Effect of Freeze–Thaw Cycles on the Performance of Concrete Containing Water-Cooled and Air-Cooled Slag

Abstract

:1. Introduction

2. Experimental Procedure

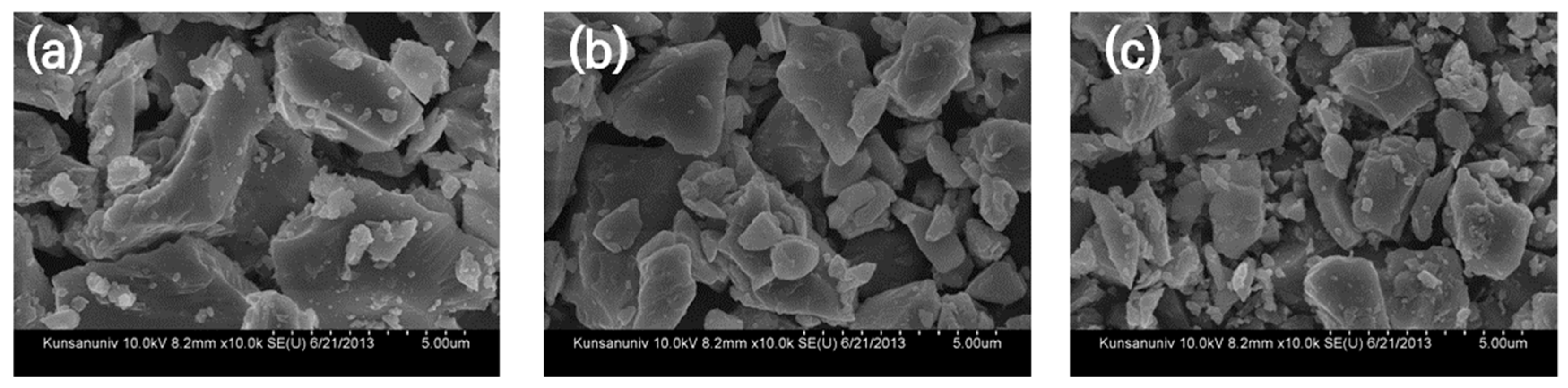

2.1. Materials

2.2. Mix Proportions

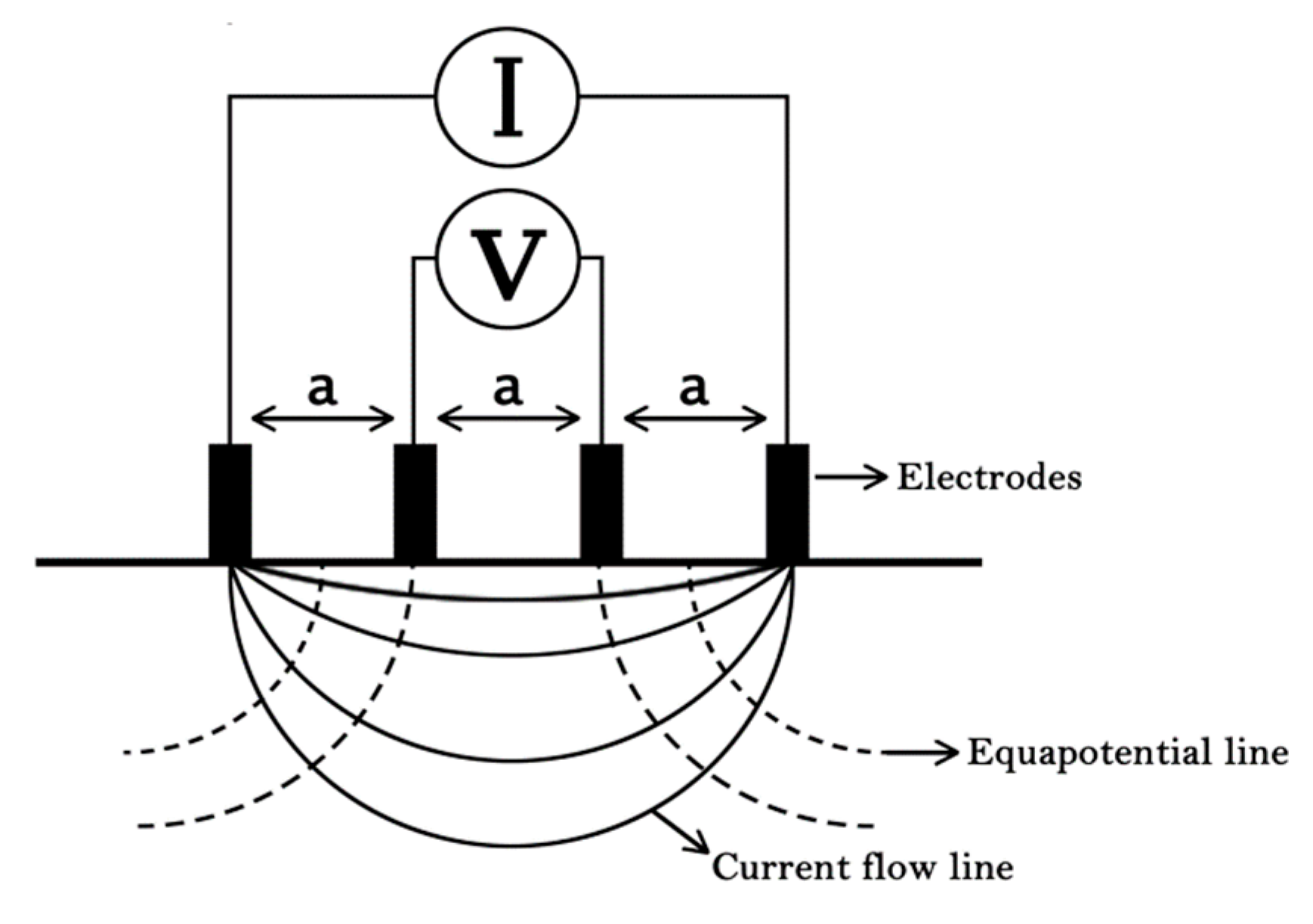

2.3. Test Methods

3. Results and Discussion

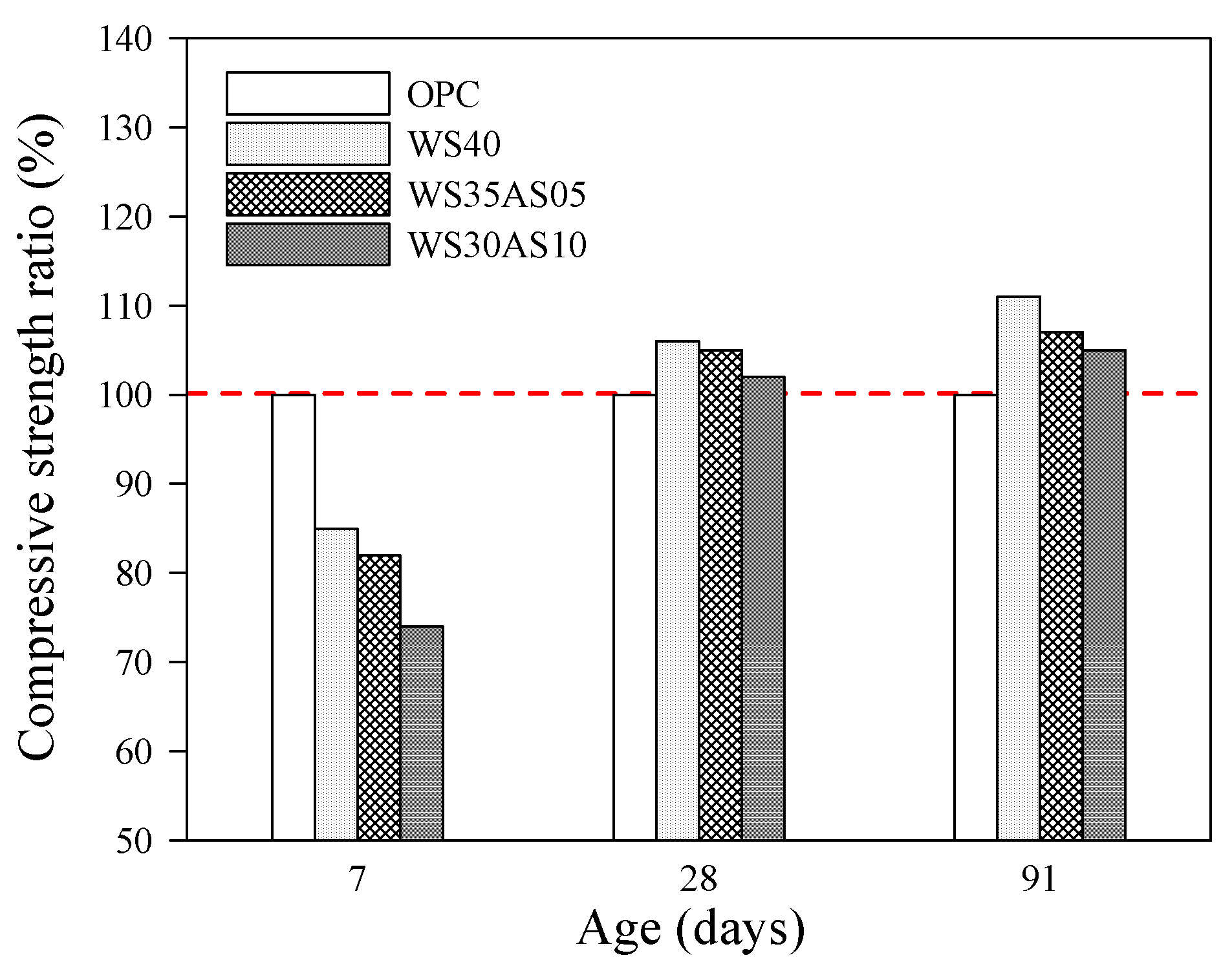

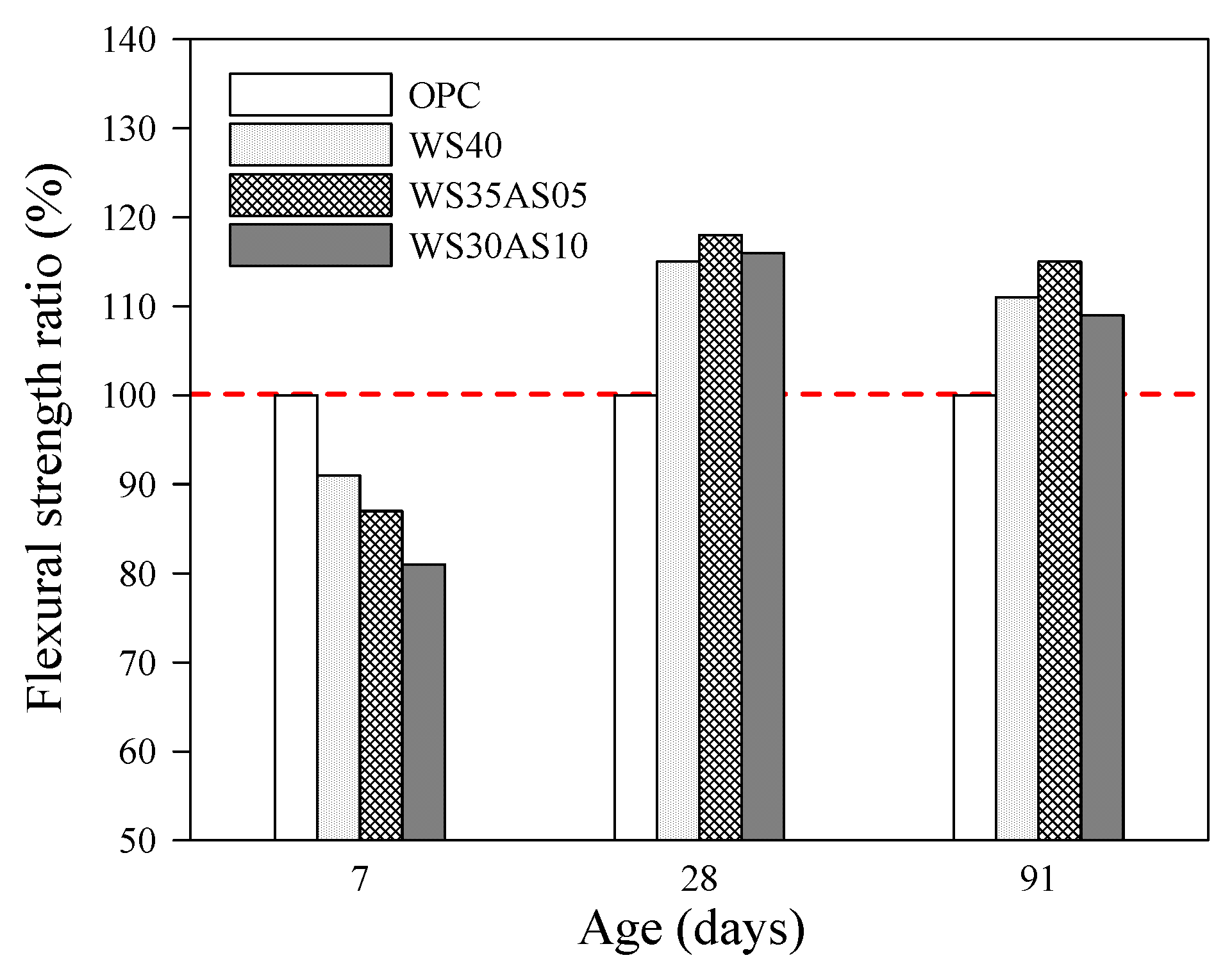

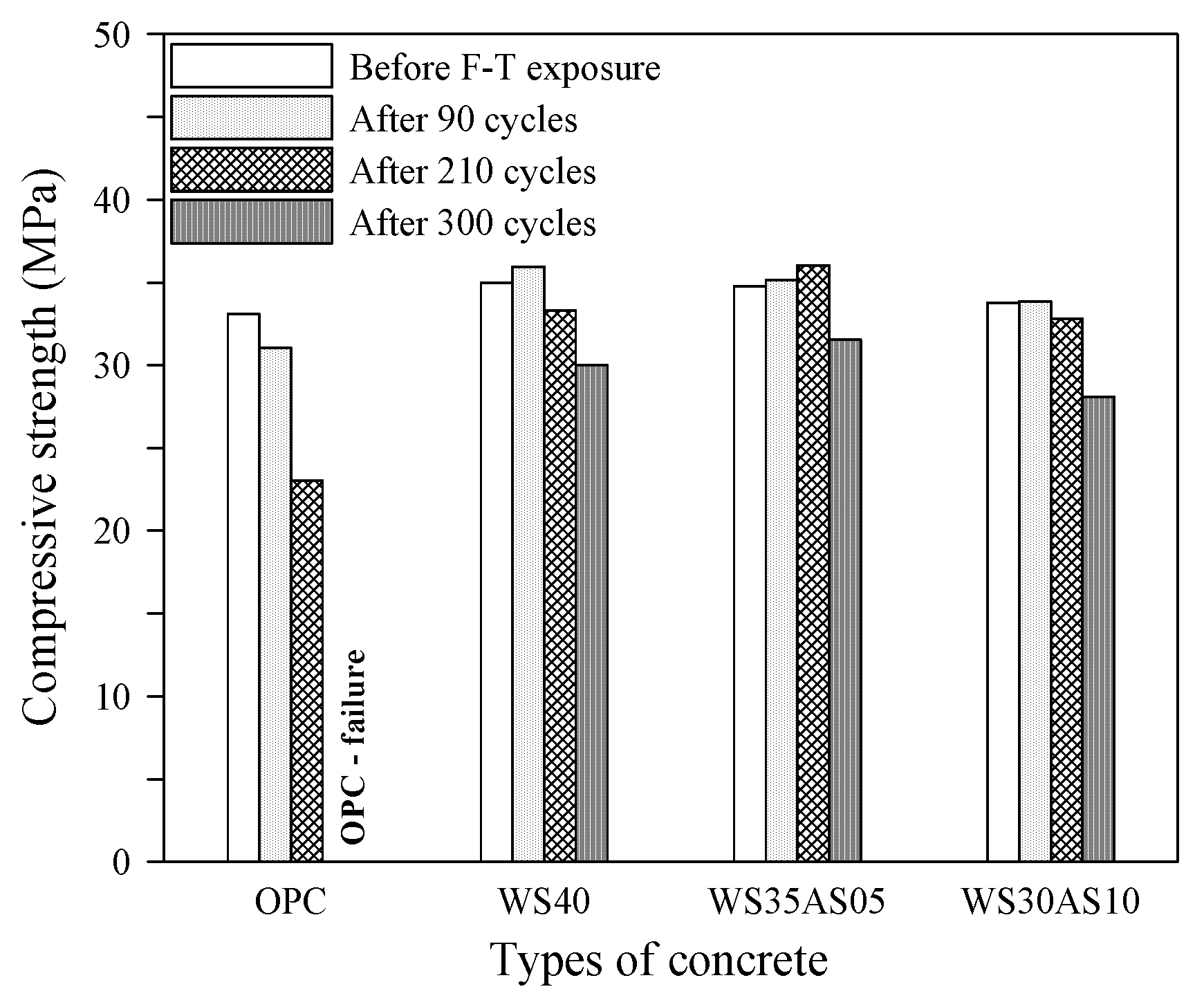

3.1. Strength Characteristics

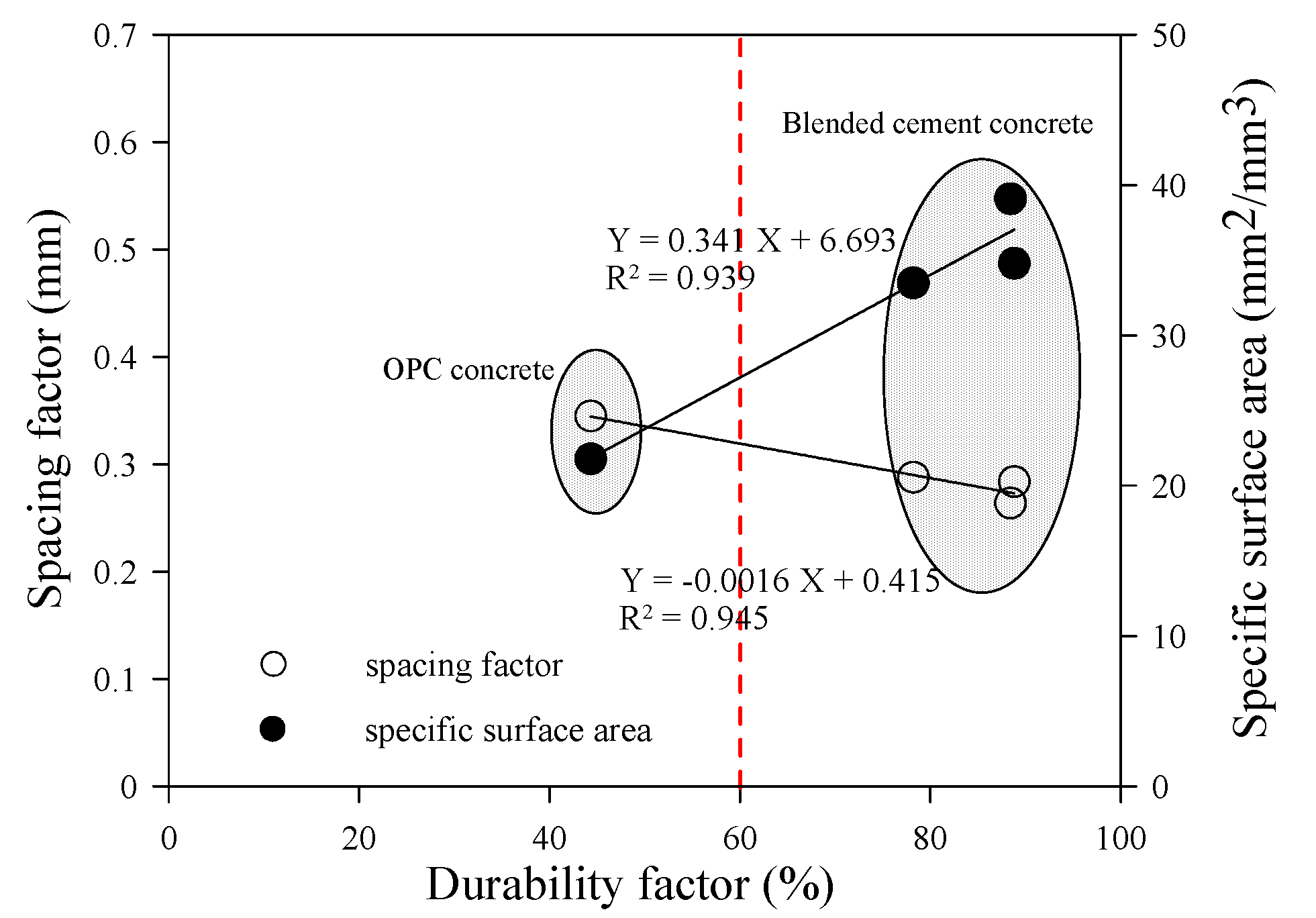

3.2. Air-Void System of Concrete

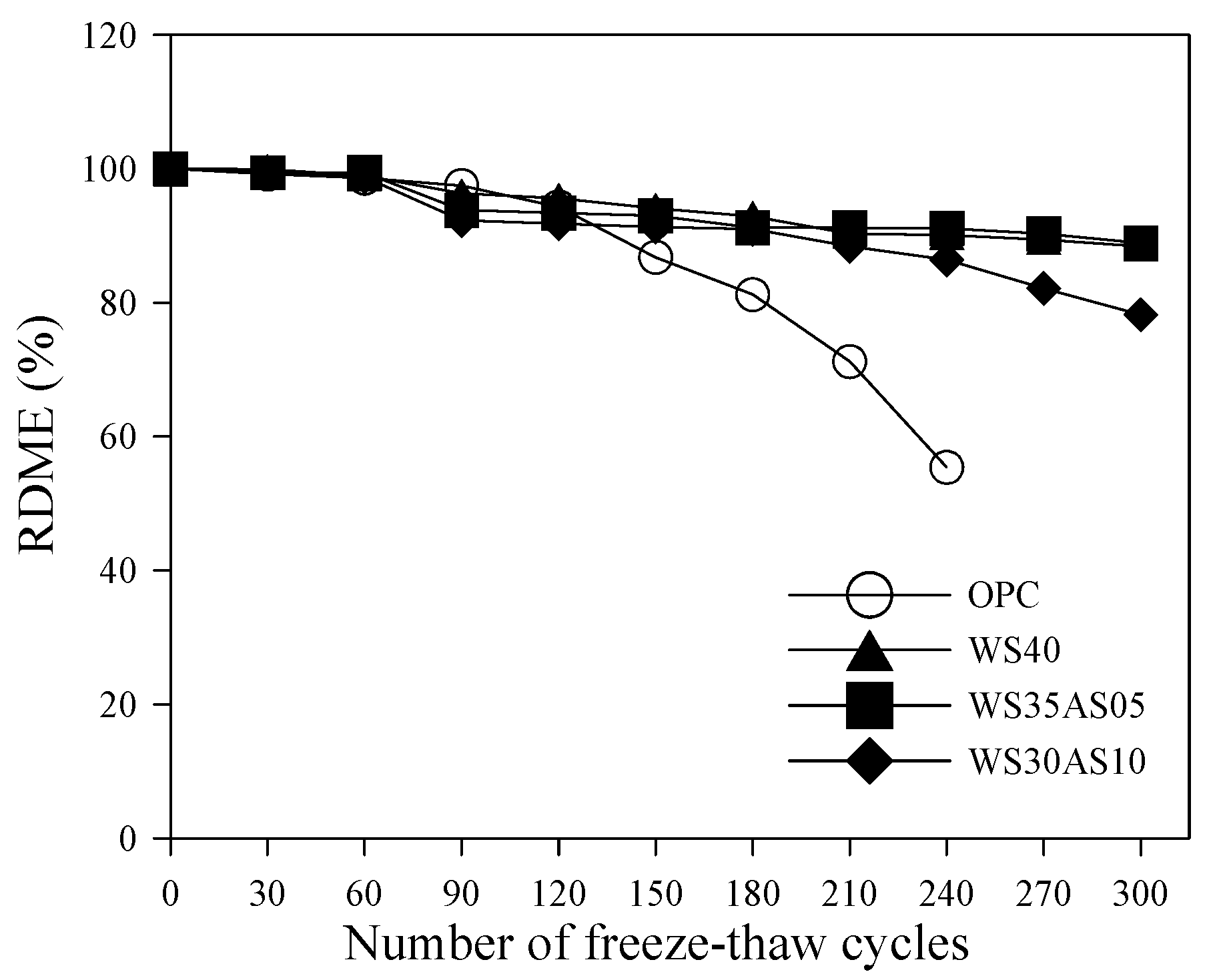

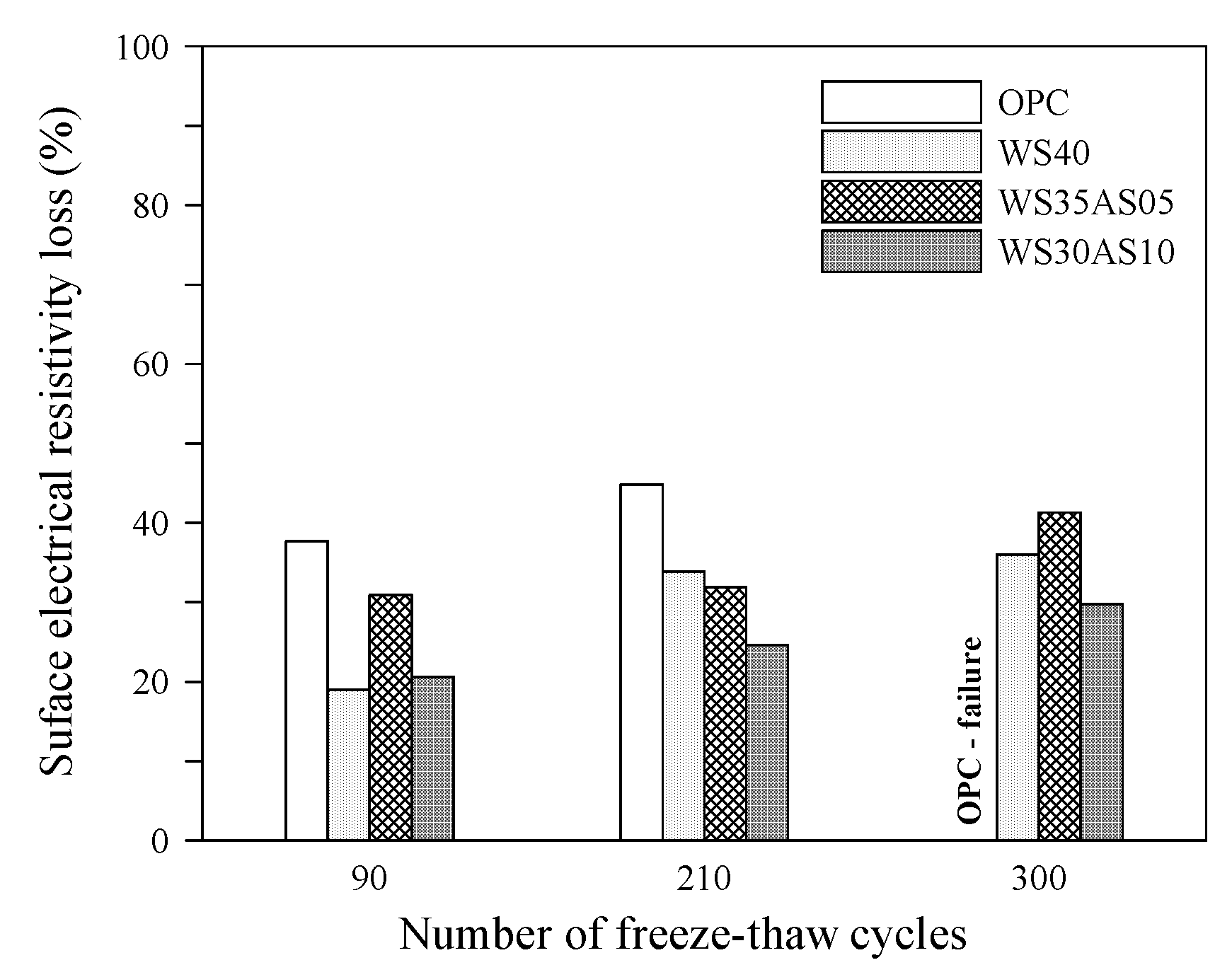

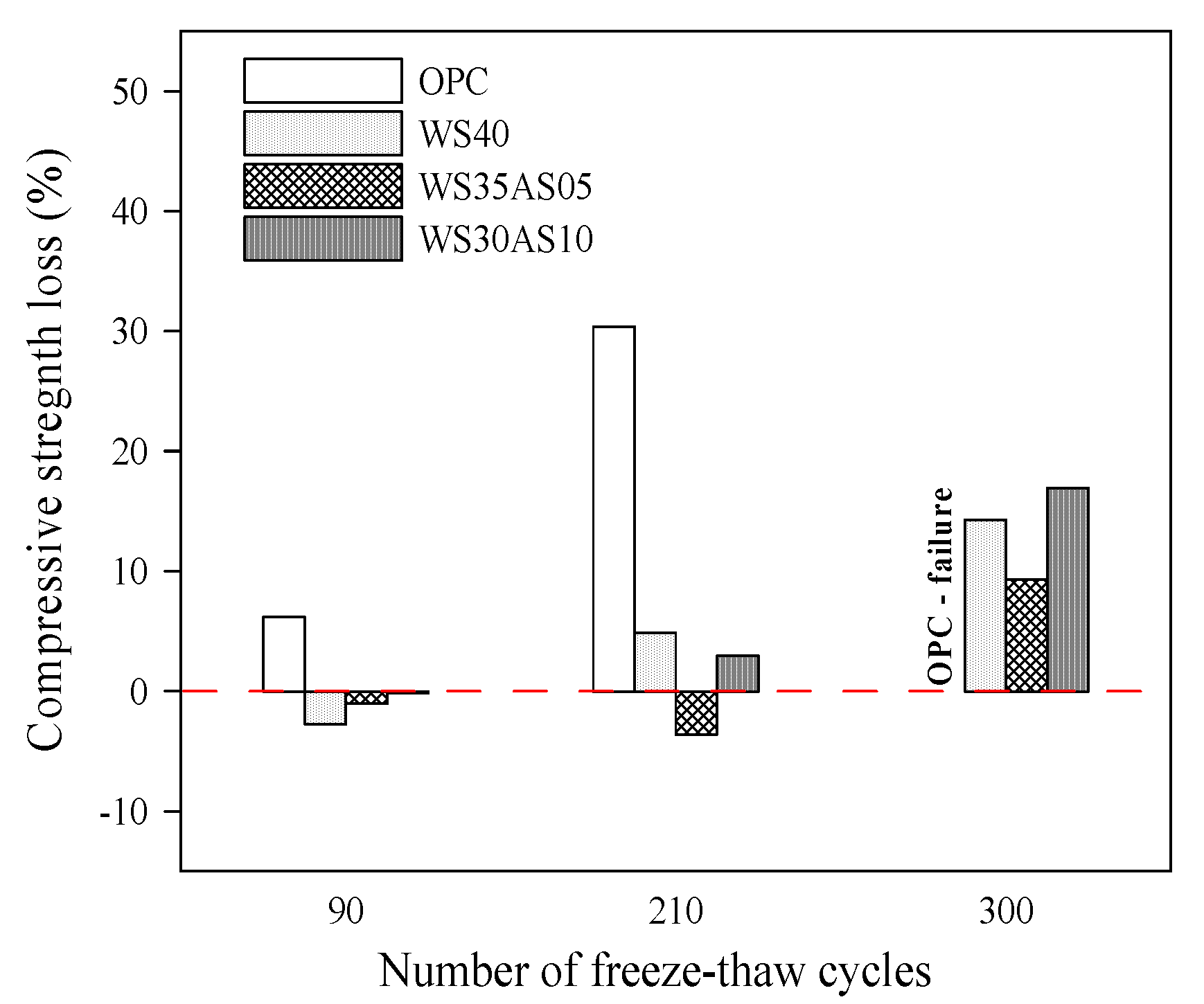

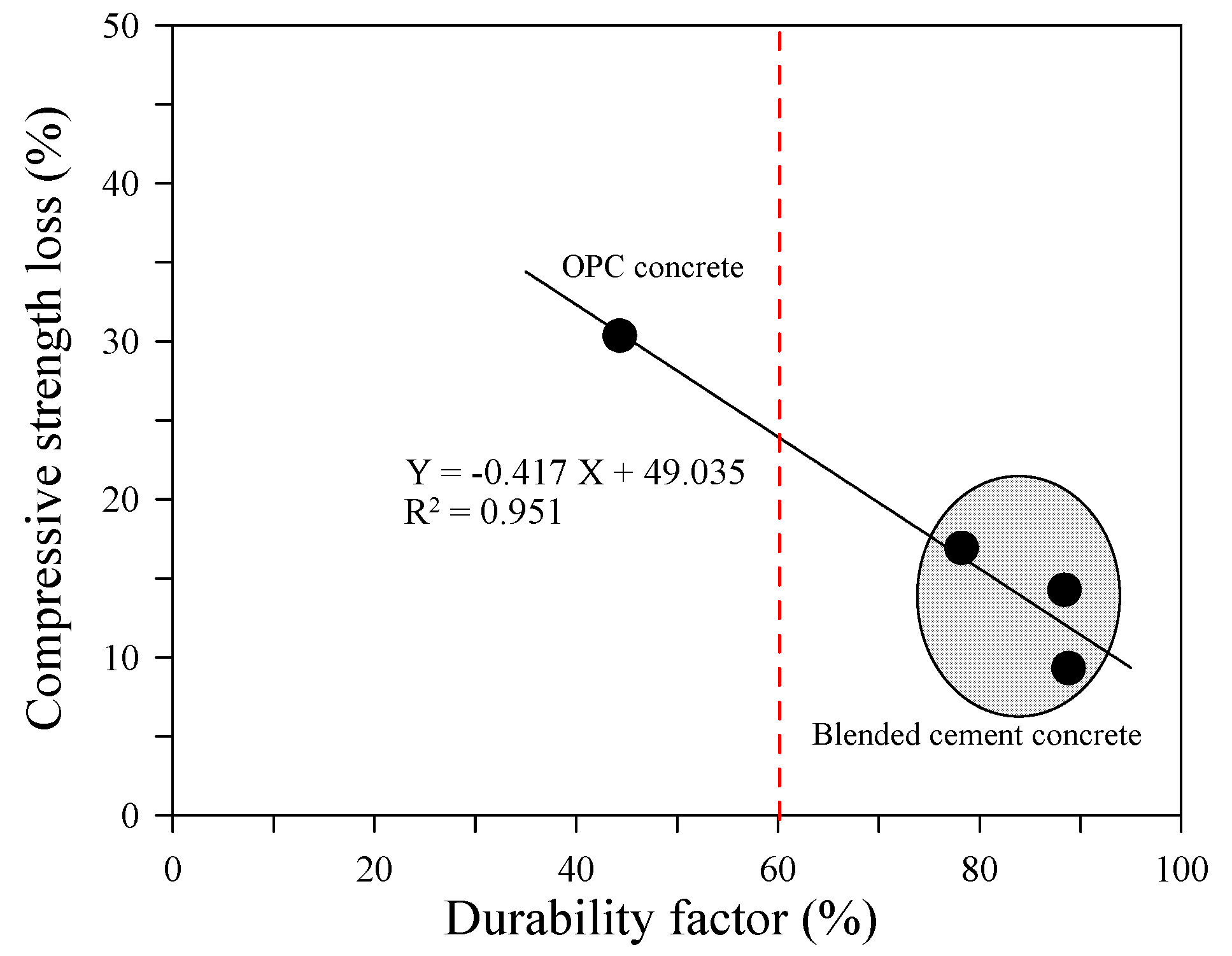

3.3. Freeze–Thaw Resistance

3.4. Microstructure Studies by SEM

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lee, S.T.; Park, S.H. Scaling resistance of cement concrete incorporating mineral admixtures. Int. J. High. Eng. 2015, 17, 47–53. (In Korean) [Google Scholar]

- Lee, S.T.; Hooton, R.D. Influence of limestone addition on the performance of cement mortars and pastes exposed to a cold sodium sulfate solution. J. Test. Eval. 2016, 44, 414–423. [Google Scholar] [CrossRef]

- Powers, T.C. Freezing effects in concrete. In Durability of Concrete; ACI Publication: Farmington Hills, MI, USA, 1975. [Google Scholar]

- Valenza, J.J.; Scherer, G.W. Mechanism of frost damage. Mater. Sci. Concr. 2005, 7, 209–246. [Google Scholar]

- Deja, J. Freezing and de-icing salt resistance of blast furnace slag concretes. Cem. Concr. Compos. 2003, 25, 357–361. [Google Scholar] [CrossRef]

- Sabir, B.; Kouyiali, K. Freeze-thaw durability of air-entrained CSF concrete. Cem. Concr. Compos. 1991, 13, 203–208. [Google Scholar] [CrossRef]

- Gao, P.W.; Wu, S.X.; Lin, P.H.; Wu, Z.R.; Tang, M.S. The characteristics of air void and frost resistance of RCC with fly ash and expansive agent. Constr. Build. Mater. 2006, 20, 586–590. [Google Scholar] [CrossRef]

- Ozbakkaloglu, T.; Gu, L.; Pour, A.F. Normal and high strength concretes incorporating air-cooled blast furnace slag coarse aggregates: Effect of slag size and content on the behavior. Constr. Build. Mater. 2016, 126, 138–146. [Google Scholar] [CrossRef]

- Morioka, N.Y. Influence of fine powder of air-cooled blast furnace slag on fluidity and its mechanism. Cem. Sci. Concr. Technol. 2002, 56, 72–77. [Google Scholar]

- Mostafa, N.Y.; El-Hemaly, S.A.S.; Al-Wakeel, E.I.; El-Korashy, S.A.; Brown, P.W. Characterization and evaluation of the hydraulic activity of water-cooled slag and air-cooled slag. Cem. Concr. Res. 2001, 31, 899–904. [Google Scholar] [CrossRef]

- El-Didamony, H.; Amer, A.A.; El-Sokkary, T.M.; Abd-El-Aziz, H. Effect of substitution of granulated slag by air-cooled slag on the properties of alkali activated slag. Cer. Int. 2013, 39, 171–181. [Google Scholar] [CrossRef]

- Verian, K.P.; Behnood, A. Effect of deicers on the performance of concrete pavements containing air-cooled blast furnace slag and supplementary cementitious materials. Cem. Concr. Compos. 2018, 90, 27–41. [Google Scholar] [CrossRef]

- ASTM International. ASTM C33/C33M-18, Standard Specification for Concrete Aggregates; ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar]

- ASTM International. ASTM C39/C39M-20, Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens; ASTM International: West Conshohocken, PA, USA, 2020. [Google Scholar]

- ASTM International. ASTM C293/C293M-16, Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Center-Point Loading); ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- ASTM International. ASTM C457/C457M-16, Standard Test Method for Microscopical Determination of Parameters of the Air-Void System in Hardened Concrete; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- ASTM International. ASTM C666/C666M-15, Standard Test Method for Resistance of Concrete to Rapid Freezing and Thawing; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- Shock, J.; Liebl, S.; Achterhold, K.; Pfeiffer, F. Obtaining the spacing factor of microporous concrete using high-resolution Dual Energy X-ray Micro CT. Cem. Concr. Res. 2016, 89, 200–205. [Google Scholar] [CrossRef]

- Sahin, Y.; Akkaya, Y.; Tasdemir, M.A. Effects of freezing conditions on the frost resistance and microstructure of concrete. Constr. Build. Mater. 2021, 270, 121458. [Google Scholar] [CrossRef]

- Haiyan, M.; Hongfa, Y.; Wei, S. Freezing-thawing durability and its improvement of high strength shrinkage compensation concrete with high volume mineral admixtures. Constr. Build. Mater. 2013, 39, 124–128. [Google Scholar]

- Allahverdi, A.; Mohammad, M.B.; Khandaker, M.H.; Mohamed, L. Resistance of chemically-activated high phosphorous slag content cement against freeze-thaw cycles. Cold Reg. Sci. Technol. 2014, 103, 107–114. [Google Scholar] [CrossRef]

- Olivier, C.; Paulo, J.M. Poroelastic model for concrete exposed to freezing temperatures. Cem. Concr. Res. 2008, 38, 40–48. [Google Scholar]

- Mehta, P.K.; Paulo, J.M. Concrete: Microstructure, Properties, and Materials; McGraw-Hill: New York, NY, USA, 2005; pp. 135–141. [Google Scholar]

- Huaishuai, S.; Yupu, S.; Jinping, O. Behavior of air-entrained concrete after freeze-thaw cycles. Acta Mech. Solida Sin. 2009, 22, 261–266. [Google Scholar]

- Jianyong, L.; Yan, Y. A study on creep and drying shrinkage of high performance concrete. Cem. Concr. Res. 2001, 31, 1203–1206. [Google Scholar]

- Matos, P.R.; Oliveira, J.C.P.; Medina, T.M.; Magalhaes, D.C.; Gleize, P.J.P.; Schankoski, R.A.; Pilar, R. Use of air-cooled blast furnace slag as supplementary cementitious material for self-compacting concrete production. Constr. Build. Mater. 2020, 262, 120102. [Google Scholar] [CrossRef]

- Shon, C.S.; Abdigaliyev, A.; Bagitova, S.; Chung, C.W.; Kim, D. Determination of air-void system and modified frost resistance number for freeze-thaw resistance evaluation of ternary blended concrete made of ordinary portland cement/silica fume/class F fly ash. Cold Reg. Sci. Technol. 2018, 155, 127–136. [Google Scholar] [CrossRef]

- Ozbay, E.; Karahan, O.; Lachemi, M.; Hossain, K.M.A.; Atis, C.D. Dual effectiveness of freezing-thawing and sulfate attack on high-volume slag-incorporated ECC. Comp. Part. B 2013, 45, 1384–1390. [Google Scholar] [CrossRef]

- Shen, A.; Lin, S.; Guo, Y.; He, T.; Lyu, Z. Relationship between flexural strength and pore structure of pavement concrete under fatigue loads and freeze-thaw interaction in seasonal frozen regions. Constr. Build. Mater. 2018, 174, 684–692. [Google Scholar] [CrossRef]

- Shin, H.; Yang, J.; Yoon, Y.; Mitchell, D. Mix desigh of concrete for pressed concrete sleepers using blast furnace slag and steel fibers. Cem. Concr. Compos. 2016, 74, 39–53. [Google Scholar] [CrossRef]

- Kazmi, S.M.S.; Munir, M.J.; Wu, Y.F.; Patnaikuni, I.; Zhou, Y.; Xing, F. Effect of different aggregate treatment techniques on the freeze-thaw and sulfate resistance of recycled aggregate concrete. Cold Reg. Sci. Technol. 2020, 178, 103126. [Google Scholar] [CrossRef]

- Park, K.P.; Kim, S.S.; Lee, S.T.; Kim, J.P.; Jung, H.S. Properties of the freeze-thaw of concrete subjected to seawater attack. J. Kor. Concr. Instit. 2011, 23, 23–30. (In Korean) [Google Scholar] [CrossRef]

| Chemical Composition (wt. %) | Physical Properties | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | LOI | Density (g/cm3) | Fineness (cm2/g) | |

| OPC | 19.8 | 4.8 | 3.1 | 61.5 | 2.9 | 2.8 | 2.96 | 3.15 | 3400 |

| WS | 31.7 | 14.5 | 0.4 | 41.7 | 5.4 | 2.1 | 2.6 | 2.9 | 4700 |

| AS | 30.8 | 12.1 | 0.71 | 49.7 | 2.71 | 1.75 | 2.2 | 2.9 | 4300 |

| Gmax (mm) | Absorption (%) | Fineness Modulus | Density (g/cm3) | |

|---|---|---|---|---|

| S | - | 1.14 | 2.9 | 2.53 |

| G1 | 19 | 0.78 | 6.2 | 2.73 |

| G2 | 32 | 0.93 | 6.8 | 2.75 |

| Mix. Code | W | C | WS | AS | S | G1 | G2 | SP * | AEA ** |

|---|---|---|---|---|---|---|---|---|---|

| OPC | 157 | 350 | - | - | 645 | 595 | 599 | 0.33 | 0.25 |

| WS40 | 157 | 210 | 140 | - | 632 | 583 | 588 | 0.3 | 0.4 |

| WS35AS05 | 157 | 210 | 122.5 | 17.5 | 639 | 590 | 594 | 0.5 | 0.5 |

| WS30AS10 | 157 | 210 | 105 | 35 | 661 | 609 | 614 | 0.55 | 0.5 |

| Mix. Code | Compressive Strength (MPa) | Flexural Strength (MPa) | ||||

|---|---|---|---|---|---|---|

| 7 d. | 28 d. | 91 d. | 7 d. | 28 d. | 91 d. | |

| OPC | 25.0 | 33.1 | 36.1 | 4.7 | 6.1 | 7.2 |

| WS40 | 21.5 | 35.0 | 40.1 | 4.3 | 7.0 | 8.0 |

| WS35AS05 | 20.4 | 34.8 | 38.5 | 4.1 | 7.2 | 8.3 |

| WS30AS10 | 18.5 | 33.8 | 38.1 | 3.8 | 7.1 | 7.9 |

| Mix. Code | Air Content (%) | Specific Surface Area (mm2/mm3) | Spacing Factor (mm) |

|---|---|---|---|

| OPC | 2.9 | 21.8 | 0.345 |

| WS40 | 2.3 | 39.1 | 0.264 |

| WS35AS05 | 2.6 | 34.8 | 0.284 |

| WS30AS10 | 2.1 | 33.5 | 0.288 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, S.-T.; Park, S.-H.; Kim, D.-G.; Kang, J.-M. Effect of Freeze–Thaw Cycles on the Performance of Concrete Containing Water-Cooled and Air-Cooled Slag. Appl. Sci. 2021, 11, 7291. https://doi.org/10.3390/app11167291

Lee S-T, Park S-H, Kim D-G, Kang J-M. Effect of Freeze–Thaw Cycles on the Performance of Concrete Containing Water-Cooled and Air-Cooled Slag. Applied Sciences. 2021; 11(16):7291. https://doi.org/10.3390/app11167291

Chicago/Turabian StyleLee, Seung-Tae, Se-Ho Park, Dong-Gyou Kim, and Jae-Mo Kang. 2021. "Effect of Freeze–Thaw Cycles on the Performance of Concrete Containing Water-Cooled and Air-Cooled Slag" Applied Sciences 11, no. 16: 7291. https://doi.org/10.3390/app11167291

APA StyleLee, S.-T., Park, S.-H., Kim, D.-G., & Kang, J.-M. (2021). Effect of Freeze–Thaw Cycles on the Performance of Concrete Containing Water-Cooled and Air-Cooled Slag. Applied Sciences, 11(16), 7291. https://doi.org/10.3390/app11167291