Abstract

The purpose of the study was to evaluate the adhesion between dental core resin and epoxy resin-based fiber post after treatment with non-thermal atmospheric pressure plasma (NTAPP) and compare with conventional methods of epoxy resin-based fiber post treatments. Contact angle was measured on the surface of epoxy resin before and after NTAPP treatment and X-ray photoelectron spectroscopy was used to analyze the surface chemistry. Finally, two shear bond strength tests were carried out; shear bond strength between core resin and epoxy resin for comparison between NTAPP treated and untreated sample, and push-out shear bond strength between core resin and NTAPP treated commercially available epoxy resin-based fiber post for comparison between NTAPP treated samples with conventionally treated samples. Contact angle on the surface of epoxy resin generally decreased with increasing NTAPP treatment time with presence of surface chemical changes. Also, there was significantly higher shear bond strength and push-out shear bond strength between epoxy resin and core resin for NTAPP treated epoxy resin, even to the conventionally treated epoxy resin-based fiber post with hydrofluoric acid or silane. In conclusion, new technology of NTAPP has potential for application on the epoxy resin-based fiber post to improve endodontic restoration success rate.

1. Introduction

Fiber-reinforced composite posts, or fiber post, are widely used to restore endodontically-treated teeth that have insufficient coronal tooth structure to retain a core for the definitive restoration in dentistry [1]. Fiber posts are made of carbon, quartz, or glass fibers embedded in a matrix of either epoxy resin or methacrylate resin [2]. Among them, epoxy resin is often preferred over methacrylate resin as a matrix due to its high degree of conversion and highly cross-linked structures [3]. However, fiber post retention depends on the strength of the chemical and micromechanical interaction between fiber post material and core resin [4] and the absence of chemical interaction between the methacrylate-based core resin composite and epoxy resin matrix of fiber posts represents the primary cause of weakness in post-to-core resin bonds [5]. Hence, numerous studies have attempted to improve the bond strength between epoxy resin-based fiber posts and core resins [6,7,8,9].

A recently highlighted method of improving the bond strength between epoxy resin-based fiber posts and core resins is using plasma technology. Yavirach et al. evaluated the tensile shear bond strength between fiber post and core resin after plasma treatment using O2, Ar, N2, and He/N2 gases under a vacuum system [10]. Costa Dantas et al. studied the push-out shear bond between epoxy resin-based fiber post and core resin after plasma treatment using Ar and ethylenediamine sources under a vacuum system and compared with conventional surface treatment [11]. From these studies, plasma treatment was shown to be an effective means of improving the bond strength between epoxy resin-based fiber posts and core resins. However, all of previous plasma treatment conditions required vacuum chamber and high temperature, which often result in damage of highly sensitive fiber posts biomaterials and not practicable as the surface treatment is only able to be carried out in factories due to the size and requirements of vacuum [12]. Such factory level of chemical surface treatment would result in so called ‘aging process’ of the device where advantageous chemical functionality on the surface of the device would be lost during the transport and the shelf lost, and therefore cannot be utilized by the time when the device has reached to the patient [13].

Non-thermal atmospheric pressure plasma (NTAPP) is a technology that is used in many aspects of industrial applications such as gas cleaning, ozone generation, surface modification, etching, thin film deposition, and sterilization [14,15,16,17,18]. Compared to previously mentioned methods of plasma technology, it has major advantages of the processes using relatively low temperature of gas while being operated at atmospheric pressure. Hence, it would be much more simple, cheap, and environmentally safe to be used, while having the advantage of not requiring complex vacuum equipment, allowing the surface chemical treatment to take place just before the clinical application even at the chairside in dental clinics [19]. Also, in recent years, applications of NTAPP on highly sensitive dental materials have shown to be effective and non-damaging [12,20]. Hence the device would avoid the worry of the aging process of the surface characteristics as it would not damage the surface while surface treatment would occur just before the clinical application [12].

The objective of this study was therefore to evaluate the adhesion between core resin and epoxy resin-based fiber post after the application of NTAPP treatment. Also, the change in the adhesion between the core resin and epoxy resin-based fiber post was linked to the change in wettability and surface chemistry that may have been caused by NTAPP. The main null hypothesis of this study was that there would be no significant difference in shear bond strength and push-out shear bond strength with core resin between non-thermal atmospheric pressure plasma jet (NTAPPJ) treated epoxy resin-based fiber post and conventionally treated epoxy resin-based fiber post. Also, another null hypothesis of this study was that there would be no difference in surface energy and surface chemistry between NTAPPJ treated epoxy resin-based fiber post and epoxy resin-based fiber post not treated with NTAPPJ.

2. Materials and Methods

2.1. Test Materials and Non-Thermal Atmospheric Pressure Plasma Treatment

The epoxy resin used in this study was prepared by mixing diglycidyl ether bisphenol A (DGEBA) monomer (Allied High Tech Products, Inc., Compton, CA, USA) with hardener (Allied High Tech Products, Inc., Compton, CA, USA) in the weight ratio of 10 to 1. The mixture was poured into the mold (30 mm in diameter and 15 mm in height) and left for 24 h. This epoxy resin surface was polished sequentially by #300, #600, and #1200 SiC polish paper and washed by immersion in distilled water for 10 min before being tested for contact angle, surface energy, X-ray photoelectron spectroscopy (XPS), and shear bond strength. Commercially available epoxy resin-based fiber post (DT Light post, Bisco Inc., Schaumburg, IL, USA) and core resin (Luxacore, DMG, Hamburg, Germany) were used for push-out shear bond strength experiment.

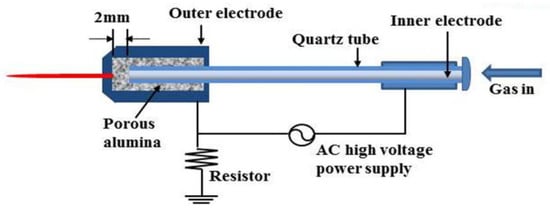

The NTAPP treatment was carried out in this experiment using a system shown schematically in Figure 1, which have been used in previous studies [21,22,23,24] and allowed the treatment in atmospheric pressure at low temperature. Briefly, the nitrogen gas was flown into the jet type of NTAPP at rate of 5 L/min while the voltage and current values of 15 kV and 13 mA, respectively, were applied. The distance of the test specimen from the exit of the plasma jet was maintained to 5 mm throughout the experiment.

Figure 1.

The schematic drawings of the non-thermal atmospheric pressure plasma jet system. Gas supplied by nitrogen gas while electrical power by AC high voltage was supplied to inner and outer electrode separated by quartz tube.

2.2. Contact Angle and Surface Energy

Surface energy changes of the treated epoxy resin surfaces were characterized by using sessile droplet contact angle measurement (Phoenix 300, Gyeonggi-do, Korea) with three different test liquids: distilled water, diiodomethane, and a resin monomer mixture (bisphenol A glycidyl methacrylate:urethane dimethacrylate:triethylene glycol dimethacrylate = 30:40:30 wt%).

The contact angles were measured before and after the NTAPP treatment, where treatment was carried out for 0.5, 1, 3, 5, 7, and 9 min. Additionally, the sample that was treated for 1 min of NTAPP was left for 1, 3, 5, and 7 days in the desiccator (26 °C and 20% relative humidity), whose contact angles were measured on this specimen on each day.

From the contact angle results for each of test liquid, the surface energy was determined by the Owens–Wendt method [25].

2.3. Surface Chemical Analysis Using X-ray Photoelectron Spectroscopy

The analysis of the chemical composition changes on the surface of the NTAPP treated and untreated epoxy resin surface was carried out by X-ray Photoelectron Spectroscopy (XPS, K-alpha, Thermo VG Scientific, East Grinstead, UK) that was equipped with a monochromatic AlKα source. The specific peaks of C1s, N1s, and O1s were analyzed to evaluate the change of surface chemistry.

2.4. Shear Bond Strength between Epoxy Resin and Core Resin

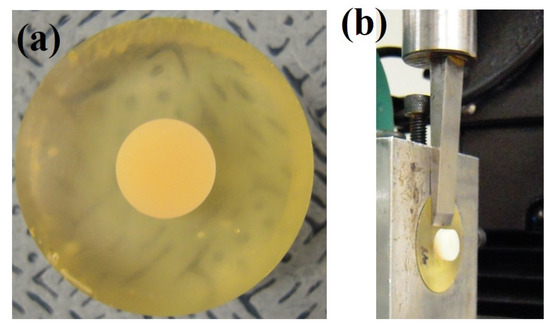

The prepared epoxy resin as mentioned above (30 mm in diameter and 15 mm in height) was treated by NTAPP for 1 min on the surface where it would be bonded with core resin (top surface with 10 mm in diameter). Then the mold with inner diameter of 10 mm and height of 5 mm was placed and fixed on the NTAPP-treated surface of epoxy resin by utility wax. Core resin was then poured into the mold where excess material was removed from the top and polymerized for 40 s using a light emitting diode curing unit (Elipar S10, 3M ESPE, Maplewood, MN, USA). The prepared sample has been illustrated in Figure 2a. The specimens were stored at 37 °C for 24 h and tested for shear bond strength by a universal testing machine (UTM) (5942, Instron, Norwood, MA, USA). The cross-head speed was set to 1 mm/min to push the lateral surface of core resin. The test was also carried out for the NTAPP untreated epoxy resin in same way as the control. The bond strength was expressed in megapascals (MPa) by dividing the load value in Newtons (N) with the surface area (mm2) of the bonded interface (Figure 2b).

Figure 2.

The photographs showing; (a) shear bond strength test specimen; (b) actual test carried out.

The change in shear bond strength according to the times passed from the NTAPP treatment on the epoxy resin surface was also evaluated to consider aging process. The epoxy resin with same size as above were treated for 1 min of NTAPP and left for 1, 3, 5, or 7 days in the desiccator (26 °C and 20% relative humidity). The shear bond strength with core resin was then measured with the same method described above.

2.5. Push-Out Shear Bond Strength between Commercially Available Epoxy Resin-Based Fiber Post and Core Resin

Commercially available epoxy resin-based fiber post (DT Light post, Bisco Inc., Schaumburg, IL, USA) was purchased, which had diameter of 2.2 mm on top that was tapered to result in a diameter of 1.2 mm on bottom. Original height was 20 mm but it was cut to 3 mm on the point that tapering was not started and therefore diameter was constant at 2.2 mm. Samples were then divided into in five different groups as shown in Table 1.

Table 1.

Summary of experimental groups for shear bond strength test.

Each surface-treated epoxy resin-based fiber post was placed in an upright position with support from specially designed metal molds with 12 mm in diameter that had a hole of 2.2 mm in diameter (same as the diameter of commercially available fiber post used in this study) and 0.5 mm in height. On top of this metal mold, another mold with 12 mm diameter that had a hole of 10 mm in diameter and 2 mm in height was placed. In the hole of the second mold, core resin was filled in so that core resin surrounded the fiber post. The core resin was then polymerized for 40 s with using a light emitting diode curing unit (Elipar S10, 3M ESPE, Maplewood, MN, USA).

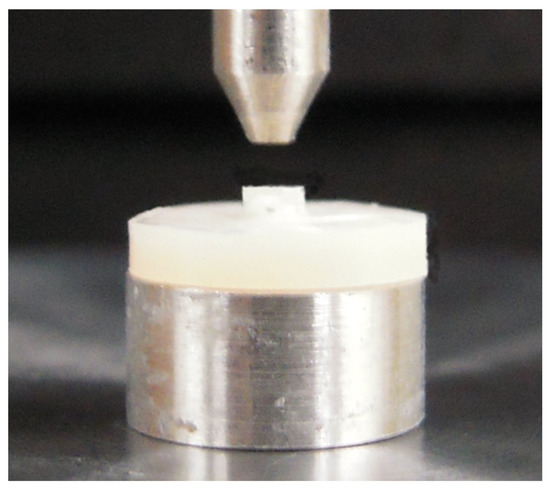

The prepared specimen was then placed into a mold for push-out shear strength, which had a height of 5 mm and diameter of 10 mm, with a hole of 2.2 mm. The push-out shear bond strength between each of the surface-treated epoxy resin-based fiber posts and core resin was then measured using a universal testing machine (5942, Instron, Norwood, MA, USA) at a cross-head speed of 1 mm/min (Figure 3).

Figure 3.

The photographs showing push-out shear bond strength test specimen holder and actual photograph of the test.

2.6. Statistical Analysis

Each of the experiments were carried out on 10 samples (n = 10), where the numbers of samples were based on the previously carried out similar studies that considered application of NTAPP on different dental biomaterials [12,20]. The data were analyzed by one-way ANOVA with Tukey test as post-hoc analysis using statistical software (PASW Statistics 18, SPSS Inc., Chicago, IL, USA). The statistical significance was declared at p < 0.05.

3. Results

3.1. Contact Angle Measurement and Surface Energy

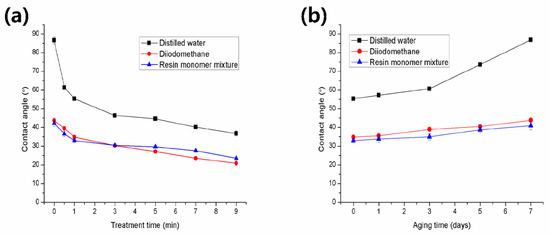

The result of contact angle with respect to NTAPP treatment time was shown in Figure 4a. The results showed the general trend of decreasing contact angle for all three liquids tested with increasing NTAPP treatment time (p < 0.05). The result of contact angle with respect to time passed from NTAPP treatment is shown in Figure 4b. Generally, the contact angle increased with time passing from the point where the NTAPP treatment occurred (p < 0.05) for all liquids used in the test.

Figure 4.

The contact angle following use of distilled water (black square), diiodomethane (red circle), and resin monomer mixture (blue triangle) on the surface of epoxy resin as; (a) increasing treatment time of non-thermal atmospheric pressure nitrogen plasma; (b) time following the treatment to non-thermal atmospheric pressure nitrogen plasma. There was a statistically significant difference (p < 0.05) between all test groups.

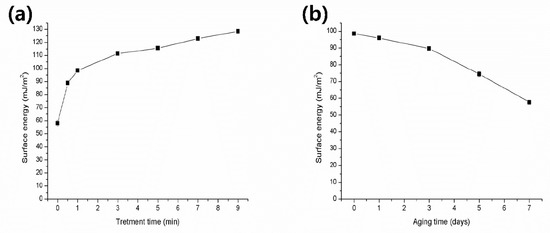

The surface energy was then calculated from each contact angle and the results showed that surface energy increased with increasing NTAPP treatment time (Figure 5a) (p < 0.05), whereas the surface energy decreased with increasing time following the NTAPP treatment (Figure 5b) (p < 0.05).

Figure 5.

The calculated surface energy on the surface of epoxy resin as; (a) increasing treatment time of non-thermal atmospheric pressure nitrogen plasma; (b) time following the treatment to non-thermal atmospheric pressure nitrogen plasma. There was a statistically significant difference (p < 0.05) between all test groups.

3.2. Surface Chemical Analysis Using X-ray Photoelectron Spectroscopy

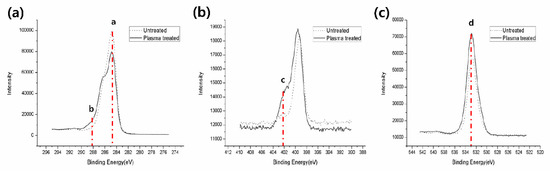

XPS analysis of NTAPP-treated and untreated epoxy resins are shown in Figure 6. The C1s spectra (Figure 6a) showed a single peak for untreated sample, corresponding to C–C (284.6 eV, peak a) [26]. The intensity of this peak was decreased after NTAPP treatment for 1 min and increased intensity at higher binding energy of 288 eV, corresponding to C=O (peak b) [27]. In terms of the N1s spectra (Figure 6b), intensity of the peak at higher binding energy corresponding to the amine groups (402.0 eV) [28] increased following NTAPP treatment for 1 min. Finally, in terms of the O1s spectra (Figure 6c), intensity of the single peak corresponding to the C–OH (532.8 eV, peak d) [29] increased after NTAPP treatment for 1 min.

Figure 6.

The surface chemical composition of the epoxy resin analyzed by X-ray Photoelectron Spectroscopy before and after the non-thermal atmospheric pressure nitrogen plasma treatment. Spectra for; (a) C1s; (b) N1s; and (c) O1.

3.3. Shear Bond Strength between Epoxy Resin and Core Resin

The results of shear bond strength test showed that shear bond strength was significantly higher for NTAPP-treated epoxy resin than NTAPP untreated epoxy resin, when each was bonded with core resin. The values of shear bond strength with core resin for NTAPP-treated epoxy resin and NTAPP untreated epoxy resin were (1.28 ± 0.20) MPa and (0.60 ± 0.08) MPa, respectively (p < 0.05).

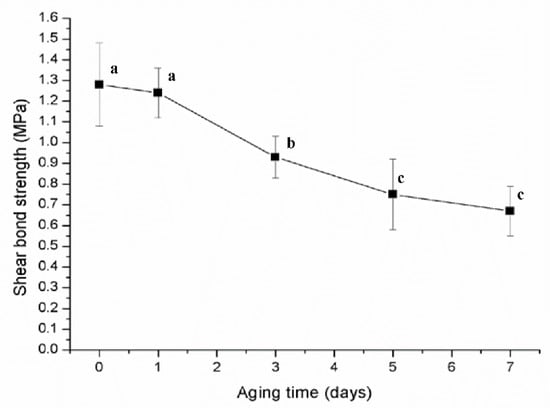

The result of shear bond strength with respect to time passed from NTAPP treatment was shown in Figure 7. The shear bond strength value of plasma treated epoxy resin decreased with increasing aging time, excluding the time periods from day 0 to day 1 and from day 5 to day 7 (p < 0.05).

Figure 7.

Shear bond strength between non-thermal atmospheric pressure nitrogen plasma-treated epoxy resin and fiber post with respect to the time passed after the treatment (different lower case alphabet letter indicates statistical difference, p < 0.05).

3.4. Push-Out Shear Bond Strength between Commercially Available Epoxy Resin-Based Fiber Post and Core Resin

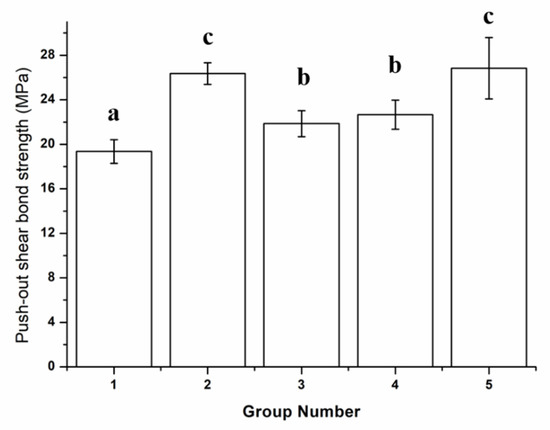

The results of push-out shear bond strength between commercially available epoxy resin-based fiber post and core resin are shown in Table 2 and Figure 8. The push-out shear bond strength values of samples treated with conventional chemicals of hydrofluoric acid only (Group 3) and silane only (Group 4) were significantly higher than samples without any treatment (Group 1) (p < 0.05) as expected. The push-out shear bond strength value of samples treated with NTAPP for 1 min (Group 2) was also significantly higher than samples without any treatment (Group 1) (p < 0.05), which was even significantly higher than those treated only with hydrofluoric acid (Group 3) or silane (Group 4) (p < 0.05). Additionally, there was no significant difference between samples treated with hydrofluoric acid followed by silane (Group 5) and samples treated with NTAPP for 1 min (Group 2) (p > 0.05).

Table 2.

The result of push-out shear bond strength between epoxy resin-based fiber post and core resin (MPa).

Figure 8.

Push-out shear bond strength between group with no surface treatment (1) NTAPP treatment for 1 min; (2) treated with 4% hydrofluoric acid gel for 60 s and then rinsed with running water for 10 s; (3) treated with silane using micro-brush for 60 s; (4) and treated with 4% hydrofluoric acid followed by silane as described earlier; (5) different lowercase letters above the bar indicate a significant difference at p < 0.05 for each group.

4. Discussion

The bonding between fiber-reinforced composite posts and core resin is an important factor in successful restoration of endodontically-treated teeth, which has insufficient coronal tooth structure to retain a core for the definitive restoration [1], and therefore the objective of this study was to use recently highlighted NTAPP for application on epoxy resin-based fiber post to improve bonding with core resin.

First, the contact angle was measured as an indicator of surfaced energy on epoxy resin. The water contact angle has been used to evaluate the surface hydrophilicity [30,31,32], but also diiodomethane and resin monomer mixture were additionally used in this experiment to evaluate the contact angle of these liquids on the epoxy resin surface following NTAPP treatment. This is because they will be more clinically relevant as they are the component liquids that will be in contact with epoxy resin in clinical situations. Surface energy has been considered in this study using the contact angle measurement of both polar and non-polar liquid, as it is a parameter that is linked to the wettability of the surface. Increased wettability is an important feature of dental materials, especially during the adhesion as improved wettability of the dental material surface would result in larger area occupied by liquid-like adherent, resulting in improved adhesions [12,20]. The results showed that the contact angles decreased for each of the three different liquids used following NTAPP treatment on epoxy resin (Figure 4a) and consequent surface energy increased with NTAPP treatment (Figure 4b). Such effects were in agreement with our previous studies that considered application of same type of NTAPP on polyvinyl siloxane based dental impression materials and dental wax [12,20] that resulted in the increase of the surface energy. It is also in agreement with study by De Geyter et al. who reported the change of surface energy against distilled water as well as diiodomethane on polyethylene (PE) film after dielectric barrier discharge plasma treatment [33]. Additionally, in a similar study where fiber post bonding with resin cement was considered along with effects of silane and hydrofluoric acid, the results showed water contact angles of 56.1° and 71.2° for silane and hydrofluoric acid treated fiber post, respectively [11]. Also, by combining silane and hydrofluoric acid treatment on fiber post, the contact angle was 59.4° in same study. Hence, it is indicated that treatment as short as 30 s with NTAPP in this study would have resulted in contact angle lower than surface treated with hydrofluoric acid, while treatment of 1 min or more would be required for the lowering of contact angle similar to silane or silane and hydrofluoric acid treatment combined. The increased surface energy by NTAPP would result in larger area of interaction between the epoxy resin-based fiber post and core resin, allowing improved adhesion between two surfaces.

The effects seen through surface energy was previously explained through change in surface chemistry of the NTAPP-treated sample due to the reactive chemical species produced from it [12,22]. In this study, XPS was used to consider changes in surface chemistry which has been previously known to be caused by NTAPP treatment [12,20,22]. Indeed, XPS results showed that there was a change in surface chemistry of epoxy resin following NTAPP treatment such as formation of C=O (Figure 6a) or C–OH (Figure 6c) chemical functional group and a decrease in intensity that corresponded to C–C chemical functional group (Figure 6a). Such formation of oxidative layer with higher binding energy along with reduction of carbon composition has been known to result in an increase in surface energy [12,34,35], which explains the results seen here. Hence, the XPS results explain the results obtained in this study as NTAPP treatment caused formation of specific chemical structure on the surface allowing improved surface energy and consequently improved adhesion between epoxy resin-based fiber post and core resin.

The change in surface chemistry and consequent change in surface energy was then correlated with bonding strength between epoxy resin and core resin. The results showed a significant increase in shear bond strength following NTAPP treatment on epoxy resin, and this was in agreement with previous studies that evaluated the bond strength of polymer and composite materials after atmospheric pressure plasma treatment [11,36,37]. In a similar study by Costa Dantas et al. who used ethylenediamine (EDA) plasma treatment to improve the bond strength between resin cement and epoxy resin-based fiber post [11], the bonding strength between two materials were compared following EDA plasma treatment, silane treatment, hydrofluoric acid treatment or silane, and hydrofluoric acid combined treatment. Although the results were different to our study as the bonded materials were different to our study (core resin compare to resin-based cement) as well as the experimental set-up, it was evident that none of silane treatment, hydrofluoric acid treatment or silane, and hydrofluoric acid combined treatment resulted in more improved bond strength than the untreated control, while only EDA plasma treatment resulted in significant improvement. The study concluded that the contact angle may not be the sole factor for improving bonding strength, while chemical functionalities may play an important role. Such findings were in agreement with other studies. Yavirach et al. reported that vacuum-based plasma treatment using nitrogen resulted in increased tensile-shear bond strength between the fiber post and core resin [10] and the possible reason for such improved adhesion was due to the result of functional groups induced on the surfaces of the fiber post. Also, Grace and Gerenser demonstrated that the amine and imine species were induced as functional groups on the surface by nitrogen plasma treatment polystyrene [38]. The majority of these functional groups usually contained terminal nitrogen (primary amine or imine), which Yavirach et al. hypothesized induced terminal nitrogen functional groups on the epoxy resin-based fiber posts surfaces treated with nitrogen supplied plasmas would react with functional groups in the composite core build-up material and therefore result in improvement in shear bond strength [10]. Indeed, our results have also demonstrated that the peak corresponding to the amine groups (402.0 eV) increased following NTAPP treatment for 1 min (Figure 6b).

Additionally, this study compared the shear bond strength of NTAPP-treated commercially available post to core resin with that of conventional hydrofluoric acid or silane-treated post. The hydrofluoric acid treatment is often used as the surface treatment of fiber post as it increased the number of exposed glass fibers and it is often used in conjunction with silane to increase the surface area available for reaction and forms the stronger bond between fiber post and core resin [7]. In this study, it was demonstrated that the samples treated with NTAPP for only 1 min showed significantly higher shear bond strength compared to conventional hydrofluoric acid or silane-treated samples, and did not show any significant difference in shear bond strength with samples treated with a combination of hydrofluoric acid and silane. In another study as mentioned above, ethylenediamine (EDA) plasma treatment was used to improve the bond strength between resin cement and epoxy resin-based fiber post [11]. However, EDA plasma caused not only a significant chemical modification on the surface, but also surface morphological changes of the fiber post, which was indicated by observation through the scanning electron microscope. Additionally, previous studies using the vacuum-based plasma treatment required 5 to 10 min to achieve the effects seen here [10,11], whereas application of NTAPP in this experiment was performed under atmosphere and the shear bond strength of plasma-treated post was still significantly higher than the untreated post even with a very short duration of exposure (1 min).

Despite all of above advantages, limitations were also identified with application of NTAPP on resin-based fiber posts. The results showed that high surface energy of epoxy resin caused by NTAPP treatment decreased significantly with aging time (Figure 5b). This was in agreement with the shear bond strength with resin core, as the value dropped significantly with the aging time (Figure 7). Such effects were also reported previously by Ye et al., who used non-thermal plasma with air or helium mixed with 2% oxygen [39] and showed that bonding strength decreased as they are left in atmosphere for 1, 12, or 24 h. This limitation, however, is a possible reason for requiring relatively portable and easily applicable plasma device, which may be able to be used by the chair-side of the clinic, where the fiber post can be exposed to plasma just before the bonding, rather than the use of the vacuum-based plasma treatment that requires vacuum chamber and therefore only able to be carried out in manufacturing stage with inevitable shelf lives [13]. Another area that we have not explored in this study was the combination effects of various treatment with NTAPP. As our main objective was to consider the effect of NTAPP in comparison to conventional treatments, groups outlined in Table 1 were considered. Still, there may be an effect from using NTAPP on 4% hydrofluoric acid treated surface or silane treated surface. This warrants future investigations of this study. Hence, with limitations of this study and need of further investigations, it may be carefully concluded that use of NTAPP treatment on resin-based fiber posts would benefit the process of endodontic restoration in dental clinics.

5. Conclusions

From the results of this study, the main null hypothesis stating that there would be no significant difference in push-out shear bond strength with core resin between NTAPP-treated epoxy resin-based fiber past and conventional treated epoxy-resin based fiber post was partially accepted. Also, another null hypothesis of this study was that there would be no difference in surface energy and surface chemistry between NTAPPJ-treated epoxy resin-based fiber post and epoxy resin-based fiber post not treated with NTAPPJ was rejected. NTAPP treatment favored the surface energy of the epoxy resin-based fiber post by modifying its surface chemically, which consequently improved bond strength between core resin and epoxy resin-based fiber post. The results were similar with conventional combined treatment of 4% hydrofluoric acid and silane, while the results were superior than treatment of 4% hydrofluoric acid or silane alone. The method of NTAPP application on the epoxy resin-based fiber post by the chair-side of the clinic is expected to be promising for the improved bond strength between core resin and epoxy resin-based fiber post.

Author Contributions

Conceptualization, H.-S.K. and J.-S.K.; methodology, H.-S.K., K.-M.K., E.H.C., and J.-S.K.; validation, K.-M.K. and J.-S.K.; formal analysis, H.-S.K. and S.-Y.Y.; investigation, H.-S.K. and S.-Y.Y.; resources, E.H.C. and K.-M.K.; data curation, H.-S.K. and J.-S.K.; writing—original draft preparation, H.-S.K. and J.-S.K.; writing—review and editing, K.-M.K., E.H.C., and J.-S.K.; supervision, K.-M.K.; project administration, E.H.C. and J.-S.K.; funding acquisition, K.-M.K. and J.-S.K. All authors have read and agreed to the published version of the manuscript.

Funding

This study was supported by the Yonsei University College of Dentistry (6-2019-0021) and program through the National Research Foundation of Korea (NRF) funded by the Korea government (MSIT) (NRF-2016K1A4A3914113).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Balbosh, A.; Kern, M. Effect of surface treatment on retention of glass-fiber endodontic posts. J. Prosthet. Dent. 2006, 95, 218–223. [Google Scholar] [CrossRef] [PubMed]

- Baba, N.Z.; Golden, G.; Goodacre, C.J. Nonmetallic Prefabricated Dowels: A Review of Compositions, Properties, Laboratory, and Clinical Test Results. J. Prosthodont. 2009, 18, 527–536. [Google Scholar] [CrossRef] [PubMed]

- Goracci, C.; Ferrari, M. Current perspectives on post systems: A literature review. Aust. Dent. J. 2011, 56 (Suppl. 1), 77–83. [Google Scholar] [CrossRef]

- Menezes, M.D.; Queiroz, E.C.; Soares, P.V.; Faria-e-Silva, A.L.; Soares, C.J.; Martins, L.R.M. Fiber Post Etching with Hydrogen Peroxide: Effect of Concentration and Application Time. J. Endod. 2011, 37, 398–402. [Google Scholar] [CrossRef] [PubMed]

- Ozcan, M.; Vallittu, P.K. Effect of surface conditioning methods on the bond strength of luting cement to ceramics. Dent. Mater. 2003, 19, 725–731. [Google Scholar] [CrossRef]

- Wang, Z.; Ji, Y.; Zhang, F. Bond strengths of an epoxy resin-based fiber post with four adhesive systems. Quintessence Int. 2010, 41, e173–e180. [Google Scholar]

- Cekic-Nagas, I.; Sukuroglu, E.; Canay, S. Does the surface treatment affect the bond strength of various fibre-post systems to resin-core materials? J. Dent. 2011, 39, 171–179. [Google Scholar] [CrossRef]

- Monticelli, F.; Toledano, M.; Tay, F.R.; Sadek, F.T.; Goracci, C.; Ferrari, M. A simple etching technique for improving the retention of fiber posts to resin composites. J. Endod. 2006, 32, 44–47. [Google Scholar] [CrossRef]

- Yenisey, M.; Kulunk, S. Effects of chemical surface treatments of quartz and glass fiber posts on the retention of a composite resin. J. Prosthet. Dent. 2008, 99, 38–45. [Google Scholar] [CrossRef]

- Yavirach, P.; Chaijareenont, P.; Boonyawan, D.; Pattamapun, K.; Tunma, S.; Takahashi, H.; Arksornnukit, M. Effects of plasma treatment on the shear bond strength between fiber-reinforced composite posts and resin composite for core build-up. Dent. Mater. J. 2009, 28, 686–692. [Google Scholar] [CrossRef]

- Costa Dantas, M.C.; do Prado, M.; Costa, V.S.; Gaiotte, M.G.; Simão, R.A.; Bastian, F.L. Comparison between the Effect of Plasma and Chemical Treatments on Fiber Post Surface. J. Endod. 2012, 38, 215–218. [Google Scholar] [CrossRef] [PubMed]

- Kwon, J.S.; Kim, Y.H.; Choi, E.H.; Kim, K.N. Development of ultra-hydrophilic and non-cytotoxic dental vinyl polysiloxane impression materials using a non-thermal atmospheric-pressure plasma jet. J. Phys. D Appl. Phys. 2013, 46, 195201. [Google Scholar] [CrossRef]

- Modic, M.; Junkar, I.; Vesel, A.; Mozetic, M. Aging of plasma treated surfaces and their effects on platelet adhesion and activation. Surf. Coat. Technol. 2012, 213, 98–104. [Google Scholar] [CrossRef]

- Schutze, A.; Jeong, J.Y.; Babayan, S.E.; Jaeyoung, P.; Selwyn, G.S.; Hicks, R.F. The atmospheric-pressure plasma jet: A review and comparison to other plasma sources. IEEE Trans. Plasma Sci. 1998, 26, 1685–1694. [Google Scholar] [CrossRef]

- Selwyn, G.S.; Herrmann, H.W.; Park, J.; Henins, I. Materials processing using an atmospheric pressure, RF-generated plasma source. Contrib. Plasma Phys. 2001, 41, 610–619. [Google Scholar] [CrossRef]

- Kogelschatz, U. Atmospheric-pressure plasma technology. Plasma Phys. Control. Fusion 2004, 46, B63. [Google Scholar] [CrossRef]

- Tendero, C.; Tixier, C.; Tristant, P.; Desmaison, J.; Leprince, P. Atmospheric pressure plasmas: A review. Spectrochim. Acta Part B At. Spectrosc. 2006, 61, 2–30. [Google Scholar] [CrossRef]

- Laroussi, M.; Akan, T. Arc-Free Atmospheric Pressure Cold Plasma Jets: A Review. Plasma Process. Polym. 2007, 4, 777–788. [Google Scholar] [CrossRef]

- Moreau, M.; Orange, N.; Feuilloley, M.G.J. Non-thermal plasma technologies: New tools for bio-decontamination. Biotechnol. Adv. 2008, 26, 610–617. [Google Scholar] [CrossRef]

- Lee, J.H.; Kim, Y.H.; Choi, E.H.; Kim, K.M.; Kim, K.N. Development of hydrophilic dental wax without surfactant using a non-thermal air atmospheric pressure plasma jet. J. Phys. D Appl. Phys. 2014, 47, 235402. [Google Scholar] [CrossRef]

- Kwon, J.S.; Kim, Y.H.; Choi, E.H.; Kim, K.N. The effects of non-thermal atmospheric pressure plasma jet on attachment of osteoblast. Curr. Appl. Phys. 2013, 13, S42–S47. [Google Scholar] [CrossRef]

- Lee, E.J.; Kwon, J.S.; Uhm, S.H.; Song, D.H.; Kim, Y.H.; Choi, E.H.; Kim, K.N. The effects of non-thermal atmospheric pressure plasma jet on cellular activity at SLA-treated titanium surfaces. Curr. Appl. Phys. 2013, 13, S36–S41. [Google Scholar] [CrossRef]

- Seo, H.Y.; Kwon, J.S.; Choi, Y.R.; Kim, K.M.; Choi, E.H.; Kim, K.N. Cellular Attachment and Differentiation on Titania Nanotubes Exposed to Air- or Nitrogen-Based Non-Thermal Atmospheric Pressure Plasma. PLoS ONE 2014, 9, e113477. [Google Scholar] [CrossRef] [PubMed]

- Yoo, E.M.; Uhm, S.H.; Kwon, J.S.; Choi, H.S.; Choi, E.H.; Kim, K.M.; Kim, K.N. The Study on Inhibition of Planktonic Bacterial Growth by Non-Thermal Atmospheric Pressure Plasma Jet Treated Surfaces for Dental Application. J. Biomed. Nanotechnol. 2015, 11, 334–341. [Google Scholar] [CrossRef]

- Owens, D.K.; Wendt, R.C. Estimation of the surface free energy of polymers. J. Appl. Polym. Sci. 1969, 13, 1741–1747. [Google Scholar] [CrossRef]

- Hamwi, A.; Latouche, C.; Marchand, V.; Dupuis, J.; Benoit, R. Perfluorofullerenes: Characterization and structural aspects. J. Phys. Chem. Solids 1996, 57, 991–998. [Google Scholar] [CrossRef]

- Rats, D.; Vandenbulcke, L.; Herbin, R.; Benoit, R.; Erre, R.; Serin, V.; Sevely, J. Characterization of diamond films deposited on titanium and its alloys. Thin Solid Films 1995, 270, 177–183. [Google Scholar] [CrossRef]

- Vanini, A.S.; Audouard, J.P.; Marcus, P. The Role of Nitrogen in the Passivity of Austenitic Stainless-Steels. Corros. Sci. 1994, 36, 1825–1834. [Google Scholar] [CrossRef]

- Gardner, S.D.; Singamsetty, C.S.K.; Booth, G.L.; He, G.R.; Pittman, C.U. Surface Characterization of Carbon-Fibers Using Angle-Resolved Xps and Iss. Carbon 1995, 33, 587–595. [Google Scholar] [CrossRef]

- Sangprasert, W.; Nimmanpipug, P.; Yavirach, P.; Lee, V.S.; Boonyawan, D. Epoxy resin surface functionalization using atmospheric pressure plasma jet treatment. Jpn. J. Appl. Phys. 2012, 51, 01AJ04. [Google Scholar] [CrossRef]

- Lommatzsch, U.; Pasedag, D.; Baalmann, A.; Ellinghorst, G.; Wagner, H.E. Atmospheric Pressure Plasma Jet Treatment of Polyethylene Surfaces for Adhesion Improvement. Plasma Process. Polym. 2007, 4, S1041–S1045. [Google Scholar] [CrossRef]

- Jokinen, V.; Suvanto, P.; Franssila, S. Oxygen and nitrogen plasma hydrophilization and hydrophobic recovery of polymers. Biomicrofluidics 2012, 6, 016501. [Google Scholar] [CrossRef] [PubMed]

- De Geyter, N.; Morent, R.; Leys, C. Surface characterization of plasma-modified polyethylene by contact angle experiments and ATR-FTIR spectroscopy. Surf. Interface Anal. 2008, 40, 608–611. [Google Scholar] [CrossRef]

- Akram, M.; Jansen, K.M.B.; Ernst, L.J.; Bhowmik, S. Atmospheric pressure plasma surface modification of titanium for high temperature adhesive bonding. Int. J. Adhes. Adhes. 2011, 31, 598–604. [Google Scholar] [CrossRef][Green Version]

- Panousis, E.; Clement, F.; Loiseau, J.F.; Spyrou, N.; Held, B.; Larrieu, J.; Lecoq, E.; Guimon, C. Titanium alloy surface treatment using an atmospheric plasma jet in nitrogen pulsed discharge conditions. Surf. Coat. Technol. 2007, 201, 7292–7302. [Google Scholar] [CrossRef]

- Sim, M.K.; Seul, S.D. Surface Modification of Polymeric Material Using Atmospheric Plasma. Polym. Korea 2008, 32, 433–439. [Google Scholar]

- Seo, S.H.; Chang, S.H.; Yoo, Y.E.; Chung, J.D. Adhesion Characteristics of Polymer Material Treated by Atmospheric Pressure Plasma. Trans. Korean Soc. Mech. Eng. B 2011, 35, 445–450. [Google Scholar] [CrossRef][Green Version]

- Grace, J.M.; Gerenser, L.J. Plasma Treatment of Polymers. J. Dispers. Sci. Technol. 2003, 24, 305–341. [Google Scholar] [CrossRef]

- Ye, H.; Zhang, Q.; Sun, K.; Zhang, J.; Jiao, Y.; Zhou, Y. Aging effects of fiber post surface treatment with nonthermal plasma. Int. J. Prosthodont. 2012, 25, 509–511. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).