Implementation of Digital Twin for Engine Block Manufacturing Processes

Abstract

1. Introduction

2. Literature Review

3. Materials and Methods

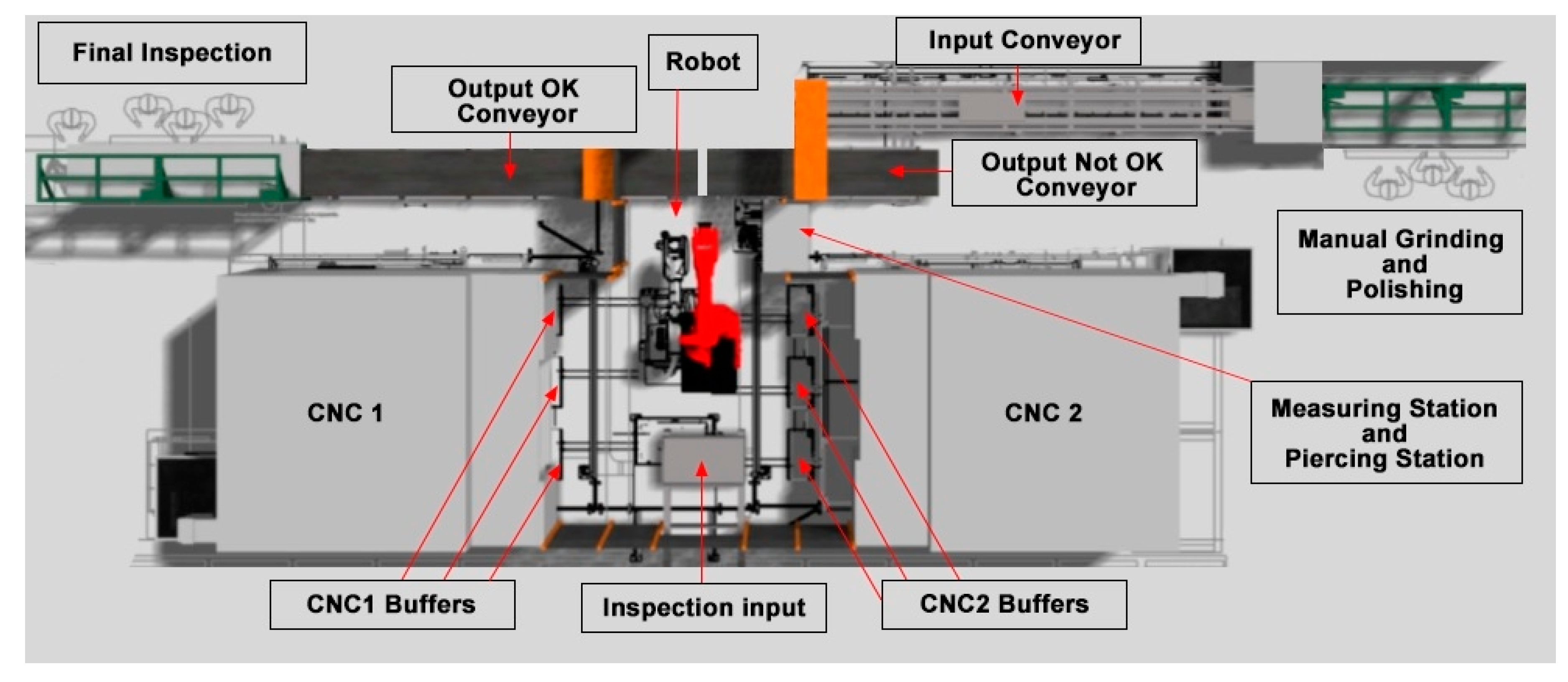

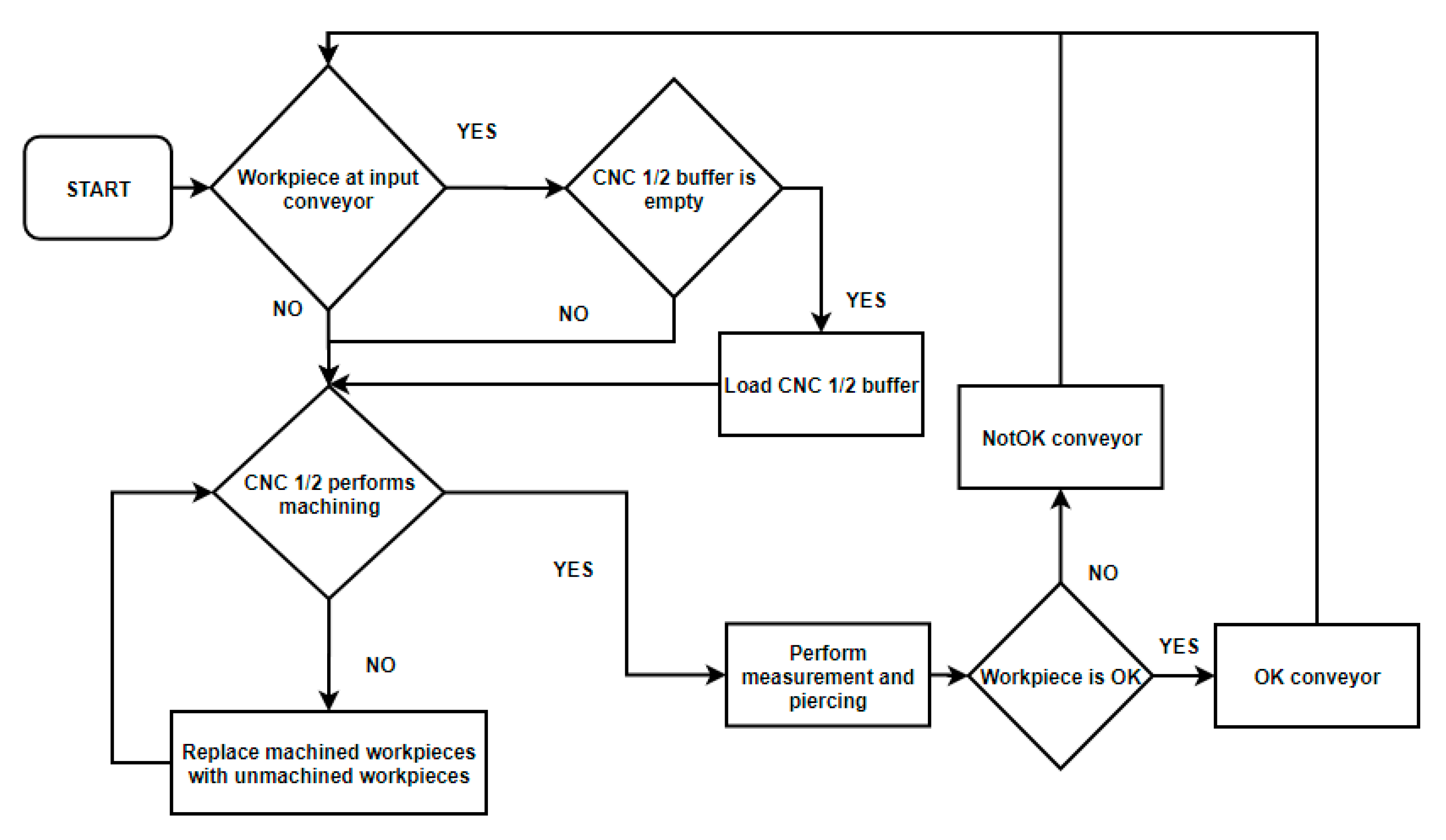

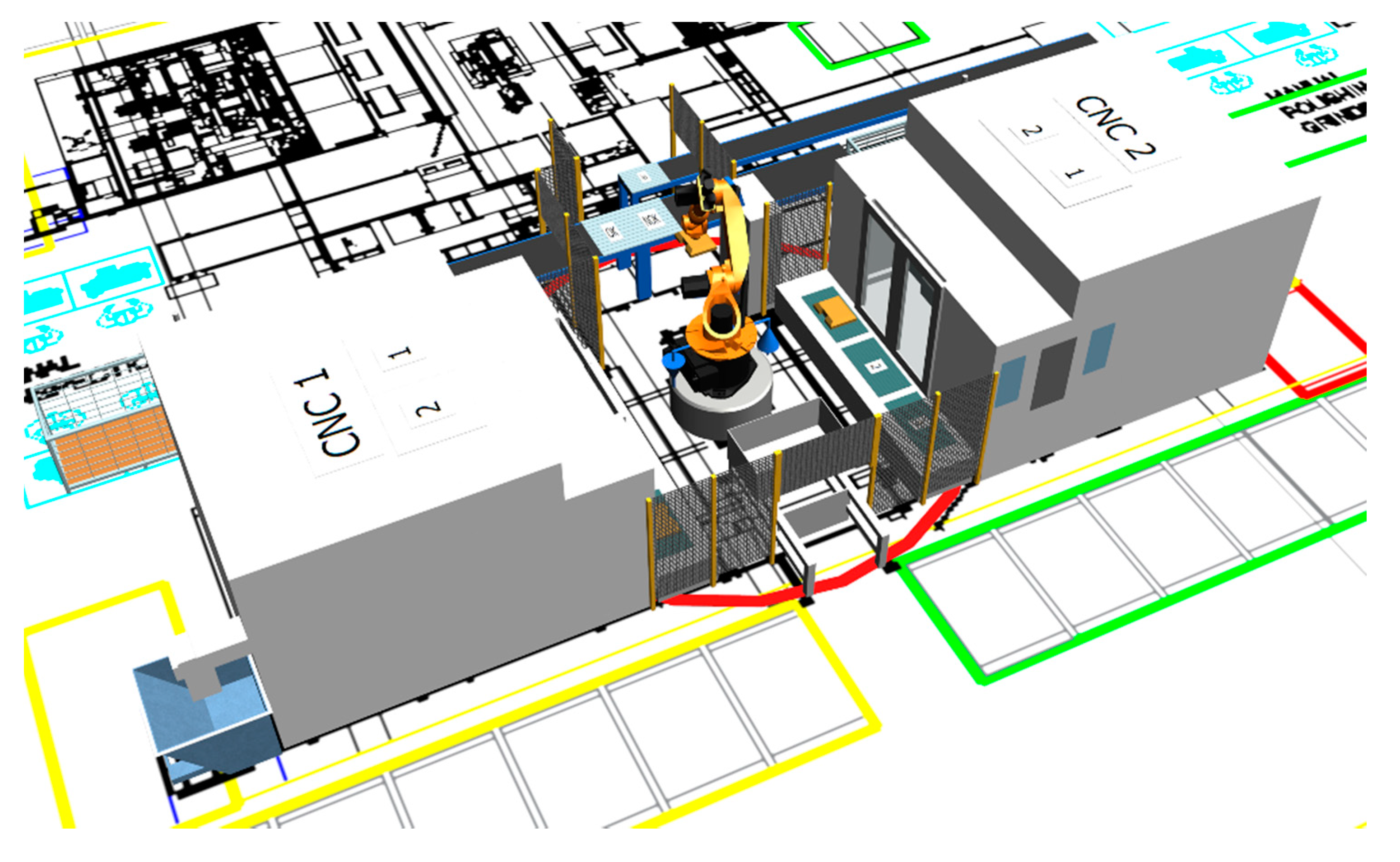

3.1. Characteristics of Production Line

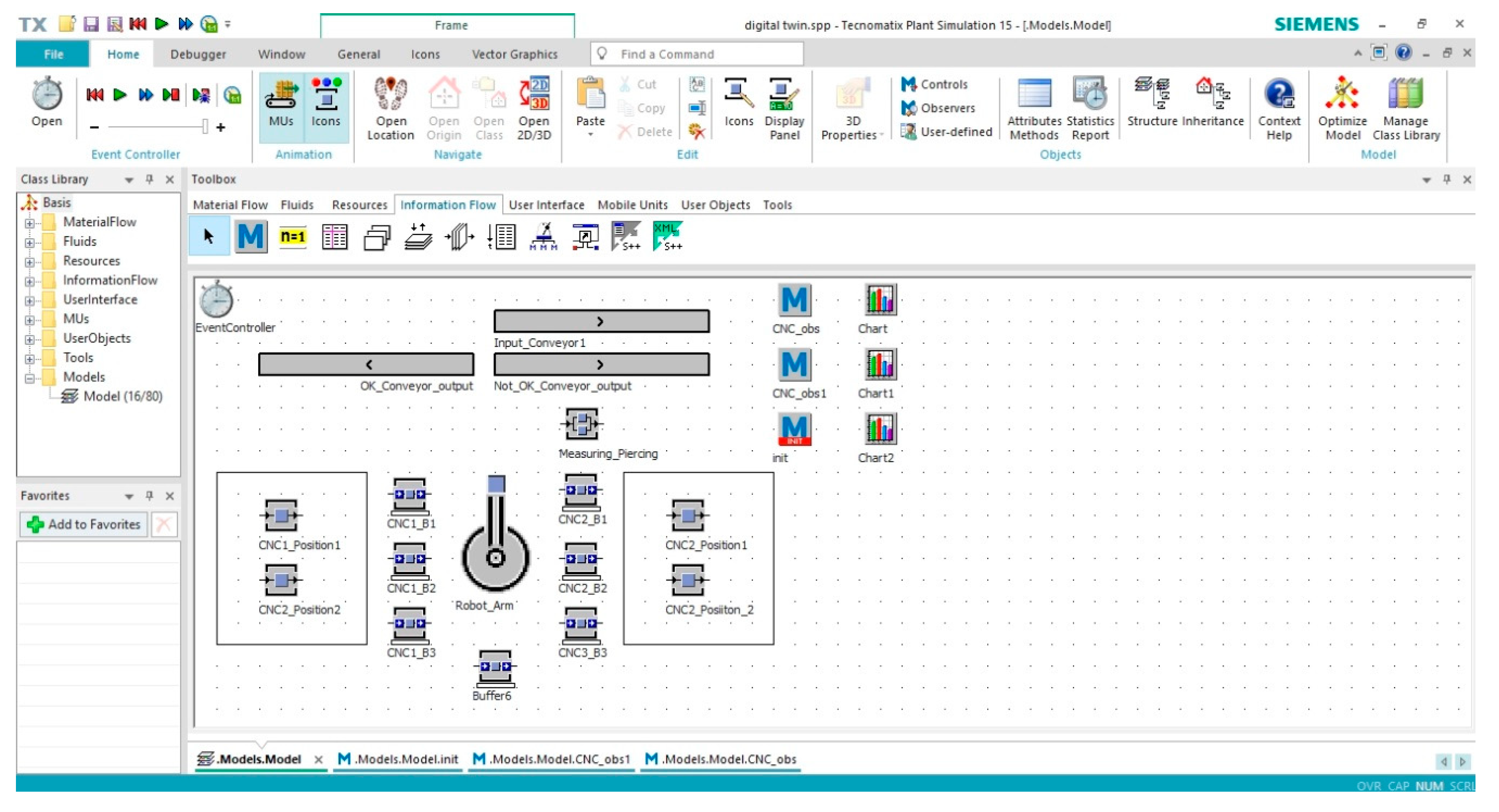

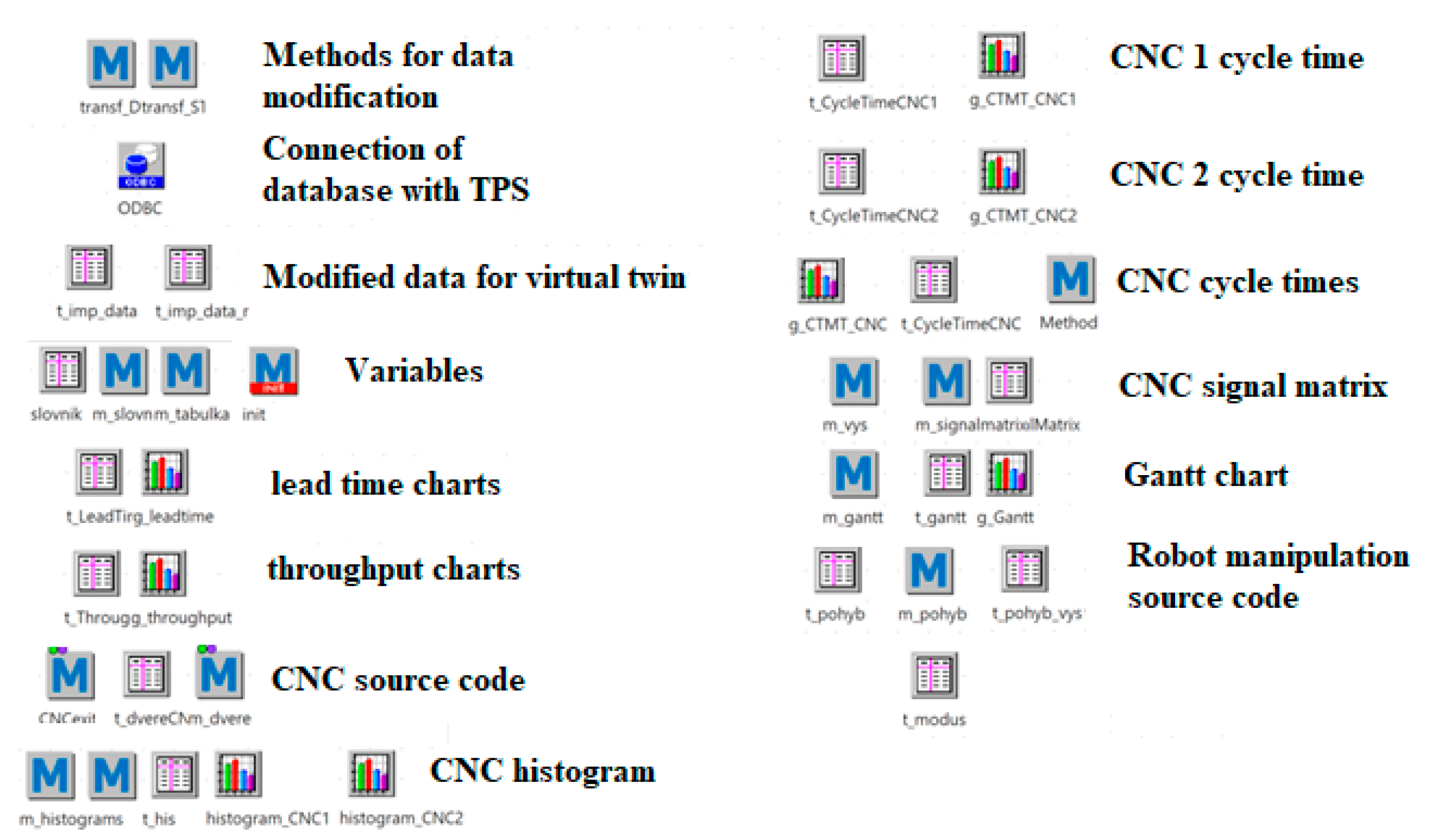

3.2. Development of Simulation Model

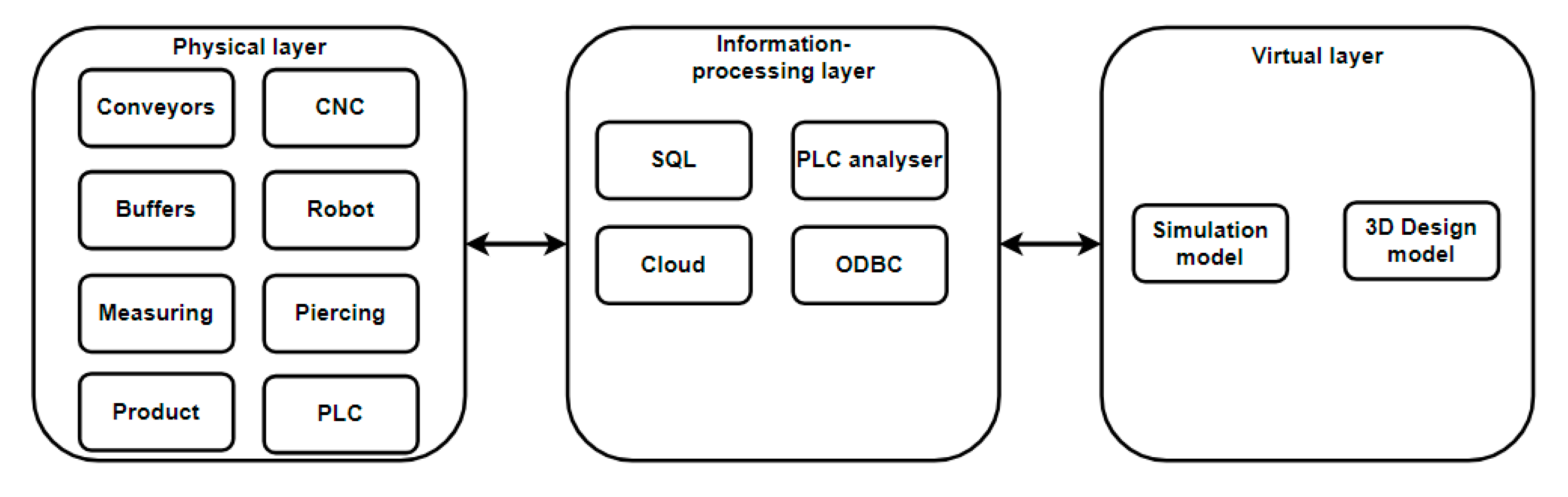

3.3. Development of Communication Interface

4. Results

- lead time (time interval from entry of the workpiece into the production process through the input conveyor to the removal of the workpiece from the output conveyor);

- cycle times and histograms for the CNC machines;

- throughput (the interval of occurrence of a casting at a given point);

- Gantt chart of the entire production line.

5. Discussion

6. Conclusions and Future Work

- The simulation model of the engine block machining process was developed and validated.

- Real-time interaction between physical and virtual entities of the production line was established.

- To increase production line productivity, an algorithm for the bottleneck detection was developed and implemented in the DT.

Author Contributions

Funding

Conflicts of Interest

References

- Jones, D.; Snider, C.; Nassehi, A.; Yon, J.; Hicks, B. Characterising the Digital Twin: A systematic literature review. CIRP-JMSTP 2020, 29, 36–52. [Google Scholar] [CrossRef]

- Stark, R.; Damerau, T. Digital Twin. In CIRP Encyclopedia of Production Engineering; Chatti, S., Tolio, T., Eds.; The International Academy for Production Engineering; Springer: Berlin, Germany, 2019. [Google Scholar]

- Roy, R.B.; Mishra, D.; Pal, S.K.; Chakravarty, T.; Panda, S.; Chandra, M.G.; Pal, A.; Misra, P.; Chakravarty, D.; Misra, S. Digital Twin: Current scenario and case study on manufacturing process. Int. J. Adv. Manuf. Technol. 2020, 107, 3691–3714. [Google Scholar] [CrossRef]

- Fuller, A.; Fan, Z.; Day, C.; Barlow, C. Digital Twin: Enabling Technologies, Challenges and Open Research. IEEE Access 2020, 108952–108971. [Google Scholar] [CrossRef]

- Qi, Q.; Tao, F.; Hu, T.; Anwer, N.; Liu, A.; Wei, Y.; Wang, L.; Nee, A.Y.C. Enabling technologies and tools for digital twin. J. Manuf. Syst. 2020. [Google Scholar] [CrossRef]

- Feofanov, A.; Baranov, N. Risk analysis in digital twin creation of machine building production. In MATEC Web of Conferences; EDP Sciences: Les Ulis, France, 2019; Volume 298. [Google Scholar]

- ISO/DIS 23247-1. Automation Systems and Integration. Digital Twin Framework for Manufacturing. Part 1: Overview and General Principles; International Organization for Standardization: Geneva, Switzerland, 2020. [Google Scholar]

- ISO/DIS 23247-2. Automation Systems and Integration. Digital Twin Framework for Manufacturing. Part 2: Reference Architecture; International Organization for Standardization: Geneva, Switzerland, 2020. [Google Scholar]

- ISO/DIS 23247-3. Automation Systems and Integration. Digital Twin Framework for Manufacturing. Part 3: Digital Representation of Manufacturing Elements; International Organization for Standardization: Geneva, Switzerland, 2020. [Google Scholar]

- ISO/DIS 23247-4. Automation Systems and Integration. Digital Twin Framework for Manufacturing. Part 4: Information Exchange; International Organization for Standardization: Geneva, Switzerland, 2020. [Google Scholar]

- Tan, Y.; Yang, W.; Yoshida, K.; Takakuwa, S. Application of IoT-Aided Simulation to Manufacturing Systems in Cyber-Physical System. Machines 2019, 7, 2. [Google Scholar] [CrossRef]

- Zheng, Y.; Yang, S.; Cheng, H. An application framework of digital twin and its case study. J. Ambient. Intell. Humaniz. Comput. 2019, 10, 1141–1153. [Google Scholar] [CrossRef]

- Negri, E.; Fumagalli, L.; Macchi, M. A Review of the Roles of Digital Twin in CPS-based Production Systems. In Value Based and Intelligent Asset Management; Márquez, A.C., Macchi, M., Parlikad, A.K., Eds.; Springer: Cham, Switzerland, 2019; pp. 291–307. [Google Scholar]

- Zhang, H.; Liu, Q.; Chen, X.; Zhang, D.; Leng, J. A Digital Twin-Based Approach for Designing and Multi-Objective Optimization of Hollow Glass Production Line. IEEE Access 2017, 5, 26901–26911. [Google Scholar] [CrossRef]

- Cao, J.; Wang, J.; Lu, J. A Referenced Cyber Physical System for Compressor Manufacturing. MATEC Web Conf. 2020, 306, 02005. [Google Scholar] [CrossRef][Green Version]

- Bao, J.; Guo, D.; Li, J.; Zhang, J. The modelling and operations for the digital twin in the context of manufacturing. Enterp. Inf. Syst. 2019, 13, 534–556. [Google Scholar] [CrossRef]

- Liu, Q.; Zhang, H.; Leng, J.; Chen, X. Digital twin-driven individualized designing of automated flow-shop manufacturing system. Int. J. Prod. Res. 2019, 57, 3903–3919. [Google Scholar] [CrossRef]

- Ding, K.; Chan, F.T.S.; Zhang, X.; Zhou, G.; Zhang, F. Defining a Digital Twin-based Cyber-Physical Production System for autonomous manufacturing in smart shop floors. Int. J. Prod. Res. 2019, 57, 6315–6334. [Google Scholar] [CrossRef]

- Zhou, G.; Zhang, C.; Li, Z.; Ding, K.; Wang, C. Knowledge-driven digital twin manufacturing cell towards intelligent manufacturing. Int. J. Prod. Res. 2020, 58, 1034–1051. [Google Scholar] [CrossRef]

- Zhuang, C.; Liu, J.; Xiong, H. Digital twin-based smart production management and control framework for the complex product assembly shop-floor. Int. J. Adv. Manuf. Technol. 2018, 96, 1149–1163. [Google Scholar] [CrossRef]

- Bilberg, A.; Malik, A.A. Digital twin driven human-robot collaborative assembly. CIRP Ann. 2019, 68, 499–502. [Google Scholar] [CrossRef]

- He, B.; Bai, K.J. Digital twin-based sustainable intelligent manufacturing: A review. Adv. Manuf. 2020, 1–21. [Google Scholar] [CrossRef]

- Liu, C.; Le Roux, L.; Körner, C.; Tabaste, O.; Lacan, F.; Bigot, S. Digital Twin-enabled Collaborative Data Management for Metal Additive Manufacturing Systems. J. Manuf. Syst. 2020. [Google Scholar] [CrossRef]

- Zambal, S.; Eitzinger, C.; Clarke, M.; Klintworth, J.; Mechin, P. A digital twin for composite parts manufacturing: Effects of defects analysis based on manufacturing data. In Proceedings of the IEEE 16th International Conference on Industrial Informatics (INDIN), Porto, Portugal, 18–20 July 2018; pp. 803–808. [Google Scholar]

- Sujová, E.; Čierna, H.; Zabinska, I. Application of digitization procedures of production in practice. Manag. Syst. Prod. Eng. 2019, 27, 23–28. [Google Scholar] [CrossRef]

- Cimino, C.; Negri, E.; Fumagalli, L. Review of digital twin applications in manufacturing. Comp. Ind. 2019, 113, 103130. [Google Scholar] [CrossRef]

- Redelinghuys, A.J.H.; Basson, A.H.; Kruger, H. A six-layer architecture for the digital twin: A manufacturing case study implementation. J. Intell. Manuf. 2020, 31, 1383–1402. [Google Scholar] [CrossRef]

- Sun, H.; Li, C.; Fang, X.; Gu, H. Optimized throughput improvement of assembly flow line with digital twin online analytics. In Proceedings of the 2017 IEEE International Conference on Robotics and Biomimetics (ROBIO), Macau, China, 5–8 December 2017; pp. 1833–1837. [Google Scholar]

- Liau, Y.; Lee, H.; Ryu, K. Digital twin concept for smart injection molding. IOP Conf. Ser. Mater. Sci. Eng. 2018, 324, 012077. [Google Scholar] [CrossRef]

- Talkhestani, B.A.; Jazdi, N.; Schlogl, W.; Weyrich, M. A concept in synchronization of virtual production system with real factory based on anchor-point method. Proceedia CIRP 2018, 67, 13–17. [Google Scholar] [CrossRef]

| Occurrence | Bottleneck |

|---|---|

| 15 | extended measuring time |

| 62 | full output OK conveyor (robot must wait to free up space on the conveyor) |

| 66 | extended time since the casting was placed on the OK conveyor until it left the OK conveyor |

| 10 | extended time since the casting was placed on the Not OK conveyor until it left the Not OK conveyor |

| 24 | extended time for which the casting is ready to be removed from the inspection input |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bambura, R.; Šolc, M.; Dado, M.; Kotek, L. Implementation of Digital Twin for Engine Block Manufacturing Processes. Appl. Sci. 2020, 10, 6578. https://doi.org/10.3390/app10186578

Bambura R, Šolc M, Dado M, Kotek L. Implementation of Digital Twin for Engine Block Manufacturing Processes. Applied Sciences. 2020; 10(18):6578. https://doi.org/10.3390/app10186578

Chicago/Turabian StyleBambura, Roman, Marek Šolc, Miroslav Dado, and Luboš Kotek. 2020. "Implementation of Digital Twin for Engine Block Manufacturing Processes" Applied Sciences 10, no. 18: 6578. https://doi.org/10.3390/app10186578

APA StyleBambura, R., Šolc, M., Dado, M., & Kotek, L. (2020). Implementation of Digital Twin for Engine Block Manufacturing Processes. Applied Sciences, 10(18), 6578. https://doi.org/10.3390/app10186578