An Empirical Study on Greenhouse Gas Emission Calculations Under Different Municipal Solid Waste Management Strategies

Abstract

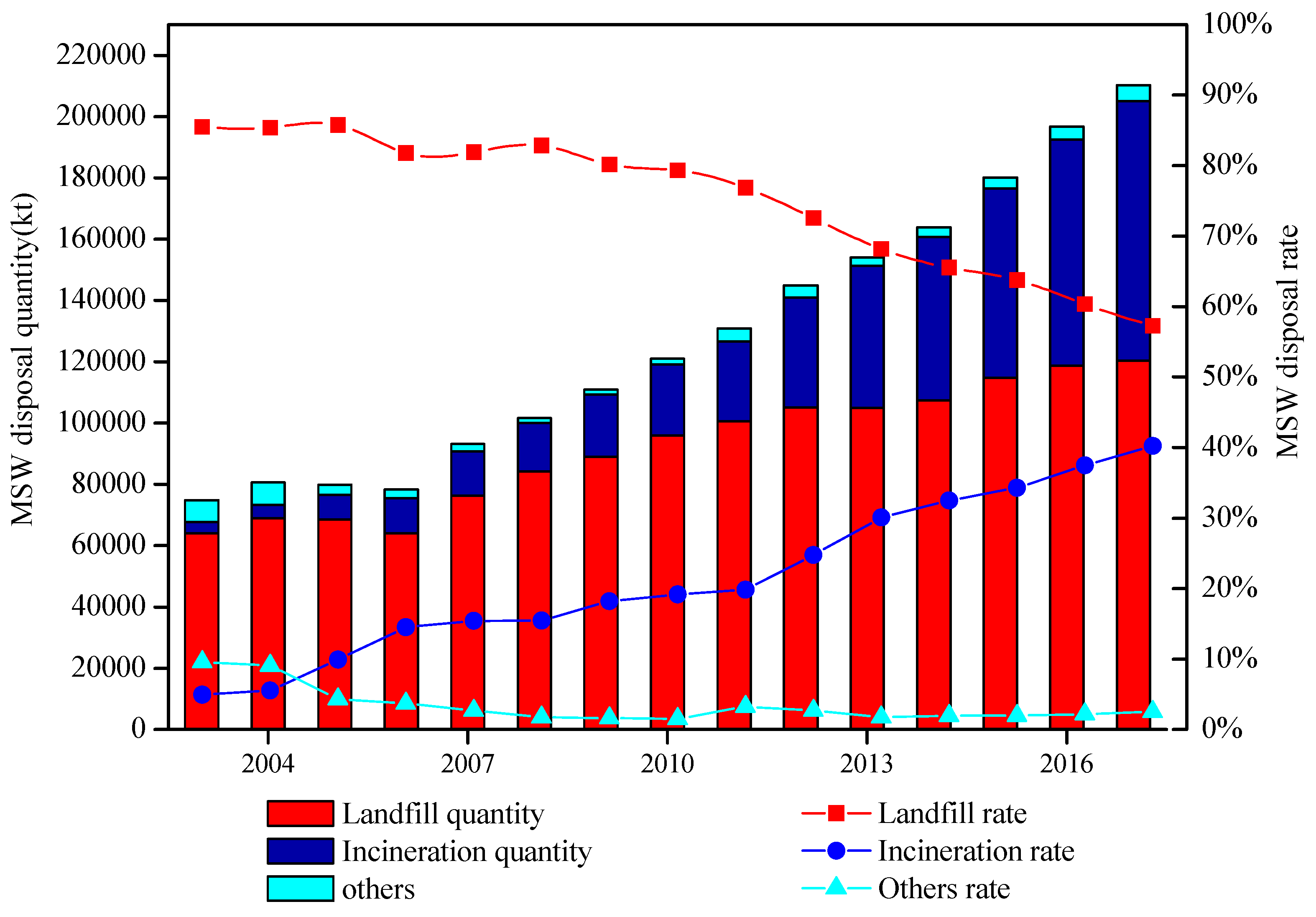

:1. Introduction

2. Materials and Methods

2.1. Materials

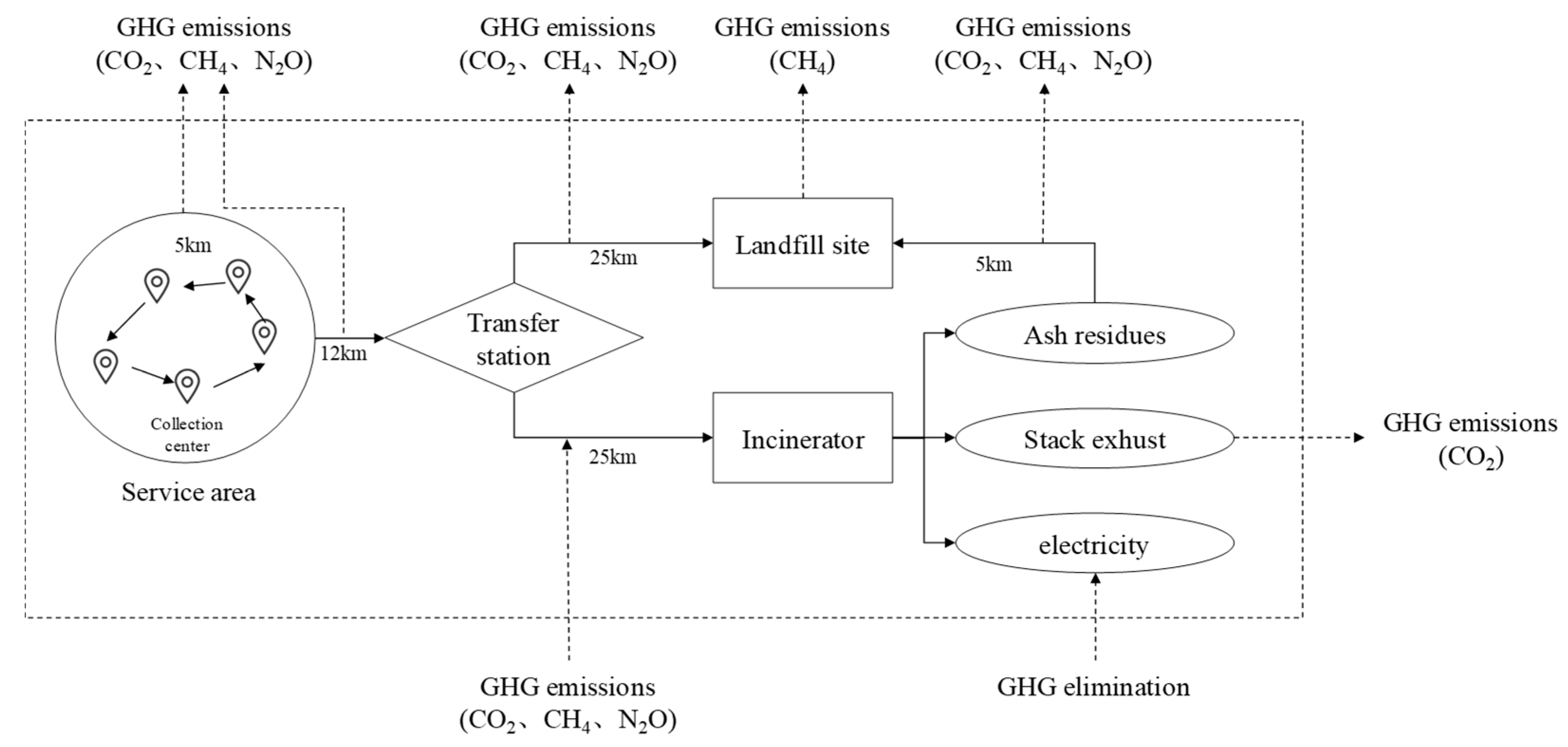

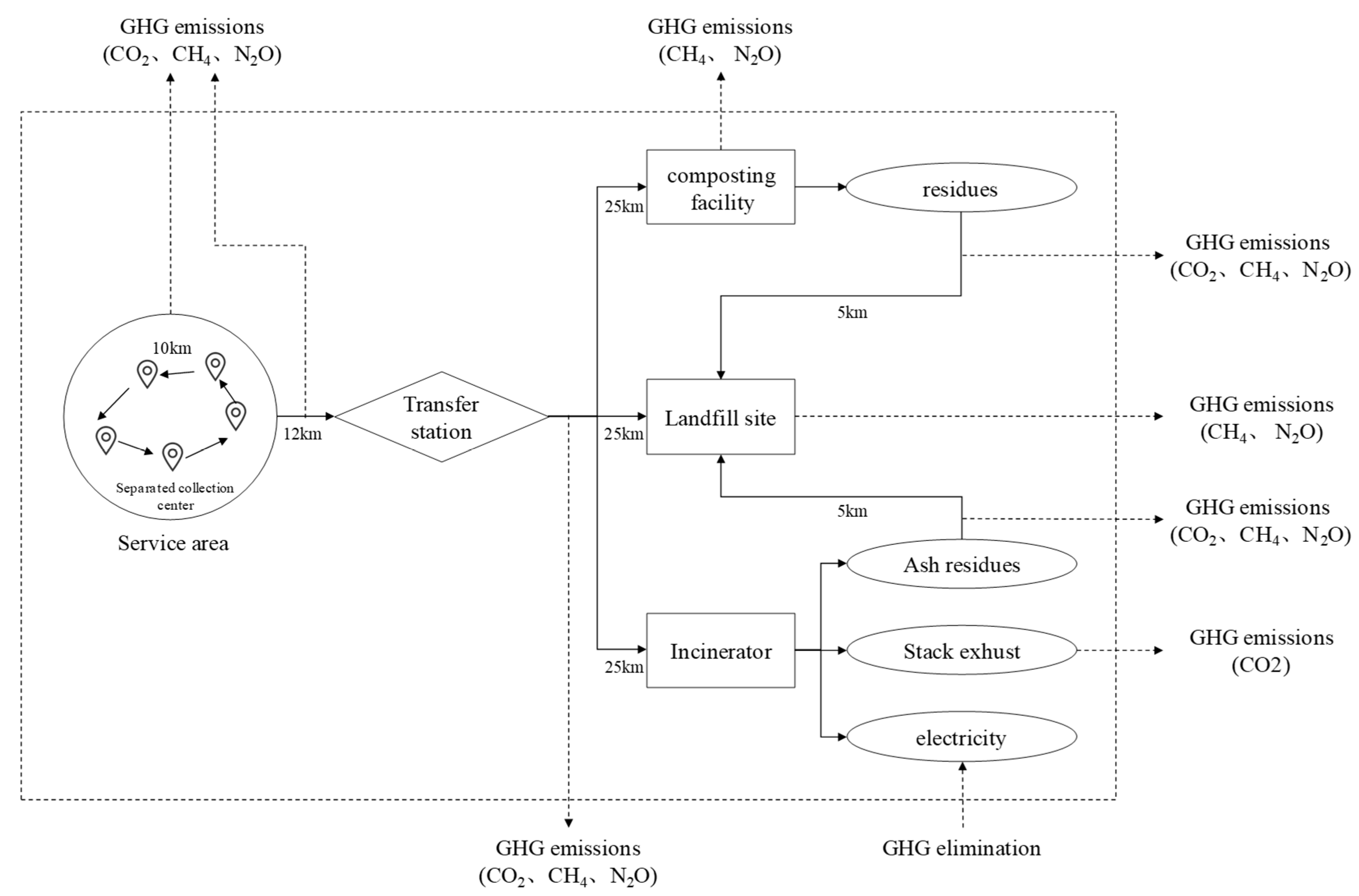

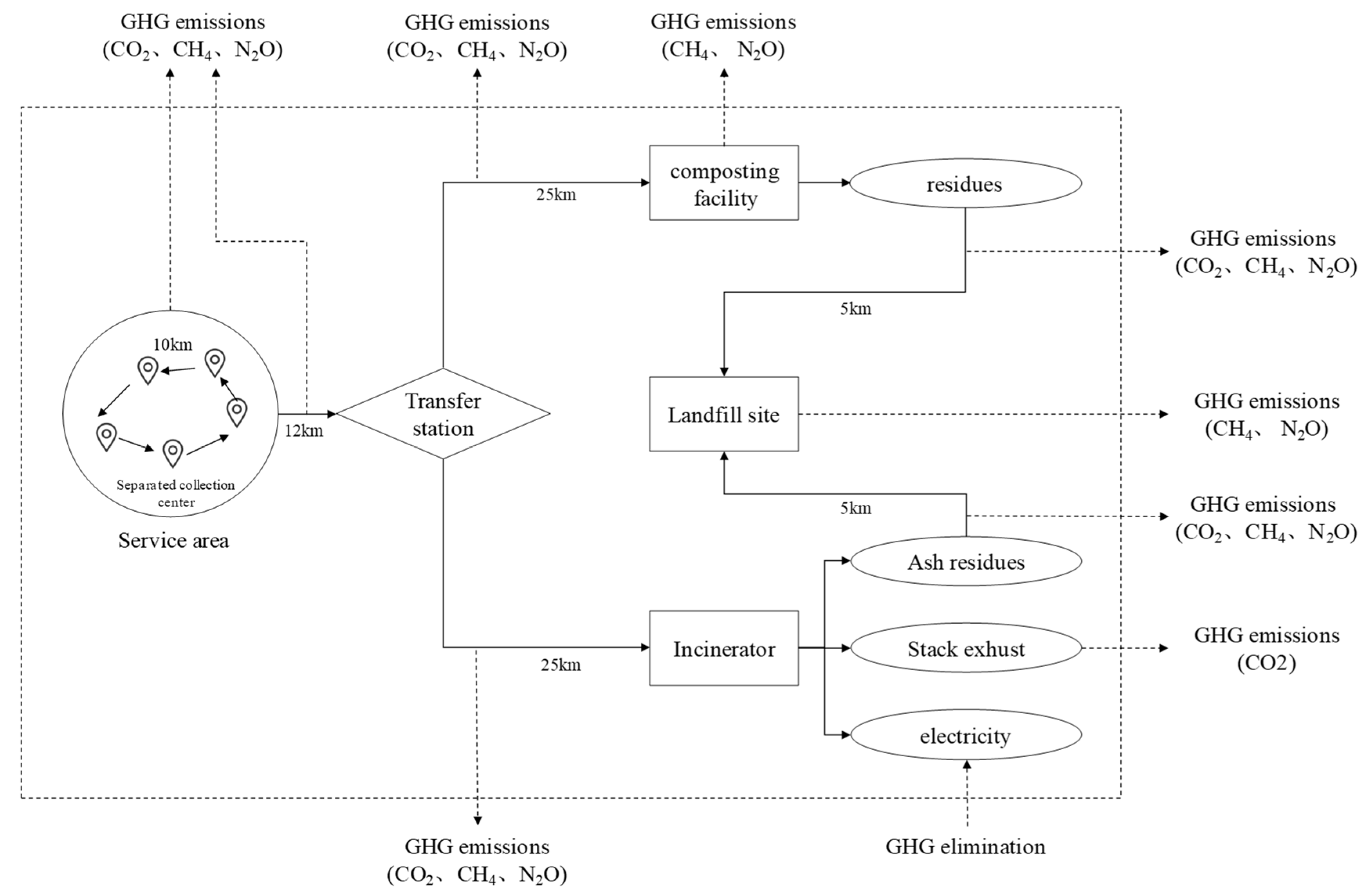

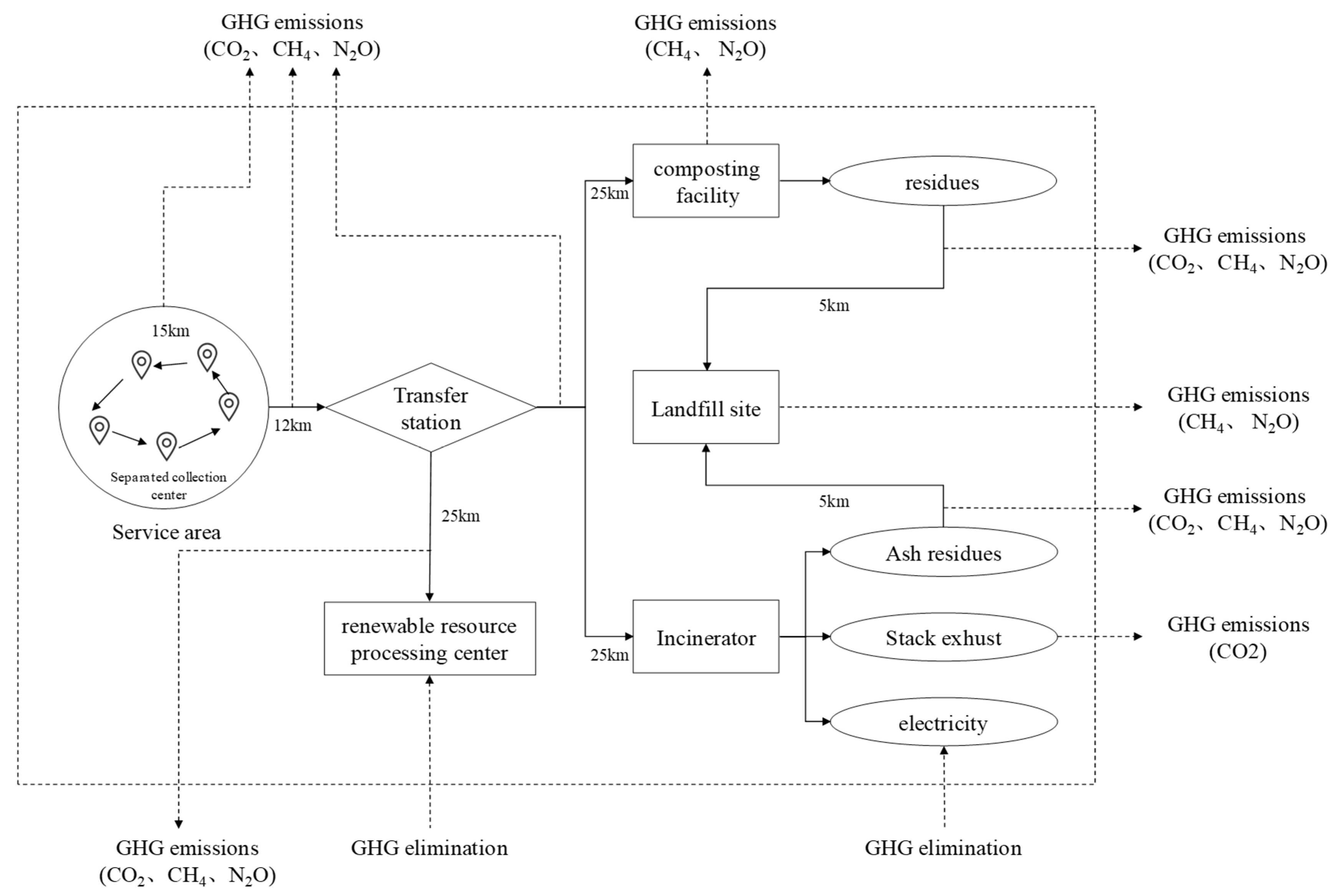

2.2. System Boundary

2.3. Scenario Design

2.4. Estimation Method

2.4.1. GHG Emissions from Transportation

2.4.2. GHG emissions from Landfill

2.4.3. GHG Emissions from Incineration of Waste

2.4.4. GHG Emissions from Composting of Kitchen Waste

2.4.5. Calculation of Emission Reduction of GHG from Recycling of Renewable Resources

3. Results and Discussion

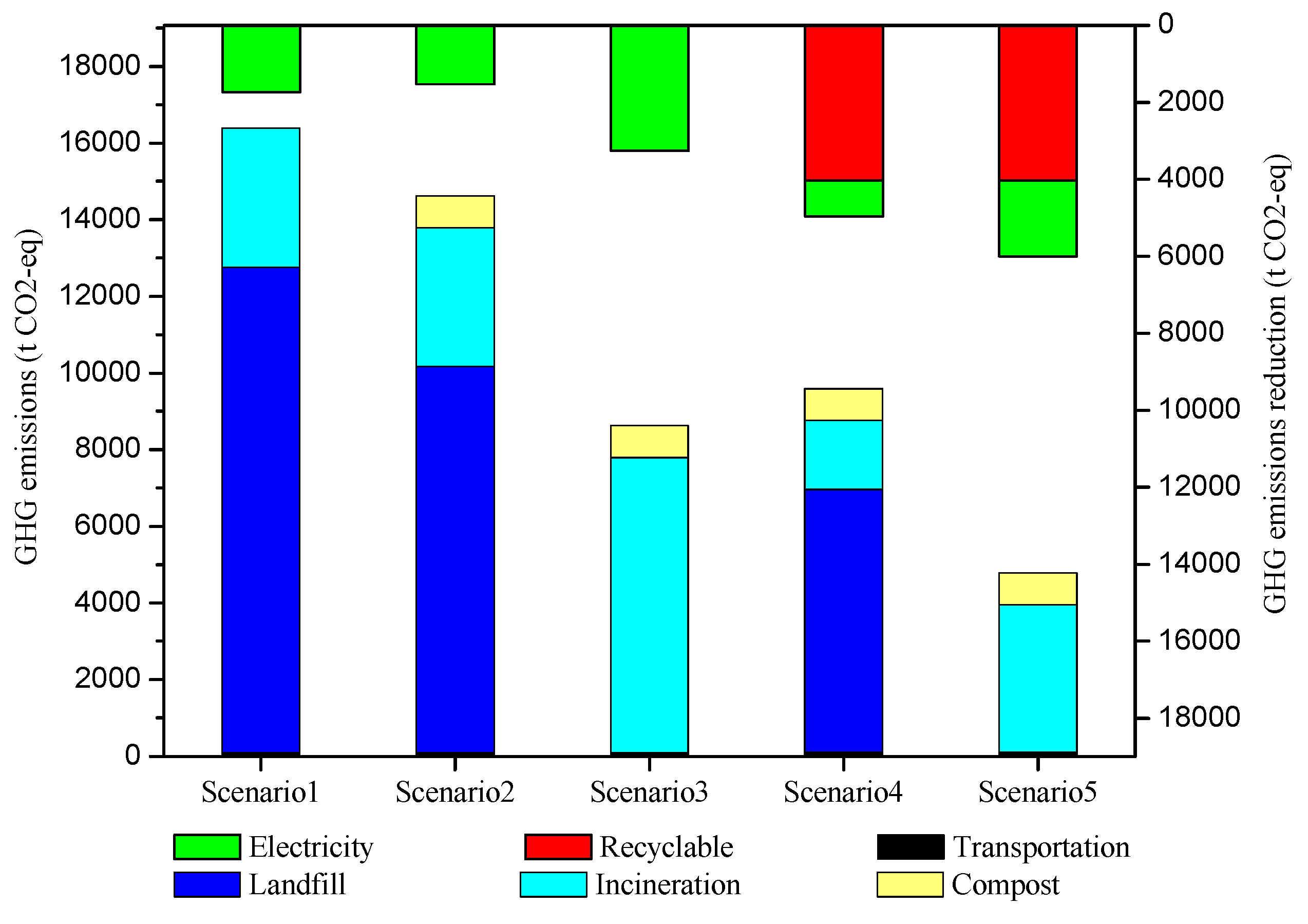

3.1. GHG Emissions under Each Scenario

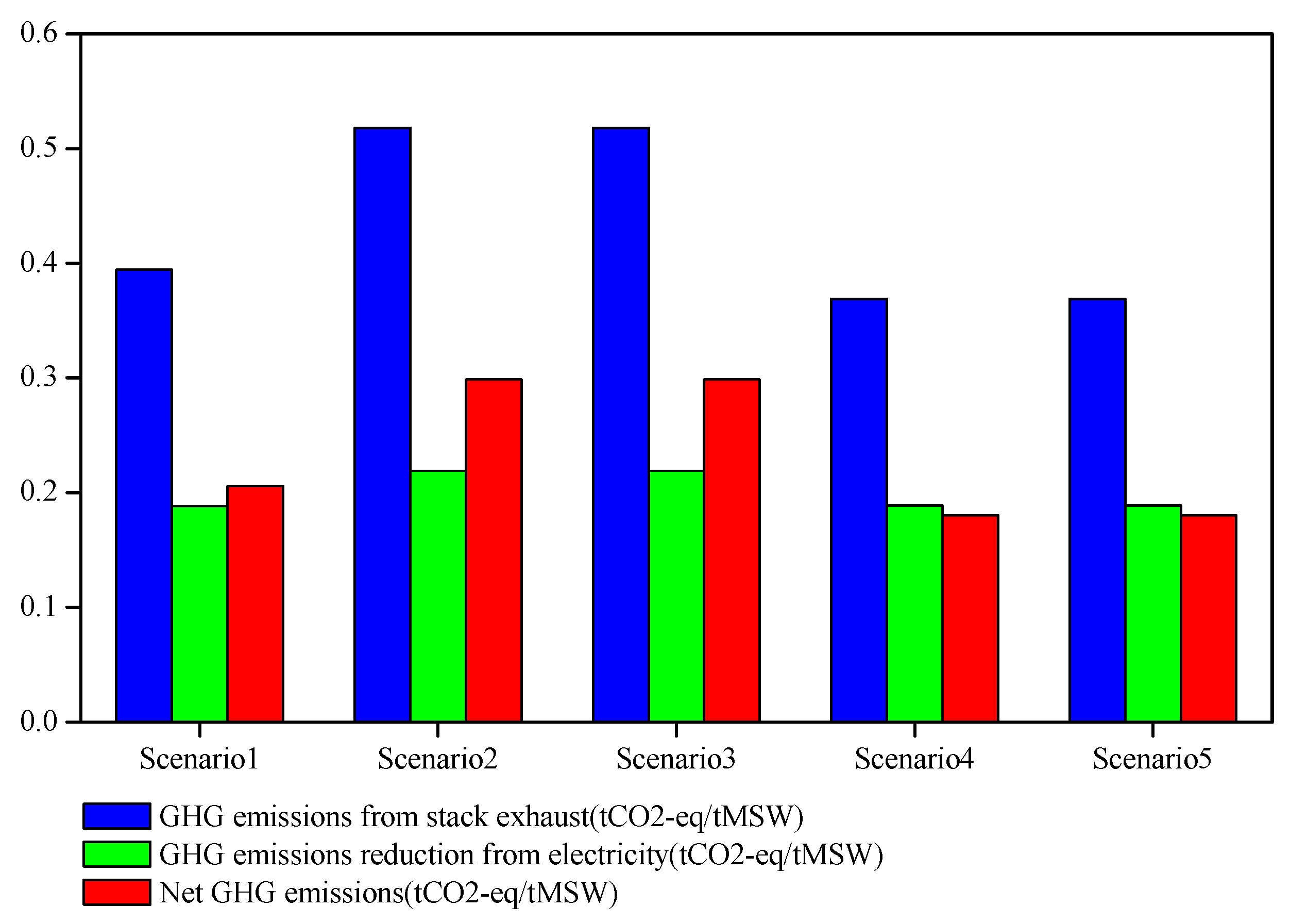

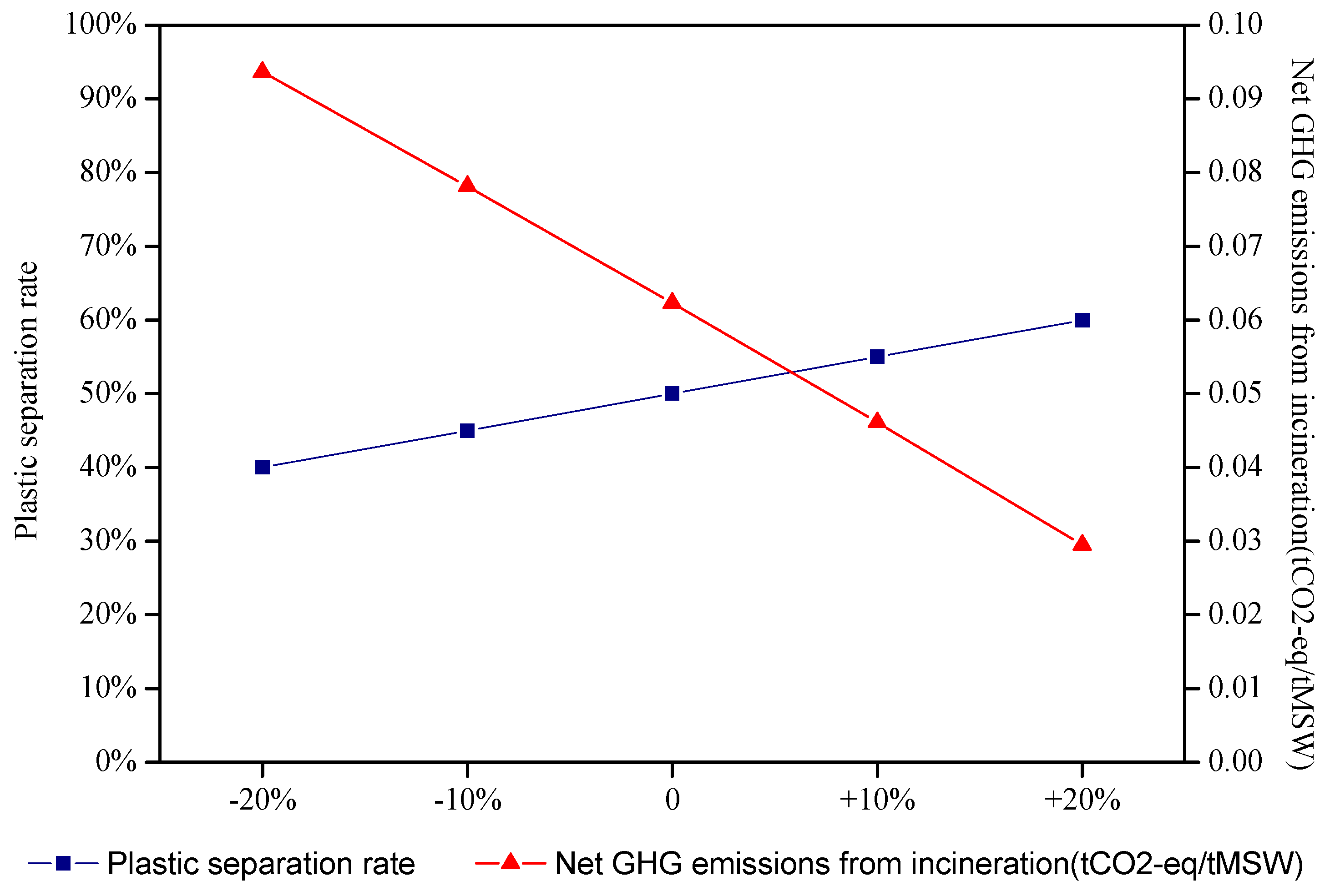

3.2. GHG Emitted from Waste Incineration

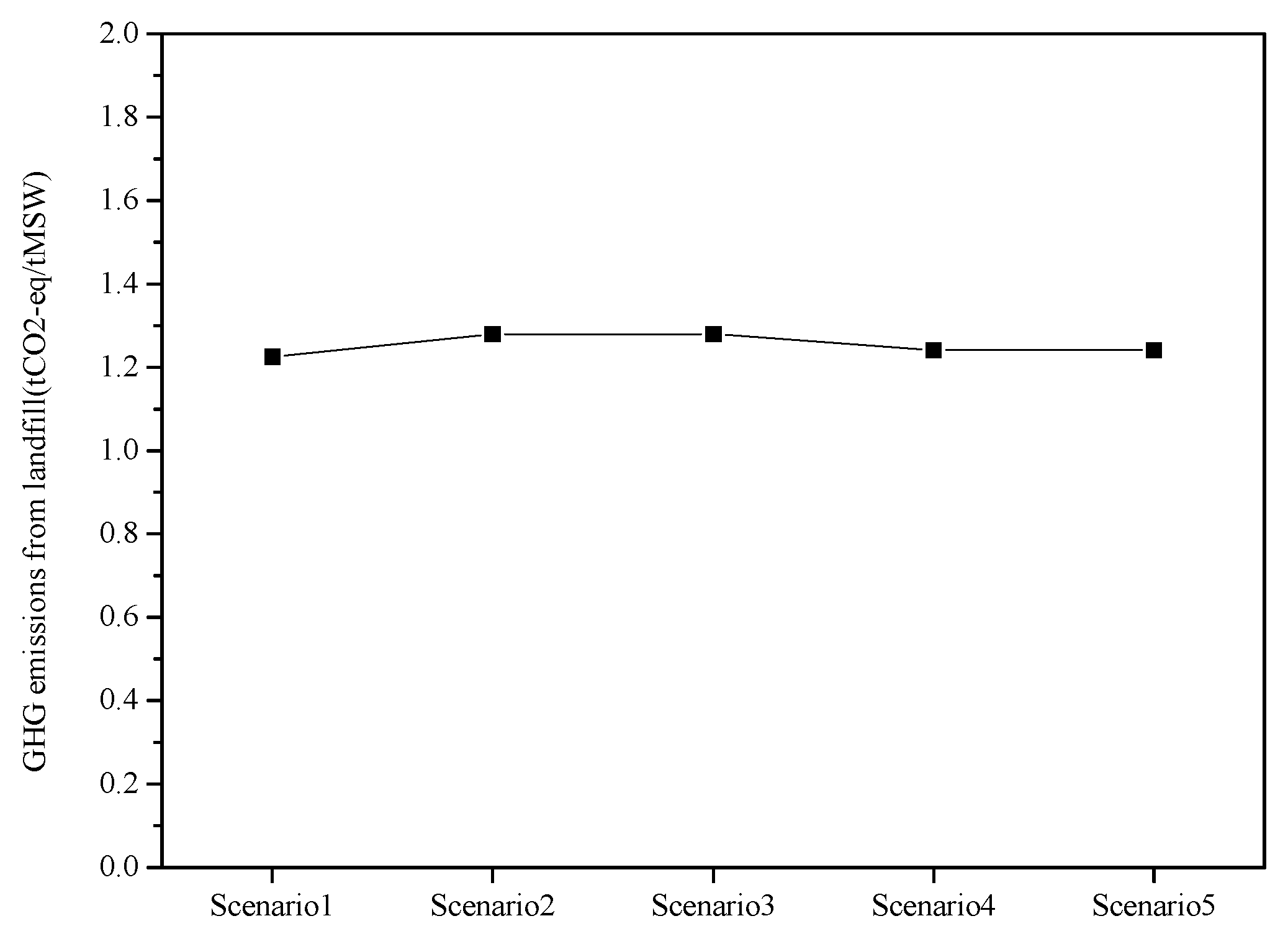

3.3. GHG Emitted from Landfill

3.4. GHG Emitted from Composting of Waste

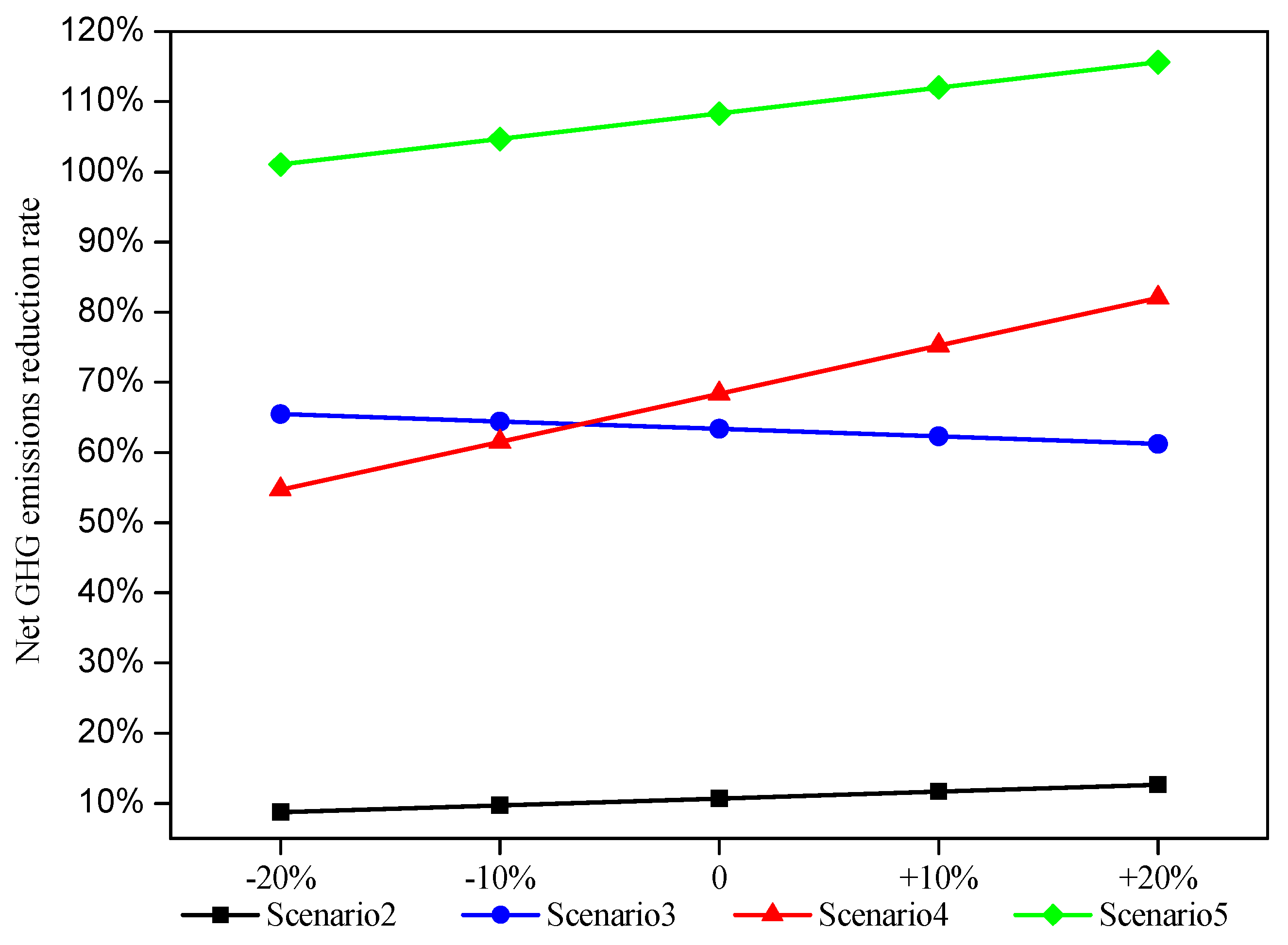

3.5. Contribution of Separation and Recycling of Waste to Emission Reduction of GHG

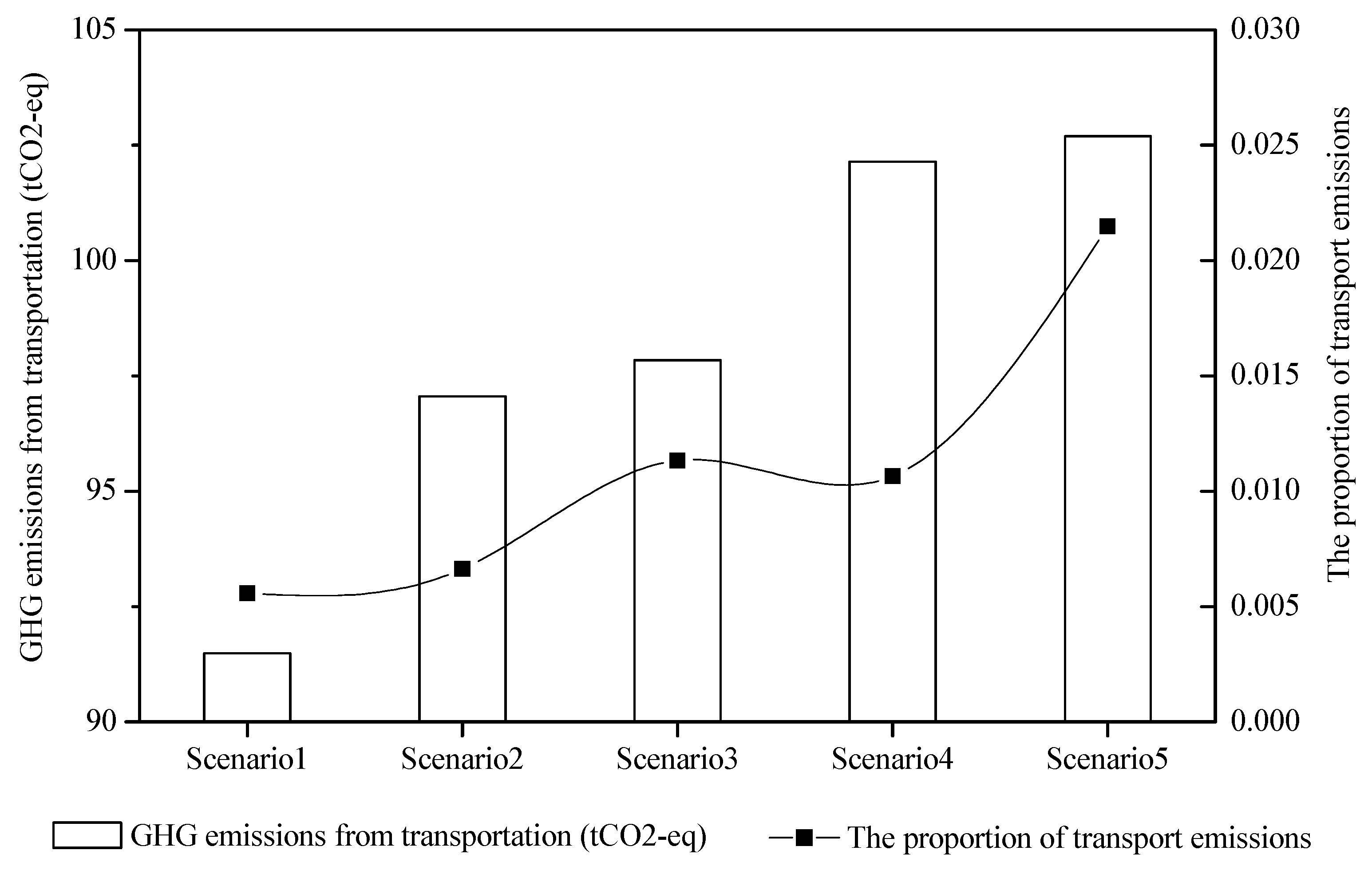

3.6. GHG Emitted from Transportation of Waste

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- World Bank CO2 Emissions (Metric Tons Per Capita) in China. Available online: https://data.worldbank.org.cn/ (accessed on 16 June 2019).

- Le Quéré, C.; Moriarty, R.; Andrew, R.M.; Peters, G.P.; Ciais, P.; Friedlingstein, P.; Jones, S.D.; Sitch, S.; Tans, P.; Arneth, A.; et al. Global carbon budget 2014. Earth Syst. Sci. Data 2015, 7, 47–85. [Google Scholar] [CrossRef] [Green Version]

- den Elzen, M.; Fekete, H.; Höhne, N.; Admiraal, A.; Forsell, N.; Hof, A.F.; Olivier, J.G.J.; Roelfsema, M.; van Soest, H. Greenhouse gas emissions from current and enhanced policies of China until 2030: Can emissions peak before 2030? Energy Policy 2016, 89, 224–236. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Zhao, X.; Jiang, Z.; Shao, S. How to achieve the 2030 CO2 emission-reduction targets for China’s industrial sector: Retrospective decomposition and prospective trajectories. Glob. Environ. Chang. 2017, 44, 83–97. [Google Scholar] [CrossRef]

- Pham, T.P.T.; Kaushik, R.; Parshetti, G.K.; Mahmood, R.; Balasubramanian, R. Food waste-to-energy conversion technologies: Current status and future directions. Waste Manag. 2015, 38, 399–408. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.Q.; Tan, S.K.; Gersberg, R.M. Municipal solid waste management in China: Status, problems and challenges. J. Environ. Manag. 2010, 91, 1623–1633. [Google Scholar] [CrossRef] [PubMed]

- Statistics, N. China Statistical Yearbook 2018; China Statistics Press: Beijing, China, 2018. [Google Scholar]

- Du, W.; Gao, Q.; Zhang, E.; Miao, Q.; Wu, J. The emission status and composition analysis of municipal solid waste in China. J. Res. Environ. Sci. 2006, 19, 85–90. [Google Scholar]

- Cai, B.-F.; Liu, J.-G.; Gao, Q.-X.; Nie, X.-Q.; Cao, D.; Liu, L.-C.; Zhou, Y.; Zhang, Z.-S. Estimation of methane emissions from municipal solid waste landfills in china based on point emission sources. Adv. Clim. Chang. Res. 2014, 5, 81–91. [Google Scholar]

- Yang, N.; Zhang, H.; Shao, L.-M.; Lu, F.; He, P.-J. Greenhouse gas emissions during MSW landfilling in China: Influence of waste characteristics and LFG treatment measures. J. Environ. Manag. 2013, 129, 510–521. [Google Scholar] [CrossRef]

- Chen, Y.C.; Lo, S.L. Evaluation of greenhouse gas emissions for several municipal solid waste management strategies. J. Clean. Prod. 2016, 113, 606–612. [Google Scholar] [CrossRef]

- Liu, Y.; Ni, Z.; Kong, X.; Liu, J. Greenhouse gas emissions from municipal solid waste with a high organic fraction under different management scenarios. J. Clean. Prod. 2017, 147, 451–457. [Google Scholar] [CrossRef]

- Liu, Y.; Xing, P.; Liu, J. Environmental performance evaluation of different municipal solid waste management scenarios in China. Resour. Conserv. Recycl. 2017, 125, 98–106. [Google Scholar] [CrossRef]

- Salhofer, S.; Schneider, F.; Obersteiner, G. The ecological relevance of transport in waste disposal systems in Western Europe. Waste Manag. 2007, 27, S47–S57. [Google Scholar] [CrossRef] [PubMed]

- Bektaş, T.; Laporte, G. The Pollution-Routing Problem. Transp. Res. Part B Methodol. 2011, 45, 1232–1250. [Google Scholar] [CrossRef]

- Bing, X.; de Keizer, M.; Bloemhof-Ruwaard, J.M.; van der Vorst, J.G.A.J. Vehicle routing for the eco-efficient collection of household plastic waste. Waste Manag. 2014, 34, 719–729. [Google Scholar] [CrossRef]

- Tavares, G.; Zsigraiova, Z.; Semiao, V.; Carvalho, M.G. Optimisation of MSW collection routes for minimum fuel consumption using 3D GIS modelling. Waste Manag. 2009, 29, 1176–1185. [Google Scholar] [CrossRef]

- Iqbal, A.; Zan, F.; Liu, X.; Chen, G.-H. Integrated municipal solid waste management scheme of Hong Kong: A comprehensive analysis in terms of global warming potential and energy use. J. Clean. Prod. 2019, 225, 1079–1088. [Google Scholar] [CrossRef]

- Liu, Y.; Sun, W.; Liu, J. Greenhouse gas emissions from different municipal solid waste management scenarios in China: Based on carbon and energy flow analysis. Waste Manag. 2017, 68, 653–661. [Google Scholar] [CrossRef]

- Wang, Z.; Geng, L. Carbon emissions calculation from municipal solid waste and the influencing factors analysis in China. J. Clean. Prod. 2015, 104, 177–184. [Google Scholar] [CrossRef]

- Kormi, T.; Ali, N.B.H.; Abichou, T.; Green, R. Estimation of landfill methane emissions using stochastic search methods. Atmos. Pollut. Res. 2017, 8, 597–605. [Google Scholar] [CrossRef]

- Du, M.; Peng, C.; Wang, X.; Chen, H.; Wang, M.; Zhu, Q. Quantification of methane emissions from municipal solid waste landfills in China during the past decade. Renew. Sustain. Energy Rev. 2017, 78, 272–279. [Google Scholar] [CrossRef]

- Couth, R.; Trois, C.; Vaughan-Jones, S. Modelling of greenhouse gas emissions from municipal solid waste disposal in Africa. Int. J. Greenh. Gas Control 2011, 5, 1443–1453. [Google Scholar] [CrossRef]

- Friedrich, E.; Trois, C. Current and future greenhouse gas (GHG) emissions from the management of municipal solid waste in the eThekwini Municipality—South Africa. J. Clean. Prod. 2016, 112, 4071–4083. [Google Scholar] [CrossRef]

- Ghosh, P.; Shah, G.; Chandra, R.; Sahota, S.; Kumar, H.; Vijay, V.K.; Thakur, I.S. Assessment of methane emissions and energy recovery potential from the municipal solid waste landfills of Delhi, India. Bioresour. Technol. 2019, 272, 611–615. [Google Scholar] [CrossRef] [PubMed]

- Molino, A.; Mehariya, S.; Karatza, D.; Chianese, S.; Iovine, A.; Casella, P.; Marino, T.; Musmarra, D. Bench-scale cultivation of microalgae scenedesmus almeriensis for CO2 capture and lutein production. Energies 2019, 12, 2806. [Google Scholar] [CrossRef] [Green Version]

- Valdovinos-García, E.M.; Barajas-Fernández, J.; Olán-Acosta, M.D.L.Á.; Petriz-Prieto, M.A.; Guzmán-López, A.; Bravo-Sánchez, M.G. Techno-economic study of CO2 capture of a thermoelectric plant using microalgae (chlorella vulgaris) for production of feedstock for bioenergy. Energies 2020, 13, 413. [Google Scholar]

- Chen, Y.-C. Evaluating greenhouse gas emissions and energy recovery from municipal and industrial solid waste using waste-to-energy technology. J. Clean. Prod. 2018, 192, 262–269. [Google Scholar] [CrossRef]

- Zhao, Y.; Xing, W.; Lu, W.; Zhang, X.; Christensen, T.H. Environmental impact assessment of the incineration of municipal solid waste with auxiliary coal in China. Waste Manag. 2012, 32, 1989–1998. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, S.; Liu, B. Degradation technologies and mechanisms of dioxins in municipal solid waste incineration fly ash: A review. J. Clean. Prod. 2020, 250, 119507. [Google Scholar] [CrossRef]

- Asl, S.M.H.; Javadian, H.; Khavarpour, M.; Belviso, C.; Taghavi, M.; Maghsudi, M. Porous adsorbents derived from coal fly ash as cost-effective and environmentally-friendly sources of aluminosilicate for sequestration of aqueous and gaseous pollutants: A review. J. Clean. Prod. 2019, 208, 1131–1147. [Google Scholar]

- Karatza, D.; Prisciandaro, M.; Lancia, A.; Musmarra, D. Sulfite oxidation catalyzed by cobalt ions in flue gas desulfurization processes. J. Air Waste Manag. Assoc. 2010, 60, 675–680. [Google Scholar] [CrossRef]

- Zhang, C.; Song, W.; Zhang, X.; Li, R.; Zhao, S.; Fan, C. Synthesis, characterization and evaluation of resin-based carbon spheres modified by oxygen functional groups for gaseous elemental mercury capture. J. Mater. Sci. 2018, 53, 9429–9448. [Google Scholar] [CrossRef]

- Wang, Y.; Yan, Y.; Chen, G.; Zuo, J.; Yan, B.; Yin, P. Effectiveness of waste-to-energy approaches in China: From the perspective of greenhouse gas emission reduction. J. Clean. Prod. 2017, 163, 99–105. [Google Scholar] [CrossRef]

- Wang, Y.; Yan, Y.; Chen, G.; Zuo, J.; Du, H. Effective approaches to reduce greenhouse gas emissions from waste to energy process: A China study. Resour. Conserv. Recycl. 2015, 104, 103–108. [Google Scholar] [CrossRef]

- Havukainen, J.; Zhan, M.; Dong, J.; Liikanen, M.; Deviatkin, I.; Li, X.; Horttanainen, M. Environmental impact assessment of municipal solid waste management incorporating mechanical treatment of waste and incineration in Hangzhou, China. J. Clean. Prod. 2017, 141, 453–461. [Google Scholar] [CrossRef]

- Chen, Y.-C. Potential for energy recovery and greenhouse gas mitigation from municipal solid waste using a waste-to-material approach. Waste Manag. 2016, 58, 408–414. [Google Scholar] [CrossRef] [PubMed]

- Calabrò, P.S. Greenhouse gases emission from municipal waste management: The role of separate collection. Waste Manag. 2009, 29, 2178–2187. [Google Scholar] [CrossRef]

- Turner, D.A.; Williams, I.D.; Kemp, S. Greenhouse gas emission factors for recycling of source-segregated waste materials. Resour. Conserv. Recycl. 2015, 105, 186–197. [Google Scholar] [CrossRef] [Green Version]

- Lee, S.; Kim, J.; Chong, W.K.O. The causes of the municipal solid waste and the greenhouse gas emissions from the waste sector in the United States. Waste Manag. 2016, 56, 593–599. [Google Scholar] [CrossRef]

- Eggleston, S.; Buendia, L.; Miwa, K.; Ngara, T.; Tanabe, K. 2006 IPCC Guidelines for National Greenhouse Gas Inventories; Institute for Global Environmental Strategies: Hayama, Japan, 2006; Volume 5. [Google Scholar]

- ISO. Environmental Management—Life Cycle Assessment—Principles and Framework. 2006. Available online: https://www.iso.org/standard/37456.html (accessed on 8 January 2020).

- Lee, U.; Han, J.; Wang, M. Evaluation of landfill gas emissions from municipal solid waste landfills for the life-cycle analysis of waste-to-energy pathways. J. Clean. Prod. 2017, 166, 335–342. [Google Scholar] [CrossRef]

- Couth, R.; Trois, C. Sustainable waste management in Africa through CDM projects. Waste Manag. 2012, 32, 2115–2125. [Google Scholar] [CrossRef]

- Maalouf, A.; El-Fadel, M. Towards improving emissions accounting methods in waste management: A proposed framework. J. Clean. Prod. 2019, 206, 197–210. [Google Scholar] [CrossRef]

- Potdar, A.; Singh, A.; Unnikrishnan, S.; Naik, N.; Naik, M.; Nimkar, I.; Patil, V. Innovation in solid waste management through clean development mechanism in developing countries. Procedia Environ. Sci. 2016, 35, 193–200. [Google Scholar] [CrossRef]

- Santos, M.M.O.; van Elk, A.G.P.; Romanel, C. A correction in the CDM methodological tool for estimating methane emissions from solid waste disposal sites. J. Environ. Manag. 2015, 164, 151–160. [Google Scholar] [CrossRef] [PubMed]

- Unnikrishnan, S.; Singh, A. Energy recovery in solid waste management through CDM in India and other countries. Resour. Conserv. Recycl. 2010, 54, 630–640. [Google Scholar] [CrossRef]

- Fallahizadeh, S.; Rahmatinia, M.; Mohammadi, Z.; Vaezzadeh, M.; Tajamiri, A.; Soleimani, H. Estimation of methane gas by LandGEM model from Yasuj municipal solid waste landfill, Iran. MethodsX 2019, 6, 391–398. [Google Scholar] [CrossRef] [PubMed]

- Nikkhah, A.; Khojastehpour, M.; Abbaspour-Fard, M.H. Hybrid landfill gas emissions modeling and life cycle assessment for determining the appropriate period to install biogas system. J. Clean. Prod. 2018, 185, 772–780. [Google Scholar] [CrossRef]

- Zhang, X. Determination and Evaluation on Calculation Model of Calorific Value of Municipal Solid Waste in Beijing. Presented at ”Environmental Engineering”2018 National Academic Annual Meeting, Beijing, China, 2018. [Google Scholar]

- Yang, N.; Shao, L.; He, P. Study on the moisture content and its features for municipal solid waste fractions in China. China Environ. Sci. 2018, 38, 1033–1038. [Google Scholar]

- Beijing Municipal Commission of Development and Reform. Guidelines for Accounting of Greenhouse Gas Emissions from Municipal Solid Wastes Incineration Enterprise; Beijing Municipal Commission of Development and Reform: Beijing, China, 2019.

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Sampling and Analysis Methods for Domestic Waste; Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2009.

- Park, S.; Lah, T.J. Analyzing the success of the volume-based waste fee system in South Korea. Waste Manag. 2015, 43, 533–538. [Google Scholar] [CrossRef]

- Chen, S.; Huang, J.; Xiao, T.; Gao, J.; Bai, J.; Luo, W.; Dong, B. Carbon emissions under different domestic waste treatment modes induced by garbage classification: Case study in pilot communities in Shanghai, China. Sci. Total Environ. 2020, 717, 137193. [Google Scholar] [CrossRef]

- Statistics, N. China Energy Statistical Yearbook 2018; China Statistics Press: Beijing, China, 2013. [Google Scholar]

- Zhuo, Y.; Liu, Y.; Liu, B. Measuring method and application of urea aqueous solution consumption for SCR after-treatment system. Bus Coach Technol. Res. 2014, 36, 50–52. [Google Scholar]

- Scora, G.; Barth, M. Comprehensive Modal Emission Model (CMEM). Cent. Environ. Res. Technol. 2006, 23, 24. [Google Scholar]

- Demir, E.; Bektaş, T.; Laporte, G. An adaptive large neighborhood search heuristic for the pollution-routing problem. Eur. J. Oper. Res. 2012, 223, 346–359. [Google Scholar] [CrossRef]

- Wang, L.; Li, Y. Greenhouse gas (GHG) emissions and its influencing factors in Beijing municipal solid waste incineration power plant. Chin. J. Environ. Eng. 2017, 11, 6490–6496. [Google Scholar]

- Ibikunle, R.A.; Titiladunayo, I.F.; Akinnuli, B.O.; Dahunsi, S.O.; Olayanju, T.M.A. Estimation of power generation from municipal solid wastes: A case study of Ilorin metropolis, Nigeria. Energy Rep. 2019, 5, 126–135. [Google Scholar] [CrossRef]

- Guo, Q.; Dai, X. Analysis on carbon dioxide emission reduction during the anaerobic synergetic digestion technology of sludge and kitchen waste: Taking kitchen waste synergetic digestion project in Zhenjiang as an example. Waste Manag. 2017, 69, 360–364. [Google Scholar] [CrossRef]

- Kathirvale, S.; Yunus, M.N.M.; Sopian, K.; Samsuddin, A.H. Energy potential from municipal solid waste in Malaysia. Renew. Energy 2004, 29, 559–567. [Google Scholar] [CrossRef]

- Morris, J. Recycling versus incineration: An energy conservation analysis. J. Hazard. Mater. 1996, 47, 277–293. [Google Scholar] [CrossRef]

- Sevigné-Itoiz, E.; Gasol, C.M.; Rieradevall, J.; Gabarrell, X. Contribution of plastic waste recovery to greenhouse gas (GHG) savings in Spain. Waste Manag. 2015, 46, 557–567. [Google Scholar] [CrossRef] [Green Version]

- Srinivasa, K.G.; Sowmya, B.J.; Shikhar, A.; Utkarsha, R.; Singh, A. Data analytics assisted internet of things towards building intelligent healthcare monitoring systems: Iot for healthcare. J. Organ. User Comput. 2018, 30, 83–103. [Google Scholar] [CrossRef]

- Biswas, S.; Devi, D.; Chakraborty, M. A hybrid case based reasoning model for classification in internet of things (Iot) environment. J. Organ. User Comput. 2018, 30, 104–122. [Google Scholar] [CrossRef]

- Reddy, M.R.; Srinivasa, K.G.; Reddy, B.E. Smart vehicular system based on the internet of things. J. Organ. User Comput. 2018, 30, 45–62. [Google Scholar] [CrossRef]

- Sousa Matos, M.R.; Frota, Y.; Ochi, L.S. Green vehicle routing and scheduling problem with split delivery. Electron. Notes Discret. Math. 2018, 69, 13–20. [Google Scholar] [CrossRef]

| Waste Components | Waste Composition (%) [51] | Moisture Content (%) [52] | Total Carbon Content on Dry Basis (%) [53] | Fraction of Fossil Carbon in Total Carbon Content (%) [41] | Fraction of Degradable Organic Carbon on Wet Basis (%) [41] | Heat Value on Dry Basis (MJ/t) [54] |

|---|---|---|---|---|---|---|

| Kitchen waste | 47.85 | 82.1 | 50.6 | 0 | 15 | 4650 |

| Ash and brick | 3.48 | 11.5 | 0 | 100 | 0 | 6980 |

| Wood | 3.33 | 21.6 | 53.03 | 0 | 43 | 18,610 |

| Paper | 20.83 | 29.2 | 46.13 | 1 | 4 | 16,600 |

| Textile | 2.34 | 22.9 | 61.03 | 20 | 24 | 17,450 |

| Plastics | 20.74 | 32.5 | 78.77 | 100 | 0 | 23,260 |

| Glass | 1.23 | 2.4 | 0 | 0 | 0 | 140 |

| Metal | 0.2 | 5.4 | 0 | 0 | 0 | 700 |

| Waste Management Activities | Including or Not |

|---|---|

| Collection and transportation | √ |

| Fixed facility operation | × |

| Landfill | √ |

| Energy recover from landfill | × |

| Composting | √ |

| Incineration | √ |

| Energy recover from incineration | √ |

| Recycling of renewable resources | √ |

| Scenario | Landfill (t/d) | Incineration (t/d) | Composting (t/d) | Recycling (t/d) |

|---|---|---|---|---|

| Scenario 1 | 10341 | 9200 | —— | —— |

| Scenario 2 | 7867 | 6999 | 4675 | —— |

| Scenario 3 | —— | 14,866 | 4675 | —— |

| Scenario 4 | 5523 | 4913 | 4675 | 4430 |

| Scenario 5 | —— | 10,436 | 4675 | 4430 |

| Waste Composition | Scenario 1 | Scenario 2 | Scenario 3 | Scenario 4 | Scenario 5 |

|---|---|---|---|---|---|

| Kitchen waste (%) | 47.85 | 31.45 | 31.45 | 44.80 | 44.80 |

| Ash and brick (%) | 3.48 | 4.57 | 4.57 | 6.52 | 6.52 |

| Wood (%) | 3.33 | 4.38 | 4.38 | 6.24 | 6.24 |

| Paper (%) | 20.83 | 27.38 | 27.38 | 19.50 | 19.50 |

| Textile (%) | 2.34 | 3.08 | 3.08 | 2.19 | 2.19 |

| Plastics (%) | 20.74 | 27.26 | 27.26 | 19.42 | 19.42 |

| Glass (%) | 1.23 | 1.62 | 1.62 | 1.15 | 1.15 |

| Metal (%) | 0.2 | 0.26 | 0.26 | 0.19 | 0.19 |

| Heat value on dry basis (MJ/t) | 9407 | 10952 | 10952 | 9427 | 9427 |

| Notation | Description | Typical Values |

|---|---|---|

| κd | the low heating value of diesel(GJ/t) | 42.652 |

| CCd | the carbon content per unit heating value of diesel(tC/GJ) | 0.0202 |

| OFd | the oxidation factor of diesel consumption | 98% |

| the CH4 emission factor of diesel consumed by heavy duty vehicle under State-Ⅴ emission standard in China (mgCH4/km) | 175 | |

| the N2O emission factor of diesel consumed by heavy duty vehicle under State-Ⅴ emission standard in China (mgN2O/km) | 30 | |

| GWPCH4 | the global warming potential of CH4 | 21 |

| GWPN2OOO | the global warming potential of N2O | 310 |

| L | the mass ratio of urea in the urea additive | 32.5% |

| Notation | Description | Typical Values |

|---|---|---|

| ϕ | Fuel-to-air mass ratio | 1 |

| k | Engine friction factor (J/r/L) | 0.2 |

| N | Engine speed (r/s) | 33 |

| V | Engine displacement (L) | 5 |

| η | Efficiency parameter for diesel engines | 0.45 |

| κd | Heating value of a typical diesel fuel (J/g) | 42652 |

| ε | Vehicle drive train efficiency | 0.4 |

| w1 | Curb-weight (kg) | 5000 |

| w2 | Vehicle load (kg) | 10,000 |

| a | Acceleration (m/s2) | 0 |

| g | Gravitational constant (m/s2) | 9.81 |

| θ | Road angle | 0 |

| Cd | Coefficient of aerodynamic drag | 0.7 |

| A | Frontal surface area (m2) | 5 |

| ρ | Air density (kg/m3) | 1.2041 |

| Cr | Coefficient of rolling resistance | 0.01 |

| Notation | Description | Typical Values |

|---|---|---|

| DOC | Fraction of degradable organic carbon | —— |

| DOCi | Degradable organic carbon for waste fraction i | shown in Table 1 |

| fi | Waste composition | shown in Table 4 |

| DDOC | Mass of decomposable DOC | —— |

| MSWl | Mass of waste landfilled | shown in Table 3 |

| DOCf | Fraction of DOC that can decompose | 0.5 |

| MCF | CH4 correction factor for aerobic decomposition 4 correction factor for aerobic decomposition | 1 |

| F | Fraction of CH4 in generated landfill gas 4 in generated landfill gas | 0.5 |

| Rl | CH4 recovered rate | 0 |

| OX | Oxidation factor | 0 |

| Mass of CH4 emissions in landfill | —— | |

| Carbon dioxide equivalent of CH4 emissions | —— |

| Notation | Description | Typical Values |

|---|---|---|

| EI | GHG emissions in incineration (t) | —— |

| Ei | Direct emissions from mineral carbon incineration (t) | —— |

| Ee | GHG emissions reduction from electricity generation (t) | —— |

| MSWi | Mass of waste incinerated (t) | shown in Table 3 |

| fi | Waste composition | shown in Table 4 |

| dmi | Dry matter content of wet weight | shown in Table 1 |

| CFi | DOC content of dry weight | shown in Table 1 |

| FCFi,t | Fossil carbon fraction of total carbon total carbon | shown in Table 1 |

| OFw | Oxidation factor | 0.95 |

| ADe | Mass of on-grid energy from incineration (MWh) | —— |

| EFe | Electricity GHG emissions factor (tCO2/MWh) | 0.4506 |

| HVMSW | Heat value (kJ/kg MSW) | shown in Table 4 |

| ξ | Heat efficiency for incineration plant | 20% |

| ζ | Self-used electricity rate for incineration plant | 20% |

| Activities | Scenario1 (tCO2e) | Scenario2 (tCO2e) | Scenario3 (tCO2e) | Scenario4 (tCO2e) | Scenario5 (tCO2e) |

|---|---|---|---|---|---|

| Transportation | 91.49 | 97.06 | 97.84 | 102.14 | 102.69 |

| Landfill | 12,669.90 | 10,072.22 | 0.00 | 6853.69 | 0.00 |

| Incineration | 3626.29 | 3626.34 | 7702.41 | 1813.05 | 3851.21 |

| Compost | 0.00 | 827.48 | 827.48 | 827.48 | 827.48 |

| Recyclable | 0.00 | 0.00 | 0.00 | −4033.40 | −4033.40 |

| Electricity | −1733.20 | −1535.11 | −3260.59 | −927.53 | −1970.23 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xin, C.; Zhang, T.; Tsai, S.-B.; Zhai, Y.-M.; Wang, J. An Empirical Study on Greenhouse Gas Emission Calculations Under Different Municipal Solid Waste Management Strategies. Appl. Sci. 2020, 10, 1673. https://doi.org/10.3390/app10051673

Xin C, Zhang T, Tsai S-B, Zhai Y-M, Wang J. An Empirical Study on Greenhouse Gas Emission Calculations Under Different Municipal Solid Waste Management Strategies. Applied Sciences. 2020; 10(5):1673. https://doi.org/10.3390/app10051673

Chicago/Turabian StyleXin, Chunlin, Tingting Zhang, Sang-Bing Tsai, Yu-Ming Zhai, and Jiangtao Wang. 2020. "An Empirical Study on Greenhouse Gas Emission Calculations Under Different Municipal Solid Waste Management Strategies" Applied Sciences 10, no. 5: 1673. https://doi.org/10.3390/app10051673

APA StyleXin, C., Zhang, T., Tsai, S.-B., Zhai, Y.-M., & Wang, J. (2020). An Empirical Study on Greenhouse Gas Emission Calculations Under Different Municipal Solid Waste Management Strategies. Applied Sciences, 10(5), 1673. https://doi.org/10.3390/app10051673