Positioning Accuracy of the Shearer Based on a Strapdown Inertial Navigation System in Underground Coal Mining

Abstract

1. Introduction

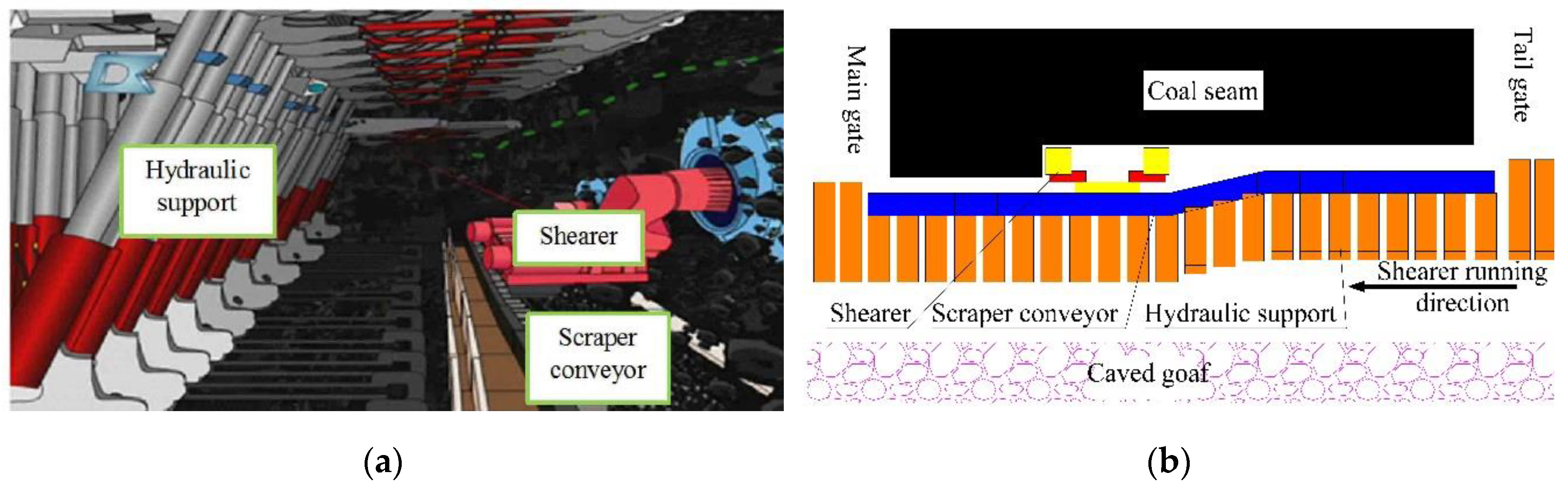

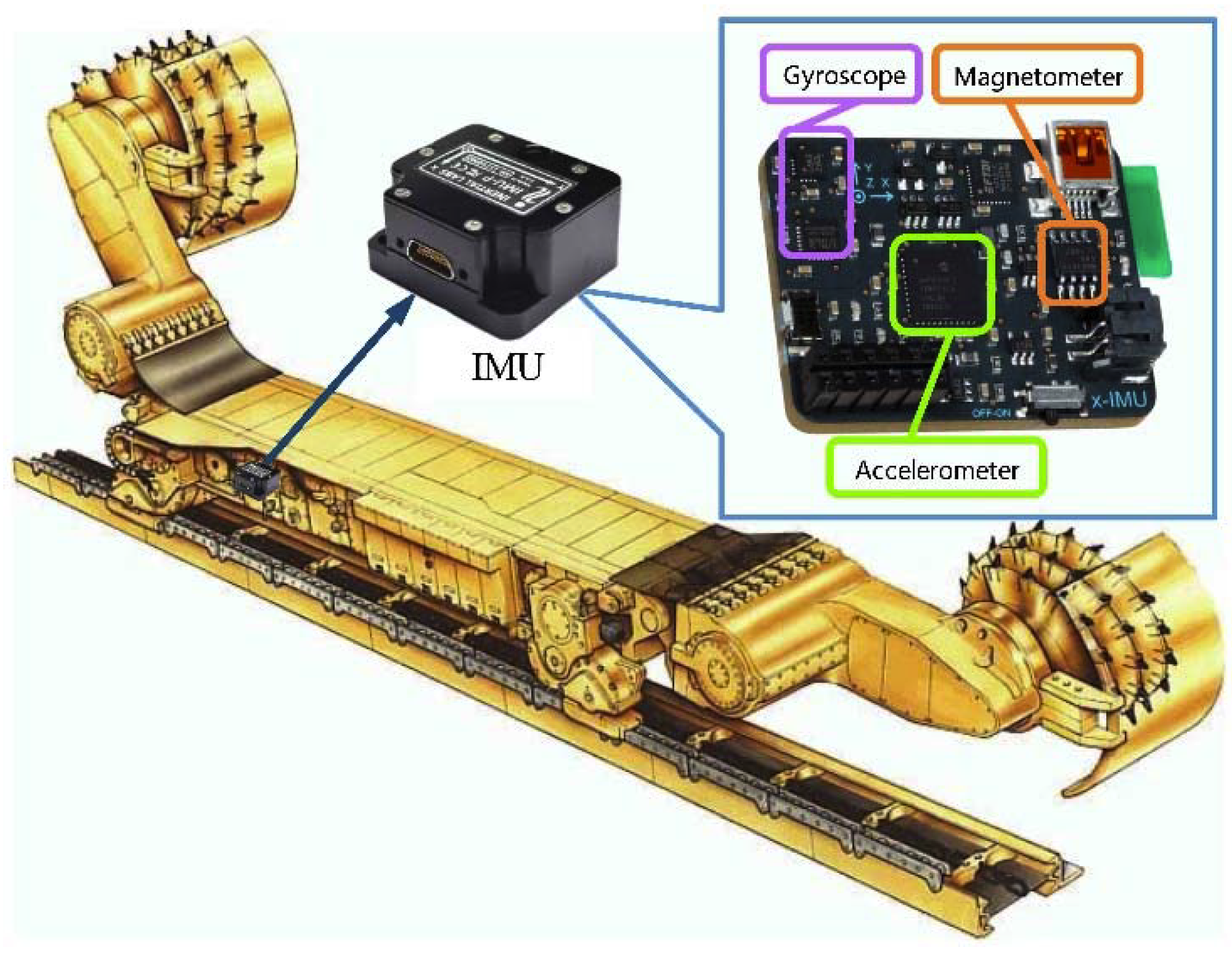

2. Shearer Positioning System Based on SINS

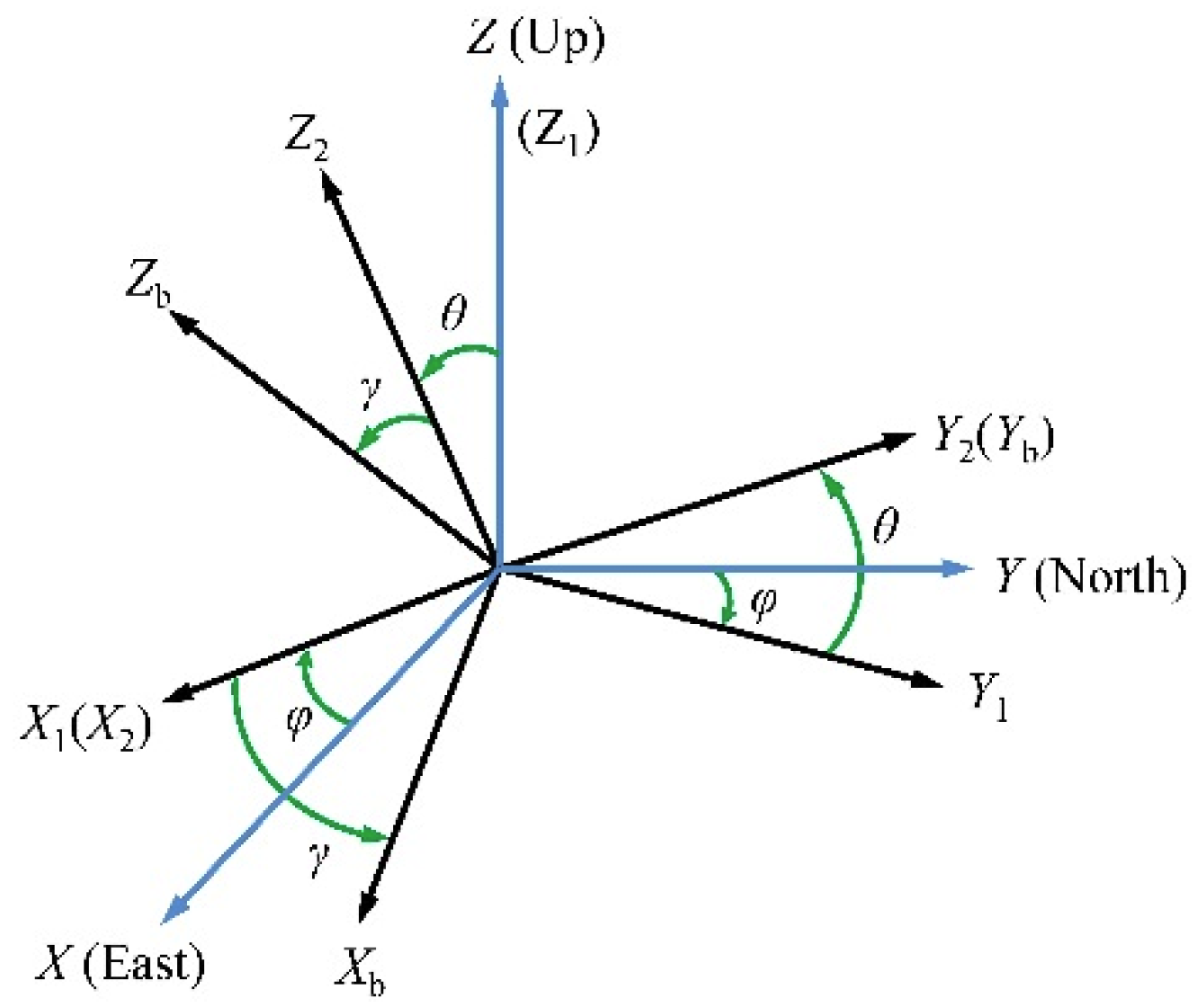

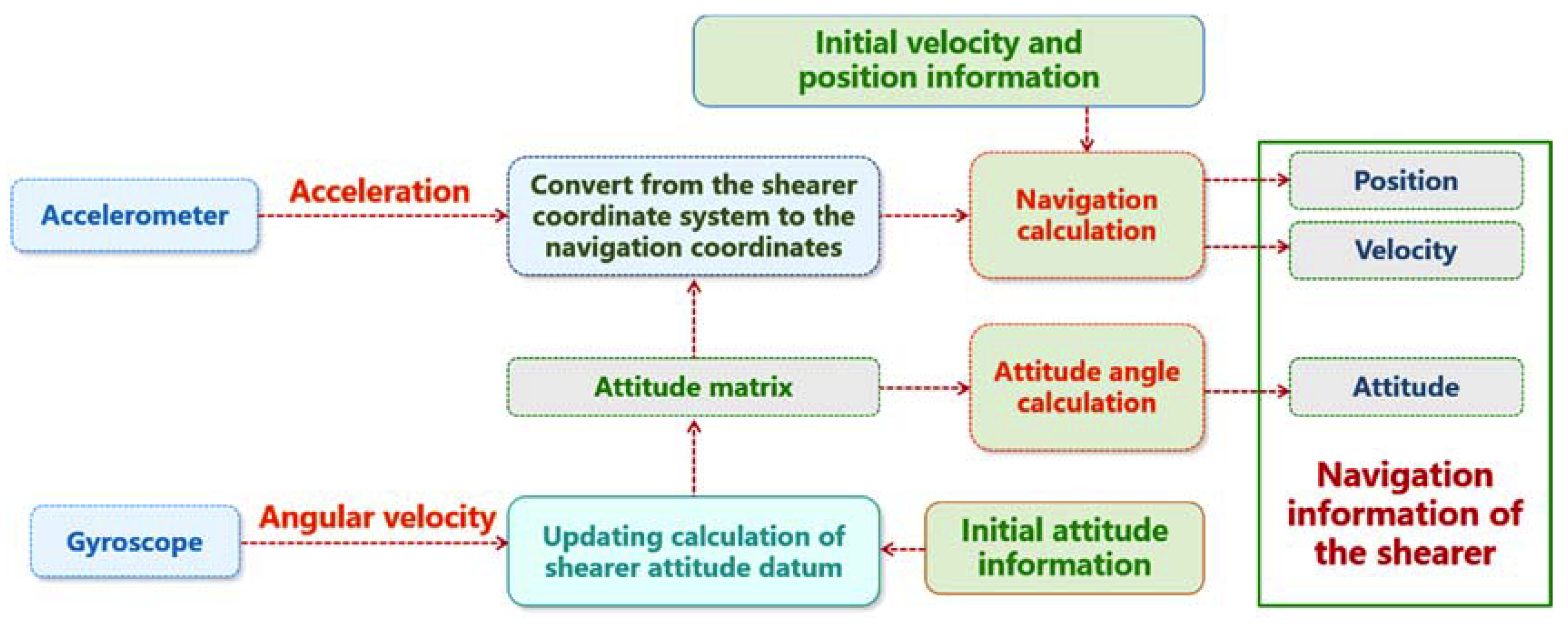

2.1. Principle of the Shearer Positioning System Based on SINS

2.2. Calculation of the Shearer Positioning System Based on SINS

3. Shearer Positioning System Based on SINS

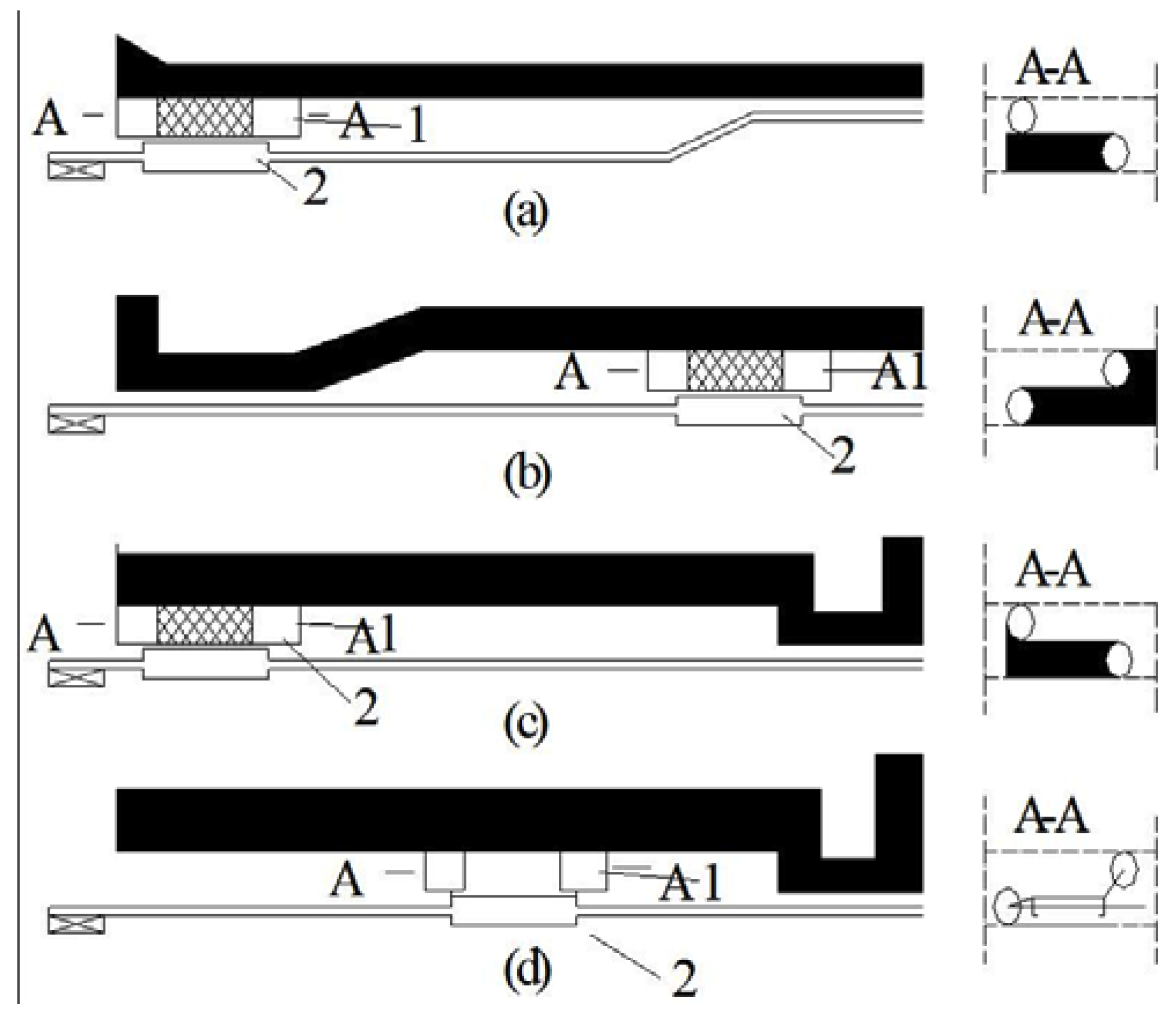

3.1. Motion Characteristics of the Shearer

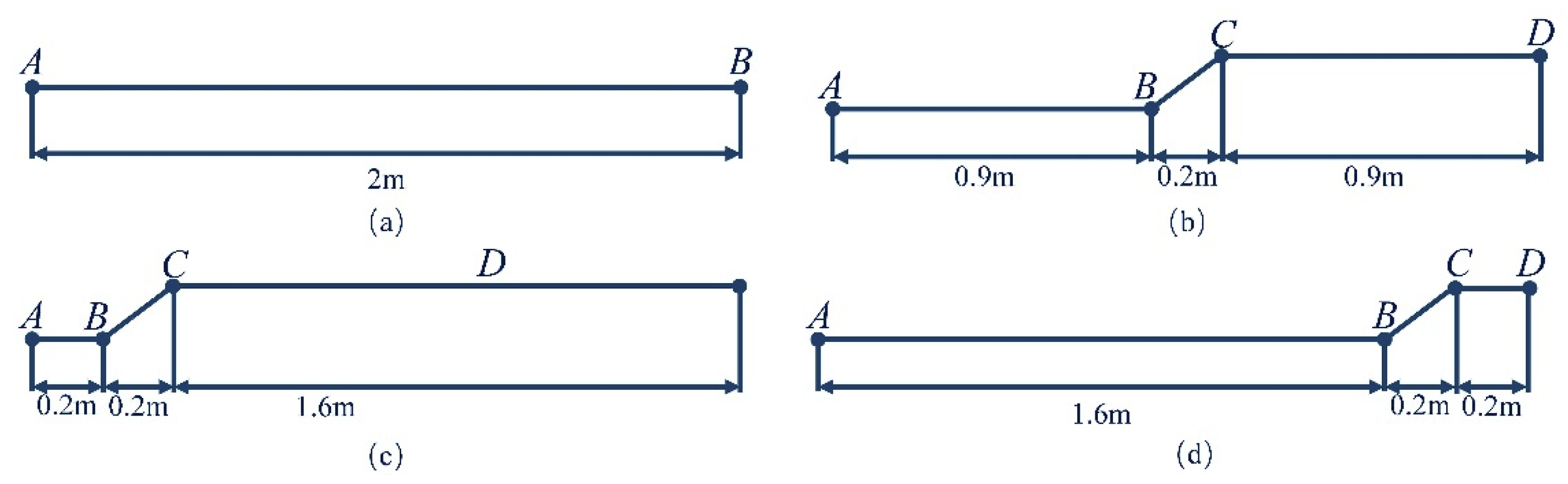

3.2. Experimental Design

3.3. Experimental Data Processing Methods

4. Analysis of the Experimental Results

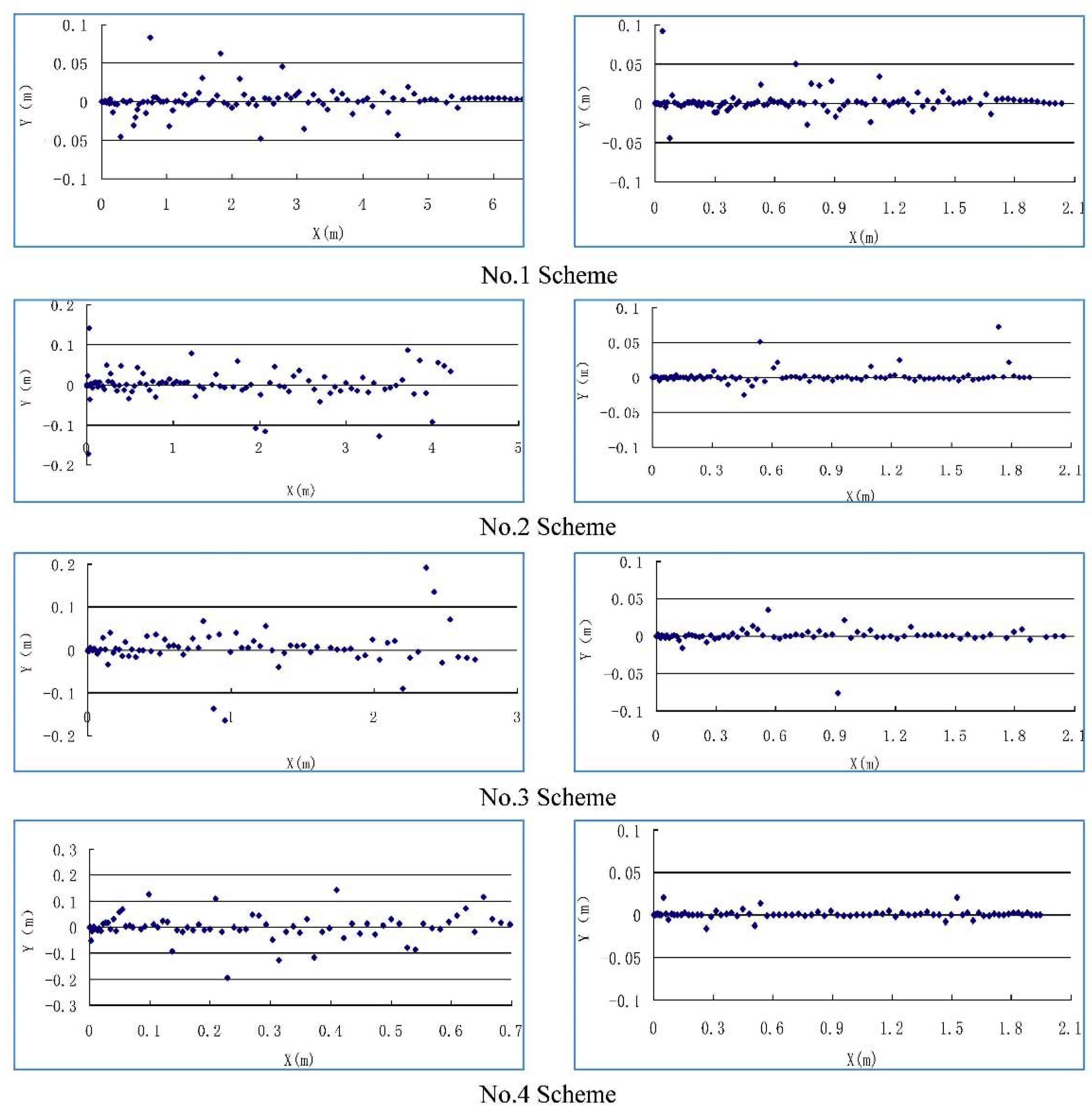

4.1. Straight-Line Running Positioning Experiments

- The estimated points of the integral calculation after error compensation accurately reflect the linear operation characteristics of the shearer. By comparing the positioning results obtained before and after compensation, it can be seen that, after 10-point smoothing preprocessing, zero bias compensation, and Kalman filter compensation of the output gyroscope and accelerometer data, the validity of the data increases greatly, and the error is significantly reduced. The position of the shearer estimated by the positioning system surrounds the actual trajectory;

- The error of the position point on the X axis is greater than that on the Y axis. The maximum error measured along the direction of the shearer movement is 0.11 m. Therefore, there is an error in measuring the displacement of the shearer by relying solely on the accelerometer. The error is mainly related to the working principle of the instrument. The data measured by the accelerometer needs to be integrated twice to obtain the distance information. In practice, the map-matching technique can be used for correction;

- The displacement accuracy measured by the odometer is higher than that of the accelerometer. The displacement measured by the odometer is less than the actual displacement. The main reason for this error is the slip between the walking wheel and the track. Moreover, slip is less likely to occur on the chainless shearer, so the odometer has higher reliability and can correct the acceleration integral result;

- The number of isolated points is proportional to the running time. By comparing the four experimental schemes, it can be found that the longer the running time, the greater the number of isolated points and the greater the absolute value of the discrete quantities. This is related to the drift characteristics of the inertial meter over time. To meet the long-term positioning requirements, a more accurate instrument can be used. In the case of straight line running, the discrete amount of the isolated points in the Y direction can be corrected by map matching. By projecting the isolated points on a straight line map, it can be ensured that the shearer is positioned on the scraper conveyor and reducing positioning errors. The positioning results after the map matching is shown in Figure 8;

- The density of the coordinate points reflects the operating speed of the shearer. In the experiment, the cycle of positioning calculation is controlled by the system time. At the same sampling frequency, the slower the running speed, the more detailed the sampling data is. Therefore, the running speed of the coal shearer is related to the density of the coordinate points. The slower the shearer runs, the denser the coordinate points. Therefore, the positioning system can not only reflect the position information of the shearer in real time, but also display the speed in each operating section.

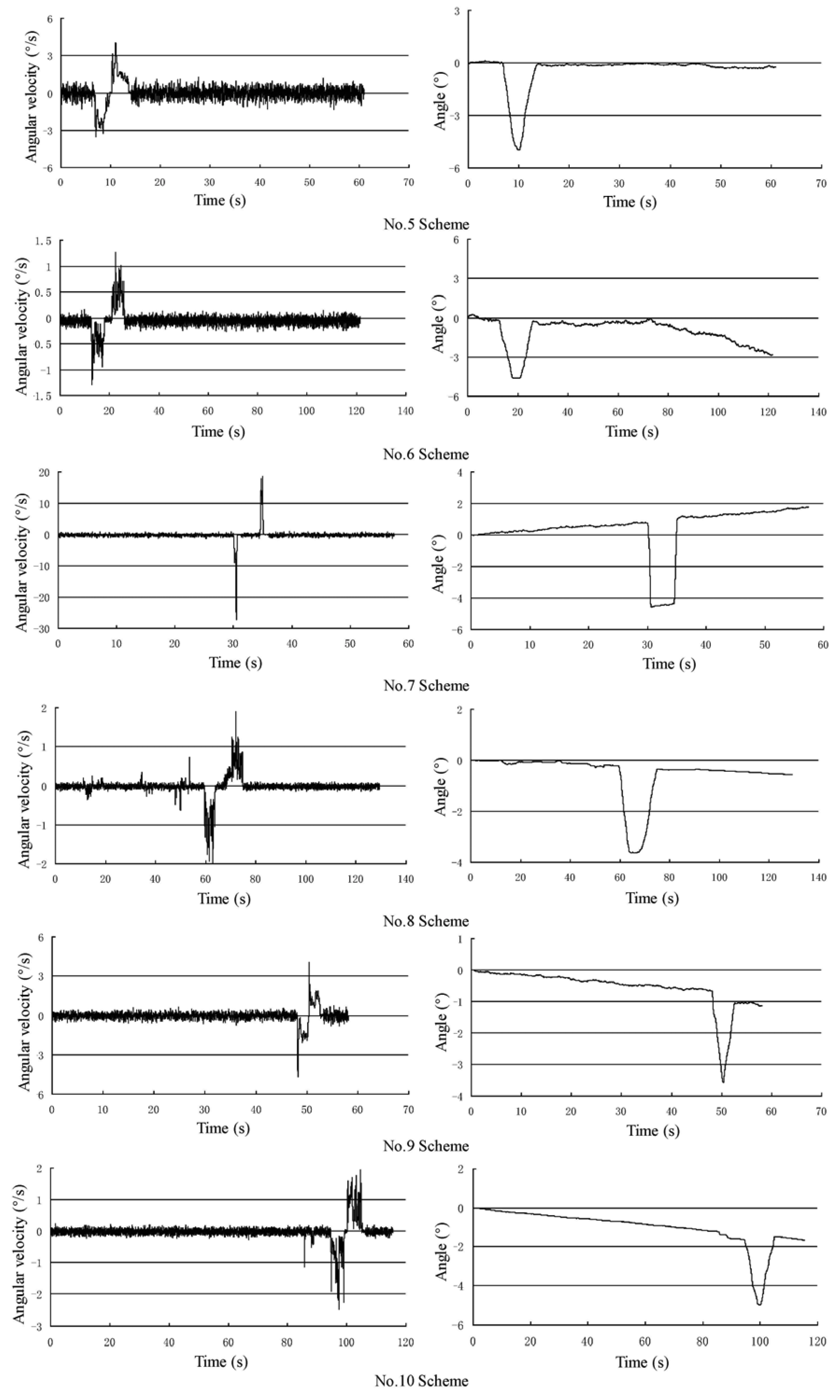

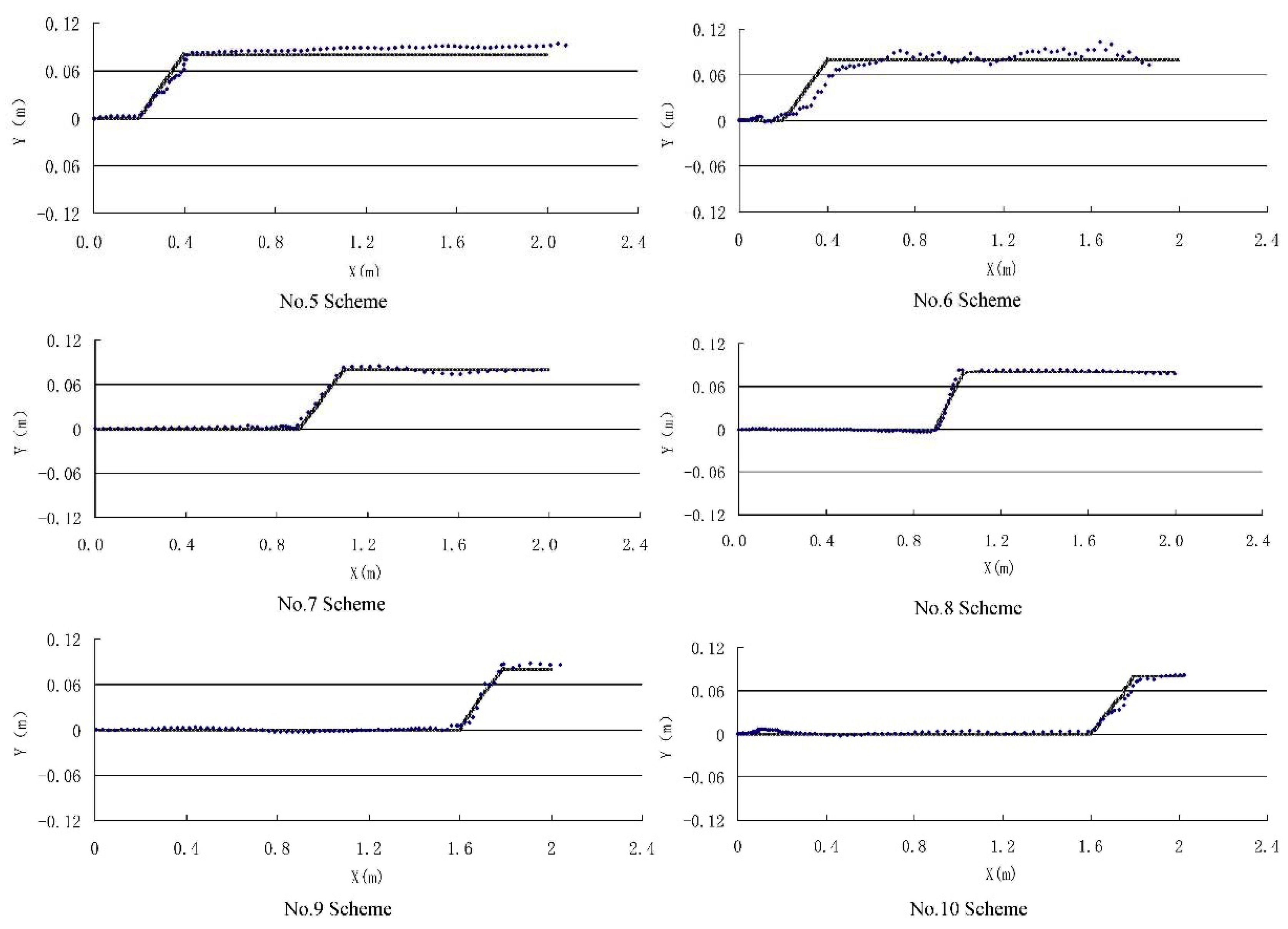

4.2. Inclined-Sumping Running Positioning Experiments

4.2.1. Identification of the Curved Section

4.2.2. Analysis of Positioning Results

- Compared with the current shearer positioning technology, the shearer positioning system in this paper can not only accurately describe the shape of the scraper conveyor, but also provide information such as the sumping position and angle and length of the shearer and can achieve higher precision positioning of the shearer;

- The random error of inertial navigation instruments cannot be completely eliminated. Methods to improve the accuracy of the system include the use of high-precision instruments and better data processing methods, including high-efficiency filtering techniques and map-matching algorithms;

- The positioning accuracy of the inertial navigation instrument is related to the system running time. Periodic correction of the positioning data by the odometer can reduce the influence of time on the system. Initial calibration of the instrument can be performed when the shearer starts running, and the high-precision inertial navigation instrument can achieve the above function. Moreover, the odometer accumulates little error over time; therefore, the navigation data can be corrected by the odometer to achieve higher precision shearer positioning.

5. Conclusions

- Based on strapdown inertial navigation technology, we analyzed the movement characteristics of the shearer on the working face, and we used inertial navigation instruments such as gyroscopes and accelerometers and the dead reckoning principle to propose a shearer positioning system on a fully mechanized working face;

- In the shearer positioning experiments, the positioning system can accurately reflect the trajectory of the shearer running, including straight line running, inclined-sumping running, and straight line running after sumping. The experiments also show that the shearer positioning system based on SINS is indeed a very accurate shearer positioning technology;

- To improve the positioning accuracy of the shearer positioning system and meet long-term positioning requirements, high-precision instruments and better data processing methods, including high-efficiency filtering technology and map-matching algorithms, can be used or an odometer can be used to correct the navigation data.

6. Limitations

- Compared to an actual operating longwall operation (e.g., 200–400 m for 50–70 min), scale (2 m) and time duration (<120 s) of the experimental evaluation is indeed very small. This also leads to the fact that the experimental results may not reflect the actual situation very accurately. In the future, field experiments will be carried out in the coal mine to verify the conclusions in this paper;

- Compared with existing commercially available solutions, such as Longwall Automation Steering Committee (LASC), Commonwealth Scientific and Industrial Research Organisation (CSIRO), Advanced Shearer Automation (ASA), Joy Global (JOY), etc., those listed may be better than the solutions in this article in terms of accuracy. However, it is well known that the SINS instruments can be used in military weapons, such as missiles, fighter jets and other weapons. An embargo has been imposed upon advanced SINS instruments in China. Even if there are SINS instruments that can be used in China, there are very strict restrictions on their use. On the other hand, the existing commercially available solutions are still too expensive and most coal mines in China cannot afford it. In the event that China cannot obtain advanced SINS instruments, it can look to improve the SINS accuracy based on algorithms, experiments and other aspects. We hope readers can understand the limitations of China’s scientific research in this regard, and also eagerly hope this article will attract the attention of relevant researchers around the world, and to obtain help and guidance from them to improve the theoretical and technical research of shearer positioning in China.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Jinhua, W.; Zenghua, H. The recent technological development of intelligent mining in China. Engineering 2017, 3, 439–444. [Google Scholar]

- Ge, S. Key Technology of Intelligent Coal Mining Equipment. Coal Sci. Technol. 2014, 42, 7–11. [Google Scholar]

- Wang, J.; Huang, Z. Innovation and Development of Intelligent Coal Mining Science and Technology in China. Coal Sci. Technol. 2014, 42, 1–6. [Google Scholar]

- Wang, G.; Zhang, D. Innovation practice and development prospect of intelligent fully mechanized technology for coal mining. J. China Univ. Min. Technol. 2018, 47, 459–467. [Google Scholar]

- Robert, R.; Rahinul, H. Augmenting GPS with Geolocated Fiducials to Improve Accuracy for Mobile Robot Applications. Appl. Sci. 2020, 10, 146. [Google Scholar] [CrossRef]

- Fang, X.; Zhao, J.; Hu, Y. Tests and error analysis of a self-positioning shearer operating at a manless working face. Min. Sci. Technol. 2010, 20, 53–58. [Google Scholar] [CrossRef]

- Wang, G. New development of longwall mining equipment based on automation and intelligent technology for thin seam coal. J. Coal Sci. Eng. 2013, 19, 97–103. [Google Scholar] [CrossRef]

- Zhang, B.; Fang, X.; Zou, Y.; Yu, R.; Cheng, Y. Auto-positioning system of shearer operating on manless working face based on gyroscope and odometer. Min. Process. Equip. 2010, 38, 10–13. [Google Scholar] [CrossRef]

- Reid, D.C.; Dunn, M.T.; Reid, P.B.; Ralston, J.C. A practical inertial navigation solution for continuous miner automation. In Proceedings of the 12th Coal Operators Conference, Univ Wollongong, Wollongong, Australia, 16–17 February 2012; pp. 115–120. [Google Scholar]

- Xinqiu, F.; Jie, H.; Bin, Z.; Minjiang, G. Self-positioning system of the shearer in unmanned workface. J. Xi’an Univ. Sci. Technol. 2008, 28, 349–353. [Google Scholar]

- Reid, D.C.; Hainsworth, D.W.; Ralston, J.C.; McPhee, R.J. Shearer guidance: A major advance in longwall mining. In Proceedings of the 4th International Conference on Field and Service Robotics, Mt Fuji, Japan, 14–16 July 2003. [Google Scholar]

- Zhang, X.; Zhang, P.; Meng, G.; Zhang, X. Development of on time monitoring and measuring system and visualized platform for coal cutting performances of coal shearer. Coal Eng. 2008, 2008, 101–103. [Google Scholar]

- Pytka, J.; Budzynski, P.; Jozwik, J.; Michalowska, J.; Tofil, A.; Lyszczyk, T.; Blazejczak, D. Application of GNSS/INS and an Optical Sensor for Determining Airplane Takeoff and Landing Performance on a Grassy Airfield. Sensors 2019, 19, 5492. [Google Scholar] [CrossRef] [PubMed]

- Hai, Y.; Wei, L.; Chengming, L.; Jinyao, Z.; Zhuoyin, S. Research on error compensation property of strapdown inertial navigation system using dynamic model of shearer. IEEE Access 2016, 4, 2045–2055. [Google Scholar]

- Shixin, L.; Fengrong, H.; Shiqian, Q.; Chaonan, F. SINS/Odometer integrated navigation method based on adaptive strong tracking filter. J. Chin. Inert. Technol. 2018, 26, 156–161. [Google Scholar]

- Hongsong, Z.; Lingjuan, M.; Jun, S. High accuracy algorithm for SINS/Odometer integrated navigation system. Acta Armamentarii 2014, 35, 433–440. [Google Scholar]

- Xiaoyue, Z.; Gongliu, Y.; Chunxi, Z. Integrated navigation method for SINS and odometer. J. Beijing Univ. Aeronaut. Astronaut. 2013, 39, 922–926. [Google Scholar]

- Yang, H.; Li, W.; Chengming, L.; Mengbao, F.; Baohua, Y. Experimental study on position and attitude technique for shearer using SINS measurement. J. China Coal Soc. 2014, 39, 2550–2556. [Google Scholar]

- Qigao, F.; Wei, L.; Chengming, L. Error Analysis and Reduction for Shearer Positioning using the Strapdown Inertial Navigation System. Int. J. Comput. Sci. Issues 2012, 9, 49–54. [Google Scholar]

- Xin, Z.; Zhongbin, W.; Chao, T.; Rui, J.; Xinhua, L. A novel approach for shearer memory cutting based on fuzzy optimization method. Adv. Mech. Eng. 2013, 1, 1–10. [Google Scholar]

- Dolipski, M.; Jaszczuk, M.; Cheluszka, P.; Sobota, P.; Kusak, E.; Kurek, M. Dynamic model of a Shearer’s cutting system. In Proceedings of the 9th International Symposium on Mine Planning Equipment Selection, Athens, Greece, 6–9 November 2000; pp. 541–546. [Google Scholar]

- Bo, W.; Qian, R.; Zhihong, D.; Mengyin, F. A self-calibration method for nonorthogonal angles between gimbals of rotational inertial navigation system. IEEE Trans. Ind. Electron. 2015, 62, 2353–2362. [Google Scholar]

- Feng, Q.; Xingqun, Z.; Lei, Z. Performance assessment of a low-cost inertial measurement unit based ultra-tight global navigation satellite system/inertial navigation system integration for high dynamic applications. IET Radar Sonar Navig. 2014, 8, 828–836. [Google Scholar]

- Bin, Z.; Jiangfeng, Y. Vibration analysis of base structure on SINS using PZT actuators. Turk. Electr. Eng. Comput. Sci. 2012, 20, 901–913. [Google Scholar]

- Paul, S. Coning algorithm design by explicit frequency shaping. J. Guid. Control Dyn. 2010, 33, 1123–1132. [Google Scholar]

- Mario, I. Optimal sculling and coning algorithms for analog-sensor systems. J. Guid. Control Dyn. 2012, 35, 851–860. [Google Scholar]

- John, B. A new mathematical formulation for strapdown inertial navigation. IEEE Trans. Aerosp. Electron. Syst. 1971, AES-7, 61–66. [Google Scholar]

- Oleg, S. Applied Inertial Navigation: Problems and Solutions; BMSTU Press: Moscow, Russia, 2004. [Google Scholar]

- Chul Woo, K.; Nam Ik, C.; Chan Gook, P. Approach to direct coning/sculling error compensation based on the sinusoidal modelling of IMU signal. IET Radar Sonar Navig. 2013, 7, 527–534. [Google Scholar]

- Jizhou, L.; Pin, L.; Jianye, L.; Bin, J. Noncommutativity error analysis of strapdown inertial navigation system under the vibration in UAVs. Int. J. Adv. Robot. Syst. 2012, 9, 1–8. [Google Scholar]

- Qigao, F.; Wei, L.; Yuqiao, W.; Xuefeng, Y. A shearer dynamic positioning method using strap down inertial navigation. J. China Coal Soc. 2011, 36, 1758–1761. [Google Scholar]

- Hai, Y.; Tao, L.; Wei, L.; Li, L.; Yue, R.; ChengMing, L. A Stable SINS/UWB Integrated Positioning Method of Shearer Based on the Multi Model Intelligent Switching Algorithm. IEEE Access 2019, 7, 29128–29138. [Google Scholar]

- Nikitenko, M.S.; Kizilov, S.A.; Kuleshov, V.K. Functional schemes of automated and robotic control of equipment in longwall top coal caving. In Proceedings of the Conference on Challenges for Development in Mining Science and Mining Industry, Russian Academy of Sciences, Siberian Branch, Inst Min, Novosibirsk, Russia, 1–5 October 2018. [Google Scholar]

- Yaping, J.; Zhipeng, X.; Zeyin, Z.; Xinggao, L. A novel shearer cutting pattern recognition model with chaotic gravitational search optimization. Measurement 2019, 144, 225–233. [Google Scholar]

- Post, M.A.; Bianco, A.; Yan, X.T. Autonomous Navigation with Open Software Platform for Field Robots. In Proceedings of the 14th International Conference on Informatics in Control, Automation and Robotics (ICINCO), Madrid, Spain, 26–28 July 2017. [Google Scholar]

- Yong, J.; Suilao, L.; Yongyuan, Q.; Richeng, C. Error analysis and compensation of MEMS rotation modulation inertial navigation system. IEEE Sens. J. 2018, 18, 2023–2030. [Google Scholar] [CrossRef]

- Gustaysson, A. An Efficient Approach for Detecting Moving Objects and Deriving Their Positions and Velocities. In Proceedings of the Computer Vision Conference (CVC), Las Vegas, NV, USA, 25–26 April 2019. [Google Scholar]

- Bo, L.; Yunpei, L.; Quanle, Z. Determination of working resistance based on movement type of the first subordinate key stratum in a fully mechanized face with large mining height. Energy Sci. Eng. 2019, 7, 777–798. [Google Scholar]

- Markiewicz, J.; Abratkiewicz, K.; Gromek, A.; Samczynski, W.; Gromek, D. Geometrical Matching of SAR and Optical Images Utilizing ASIFT Features for SAR-based Navigation Aided Systems. Sensors 2019, 19, 5500. [Google Scholar] [CrossRef] [PubMed]

- Michal, R.; Matej, H. Dead reckoning in a dynamic quadruped robot: Inertial navigation system aided by a legged odometer. In Proceedings of the 2011 IEEE International Conference on Robotics and Automation, Shanghai, China, 9–13 May 2011. [Google Scholar]

- Lubin, C.; Hongyang, H.; Fangjun, Q. In-Motion Initial Alignment for Odometer-Aided Strapdown Inertial Navigation System Based on Attitude Estimation. IEEE Sens. J. 2017, 17, 766–773. [Google Scholar]

- Valmorbida, A.; Mazzucato, M.; Pertile, M. Calibration procedures of a vision-based system for relative motion estimation between satellites flying in proximity. Measurement 2020, 151, 107161. [Google Scholar] [CrossRef]

- Yuming, C.; Wei, L.; Hai, Y.; Ting, X. Research on the Compensation Strategy of the Initial Alignment of the SINS Based on the Dynamic Model of the Shearer. IEEE Access 2019, 7, 36736–36747. [Google Scholar]

- Yuming, C.; Wei, L.; Gaifang, X.; Hai, Y.; Ting, X. An Improved Strong Tracking Kalman Filter Algorithm for the Initial Alignment of the Shearer. Complexity 2019. [Google Scholar] [CrossRef]

- Honglu, H.; Guangyao, L.; Yuan, L. Temperature Characteristic and Compensation of FOG Zero Bias Drift. Process Autom. Instrum. 2019, 40, 59–63, 68. [Google Scholar]

- Siying, G.; Jiangning, X.; Feng, L.; Hongyang, H. Modeling and compensation algorithm of FOG temperature drift with optimized BP neural network. J. Chin. Inert. Technol. 2016, 24, 93–97. [Google Scholar]

| Scheme | Number of Signals | Running Distance (cm) | Displacement Error (cm) |

|---|---|---|---|

| No. 1 | 601 | 198.15 | 1.85 |

| No. 2 | 604 | 199.14 | 0.86 |

| No. 3 | 603 | 198.81 | 1.19 |

| No. 4 | 603 | 198.81 | 1.19 |

| Average value | 602.75 | 198.73 | 1.27 |

| Scheme | Endpoint Coordinates | Running Distance Error (cm) | Angle Error (°) |

|---|---|---|---|

| No. 1 | (2.03,−0.01) | 3 | −0.04 |

| No. 2 | (1.89,−0.01) | 11 | −0.25 |

| No. 3 | (2.04,0.01) | 4 | 0.02 |

| No. 4 | (1.95,−0.01) | 5 | −0.03 |

| Average value | — | 5.8 | 0.085 |

| Scheme | Sumping Position (m) | Running Time (s) |

|---|---|---|

| No. 5 | 0.2 | 60 |

| No. 6 | 0.2 | 120 |

| No. 7 | 0.9 | 60 |

| No. 8 | 0.9 | 120 |

| No. 9 | 1.6 | 60 |

| No. 10 | 1.6 | 120 |

| Scheme | Heading Angle in Curved Section (°) | Angle Error in Curved Section (°) | Heading Angle at the Endpoint (°) | Angle Error at the Endpoint (°) |

|---|---|---|---|---|

| No. 5 | −4.96 | 0.04 | −0.23 | 0.23 |

| No. 6 | −4.49 | 0.51 | −2.82 | 2.82 |

| No. 7 | −4.53 | 0.47 | 1.76 | 1.76 |

| No. 8 | −3.62 | 1.38 | −0.55 | 0.55 |

| No. 9 | −3.53 | 1.47 | −1.13 | 1.13 |

| No. 10 | −4.94 | 0.06 | −1.66 | 1.66 |

| Average value | — | 0.655 | — | 1.35 |

| Scheme | Number of Signals | Running Distance (cm) | Displacement Error (cm) |

|---|---|---|---|

| No. 5 | 605 | 199.47 | 0.53 |

| No. 6 | 604 | 199.14 | 0.86 |

| No. 7 | 604 | 199.14 | 0.86 |

| No. 8 | 605 | 199.47 | 0.53 |

| No. 9 | 605 | 199.47 | 0.53 |

| No. 10 | 604 | 199.14 | 0.86 |

| Average value | 604.5 | 199.305 | 0.695 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, G.; Fang, X.; Zhang, L.; Liang, M.; Lv, J.; Quan, Z. Positioning Accuracy of the Shearer Based on a Strapdown Inertial Navigation System in Underground Coal Mining. Appl. Sci. 2020, 10, 2176. https://doi.org/10.3390/app10062176

Wu G, Fang X, Zhang L, Liang M, Lv J, Quan Z. Positioning Accuracy of the Shearer Based on a Strapdown Inertial Navigation System in Underground Coal Mining. Applied Sciences. 2020; 10(6):2176. https://doi.org/10.3390/app10062176

Chicago/Turabian StyleWu, Gang, Xinqiu Fang, Lei Zhang, Minfu Liang, Jiakun Lv, and Zhiqiao Quan. 2020. "Positioning Accuracy of the Shearer Based on a Strapdown Inertial Navigation System in Underground Coal Mining" Applied Sciences 10, no. 6: 2176. https://doi.org/10.3390/app10062176

APA StyleWu, G., Fang, X., Zhang, L., Liang, M., Lv, J., & Quan, Z. (2020). Positioning Accuracy of the Shearer Based on a Strapdown Inertial Navigation System in Underground Coal Mining. Applied Sciences, 10(6), 2176. https://doi.org/10.3390/app10062176