Eliminating the Effect of Uncertainties of Cutting Forces by Fuzzy Controller for Robots in Milling Process

Abstract

1. Introduction

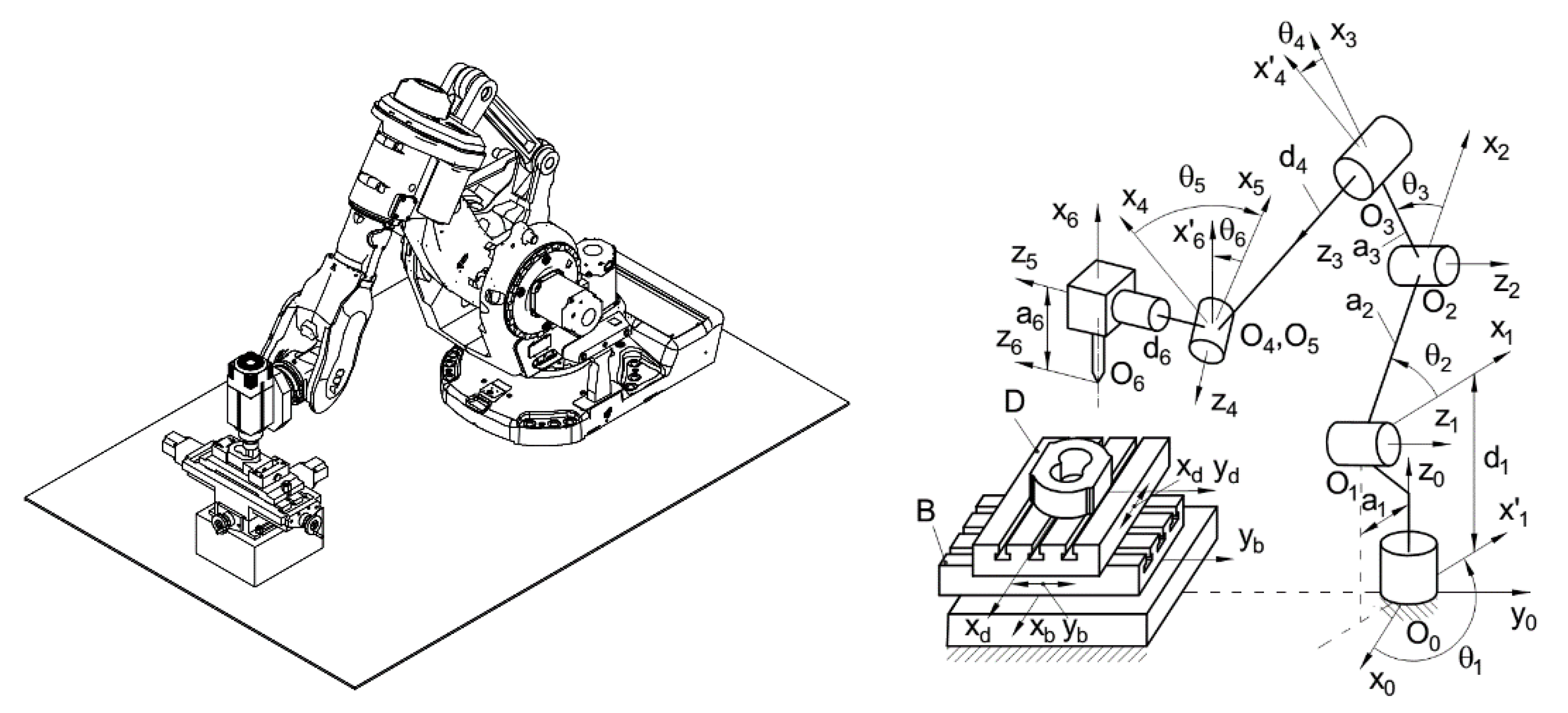

2. Robot Kinematic Modeling

3. Robot Dynamic Modeling

3.1. Differential Equations of Motion of the Robot

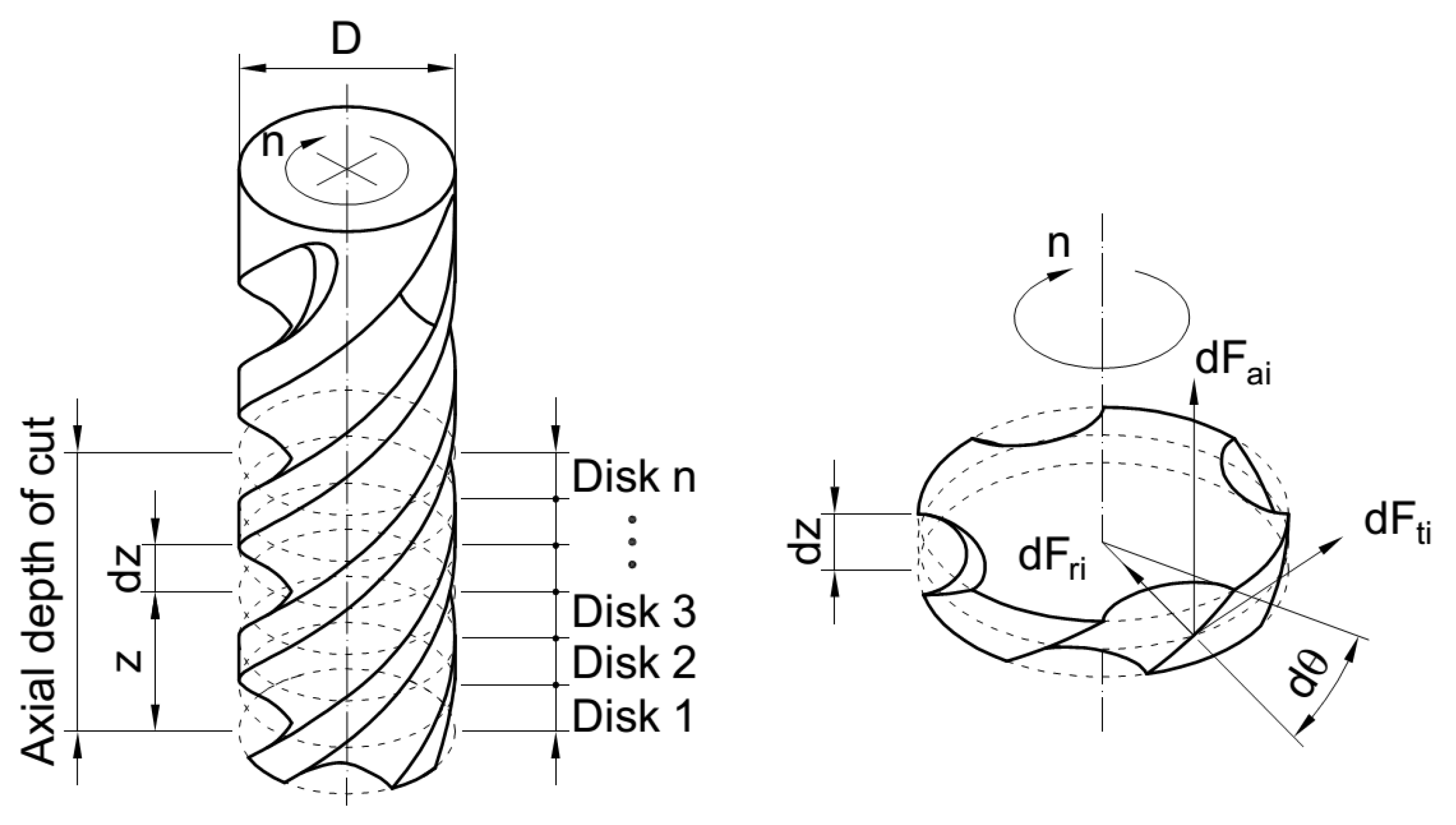

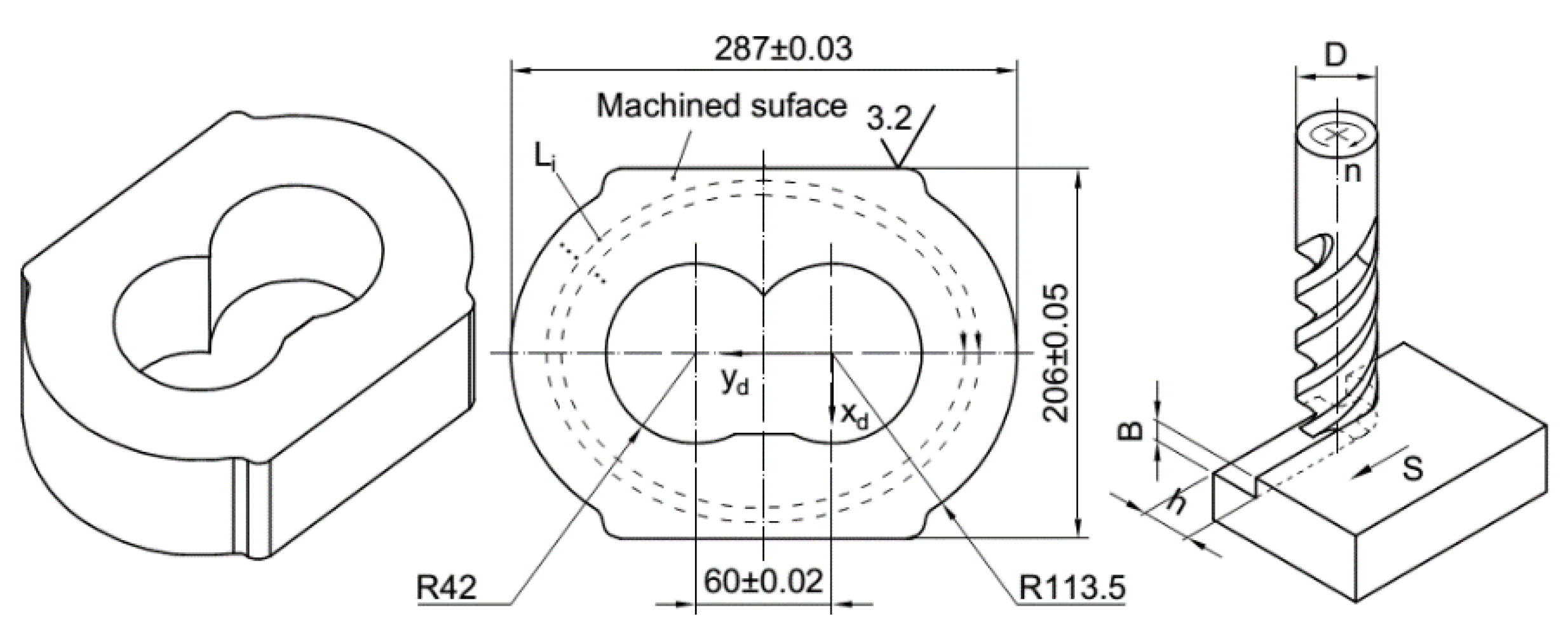

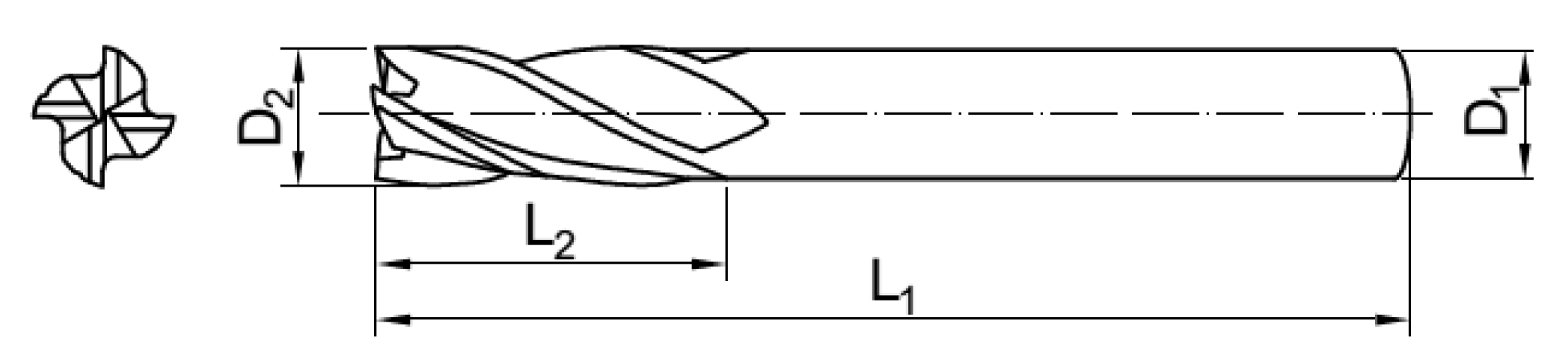

3.2. Cutting Forces in Milling

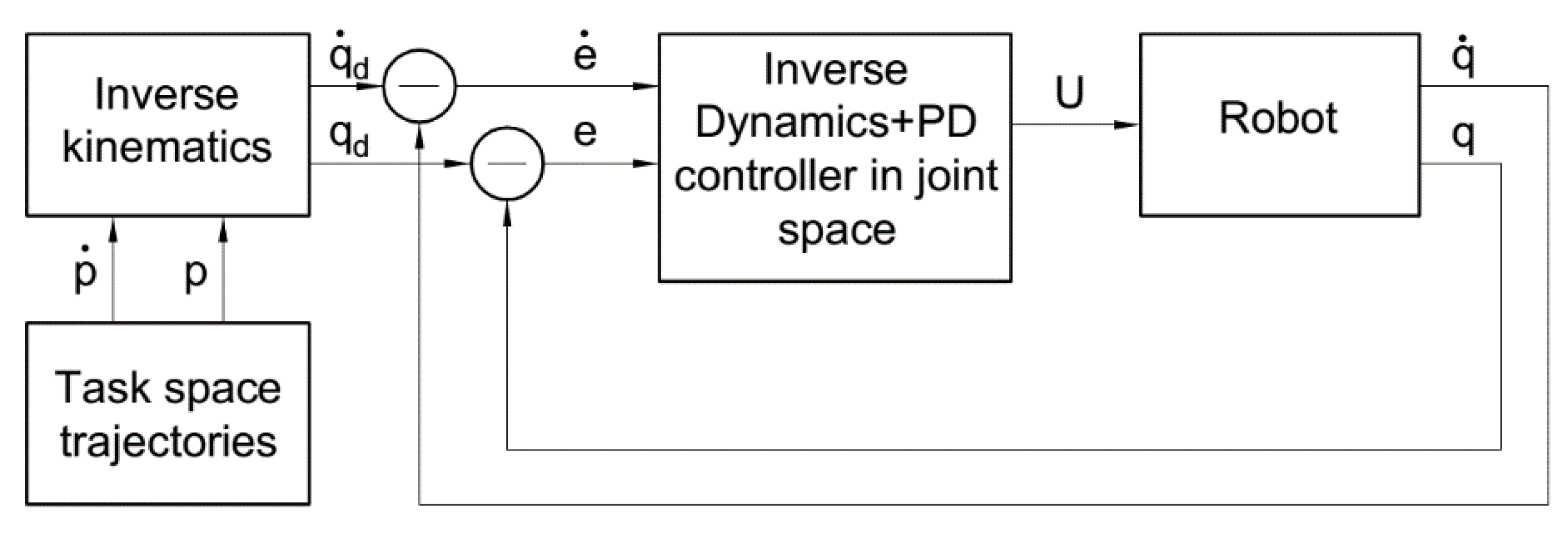

4. Inverse Dynamics + PD Controller

5. The Controller Based on Fuzzy Logic

5.1. Select the Input, Output Signals and Physical Value Domains

5.1.1. Select Input and Output Signals

5.1.2. Determine the Physical Value Domains for Control Signals

5.2. Fuzzification of Input and Output Signal Datas

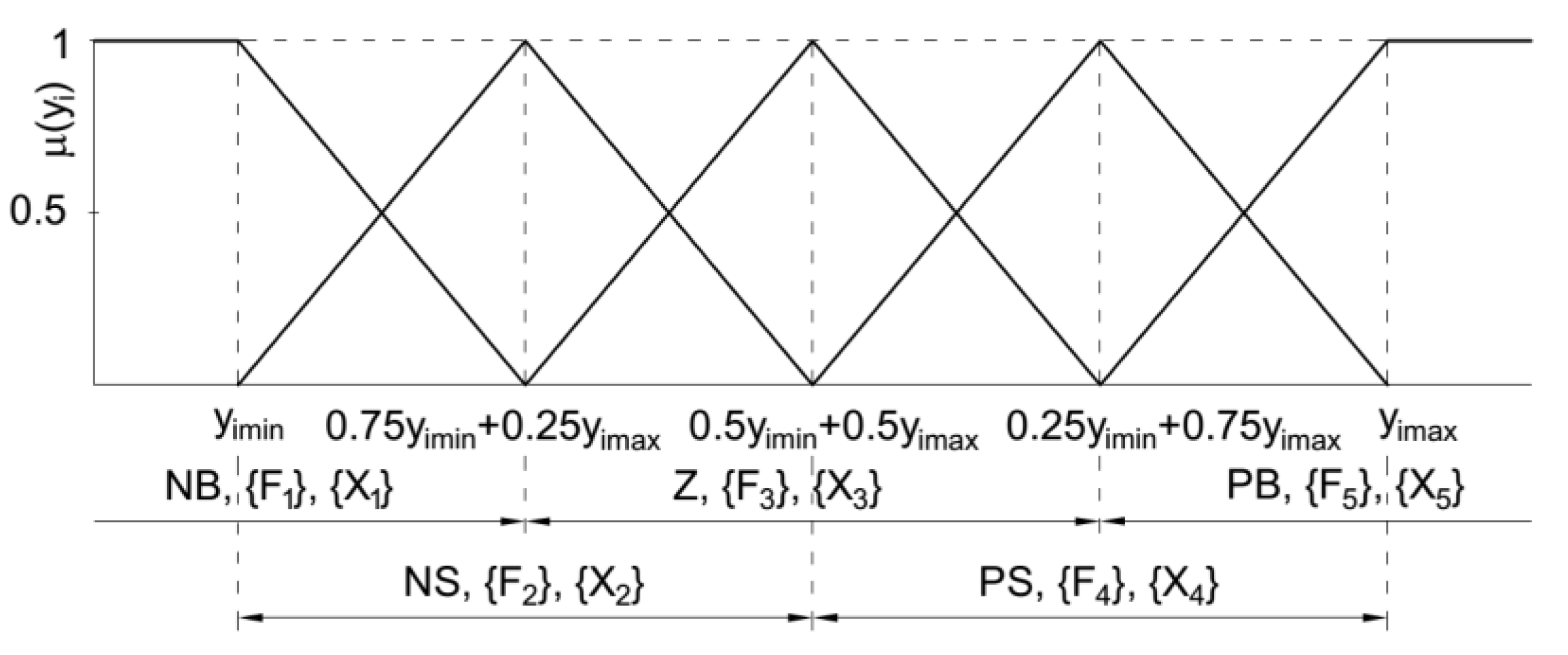

5.2.1. Build Linguistic Variables

5.2.2. Set up Membership Function of the Errors of Position, Velocity and the Amount of Joint Force/Torque Adjustments

5.3. Set up the Control Laws

5.4. Set up the Compositional Rule of Inference for the Fuzzy Controller

5.5. Defuzzification

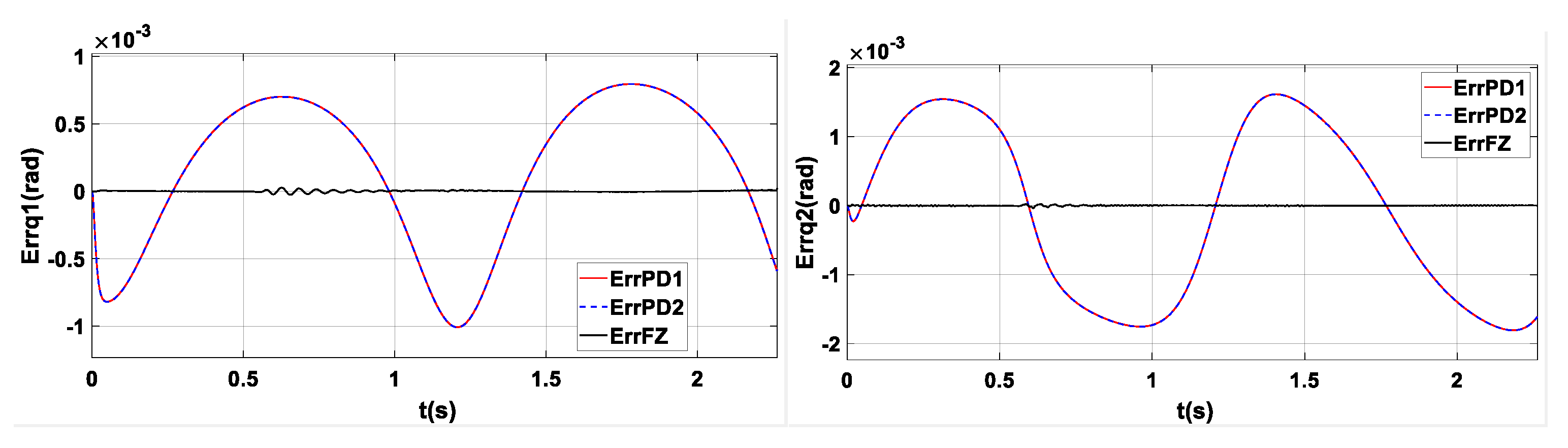

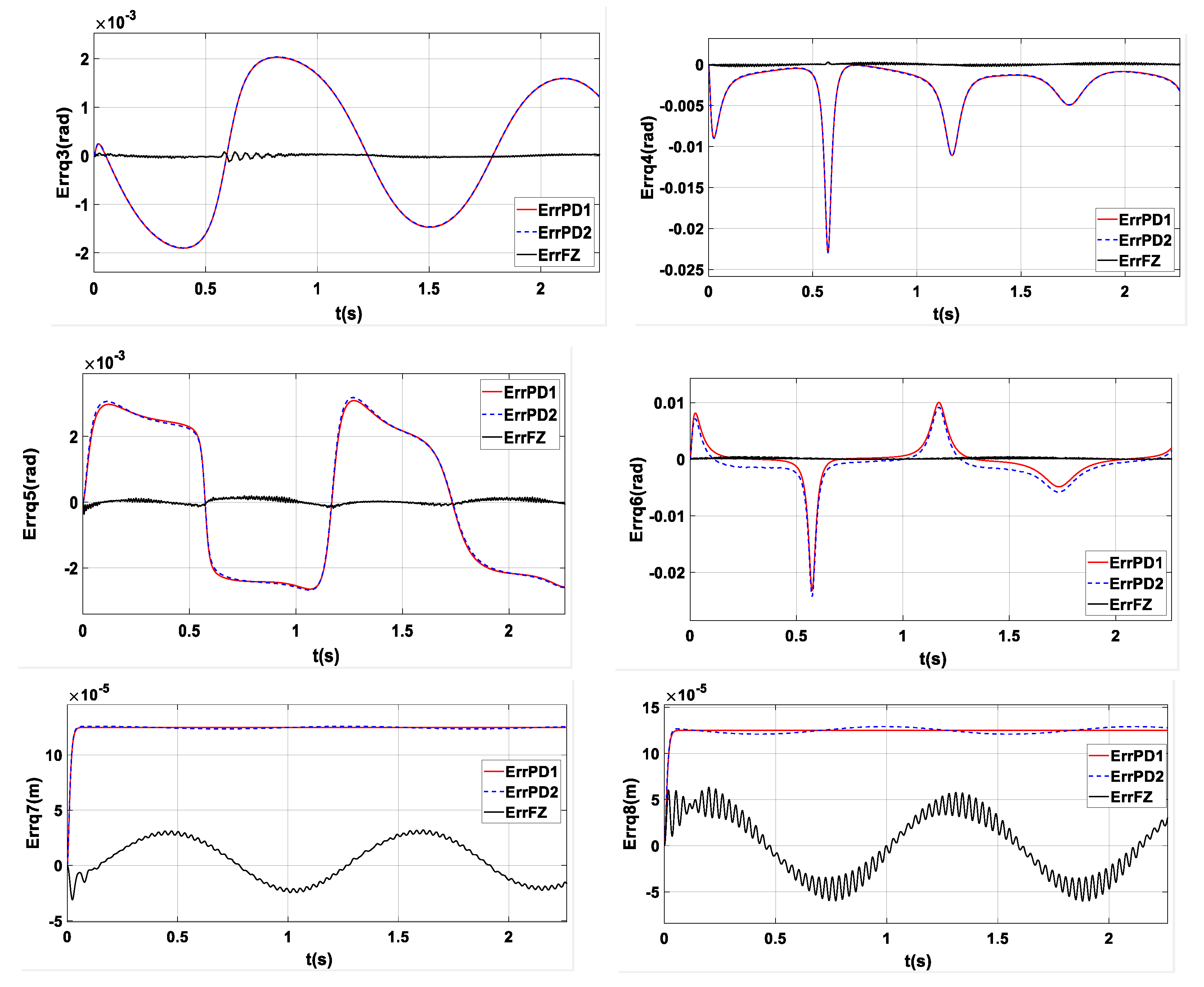

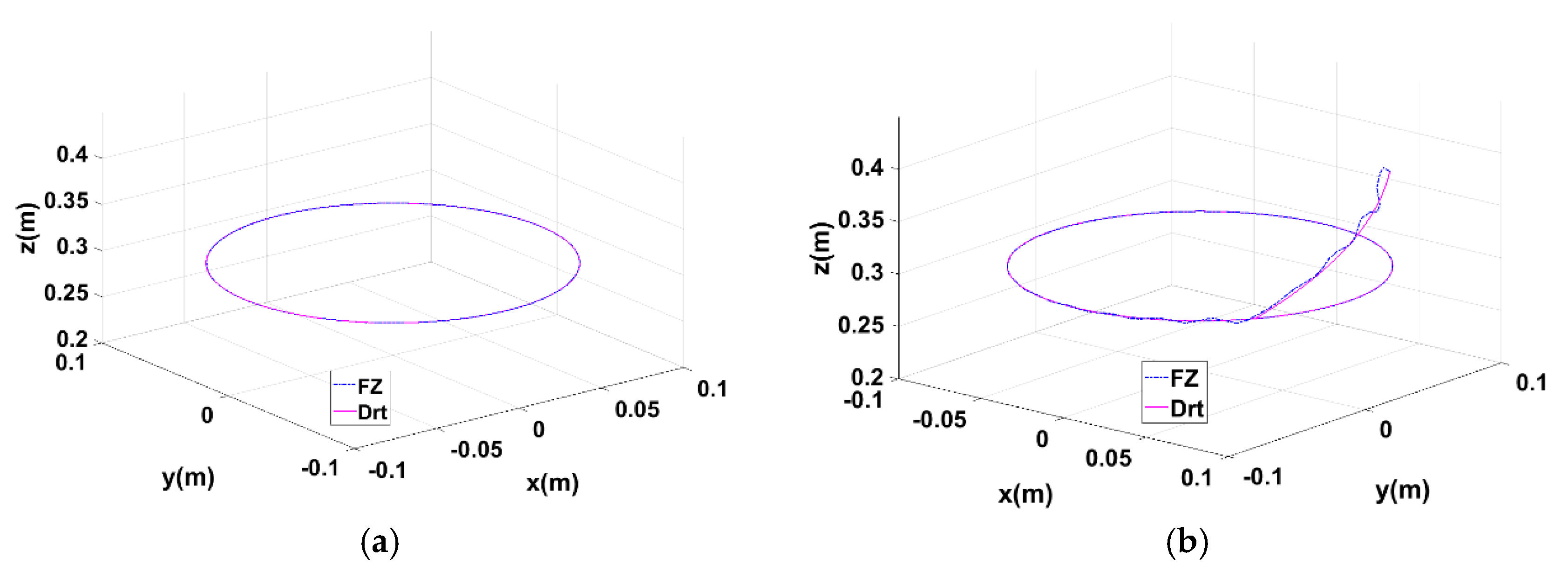

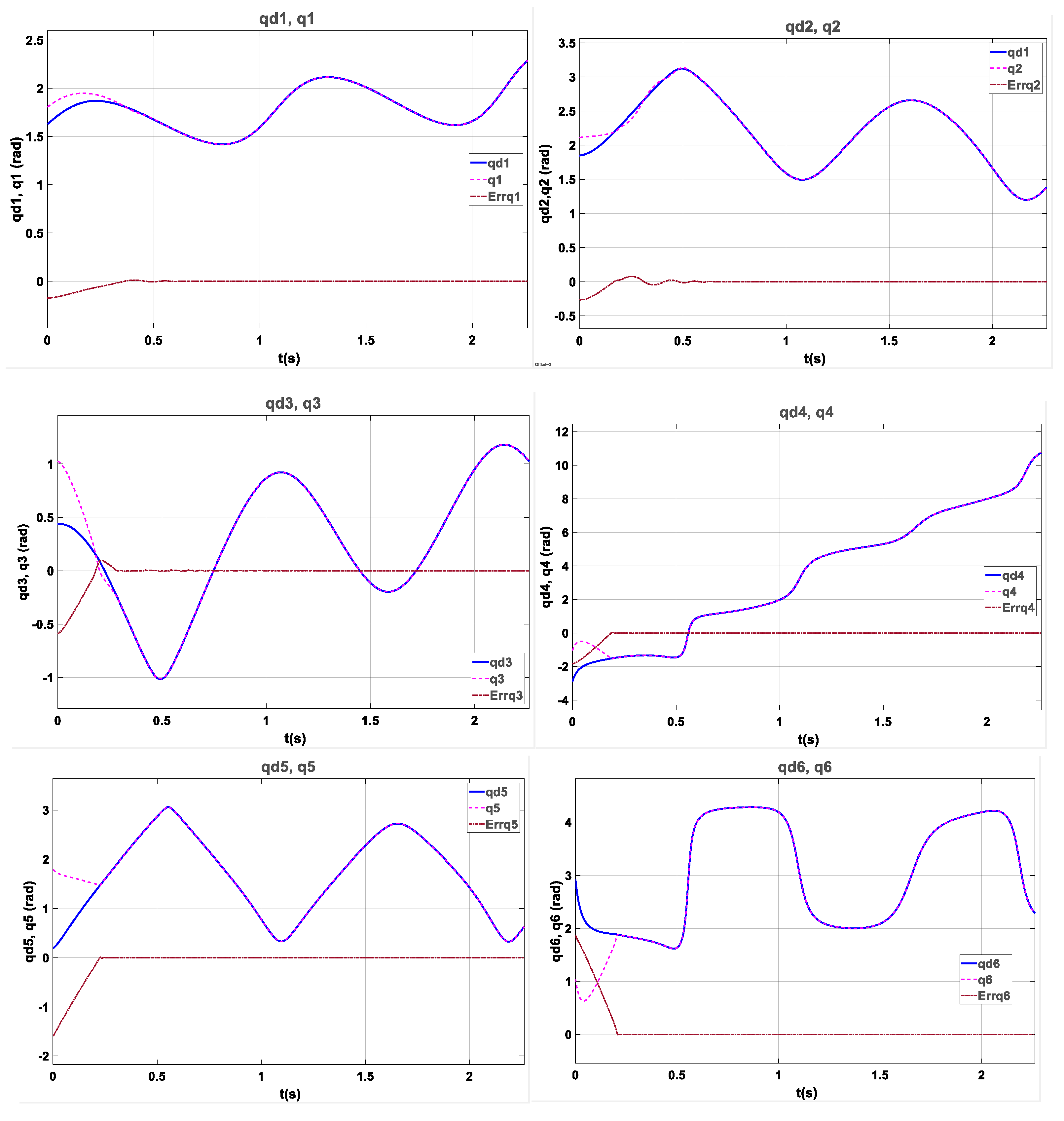

6. Simulation Results

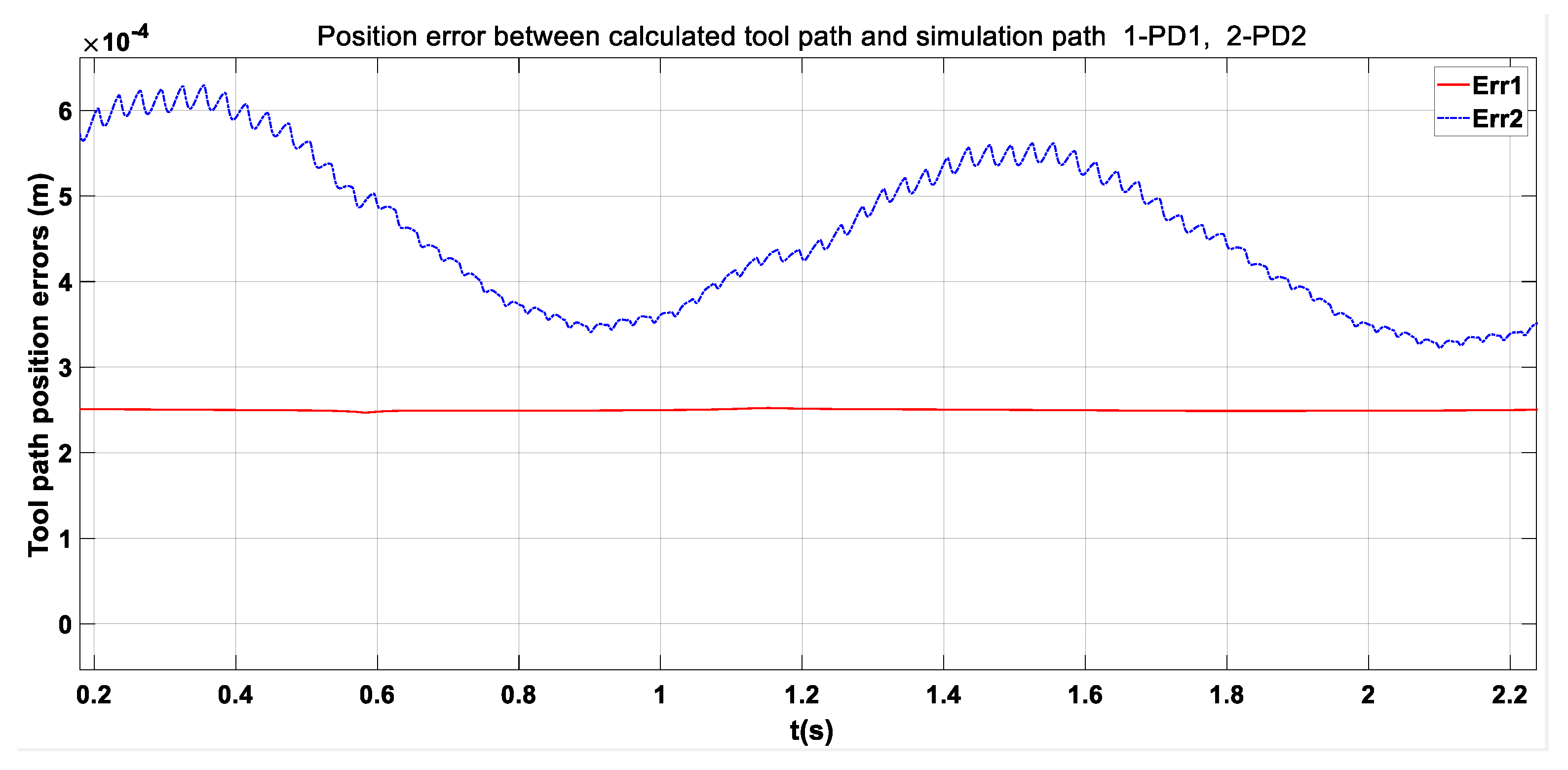

6.1. Simulation of Inverse Dynamics + PD Controller

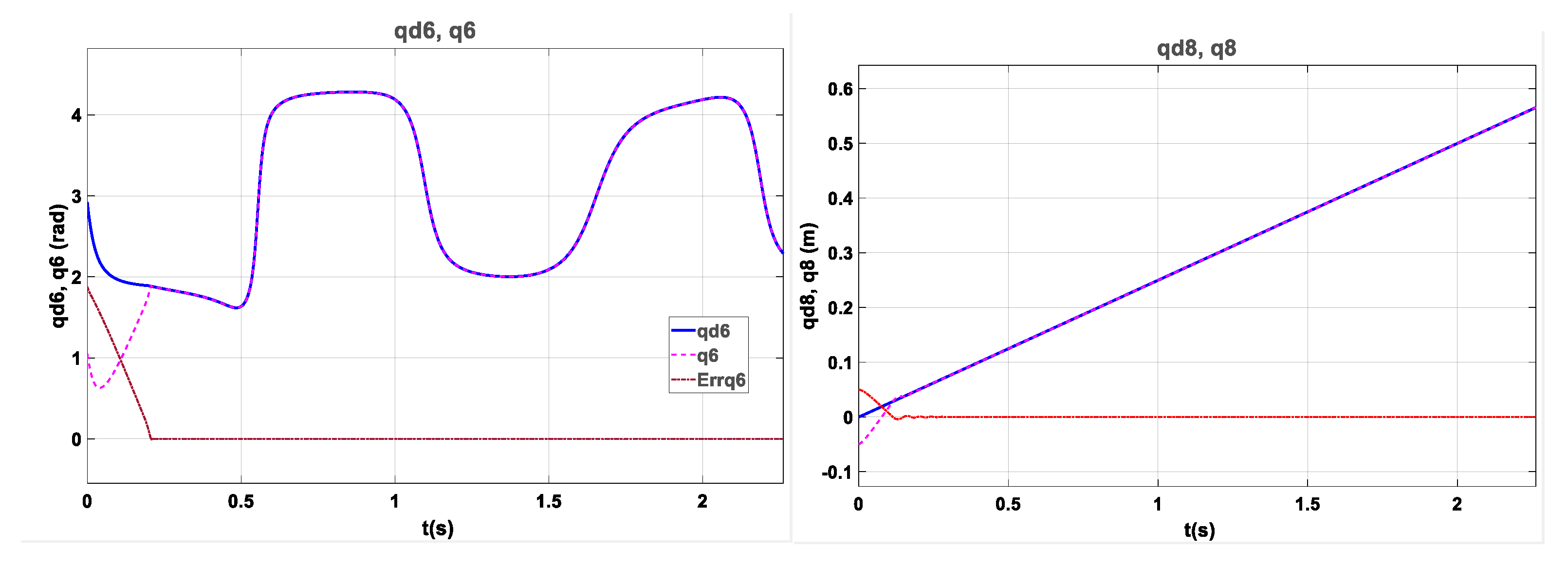

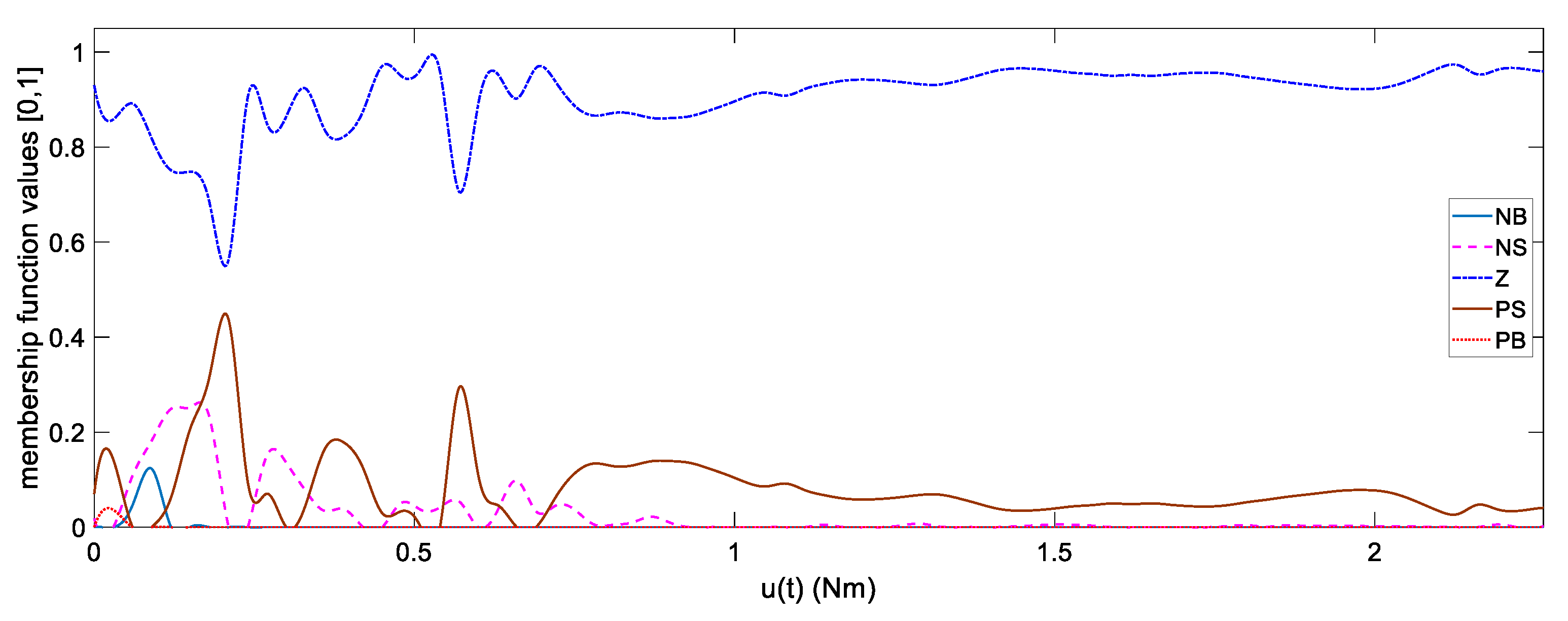

6.2. Simulation of the Fuzzy Controller

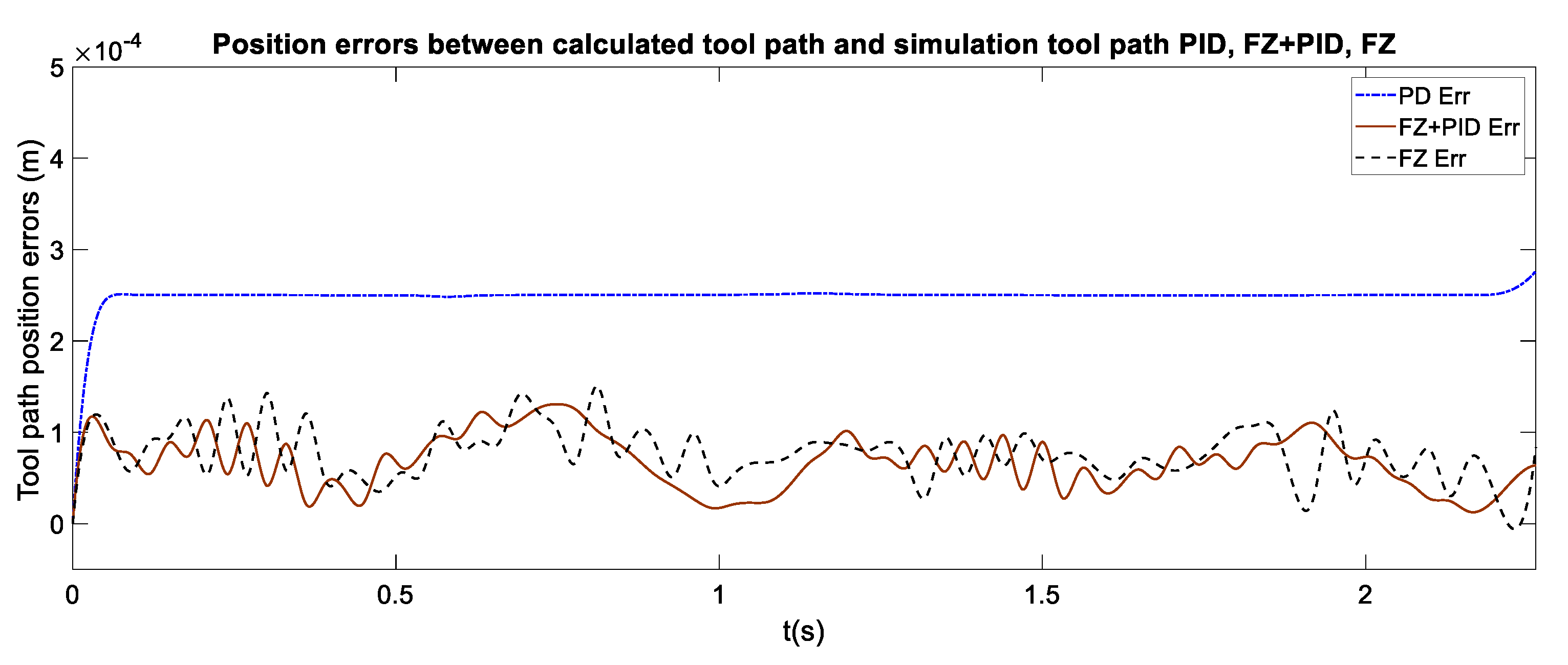

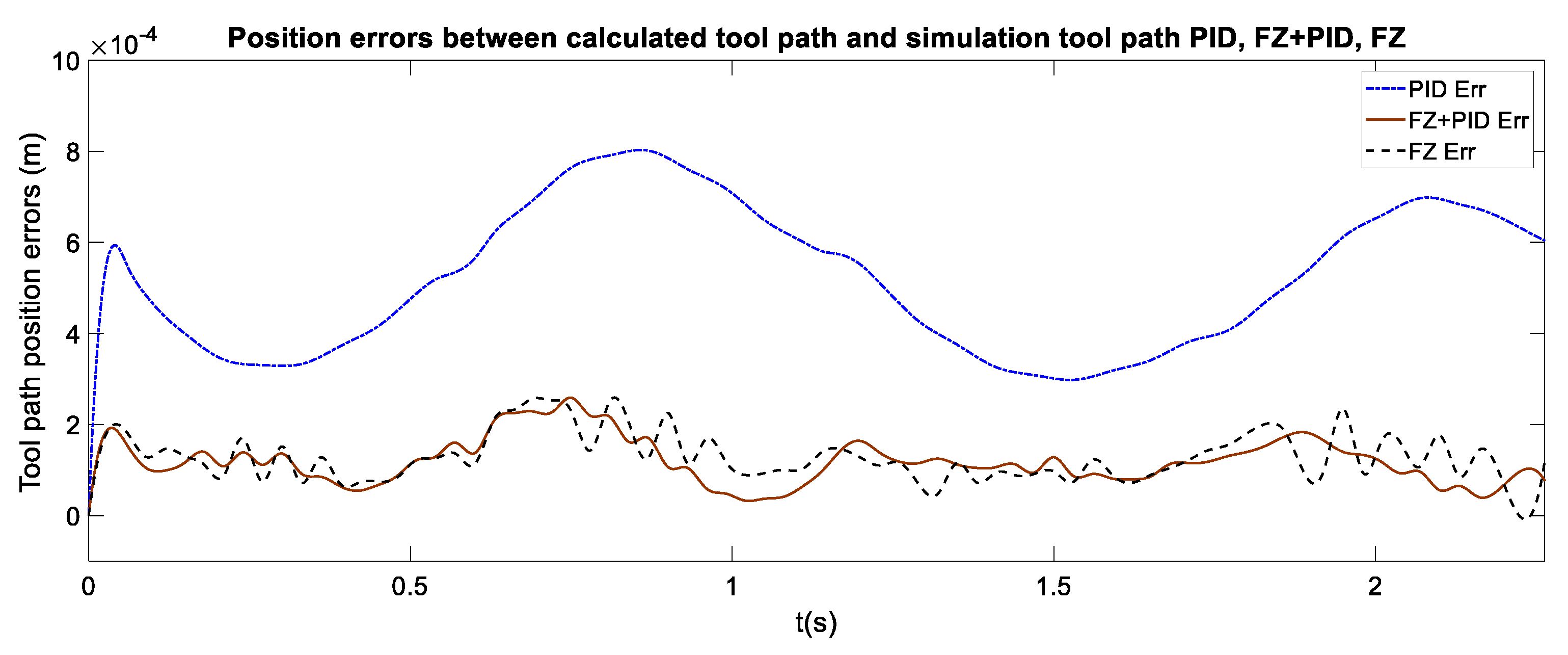

6.3. Stability Analysis

- -

- the fuzzy controller has an integrated PID control unit,

- -

- the fuzzy controller without integrated PID unit can still be stable and ensure the accuracy, by choosing a good fuzzy rule and physical value domain of appropriate input and output variables.

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A. Summary Fuzzy Logic

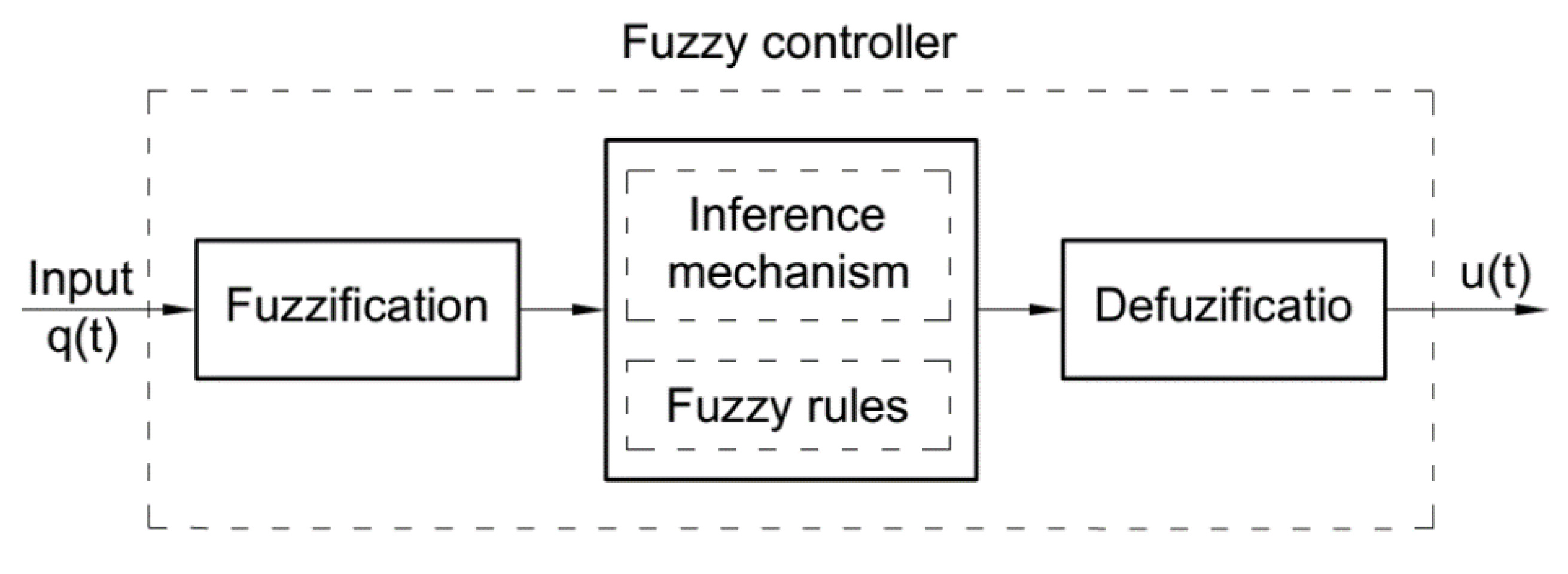

Appendix B. Fuzzy Logic Controller

- The interface consists of a fuzzification module and some additional ones for solving problems such as generating trajectories of motion, differentiation, integration… Fuzzification is the method of translating a crisp quantity into a fuzzy quantity.

- The compositional device consists of two main modules that are fuzzy rules and the inference mechanism. Two approaches for construction of fuzzy logic control are Mamdani and Takagi—Sugeno’s approaches. This paper uses the Mamdani approach in developing fuzzy rules as well as fuzzy inference. In order to develop fuzzy rule systems, the essential nature and key characteristics of the object being controlled are analyzed based on expert knowledge and experience. The effectiveness of these based on the fuzzy approach are the most important factors, i.e., deciding whether fuzzy rules are good or not, to ensure good quality control.

- Defuzzification is the operation process that inverses the process of fuzzification, where the fuzzy results are converted into crisp values for the controller to perform physical operations.

References

- Appleton, E.; Williams, D.J. Industrial Robot Applications; Springer Science & Business Media: Berlin, Germany, 2012. [Google Scholar]

- Ji, W.; Wang, L. Industrial robotic Machining: A review. Int. J. Adv. Manuf. Technol. 2019, 103, 1239–1255. [Google Scholar] [CrossRef]

- Pandremenos, J.; Doukas, C.; Stavropoulos, P.; Chryssolouris, G. Machining with robots: A critical review. In Proceedings of the DET 2011, Athens, Greece, 28–30 September 2011; pp. 1–8. [Google Scholar]

- Petko, M.; Gac, K.; Góra, G.; Karpiel, G.; Ochoński, J.; Kobus, K. CNC system of the 5-axis hybrid robot for milling. Mechatronics 2016, 37, 89–99. [Google Scholar] [CrossRef]

- Cen, L.; Melkote, S.N. CCT-based mode coupling chatter avoidance in robotic milling. J. Manuf. Process. 2017, 29, 50–61. [Google Scholar] [CrossRef]

- COMET, E.U. FP7-Project: Plug-and-Produce Components and Methods for Adaptive Control of Industrial Robots Enabling Cost Effective, High Precision Manufacturing in Factories of the Future. Available online: http://www.cometproject.eu (accessed on 1 September 2010).

- Petko, M.; Karpiel, G.; Gac, K.; Góra, G.; Kobus, K.; Ochoński, J. Trajectory tracking controller of the hybrid robot for milling. Mechatronics 2016, 37, 100–111. [Google Scholar] [CrossRef]

- Gołda, G.; Kampa, A. Modelling of cutting force and robot load during machining. In Advanced Materials Research. Trans Tech Publ. 2014, 1036, 715–720. [Google Scholar]

- Cen, L.; Melkote, S.N. Effect of robot dynamics on the machining forces in robotic milling. Procedia Manuf. 2017, 10, 486–496. [Google Scholar] [CrossRef]

- Perrusquía, A.; Yu, W.; Soria, A. Position/force control of robot manipulators using reinforcement learning. Ind. Robot Int. J. Robot. Res. Appl. 2019, 46, 267–280. [Google Scholar] [CrossRef]

- Lacerda, H.B.; Lima, V.T. Evaluation of cutting forces and prediction of chatter vibrations in milling. J. Braz. Soc. Mech. Sci. Eng. 2004, 26, 74–81. [Google Scholar] [CrossRef][Green Version]

- Leonesio, M.; Villagrossi, E.; Beschi, M.; Marini, A.; Bianchi, G.; Pedrocchi, N.; Isaev, A. Vibration analysis of robotic milling tasks. Procedia Cirp 2018, 67, 262–267. [Google Scholar] [CrossRef]

- Wang, G.; Dong, H.; Guo, Y.; Ke, Y. Dynamic cutting force modeling and experimental study of industrial robotic boring. Int. J. Adv. Manuf. Technol. 2016, 86, 179–190. [Google Scholar] [CrossRef]

- Lazoglu, I. A new identification method of specific cutting coefficients for ball end milling. Procedia Cirp 2014, 14, 182–187. [Google Scholar]

- Ghorbani, H.; Moetakef-Imani, B. Specific cutting force and cutting condition interaction modeling for round insert face milling operation. Int. J. Adv. Manuf. Technol. 2016, 84, 1705–1715. [Google Scholar] [CrossRef]

- Nan, C.; Liu, D. Analytical Calculation of Cutting Forces in Ball-End Milling with Inclination Angle. J. Manuf. Mater. Process. 2018, 2, 35. [Google Scholar] [CrossRef]

- Kaymakci, M.; Kilic, Z.M.; Altintas, Y. Unified cutting force model for turning, boring, drilling and milling operations. Int. J. Mach. Tools Manuf. 2012, 54, 34–45. [Google Scholar] [CrossRef]

- Davoudinejad, A.; Tosello, G.; Parenti, P.; Annoni, M. 3D finite element simulation of micro end-milling by considering the effect of tool run-out. Micromachines 2017, 8, 187. [Google Scholar] [CrossRef]

- Huo, D.; Chen, W.; Teng, X.; Lin, C.; Yang, K. Modeling the influence of tool deflection on cutting force and surface generation in micro-milling. Micromachine 2017, 8, 188. [Google Scholar] [CrossRef]

- Luo, M.; Chong, Z.; Liu, D. Cutting forces measurement for milling process by using working tables with integrated PVDF thin-film sensors. Sensors 2018, 18, 4031. [Google Scholar] [CrossRef]

- Tuysuz, O.; Altintas, Y.; Feng, H.Y. Prediction of cutting forces in three and five-axis ball-end milling with tool indentation effect. Int. J. Mach. Tools Manuf. 2013, 66, 66–81. [Google Scholar] [CrossRef]

- Wang, M.; Gao, L.; Zheng, Y. An examination of the fundamental mechanics of cutting force coefficients. Int. J. Mach. Tools Manuf. 2014, 78, 1–7. [Google Scholar] [CrossRef]

- Díaz-Tena, E.; Ugalde, U.; De Lacalle, L.L.; De la Iglesia, A.; Calleja, A.; Campa, F.J. Propagation of assembly errors in multitasking machines by the homogenous matrix method. Int. J. Adv. Manuf. Technol. 2013, 68, 149–164. [Google Scholar]

- Aydın, M.; Köklü, U. Identification and modeling of cutting forces in ball-end milling based on two different finite element models with Arbitrary Lagrangian Eulerian technique. Int. J. Adv. Manuf. Technol. 2017, 92, 1465–1480. [Google Scholar] [CrossRef]

- Artetxe, E.; Urbikain, G.; Lamikiz, A.; López-de-Lacalle, L.N.; González, R.; Rodal, P. A mechanistic cutting force model for new barrel end mills. Procedia Eng. 2015, 132, 553–560. [Google Scholar] [CrossRef]

- Lamikiz, A.; De Lacalle, L.L.; Sánchez, J.A.; Salgado, M.A. Cutting force integration at the CAM stage in the high-speed milling of complex surfaces. Int. J. Comput. Integr. Manuf. 2005, 18, 586–600. [Google Scholar] [CrossRef]

- Gonzalo, O.; Jauregi, H.; Uriarte, L.G.; de Lacalle, L.L. Prediction of specific force coefficients from a FEM cutting model. Int. J. Adv. Manuf. Technol. 2009, 43, 348. [Google Scholar] [CrossRef]

- Lamikiz, A.D.; De Lacalle, L.L.; Sanchez, J.A.; Salgado, M.A. Cutting force estimation in sculptured surface milling. Int. J. Mach. Tools Manuf. 2004, 44, 1511–1526. [Google Scholar] [CrossRef]

- Lin, X.; Wu, G.; Zhang, Y.; Cui, T.; Zhang, B.; Sun, P. The identification of the cutting force coefficients for ball-end finish milling. Int. J. Adv. Manuf. Technol. 2019, 102, 4121–4135. [Google Scholar] [CrossRef]

- Moges, T.M.; Desai, K.A.; Rao, P.V.M. Modeling of cutting force, tool deflection, and surface error in micro-milling operation. Int. J. Adv. Manuf. Technol. 2018, 98, 2865–2881. [Google Scholar] [CrossRef]

- Peng, B.; Bergs, T.; Schraknepper, D.; Klocke, F.; Döbbeler, B. A hybrid approach using machine learning to predict the cutting forces under consideration of the tool wear. Procedia Cirp 2019, 82, 302–307. [Google Scholar] [CrossRef]

- Zhang, X.; Yu, T.; Wang, W. Cutting forces modeling for micro flat end milling by considering tool run-out and bottom edge cutting effect. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2019, 233, 470–485. [Google Scholar] [CrossRef]

- Zadeh, L.A. Fuzzy sets. Inf. Control 1965, 8, 338–353. [Google Scholar] [CrossRef]

- Mamdani, E.H. Twenty years of fuzzy control: Experiences gained and lessons learnt. In Proceedings of the 1993 Second IEEE International Conference on Fuzzy Systems, San Francisco, CA, USA, 28 March–1 April 1993; pp. 339–344. [Google Scholar]

- Kumar, V.; Nakra, B.C.; Mittal, A.P. A review on classical and fuzzy PID controllers. Int. J. Intell. Control Syst. 2011, 16, 170–181. [Google Scholar]

- Hampel, R.; Wagenknecht, M.; Chaker, N. (Eds.) Fuzzy Control: Theory and Practice; Springer Science & Business Media: Berlin, Germany, 2013. [Google Scholar]

- Boutalis, Y.; Christodoulou, M.A.; Theodoridis, D.; Kottas, T. System identification and adaptive control. Theory and Applications of the Neurofuzzy and Fuzzy Cognitive Network Models; Springer International Publishing: Cham, Switzerland, 2014; 313p. [Google Scholar]

- Matía, F.; Marichal, G.N.; Jiménez, E. (Eds.) Fuzzy Modeling and Control: Theory and Applications; Atlantis Press: Paris, France, 2014; 288p. [Google Scholar]

- Hooda, D.S.; Raich, V. Fuzzy Logic Models and Fuzzy Control: An Introduction; Alpha Science International: Oxford, UK, 2017. [Google Scholar]

- Sharma, K.D.; Chatterjee, A.; Rakshit, A. Intelligent Adaptive Fuzzy Control. In Intelligent Control; Springer: Singapore, 2018; pp. 3–21. [Google Scholar]

- De Silva, C.W. Intelligent Control: Fuzzy Logic Applications; CRC press: Boca Raton, FL, USA, 2018. [Google Scholar]

- Lee, K.H. First Course on Fuzzy Theory and Applications; Springer Science & Business Media: Berlin, Germany, 2004. [Google Scholar]

- Barros, L.C.D.; Bassanezi, R.C.; Lodwick, W.A. A First Course in Fuzzy Logic, Fuzzy Dynamical Systems, and Biomathematics: Theory and Applications; Springer-Verlag: Berlin/Heidelberg, Germany, 2017; 299p. [Google Scholar]

- Liu, H.; Wang, T.; Wang, D. Constant cutting force control for CNC machining using dynamic characteristic-based fuzzy controller. Shock Vib. 2015, 2015. [Google Scholar] [CrossRef]

- Kovač, P.; Rodić, D.; Gostimirović, M.; Savković, B.; Ješić, D. Application of adaptive neuro fuzzy systems for grinding process modeling. In Proceedings of the 6th International Conference on Information Society and Technology ICIST, Society for Information Systems and Computer Networks Pub., Belgrade, Serbia, 28 February–2 March 2016; 2016; pp. 247–250. [Google Scholar]

- Huang, S.J.; Shy, C.Y. Fuzzy logic for constant force control of end milling. IEEE Trans. Ind. Electron. 1999, 46, 169–176. [Google Scholar] [CrossRef]

- Zhao, Y.; Collins, E.G. Fuzzy PI control design for an industrial weigh belt feeder. IEEE Trans. Fuzzy Syst. 2003, 11, 311–319. [Google Scholar] [CrossRef]

- Huang, L.; Ge, S.S.; Lee, T.H. Fuzzy unidirectional force control of constrained robotic manipulators. Fuzzy Sets Syst. 2003, 134, 135–146. [Google Scholar]

- Kizir, S.; BİNGÜL, Z. Fuzzy impedance and force control of a Stewart platform. Turk. J. Electr. Eng. Comput. Sci. 2014, 22, 924–939. [Google Scholar] [CrossRef]

- Chen, C.H.; Wang, C.C.; Wang, Y.T.; Wang, P.T. Fuzzy logic controller design for intelligent robots. Math. Probl. Eng. 2017, 1–12. [Google Scholar] [CrossRef]

- Stoian, V.; Ivanescu, M. Robot Control by Fuzzy Logic. In Frontiers in Robotics, Automation and Control; IntechOpen Pub.: Rijeka, Croatia, 2008; pp. 111–132. [Google Scholar]

- Vashisth, H.; Woo, P.Y. Application of fuzzy logic to robotic control. In Proceedings of the 1996 IEEE IECON. 22nd International Conference on Industrial Electronics, Control, and Instrumentation, Taipei, Taiwan, 9 August 1996; Volume 3, pp. 1867–1872. [Google Scholar]

- Chaudhary, H.; Panwar, V.; Sukavanum, N.; Prasad, R. Fuzzy PD+ I based hybrid force/position control of an industrial robot manipulator. Ifac Proc. Vol. 2014, 47, 429–436. [Google Scholar] [CrossRef]

- de Silva, C.W. Applications of fuzzy logic in the control of robotic manipulators. Fuzzy Sets Syst. 1995, 70, 223–234. [Google Scholar] [CrossRef]

- Mendes, N.; Neto, P.; Pires, J.N.; Loureiro, A. An optimal fuzzy-PI force/motion controller to increase industrial robot autonomy. Int. J. Adv. Manuf. Technol. 2013, 68, 435–441. [Google Scholar]

- Mendes, N.; Neto, P. Indirect adaptive fuzzy control for industrial robots: A solution for contact applications. Expert Syst. Appl. 2015, 42, 8929–8935. [Google Scholar] [CrossRef]

- Khoi, P.B.; Van Toan, N. Hedge-Algebras-Based Controller for Mechanisms of Relative Manipulation. Int. J. Precis. Eng. Manuf. 2018, 19, 377–385. [Google Scholar] [CrossRef]

- Toan, N.V.; Khoi, P.B. Fuzzy-based-admittance controller for safe natural human–robot interaction. Adv. Robot. 2019, 1–9. [Google Scholar] [CrossRef]

- Wakileh, B.A.M.; Gill, K.F. Use of fuzzy logic in robotics. Comput. Ind. 1988, 10, 35–46. [Google Scholar] [CrossRef]

- Khoi, P.B.; Van Toan, N. Optimizing Neuro-Fuzzy System for Robot Control. J. Sci. Technol. 2014, 52, 685–699. [Google Scholar]

- Lin, C.H.; Wang, S.H.; Lin, C.J. Interval Type-2 Neural Fuzzy Controller-Based Navigation of Cooperative Load-Carrying Mobile Robots in Unknown Environments. Sensors 2018, 18, 4181. [Google Scholar] [CrossRef]

- Van Toan, N.; Khoi, P.B. A control solution for closed-form mechanisms of relative manipulation based on fuzzy approach. Int. J. Adv. Robot. Syst. 2019, 16, 1–11. [Google Scholar] [CrossRef]

- Hsu, F.Y.; Fu, L.C. A new adaptive fuzzy hybrid force/position control for intelligent robot deburring. In Proceedings of the 1999 IEEE International Conference on Robotics and Automation, Detroit, MI, USA, 10–15 May 1999; Volume 3, pp. 2476–2481. [Google Scholar]

- Hendzel, Z.; Burghardt, A.; Gierlak, P.; Szuster, M. Conventional and fuzzy force control in robotised machining. Solid State Phenom. Trans Tech Publ. 2014, 210, 178–185. [Google Scholar] [CrossRef]

- Cuka, B.; Kim, D.W. Fuzzy logic based tool condition monitoring for end-milling. Robot. Comput.-Integr. Manuf. 2017, 47, 22–36. [Google Scholar] [CrossRef]

- Hsu, F.Y.; Fu, L.C. Intelligent robot deburring using adaptive fuzzy hybrid position/force control. IEEE Trans. Robot. Autom. 2000, 16, 325–335. [Google Scholar] [CrossRef]

- Khoi, P.B.; Van Toan, N. Application of fuzzy logic for controlling mechanisms of relative manipulation robot (MRM robot). J. Sci. Technol. 2016, 54, 385–401. [Google Scholar] [CrossRef]

- Khoi, P.B. Calculation and simulation the program motion of mechanisms of relative manipulation (MRM). J. Sci. Technol. 2009, 3, 19–28. [Google Scholar]

- Khoi, P.B. Kinematic problems of programming control of mechanism of relative manipulation. In Proceedings of the National Conference on Mechanics, Hanoi, Vietnam, 8–9 April 2009; pp. 317–323. [Google Scholar]

- Khoi, P.B.; Hai, H.T. Investigation of kinematics and motion planning for mechanical machining robots. Proc. Natl. Conf. Eng. Mech. Vietnam 2015, 2, 407–418. [Google Scholar]

- Hai, H.T. Kinematic Modelling of a Robot in Form-shaping Milling Complex Surfaces. Eur. J. Eng. Res. Sci. 2019, 4, 26–31. [Google Scholar] [CrossRef]

- Khoi, P.B.; Huy, L.Q. (Eds.) Kinematic modeling of of the process of grinding turbine blades by using robots. In Proceedings of the 10th National conference on Mechanics, Hanoi, Vietnam, 8–9 December 2017; Volume 1, pp. 803–812. [Google Scholar]

- Afonin, V.L.; Khoi, P.B. Method for Calculating Action and Constrained Reactions Forces in Mechanisms of Relative Manipulation while Executing Programming Motion; IMASH, RAS: Moscow, Russia, 1997. [Google Scholar]

- Khoi, P.B. Applying Principle of Compatibility for Analyzing Forces of Mechanism of Relative Manipulation Robot. PhD Thesis, Mechanical Engineering Research Institute of the Russian Academy of Sciences (IMASH RAS), Moscow, Russia, 4 December 1997. [Google Scholar]

- Khoi, P.B. Dynamical investigation of relation manipulation mechanisms in mechanical processing. In Proceedings of the National Conference on Mechanics, Hanoi, Vietnam, 8–9 April 2004; pp. 181–190. [Google Scholar]

- Khoi, P.B.; Hai, H.T. Robot dynamics in mechanical processing. Proc. Natl. Conf. Eng. Mech. Vietnam 2015, 2, 419–427. [Google Scholar]

- Khoi, P.B.; Hai, H.T. Force analysis of a robot in machining process. Proc. Natl. Conf. Mach. Mech. Vietnam 2015, 1, 346–359. [Google Scholar]

- Hai, H.T. Effect of cutting forces on the form-shaping motion in robotic milling. Am. J. Eng. Res. 2019, 8, 176–185. [Google Scholar]

- Hai, H.T. Inverse dynamic analysis of miling machining robot: Application in calibration of cutting force. Vietnam J. Sci. Technol. 2019, 57, 773–787. [Google Scholar]

- Khoi, P.B.; Hai, H.T.; Sinh, H.V. Control of inverse dynamics of robot in milling. Proc. Natl. Conf. Eng. Mech. Vietnam 2017, 1, 352–361. [Google Scholar]

- Abele, E.; Bauer, J.; Pischan, M.; Stryk, O.V.; Friedmann, M.; Hemker, T. Prediction of the tool displacement for robot milling applications using coupled models of an industrial robot and removal simulation. In Proceedings of the CIRP 2nd Inter Confernce on Process Machine Interactions, Vancouver, BC, Canada, 10–11 June 2010. [Google Scholar]

| Links | Frame | Kin. Parameters | i−1Ai | 0Ai |

|---|---|---|---|---|

| The robot kinematic chain | ||||

| L0 | O0x0y0z0 | 0, …, 0 | E | E |

| L1 | O1x1y1z1 | θ1, d1, a1, α1 | 0A1(θ1) | 0A1(θ1) |

| … | … | … | … | … |

| L6 | O6x6y6z6 | θ6, d6, a6, α6 | 5A6(θ6) | 0A1(θ1)... 5A6(θ6) |

| Cutting tool | OExEyEzE | 6xE, 6yE, 6zE, 6αE, 6βE, 6ηE | 6AE | 0A1(θ1)... 5A6(θ6)6AE |

| The platform kinematic chain | ||||

| L0 | O0x0y0z0 | 0, …, 0 | E | E |

| L0’ | O0’x0’y0’z0’ | x0’, y0’, z0’, α0’, β 0’, η 0’ | 0A0’ | 0A0’ |

| B | Obxbybzb | xb, yb, zb, αb, β b, η b | 0’Ab(yb) | 0A0’0’Ab(yb) |

| D | Odxdydzd | xd, yd, zd, αd, β d, ηd | bAd(xd) | 0A0’0’Ab(yb) bAd(xd) |

| Cutting tool | OExEyEzE | dxE, dyE, dzE, dαE, dβE, dηE | dAE | 0A0’0’Ab(yb) bAd(xd) dAE |

| Serial No. | Physical Domain Xj | Fuzzy Set Fj | Name of Linguistic Value | Notation of Linguistic Value |

|---|---|---|---|---|

| 1 | X1 | F1 | Big Negative | NB |

| 2 | X2 | F2 | Small Negative | NS |

| 3 | X3 | F3 | Zero | Z |

| 4 | X4 | F4 | Small Positive | PS |

| 5 | X5 | F5 | Big Positive | PB |

| Adjustment | ||||||

|---|---|---|---|---|---|---|

| Amount u(t) | NB | NS | Z | PS | PB | |

| Position error e(t) | NB | PB | PB | PB | PS | Z |

| NS | PB | PS | PS | Z | NS | |

| Z | PB | PS | Z | NS | NB | |

| PS | PS | Z | NS | NS | NB | |

| PB | Z | NS | NB | NB | NB | |

| Cutter’s Material | D1 (mm) | D2 (mm) | L1 (mm) | L2 (mm) | Z (tooth) | vc (m/min) | vr (mm/s) | Sz (mm/tooth) | h0 (mm) | Cooling Liquor |

|---|---|---|---|---|---|---|---|---|---|---|

| Carbide | 20 | 20 | 125 | 50 | 4 | 31.3 | 3.3 | 0.1 | 2.2 | Emunxi |

| Case | Ktc (N/mm2) | Krc (N/mm2) | Kac (N/mm2) | Kte (N/mm) | Kre (N/mm) | Kae (N/mm) |

|---|---|---|---|---|---|---|

| 1 | 1825 | 770 | 735 | 29.7 | 55.7 | 1.8 |

| 2 | 1963 | 646 | 778 | 29.7 | 55.7 | 1.8 |

| Link | ei | ui | |

|---|---|---|---|

| 1 | [−0.001,0.001] (rad) | [−0.5,0.5] (rad/s) | [−18,000,18,000] (Nm) |

| 2 | [−0.001,0.001] (rad) | [−2.4,2.4] (rad/s) | [−44,000,44,000] (Nm) |

| 3 | [−0.006,0.006] (rad) | [−2.5,2.5] (rad/s) | [−42,000,42,000] (Nm) |

| 4 | [−0.009,0.009] (rad) | [−12.0,12.0] (rad/s) | [−18,000,18,000] (Nm) |

| 5 | [−0.008,0.008] (rad) | [−7.0,7.0] (rad/s) | [−9800,9800] (Nm) |

| 6 | [−0.008,0.008] (rad) | [−10.0,10.0] (rad/s) | [−5200,5200] (Nm) |

| 7 | [−0.001,0.001] (m) | [−0.2,0.2] (m/s) | [−4700,4700] (N) |

| 8 | [−0.001,0.001] (m) | [−0.5,0.5] (m/s) | [−3100,3100] (N) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Phan, K.B.; Ha, H.T.; Hoang, S.V. Eliminating the Effect of Uncertainties of Cutting Forces by Fuzzy Controller for Robots in Milling Process. Appl. Sci. 2020, 10, 1685. https://doi.org/10.3390/app10051685

Phan KB, Ha HT, Hoang SV. Eliminating the Effect of Uncertainties of Cutting Forces by Fuzzy Controller for Robots in Milling Process. Applied Sciences. 2020; 10(5):1685. https://doi.org/10.3390/app10051685

Chicago/Turabian StylePhan, Khoi Bui, Hai Thanh Ha, and Sinh Vinh Hoang. 2020. "Eliminating the Effect of Uncertainties of Cutting Forces by Fuzzy Controller for Robots in Milling Process" Applied Sciences 10, no. 5: 1685. https://doi.org/10.3390/app10051685

APA StylePhan, K. B., Ha, H. T., & Hoang, S. V. (2020). Eliminating the Effect of Uncertainties of Cutting Forces by Fuzzy Controller for Robots in Milling Process. Applied Sciences, 10(5), 1685. https://doi.org/10.3390/app10051685