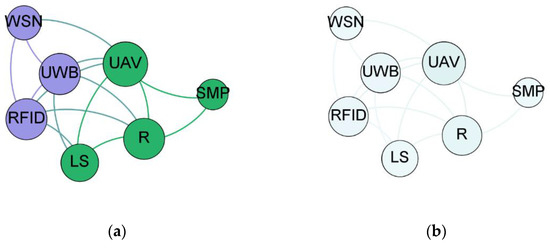

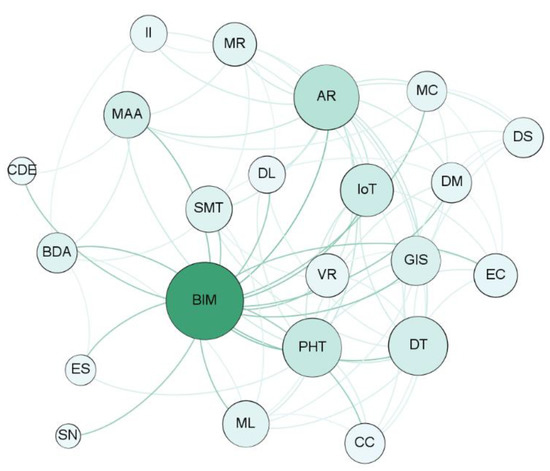

For intra-FCCT connections, specifically in field data capture technologies, Figure 5 presents the metrics of modularity and centrality of the intermediary, (a) and (b), respectively.

Figure 5.

Intra-FDCT network analysis. (a) Modularity: capture technologies form two communities. (b) Betweenness: UAV stands out subtly; the balance of betweenness between capture technologies is maintained, as represented by the pale green color.

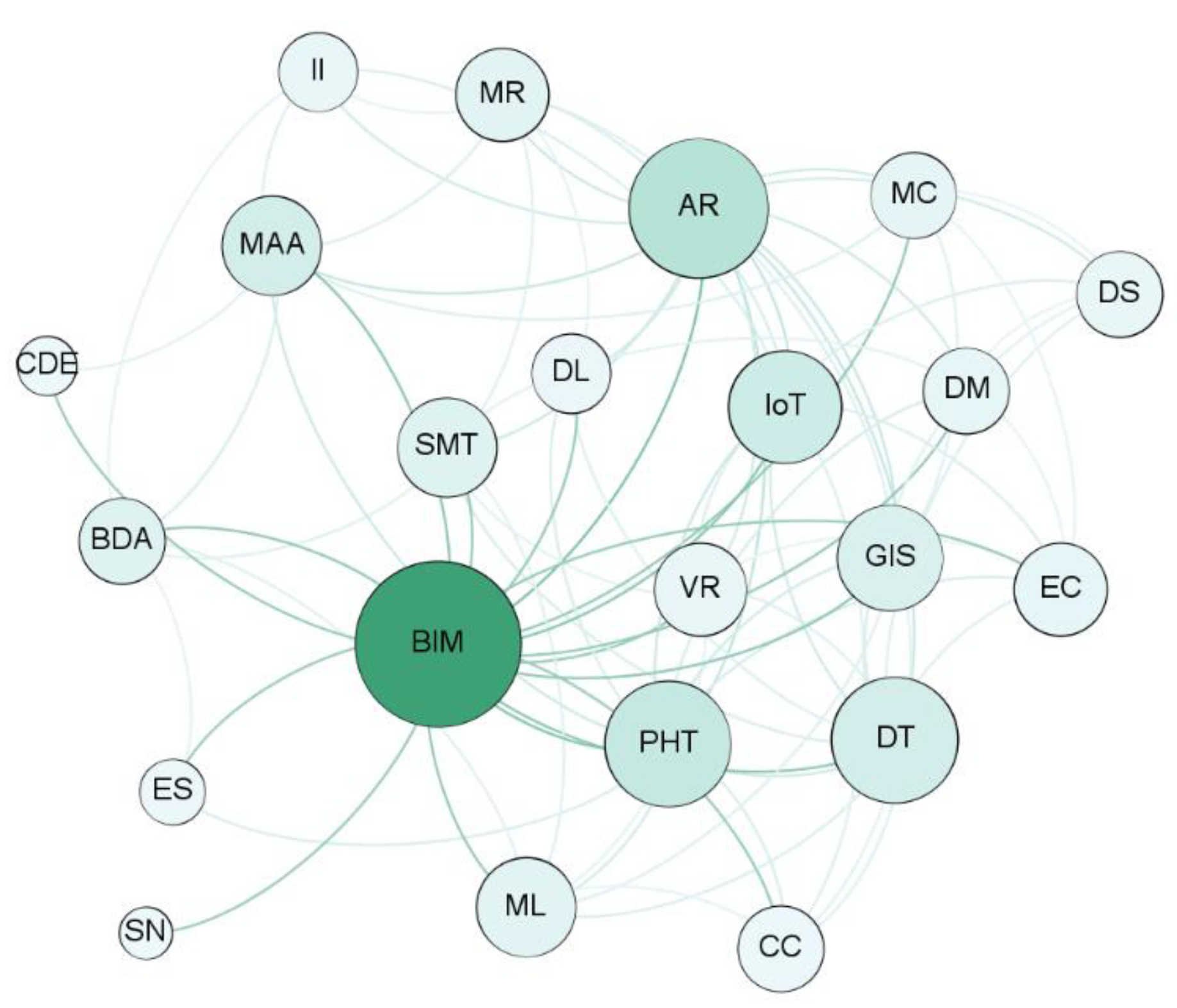

The purple group is characterized by technologies that are highly automated, i.e., the man–machine relationship for acquiring information is almost nil. On the other hand, it is natural that the analysis of betweenness maintains the balance, since each technology has its capabilities, and none is better than another. Thus, each technology is selected according to the function it satisfies. In contrast, for the intra-connections’ analysis of the CTs, Figure 6 shows that BIM is the most powerful intermediary or the intermediary with the highest interoperability among the TC tools, i.e., it can exchange a large amount of data and knowledge. The technologies that achieve this to a lesser extent but still significantly are augmented reality (AR), photogrammetry (PHT), the Internet of Things (IoT) and digital twins (DT).

Figure 6.

Analysis of intra-connections networks CT—betweenness.

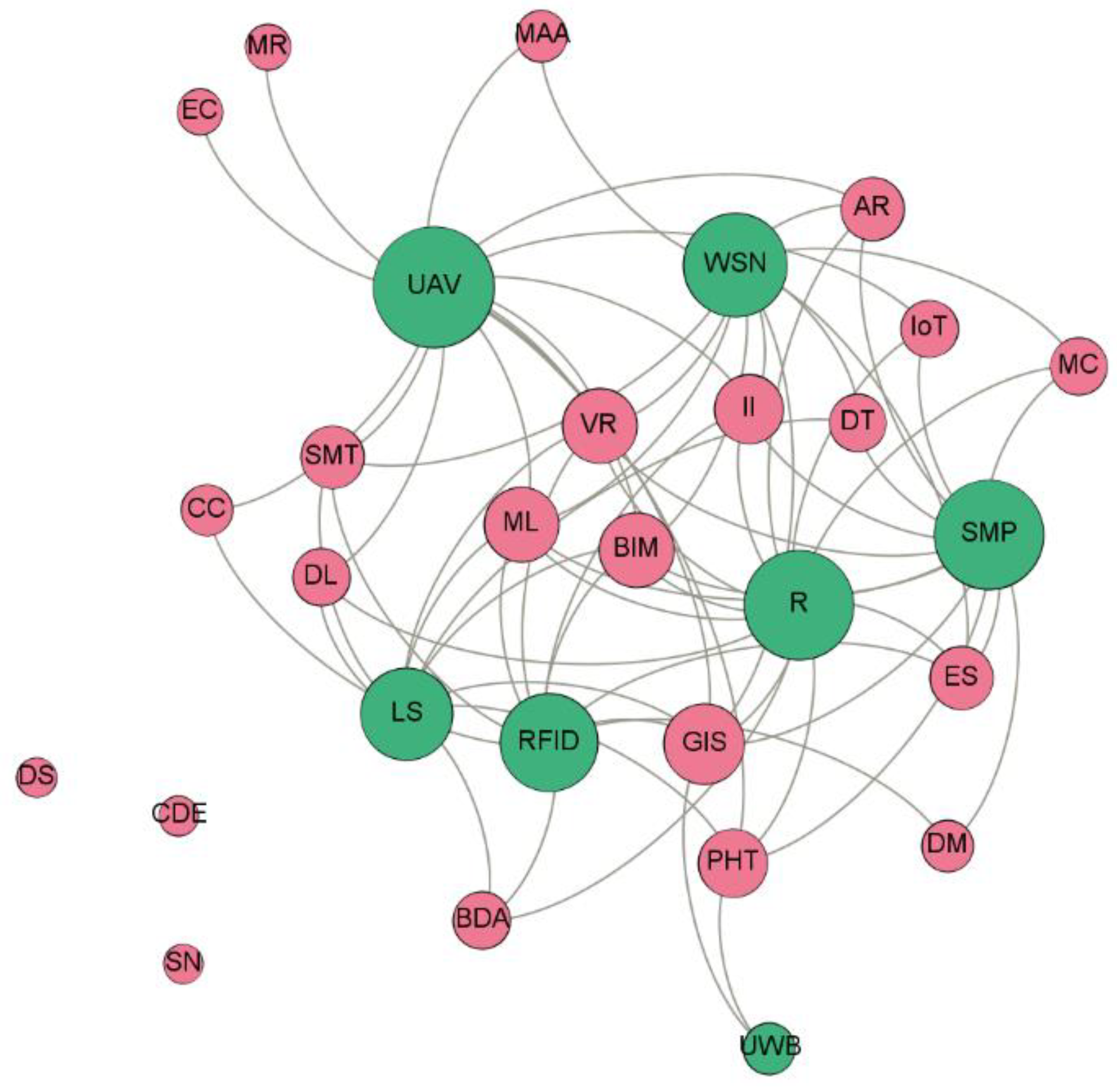

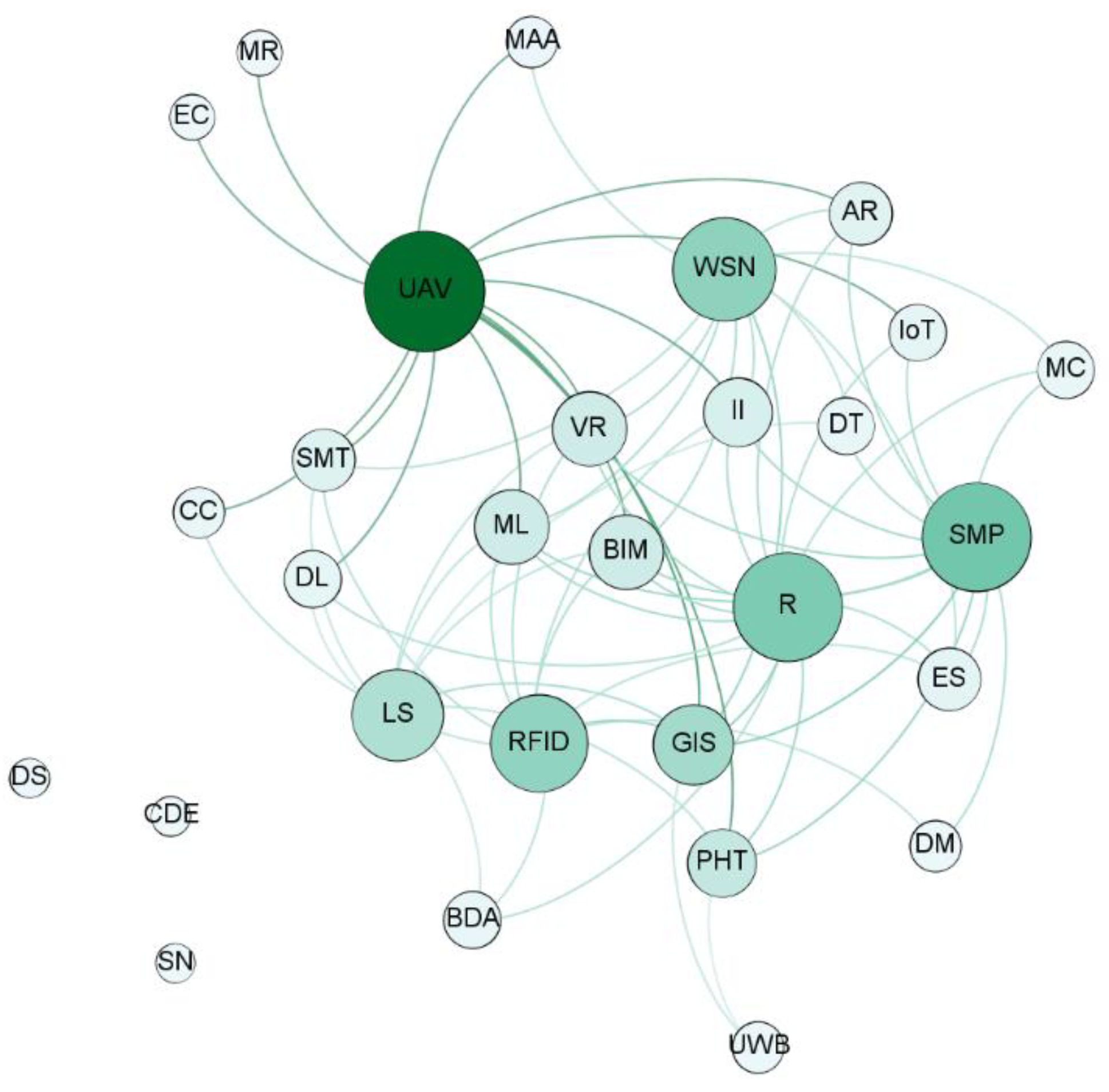

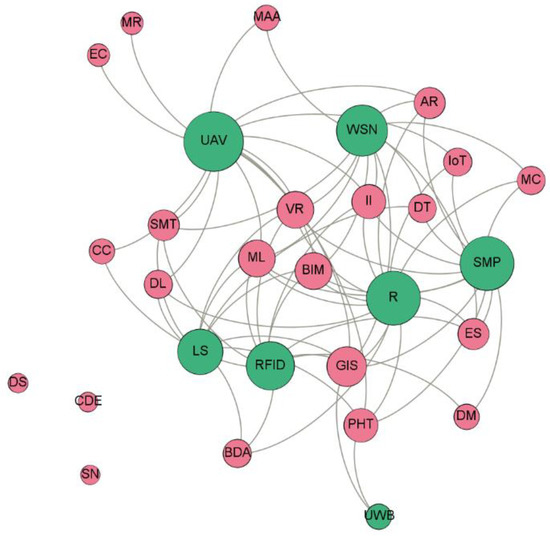

Figure 7 shows the interconnections, with FDCT technologies in red and CT technologies in green. Given the magnitude of the nodes, FDCT technologies take the leading role, and drones (UAVs) again become an influential technology within the group, which is related to technologies that have different functions, mainly reconstruction, simulation and visualization. Regarding the role of intermediaries, in general, FDCTs stand out over TCs, in this case, R, WSN, SMP and RFID. It is worth mentioning that BIM, under this arrangement, does not have a major role because BIM is characterized by being a communicative and collaborative technology (refer to Figure 8).

Figure 7.

Interconnection network analysis—category.

Figure 8.

Interconnection network analysis—betweenness.

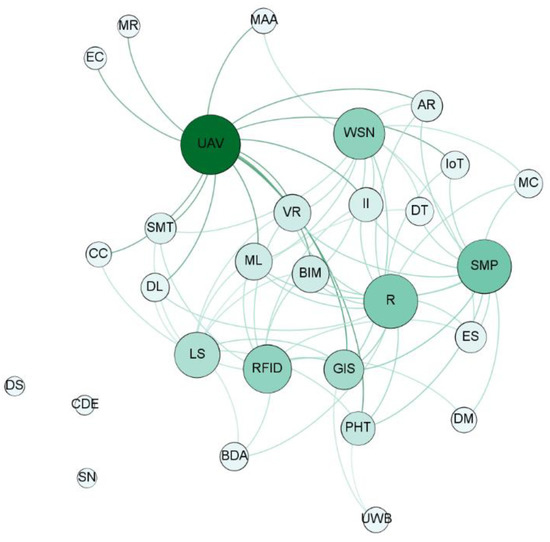

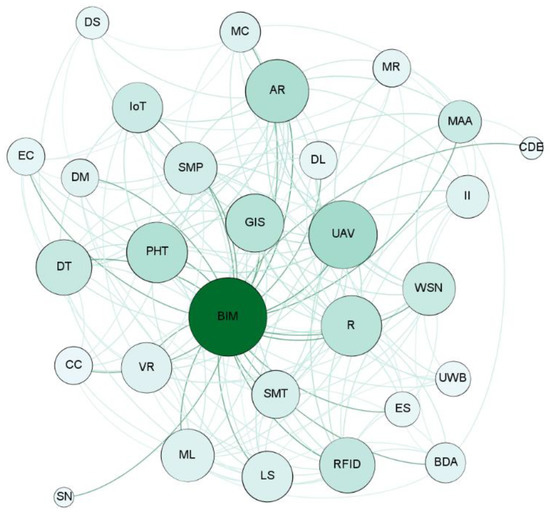

Figure 9 shows the full connections, where it is evident that BIM, at the moment of relating with the totality of the interactions, undoubtedly becomes the major intermediary. BIM has great potential to be employed with other technologies, whether FDCT or CT. BIM is able to connect with 80% of the technologies that have the potential to be utilized for monitoring and control in construction projects according to the evidence found in the literature.

Figure 9.

Full network analysis—betweenness.

In general, three communities can be distinguished in Figure 10, where the leaders are building information modeling (BIM), unmanned aerial vehicles (UAVs) and photogrammetry (PHT). The first group, led by BIM, is in charge of being the intermediary with the technologies that present less interoperability. The second group, led by UAVs, presents mostly CT-type technologies. For the orange community, CT technologies are mainly grouped and influential for data transfer, reconstruction and simulations.

Figure 10.

Full network analysis—modularity.

This triad formed by BIM, UAVs and PHTs does not coincide; the construction industry has been widely adopting these technologies, and there is evidence of success in their application. The benefits of their use extend to not only monitoring and control but also all phases of the construction process, including operation. In addition, the models generated can also be integrated with surveys of other technologies, such as laser scanners, which provide more accurate information.

Regarding the groups or communities formed in Figure 6, it can be seen that each group is formed by FDCT and CT technologies, which shows the need to have a source of data capture for the subsequent communication and collaboration that they provide. It is noteworthy that the group led by UAV is not connected to PHT or GIS.

Figure 11 shows the abovementioned BIM, which is in charge of housing the information that is extracted and analyzed by means of the other technologies. BIM becomes a valuable platform due to its high interoperability, which allows for the integration of the tools, allowing those involved in the construction process to unify the information collected in a single platform.

Figure 11.

Full network analysis—closeness.

4.3. Validation of Digital Tools

To validate the performance of the 30 technologies that present the potential use for monitoring and control within the AIC industry, the judgment of five experts was used to consider the evaluations determined by the author. Each expert gave their judgment on each of the six criteria for the FDCT and CT groups, the ratings of which are shown in Tables 12 and 14, respectively.

In the frequency tables (refer to Tables 12 and 14), it is possible to note the level of performance achieved by each technology according to the criteria of each group, excluding the “not applicable” cases (Table 12).

Table 12.

Performance matrix of digital tools for in situ data acquisition.

Note that, in general (Table 13), technologies have a general solution or certain limitations; only smartphones have limited usefulness. For time efficiency, 100% of the technologies do not take more time than the traditional method, and 57% of the technologies meet the objective of obtaining as-built data in less time compared to the traditional method, where those that would take more time are matched by the accuracy of the information obtained, with the exception of smartphones. The accuracy of the data is 86% reliable and provides accurate information about the current state of progress. Automation is achieved in 86% of the technologies, where smartphones are again the exception.

Table 13.

Frequencies obtained according to the criteria for FDCT.

The obstacles to the implementation of technologies, as usual, are centered on the required training and equipment. It is essential to have qualified personnel with the necessary knowledge to perform the methods. Although these technologies have become more prevalent in recent years, as they are complex techniques, their manipulation is not trivial. UAVs have become the tool that has been able to close this gap and are increasingly implemented with greater frequency due to their versatility, ease of learning and portable equipment.

For the results in Table 14, the interoperability of the technologies was measured based on the information obtained in the previous chapter, considering the full relationships, that is, the combination between the intra-connections relationship and interconnections relationship of the FDCT and CT technologies. Some technologies received a score of 0 because no document was identified where these technologies interact with others. A score of 1 was assigned to technologies that presented a betweenness less than or equal to 5. Technologies with a score of 1 or 2 presented the highest values: in decreasing order, building information modeling, photogrammetry, digital twins, mobile applications and the Internet of Things.

Table 14.

Communication and collaboration technology tool performance matrix.

All of the technologies collect information via electronic means; however, 39% still use the traditional method as a complementary method. In terms of decentralization, there is a distinct trend towards partial delegation of actions and/or decisions at the CSC level. On the other hand, 80% of communicative and collaborative technologies present an instantaneous retrieval of information or take less time than the traditional method.

There is a balance towards meeting the needs of stakeholders within the capabilities offered by each of the technologies. However, there is a medium adaptation to changing requirements, especially for visualization or simulation technologies such as AR, VR, DT, MR and SMT, since the changes generated in the field will not always be represented in these technologies (Table 15).

Table 15.

Frequencies obtained according to the criteria for CT.

5. Conclusions

The use of technologies for monitoring and control in construction projects involves challenges and opportunities for the AIC industry. With the current progress, it has been possible to facilitate data acquisition in the field due to the key features offered by their implementation, including automation, digitization, integration and interoperability, which are supported by the Industry 4.0 revolution.

While there is a wide range of technologies on the market that promise different functions, their use and the interoperability among them are still limited. The contribution of this research is to show an analysis of the integration and interoperability of digital tools for monitoring and control of construction projects during the execution phase. The most widely used technologies in recent decades, such as BIM, unmanned aerial vehicles and photogrammetry, are technologies that present a greater compatibility, which allows for a reduction in the fragmentation of information and automation to a certain extent, since human support is still required. As evidenced, BIM is a tool with a great capacity to store data and it allows for the dissemination of this information to stakeholders. BIM marks a new paradigm, and the interoperability and integration it has with different technologies allows us to improve the efficiency of information management in construction due to the unification of information. In summary, BIM was characterized by generating connections with emerging technologies in the industry and, therefore, its potential is evidently superior to that of other technologies.

A limitation that emerged from the research was the limited evidence found in the literature. Although technological advances have increased, the AEC industry has slowly adopted these innovative techniques, even more so for the function and stage of focus of this research. Implementing this type of technique in monitoring and control is still considered experimental in nature and, therefore, requires a significant investment from companies (whether public or private). Only a minority of companies dare to innovate and leave behind the traditional method. Another limitation of the study was that a set of tools was not applied in a real case of professional practice with the objective of analyzing and evaluating the benefits and obstacles of implementing this type of technologies associated with Construction 4.0; therefore, it is recommended to carry out studies in real cases and evaluate the impact of their implementation from a quantitative and qualitative perspective.

On the other hand, it is difficult to point out which technology or technologies will lead the monitoring and control process, since the technologies investigated in this paper will not necessarily be the technologies used in the medium term. In addition, given the dynamic and changing nature of construction, it is currently difficult to standardize the monitoring and control process. Defining which technologies and the sequence of the process is complex, since there are different factors and variables that must be controlled according to the particularity of each project. In addition, it is necessary to individually or jointly evaluate the benefits and limitations of the technologies according to a given context. It is also a challenge to promote a culture of implementation and adaptation of these innovative methods.

From a practical point of view, this research seeks to contribute to the discussion and promotion of other studies on the integration and interoperability of these tools studied. It is interesting to study the advances made by the industry, analyze how these technologies are implemented and evaluate the added value in the projects where they are implemented. Researchers are also encouraged to experiment with finding interoperability, which was not possible in the current literature. In this way, researchers can document them and provide more information to contribute to a greater supply of techniques to achieve full automation of the process.

As a future line of work, to complement what has been pointed out in this document, it is possible to work on new criteria considered critical to allow for the automation of a monitoring and control system. Adding new criteria, weighting them, adding multiplying factors, etc. would make it possible to determine with greater certainty and rigor which are more relevant when choosing one tool over another.

Additionally, we encourage developing an incremental methodology of adoption of a group of technologies, where the levels of adoption of automation are defined and where the technologies are subject to the functionality according to the objective to be achieved due to the flexibility provided by the technologies. Thus, they can manage the construction process of any building by (1) allowing for the development of integrated solutions via a shift towards the flexibility of processes and autonomy and communication among devices connected by multiple parallel processes and (2) allowing for new modes of networked and collective construction in common construction tasks.

Author Contributions

Conceptualization, R.F.H. and L.D.-V.; methodology, R.F.H.; software, L.D.-V.; validation, F.M.-L.R. and E.A.; formal analysis, L.D.-V.; writing—original draft preparation, L.D.-V.; writing—review and editing, R.F.H., E.A. and F.M.-L.R.; visualization, L.D.-V. and F.M.-L.R.; supervision, R.F.H. and E.A. All authors have read and agreed to the published version of the manuscript.

Funding

The APC was paid by Pontificia Universidad Católica de Valparaíso. This research was funded by CONICYT grant number CONICYT-PCHA/InternationalDoctorate/2019-72200306 for funding the graduate research of Muñoz-La Rivera.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors wish to thank the TIMS space (Technology, Innovation, Management, and Innovation) of the School of Civil Engineering of the Pontificia Universidad Católica de Valparaíso (Chile), where part of the research was carried out.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Restrepo, D. La Importancia del Sector de la Construcción en Materia Económica—LA.Network. Available online: https://la.network/la-importancia-del-sector-de-la-construccion-en-materia-economica/ (accessed on 27 October 2021).

- Alarcón, L.F. ¿Sabías que la Productividad de la Construcción es más baja que la de toda la Economía? Available online: https://www.claseejecutiva.com.ec/blog/articulos/sabias-que-la-productividad-de-la-construccion-es-mas-baja-que-la-de-toda-la-economia/ (accessed on 21 October 2021).

- CICA; CCHC; FIIC. Situación Mundial COVID-19 Industria de la Construcción y General; Informe Internacional: Santiago, Chile, 2020. [Google Scholar]

- Sanchéz, A. Digitalización y Sostenibilidad, los Principales Desafíos para la Reactivación de las Empresas tras la Crisis del COVID-19. Available online: https://www.eurochile.cl/es/noticias/cooperacion-empresarial/digitalizacion-y-sostenibilidad-los-principales-desafios-para-la-reactivacion-de-las-empresas-tras-la-crisis-del-covid-19/ (accessed on 27 October 2021).

- Griffor, E.R.; Greer, C.; Wollman, D.A.; Burns, M.J. Framework for Cyber-Physical Systems: Volume 1, Overview NIST Special Publication 1500-201 Framework for Cyber-Physical Systems: Volume 1. Overview. Nist 2017, 1, 79. [Google Scholar]

- Muñoz-La Rivera, F.; Mora-Serrano, J.; Valero, I.; Oñate, E. Methodological-Technological Framework for Construction 4.0. Arch. Comput. Methods Eng. 2021, 28, 689–711. [Google Scholar] [CrossRef]

- Chen, J.; Zhou, J. Revisiting Industry 4.0 with a Case Study. In Proceedings of the IEEE 2018 International Congress on Cybermatics: 2018 IEEE Conferences on Internet of Things, Green Computing and Communications, Cyber, Physical and Social Computing, Smart Data, Blockchain, Computer and Information Technology, iThings/Gree, Halifax, NS, Canada, 30 July–3 August 2018; pp. 1–6. [Google Scholar]

- Sawhney, A.; Riley, M.; Irizarry, J. Construction 4.0: An Innovation Platform for the Built Environment, 2020th ed.; Sawhney, A., Riley, M., Irizarry, J., Eds.; Routledge: New York, NY, USA, 2020; Volume 53, ISBN 9788578110796. [Google Scholar]

- Braun, A.; Tuttas, S.; Borrmann, A.; Stilla, U. A Concept for Automated Construction Progress Monitoring Using BIM-based Geometric Constraints and Photogrammetric Point Clouds. J. Inf. Technol. Constr. 2015, 20, 68–79. [Google Scholar]

- Kopsida, M.; Brilakis, I.; Vela, P. A Review of Automated Construction Progress and Inspection Methods. In Proceedings of the 32nd CIB W78 Conference on Construction IT, Eindhoven, The Netherlands, 27–29 October 2015; pp. 1–12. [Google Scholar]

- Dib, H.; Adamo-Villani, N.; Issa, R.A. Gis-Based Integrated Information Model to Improve Building Construction Management: Design and Initial evaluation. Proc. CONVR 2014, 769–781. [Google Scholar]

- Li, Y.; Liu, C. Applications of Multirotor Drone Technologies in Construction Management. Int. J. Constr. Manag. 2019, 19, 401–412. [Google Scholar] [CrossRef]

- García, J.; Salazar, P. Métodos de Administración y Evaluación de Riesgos. Bachelor’s Thesis, Universidad de Chile, Santiago, Chile, 2005. [Google Scholar]

- Trejo, N. Estudio de Impacto del uso de la Metodología BIM en la Planifiación y Control de Proyectos de Ingeniería y Construcción. Bachelor’s Thesis, Universidad de Chile, Santiago, Chile, 2018. [Google Scholar]

- Jrade, A.; Lessard, J. An Integrated BIM System to Track the Time and Cost of Construction Projects: A Case Study. J. Constr. Eng. 2015, 2015, 579486. [Google Scholar] [CrossRef]

- GMC Ingeniería Planificación y Control de la Edificación y Obra Civil. Available online: https://www.gmcingenieria.com/servicios/planificacion-y-control-de-la-edificacion-y-obra-civil/ (accessed on 21 May 2020).

- Dirección de Planeamiento MOP Gestión y Monitoreo de Planes de Obras Públicas Implementación, Metas e Indicadores; MOP Chile: Santiago de Chile, Chile, 2012.

- Villavicencio, A.; Gabriela, M.; Fajardo, M.; De Fátima, A. Uso de Tecnologías de Adquisición de datos para Optimizar los Tiempos de Monitoreo del Progreso de la Construcción en Edificios Residenciales. Bachelor’s Thesis, Universidad Peruana de Ciencias Aplicadas, Lima, Peru, 2019. [Google Scholar]

- Mahami, H.; Nasirzadeh, F.; Ahmadabadian, A.H.; Nahavandi, S. Automated progress controlling and monitoring using daily site images and building information modelling. Buildings 2019, 9, 70. [Google Scholar] [CrossRef]

- Project Management Institute. Guía de los Fundamentos para la Dirección de Proyectos (Guía del PMBOOK); Quinta Edition; Project Management Institute, Inc.: Newtown Square, PA, USA, 2013; ISBN 0428630790. [Google Scholar]

- CORFO. PMG Informe final fase 3, Hoja de Ruta PyCS 2025. In Programa Estratégico Nac. Product. y Sustentabilidad en la Construcción 2016; CORFO Chile: Santiago de Chile, Chile, 2016; p. 172. [Google Scholar]

- Navon, R.; Goldschmidt, E. Can Labor Inputs be Measured and Controlled Automatically? J. Constr. Eng. Manag. 2003, 129, 437–445. [Google Scholar] [CrossRef]

- Muñoz Velasco, M. Aplicación de un Modelo de Planificaciòn Financiera en Pequeñas y Medianas Empresas Constructoras en Chile (AVG). Bachelor’s Thesis, Universidad del Bío-Bío, Concepción, Chile, 2016. [Google Scholar]

- Petrov, I.; Hakimov, A. Digital Technologies in Construction Monitoring and Construction Control. In Proceedings of the IOP Conference Series: Materials Science and Engineering; IOP Publishing: St. Petersburg, Russia, 2019; Volume 497, pp. 1–9. [Google Scholar]

- Alvarenga, T.W.; Neves Da Silva, E.; Brasil de Brito Mello, L. BIM and Lean Construction: The Evolution Obstacle in the Brazilian Civil Construction Industry. Technol. Appl. Sci. Res. 2017, 7, 1904–1908. [Google Scholar] [CrossRef]

- de, M. Nascimento, D.L.; Sotelino, E.D.; Caiado, R.G.G.; Ivson, P.; Faria, P.S. Sinergia entre Princípios do Lean Thinking e Funcionalidades de BIM na Interdisciplinaridade de Gestão em Plantas Industriais. J. Lean Syst. 2017, 2, 80–105. [Google Scholar]

- Saad, I.M.H. The project reporter: Multimedia Progress Reporting for Construction Projects. In Construction Congress VI: Building Together for a Better Tomorrow in an Increasingly Complex World; ASCE: Orlando, FL, USA, 2000; Volume 278, pp. 1165–1176. [Google Scholar] [CrossRef]

- Xu, Q.; Chong, H.Y.; Liao, P.C. Collaborative Information Integration for Construction Safety Monitoring. Autom. Constr. 2019, 102, 120–134. [Google Scholar] [CrossRef]

- Alizadehsalehi, S.; Yitmen, I. A Concept for Automated Construction Progress Monitoring: Technologies Adoption for Benchmarking Project Performance Control. Arab. J. Sci. Eng. 2019, 44, 4993–5008. [Google Scholar] [CrossRef]

- Ahmed Memon, Z.; Abd Majid, M.Z.; Mustaffar, M. Digitalizing Construction Monitoring (DCM): An Overview of Malaysian Construction Industry and Proposing Prototype Software. In Proceedings of the 6th Asia-Pacific Structural Engineering and Construction Conference (APSEC 2006), Kuala Lumpur, Malaysia, 5–6 September 2006. [Google Scholar]

- Kapogiannis, G.; Mlilo, A. Digital Construction Strategies and BIM in Railway Tunnelling Engineering. In Tunnel Engineering-Selected Topics; IntechOpen: London, UK, 2019. [Google Scholar] [CrossRef]

- Yang, L.R.; O’Connor, J.T.; Chen, J.H. Assessment of Automation and Integration Technology’s Impacts on Project Stakeholder Success. Autom. Constr. 2007, 16, 725–733. [Google Scholar] [CrossRef]

- Pour Rahimian, F.; Seyedzadeh, S.; Oliver, S.; Rodriguez, S.; Dawood, N. On-demand Monitoring of Construction Projects through a Game-like Hybrid Application of BIM and Machine Learning. Autom. Constr. 2020, 110, 103012. [Google Scholar] [CrossRef]

- Navon, R.; Shpatnitsky, Y. A Model for Automated Monitoring of Road Construction. Constr. Manag. Econ. 2005, 23, 941–951. [Google Scholar] [CrossRef]

- Memon, Z.A.; Majid, M.Z.A.; Mustaffar, M. An Automatic Project Progress Monitoring Model by Integrating Auto CAD and Digital Photos. In Proceedings of the International Conference on Computing in Civil Engineering, Cancun, Mexico, 12–15 July 2005; pp. 1–13. [Google Scholar]

- Robuffo, F. An Innovative Approach for Automated Jobsite Work Progress Assessment. Ph.D. Thesis, Università Politecnbica delle Marche, Ancona, Italy, 2013. [Google Scholar]

- Brilakis, I.; Soibelman, L.; Shinagawa, Y. Material-Based Construction Site Image Retrieval. J. Comput. Civ. Eng. 2005, 19, 341–355. [Google Scholar] [CrossRef]

- Kapogiannis, G.; Sherratt, F. Impact of Integrated Collaborative Technologies to form a Collaborative Culture in Construction Projects. Built Environ. Proj. Asset Manag. 2018, 8, 24–38. [Google Scholar] [CrossRef]

- Kuz, A.; Falco, M.; Giandini, R. Análisis de redes sociales: Un caso práctico. Comput. Sist. 2016, 20, 89–106. [Google Scholar] [CrossRef]

- Cárdenas, C.; Zapata, P.; Lozano, N. Building Information Modeling 5D and Earned Value Management methodologies integration through a computational tool. Rev. Ing. Constr. 2018, 33, 263–278. [Google Scholar] [CrossRef]

- García de Soto, B.; Agustí-Juan, I.; Hunhevicz, J.; Joss, S.; Graser, K.; Habert, G.; Adey, B.T. Productivity of digital fabrication in construction: Cost and time analysis of a robotically built wall. Autom. Constr. 2018, 92, 297–311. [Google Scholar] [CrossRef]

- Alias, C.; Jawale, M.; Goudz, A.; Noche, B. Applying Novel Future-internet-based Supply Chain Control Towers to the Transport and Logistics Domain. In Proceedings of the ASME 2014 12th Biennial Conference on Engineering Systems Design and Analysis, ESDA 2014, Copenhagen, Denmark, 25–27 June 2014; Volume 3. [Google Scholar]

- Ersoz, A.B.; Pekcan, O.; Tokdemir, O.B. Lean Project Management using Unmanned Aerial Vehicles. Tamap J. Eng. 2019, 2018, 65. [Google Scholar] [CrossRef]

- Asadi, K.; Ramshankar, H.; Pullagurla, H.; Bhandare, A.; Shanbhag, S.; Mehta, P.; Kundu, S.; Han, K.; Lobaton, E.; Wu, T. Vision-based Integrated Mobile Robotic System for Real-time Applications in Construction. Autom. Constr. 2018, 96, 470–482. [Google Scholar] [CrossRef]

- Coetzee, G.L. Smart Construction Monitoring of Dams with UAVS—Neckartal Dam Water Project Phase 1. In Proceedings of the Smart Dams and Reservoirs—Proceedings of the 20th Biennial Conference of the British Dam Society, Swansea, UK, 13–15 September 2018; pp. 445–456. [Google Scholar]

- Zohdi, T.I. Multiple UAVs for Mapping: A review of Basic Modeling, Simulation, and Applications. Annu. Rev. Environ. Resour. 2018, 43, 523–543. [Google Scholar] [CrossRef]

- Cummings, A.R.; Mckee, A.; Kulkarni, K.; Markandey, N. The Rise of UAVs. Photogramm. Eng. Remote Sens. 2017, 83, 317–325. [Google Scholar] [CrossRef]

- Jacob-Loyola, N.; Muñoz-La Rivera, F.; Herrera, R.F.; Atencio, E. Unmanned Aerial Vehicles (Uavs) for Physical Progress Monitoring of Construction. Sensors 2021, 21, 4227. [Google Scholar] [CrossRef]

- Vallejo, D.; Castro-Schez, J.J.; Glez-Morcillo, C.; Albusac, J. Multi-agent architecture for information retrieval and intelligent monitoring by UAVs in Known Environments Affected by Catastrophes. Eng. Appl. Artif. Intell. 2020, 87, 103243. [Google Scholar] [CrossRef]

- Ko, Y.D.; Song, B.D. Application of UAVs for Tourism Security and Safety. Asia Pac. J. Mark. Logist. 2021, 33, 1829–1843. [Google Scholar] [CrossRef]

- Liu, D.; Chen, J.; Hu, D.; Zhang, Z. Dynamic BIM-augmented UAV Safety Inspection for Water Diversion Project. Comput. Ind. 2019, 108, 163–177. [Google Scholar] [CrossRef]

- Jeelani, I.; Gheisari, M. Safety Challenges of UAV Integration in Construction: Conceptual Analysis and Future Research Roadmap. Saf. Sci. 2021, 144, 105473. [Google Scholar] [CrossRef]

- Wehbe, R.; Shahrour, I. Use of BIM and Smart Monitoring for buildings’ Indoor Comfort Control. In Proceedings of the MATEC Web of Conferences, Lille, France, 8–10 October 2019; Volume 295, p. 02010. [Google Scholar]

- Spengler, A.J.; Alias, C.; Magallanes, E.G.C.; Malkwitz, A. Benefits of Real-Time Monitoring and Process Mining in a Digitized Construction Supply Chain. Mobilität Zeiten Veränderung 2019, 411–435. [Google Scholar] [CrossRef]

- Prosser-Contreras, M.; Atencio, E.; La Rivera, F.M.; Herrera, R.F. Use of Unmanned Aerial Vehicles (Uavs) and Photogrammetry to Obtain the International Roughness Index (iri) on Roads. Appl. Sci. 2020, 10, 8788. [Google Scholar] [CrossRef]

- Romero-Chambi, E.; Villarroel-Quezada, S.; Atencio, E.; Rivera, F.M. La Analysis of Optimal Flight Parameters of Unmanned Aerial Vehicles (UAVs) for Detecting Potholes in Pavements. Appl. Sci. 2020, 10, 4157. [Google Scholar] [CrossRef]

- Jofré-Briceño, C.; Muñoz-La Rivera, F.; Atencio, E.; Herrera, R.F. Implementation of Facility Management for Port Infrastructure through the Use of UAVs, Photogrammetry and BIM. Sensors 2021, 21, 6686. [Google Scholar] [CrossRef] [PubMed]

- Mohamed, M. Challenges and Benefits of Industry 4.0: An overview. Int. J. Supply Oper. Manag. 2018, 5, 256–265. [Google Scholar]

- Fard, M.G.; Peña-Mora, F. Application of Visualization Techniques for Construction Progress Monitoring. In Proceedings of the Computing in Civil Engineering; American Society of Civil Engineers: Reston, VA, USA, 2007; Volume 40937, pp. 216–223. [Google Scholar]

- Sepehr, A.; Ibrahim, Y. Impact of the Virtual Collaboration on Project Progress Monitoring in the Construction Industry. In Proceedings of the AEI 2017: Resilience of the Integrated Building, Oklahoma City, OK, USA, 11–13 April 2017; pp. 964–982. [Google Scholar]

- Da Costa, M.B.; Dos Santos, L.M.A.L.; Schaefer, J.L.; Baierle, I.C.; Nara, E.O.B. Industry 4.0 technologies basic network identification. In Proceedings of the Scientometrics; Springer International Publishing: Berlin/Heidelberg, Germany, 2019; Volume 121, pp. 977–994. [Google Scholar]

- Perrier, N.; Bled, A.; Bourgault, M.; Cousin, N.; Danjou, C.; Pellerin, R.; Roland, T. Construction 4.0: A survey of research trends. J. Inf. Technol. Constr. 2020, 25, 416–437. [Google Scholar] [CrossRef]

- Valero, E.; Adán, A.; Bosché, F. Semantic 3D Reconstruction of Furnished Interiors Using Laser Scanning and RFID Technology. J. Comput. Civ. Eng. 2016, 30, 04015053. [Google Scholar] [CrossRef]

- Aryan, A. Evaluation of Ultra-Wideband Sensing Technology for Position Location in Indoor Construction Environments. Master’s Thesis, University of Waterloo, Waterloo, ON, Canada, 2011. [Google Scholar]

- Xiong, Z.; Song, Z.; Scalera, A.; Ferrera, E.; Sottile, F.; Brizzi, P.; Tomasi, R.; Spirito, M.A. Hybrid WSN and RFID indoor positioning and tracking system. EURASIP J. Embed. Syst. 2013, 2013, 6. [Google Scholar] [CrossRef]

- Won, D.; Chi, S.; Park, M.W. UAV-RFID Integration for Construction Resource Localization. KSCE J. Civ. Eng. 2020, 24, 1683–1695. [Google Scholar] [CrossRef]

- Oliveira, L.F.P.; Silva, M.F.; Moreira, A.P. Agricultural robotics: A state of the art survey. In Proceedings of the Robots in Human Life—Proceedings of the 23rd International Conference on Climbing and Walking Robots and the Support Technologies for Mobile Machines, CLAWAR 2020, Moscow, Russia, 24–26 August 2020; pp. 279–286. [Google Scholar]

- Masiero, A.; Fissore, F.; Guarnieri, A.; Pirotti, F.; Visintini, D.; Vettore, A. Performance Evaluation of Two Indoor Mapping Systems: Low-Cost UWB-aided photogrammetry and backpack laser scanning. Appl. Sci. 2018, 8, 416. [Google Scholar] [CrossRef]

- Said, K.O.; Onifade, M.; Githiria, J.M.; Abdulsalam, J.; Bodunrin, M.O.; Genc, B.; Johnson, O.; Akande, J.M. On the Application of Drones: A progress report in mining operations. Int. J. Min. Reclam. Environ. 2021, 35, 235–267. [Google Scholar] [CrossRef]

- Kim, P.; Chen, J.; Kim, J.; Cho, Y.K. SLAM-driven Intelligent Autonomous Mobile Robot Navigation for Construction Applications. In Workshop of the European Group for Intelligent Computing in Engineering; Springer: Cham, Switzerland, 2018; pp. 254–269. [Google Scholar] [CrossRef]

- Courtay, A.; Le Gentil, M.; Berder, O.; Scalart, P.; Fontaine, S.; Carer, A. Anchor Selection Algorithm for Mobile Indoor Positioning using WSN with UWB Radio. In Proceedings of the SAS 2019—2019 IEEE Sensors Applications Symposium, Sophia Antipolis, France, 11–13 March 2019; pp. 1–4. [Google Scholar]

- Lakas, A.; Belkhouche, B.; Benkraouda, O.; Shuaib, A.; Alasmawi, H.J. A Framework for a Cooperative UAV-UGV System for Path Discovery and Planning. In Proceedings of the 2018 13th International Conference on Innovations in Information Technology, IIT 2018, Al Ain, United Arab Emirates, 18–19 November 2018; pp. 42–46. [Google Scholar]

- Ahmed, S.; Shakev, N.; Milusheva, L.; Topalov, A. Neural Net tracking Control of a Mobile Platform in Robotized Wireless Sensor Networks. In Proceedings of the 2015 IEEE International Workshop of Electronics, Control, Measurement, Signals and their Application to Mechatronics, ECMSM 2015, Liberec, Czech Republic, 22–24 June 2015. [Google Scholar]

- Bulgakov, A.G.; Pakhomova, E.G. Coordination of Construction Manipulation Robotic System Using UAV. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Brasov, Romania, 7–10 October 2020; Volume 789. [Google Scholar]

- Mishra, D.; Natalizio, E. A Survey on Cellular-connected UAVs: Design Challenges, Enabling 5G/B5G Innovations, and Experimental Advancements. Comput. Netw. 2020, 182, 107451. [Google Scholar] [CrossRef]

- Hamledari, H.; McCabe, B.; Davari, S. Automated Computer Vision-based Detection of Components of Under-construction Indoor Partitions. Autom. Constr. 2017, 74, 78–94. [Google Scholar] [CrossRef]

- Turk, Ž.; Klinc, R. A social–product–process framework for construction. Build. Res. Inf. 2020, 48, 747–762. [Google Scholar] [CrossRef]

- Zhang, J.; Deng, C.; Zheng, P.; Xu, X.; Ma, Z. Development of an Edge Computing-based Cyber-physical Machine Tool. Robot. Comput. Integr. Manuf. 2021, 67, 102042. [Google Scholar] [CrossRef]

- Sodhro, A.H.; Pirbhulal, S.; De Albuquerque, V.H.C. Artificial Intelligence-Driven Mechanism for Edge Computing-Based Industrial Applications. IEEE Trans. Ind. Inform. 2019, 15, 4235–4243. [Google Scholar] [CrossRef]

- Sacco, A.; Flocco, M.; Esposito, F.; Marchetto, G. An Architecture for Adaptive Task Planning in Support of IoT-based Machine Learning Applications for Disaster Scenarios. Comput. Commun. 2020, 160, 769–778. [Google Scholar] [CrossRef]

- Kireev, V.S.; Bochkaryov, P.V.; Guseva, A.I.; Kuznetsov, I.A.; Filippov, S.A. Monitoring System for the Housing and Utility Services Based on the Digital Technologies IIoT, Big Data, Data Mining, Edge and Cloud Computing. In Proceedings of the Communications in Computer and Information Science; Springer: Istanbul, Turkey, 2019; Volume 1054, pp. 193–205. [Google Scholar]

- Kochovski, P.; Stankovski, V. Supporting Smart Construction with Dependable Edge Computing Infrastructures and Applications. Autom. Constr. 2018, 85, 182–192. [Google Scholar] [CrossRef]

- Lee, C.M.; Kuo, W.L.; Tung, T.J.; Huang, B.K.; Hsu, S.H.; Hsieh, S.H. Government Open Data and Sensing Data Integration Framework for Smart Construction Site Management. In Proceedings of the 36th International Symposium on Automation and Robotics in Construction, ISARC 2019, Banff, AB, Canada, 21–24 May 2019; pp. 1261–1267. [Google Scholar]

- Wang, X.; Yew, A.W.W.; Ong, S.K.; Nee, A.Y.C. Enhancing Smart Shop Floor Management withUbiquitous Augmented Reality. Int. J. Prod. Res. 2020, 58, 2352–2367. [Google Scholar] [CrossRef]

- Tang, S.; Wang, R.; Zhao, X.; Nie, X. Building Cloud Services for Monitoring Offshore Equipment and Operators. In Proceedings of the Annual Offshore Technology Conference, Houston, TX, USA, 30 April–3 May 2018; Volume 2, pp. 852–864. [Google Scholar]

- Gomez, J.A.; Talavera, J.; Tobon, L.E.; Culman, M.A.; Quiroz, L.A.; Aranda, J.M.; Garreta, L.E. A Case Study on Monitoring and Geolocation of Noise in Urban Environments Using the Internet of Things. In Proceedings of the Second International Conference on Internet of things, Data and Cloud Computing, Cambridge, UK, 22–23 March 2017. [Google Scholar]

- Sawamura, M.; Iwamoto, S.; Kashihara, K. First application of CIM to tunnel construction in Japan. In Proceedings of the ISRM International Symposium—8th Asian Rock Mechanics Symposium, ARMS 2014, Sapporo, Japan, 14–16 October 2014; pp. 1054–1063. [Google Scholar]

- Zhitong, S.; Liang, G.; Shaozhi, L.; Sifang, Y. Research and appilcation of intergrated 2D&3D spatial geographical information sharing and monitoring platform —case study on the Pazhou new district of Guangzhou. J. Geomatics 2019, 44, 101–103. [Google Scholar] [CrossRef]

- Panteli, C.; Kylili, A.; Fokaides, P.A. Building information modelling applications in smart buildings: From design to commissioning and beyond A critical review. J. Clean. Prod. 2020, 265, 121766. [Google Scholar] [CrossRef]

- Stransky, M. Functions of Common Data Environment Supporting Procurement of Subcontractors. Eng. Rural Dev. 2020, 19, 793–799. [Google Scholar] [CrossRef]

- Liu, C.; Le Roux, L.; Körner, C.; Tabaste, O.; Lacan, F.; Bigot, S. Digital Twin-enabled Collaborative Data Management for Metal Additive Manufacturing Systems. J. Manuf. Syst. 2020. [Google Scholar] [CrossRef]

- Mahami, H.; Nasirzadeh, F.; Hosseininaveh Ahmadabadian, A.; Esmaeili, F.; Nahavandi, S. Imaging network design to improve the automated construction progress monitoring process. Constr. Innov. 2019, 19, 386–404. [Google Scholar] [CrossRef]

- Kirti, K.C.; Singla, A. Architecture for Garbage Monitoring System using Integrated Technologies with Short Literature Survey. In Proceedings of the ICRITO 2020—IEEE 8th International Conference on Reliability, Infocom Technologies and Optimization (Trends and Future Directions), Noida, India, 4–5 June 2020; pp. 27–32. [Google Scholar]

- Štefanič, M.; Stankovski, V. A Review of Technologies and Applications for Smart Construction. Proc. Inst. Civ. Eng. Civ. Eng. 2018, 172, 83–87. [Google Scholar] [CrossRef]

- Mansouri, S.; Castronovo, F.; Akhavian, R. Analysis of the Synergistic Effect of Data Analytics and Technology Trends in the AEC/FM Industry. J. Constr. Eng. Manag. 2020, 146, 04019113. [Google Scholar] [CrossRef]

- Arif, F.; Khan, W.A. A Real-Time Productivity Tracking Framework Using Survey-Cloud-BIM Integration. Arab. J. Sci. Eng. 2020, 45, 8699–8710. [Google Scholar] [CrossRef]

- Elshafey, A.; Saar, C.C.; Aminudin, E.B.; Gheisari, M.; Usmani, A. Technology Acceptance Model for Augmented Reality and Building Information Modeling Integration in the Construction Industry. J. Inf. Technol. Constr. 2020, 25, 161–172. [Google Scholar] [CrossRef]

- Vacanas, B.; Salem, O.; John Samuel, I.; Sid, S.H.; Dewberry, R. BIM and VR/AR technologies: From project development to lifecycle asset management. Proc. Int. Struct. Eng. Constr. 2020, 1–6. [Google Scholar] [CrossRef]

- Xie, X.; Lu, Q.; Rodenas-Herraiz, D.; Parlikad, A.K.; Schooling, J.M. Visualised Inspection System For Monitoring Environmental Anomalies During Daily Operation and Maintenance. Eng. Constr. Archit. Manag. 2020, 27, 1835–1852. [Google Scholar] [CrossRef]

- Ratajczak, J.; Schimanski, C.P.; Marcher, C.; Riedl, M.; Matt, D.T. Mobile Application for Collaborative Scheduling and Monitoring of Construction Works According to Lean Construction Methods. In Proceedings of the Lecture Notes in Computer Science (Including Subseries Lecture Notes in Artificial Intelligence and Lecture Notes in Bioinformatics); Springer: Mallorca, Spain, 2017; Volume 10451, pp. 207–214. [Google Scholar]

- Santos, M.C.F.; Costa, D.B.; Ferreira, E.D.A.M. Conceptual Framework for Integrating Cost Estimating and Scheduling with BIM. In Lecture Notes in Civil Engineering; Springer: Berlin/Heidelberg, Germany, 2021; Volume 98, pp. 613–625. [Google Scholar]

- Talamo, C.; Atta, N. FM Services Procurement and Management: Scenarios of Innovation. In Springer Tracts in Civil Engineering; Springer: Berlin/Heidelberg, Germany, 2019; pp. 201–242. [Google Scholar]

- Kouhestani, S.; Nik-Bakht, M. IFC-based Process Mining for Design Authoring. Autom. Constr. 2020, 112, 103069. [Google Scholar] [CrossRef]

- Angah, O.; Chen, A.Y. Removal of Occluding Construction Workers in Job site Image Data Using U-Net based Context Encoders. Autom. Constr. 2020, 119, 103332. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, Q.; Yang, B.; Wu, T.; Lei, K.; Zhang, B.; Fang, T. Vision-Based Framework for Automatic Progress Monitoring of Precast Walls by Using Surveillance Videos during the Construction Phase. J. Comput. Civ. Eng. 2021, 35, 04020056. [Google Scholar] [CrossRef]

- Soilán, M.; Justo, A.; Sánchez-Rodríguez, A.; Riveiro, B. 3D point cloud to BIM: Semi-automated framework to define IFC alignment entities from MLS-acquired LiDAR data of highway roads. Remote Sens. 2020, 12, 2301. [Google Scholar] [CrossRef]

- Ding, K.; Shi, H.; Hui, J.; Liu, Y.; Zhu, B.; Zhang, F.; Cao, W. Smart steel bridge construction enabled by BIM and Internet of Things in industry 4.0: A framework. In Proceedings of the ICNSC 2018—15th IEEE International Conference on Networking, Sensing and Control; Institute of Electrical and Electronics Engineers Inc.: Zhuhai, China, 2018; pp. 1–5. [Google Scholar]

- Braun, A.; Tuttas, S.; Borrmann, A.; Stilla, U. Improving progress monitoring by fusing point clouds, semantic data and computer vision. Autom. Constr. 2020, 116, 103210. [Google Scholar] [CrossRef]