Ohmic Baking of Gluten-Free Bread: Role of Starch and Flour on Batter Properties

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Raw Material Characterization

2.3. GF Batter Preparation

2.4. Breadmaking

2.5. Rheological Measurements of Batters

2.6. Functional Properties of Bread

2.6.1. Baking Loss

2.6.2. Bread Volume

2.6.3. Bread Crumb Texture

2.6.4. Crumb and Crust Color

2.6.5. Crumb Porosity

2.7. Statistics

3. Results and Discussions

3.1. Starch and Flour Properties

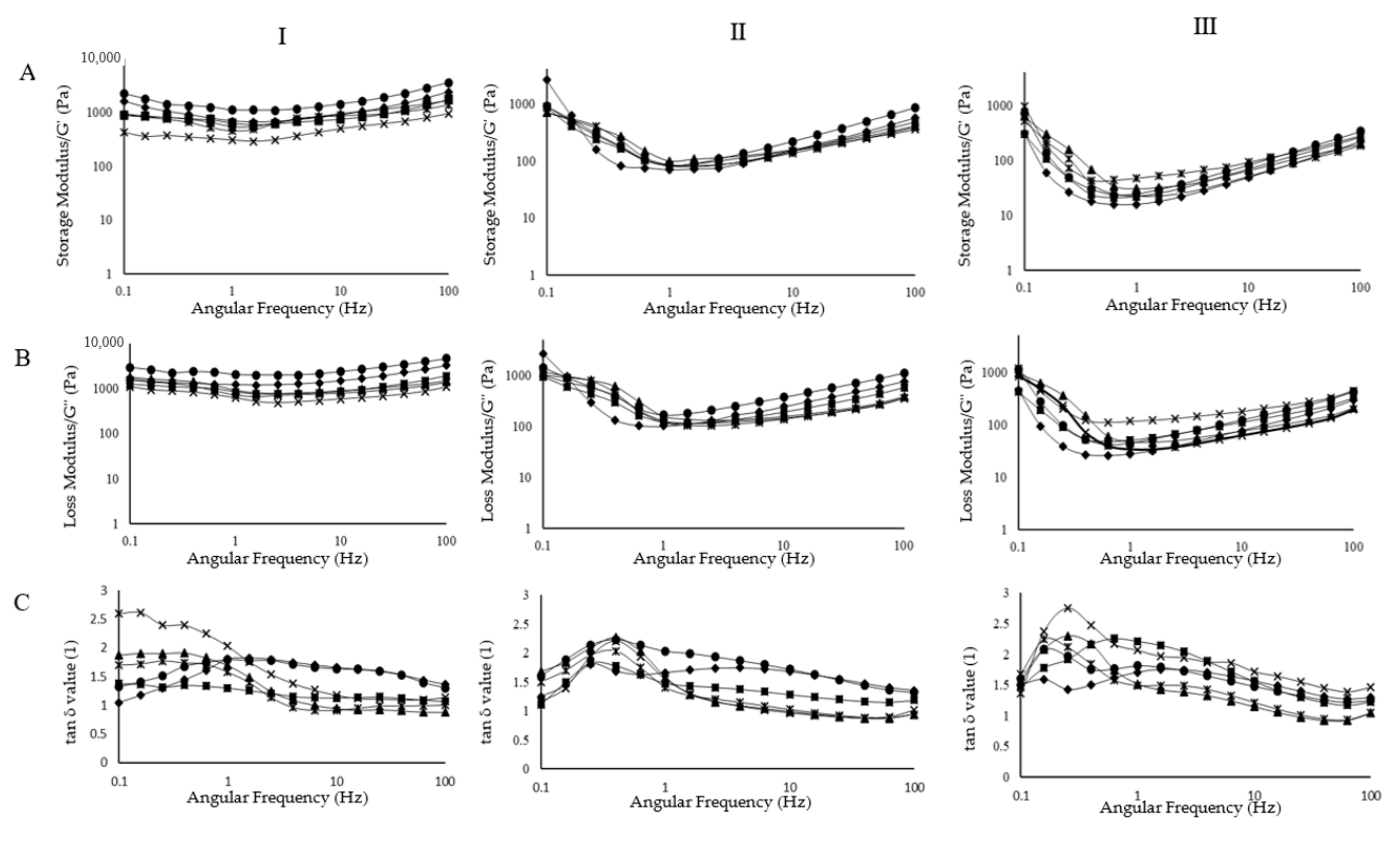

3.2. Effect of Starch:Water Ratio on the Electrical Conductivity and Rheological Properties of GF Batters

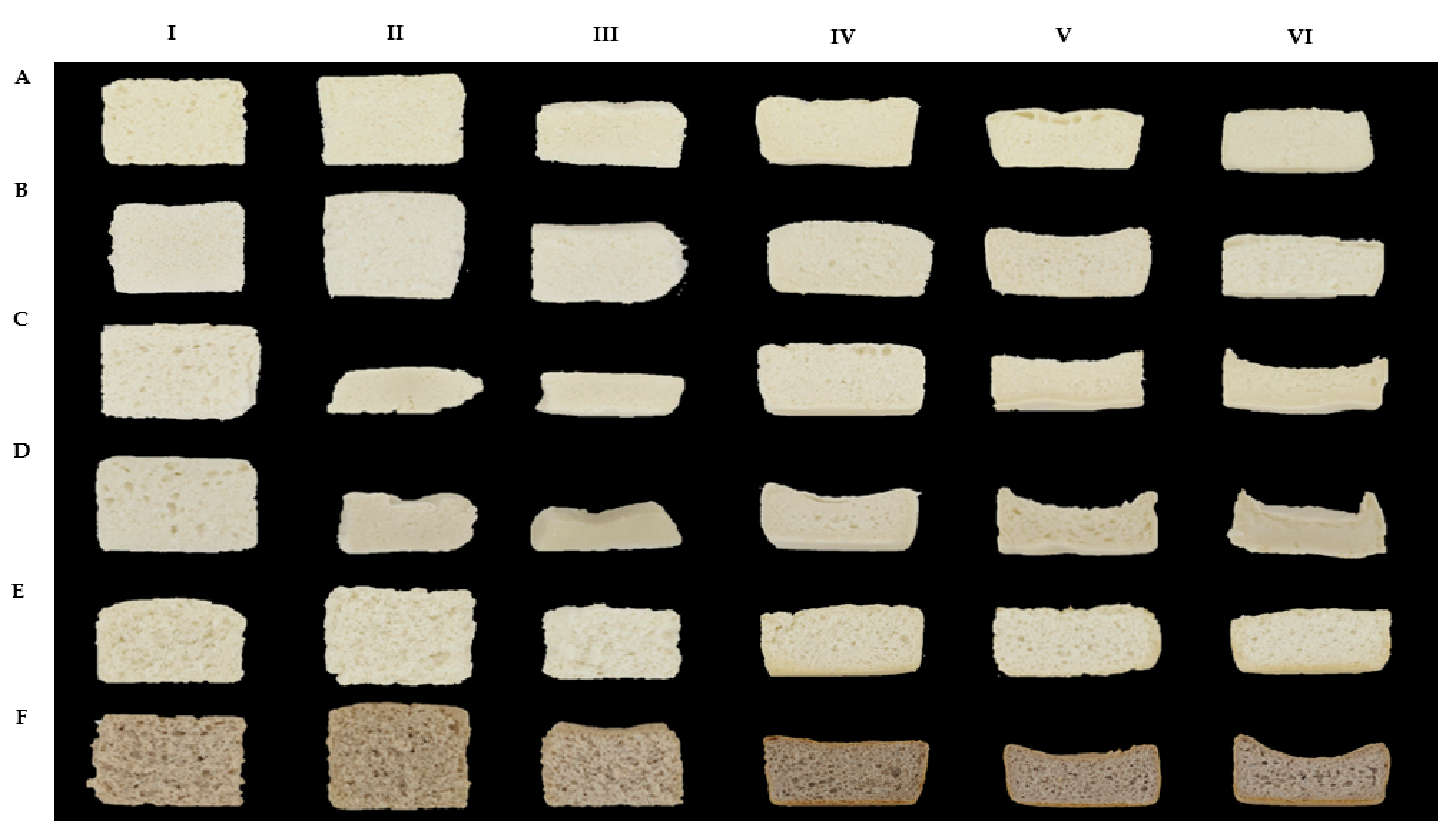

3.3. Effect of Batter Rheology on GF Bread Properties

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jaeger, H.; Roth, A.; Toepfl, S.; Holzhauser, T.; Engel, K.H.; Knorr, D.; Vogel, R.F.; Bandick, N.; Kulling, S.; Heinz, V.; et al. Opinion on the Use of Ohmic Heating for the Treatment of Foods. Trends Food Sci. Technol. 2016, 55, 84–97. [Google Scholar] [CrossRef]

- Bender, D.; Gratz, M.; Vogt, S.; Fauster, T.; Wicki, B.; Pichler, S.; Kinner, M.; Jäger, H.; Schoenlechner, R. Ohmic Heating—A Novel Approach for Gluten-Free Bread Baking. Food Bioprocess Technol. 2019, 12, 1603–1613. [Google Scholar] [CrossRef] [Green Version]

- Burešová, I.; Kráčmar, S.; Dvořáková, P.; Středa, T. The Relationship between Rheological Characteristics of Gluten-Free Dough and the Quality of Biologically Leavened Bread. J. Cereal Sci. 2014, 60, 271–275. [Google Scholar] [CrossRef]

- Schober, T.J.; Messerschmidt, M.; Bean, S.R.; Park, S.H.; Arendt, E.K. Gluten-Free Bread from Sorghum: Quality Differences among Hybrids. Cereal Chem. 2005, 82, 394–404. [Google Scholar] [CrossRef]

- Schoenlechner, R.; Mandala, I.; Kiskini, A.; Kostaropoulos, A.; Berghofer, E. Effect of Water, Albumen and Fat on the Quality of Gluten-Free Bread Containing Amaranth. Int. J. Food Sci. Technol. 2010, 45, 661–669. [Google Scholar] [CrossRef]

- Lazaridou, A.; Duta, D.; Papageorgiou, M.; Belc, N.; Biliaderis, C.G. Effects of Hydrocolloids on Dough Rheology and Bread Quality Parameters in Gluten-Free Formulations. J. Food Eng. 2007, 79, 1033–1047. [Google Scholar] [CrossRef]

- Sciarini, L.S.; Ribotta, P.D.; León, A.E.; Pérez, G.T. Incorporation of Several Additives into Gluten Free Breads: Effect on Dough Properties and Bread Quality. J. Food Eng. 2012, 111, 590–597. [Google Scholar] [CrossRef]

- Ronda, F.; Perez-Quirce, S.; Lazaridou, A.; Biliaderis, C.G. Effect of Barley and Oat β-Glucan Concentrates on Gluten-Free Rice-Based Doughs and Bread Characteristics. Food Hydrocoll. 2015, 48, 197–207. [Google Scholar] [CrossRef]

- Sabanis, D.; Lebesi, D.; Tzia, C. Effect of Dietary Fibre Enrichment on Selected Properties of Gluten-Free Bread. LWT Food Sci. Technol. 2009, 42, 1380–1389. [Google Scholar] [CrossRef]

- Matos, M.E.; Rosell, C.M. Understanding Gluten-Free Dough for Reaching Breads with Physical Quality and Nutritional Balance. J. Sci. Food Agric. 2015, 95, 653–661. [Google Scholar] [CrossRef]

- Demirkesen, I.; Mert, B.; Sumnu, G.; Sahin, S. Rheological Properties of Gluten-Free Bread Formulations. J. Food Eng. 2010, 96, 295–303. [Google Scholar] [CrossRef]

- Leite, T.S.; Sastry, S.K.; Cristianini, M. Effect of Concentration and Consistency on Ohmic Heating. J. Food Process Eng. 2018, 41, 1–9. [Google Scholar] [CrossRef]

- Li, F.D.; Li, L.T.; Li, Z.; Tatsumi, E. Determination of Starch Gelatinization Temperature by Ohmic Heating. J. Food Eng. 2004, 62, 113–120. [Google Scholar] [CrossRef]

- Eriksson, E. Physicochemical, Functional and Pasting Characteristics of Three Varieties of Cassava in Wheat Composite Flours. Br. J. Appl. Sci. Technol. 2014, 4, 1609–1621. [Google Scholar] [CrossRef]

- Turkut, G.M.; Cakmak, H.; Kumcuoglu, S.; Tavman, S. Effect of Quinoa Flour on Gluten-Free Bread Batter Rheology and Bread Quality. J. Cereal Sci. 2016, 69, 174–181. [Google Scholar] [CrossRef]

- León, A.E.; Barrera, G.N.; Pérez, G.T.; Ribotta, P.D.; Rosell, C.M. Effect of Damaged Starch Levels on Flour-Thermal Behaviour and Bread Staling. Eur. Food Res. Technol. 2006, 224, 187–192. [Google Scholar] [CrossRef]

- Ee, K.Y.; Eng, M.K.; Lee, M.L. Physicochemical, Thermal and Rheological Properties of Commercial Wheat Flours and Corresponding Starches. Food Sci. Technol. 2020, 40, 51–59. [Google Scholar] [CrossRef]

- Liu, Q. Understanding Starches and Their Role in Foods. In Food Carbohydrates, 1st ed.; Ciu, S.W., Ed.; Taylor & Francis Group: Boca Raton, FL, USA, 2005; pp. 309–355. [Google Scholar] [CrossRef]

- Blazek, J.; Copeland, L. Pasting and Swelling Properties of Wheat Flour and Starch in Relation to Amylose Content. Carbohydr. Polym. 2008, 71, 380–387. [Google Scholar] [CrossRef]

- Ragaee, S.; Abdel-Aal, E.S.M. Pasting Properties of Starch and Protein in Selected Cereals and Quality of Their Food Products. Food Chem. 2006, 95, 9–18. [Google Scholar] [CrossRef]

- Sasaki, T.; Yasui, T.; Matsuki, J. Effect of Amylose Content on Gelatinization, Retrogradation, and Pasting Properties of Starches from Waxy and Nonwaxy Wheat and Their F1 Seeds. Cereal Chem. 2000, 77, 58–63. [Google Scholar] [CrossRef]

- Torbica, A.; Hadnadev, M.; Dapčević Hadnadev, T. Rice and Buckwheat Flour Characterisation and Its Relation to Cookie Quality. Food Res. Int. 2012, 48, 277–283. [Google Scholar] [CrossRef]

- Horstmann, S.W.; Lynch, K.M.; Arendt, E.K. Starch Characteristics Linked to Gluten-Free Products. Foods 2017, 6, 29. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ai, Y.; Jane, J.L. Understanding Starch Structure and Functionality. In Starch in Food: Structure, Function and Applications, 2nd ed.; Sjöö, M., Nilsson, L., Eds.; Elsevier Ltd.: Duxford, UK, 2018; pp. 151–178. [Google Scholar] [CrossRef]

- Morales-Sánchez, E.; Reyes-Vega, M.L.; Gaytán-Martínez, M.; Figueroa-Cárdenas, J.D.; Velázquez, G. Relationship between Electrical Conductivity and Water Activity of Starch-Water Composites. Food Eng. Ser. 2015, 527–531. [Google Scholar] [CrossRef]

- Pongviratchai, P.; Park, J.W. Electrical Conductivity and Physical Properties of Surimi-Potato Starch under Ohmic Heating. J. Food Sci. 2007, 72, 503–507. [Google Scholar] [CrossRef] [PubMed]

- Marcotte, M.; Ramaswamy, H.S.; Piette, J.P.G. Ohmic Heating Behavior of Hydrocolloid Solutions. Food Res. Int. 1998, 31, 493–502. [Google Scholar] [CrossRef]

- Chaiwanichsiri, S.; Ohnishi, S.; Suzuki, T.; Takai, R.; Miyawaki, O. Measurement of Electrical Conductivity, Differential Scanning Calorimetry and Viscosity of Starch and Flour Suspensions during Gelatinisation Process. J. Sci. Food Agric. 2001, 81, 1586–1591. [Google Scholar] [CrossRef]

- Onyango, C.; Mutungi, C.; Unbehend, G.; Lindhauer, M.G. Modification of Gluten-Free Sorghum Batter and Bread Using Maize, Potato, Cassava or Rice Starch. LWT Food Sci. Technol. 2011, 44, 681–686. [Google Scholar] [CrossRef]

- Ronda, F.; Pérez-Quirce, S.; Villanueva, M. Rheological Properties of Gluten-Free Bread Doughs: Relationship with Bread Quality. In Advances in Food Rheology and Its Applications; Ahmed, J., Ptaszek, P., Basu, S., Eds.; Elsevier Ltd.: Duxford, UK, 2017; pp. 297–334. [Google Scholar] [CrossRef]

- Mancebo, C.M.; Merino, C.; Martínez, M.M.; Gómez, M. Mixture Design of Rice Flour, Maize Starch and Wheat Starch for Optimization of Gluten Free Bread Quality. J. Food Sci. Technol. 2015, 52, 6323–6333. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bockstaele, F.; Van Leyn, I.; De Eeckhout, M.; Dewettinck, K. Rheological Properties of Wheat Flour Dough and Their Relationship with Bread Volume II. Dynamic Oscillation Measurements. Cereal Chem. 2008, 85, 762–768. [Google Scholar] [CrossRef]

- Derde, L.J.; Gomand, S.V.; Courtin, C.M.; Delcour, J.A. Moisture Distribution during Conventional or Electrical Resistance Oven Baking of Bread Dough and Subsequent Storage. J. Agric. Food Chem. 2014, 62, 6445–6453. [Google Scholar] [CrossRef]

- Gil, M.J.; Callejo, M.J.; Rodríguez, G.; Ruiz, M.V. Keeping Qualities of White Pan Bread upon Storage: Effect of Selected Enzymes on Bread Firmness and Elasticity. Eur. Food Res. Technol. 1999, 208, 394–399. [Google Scholar] [CrossRef]

- Bosmans, G.M.; Lagrain, B.; Fierens, E.; Delcour, J.A. The Impact of Baking Time and Bread Storage Temperature on Bread Crumb Properties. Food Chem. 2013, 141, 3301–3308. [Google Scholar] [CrossRef] [PubMed]

- Patel, B.K.; Waniska, R.D.; Seetharaman, K. Impact of Different Baking Processes on Bread Firmness and Starch Properties in Breadcrumb. J. Cereal Sci. 2005, 42, 173–184. [Google Scholar] [CrossRef]

- Luyts, A.; Wilderjans, E.; Van Haesendonck, I.; Brijs, K.; Courtin, C.M.; Delcour, J.A. Relative Importance of Moisture Migration and Amylopectin Retrogradation for Pound Cake Crumb Firming. Food Chem. 2013, 141, 3960–3966. [Google Scholar] [CrossRef] [PubMed]

- Hayman, D.A.; Hoseney, R.C.; Faubion, J.M. Effect of Pressure (Crust Formation) on Bread Crumb Grain Development. Cereal Chem. 1998, 75, 581–584. [Google Scholar] [CrossRef]

| Samples | Water Holding Capacity (g/g) | Swelling Power (%) | Solubility Index (%) | Amylose Content (%) | Starch Damage (%) | Particle Size (μm) | Peak Viscosity (RVU) | Breakdown (RVU) | Final Viscosity (RVU) | Setback (RVU) | Pasting Temperature (°C) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Corn | 1.83 ± 0.02 a | 10.28 ± 0.22 b | 3.98 ± 0.98 a | 20.85 ± 1.17 c | 3.06 ± 0.26 c | 20.02 ± 1.04 a | 392.42 ± 13.51 b | 162.22 ± 7.44 c | 361.48 ± 5.63 c | 129.93 ± 2.45 a | 75.65 ± 0.64 d |

| Wheat | 1.80 ± 0.02 a | 8.14 ± 0.42 a | 5.96 ± 0.07 a | 26.55 ± 0.53 d | 2.20 ± 0.02 b | 42.98 ± 2.20 b | 389.31 ± 6.88 b | 63.55 ± 2.39 b | 457.26 ± 14.64 d | 131.58 ± 6.19 a | 72.58 ± 0.08 c |

| Potato | 1.92 ± 0.05 b | 15.89 ± 0.84 c | 8.91 ± 1.72 b | 21.45 ± 1.96 c | 2.34 ± 0.37 b | 49.03 ± 0.69 b | 1105.41 ± 28.01 e | 953.83 ± 25.4 e | 291.92 ± 12.69 a | 140.34 ± 10.85 a | 67.34 ± 0.42 a |

| Cassava | 1.78 ± 0.03 a | 21.17 ± 1.99 d | 16.78 ± 2.05 c | 15.70 ± 0.97 b | 1.65 ± 0.01 a | 31.72 ± 8.02 ab | 519.16 ± 12.95 d | 338.95 ± 16.04 d | 321.9 ± 5.51 b | 141.69 ± 8.6 a | 71.44 ± 0.36 b |

| Rice | 2.43 ± 0.01 d | 8.44 ± 0.09 ab | 4.29 ± 0.57 a | 22.15 ± 0.22 c | 6.16 ± 0.00 e | 164.94 ± 5.27 c | 447.12 ± 18.8 c | 171.78 ± 6.58 c | 535.69 ± 11.22 e | 260.35 ± 8.47 b | 76.63 ± 0.03 e |

| Buckwheat | 2.30 ± 0.03 c | 8.73 ± 0.81 ab | 5.57 ± 0.58 a | 18.71 ± 0.71 a | 4.05 ± 0.15 d | 266.82 ± 25.25 d | 244.58 ± 18.35 a | 7.69 ± 0.17 a | 472.29 ± 13.32 d | 254.54 ± 25.59 b | 72.51 ± 0.16 c |

| Starch or Bread Properties | Elasticity (%) | WHC (g/g) | Particle Size (μm) | Solubility (%) | Swelling Power (%) | Amylose (%) | Starch Damage (%) | Pasting Temperature (°C) | Peak Viscosity (RVU) | Breakdown (RVU) | Setback (RVU) | Final Viscosity (RVU) | Bread Volume (cm3/g) | Baking Loss (%) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| WHC (g/g) | −0.39 ** | |||||||||||||

| Particle size (μm) | −0.19 | 0.87 ** | ||||||||||||

| Solubility (%) | 0.21 | −0.47 | −0.37 ** | |||||||||||

| Swelling power (%) | 0.02 | −0.51 ** | −049 ** | 0.94 ** | ||||||||||

| Amylose (%) | 0.11 | −0.27 * | −0.52 ** | −0.37 ** | −0.34 * | |||||||||

| Starch damage (%) | −0.39 ** | 0.93 ** | 0.68 ** | −0.62 ** | −0.61 ** | −0.03 | ||||||||

| Pasting temperature (°C) | 0.03 | 0.40 ** | 0.24 | −0.52 ** | −0.58 ** | 0.11 | 0.65 ** | |||||||

| Peak viscosity (RVU) | −0.35 * | −0.26 | −0.45 ** | 0.31 * | 0.52 ** | 0.23 | −0.32 * | −0.75 ** | ||||||

| Breakdown (RVU) | −0.37 * | −0.27 * | −0.43 ** | 0.37 * | 0.59 ** | 0.11 | −0.35 * | −0.76 ** | 0.99 ** | |||||

| Setback (RVU) | −0.35 | 0.98 ** | 0.92 ** | −0.37 ** | −0.46 ** | −0.40 ** | 0.87 ** | 0.40 ** | −0.39 ** | −0.38 ** | ||||

| Final viscosity (RVU) | 0.04 | 0.74 ** | 0.69 ** | −0.61 ** | −0.79 ** | 0.12 | 0.79 ** | 0.68 * | −0.66 ** | −0.72 ** | 0.76 ** | |||

| Bread volume (cm3/g) | 0.03 | 0.12 | 0.17 | −0.55 ** | −0.65 ** | 0.31 * | 0.24 | 0.47 ** | −0.52 ** | −0.57 ** | 0.12 | 0.52 ** | ||

| Baking loss (%) | 0.06 | 0.17 | 0.12 | −0.77 ** | −0.82 ** | 0.50 ** | 0.38 ** | 0.63 ** | −0.50 ** | −0.58 ** | 0.13 | 0.60 ** | 0.67 ** | |

| Crumb firmness (N) | −0.33 * | −0.24 | −0.36 ** | 0.01 | −0.26 | 0.19 | −0.26 | −0.58 ** | 0.81 ** | 0.81 ** | −0.38 | −0.59 ** | −0.53 ** | −0.28 * |

| Sample | Ratio * | Electrical Conductivity (S/m) | Flow Behavior Index n | Consistency Coefficient K (Pa·sn) | Apparent Viscosity (Pa·s) |

|---|---|---|---|---|---|

| Corn | 1:0.9 | 0.64 ± 0.04 a | 0.48 ± 0.06 a | 266.98 ± 13.84 c | 29.11 ± 4.33 b |

| 1:1.3 | 0.53 ± 0.04 a | 0.46 ± 0.01 a | 62.36 ± 0.44 b | 4.15 ± 0.15 a | |

| 1:1.7 | 0.56 ± 0.08 a | 0.52 ± 0.02 a | 21.20 ± 1.00 a | 1.98 ± 0.09 a | |

| Wheat | 1:0.9 | 0.48 ± 0.02 b | 0.44 ± 0.04 b | 170.33 ± 10.05 c | 12.43 ± 0.95 b |

| 1:1.3 | 0.40 ± 0.01 a | 0.34 ± 0.04 a | 57.09 ± 0.75 b | 2.29 ± 1.13 a | |

| 1:1.7 | 0.38 ± 0.01 a | 0.52 ± 0.01 c | 22.32 ± 0.11 a | 1.91 ± 0.08 a | |

| Potato | 1:0.9 | 0.47 ± 0.03 a | 0.55 ± 0.06 a | 358.95 ± 13.19 c | 47.12 ± 10.09 b |

| 1:1.3 | 0.53 ± 0.01 b | 0.55 ± 0.02 a | 70.85 ± 3.86 b | 8.14 ± 0.27 a | |

| 1:1.7 | 0.46 ± 0.02 a | 0.55 ± 0.03 a | 28.06 ± 0.97 a | 2.80 ± 0.10 a | |

| Cassava | 1:0.9 | 0.52 ± 0.01 b | 0.51 ± 0.07 a | 352.83 ± 18.04 c | 56.20 ± 2.48 b |

| 1:1.3 | 0.54 ± 0.01 c | 0.44 ± 0.03 a | 65.98 ± 1.72 b | 4.57 ± 0.35 a | |

| 1:1.7 | 0.43 ± 0.01 a | 0.53 ± 0.01 a | 24.29 ± 1.06 a | 2.28 ± 0.04 a | |

| Rice | 1:0.9 | 0.57 ± 0.00 c | 0.36 ± 0.02 a | 749.23 ± 50.08 c | 63.04 ± 13.99 ba |

| 1:1.3 | 0.53 ± 0.02 b | 0.45 ± 0.02 b | 130.14 ± 6.68 b | 15.86 ± 0.71 ab | |

| 1:1.7 | 0.42 ± 0.01 a | 0.53 ± 0.04 c | 46.51 ± 0.88 a | 5.64 ± 0.07 ab | |

| Buckwheat | 1:1 | 0.50 ± 0.02 c | 0.33 ± 0.02 a | 386.33 ± 33.97 c | 28.39 ± 2.22 c |

| 1:1.5 | 0.41 ± 0.02 b | 0.47 ± 0.02 b | 100.48 ± 7.47 b | 11.94 ± 0.40 b | |

| 1:2 | 0.35 ± 0.01 a | 0.46 ± 0.02 b | 36.56 ± 2.22 a | 3.65 ± 0.17 a |

| Starch/Flour | Ratio | Baking Loss (%) | Bread Volume (cm3/g) | Relative Elasticity (%) | Crumb Firmness (N) | Pore Properties | Crumb Color | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of Pores | Average Size (mm) | Pore Area (%) | L* | a* | b* | ||||||

| Ohmic Heating | |||||||||||

| Corn | 1:0.9 | 21.03 ± 2.11 b | 3.50 ± 0.10 b | 47.90 ± 1.69 a | 9.89 ± 2.17 b | 95.33 ± 0.58 b | 0.84 ± 0.07 a | 20.42 ± 0.62 a | 90.65 ± 1.78 a | 0.77 ± 0.58 a | 17.45 ± 1.17 a |

| 1:1.3 | 20.46 ± 0.46 b | 3.50 ± 0.06 b | 61.57 ± 0.54 b | 4.87 ± 0.59 a | 102.33 ± 0.58 c | 0.89 ± 0.08 a | 22.57 ± 1.80 a | 88.74 ± 2.49 a | 0.34 ± 0.08 a | 17.32 ± 0.18 a | |

| 1:1.7 | 17.27 ± 0.77 a | 2.19 ± 0.12 a | 73.54 ± 2.15 c | 11.32 ± 1.16 b | 90.67 ± 0.58 a | 0.98 ± 0.09 a | 22.25 ± 1.92 a | 91.92 ± 0.35 a | 1.02 ± 0.36 a | 17.09 ± 0.81 a | |

| Wheat | 1:0.9 | 22.25 ± 1.24 b | 4.01 ± 0.10 b | 65.57 ± 1.54 a | 2.18 ± 0.26 b | 67.33 ± 1.53 a | 1.25 ± 0.03 a | 21.49 ± 1.21 a | 91.98 ± 0.53 a | 0.69 ± 0.14 a | 12.13 ± 0.87 a |

| 1:1.3 | 20.94 ± 0.81 ab | 3.85 ± 0.18 b | 73.79 ± 0.69 b | 1.27 ± 0.16 a | 83.67 ± 0.58 b | 1.31 ± 0.18 a | 24.93 ± 1.74 b | 91.75 ± 0.05 a | 0.42 ± 0.25 a | 13.21 ± 0.35 ab | |

| 1:1.7 | 19.48 ± 0.25 a | 2.81 ± 0.04 a | 76.49 ± 0.80 c | 1.51 ± 0.09 a | 65.33 ± 1.15 a | 1.6 ± 0.11 b | 26.15 ± 1.65 b | 89.97 ± 1.21 b | 0.68 ± 0.05 a | 13.49 ± 0.19 b | |

| Potato | 1:0.9 | 11.70 ± 0.30 a | 3.01 ± 0.10 c | 52.87 ± 0.71 a | 10.2 ± 0.45 a | 89.67 ± 2.08 a | 1.04 ± 0.14 b | 23.20 ± 2.54 b | 88.9 ± 0.18 b | 0.76 ± 0.40 a | 14.32 ± 0.60 a |

| 1:1.3 | 11.74 ± 0.76 a | 1.51 ± 0.01 b | 59.37 ± 0.84 b | 30.97 ± 1.91 b | 108.33 ± 2.52 b | 0.72 ± 0.04 a | 20.23 ± 0.71 ab | 88.07 ± 1.66 b | 1.45 ± 0.39 b | 16.23 ± 0.33 b | |

| 1:1.7 | 13.50 ± 1.40 a | 1.08 ± 0.04 a | 53.19 ± 2.09 a | 31.01 ± 0.35 b | 94.67 ± 3.06 a | 0.62 ± 0.16 a | 14.71 ± 4.21 a | 85.33 ± 0.70 a | 1.50 ± 0.04 b | 16.72 ± 0.21 b | |

| Cassava | 1:0.9 | 11.09 ± 0.83 a | 2.66 ± 0.14 c | 72.51 ± 1.03 c | 1.58 ± 0.18 b | 103.67 ± 3.21 b | 0.94 ± 0.17 a | 24.41 ± 5.16 a | 89.6 ± 1.39 c | 1.26 ± 0.24 a | 14.39 ± 0.40 a |

| 1:1.3 | 9.88 ± 0.48 a | 1.17 ± 0.07 a | 66.60± 0.48 b | 1.56 ± 0.08 b | 102.67 ± 2.31 b | 0.65 ± 0.10 a | 16.75 ± 2.57 a | 82.4 ± 1.80 b | 2.28 ± 0.20 b | 15.71 ± 0.46 b | |

| 1:1.7 | 10.31 ± 0.63 a | 1.87 ± 0.54 b | 62.23 ± 0.64 a | 0.59 ± 0.04 a | 43.00 ± 2.65 a | 0.97 ± 1.01 a | 10.71 ± 11.48 a | 74.19 ± 1.77 a | 2.98 ± 0.45 c | 16.73 ± 0.85 b | |

| Rice | 1:0.9 | 15.61 ± 2.44 a | 3.02 ± 0.17 b | 50.66 ± 0.53 a | 2.67 ± 0.67 b | 55.67 ± 1.53 a | 1.68 ± 0.37 a | 23.29 ± 4.49 a | 88.06 ± 0.54 a | 1.40 ± 0.02 c | 16.33 ± 0.18 c |

| 1:1.3 | 19.77 ± 0.91 b | 3.14 ± 0.08 b | 56.96 ± 0.27 b | 0.85 ± 0.17 a | 60.67 ± 1.53 ab | 1.46 ± 0.02 a | 22.22 ± 0.82 a | 89.46 ± 0.15 b | 1.03 ± 0.01 b | 15.34 ± 0.00 b | |

| 1:1.7 | 20.61 ± 1.80 b | 2.49 ± 0.06 a | 62.15 ± 0.34 c | 0.99 ± 0.10 a | 58.67 ± 2.52 b | 1.28 ± 0.09 a | 18.79 ± 0.82 a | 89.78 ± 0.18 b | 0.60 ± 0.22 a | 14.45 ± 0.68 a | |

| Buckwheat | 1:1 | 14.50 ± 0.01 a | 3.03 ± 0.12 b | 60.25 ± 0.80 a | 0.88 ± 0.06 b | 64.33 ± 1.53 b | 1.58 ± 0.13 b | 24.44 ± 2.28 a | 62.12 ± 0.79 a | 7.46 ± 0.20 a | 18.03 ± 0.18 b |

| 1:1.5 | 14.72 ± 0.58 b | 3.36 ± 0.08 c | 63.19 ± 0.46 b | 0.96 ± 0.11 b | 75.33 ± 1.15 c | 1.30 ± 0.10 a | 24.22 ± 1.83 a | 66.1 ± 0.28 b | 6.60 ± 0.16 a | 16.20 ± 0.54 a | |

| 1:2 | 19.46 ± 2.27 c | 2.65 ± 0.05 a | 60.91 ± 0.79 a | 0.63 ± 0.03 a | 57.33 ± 0.58 a | 2.34 ± 0.08 c | 32.77 ± 0.88 b | 65.23 ± 1.73 b | 6.64 ± 0.74 a | 15.41 ± 1.21 a | |

| Conventional Heating | |||||||||||

| Corn | 1:0.9 | 16.96 ± 2.41 a | 2.46 ± 0.05 b | 48.53 ± 0.55 a | 24.13 ± 1.09 c | 78.00 ± 1.00 cb | 0.79 ± 0.08 a | 16.67 ± 0.79 a | 90.25 ± 1.47 ab | 1.03 ± 0.51 a | 16.72 ± 0.87 a |

| 1:1.3 | 17.31 ± 1.16 a | 2.27 ± 0.25 ab | 54.76 ± 1.37 b | 15.20 ± 0.76 b | 86.67 ± 1.15 bc | 1.08 ± 0.04 b | 23.07 ± 0.92 b | 87.58 ± 2.00 a | 0.59 ± 0.29 a | 17.57 ± 0.85 a | |

| 1:1.7 | 18.53 ± 0.65 a | 1.99 ± 0.10 a | 66.83 ± 2.22 c | 10.24 ± 0.71 a | 45.67 ± 0.58 a | 1.70 ± 0.07 c | 22.24 ± 0.44 b | 91.68 ± 0.27 b | 0.86 ± 0.56 a | 16.38 ± 0.58 a | |

| Wheat | 1:0.9 | 14.57 ± 1.11 a | 2.78 ± 0.09 b | 64.25 ± 1.03 a | 6.11 ± 1.17 c | 90.70 ± 0.38 b | 1.54 ± 0.55 a | 16.78 ± 0.67 a | 88.58 ± 1.58 a | 1.06 ± 0.03 a | 13.79 ± 0.00 a |

| 1:1.3 | 17.74 ± 0.19 b | 2.23 ± 0.08 a | 75.04 ± 0.44 b | 3.63 ± 0.05 b | 87.43 ± 1.49 a | 1.33 ± 0.09 a | 16.33 ± 0.38 a | 88.98 ± 0.52 a | 0.74 ± 0.06 a | 14.92 ± 0.37 b | |

| 1:1.7 | 18.85 ± 0.71 b | 2.07 ± 0.16 a | 76.47 ± 0.34 c | 1.95 ± 0.04 a | 88.16 ± 1.78 ab | 1.91 ± 0.56 a | 16.62 ± 0.59 a | 89.49 ± 0.20 a | 1.03 ± 0.57 a | 15.34 ± 0.67 b | |

| Potato | 1:0.9 | 12.04 ± 0.71 a | 2.35 ± 0.04 c | 64.89 ± 0.33 a | 6.60 ± 0.39 b | 46.67 ± 1.53 ca | 1.37 ± 0.04 a | 17.65 ± 1.06 ac | 87.6 ± 0.54 b | 0.89 ± 0.05 a | 15.17 ± 0.35 a |

| 1:1.3 | 15.75 ± 0.23 b | 1.67 ± 0.11 b | 69.03 ± 2.03 b | 3.85 ± 0.59 a | 85.33 ± 1.53 ab | 1.14 ± 0.1 b | 20.9 ± 1.10 b | 87.01 ± 1.07 b | 1.37 ± 0.12 ab | 16.84 ± 0.77 b | |

| 1:1.7 | 18.82 ± 0.94 c | 1.42 ± 0.13 a | 67.31 ± 1.39 ab | 4.67 ± 0.39 a | 92.00 ± 2.00 bc | 1.18 ± 0.12 a | 28.31 ± 2.01 ac | 83.62 ± 0.35 a | 1.61 ± 0.40 b | 17.82 ± 0.43 b | |

| Cassava | 1:0.9 | 12.47 ± 0.65 a | 2.00 ± 0.05 b | 72.55 ± 1.47 b | 1.64 ± 0.60 b | 77.33 ± 1.15 c | 1.05 ± 0.12 a | 20.7 ± 2.39 c | 86.35 ± 0.76 c | 1.97 ± 0.38 b | 15.52 ± 0.46 a |

| 1:1.3 | 15.42 ± 0.86 b | 1.80 ± 0.03 a | 59.58 ± 1.27 a | 0.60 ± 0.05 a | 37.67 ± 2.52 a | 1.68 ± 0.47 b | 16.08 ± 2.74 b | 81.79 ± 2.24 b | 2.64 ± 0.46 ab | 17.73 ± 0.39 b | |

| 1:1.7 | 15.3 ± 0.77 b | 1.79 ± 0.14 a | 59.19 ± 1.62 a | 0.52 ± 0.09 a | 41.33 ± 1.53 b | 0.70 ± 0.09 a | 9.24 ± 0.92 a | 74.71 ± 1.70 a | 3.15 ± 0.50 a | 17.33 ± 0.74 b | |

| Rice | 1:0.9 | 14.19 ± 0.25 a | 2.39 ± 0.06 b | 53.11 ± 2.31 ca | 4.79 ± 0.48 c | 59.00 ± 3.00 a | 1.66 ± 0.07 c | 24.50 ± 0.61 c | 86.77 ± 0.3 a | 1.48 ± 0.06 b | 16.09 ± 0.37 c |

| 1:1.3 | 14.99 ± 0.30 a | 2.34 ± 0.05 b | 62.95 ± 1.70 b | 3.40 ± 0.84 b | 73.00 ± 2.65 b | 1.30 ± 0.06 b | 22.54 ± 0.66 b | 88.09 ± 0.29 b | 0.88 ± 0.06 a | 14.08 ± 0.38 b | |

| 1:1.7 | 17.44 ± 3.48 a | 2.19 ± 0.05 a | 67.88 ± 1.25 ac | 1.83 ± 0.03 a | 70.67 ± 2.08 b | 1.00 ± 0.06 a | 17.69 ± 1.38 a | 88.57 ± 0.10 b | 0.81 ± 0.41 a | 13.25 ± 0.42 a | |

| Buckwheat | 1:1 | 15.17 ± 0.34 a | 2.64 ± 0.06 b | 63.05 ± 0.12 b | 1.69 ± 0.32 a | 63.67 ± 1.53 a | 2.02 ± 0.41 b | 32.97 ± 5.24 b | 55.10 ± 1.20 a | 6.65 ± 0.32 a | 13.82 ± 0.32 b |

| 1:1.5 | 16.43 ± 0.71 ab | 2.44 ± 0.15 b | 63.34 ± 0.53 b | 1.52 ± 0.15 a | 81.00 ± 1.73 b | 1.43 ± 0.10 a | 29.48 ± 1.06 ab | 59.14 ± 0.93 b | 6.67 ± 0.01 a | 12.35 ± 0.32 a | |

| 1:2 | 18.20 ± 1.99 b | 2.21 ± 0.07 a | 60.95 ± 1.30 a | 1.79 ± 0.49 a | 87.00 ± 2.00 c | 1.11 ± 0.11 a | 23.15 ± 2.28 a | 59.74 ± 0.91 b | 6.48 ± 0.34 a | 11.79 ± 0.31 a | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Waziiroh, E.; Bender, D.; Saric, A.; Jaeger, H.; Schoenlechner, R. Ohmic Baking of Gluten-Free Bread: Role of Starch and Flour on Batter Properties. Appl. Sci. 2021, 11, 6567. https://doi.org/10.3390/app11146567

Waziiroh E, Bender D, Saric A, Jaeger H, Schoenlechner R. Ohmic Baking of Gluten-Free Bread: Role of Starch and Flour on Batter Properties. Applied Sciences. 2021; 11(14):6567. https://doi.org/10.3390/app11146567

Chicago/Turabian StyleWaziiroh, Elok, Denisse Bender, Anisa Saric, Henry Jaeger, and Regine Schoenlechner. 2021. "Ohmic Baking of Gluten-Free Bread: Role of Starch and Flour on Batter Properties" Applied Sciences 11, no. 14: 6567. https://doi.org/10.3390/app11146567

APA StyleWaziiroh, E., Bender, D., Saric, A., Jaeger, H., & Schoenlechner, R. (2021). Ohmic Baking of Gluten-Free Bread: Role of Starch and Flour on Batter Properties. Applied Sciences, 11(14), 6567. https://doi.org/10.3390/app11146567