Removal of Cu(II) from Aqueous Solutions Using Amine-Doped Polyacrylonitrile Fibers

Abstract

1. Introduction

2. Materials and Methods

2.1. Reagents

2.2. Preparation of Electrospun PAN Fiber

2.3. Modification of PAN Fibers

2.4. Adsorption Experiments

2.5. Adsorption Model Analyses

3. Results and Discussion

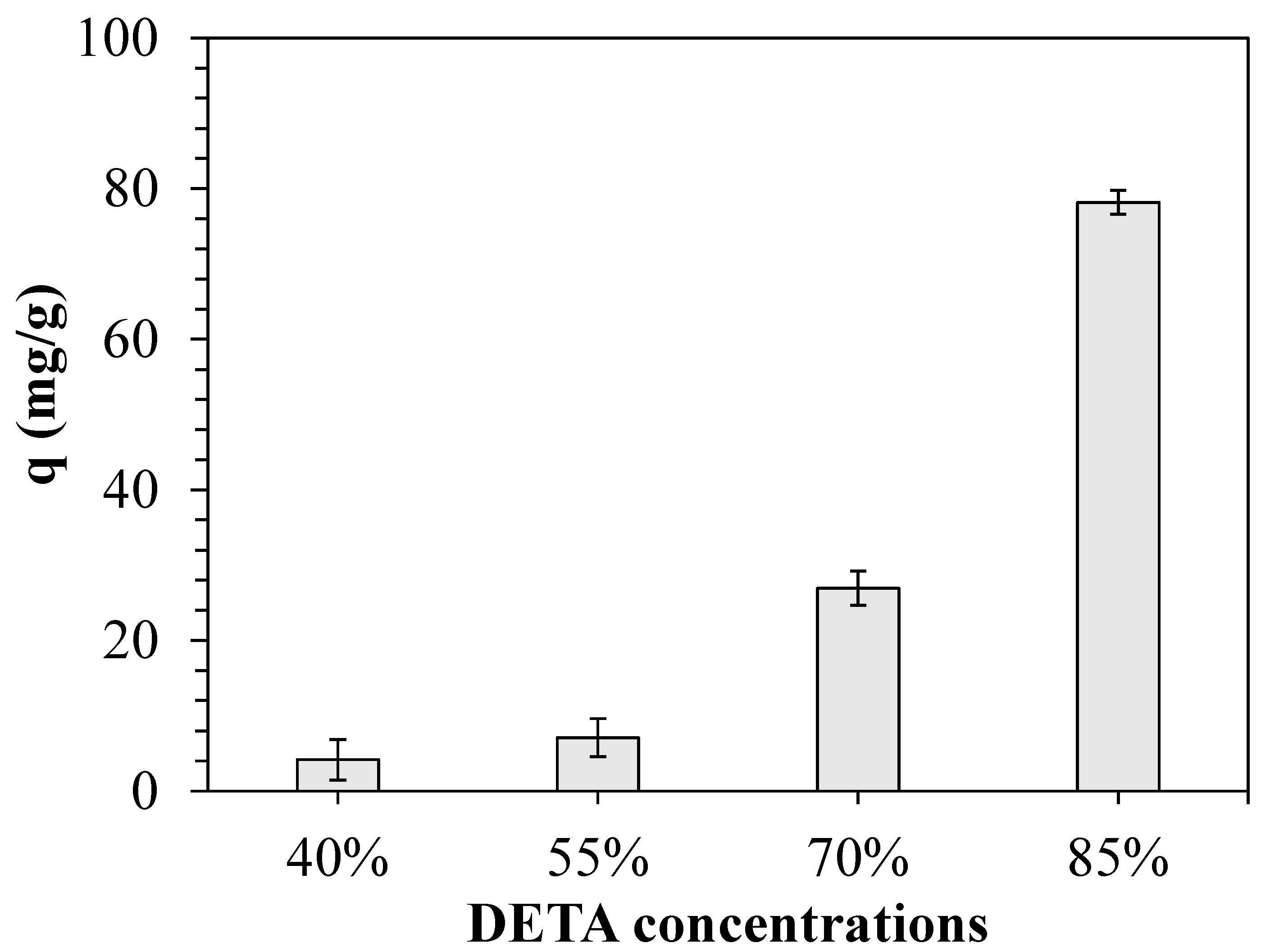

3.1. Effect of DETA Concentration on Surface Modification of PAN Fibers Used for Cu(II) Removal

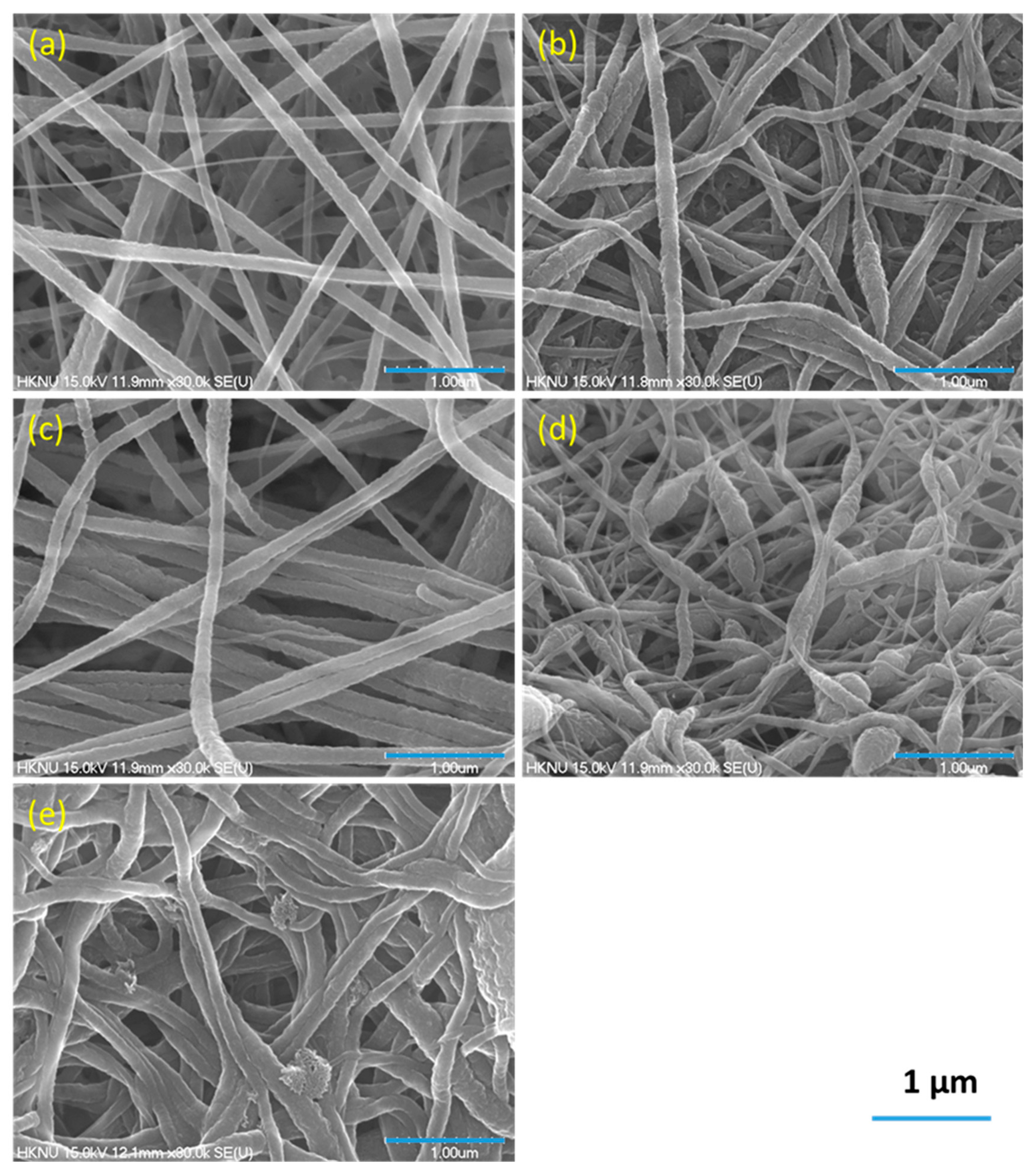

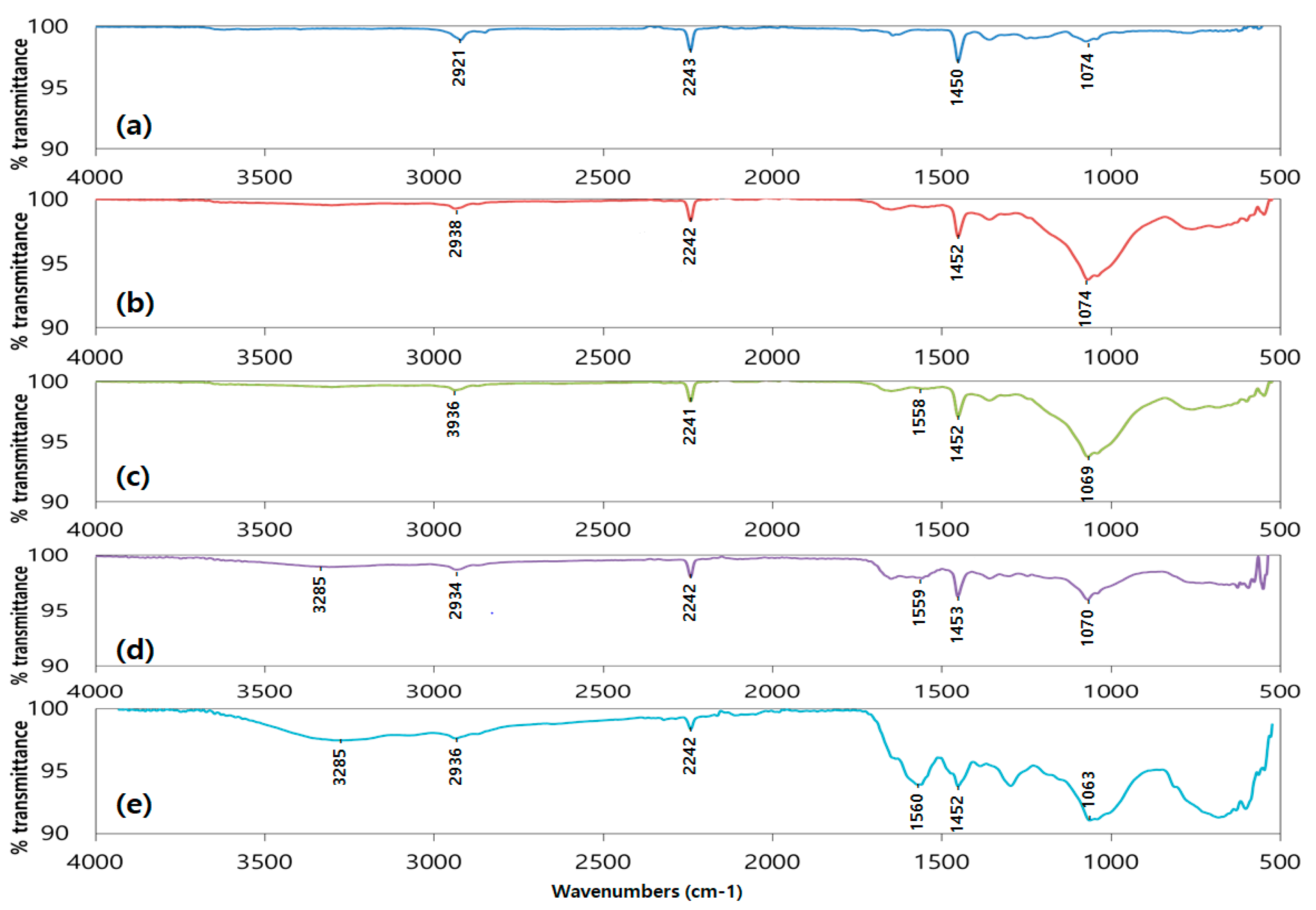

3.2. Characterization of Surface Modification of PAN Fibers

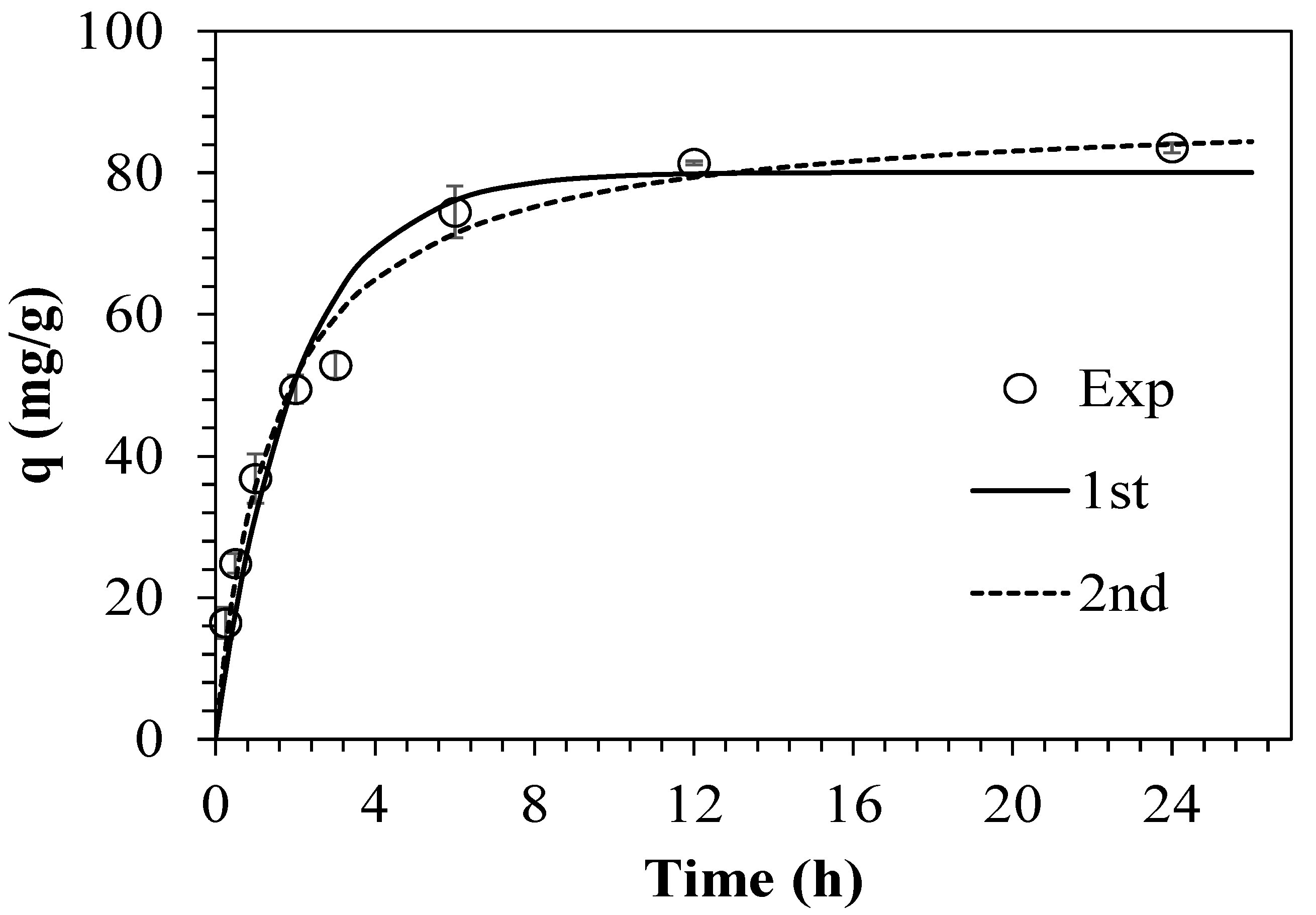

3.3. Adsorption Kinetics

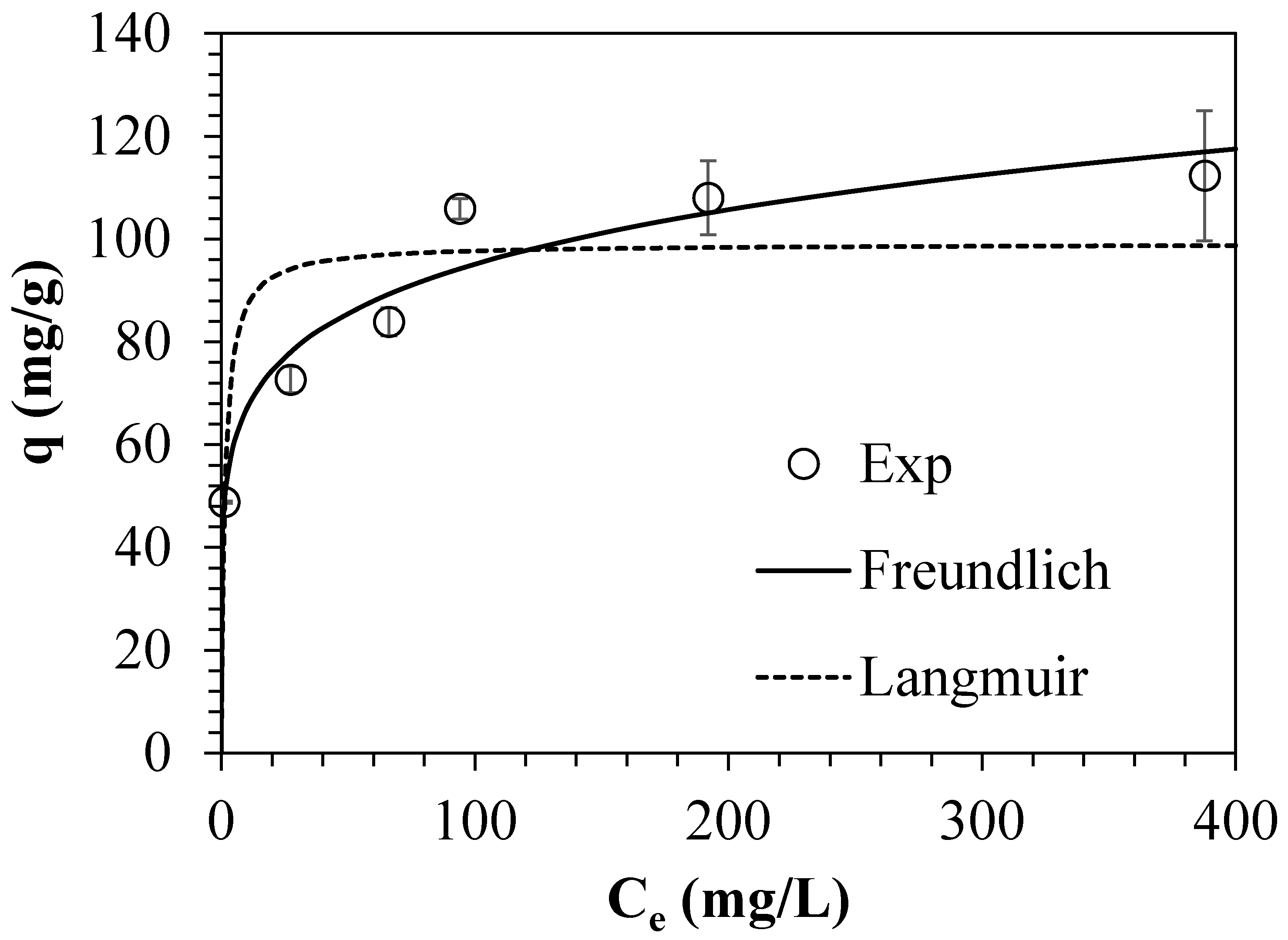

3.4. Adsorption Isotherms

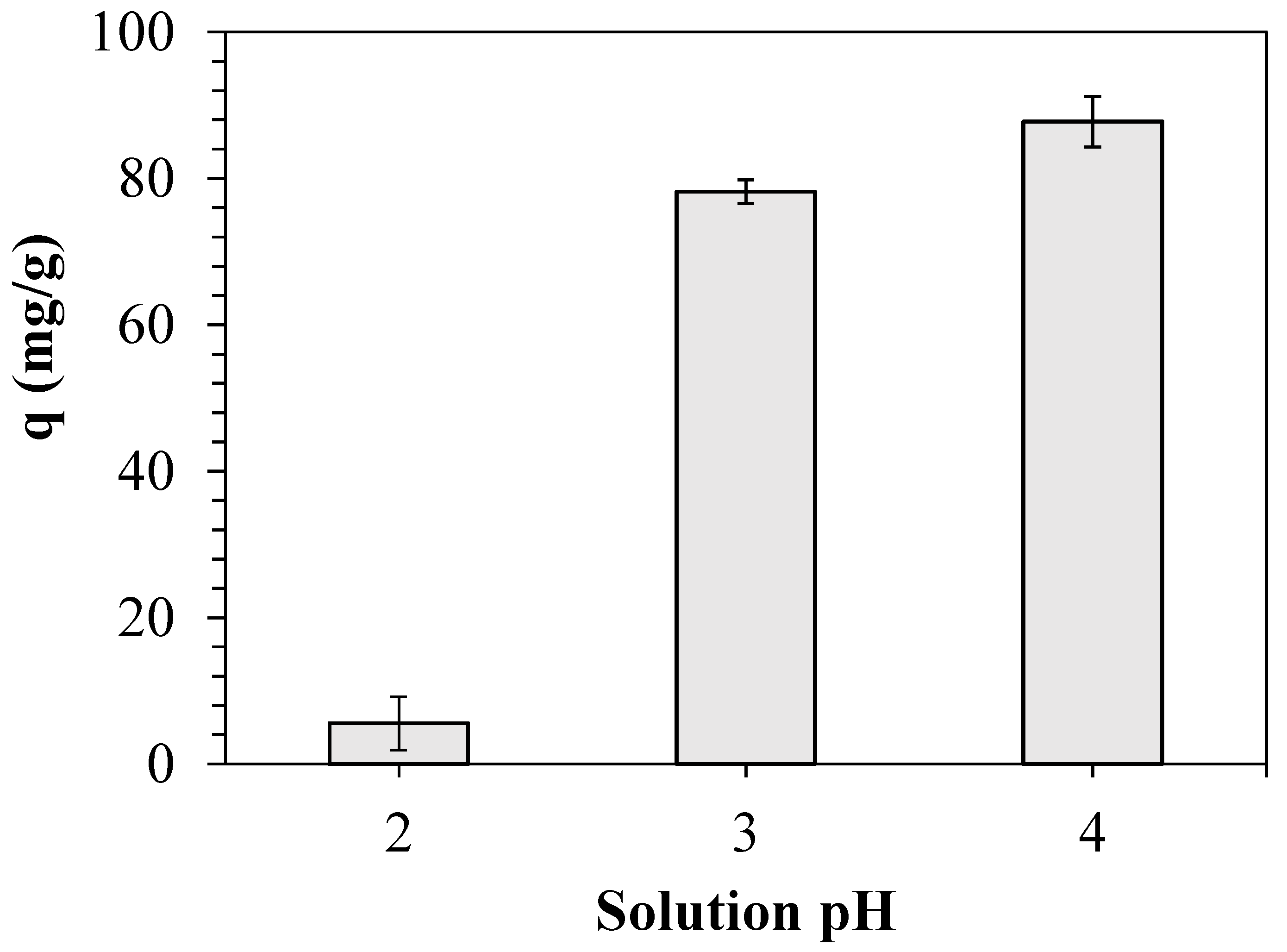

3.5. Effect of Solution pH on Cu(II) Adsorption

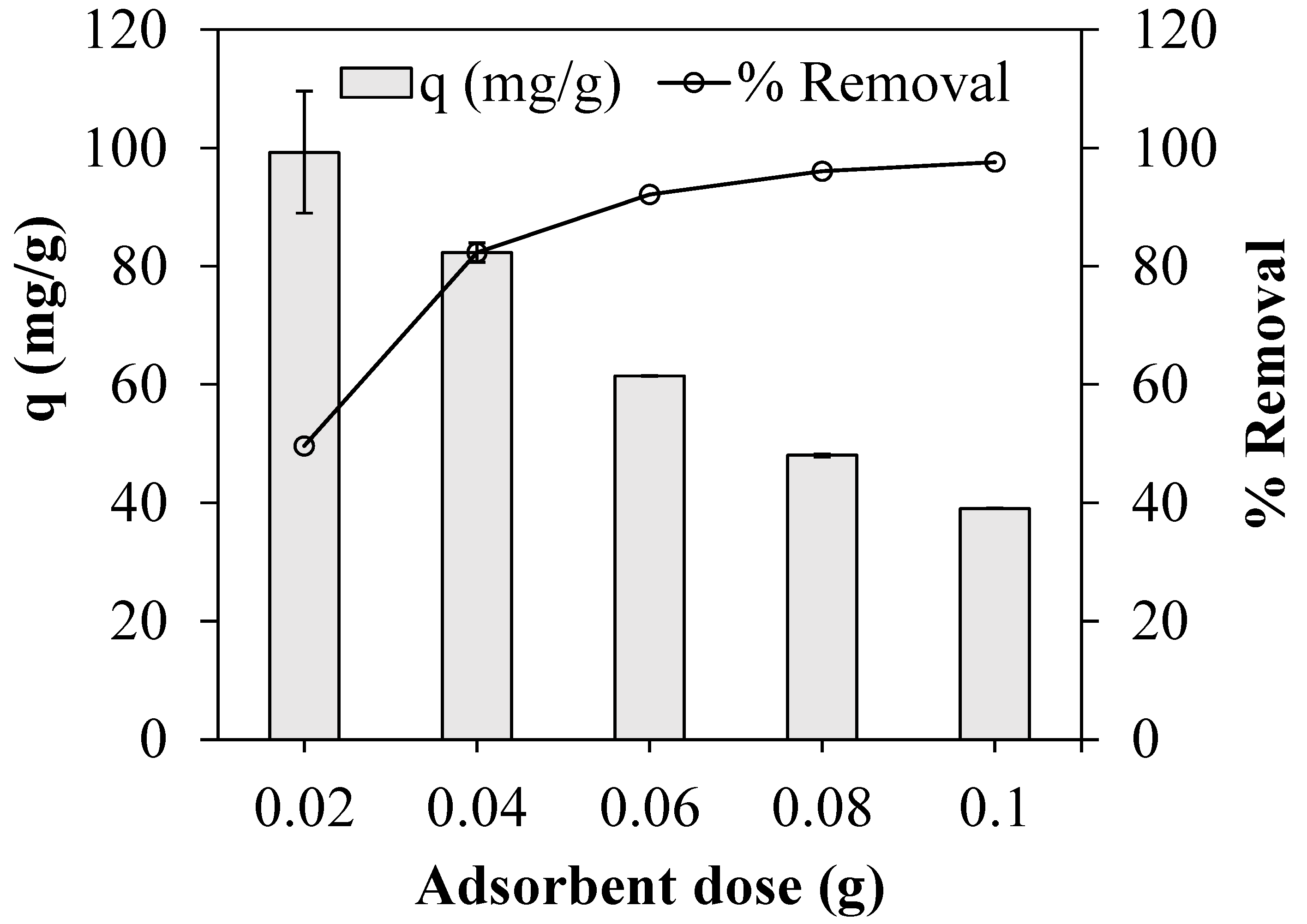

3.6. Effect of Adsorbent Dosage

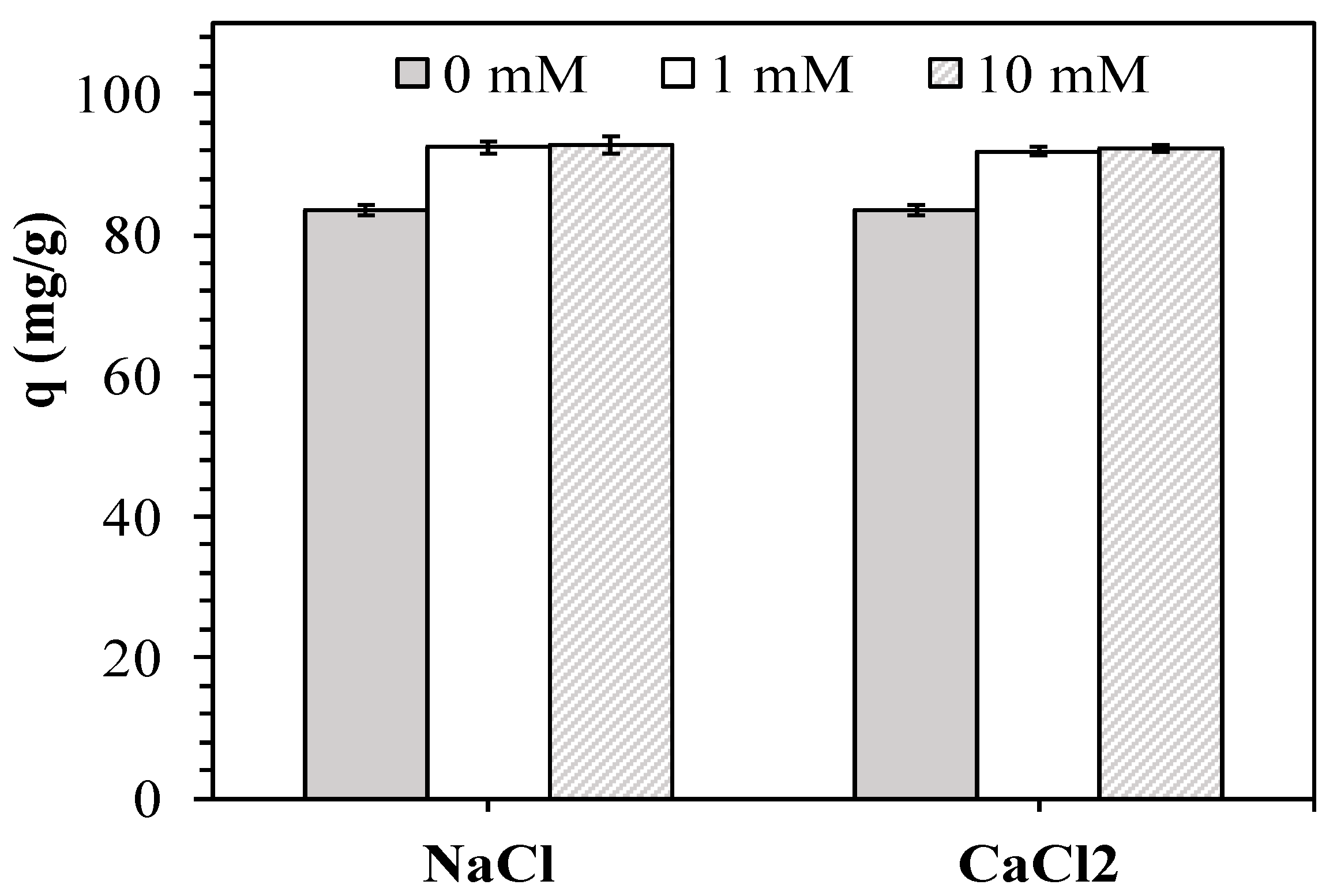

3.7. Effect of Coexisting Cations

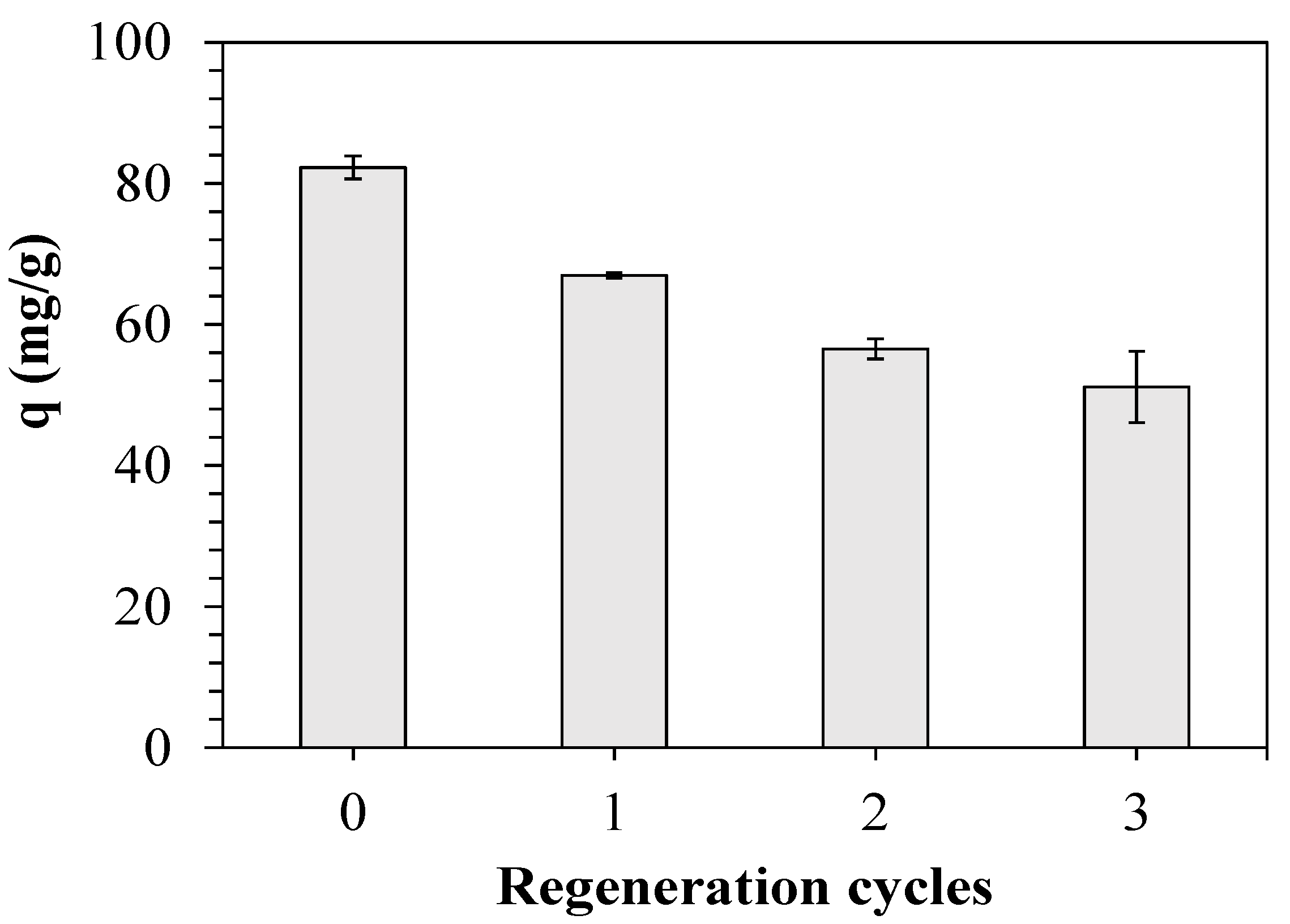

3.8. Regeneration Study

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Abdouss, M.; Shoushtari, M.A.; Haji, A.; Moshref, B. Fabrication of chelating diethylenetriaminated pan micro-and nano-fibers for heavy metal removal. Chem. Ind. Chem. Eng. Q. 2012, 18, 27–34. [Google Scholar] [CrossRef]

- Kampalanonwat, P.; Supaphol, P. Preparation and adsorption behavior of aminated electrospun polyacrylonitrile nanofiber mats for heavy metal ion removal. ACS Appl. Mater. Interfaces 2010, 2, 3619–3627. [Google Scholar] [CrossRef] [PubMed]

- Haider, S.; Park, S.-Y. Preparation of the electrospun chitosan nanofibers and their applications to the adsorption of Cu (II) and Pb (II) ions from an aqueous solution. J. Membr. Sci. 2009, 328, 90–96. [Google Scholar] [CrossRef]

- IPCS; World Health Organization. International Programme on Chemical Safety; World Health Organization: Geneva, Switzerland, 1998. [Google Scholar]

- Holleman, A.; Wiberg, E. Inorganic Chemistry; Academic Press: Berlin, Germany; New York, NY, USA, 2001. [Google Scholar]

- Trammell, R.; Rajabimoghadam, K.; Garcia-Bosch, I. Copper-promoted functionalization of organic molecules: From biologically relevant Cu/O2 model systems to organometallic transformations. Chem. Rev. 2019, 119, 2954–3031. [Google Scholar] [CrossRef]

- Rengaraj, S.; Yeon, J.-W.; Kim, Y.; Jung, Y.; Ha, Y.-K.; Kim, W.-H. Adsorption characteristics of Cu (II) onto ion exchange resins 252H and 1500H: Kinetics, isotherms and error analysis. J. Hazard. Mater. 2007, 143, 469–477. [Google Scholar] [CrossRef]

- Yang, C.Y.; Fang, L.; Nguyen, N.T.; Ma, C.M.; Chang, C.T. Preparation of amine-modified polyacrylonitrile fibers: Copper removal in aqueous solution. J. Nanosci. Nanotechnol. 2016, 16, 1945–1951. [Google Scholar] [CrossRef]

- World Health Organization. Copper in Drinking-Water: Background Document for Development of WHO Guidelines for Drinking Water Quality; World Health Organization: Geneva, Switzerland, 2004. [Google Scholar]

- Adeeyo, R.O.; Edokpayi, J.N.; Bello, O.S.; Adeeyo, A.O.; Odiyo, J.O. Influence of selective conditions on various composite sorbents for enhanced removal of copper (II) ions from aqueous environments. Int. J. Environ. Res. Public Health 2019, 16, 4596. [Google Scholar] [CrossRef]

- Neghlani, P.K.; Rafizadeh, M.; Taromi, F.A. Preparation of aminated-polyacrylonitrile nanofiber membranes for the adsorption of metal ions: Comparison with microfibers. J. Hazard. Mater. 2011, 186, 182–189. [Google Scholar] [CrossRef]

- Rosskopfová, O.; Galamboš, M.; Ometáková, J.; Čaplovičová, M.; Rajec, P. Study of sorption processes of copper on synthetic hydroxyapatite. J. Radioanal. Nucl. Chem. 2012, 293, 641–647. [Google Scholar] [CrossRef]

- Viglašová, E.; Daňo, M.; Galamboš, M.; Krajňák, A.; Rosskopfová, O.; Rajec, P. Investigation of Cu(II) adsorption on Slovak bentonites and illite/smectite for agricultural applications. J. Radioanal. Nucl. Chem. 2017, 314, 2425–2435. [Google Scholar] [CrossRef]

- Wang, H.-S.; Fu, G.-D.; Li, X.-S. Functional polymeric nanofibers from electrospinning. Recent Pat. Nanotechnol. 2009, 3, 21–31. [Google Scholar] [CrossRef] [PubMed]

- Pereao, O.; Bode-Aluko, C.; Ndayambaje, G.; Fatoba, O.; Petrik, L. Electrospinning: Polymer nanofibre adsorbent applications for metal ion removal. J. Polym. Environ. 2017, 25, 1175–1189. [Google Scholar] [CrossRef]

- Gallo-Cordova, A.; Morales, M.d.P.; Mazarío, E. Effect of the surface charge on the adsorption capacity of chromium(VI) of iron oxide magnetic nanoparticles prepared by microwave-assisted synthesis. Water 2019, 11, 2372. [Google Scholar] [CrossRef]

- Almasian, A.; Olya, M.E.; Mahmoodi, N.M. Preparation and adsorption behavior of diethylenetriamine/polyacrylonitrile composite nanofibers for a direct dye removal. Fiber Polym. 2015, 16, 1925–1934. [Google Scholar] [CrossRef]

- Nesteronok, P.V.; Soldatov, V.S. Acid–base properties of ion exchangers: V. Synthesis and properties of ion exchangers on the base of modacrylic polyacrylonitrile–vinylchloride fibers. React. Funct. Polym. 2011, 71, 1033–1039. [Google Scholar] [CrossRef]

- Lee, C.G.; Alvarez, P.J.; Nam, A.; Park, S.J.; Do, T.; Choi, U.S.; Lee, S.H. Arsenic(V) removal using an amine-doped acrylic ion exchange fiber: Kinetic, equilibrium, and regeneration studies. J. Hazard. Mater. 2017, 325, 223–229. [Google Scholar] [CrossRef]

- El-Newehy, M.H.; Alamri, A.; Al-Deyab, S.S. Optimization of amine-terminated polyacrylonitrile synthesis and characterization. Arab. J. Chem. 2014, 7, 235–241. [Google Scholar] [CrossRef]

- Karacan, I.; Erdogan, G. The influence of thermal stabilization stage on the molecular structure of polyacrylonitrile fibers prior to the carbonization stage. Fiber Polym. 2012, 13, 295–302. [Google Scholar] [CrossRef]

- Lim, A.; Song, M.-H.; Cho, C.-W.; Yun, Y.-S. Development of surface-modified polyacrylonitrile fibers and their selective sorption behavior of precious metals. Appl. Sci. 2016, 6, 378. [Google Scholar] [CrossRef]

- Fu, H.; Quan, X. Complexes of fulvic acid on the surface of hematite, goethite, and akaganeite: FTIR observation. Chemosphere 2006, 63, 403–410. [Google Scholar] [CrossRef]

- Chaúque, E.F.; Dlamini, L.N.; Adelodun, A.A.; Greyling, C.J.; Ngila, J.C. Electrospun polyacrylonitrile nanofibers functionalized with EDTA for adsorption of ionic dyes. Phys. Chem. Earth Part A Solid Earth Geod. 2017, 100, 201–211. [Google Scholar] [CrossRef]

- Ren, J.; Yan, C.; Liu, Q.; Yang, Q.; Lu, G.; Song, Y.; Li, Y. Preparation of amidoxime-modified polyacrylonitrile nanofibrous adsorbents for the extraction of copper (II) and lead (II) ions and dye from aqueous media. J. Appl. Polym. Sci. 2018, 135, 45697. [Google Scholar] [CrossRef]

- Lee, C.-G.; Park, J.-A.; Choi, J.-W.; Ko, S.-O.; Lee, S.-H. Removal and recovery of Cr(VI) from industrial plating wastewater using fibrous anion exchanger. Water Air Soil Pollut. 2016, 227. [Google Scholar] [CrossRef]

- Zhang, X.; Guo, S.; Liu, J.; Zhang, Z.; Song, K.; Tan, C.; Li, H. A Study on the removal of copper (II) from aqueous solution using lime sand bricks. Appl. Sci. 2019, 9, 670. [Google Scholar] [CrossRef]

- Lee, J.I.; Hong, S.H.; Lee, C.G.; Park, S.J. Experimental and model study for fluoride removal by thermally activated sepiolite. Chemosphere 2020, 241, 125094. [Google Scholar] [CrossRef] [PubMed]

- Acisli, O.; Khataee, A.; Darvishi Cheshmeh Soltani, R.; Karaca, S. Ultrasound-assisted Fenton process using siderite nanoparticles prepared via planetary ball milling for removal of reactive yellow 81 in aqueous phase. Ultrason. Sonochem. 2017, 35, 210–218. [Google Scholar] [CrossRef]

- Chang, D.T.; Park, D.; Zhu, J.-J.; Fan, H.-J. Assessment of an MnCe-GAC treatment process for tetramethylammonium-contaminated wastewater from optoelectronic industries. Appl. Sci. 2019, 9, 4578. [Google Scholar] [CrossRef]

| Pseudo-First-Order Kinetic Model | Pseudo-Second-Order Kinetic Model | ||||

|---|---|---|---|---|---|

| k1 (1/h) | qe (mg/g) | R2 | k2 (g/(mg h)) | qe (mg/g) | R2 |

| 0.500 | 80.06 | 0.968 | 0.007 | 89.36 | 0.984 |

| Langmuir Model | Freundlich Model | ||||

|---|---|---|---|---|---|

| KL (L/mg) | qm (mg/g) | R2 | KF (L/g) | 1/n | R2 |

| 0.703 | 99.06 | 0.679 | 47.06 | 0.153 | 0.928 |

| Materials | Conditions | q (mg/g) | Reference |

|---|---|---|---|

| Synthetic hydroxyapatite | Initial concentration = 6355 mg/L; pH = 3 | 50.2 | [12] |

| Bentonite | Initial concentration = 3177 mg/L; pH = 5 | 27.6 | [13] |

| Lime sand brick | Initial concentration = 30 mg/L; pH = 5 | 7.0 | [27] |

| Surface-doped PAN fiber | Initial concentration = 1000 mg/L; pH = 6 | 143.5 | [25] |

| Initial concentration = 10 mg/L; pH = 6 | 45.0 | [8] | |

| Initial concentration = 1000 mg/L; pH = 4 | 150.6 | [2] | |

| Initial concentration = 500 mg/L; pH = 4 | 112.3 | This study |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aung, K.T.; Hong, S.-H.; Park, S.-J.; Lee, C.-G. Removal of Cu(II) from Aqueous Solutions Using Amine-Doped Polyacrylonitrile Fibers. Appl. Sci. 2020, 10, 1738. https://doi.org/10.3390/app10051738

Aung KT, Hong S-H, Park S-J, Lee C-G. Removal of Cu(II) from Aqueous Solutions Using Amine-Doped Polyacrylonitrile Fibers. Applied Sciences. 2020; 10(5):1738. https://doi.org/10.3390/app10051738

Chicago/Turabian StyleAung, Kay Thwe, Seung-Hee Hong, Seong-Jik Park, and Chang-Gu Lee. 2020. "Removal of Cu(II) from Aqueous Solutions Using Amine-Doped Polyacrylonitrile Fibers" Applied Sciences 10, no. 5: 1738. https://doi.org/10.3390/app10051738

APA StyleAung, K. T., Hong, S.-H., Park, S.-J., & Lee, C.-G. (2020). Removal of Cu(II) from Aqueous Solutions Using Amine-Doped Polyacrylonitrile Fibers. Applied Sciences, 10(5), 1738. https://doi.org/10.3390/app10051738