Optimal Versus Equal Dimensions of Round Bales of Agricultural Materials Wrapped with Plastic Film—Conflict or Compliance?

Abstract

:1. Introduction

2. Materials and Methods

2.1. Equal and Near-Equal Optimal Bale Dimensions

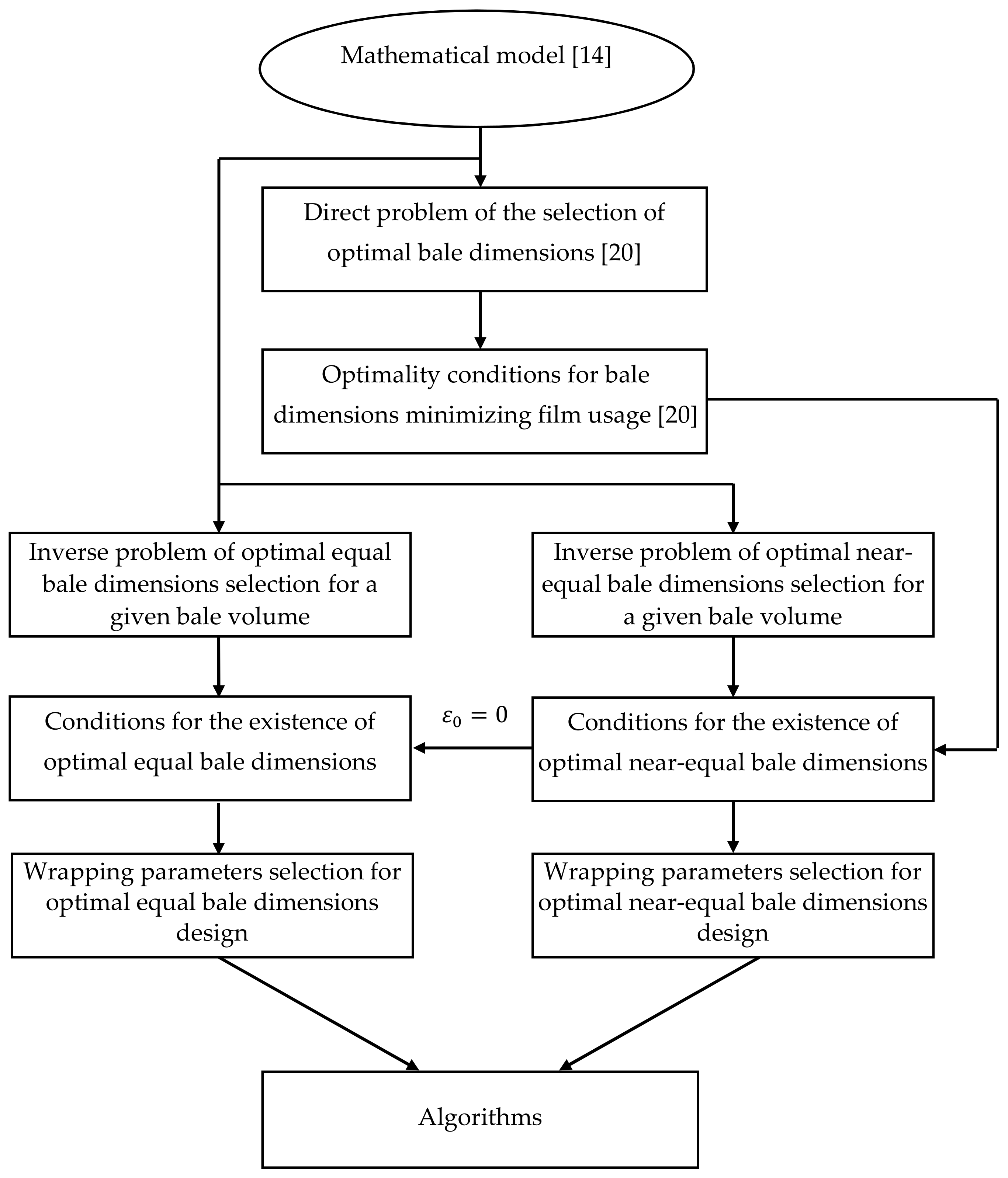

2.2. Methodology

2.3. Necessary and Sufficient Conditions of Bale Dimensions Equilibrium and Near-Equilibrium

2.3.1. Near-Equal Optimal Dimensions

- (i)

- orderand the bale, film, and wrapping parameters are related by the equation

- (ii)

- the equationsandare satisfied, simultaneously. The optimal bale diameterand heightare described by Equations (5) and (6), respectively; in case (i) for a given bale volume, in case (ii) for an arbitrary volume.

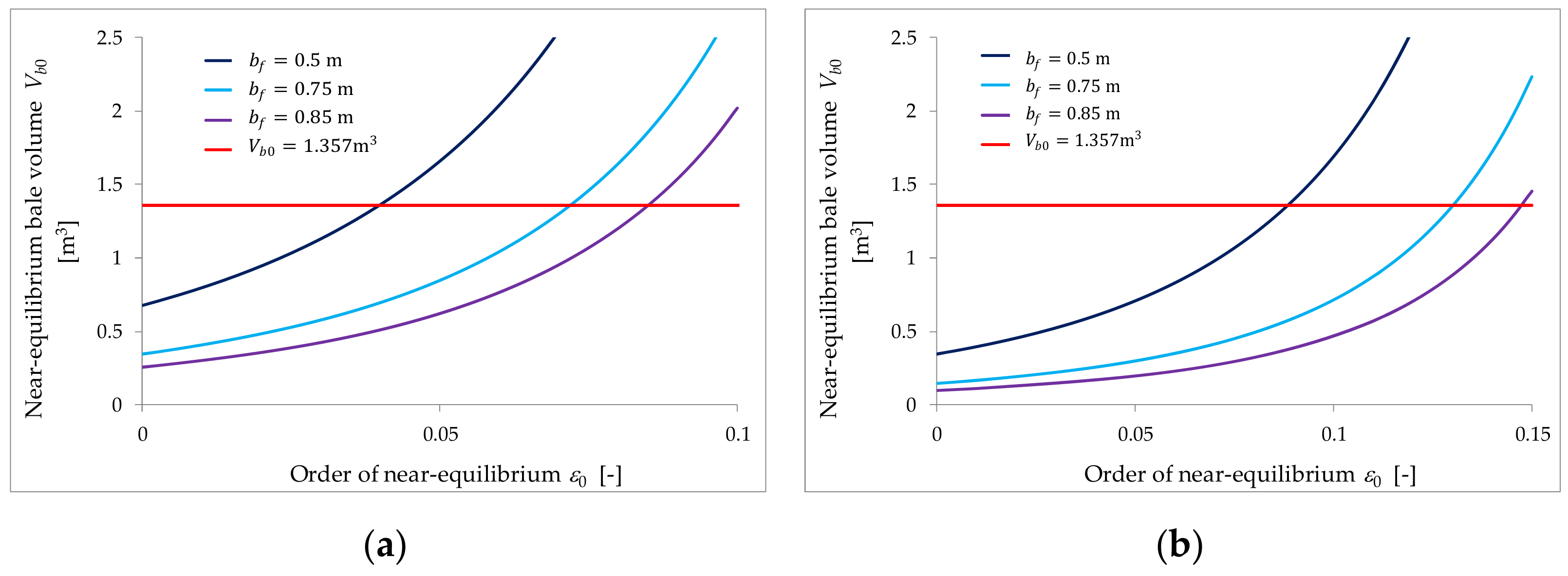

2.3.2. Bale Volume of Near-Equilibrium

- (a)

- inequality from Equation (12) holds,

- (b)

- two inequalitieshold, simultaneously. Then, for anyand volumeEquation (7) holds for. The optimal bale dimensions,are expressed by equations:In case (a),and,are monotonically increasing for. In case (b),and,are monotonically decreasing for. If inequalities from Equations (13) and (14) hold, but inequality expressed by Equation (15) not, then there exists positivesuch thatandFor anybale volumesatisfying Equation (7) and optimal bale dimensions,are near-equal in the sense of the inequalitiesBothand,are monotonically decreasing for.

2.3.3. Equal Optimal Dimensions

- (i)

- the bale, film and wrapping parameters are related by the equation

- (ii)

- the equationand Equation (9) are satisfied, simultaneously. The optimal bale dimensions are given directly by Equation (19) for fixed volumein case (i) or for arbitrary volume in case (ii).

3. Results and Discussion

3.1. Volume-Free Near-Equal Optimal Bale Dimensions Design

3.1.1. Algorithm 1

- Determine the set of all integer defined by the inequalitiesfor which there exists satisfying applicability condition, Equation (21).

- If the set is empty, then the solution to Problem 1 does not exist—go to step 3. Otherwise, go to step 4.

- Change the lower , or upper , bounds of wrapping parameters, or the order , or the film width and repeat the computations starting from step 1.

- For any compute the overlap ratio according to Equation (27) and, next, the overlap .

- If a bale volume is assumed, then for any compute film usage obtained for optimal , , Equations (5) and (6), using Equation (A2) and choose that which yields the minimal film consumption.

3.1.2. Example 1

3.1.3. Effect of the Non-Equilibrium Order

3.1.4. Effect of the Film Width

3.2. Volume-Fixed Near-Equal Optimal Bale Dimensions Design

3.2.1. Algorithm 2

- Determine the set of all integer for which there exists satisfying applicability condition, Equation (21), and the set of overlap ratios defined by the inequalities expressed by Equations (29) and (30) is nonempty.

- If the set is empty, then the solution to Problem 2 does not exist—go to step 3. Otherwise, go to step 4.

- Change the lower , or upper , bounds of wrapping parameters, or the order , or the film width and go to step 1.

- Solve in the integer programming task expressed by Equation (36) for .

- For the best choose practically reasonable , compute the overlap according to Equation (34) and optimal , using Equations (5) and (6). The minimal film consumption is equal to computed in step 4.

3.2.2. Example 2

3.3. Volume-Free Optimal Equal Bale Dimensions Design

3.3.1. Algorithm 3

- Determine the set of all integer defined by the inequalities from Equation (39) for which there exists satisfying applicability condition, Equation (21).

- If the set is empty, then the solution to Problem 3 does not exist—go to step 3. Otherwise, go to step 4.

- Change the lower , or upper , bounds of wrapping parameters or the film width and go to step 1.

- For any compute the overlap ratio and, next, overlap according to Equation (40).

- For any and assumed bale volume compute film usage obtained for the optimal , , Equation (19), using Equation (A2) and choose that which yields the minimal film consumption.

3.3.2. Example 3

3.4. Volume-Fixed Optimal Equal Bale Dimensions Design

Example 4

3.5. Optimal Film Usage

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

Appendix A

Appendix A1. Film Consumption

Appendix A2. Film Consumption Minimization

Appendix B

- (i)

- the wrapping parameters and order are such that

- (ii)

- for the wrapping parameters and the following equality holds

- in case (i) inequality expressed by Equation (13) is satisfied,

- in case (ii)

Appendix C

Appendix C1. Nomenclature

| width of un-stretched film, m | |

| width of stretched film, Equation (A1), m | |

| , | bale diameter and height, m |

| optimal bale diameter, solution of Equation (1), m | |

| optimal bale height given by Equation (2), m | |

| film consumption index, Equation (A2), m−1 | |

| , | overlap ratios applied to wrap bottom and upper film layers |

| , | the smallest and largest admissible , Equation (23) |

| lower bound of solving Problem 2, Equation (32) | |

| , | upper bounds of solving Problem 2, Equations (33) and (31) |

| lower bound of solving Problem 4, Equation (41) | |

| , | bounds of solving Problem 4, Equations (43) and (44) |

| set of overlap ratios defined for by Equations (29) and (30) | |

| integer number | |

| set of all positive integer numbers | |

| global number of basic film layers | |

| , | numbers of basic film layers in bottom and upper layers |

| optimal solving Problems 2 and 4 defined in Equation (36) | |

| set of for which Problem 1 has solution, defined in Equation (28) | |

| , | sets of for which Problems 2,3 have solution |

| Poisson’s ratio of the stretch film | |

| pre-assumed bale volume, m3 | |

| order of nearly-equal bale dimensions introduced in Equation (4) | |

| unit deformation of the stretch film | |

| function of the overlap ratio defined by Equation (A3) | |

| overlap of extreme film strips at base of bale, m | |

| , | the smallest and largest admissible overlap δ, Equation (22), m |

Appendix C2. Mathematical Terminology

| the smallest integer not less than , ceiling function | |

| the largest integer not greater than , floor function |

References

- Muise, I.; Adams, M.; Côté, R.; Price, G. Attitudes to the recovery and recycling of agricultural plastics waste: A case study of Nova Scotia, Canada. Resour. Conserv. Recycl. 2016, 109, 137–145. [Google Scholar] [CrossRef]

- Pazienza, P.; De Lucia, C. For a new plastics economy in agriculture: Policy reflections on the EU strategy from a local perspective. J. Clean. Prod. 2020, 253, 119844. [Google Scholar] [CrossRef]

- Rotz, C.A.; Stout, R.; Leytem, A.; Feyereisen, G.; Waldrip, H.; Thoma, G.; Holly, M.; Bjorneberg, D.; Baker, J.; Vadas, P.; et al. Environmental assessment of United States dairy farms. J. Clean. Prod. 2021, 315, 128153. [Google Scholar] [CrossRef]

- Tkaczyk, S.; Drozd, M.; Kędzierski, Ł.; Santarek, K. Study of the Stability of Palletized Cargo by Dynamic Test Method Performed on Laboratory Test Bench. Sensors 2021, 21, 5129. [Google Scholar] [CrossRef]

- Baldasano, J.; Gassó, S.; Pérez, C. Environmental performance review and cost analysis of MSW landfilling by baling-wrapping technology versus conventional system. Waste Manag. 2003, 23, 795–806. [Google Scholar] [CrossRef]

- Borreani, G.; Bisaglia, C.; Tabacco, E. Effects of a New-Concept Wrapping System on Alfalfa Round-Bale Silage. Trans. ASABE 2007, 50, 781–787. [Google Scholar] [CrossRef]

- Hong, S.; Kang, D.; Kim, D.; Lee, S. Analysis of bale surface pressure according to stretch film layer changes on round bale wrapping. J. Biosyst. Eng. 2017, 42, 136–146. [Google Scholar]

- Li, L.; Wang, D.; Yang, X. Study on round rice straw bale wrapping silage technology and facilities. Int. J. Agric. Biol. Eng. 2018, 11, 88–95. [Google Scholar] [CrossRef]

- Tabacco, E.; Bisaglia, C.; Revello-Chion, A.; Borreani, G. Assessing the Effect of Securing Bales with either Polyethylene Film or Netting on the Fermentation Profiles, Fungal Load, and Plastic Consumption in Baled Silage of Grass-Legume Mixtures. Appl. Eng. Agric. 2013, 29, 795–804. [Google Scholar]

- Ivanovs, S.; Gach, S.; Skonieczny, I.; Adamovičs, A. Impact of the parameters of round and square haylage bales on the consumption of the sealing film for individual and in-line wrapping. Agron. Res. 2013, 11, 53–60. [Google Scholar]

- Gach, S.; Piotrowska, E.; Skonieczny, I. Foil consumption in wrapping of the single green forage bales. Ann. Wars. Agric. Univ. Life Sci.-SGGW Agric. 2010, 56, 13–20. [Google Scholar]

- Stępniewski, A.; Nowak, J.; Stankiewicz, A. Analytical model of foil consumption for cylindrical bale wrapping. Econtechmod Int. Q. J. Econ. Technol. Model. Process. 2016, 5, 78–82. [Google Scholar]

- Stępniewski, A.; Nowak, J. The effect of additional foil wraps on the tightness of the packaging of bales. Econtechmod Int. Q. J. Econ. Technol. Model. Process. 2018, 7, 145–150. [Google Scholar]

- Stankiewicz, A. Model-Based Analysis of Stretch Film Consumption for Wrapping Cylindrical Baled Silage Using Combined 3D Method. Trans. ASABE 2019, 62, 803–820. [Google Scholar] [CrossRef]

- Stankiewicz, A.; Stępniewski, A.; Nowak, J. On the mathematical modelling and optimization of foil consumption for cylindrical bale wrapping. Econtechmod Int. Q. J. Econ. Technol. Model. Process. 2016, 5, 101–110. [Google Scholar]

- Stankiewicz, A. Minimizing the Consumption of Stretch Film for Wrapping Cylindrical Baled Silage Using the IntelliWrap Method. Trans. ASABE 2020, 63, 967–980. [Google Scholar] [CrossRef]

- Stankiewicz, A. On the uniform distribution and optimal consumption of stretch film used for wrapping cylindrical baled silage. Grass Forage Sci. 2019, 74, 584–595. [Google Scholar] [CrossRef]

- Stankiewicz, A. Optimal and Robustly Optimal Consumption of Stretch Film Used for Wrapping Cylindrical Baled Silage. Agriculture 2019, 9, 248. [Google Scholar] [CrossRef] [Green Version]

- Stankiewicz, A. Modelling and Optimisation of the Consumption of Stretch Film for Wrapping Baled Silages, 1st ed.; Polihymnia: Lublin, Poland, 2020. [Google Scholar]

- Stankiewicz, A. Optimization and Analysis of Plastic Film Consumption for Wrapping Round Baled Silage Using Combined 3D Method Considering Effects of Bale Dimensions. Trans. ASABE 2021, 64, 727–743. [Google Scholar] [CrossRef]

- Bale Wrappers. BW 1100-1104-1200-1400-1600-1604-1850. Brochure. Vicon. Available online: http://www.to-da.si/wp-content/uploads/2009/12/ovijalke.pdf (accessed on 26 June 2021).

- Baler-Wrapper Combinations. i-BIO+, FBP, VBP. Brochure. Saverne, France: Kuhn. Available online: https://docplayer.net/146964369-Baler-wrapper-combinations-i-bio-fbp-vbp-be-strong-be.html (accessed on 26 June 2021).

- WRAPMASTER.1121•1221•1431•1631•1851•1124•1634•4034. Brochure. Deutz-Fahr Evolving Agriculture. Available online: http://www.expansaolda.pt/conteudos/File/Catalogo/Deutz%20Fahr/deutz%20fahr%20WrapMaster%20GB.pdf (accessed on 26 June 2021).

- Bortolini, M.; Cascini, A.; Gamberi, M.; Mora, C. Environmental assessment of an innovative agricultural machinery. Int. J. Oper. Quant. Manag. 2014, 20, 243–258. [Google Scholar]

- Coblentz, W.; Akins, M.; Cavadini, J. Fermentation characteristics and nutritive value of baled grass silages made from meadow fescue, tall fescue, or an orchardgrass cultivar exhibiting a unique nonflowering growth response. J. Dairy Sci. 2020, 103, 3219–3233. [Google Scholar] [CrossRef]

- Borreani, G.; Tabacco, E. New Oxygen Barrier Stretch Film Enhances Quality of Alfalfa Wrapped Silage. Agron. J. 2008, 100, 942–948. [Google Scholar] [CrossRef]

- Borreani, G.; Tabacco, E. Use of New Plastic Stretch Films with Enhanced Oxygen Impermeability to Wrap Baled Alfalfa Silage. Trans. ASABE 2010, 53, 635–641. [Google Scholar] [CrossRef]

- McEniry, J.; Forristal, P.D.; O’Kiely, P. Gas composition of baled grass silage as influenced by the amount, stretch, colour and type of plastic stretch-film used to wrap the bales, and by the frequency of bale handling. Grass Forage Sci. 2011, 66, 277–289. [Google Scholar] [CrossRef]

- McEniry, J.; Forristal, P.D.; O’Kiely, P. Factors influencing the conservation characteristics of baled and precision-chop grass silages. Ir. J. Agric. Food Res. 2011, 50, 175–188. [Google Scholar]

- Sun, Y.; Cheng, Q.; Meng, F.; Buescher, W.; Maack, C.; Ross, F.; Lin, J. Image-based comparison between a γ-ray scanner and a dual-sensor penetrometer technique for visual assessment of bale density distribution. Comput. Electron. Agric. 2012, 82, 1–7. [Google Scholar] [CrossRef]

- Li, P.; Gou, W.; Zhang, Y.; Yang, F.; You, M.; Bai, S.; Shen, Y. Fluctuant storage temperature increased the heterogeneous distributions of pH and fermentation products in large round bale silage. Grassl. Sci. 2019, 65, 155–161. [Google Scholar] [CrossRef]

- Coblentz, W.; Coffey, K.; Chow, E. Storage characteristics, nutritive value, and fermentation characteristics of alfalfa packaged in large-round bales and wrapped in stretch film after extended time delays. J. Dairy Sci. 2016, 99, 3497–3511. [Google Scholar] [CrossRef] [PubMed]

- Martelli, R.; Bentini, M.; Monti, A. Harvest storage and handling of round and square bales of giant reed and switchgrass: An economic and technical evaluation. Biomass Bioenergy 2015, 83, 551–558. [Google Scholar] [CrossRef]

- Román, F.D.; Hensel, O. Numerical simulations and experimental measurements on the distribution of air and drying of round hay bales. Biosyst. Eng. 2014, 122, 1–15. [Google Scholar] [CrossRef]

- Schenck, J.; Müller, C.; Djurle, A.; Jensen, D.F.; O’Brien, M.; Johansen, A.; Rasmussen, P.H.; Spörndly, R. Occurrence of filamentous fungi and mycotoxins in wrapped forages in Sweden and Norway and their relation to chemical composition and management. Grass Forage Sci. 2019, 74, 613–625. [Google Scholar] [CrossRef]

- Arco-Pérez, A.; Ramos-Morales, E.; Yáñez-Ruiz, D.; Abecia, L.; Martin-Garcia, A.I. Nutritive evaluation and milk quality of including of tomato or olive by-products silages with sunflower oil in the diet of dairy goats. Anim. Feed. Sci. Technol. 2017, 232, 57–70. [Google Scholar] [CrossRef]

- Nowak, J.W.; Stępniewski, A.; Bulgakov, V. Machines for Wrapping of the Ensiled Forage with Film; University of Life Sciences Publishing House: Lublin, Poland, 2019. (In Polish) [Google Scholar]

- Zhang, S.L.; Li, J.C.M. Anisotropic elastic moduli and Poisson’s ratios of a poly(ethylene terephthalate) film. J. Polym. Sci. B Polym. Phys. 2004, 42, 260–266. [Google Scholar] [CrossRef]

- Borreani, G.; Tabacco, E. New concepts on baled silage. In Proceedings of the 2nd International Conference on Forages, Lavras, Brazil, 28–30 May 2018; Ávila, C.L.S., Casagrande, D.R., Lara, M.A.S., Bernardes, T.F., Eds.; SUPREMA Gráfica e Editora Ltda: Lavras, Brazil, 2018; pp. 49–73. [Google Scholar]

- Nonaka, K.; Nakuit, T.; Ohshita, T. The effects of the number of film wrapping layers and moisture content on the quality of round bales of low moisture timothy silage. Grassl. Sci. 1999, 45, 270–277. [Google Scholar]

- Coblentz, W.; Akins, M. Silage review: Recent advances and future technologies for baled silages. J. Dairy Sci. 2018, 101, 4075–4092. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Bu, D.; Guo, W.; Song, Z.; Zhang, J. Effect of storing total mixed rations anaerobically in bales on feed quality. Anim. Feed. Sci. Technol. 2010, 161, 94–102. [Google Scholar] [CrossRef]

- Wilkinson, J.M.; Rinne, M. Highlights of progress in silage conservation and future perspectives. Grass Forage Sci. 2018, 73, 40–52. [Google Scholar] [CrossRef]

- Gaillard, F. L’ensilage en balles rondes sous film étirable. Fourrages 1990, 123, 289–304. [Google Scholar]

- Graham, R.L.; Knuth, D.E.; Patashnik, O.; Liu, S. Concrete Mathematics: A Foundation for Computer Science. Comput. Phys. 1989, 3, 106–107. [Google Scholar] [CrossRef]

- Geletukha, G.; Drahniev, S.; Zheliezna, T.; Zubenko, V.; Haidai, O. Technologies for energy production from lignocellulosic agricultural residues. In Innovative Renewable Waste Conversion Technologies; Springer Science and Business Media LLC: Cham, Switzerland, 2021; pp. 281–345. [Google Scholar]

- Tang, Z.; Zhang, B.; Liu, X.; Ren, H.; Li, X.; Li, Y. Structural model and bundling capacity of crawler picking and baling machine for straw wasted in field. Comput. Electron. Agric. 2020, 175, 105622. [Google Scholar] [CrossRef]

- Tumuluru, J.S.; Yancey, N.A.; Kane, J.J. Pilot-scale grinding and briquetting studies on variable moisture content municipal solid waste bales—Impact on physical properties, chemical composition, and calorific value. Waste Manag. 2021, 125, 316–327. [Google Scholar] [CrossRef] [PubMed]

- Ozbay, I.; Durmusoglu, E. Temporal variation of decomposition gases from baled municipal solid wastes. Bioresour. Technol. 2012, 112, 105–110. [Google Scholar] [CrossRef] [PubMed]

| 0.05 | 10 | 4 | 0.394 | 0.113 | 50.815 |

| 12 | 5 | 0.351 | 0.100 | 61.958 | |

| 0.1 | 10 | 4 | 0.444 | 0.127 | 50.815 |

| 12 | 5 | 0.405 | 0.116 | 61.958 | |

| 14 | 6 | 0.375 | 0.107 | 71.541 | |

| 16 | 7 | 0.352 | 0.101 | 81.124 | |

| 0.15 | 14 | 6 | 0.423 | 0.121 | 71.541 |

| 16 | 7 | 0.402 | 0.115 | 81.124 |

| 0.05 | 10 | 4 | 0.394 | 0.135 | 49.478 |

| 12 | 5 | 0.351 | 0.120 | 59.507 | |

| 14 | 6 | 0.318 | 0.109 | 67.664 | |

| 16 | 7 | 0.293 | 0.100 | 77.693 | |

| 0.1 | 10 | 4 | 0.444 | 0.152 | 55.360 |

| 12 | 5 | 0.405 | 0.139 | 59.507 | |

| 14 | 6 | 0.375 | 0.129 | 67.664 | |

| 16 | 7 | 0.352 | 0.121 | 77.693 | |

| 0.15 | 14 | 6 | 0.423 | 0.145 | 67.664 |

| 16 | 7 | 0.402 | 0.138 | 77.693 |

| 0.05 | 4 | 2 | 0.091 | 0.225 | 0.348 | 0.387 | [0.225, 0.348] | 20.804 | |

| 6 | 3 | 0.091 | 0.225 | 0.348 | 0.387 | [0.225, 0.348] | 31.979 | ||

| 8 | 4 | 0.091 | 0.225 | 0.348 | 0.387 | [0.225, 0.348] | 41.607 | ||

| 10 | 4 | 0.394 | 0.424 | 0.447 | 0.545 | [0.424, 0.447] | 52.445 | ||

| 10 | 5 | 0.091 | 0.225 | 0.348 | 0.387 | [0.225, 0.348] | 51.235 | ||

| 10 | 6 | −0.364 | 0.200 | 0.260 | 0.204 | [0.200, 0.204] | 51.573 | ||

| 12 | 5 | 0.351 | 0.393 | 0.430 | 0.520 | [0.393, 0.430] | 62.073 | ||

| 12 | 6 | 0.091 | 0.225 | 0.348 | 0.387 | [0.225, 0.348] | 62.411 | ||

| 12 | 7 | −0.273 | 0.200 | 0.274 | 0.237 | [0.200, 0.237] | 61.200 | ||

| 14 | 6 | 0.318 | 0.370 | 0.418 | 0.502 | [0.370, 0.418] | 71.700 | ||

| 14 | 7 | 0.091 | 0.225 | 0.348 | 0.387 | [0.225, 0.348] | 72.038 | ||

| 14 | 8 | −0.212 | 0.200 | 0.284 | 0.259 | [0.200, 0.259] | 72.376 | ||

| 16 | 7 | 0.293 | 0.353 | 0.409 | 0.488 | [0.353, 0.409] | 82.876 | ||

| 16 | 8 | 0.091 | 0.225 | 0.348 | 0.387 | [0.225, 0.348] | 81.666 | ||

| 16 | 9 | −0.169 | 0.200 | 0.292 | 0.276 | [0.200, 0.276] | 82.004 | ||

| 0.1 | 4 | 2 | 0.167 | 0.273 | 0.381 | 0.429 | [0.273, 0.381] | 20.885 | |

| 6 | 3 | 0.167 | 0.273 | 0.381 | 0.429 | [0.273, 0.381] | 32.096 | ||

| 8 | 4 | 0.167 | 0.273 | 0.381 | 0.429 | [0.273, 0.381] | 41.769 | ||

| 8 | 5 | −0.389 | 0.200 | 0.273 | 0.206 | [0.200, 0.206] | 42.217 | ||

| 10 | 5 | 0.167 | 0.273 | 0.381 | 0.429 | [0.273, 0.381] | 52.980 | ||

| 10 | 6 | −0.250 | 0.200 | 0.293 | 0.255 | [0.200, 0.255] | 51.890 | ||

| 12 | 5 | 0.405 | 0.433 | 0.461 | 0.554 | [0.433, 0.450] | 62.206 | ||

| 12 | 6 | 0.167 | 0.273 | 0.381 | 0.429 | [0.273, 0.381] | 62.654 | ||

| 12 | 7 | −0.167 | 0.200 | 0.307 | 0.286 | [0.200, 0.286] | 63.102 | ||

| 14 | 6 | 0.375 | 0.411 | 0.449 | 0.538 | [0.411, 0.449] | 73.417 | ||

| 14 | 7 | 0.167 | 0.273 | 0.381 | 0.429 | [0.273, 0.381] | 72.327 | ||

| 14 | 8 | −0.111 | 0.200 | 0.317 | 0.308 | [0.200, 0.308] | 72.775 | ||

| 16 | 7 | 0.352 | 0.395 | 0.440 | 0.525 | [0.395, 0.440] | 83.091 | ||

| 16 | 8 | 0.167 | 0.273 | 0.381 | 0.429 | [0.273, 0.381] | 83.538 | ||

| 16 | 9 | −0.071 | 0.200 | 0.325 | 0.324 | [0.200, 0.324] | 82.448 | ||

| 16 | 10 | −0.389 | 0.200 | 0.273 | 0.206 | [0.200, 0.206] | 82.896 |

| 0.1 | 0.75 | 8 | 3 | 0.400 | 0.114 | 41.047 |

| 14 | 5 | 0.444 | 0.127 | 72.524 | ||

| 16 | 6 | 0.400 | 0.114 | 82.095 | ||

| 0.9 | 8 | 3 | 0.400 | 0.137 | 39.449 | |

| 10 | 4 | 0.333 | 0.114 | 49.478 | ||

| 14 | 5 | 0.444 | 0.152 | 76.222 | ||

| 16 | 6 | 0.400 | 0.137 | 78.898 | ||

| 0.15 | 14 | 5 | 0.444 | 0.152 | 76.222 |

| 0.75 | 4 | 2 | [0.200, 0.311] | 20.726 | |

| 6 | 3 | [0.200, 0.311] | 30.309 | ||

| 8 | 3 | [0.428, 0.439] | 41.232 | ||

| 8 | 4 | [0.200, 0.311] | 41.453 | ||

| 10 | 4 | [0.380, 0.412] | 50.815 | ||

| 10 | 5 | [0.200, 0.311] | 51.036 | ||

| 12 | 5 | [0.346, 0.394] | 61.958 | ||

| 12 | 6 | [0.200, 0.311] | 60.619 | ||

| 14 | 6 | [0.322, 0.382] | 71.541 | ||

| 14 | 7 | [0.200, 0.311] | 71.762 | ||

| 14 | 8 | [0.200, 0.204 | 70.423 | ||

| 16 | 6 | [0.428, 0.439] | 80.903 | ||

| 16 | 7 | [0.304, 0.372] | 81.124 | ||

| 16 | 8 | [0.200, 0.311] | 81.345 | ||

| 16 | 9 | [0.200, 0.222] | 81.566 | ||

| 0.9 | 4 | 2 | [0.200, 0.263] | 20.058 | |

| 6 | 3 | [0.200, 0.263] | 30.087 | ||

| 8 | 3 | [0.410, 0.450] | 43.861 | ||

| 8 | 4 | [0.200, 0.263] | 38.244 | ||

| 10 | 4 | [0.362, 0.377] | 49.478 | ||

| 10 | 5 | [0.200, 0.263] | 48.273 | ||

| 12 | 5 | [0.330, 0.357] | 59.507 | ||

| 12 | 6 | [0.200, 0.263] | 58.302 | ||

| 14 | 5 | [0.443, 0.450] | 76.222 | ||

| 14 | 6 | [0.306, 0.343] | 67.664 | ||

| 14 | 7 | [0.200, 0.263] | 68.331 | ||

| 16 | 6 | [0.410, 0.450] | 87.722 | ||

| 16 | 7 | [0.288, 0.333] | 77.693 | ||

| 16 | 8 | [0.200, 0.263] | 76.487 | ||

| 16 | 9 | [0.200, 0.206] | 90.389 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stankiewicz, A. Optimal Versus Equal Dimensions of Round Bales of Agricultural Materials Wrapped with Plastic Film—Conflict or Compliance? Appl. Sci. 2021, 11, 10246. https://doi.org/10.3390/app112110246

Stankiewicz A. Optimal Versus Equal Dimensions of Round Bales of Agricultural Materials Wrapped with Plastic Film—Conflict or Compliance? Applied Sciences. 2021; 11(21):10246. https://doi.org/10.3390/app112110246

Chicago/Turabian StyleStankiewicz, Anna. 2021. "Optimal Versus Equal Dimensions of Round Bales of Agricultural Materials Wrapped with Plastic Film—Conflict or Compliance?" Applied Sciences 11, no. 21: 10246. https://doi.org/10.3390/app112110246

APA StyleStankiewicz, A. (2021). Optimal Versus Equal Dimensions of Round Bales of Agricultural Materials Wrapped with Plastic Film—Conflict or Compliance? Applied Sciences, 11(21), 10246. https://doi.org/10.3390/app112110246