Estimation of Grey-Box Dynamic Model of 2-DOF Pneumatic Actuator Robotic Arm Using Gravity Tests

Abstract

1. Introduction and Related Works

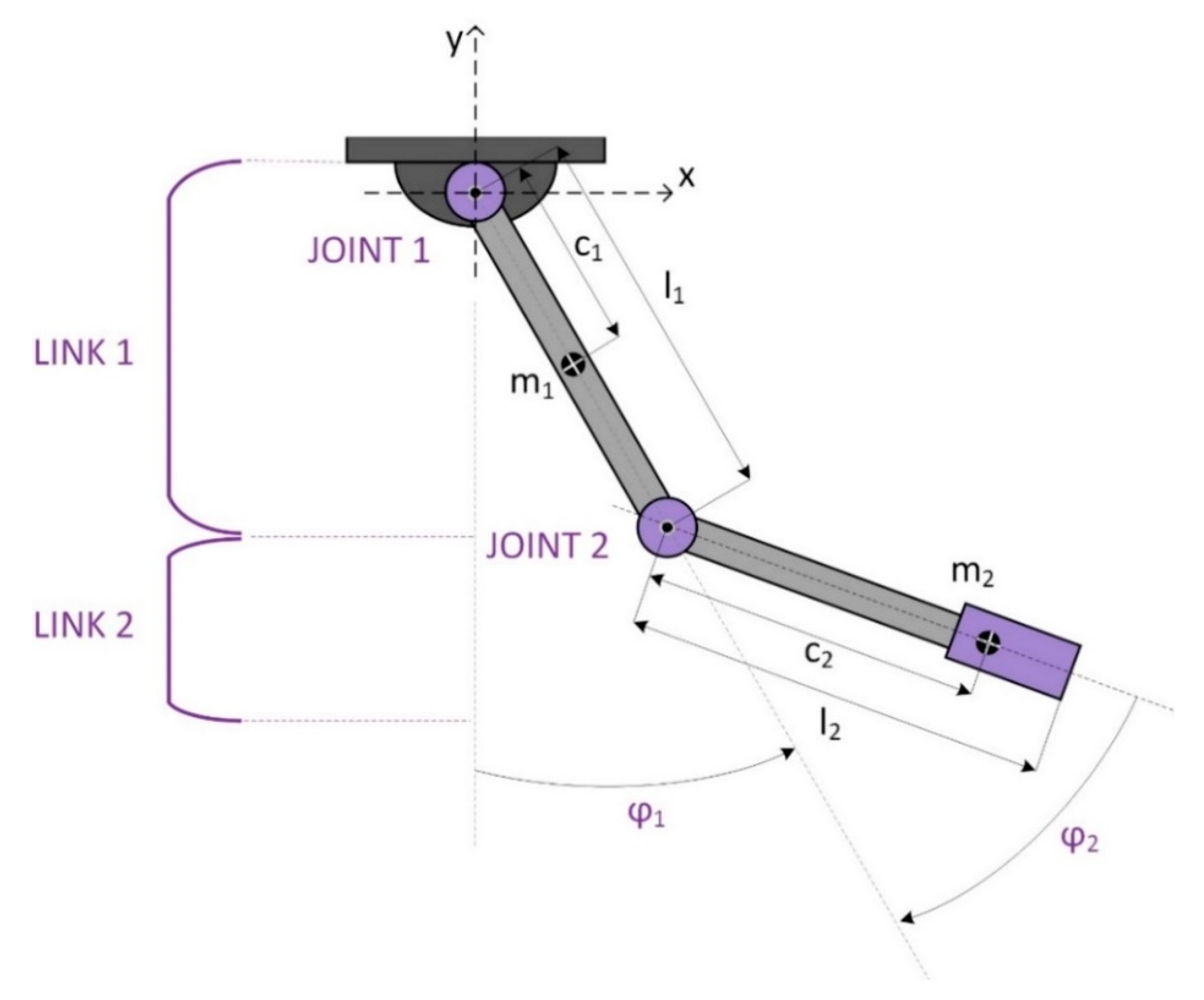

2. Dynamic Model of the System

Determination Lagrange’s Equations

3. Experimental System—Planar Robotic Arm

4. Measured Data

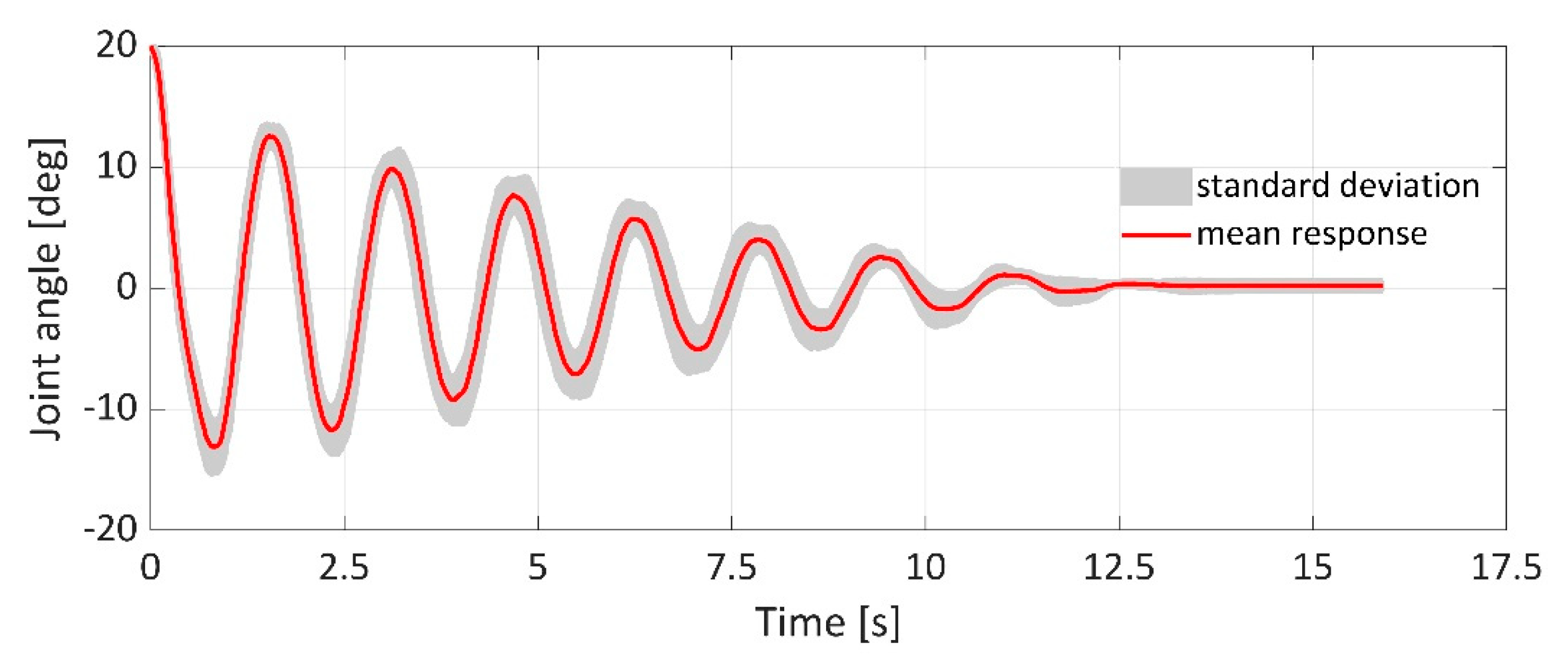

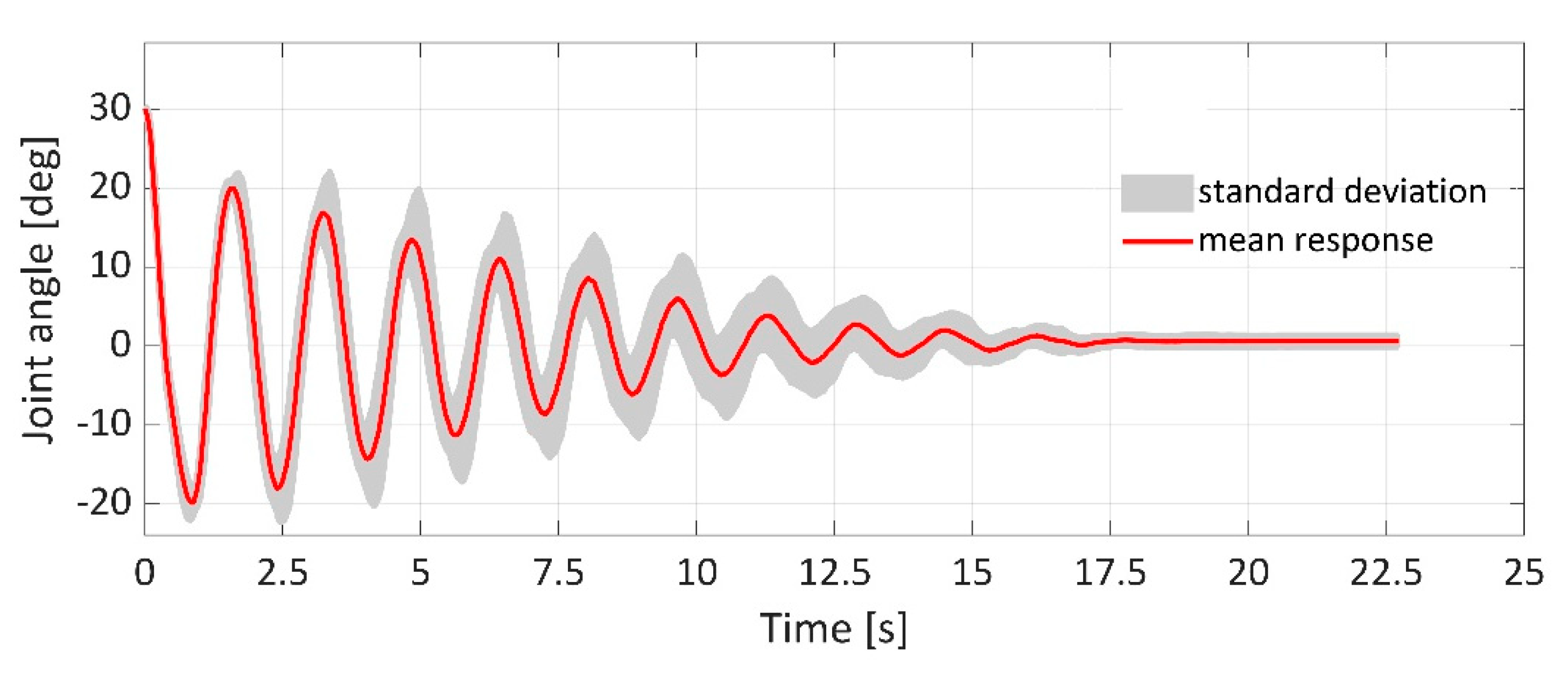

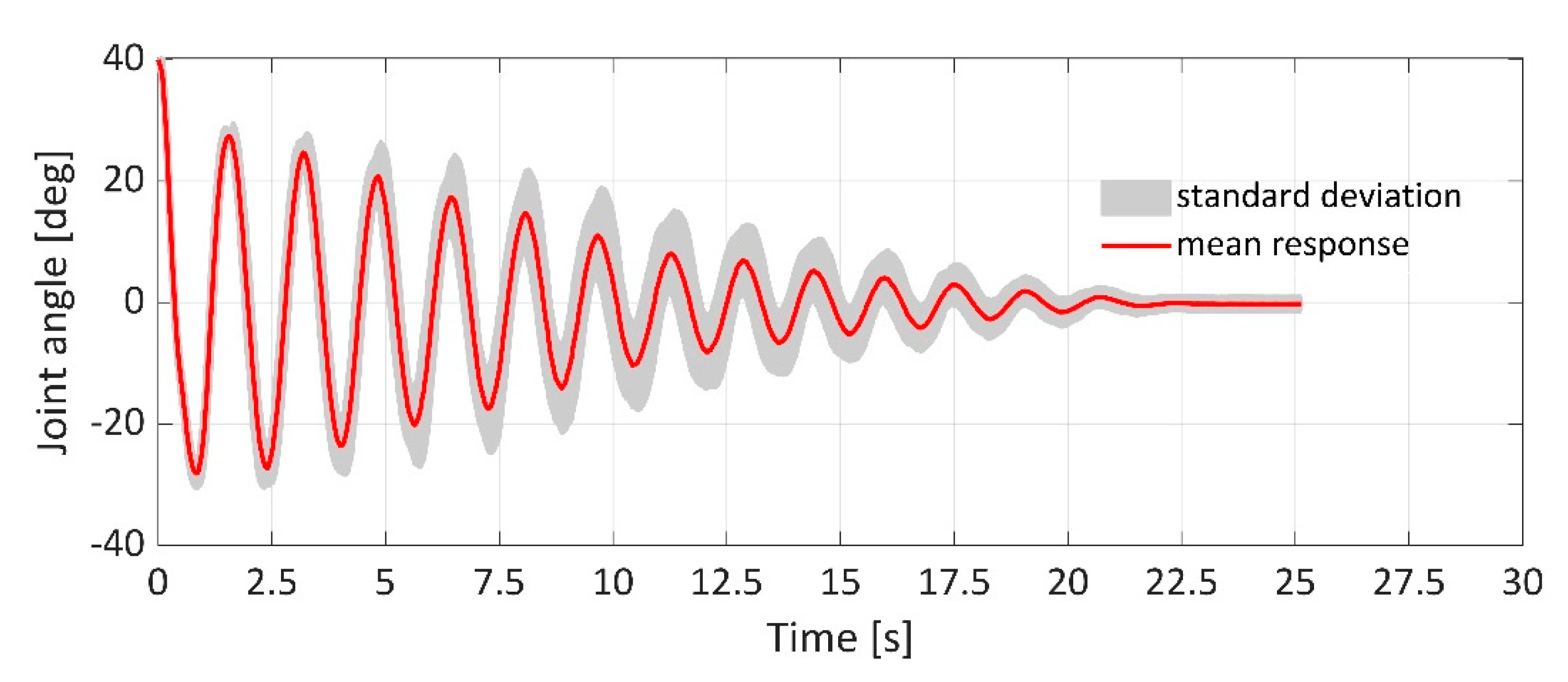

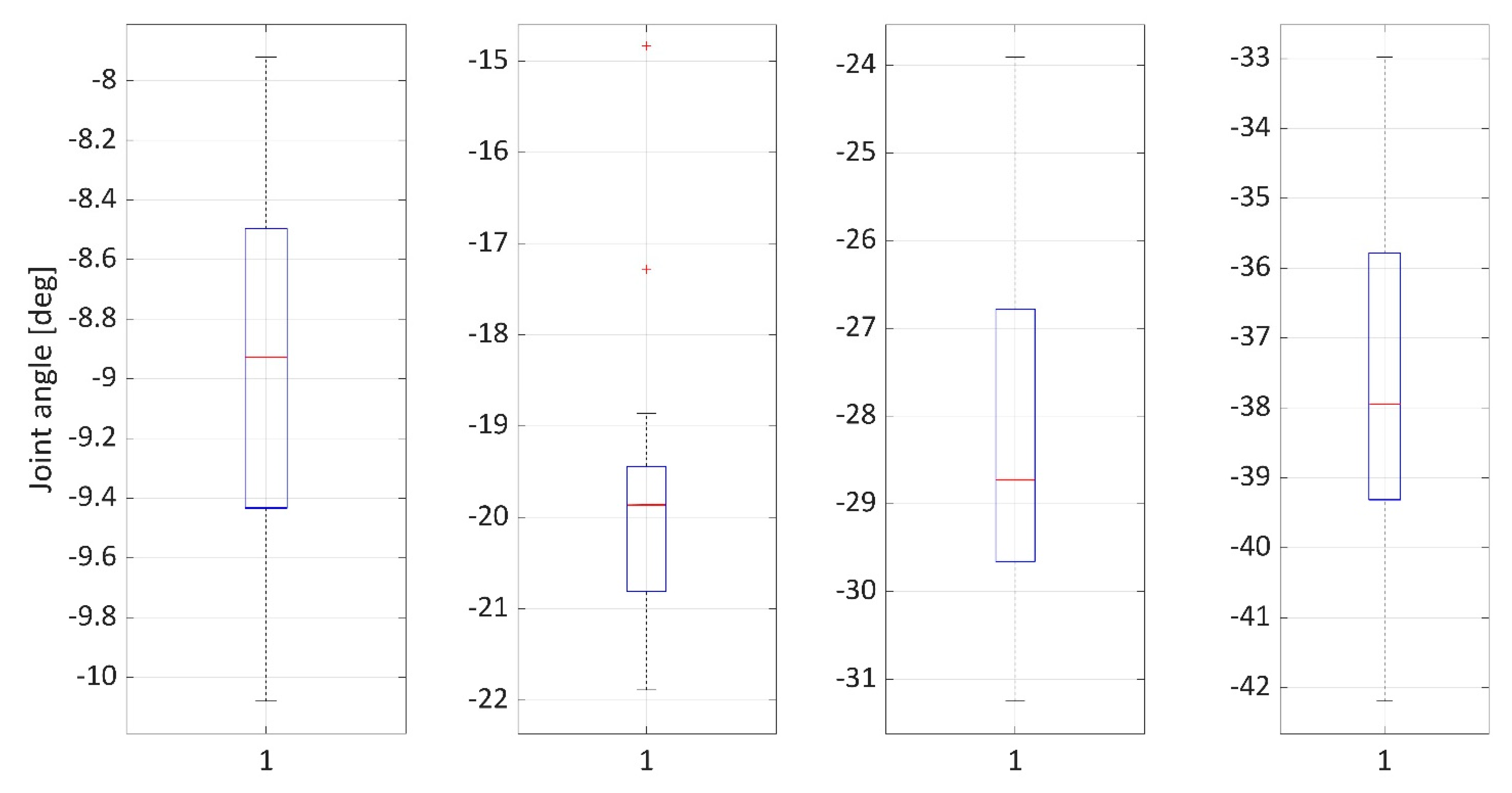

4.1. Measured Data—Link 1

4.2. Measured Data—Link 2

5. Validation

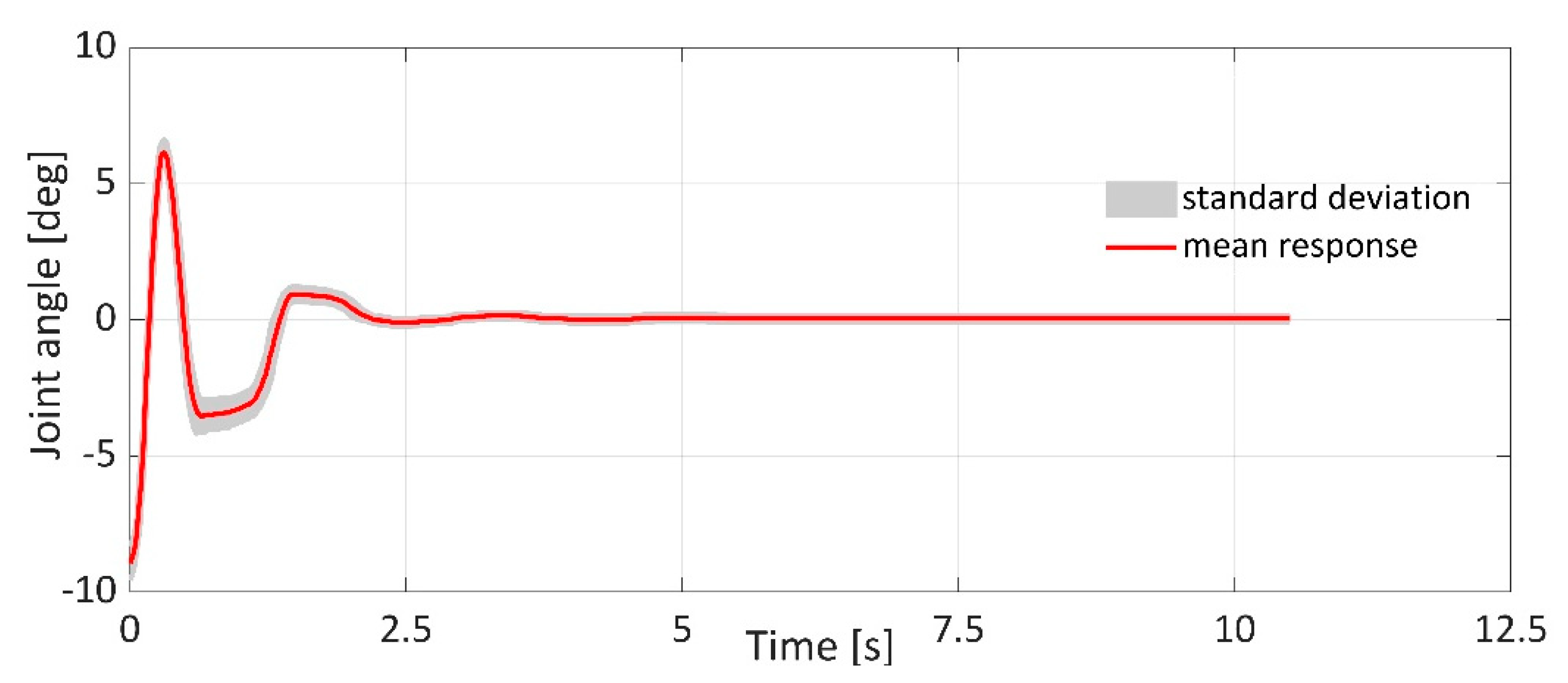

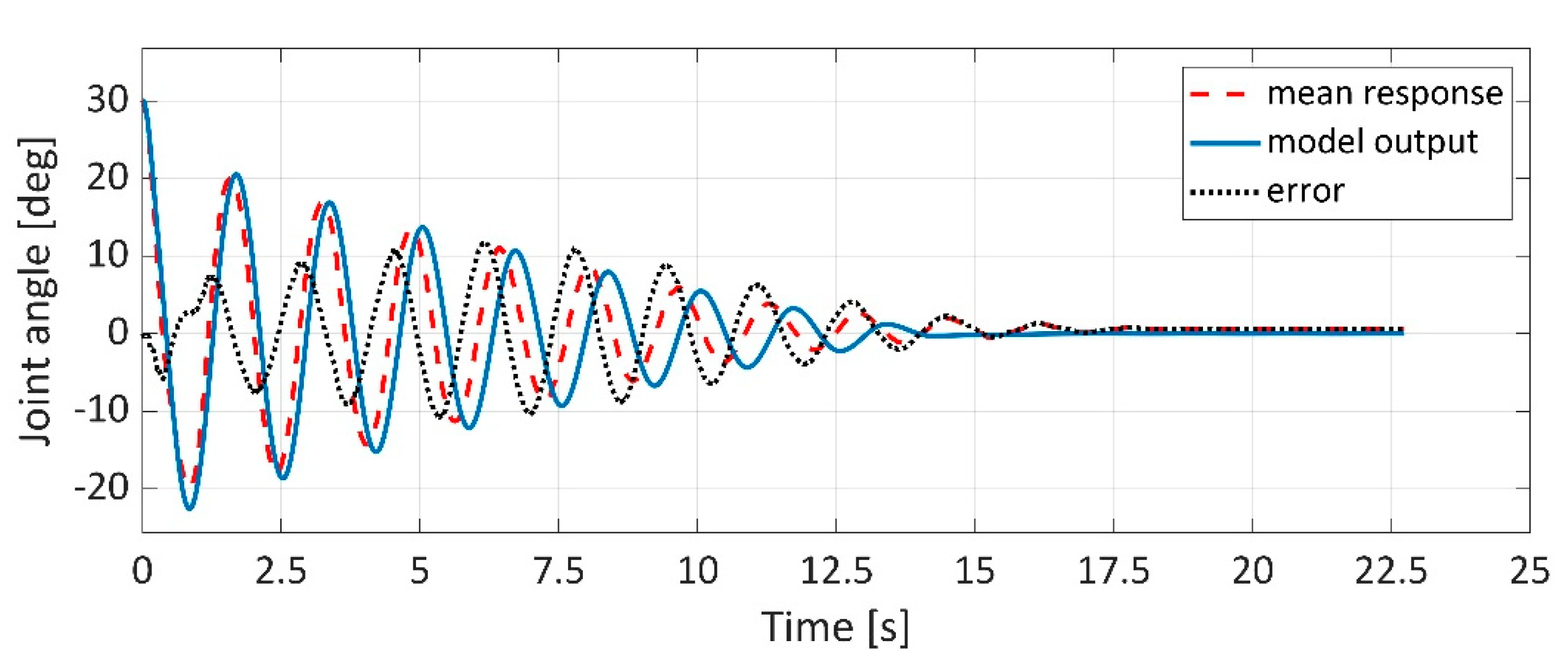

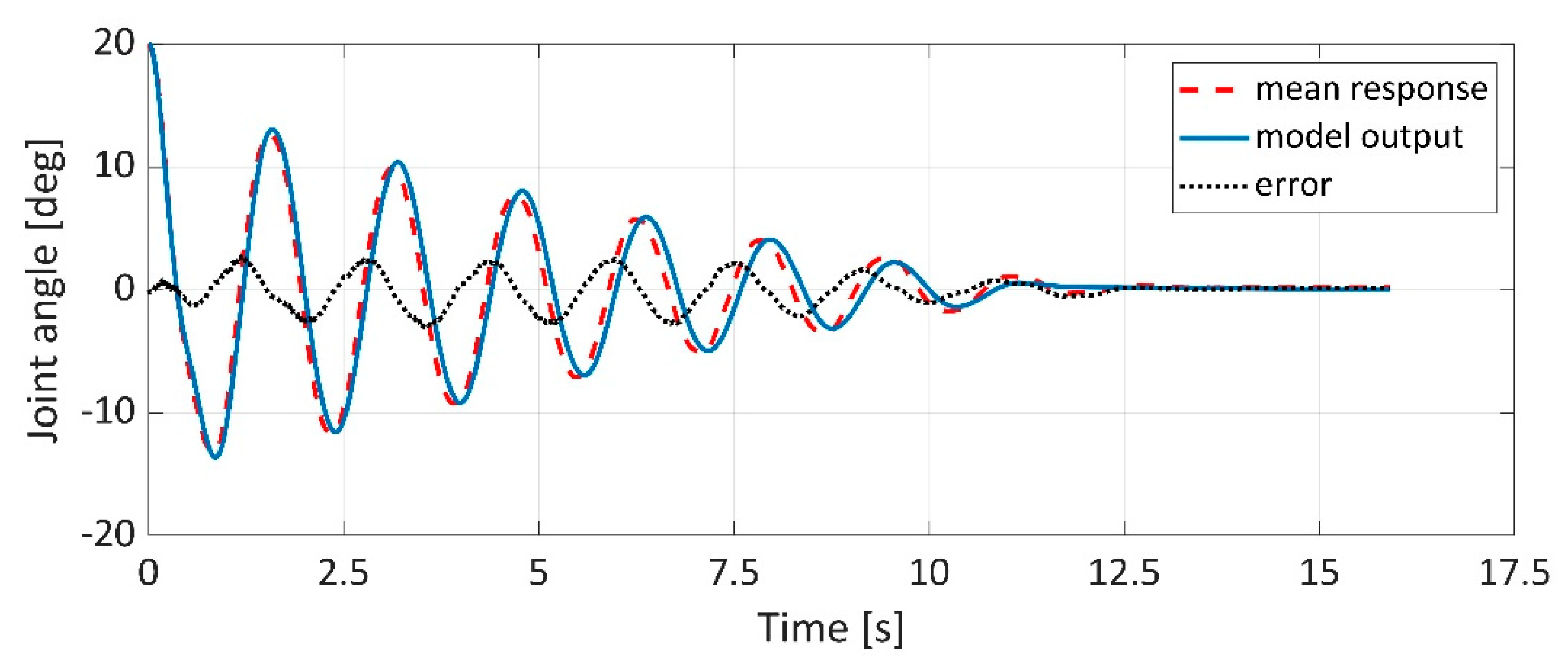

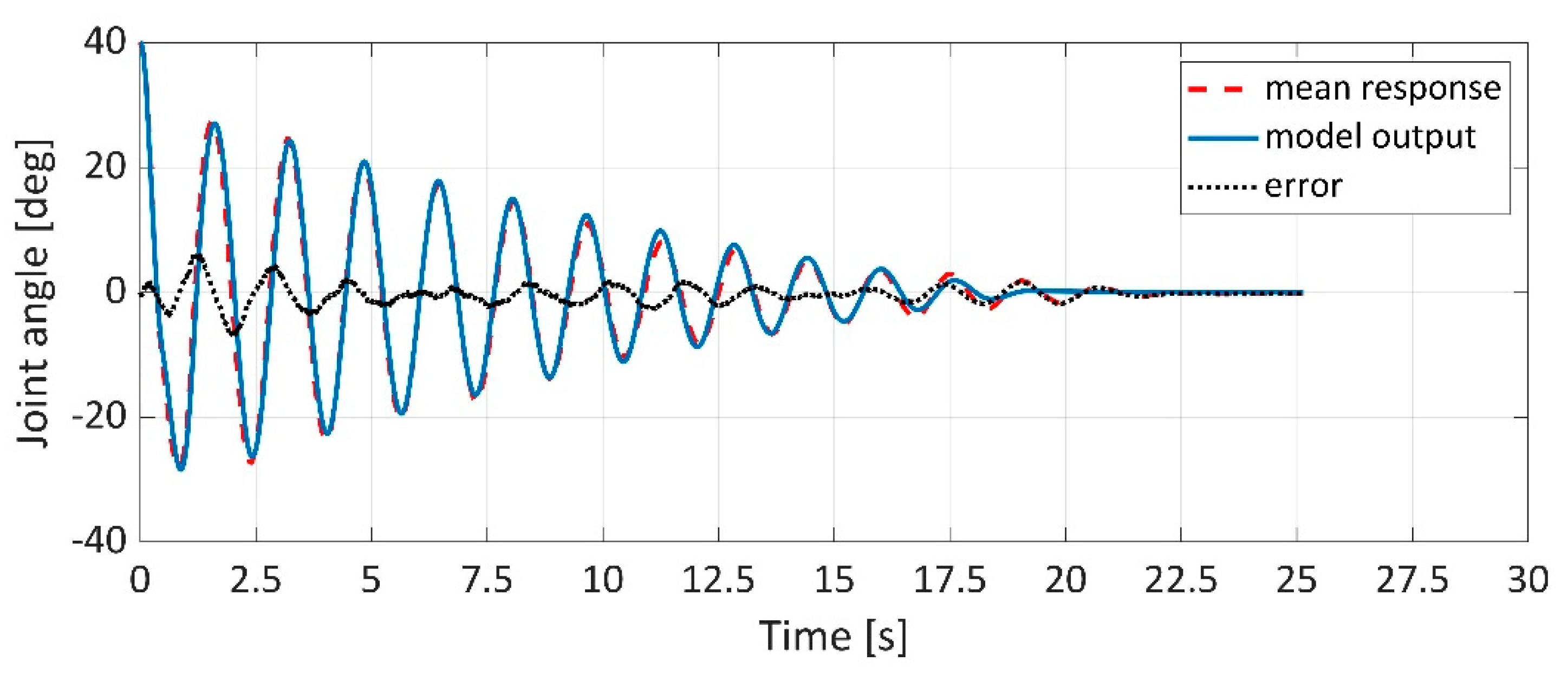

5.1. Results of Validation—Link 1

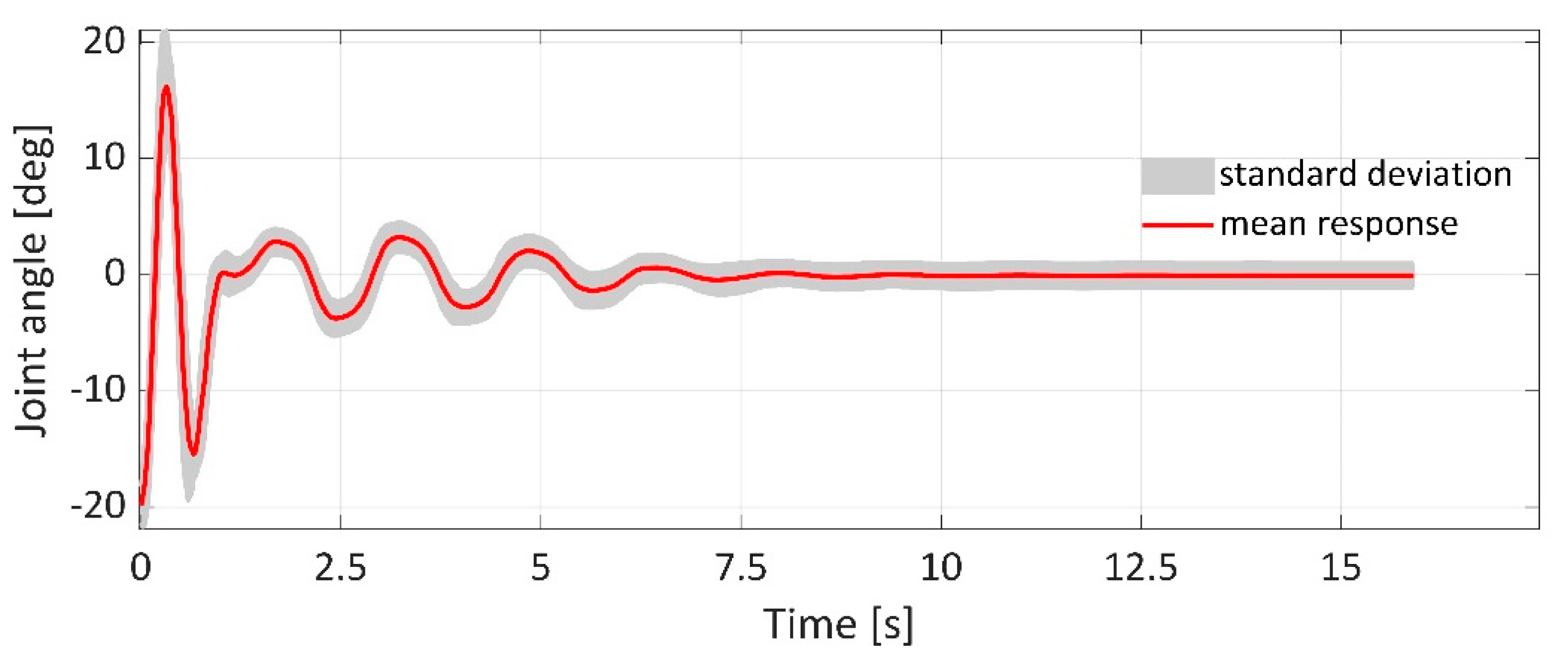

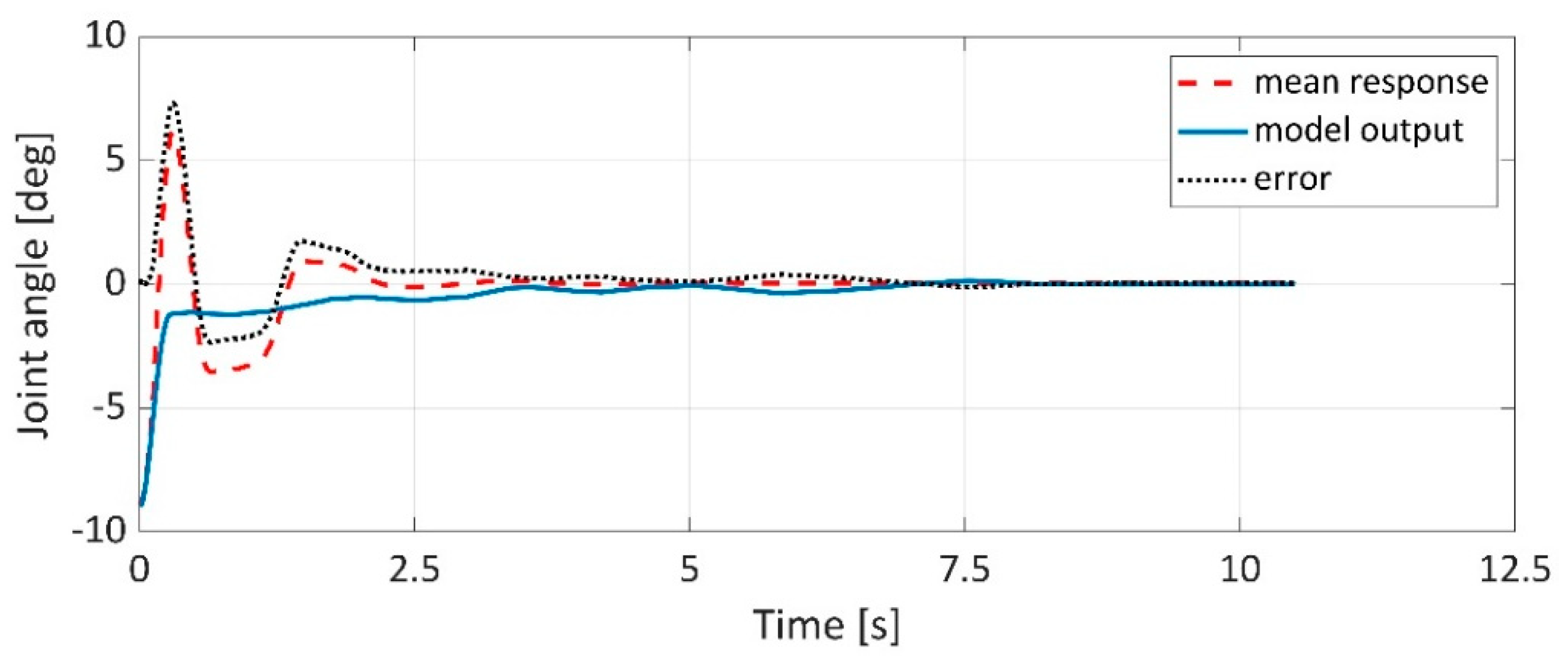

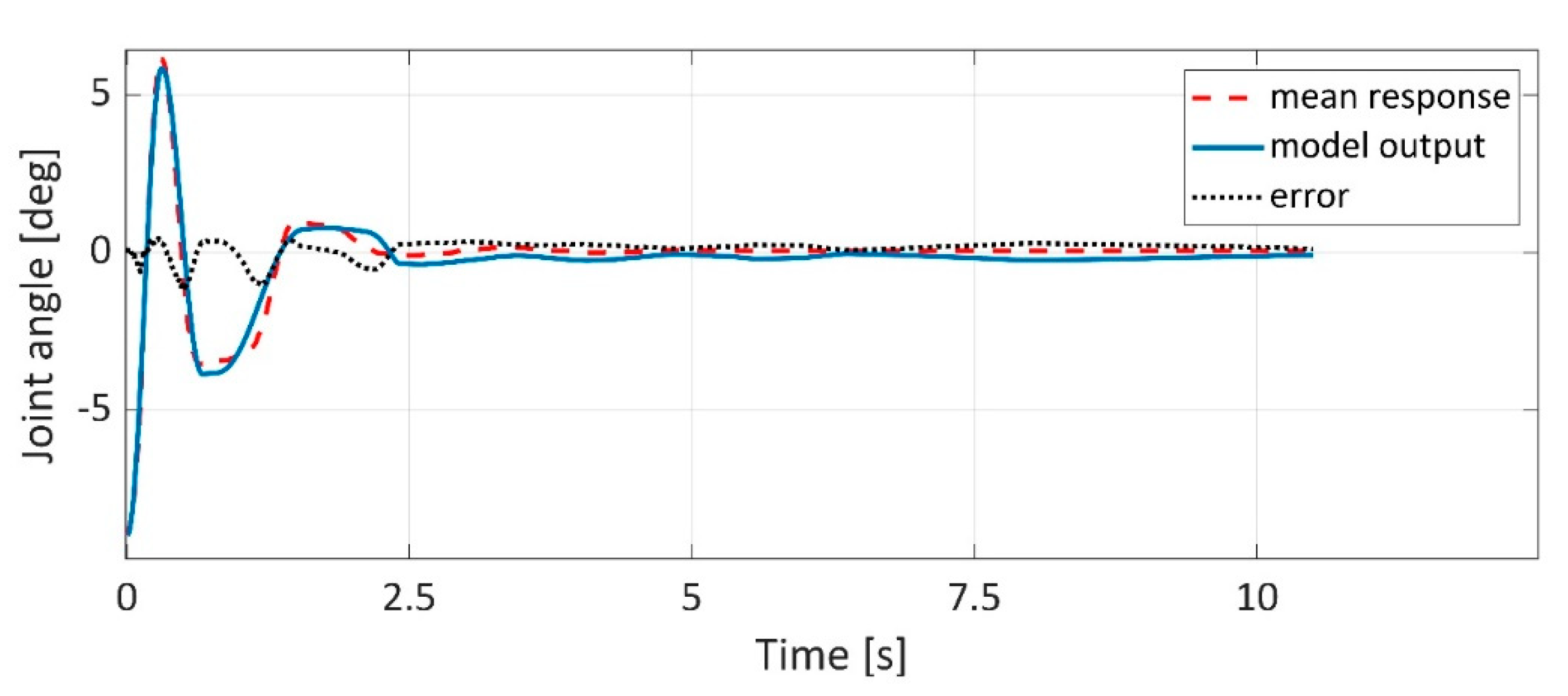

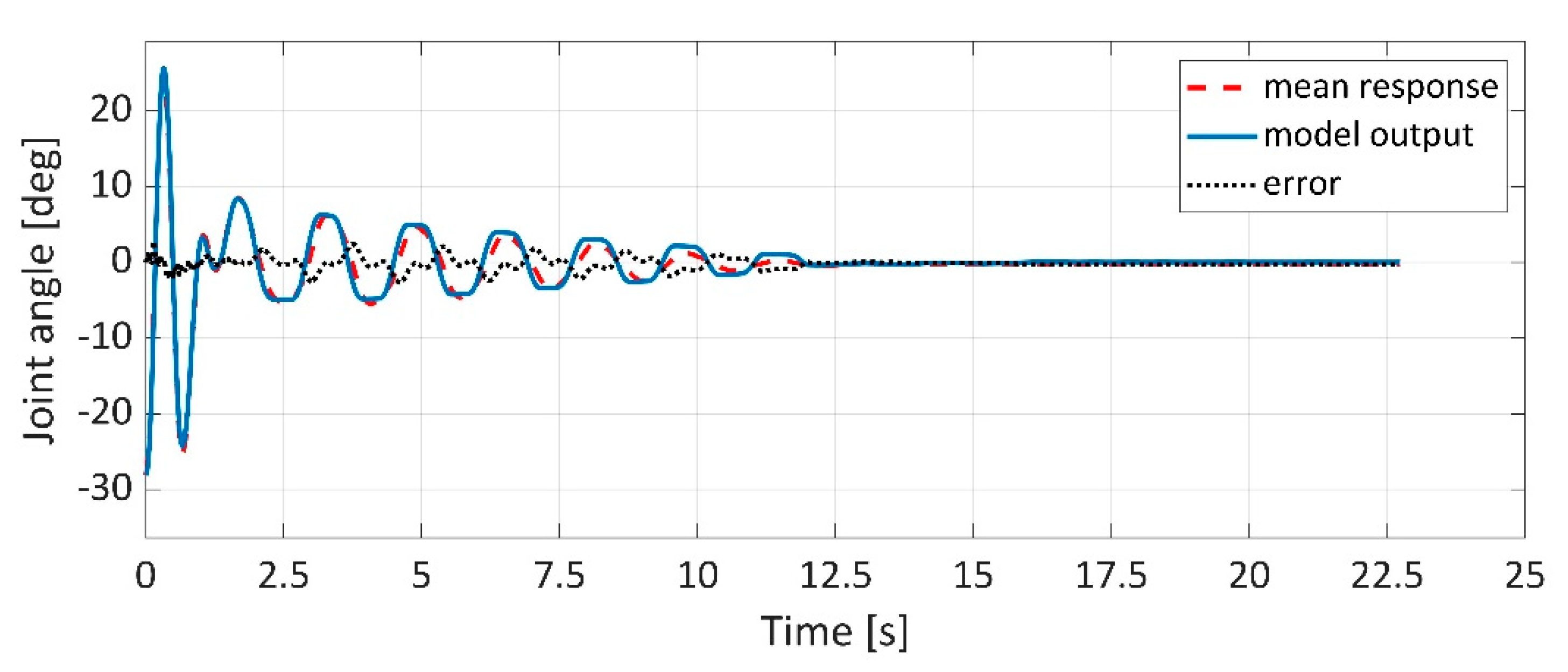

5.2. Results of Validation—Link 2

6. Parameter Estimation of 2-DOF Planar Arm

Trust Region Algorithm for Nonlinear Least Squares

| Algorithm 1 [34] |

Solve is Sk

Choose Δk+1 that satisfies

bk+1; k: = k+1; go to 2. Step. |

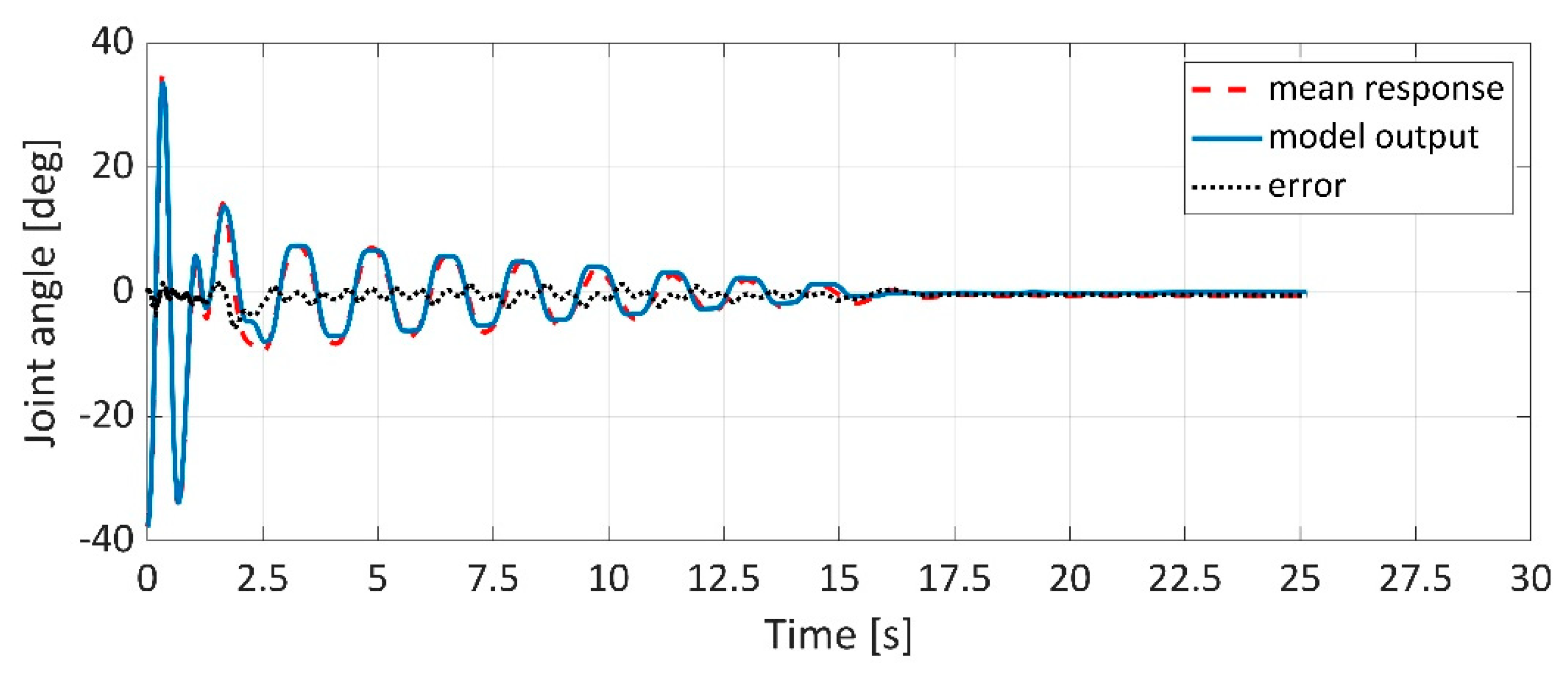

7. Parameter Estimation of Simulink Model

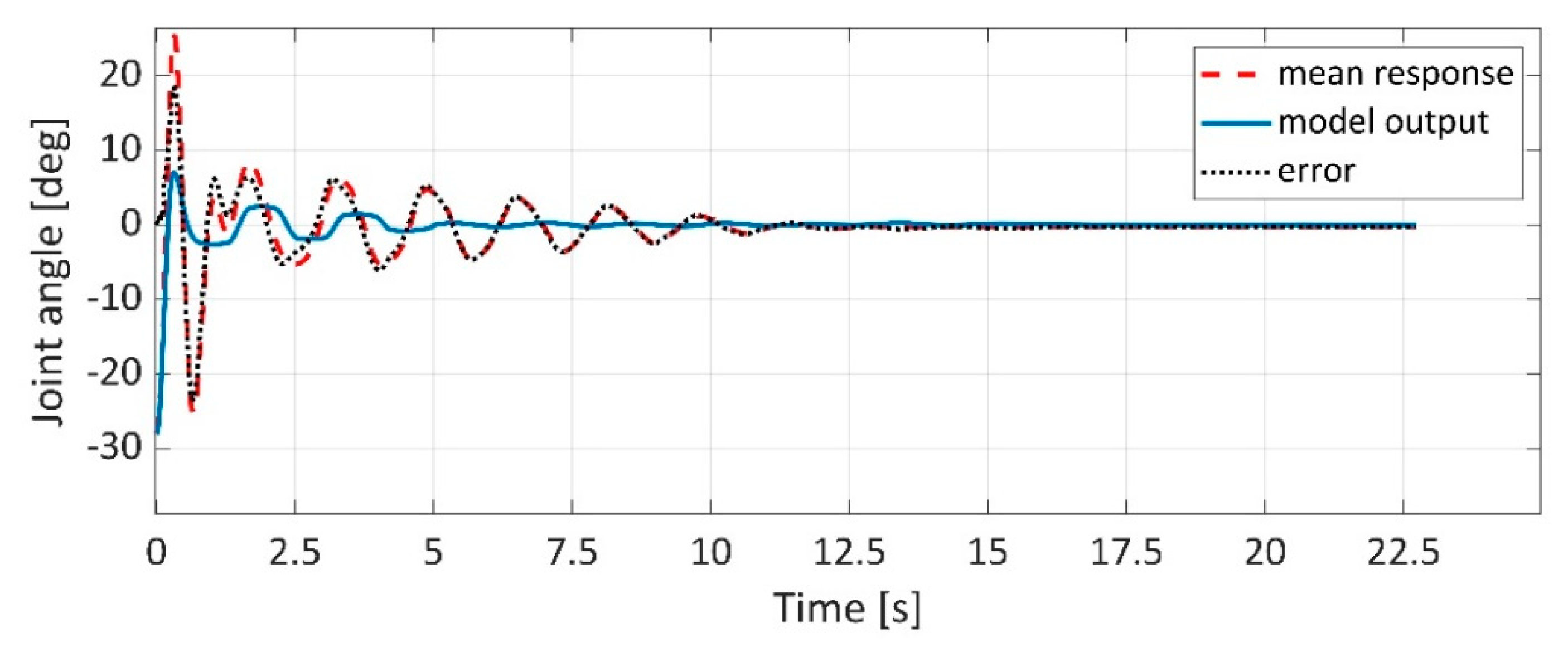

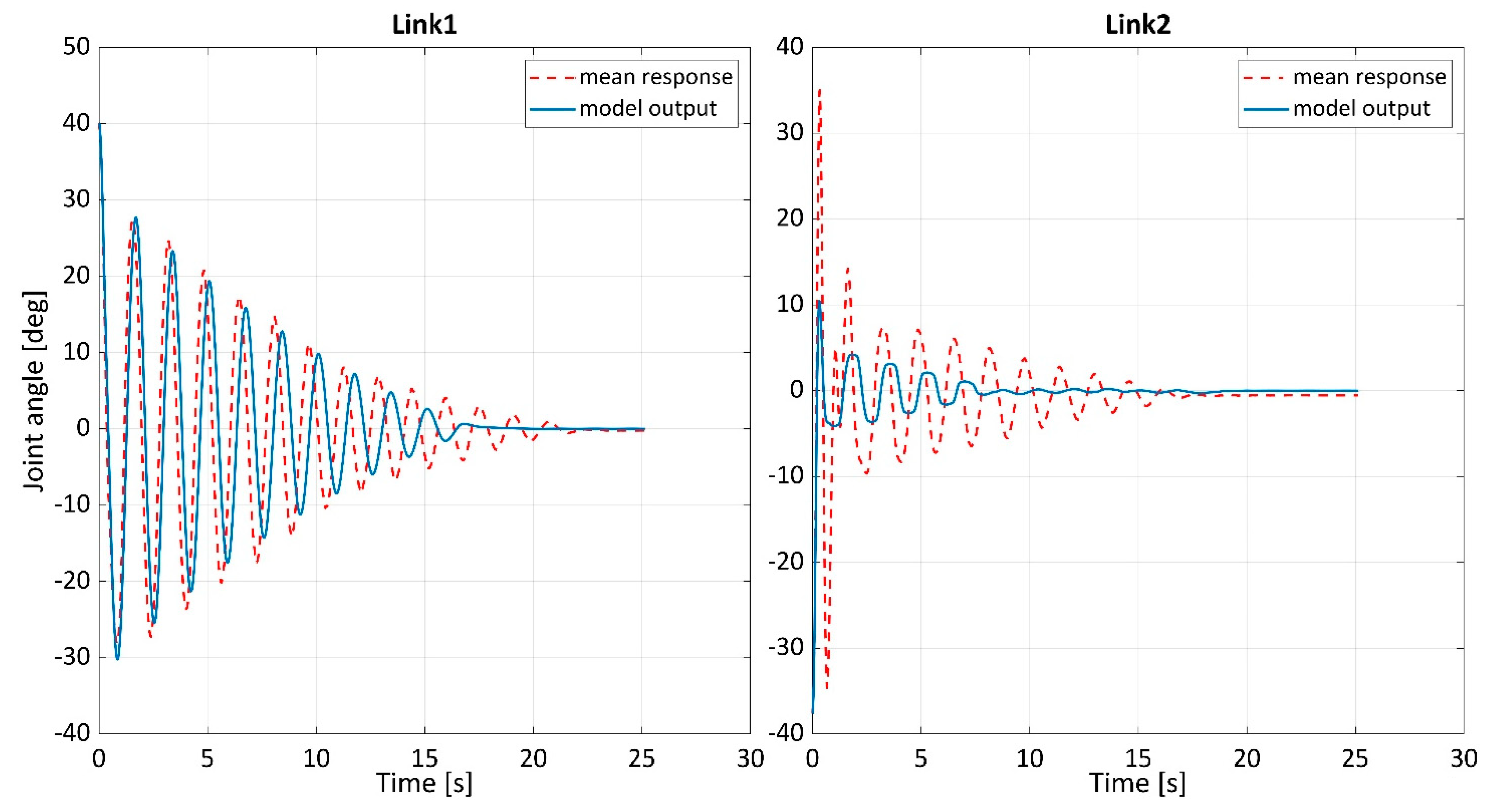

7.1. Results of Validation after Parameter Estimation—Link 1

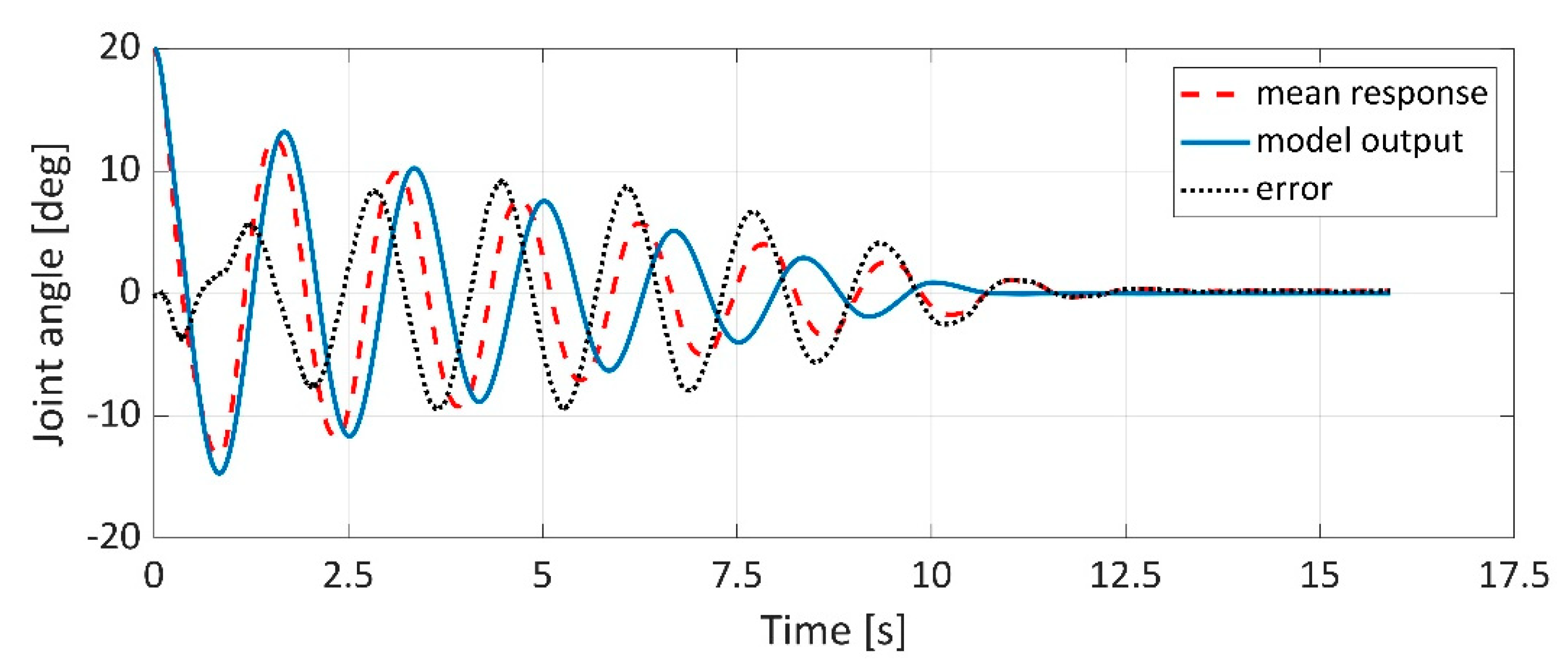

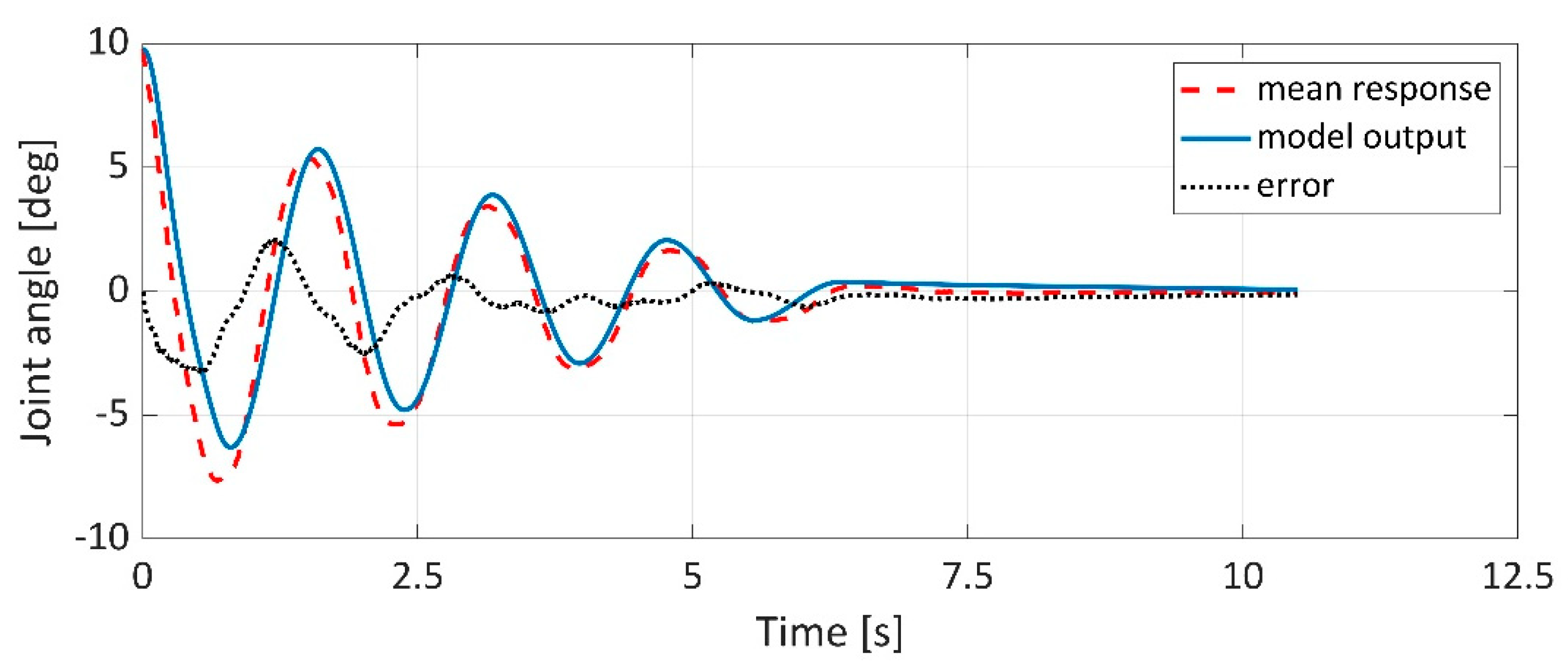

7.2. Results of Validation after Parameter Estimation—Link 2

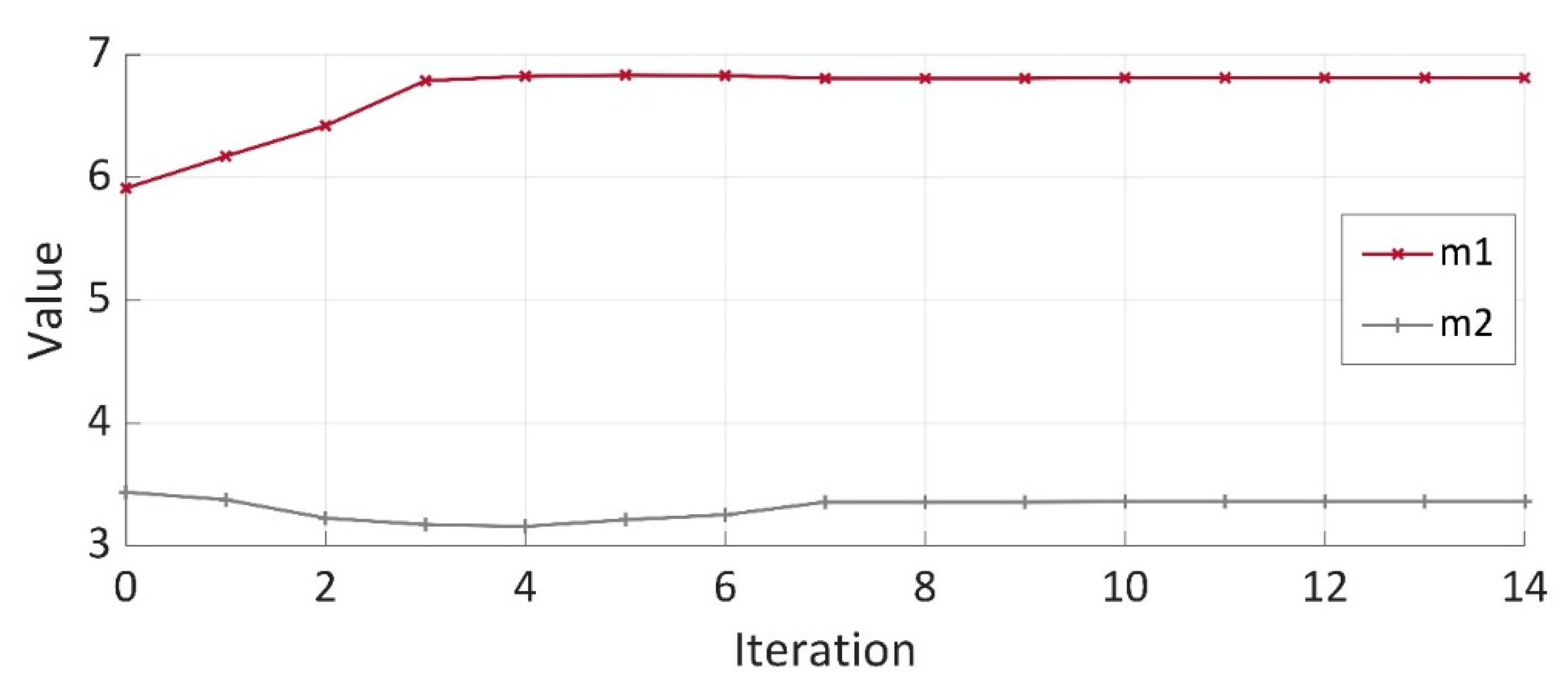

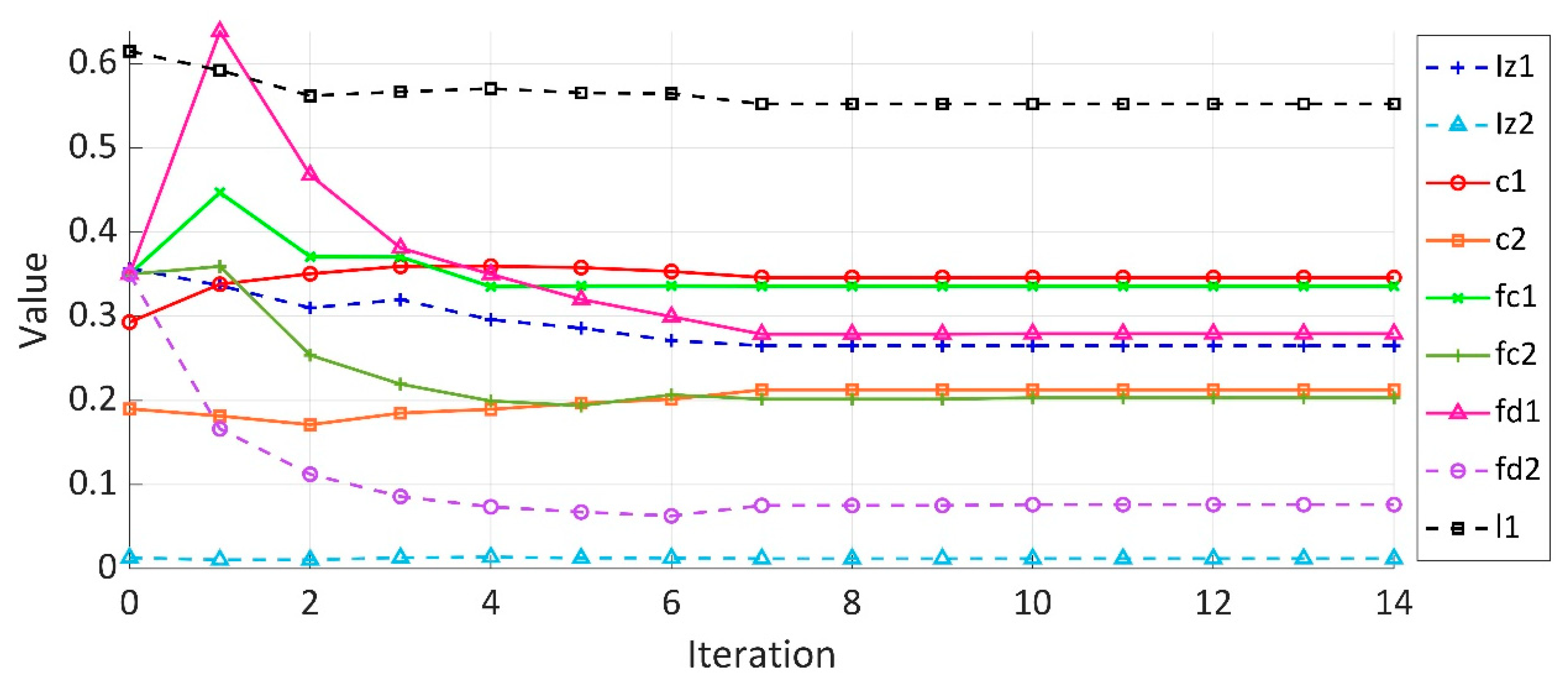

8. Discussion

- The weights m1 and m2 that were exported from the CAD software did not take into account the total weight of the arms even with connected muscles, chain, etc. Based on which the resulting weight could increase by estimation (this phenomenon is visible especially for axis 1—weight m1).

- Given the first hypothesis, it is possible to follow up. By changing the weight and shape of the arm, its length, the estimation of the parameter Distance to the center of mass for link 1 and 2—c1 and c2 (a visible increase of these parameters during estimation) is influenced.

- Changes in the estimation of the moment of inertia parameters Iz1 and Iz2 may also be closely related to the change in mass and the shift of the center of gravity.

- In terms of the use of a chain and a sprocket, it was assumed that the friction would be more pronounced (than if another gear had been used), so the value of the coefficients was set to 0.35. However, it is clear from the estimation that the experimentally determined initial values of the friction coefficients were oversized, as evidenced by the courses of the estimated parameters fc1, fc2 and fd1, fd2.

9. Conclusions

- Obtain a representative set of joint angle data by performing gravity tests.

- Creation of a simulation model in the Matlab and Simulink, which presented the dynamics of a real system—a planar robotic arm with two degrees of freedom (taking into account the friction component).

- The validation of a dynamic model built based on Lagrange formalism. However, at this stage, the expected results based on the MAE and NRMSE indicators were not achieved.

- The estimation of parameters—as the initial results of validation were insufficient, the research was extended to the estimation of model parameters using the Trust Region Algorithm, which helped to significantly improve the values of MAE and NRSME.

- Accurate identification of system parameter values, including drive parameters.

- The inclusion of drive dynamics, which would create a more complex dynamic system model.

- The addition of a part of the drives to the simulation scheme in Simulink, the use of other tools, such as SimMechanics.

Author Contributions

Funding

Conflicts of Interest

References

- Liu, C.; Tang, T.; Lin, H.-C.; Tomizuka, M. Designing Robot Behavior in Human-Robot Interactions, 1st ed.; CRC Press: Boca Raton, FL, USA, 2019; ISBN 978-0-367-17969-4. [Google Scholar]

- Gasparetto, A.; Ceccarelli, M. Mechanisms and Machine Science. In Mechanism Design for Robotics: Proceedings of the 4th IFToMM Symposium on Mechanism Design for Robotics; Springer: Cham, Switzerland, 2019; ISBN 978-3-030-00364-7. [Google Scholar]

- Kroff, J. Modern Robotics: Designs, Systems and Control; Willford Press: Forest Hills, NY, USA, 2019; ISBN 978-1-68285-676-5. [Google Scholar]

- Yang, C.; Ma, H.; Fu, M. Advanced Technologies in Modern Robotic Applications; Springer: Singapore, 2016; ISBN 978-981-10-0829-0. [Google Scholar]

- Miller, R.; Miller, M. Robots and Robotics: Principles, Systems, and Industrial Applications, 1st ed.; McGraw-Hill Education: New York, NY, USA, 2017; ISBN 978-1-259-85978-6. [Google Scholar]

- Ross, L.T.; Fardo, S.W.; Walach, M.F. Industrial Robotics Fundamentals: Theory and Applications, 3rd ed.; Goodheart-Willcox Publ: Tinley Park, IL, USA, 2017; ISBN 978-1-63126-941-7. [Google Scholar]

- Colombo, R.; Sanguineti, V. Rehabilitation Robotics. Elsevier Science Publishing Co., Inc.: Amsterdam, The Netherlands, 2018; ISBN 978-0-12-811995-2. [Google Scholar]

- Barrett, L. Recent Advances in Robotics; NY Research Press: Forest Hills, NY, USA, 2020; ISBN 978-1-63238-723-3. [Google Scholar]

- Kurfess, T.R. Robotics and Automation Handbook; CRC Press: Boca Raton, FL, USA, 2018; ISBN 978-1-4200-3973-3. [Google Scholar]

- Siciliano, B.; Khatib, O. Springer Handbook of Robotics; Springer: Heidelberg, Berlin, 2016; ISBN 978-3-319-32552-1. [Google Scholar]

- Barrett, L. Handbook of Robotics; Willford Press: Forest Hills, NY, USA, 2020; ISBN 978-1-68285-776-2. [Google Scholar]

- Hurmuzlu, Y.; Nwokah, O.D.I. The Mechanical Systems Design Handbook: Modeling, Measurement, and Control; CRC Press: Boca Raton, FL, USA, 2017; ISBN 978-1-4200-3674-9. [Google Scholar]

- Nezhad, M.N.; Korayem, A.H. Dynamic Modeling of Industrial Manipulator Hyundai HS165 in Order to Determine the Dynamic Load-Carrying Capacity for a Specified Trajectory. In Proceedings of the 7th International Conference on Robotics and Mechatronics (ICRoM), Teheran, Iran, 20–21 November 2019; pp. 538–543. [Google Scholar]

- Varela-Aldás, J.; Andaluz, V.H.; Chicaiza, F.A. Modelling and Control of a Mobile Manipulator for Trajectory Tracking. In Proceedings of the International Conference on Information Systems and Computer Science (INCISCOS), Quito, Ecuador, 13–15 November 2018; pp. 69–74. [Google Scholar]

- Leborne, F.; Creuze, V.; Chemori, A.; Brignone, L. Dynamic Modeling and Identification of an Heterogeneously Actuated Underwater Manipulator Arm. In Proceedings of the IEEE International Conference on Robotics and Automation (ICRA), Brisbane, Australia, 21–25 May 2018. [Google Scholar]

- Hošovský, A.; Piteľ, J.; Židek, K.; Tóthová, M.; Sárosi, J.; Cveticanin, L. Dynamic Characterization and Simulation of Two-Link Soft Robot Arm with Pneumatic Muscles. Mech. Mach. Theory 2016, 103, 98–116. [Google Scholar] [CrossRef]

- Spong, M.W.; Hutchinson, S.; Vidyasagar, M. Robot Modeling and Control; John Wiley & Sons: Hoboken, NJ, USA, 2020; ISBN 978-1-119-52399-4. [Google Scholar]

- Al-Qahtani, H.M.; Mohammed, A.A.; Sunar, M. Dynamics and Control of a Robotic Arm Having Four Links. Arab. J. Sci. Eng. 2017, 42, 1841–1852. [Google Scholar] [CrossRef]

- Yuguang, Z.; Fan, Y. Dynamic Modeling and Adaptive Fuzzy Sliding Mode Control for Multi-Link Underwater Manipulators. Ocean Eng. 2019, 187, 106202. [Google Scholar] [CrossRef]

- Naing, S.Y.; Rain, T. Analysis of Position and Angular Velocity of Four-Legged Robot (Mini-Bot) from Dynamic Model Using Euler-Lagrange Method. In Proceedings of the International Conference on Industrial Engineering, Applications and Manufacturing (ICIEAM), Sochi, Russia, 25–29 March 2019; pp. 1–4. [Google Scholar]

- Korayem, M.H.; Dehkordi, S.F. Dynamic Modeling of Flexible Cooperative Mobile Manipulator with Revolute-Prismatic Joints for the Purpose of Moving Common Object with Closed Kinematic Chain Using the Recursive Gibbs–Appell Formulation. Mech. Mach. Theory 2019, 137, 254–279. [Google Scholar] [CrossRef]

- Hasnaa, E.H.; Mohammed, B. Robust Control of Two Link Rigid Manipulator with Nonlinear Dynamic Model. In Proceedings of the International Conference on Electrical and Information Technologies (ICEIT), Rabat, Morocco, 15–18 November 2017; pp. 1–6. [Google Scholar]

- Zhang, L.; Wang, J.; Chen, J.; Chen, K.; Lin, B.; Xu, F. Dynamic Modeling for a 6-DOF Robot Manipulator Based on a Centrosymmetric Static Friction Model and Whale Genetic Optimization Algorithm. Adv. Eng. Softw. 2019, 135, 102684. [Google Scholar] [CrossRef]

- Lloyd, S.; Irani, R.; Ahmadi, M. A Numeric Derivation for Fast Regressive Modeling of Manipulator Dynamics. Mech. Mach. Theory 2021, 156, 104149. [Google Scholar] [CrossRef]

- Izmailov, A.; Kurennoy, A.; Stetsyuk, P. Levenberg–Marquardt Method for Unconstrained Optimization. Tambov Univ. Rep. Ser. Nat. Tech. Sci. 2019, 60–74. [Google Scholar] [CrossRef]

- Quan, N.; Nguyen-Hoai, S.; Chuong-Thiet, T.; Lam-Phat, T. Optimization of the Longitudinal Cooling Fin by Levenberg–Marquardt Method. In ACOME 2017, Proceedings of the International Conference on Advances in Computational Mechanics 2017, Phu Quoc, Vietnam, 2–4 August 2017; Lecture Notes in Mechanical Engineering; Springer: Singapore, 2018; pp. 217–227. ISBN 978-981-10-7148-5. [Google Scholar]

- Rezapour, M.; Asaki, T. Adaptive Trust-Region Algorithms for Unconstrained Optimization. Optim. Methods Softw. 2019, 1–23. [Google Scholar] [CrossRef]

- Sharifzadeh, M.; Akbari, A.; Timpone, F.; Daryani, R. Vehicle Tyre/Road Interaction Modeling and Identification of Its Parameters Using Real-Time Trust-Region Methods. IFAC Pap. 2016, 49, 111–116. [Google Scholar] [CrossRef]

- Kelly, R.; Davila, V.S.; Loría, A. Introduction to Adaptive Robot Control. In Advanced Textbooks in Control and Signal Processing; Springer: London, UK, 2005; ISBN 978-1-85233-999-9. [Google Scholar]

- Papageorgiou, D.; Blanke, M.; Niemann, H.H.; Richter, J.H. Online Friction Parameter Estimation for Machine Tools. Adv. Control Appl. 2020, 2, e28. [Google Scholar] [CrossRef]

- Tulsyan, A.; Barton, P.I. PERKS: Software for Parameter Estimation in Reaction Kinetic Systems. In Computer Aided Chemical Engineering; 26 European Symposium on Computer Aided Process Engineering; Kravanja, Z., Bogataj, M., Eds.; Elsevier: Amsterdam, The Netherlands, 2016; Volume 38, pp. 25–30. [Google Scholar]

- Byrd, R.H.; Schnabel, R.B.; Shultz, G.A. A Trust Region Algorithm for Nonlinearly Constrained Optimization. SIAM J. Numer. Anal. 1987, 24, 1152–1170. [Google Scholar] [CrossRef]

- Santos, S.A. Trust-Region-Based Methods for Nonlinear Programming: Recent Advances and Perspectives. Pesqui. Oper. 2014, 34, 447–462. [Google Scholar] [CrossRef]

- Yuan, Y. Recent Advances in Trust Region Algorithms. Math. Program. 2015, 151. [Google Scholar] [CrossRef]

- Zhu, B.; Zhang, X.; Zhang, H.; Liang, J.; Zang, H.; Li, H.; Wang, R. Design of Compliant Mechanisms Using Continuum Topology Optimization: A Review. Mech. Mach. Theory 2020, 143, 103622. [Google Scholar] [CrossRef]

- Kanzow, C.; Yamashita, N. Levenberg-Marquardt Methods for Constrained; Universität Würzburg: Würzburg, Germany, 2002. [Google Scholar]

| Component | Parameter Name | Value | Component | Parameter Name | Value |

|---|---|---|---|---|---|

| Fluid muscle FESTO MAS-20-250N-AA-MC-K | Diameter | 0.02 m | Incremental encoder KUBLER 3610 | Power supply Max. resolution | 5–30 V DC 2500 pulse/rev. |

| Length | 0.25 m | ||||

| Max. muscle force | 1200 N | ||||

| Max. working pressure | 6 bar | ||||

| Electronic pressure regulator MATRIX EPR50 | Input signal | 4–20 mA | Compressor FIAC LEONARDO | Max. pressure Flow Power | 8 bar 105 L/min 750 W |

| Input pressure | 1–8 bar | ||||

| Max. flow | 60 L/min | ||||

| Power supply | 24 V DC | ||||

| Output pressure | 0–7 bar | ||||

| Response | 60–100 ms | ||||

| Reaction time | less than 5 ms |

| Notation | Description | Value and Unit |

|---|---|---|

| m1 | Mass—link 1 | 5.914 kg |

| m2 | Mass—link 2 | 3.437 kg |

| l1 | Length—link 1 | 0.615 m |

| c1 | Distance to the center of mass—link 1 | 0.293 m |

| c2 | Distance to the center of mass—link 2 | 0.19 m |

| I1 | Moment of inertia—link 1 | 0.357 kg⋅m2 |

| I2 | Moment of inertia—link 2 | 0.013 kg⋅m2 |

| fc1 | Viscous friction coefficient—link 1 | 0.35 N⋅m⋅s⋅rad−1 |

| fc2 | Viscous friction coefficient—link 2 | 0.35 N⋅m⋅s⋅rad−1 |

| fd1 | Coulomb friction magnitude—link 1 | 0.35 N⋅m |

| fd2 | Coulomb friction magnitude—link 2 | 0.35 N⋅m |

| Angle of Rotation | MAE | NRMSE |

|---|---|---|

| 10° | 1.0932 | 35.47% |

| 20° | 2.9180 | 20.29% |

| 30° | 3.2550 | 34.37% |

| 40° | 6.1717 | 16.69% |

| Angle of Rotation | MAE | NRMSE |

|---|---|---|

| 10° | 0.5655 | 14.94% |

| 20° | 1.1078 | 16.36% |

| 30° | 1.7524 | 18.14% |

| 40° | 2.8270 | 16.88% |

| Angle of Rotation | K | Notation | Parameter Estimation Bounds |

|---|---|---|---|

| 10° | 2100 | m1 | 5–7 kg |

| 20° | 3182 | m2 | 3–5 kg |

| 30° | 4546 | l1 | 0.5–0.7 m |

| 40° | 5028 | c1 | 0.2–0.4 m |

| c2 | 0.13–0.25 m | ||

| I1 | 0.25–0.45 kg⋅m2 | ||

| I2 | 0.009–0.017 kg⋅m2 | ||

| fc1 | 0.00001–20 N⋅m⋅s⋅rad−1 | ||

| fc2 | 0.00001–20 N⋅m⋅s⋅rad−1 | ||

| fd1 | 0.00001–20 N⋅m | ||

| fd2 | 0.00001–20 N⋅m |

| Notation | Value and Unit | Notation | Value and Unit |

|---|---|---|---|

| m1 | 6.813 kg | I1 | 0.264 kg⋅m2 |

| m2 | 3.361 kg | I2 | 0.012 kg⋅m2 |

| l1 | 0.552 m | fc1 | 0.335 N⋅m⋅s⋅rad−1 |

| c1 | 0.346 m | fc2 | 0.279 N⋅m⋅s⋅rad−1 |

| c2 | 0.212 m | fd1 | 0.203 N⋅m |

| fd2 | 0.076 N⋅m |

| Angle of Rotation | MAE | NRMSE |

|---|---|---|

| 10° | 0.6076 | 63.96% |

| 20° | 0.9420 | 75.27% |

| 30° | 1.0382 | 81.61% |

| 40° | 1.1045 | 84.62% |

| Angle of Rotation | MAE | NRMSE |

|---|---|---|

| 10° | 0.2407 | 79.64% |

| 20° | 0.3401 | 82.82% |

| 30° | 0.5159 | 81.98% |

| 40° | 0.7207 | 82.69% |

| Before | After | |||

|---|---|---|---|---|

| Angle of Rotation | MAE | NRMSE | MAE | NRMSE |

| 10° | 1.0932 | 35.47% | 0.6076 | 63.96% |

| 20° | 2.9180 | 20.29% | 0.9420 | 75.27% |

| 30° | 3.2550 | 34.37% | 1.0382 | 81.61% |

| 40° | 6.1717 | 16.69% | 1.1045 | 84.62% |

| Before | After | |||

|---|---|---|---|---|

| Angle of Rotation | MAE | NRMSE | MAE | NRMSE |

| 10° | 0.5655 | 14.94% | 0.2407 | 79.64% |

| 20° | 1.1078 | 16.36% | 0.3401 | 82.82% |

| 30° | 1.7524 | 18.14% | 0.5159 | 81.98% |

| 40° | 2.8270 | 16.88% | 0.7207 | 82.69% |

| Notation | Value and Unit before Estimation | Value and Unit after Estimation |

|---|---|---|

| m1 | 5.914 kg | 6.813 kg |

| m2 | 3.437 kg | 3.361 kg |

| l1 | 0.615 m | 0.552 m |

| c1 | 0.293 m | 0.346 m |

| c2 | 0.19 m | 0.212 m |

| I1 | 0.357 kg⋅m2 | 0.264 kg⋅m2 |

| I2 | 0.013 kg⋅m2 | 0.012 kg⋅m2 |

| fc1 | 0.35 N⋅m⋅s⋅rad−1 | 0.335 N⋅m⋅s⋅rad−1 |

| fc2 | 0.35 N⋅m⋅s⋅rad−1 | 0.279 N⋅m⋅s⋅rad−1 |

| fd1 | 0.35 N⋅m | 0.203 N⋅m |

| fd2 | 0.35 N⋅m | 0.076 N⋅m |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Trojanová, M.; Čakurda, T.; Hošovský, A.; Krenický, T. Estimation of Grey-Box Dynamic Model of 2-DOF Pneumatic Actuator Robotic Arm Using Gravity Tests. Appl. Sci. 2021, 11, 4490. https://doi.org/10.3390/app11104490

Trojanová M, Čakurda T, Hošovský A, Krenický T. Estimation of Grey-Box Dynamic Model of 2-DOF Pneumatic Actuator Robotic Arm Using Gravity Tests. Applied Sciences. 2021; 11(10):4490. https://doi.org/10.3390/app11104490

Chicago/Turabian StyleTrojanová, Monika, Tomáš Čakurda, Alexander Hošovský, and Tibor Krenický. 2021. "Estimation of Grey-Box Dynamic Model of 2-DOF Pneumatic Actuator Robotic Arm Using Gravity Tests" Applied Sciences 11, no. 10: 4490. https://doi.org/10.3390/app11104490

APA StyleTrojanová, M., Čakurda, T., Hošovský, A., & Krenický, T. (2021). Estimation of Grey-Box Dynamic Model of 2-DOF Pneumatic Actuator Robotic Arm Using Gravity Tests. Applied Sciences, 11(10), 4490. https://doi.org/10.3390/app11104490