Chimney Sweeping Robot Based on a Pneumatic Actuator

Abstract

1. Introduction

2. Related Works

3. Development of Chimney Robot

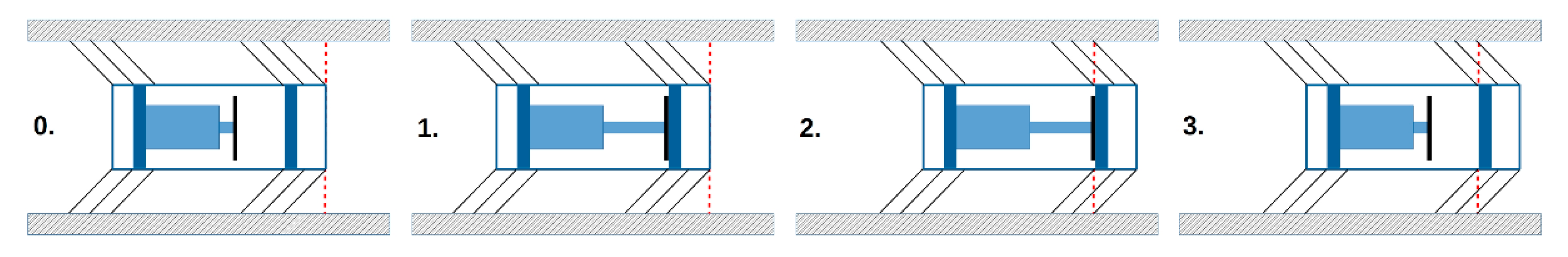

3.1. Principle of Motion

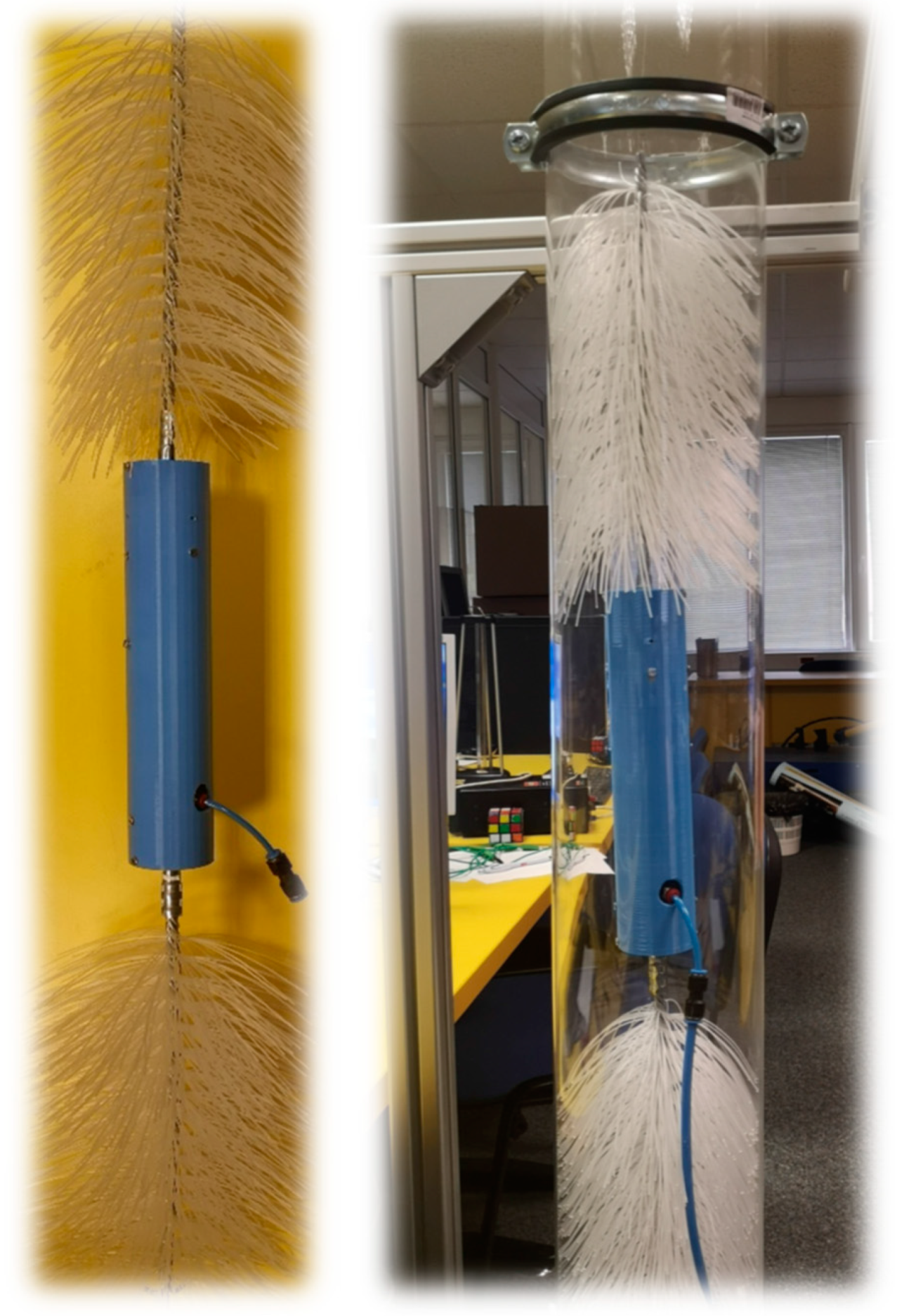

3.2. Mechanical Design

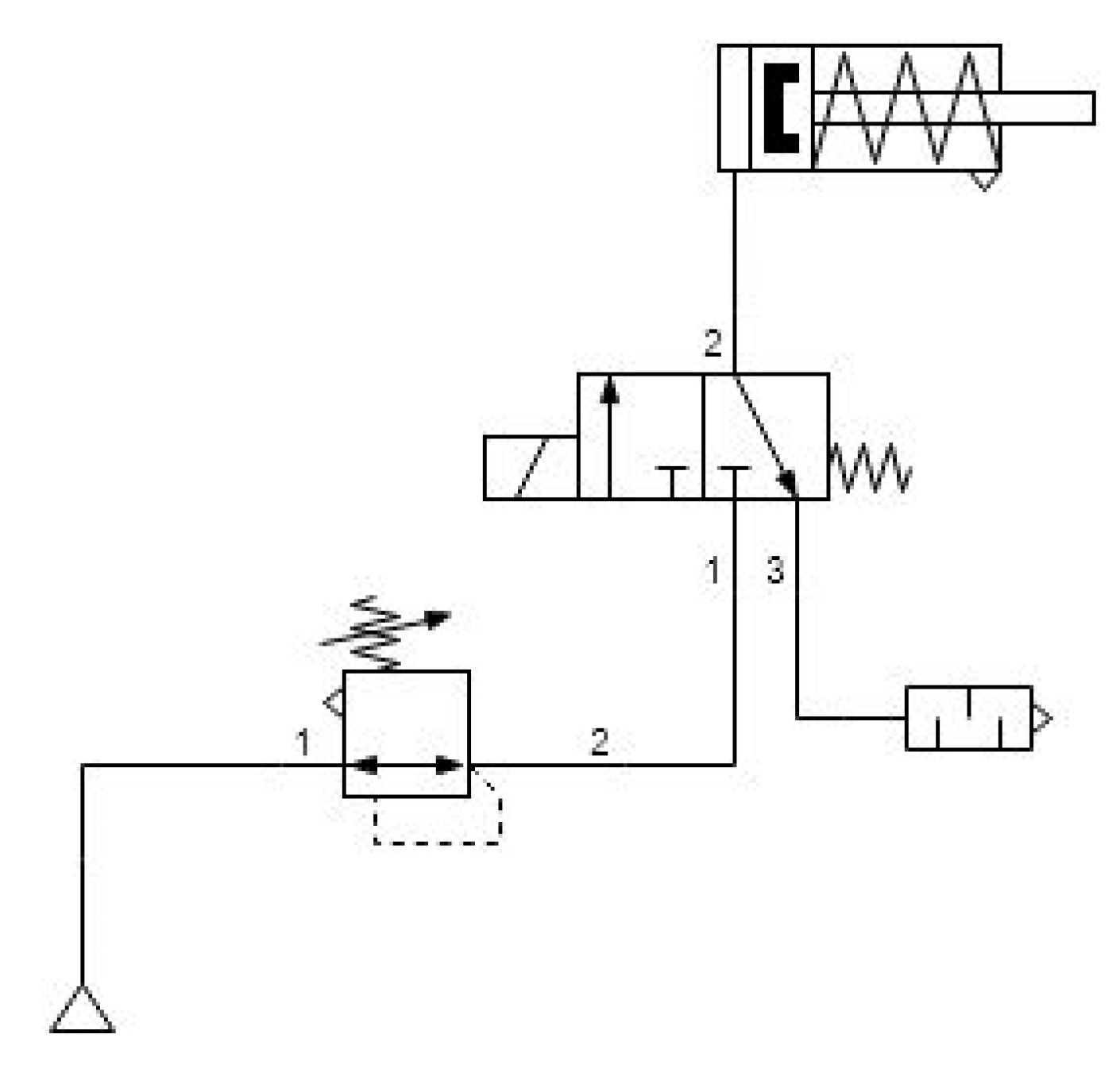

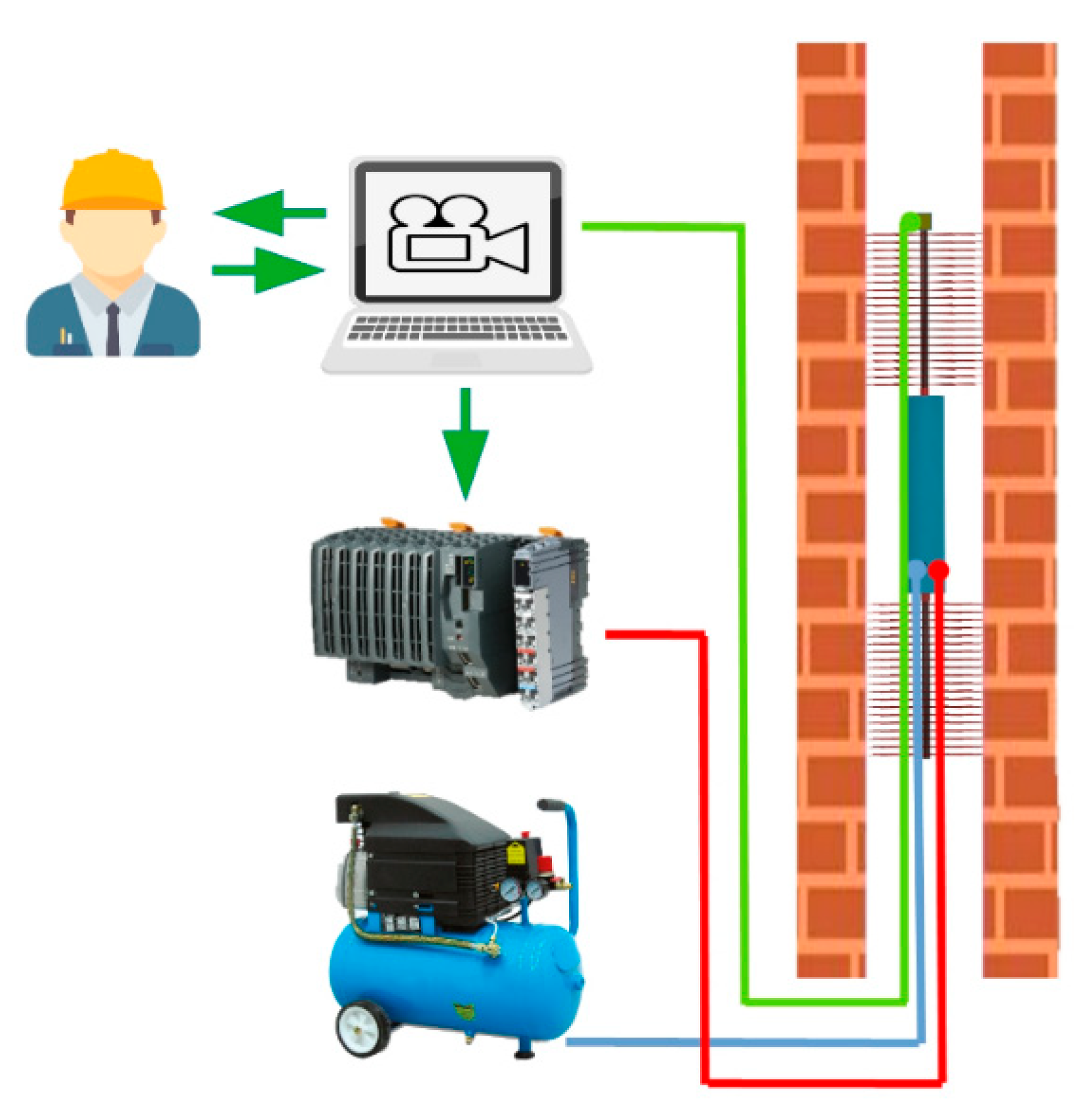

3.3. Concept of the Proposed System

4. Numerical Simulations and Experiments

4.1. Mathematical Model of the Proposed Solution

4.2. Numerical Simulation

| Algorithm 1 Numerical simulation |

| 1: Initialization of variables and constants |

| 2: FOR cycle = 1 TO Number of required cycles BY 1 |

| 3: FOR i = 0 TO T BY dt // Forward motion of pneumatic piston |

| 4: IF (i > valveDelay) THEN |

| 5: |

| 6: END |

| 7: Computation of mass 1 acceleration, velocity, position |

| 8: IF (contact < ρ) AND ( THEN |

| 9: contact++ |

| 10: |

| 11: ELSEIF (contact== ρ) AND THEN |

| 12: |

| 13: ELSEIF (contact==0) AND ( THEN |

| 14: |

| 15: END |

| 16: |

| 17: Computation of mass 2 acceleration, velocity, position |

| 18: END |

| 19: FOR i = 0 TO T BY dt // Backward motion of pneumatic piston |

| 20: IF (i > valveDelay) THEN |

| 21: |

| 22: END |

| 23: Computation of mass 1 acceleration, velocity, position |

| 24: IF ( THEN |

| 25: |

| 26: END |

| 27: Computation of mass 2 acceleration, velocity, position |

| 28: END |

| 29:END |

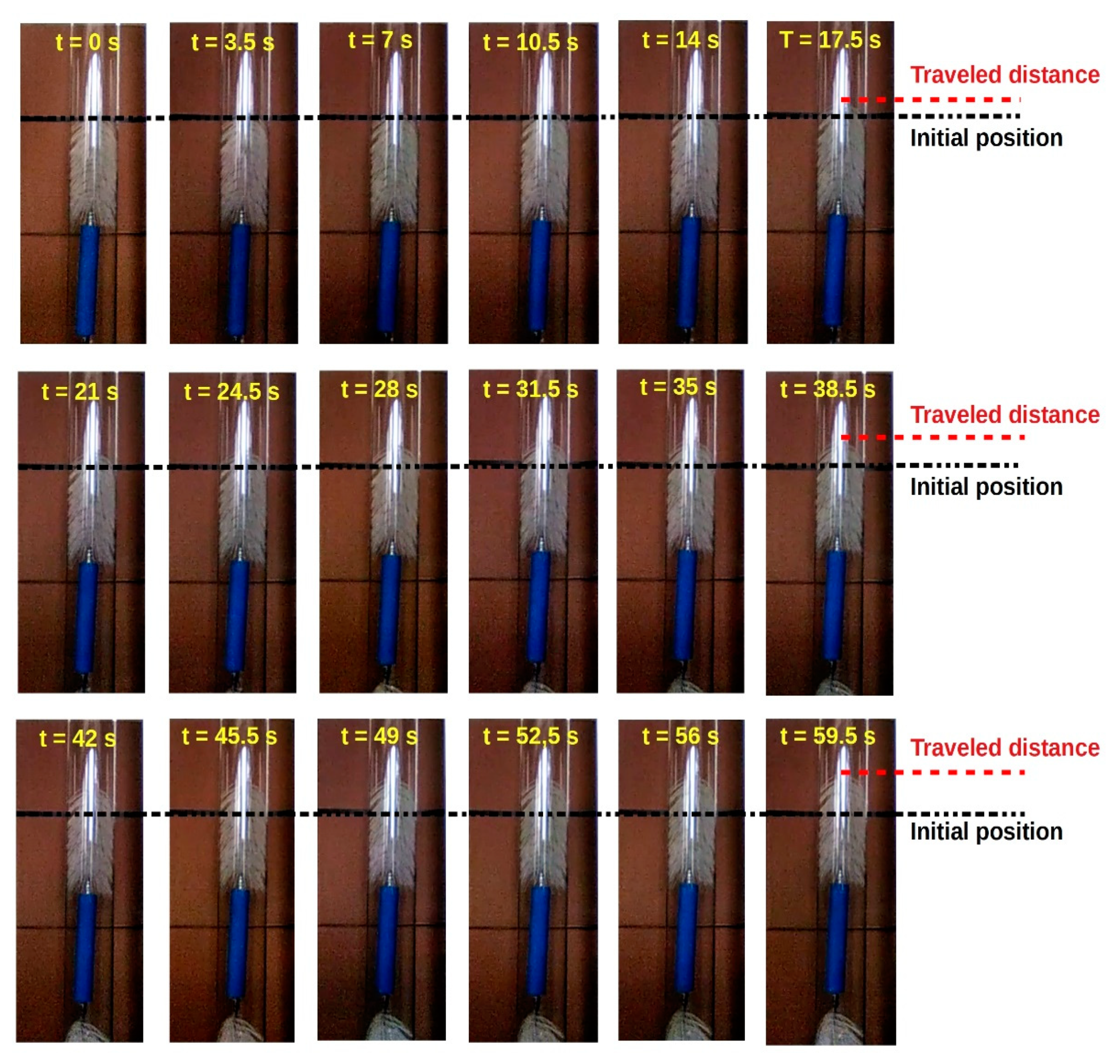

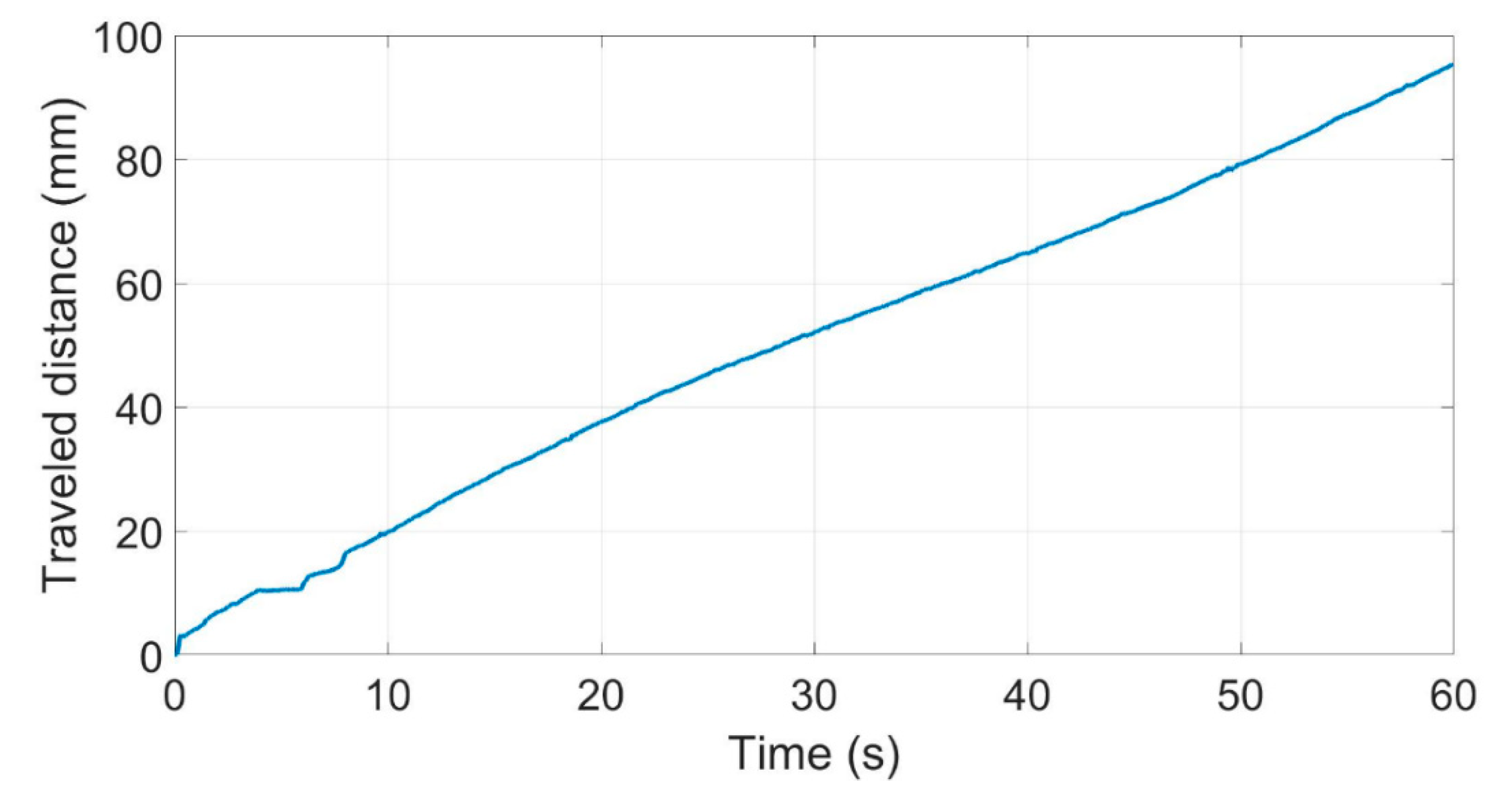

4.3. Experiments

- Verification of the functionality and the principle of the motion of the designed robot moving in the pipeline similar to a chimney. The focus is on the functionality of the robot not on the quality of the motion. In other words, this objective is not focused on the maximum speed of the robot.

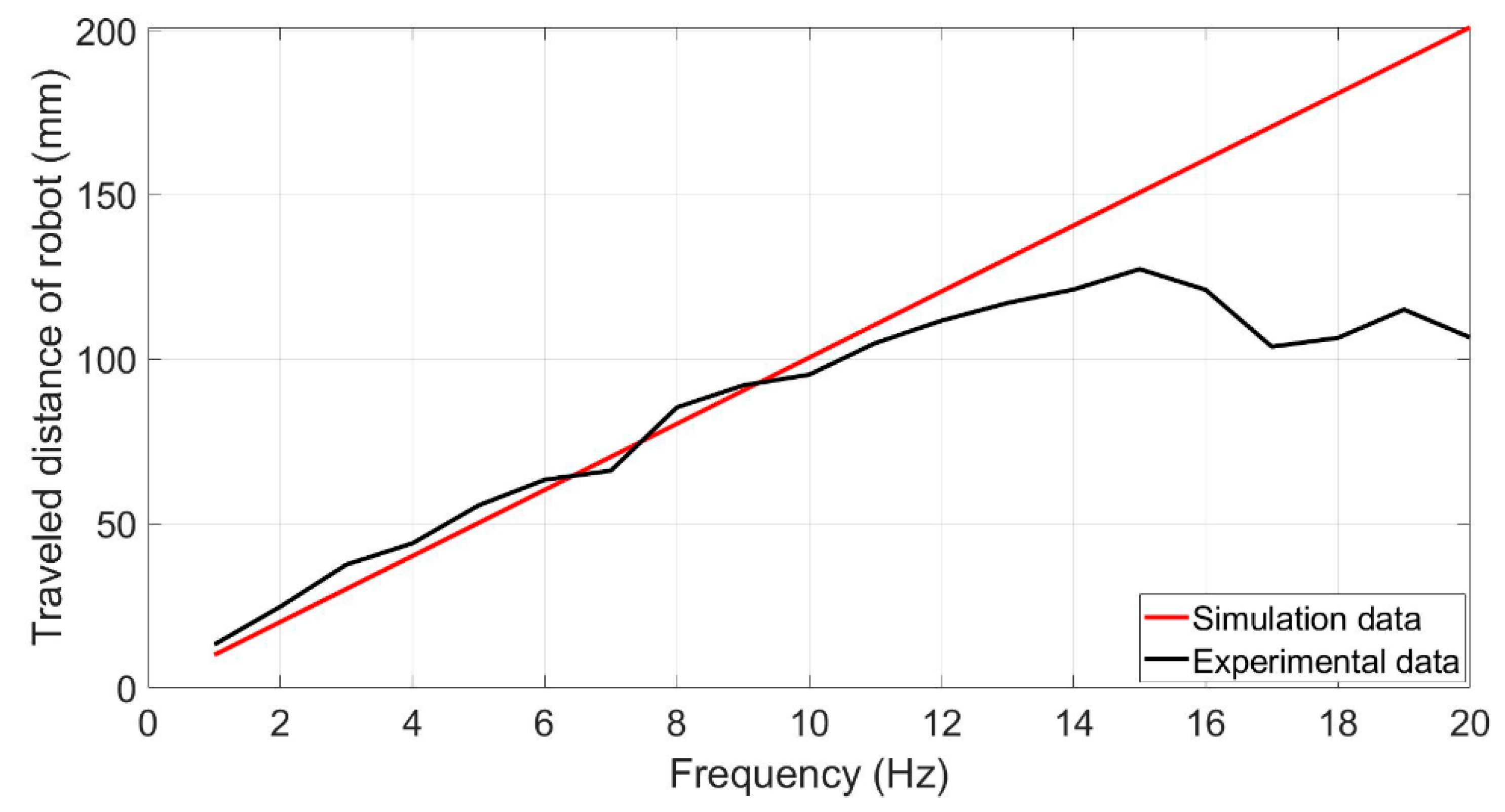

- Comparison of the experimental results with the simulation data in order to verify the quality and accuracy of the simulation model. Several measurements will be carried out, with different frequency of extension/insertion of the pneumatic piston. The travelled distance of the robot with changing frequency will be then compared with the simulated travelled distance.

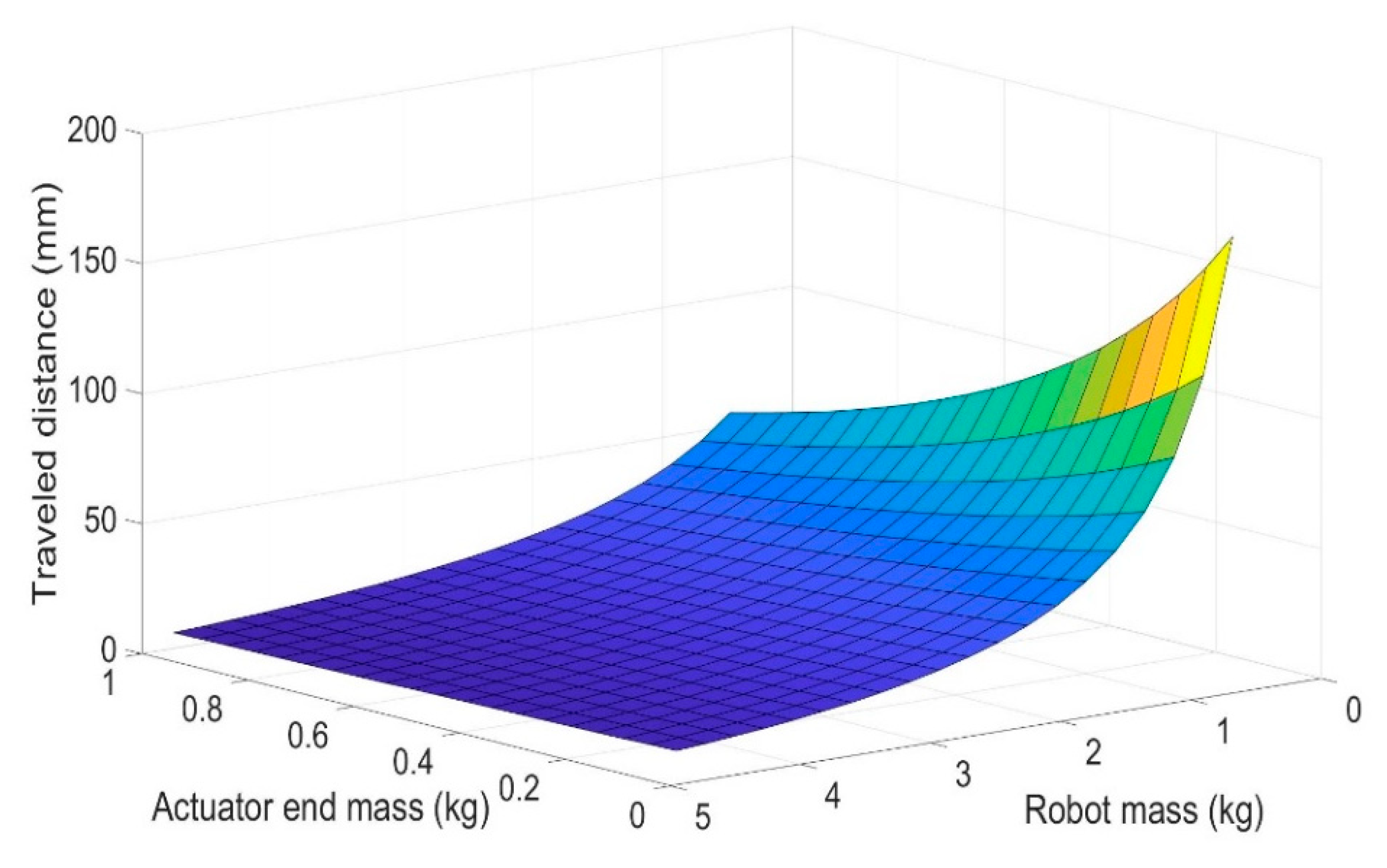

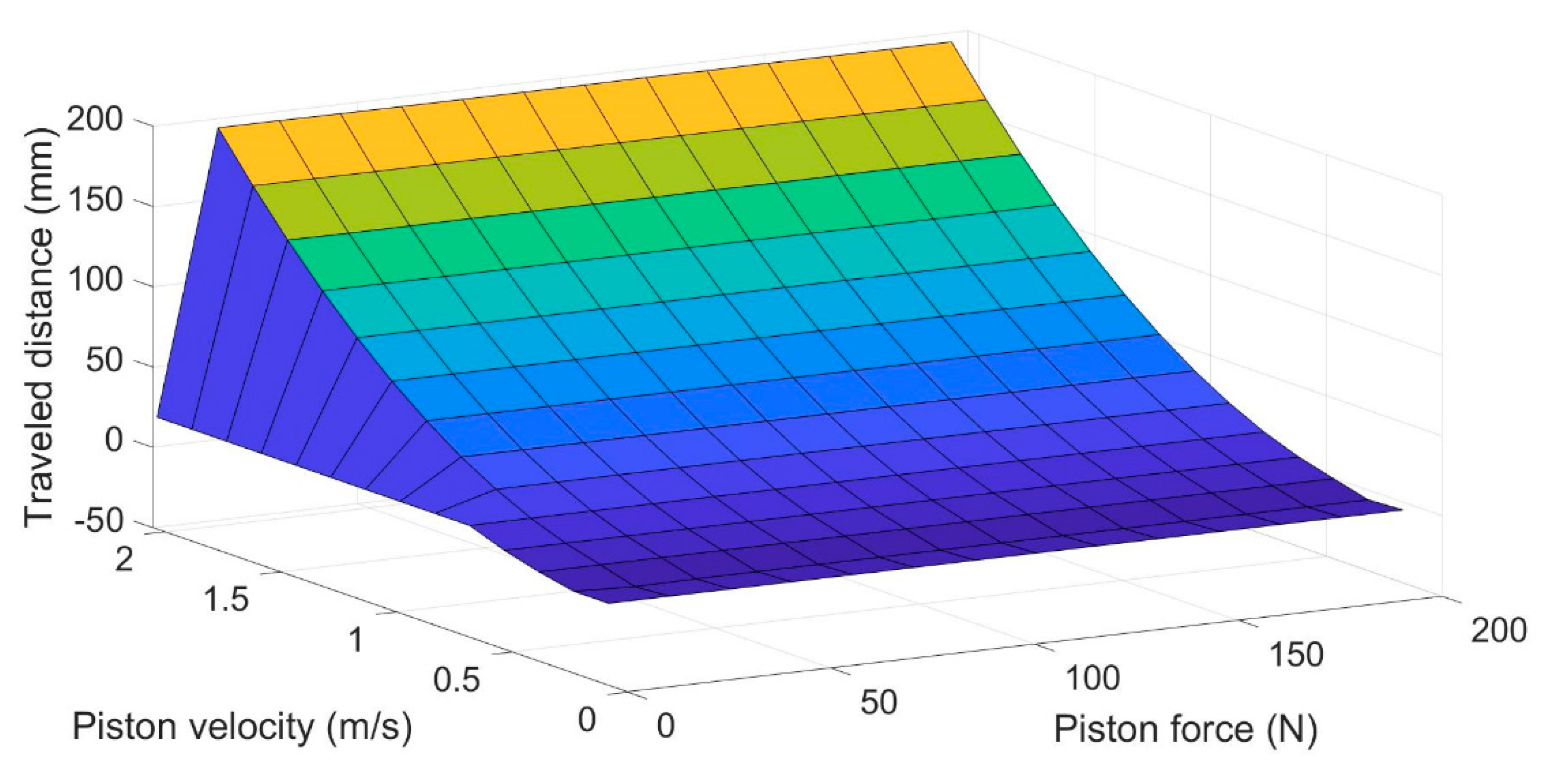

4.4. Results of the Simulations and Analyses

5. Results and Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ostertag, O.; Ostertagová, E.; Kelemen, M.; Kelemenová, T.; Buša, J.; Virgala, I. Miniature Mobile Bristled In-Pipe Machine. Int. J. Adv. Robot. Syst. 2014, 11, 189. [Google Scholar] [CrossRef]

- Virgala, I.; Kelemen, M.; Prada, E.; Sukop, M.; Kot, T.; Bobovský, Z.; Varga, M.; Ferenčík, P. A snake robot for locomotion in a pipe using trapezium-like travelling wave. Mech Mach. Theory 2020, 158, 1–21. [Google Scholar]

- Virgala, I.; Kelemen, M.; Božek, P.; Bobovský, Z.; Hagara, M.; Prada, E.; Oščádal, P.; Varga, M. Investigation of Snake Robot Locomotion Possibilities in a Pipe. Symmetry 2020, 12, 939. [Google Scholar] [CrossRef]

- Kelemen, M.; Virgala, I.; Lipták, T.; Miková, Ľ.; Filakovský, F.; Bulej, V. A Novel Approach for a Inverse Kinematics Solution of a Redundant Manipulator. Appl. Sci. 2018, 8, 2229. [Google Scholar] [CrossRef]

- Virgala, I.; Kelemen, M.; Varga, M.; Kuryło, P. Analyzing, Modeling and Simulation of Humanoid Robot Hand Motion. Procedia Eng. 2014, 96, 489–499. [Google Scholar] [CrossRef]

- Kakogawa, A.; Ma, S. Design of a multilink-articulated wheeled inspection robot for winding pipelines: AIRo-II. In Proceedings of the 2016 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Daejeon, Korea, 9–14 October 2016; pp. 2115–2121. [Google Scholar] [CrossRef]

- Lu, H.; Zhu, J.; Lin, Z.; Guo, Y. An inchworm mobile robot using electromagnetic linear actuator. Mechatronics 2009, 19, 1116–1125. [Google Scholar] [CrossRef]

- Ivanov, A.P. Analysis of an impact-driven capsule robot. Int. J. Non. Linear. Mech. 2020, 119, 103257. [Google Scholar] [CrossRef]

- Cicconofri, G.; DeSimone, A. Motility of a model bristle-bot: A theoretical analysis. Int. J. Non. Linear. Mech. 2015, 76, 233–239. [Google Scholar] [CrossRef]

- Yum, Y.-J.; Hwang, H.; Kelemen, M.; Maxim, V.; Frankovský, P. In-pipe micromachine locomotion via the inertial stepping principle. J. Mech. Sci. Technol. 2014, 28, 3237–3247. [Google Scholar] [CrossRef]

- Ragulskis, K.; Bogdevicius, M.; Mištinas, V. Behavior of Dynamic Processes in Self-Exciting Vibration of an Inpipe Robot. J. Vibroengineering 2008, 10. [Google Scholar] [CrossRef]

- Kim, Y.; Yoon, K.; Park, Y. Development of the inpipe robot for various sizes. In Proceedings of the 2009 IEEE/ASME International Conference on Advanced Intelligent Mechatronics, Singapore, 14–17 July 2009; pp. 1745–1749. [Google Scholar] [CrossRef]

- Wang, Z.; Gu, H. A Bristle-Based Pipeline Robot for Ill-Constraint Pipes. IEEE/ASME Trans. Mechatron. 2008, 13, 383–392. [Google Scholar] [CrossRef]

- Roh, S.; Kim, D.W.; Lee, J.S.; Moon, H.; Choi, H.R. In-pipe robot based on selective drive mechanism. Int. J. Control. Autom. Syst. 2009, 7, 105–112. [Google Scholar] [CrossRef]

- Kim, D.; Park, C.; Kim, H.; Kim, S. Force adjustment of an active pipe inspection robot. In Proceedings of the 2009 ICCAS-SICE, Fukuoka, Japan, 18–21 August 2009; IEEE: Piscataway, NJ, USA, 2009; pp. 3792–3797. [Google Scholar]

- Li, H.; Li, R.; Zhang, J.; Zhang, P. Development of a Pipeline Inspection Robot for the Standard Oil Pipeline of China National Petroleum Corporation. Appl. Sci. 2020, 10, 2853. [Google Scholar] [CrossRef]

- Zhu, X.; Zhang, S.; Wang, D.; Wang, W.; Liu, S. The impact of pipeline bend on bi-directional pig and the theories for the optimal pig design. In Proceedings of the 2013 IEEE International Conference on Mechatronics and Automation, Takamatsu, Japan, 4–7 August 2013; pp. 87–92. [Google Scholar] [CrossRef]

- Guibin, T.; Shimin, Z.; Xiaoxiao, Z.; Liyun, S.; Qingbao, Z. Research on Bypass-valve and its Resistance Characteristic of Speed Regulating PIG in Gas Pipeline. In Proceedings of the 2011 Third International Conference on Measuring Technology and Mechatronics Automation, Shanghai, China, 6–7 January 2011; pp. 1114–1117. [Google Scholar] [CrossRef]

- Alnaimi, F.B.I.; Mazraeh, A.A.; Sahari, K.S.M.; Weria, K.; Moslem, Y. Design of a multi-diameter in-line cleaning and fault detection pipe pigging device. In Proceedings of the 2015 IEEE International Symposium on Robotics and Intelligent Sensors (IRIS), Langkawi, Malaysia, 18–20 October 2015; pp. 258–265. [Google Scholar] [CrossRef]

- Xinyu, Z.; Bo, Z.; Yuanzhang, J.; Bo, L.; Rui, L.; Lin, Z.; Qiao, S.; Xiaoli, Z. Analysis of rotation of pigs during pigging in gas pipeline. In Proceedings of the 2015 International Conference on Fluid Power and Mechatronics (FPM), Harbin, China, 5–7 August 2015; pp. 892–895. [Google Scholar] [CrossRef]

- Xingping, X.; Hai, W.; Fuzheng, X.; Bin, W. Study of the Drive and Speed Governing Control for a Pipeline Pig. In Proceedings of the 2018 10th International Conference on Modelling, Identification and Control (ICMIC), Guiyang, China, 2–4 July 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Wang, Z.; Cao, Q.; Luan, N.; Zhang, L. Development of new pipeline maintenance system for repairing early-built offshore oil pipelines. In Proceedings of the 2008 IEEE International Conference on Industrial Technology, Chengdu, China, 21–24 April 2008; pp. 1–6. [Google Scholar] [CrossRef]

- Božek, P.; Nikitin, Y.; Krenický, T. Diagnostics of Mechatronic Systems (Studies in Systems, Decision and Control, 345); Springer: Berlin/Heidelberg, Germany, 2021; ISBN 978-3030670542. [Google Scholar]

- Sentyakov, K.; Peterka, J.; Smirnov, V.; Bozek, P.; Sviatskii, V. Modeling of Boring Mandrel Working Process with Vibration Damper. Materials 2020, 13, 1931. [Google Scholar] [CrossRef] [PubMed]

- Son, L.; Bur, M.; Rusli, M.; Matsuhisa, H.; Yamada, K.; Utsuno, H. Fundamental Study of Momentum Exchange Impact Damper Using Pre-straining Spring Mechanism. Int. J. Acoust. Vib. 2017, 2, 422–430. [Google Scholar] [CrossRef]

- Jönsson, A.; Bathelt, J.; Broman, G. Implications of Modelling One-Dimensional Impact by Using a Spring and Damper Element. Proc. Inst. Mech. Eng. Part. K J. Multi-Body Dyn. 2005, 219, 299–305. [Google Scholar] [CrossRef]

- Kuinian, L. Antony Darby. Modelling a buffered impact damper system using a spring-damper model of impact. In Structural Control and Health Monitoring; Wiley-Blackwell: Hoboken, NJ, USA, 2009; Volume 16, pp. 287–302. [Google Scholar] [CrossRef]

| Parameter | Value (Units) |

|---|---|

| Mass 1 | 0.05 (kg) |

| Mass 2 | 1 (kg) |

| Maximum piston speed | 1.5 (ms−1) |

| Maximum piston extension | 0.0235 (m) |

| Maximum piston force | 62.8 (N) |

| Time delay of valve | 0.005 (s) |

| Time step | 0.0001 (s) |

| Spring stiffness | 800 (Nm−1) |

| Damping coefficient | 240 (Nm−1s) |

| Time period of impact | 0.0006 (s) |

| Forward friction coefficient | 0.8 × 50 (N) |

| Backward friction coefficient | 50 (N) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sinčák, P.J.; Virgala, I.; Kelemen, M.; Prada, E.; Bobovský, Z.; Kot, T. Chimney Sweeping Robot Based on a Pneumatic Actuator. Appl. Sci. 2021, 11, 4872. https://doi.org/10.3390/app11114872

Sinčák PJ, Virgala I, Kelemen M, Prada E, Bobovský Z, Kot T. Chimney Sweeping Robot Based on a Pneumatic Actuator. Applied Sciences. 2021; 11(11):4872. https://doi.org/10.3390/app11114872

Chicago/Turabian StyleSinčák, Peter Ján, Ivan Virgala, Michal Kelemen, Erik Prada, Zdenko Bobovský, and Tomáš Kot. 2021. "Chimney Sweeping Robot Based on a Pneumatic Actuator" Applied Sciences 11, no. 11: 4872. https://doi.org/10.3390/app11114872

APA StyleSinčák, P. J., Virgala, I., Kelemen, M., Prada, E., Bobovský, Z., & Kot, T. (2021). Chimney Sweeping Robot Based on a Pneumatic Actuator. Applied Sciences, 11(11), 4872. https://doi.org/10.3390/app11114872