Thermal Action on Normal and High Strength Cement Mortars

Abstract

1. Introduction

2. Materials and Methods

- -

- MNS: normal strength mortar

- -

- MHS: high strength mortar

2.1. Materials and Mix Design

2.2. Experimental Campaign

2.2.1. Thermal Treatments

2.2.2. Capillarity Water Absorption Tests

2.2.3. Mechanical Tests

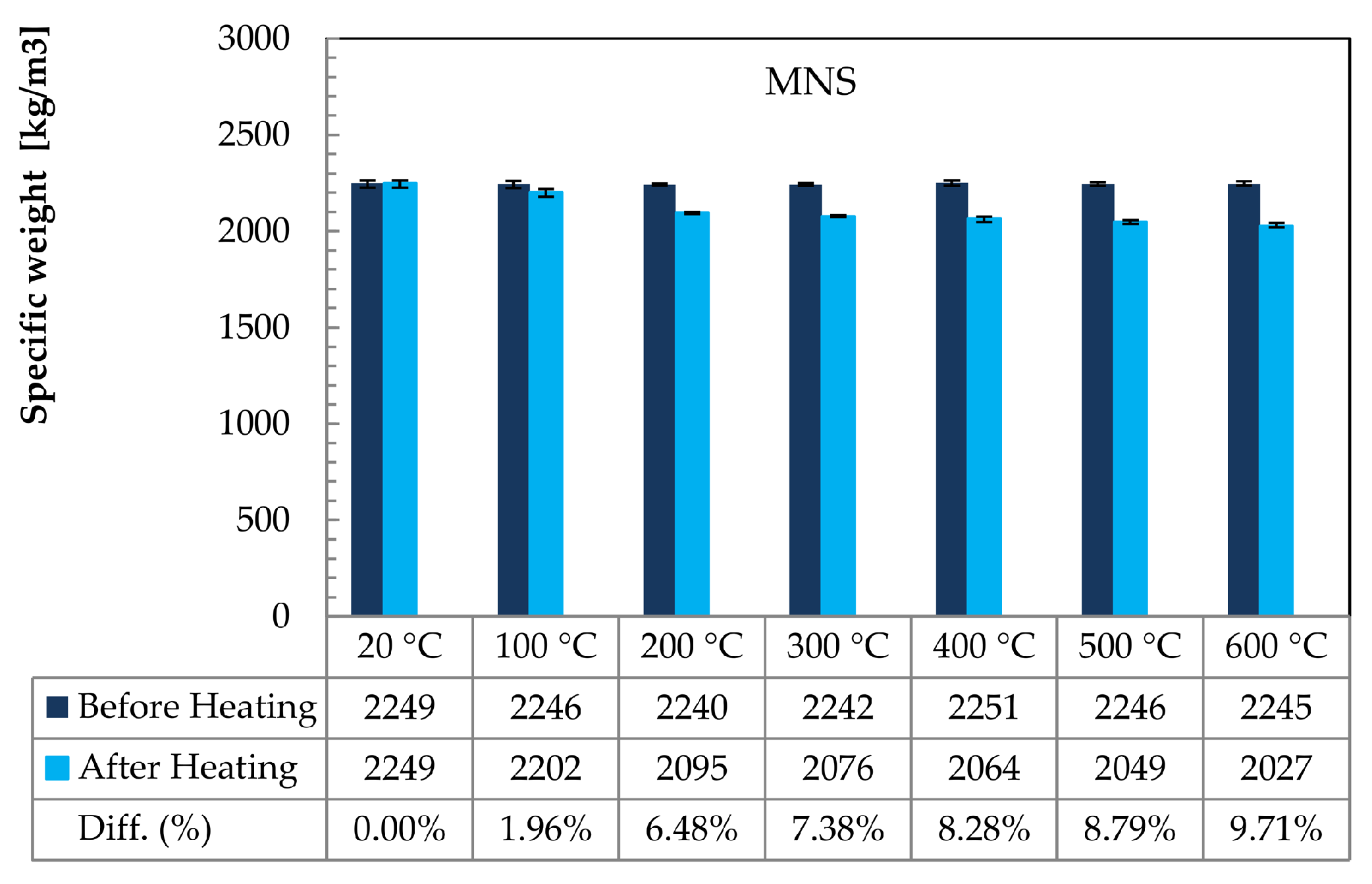

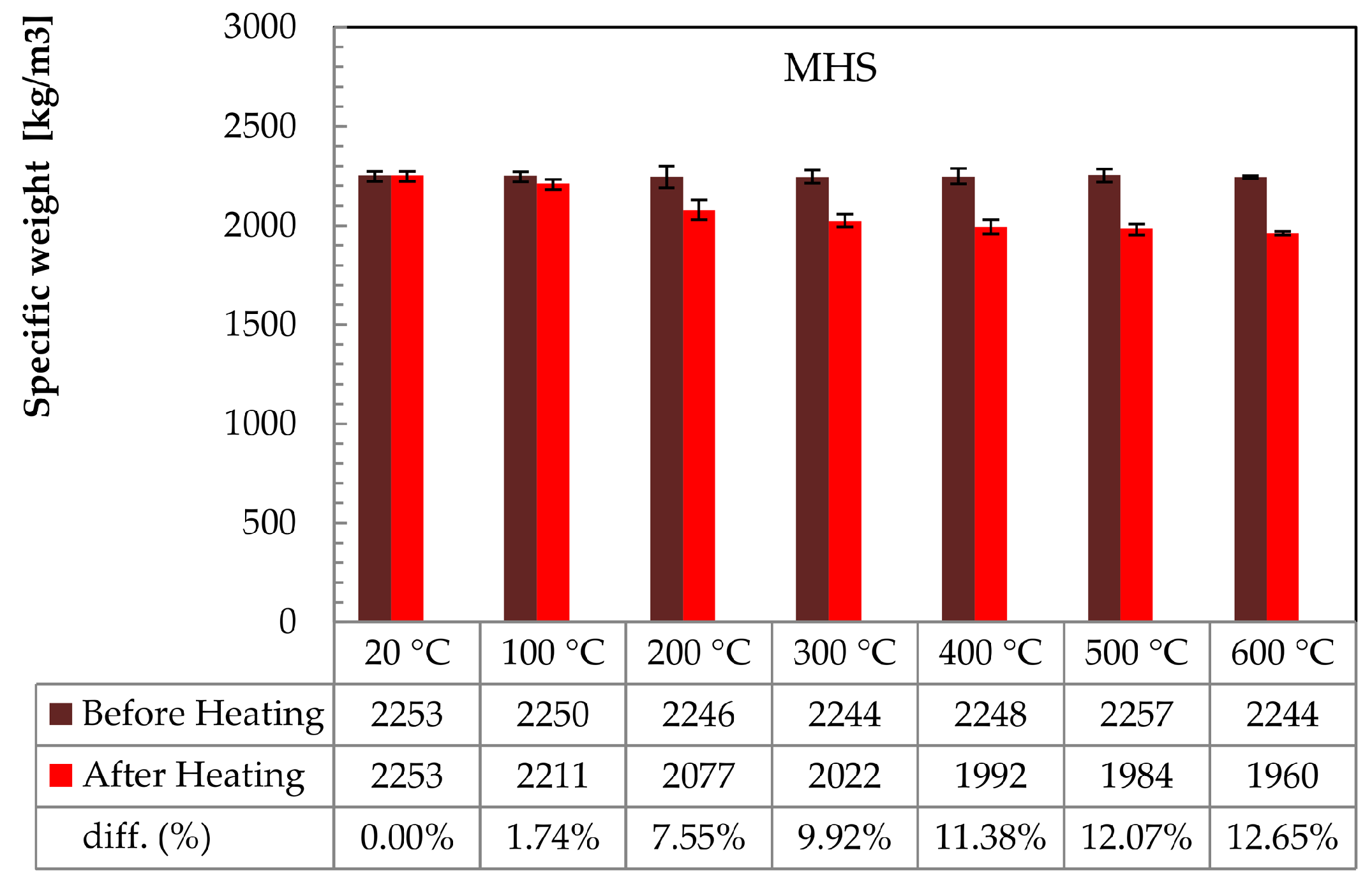

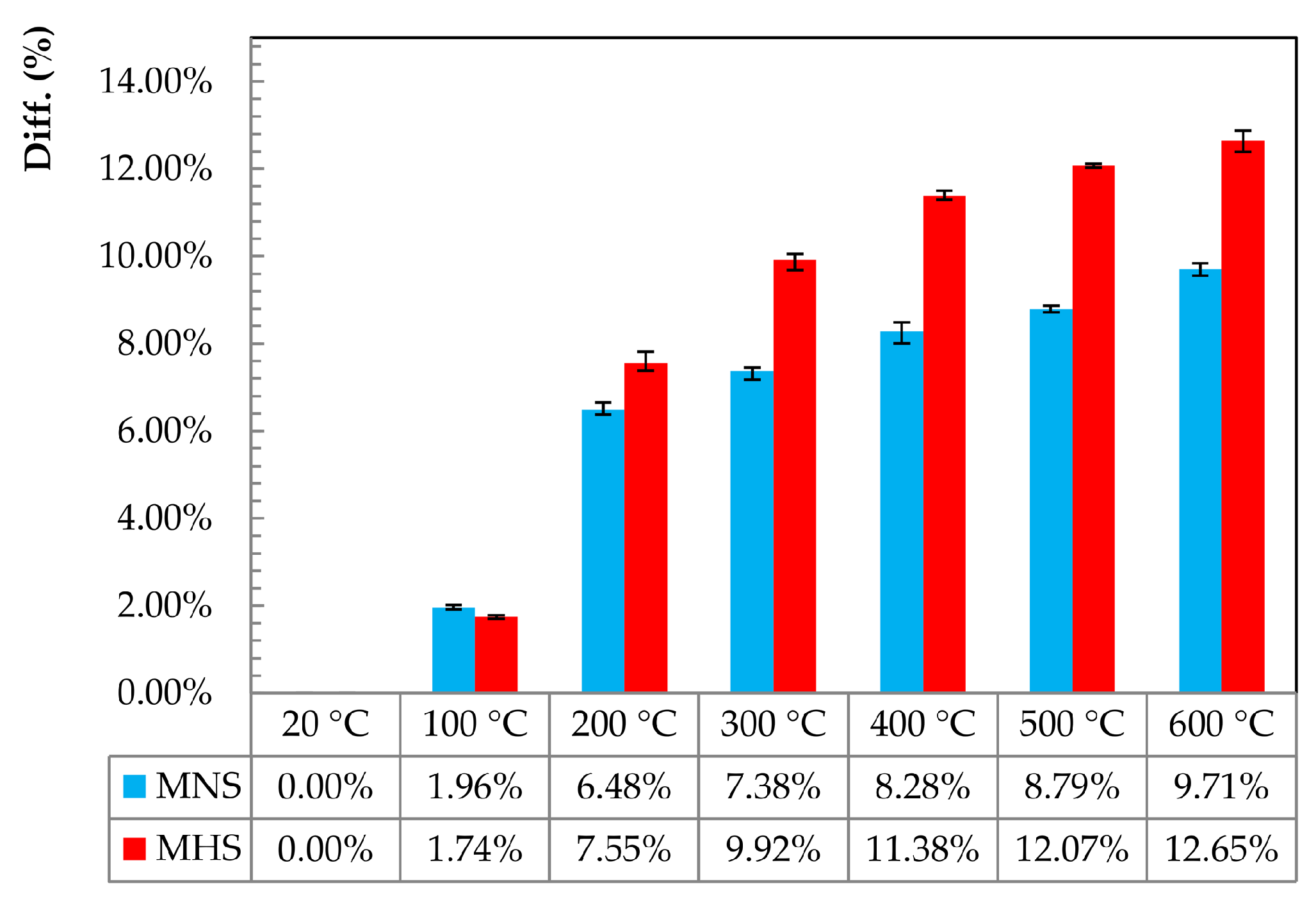

3. Thermal Damages and Weight Loss after Temperature Conditioning

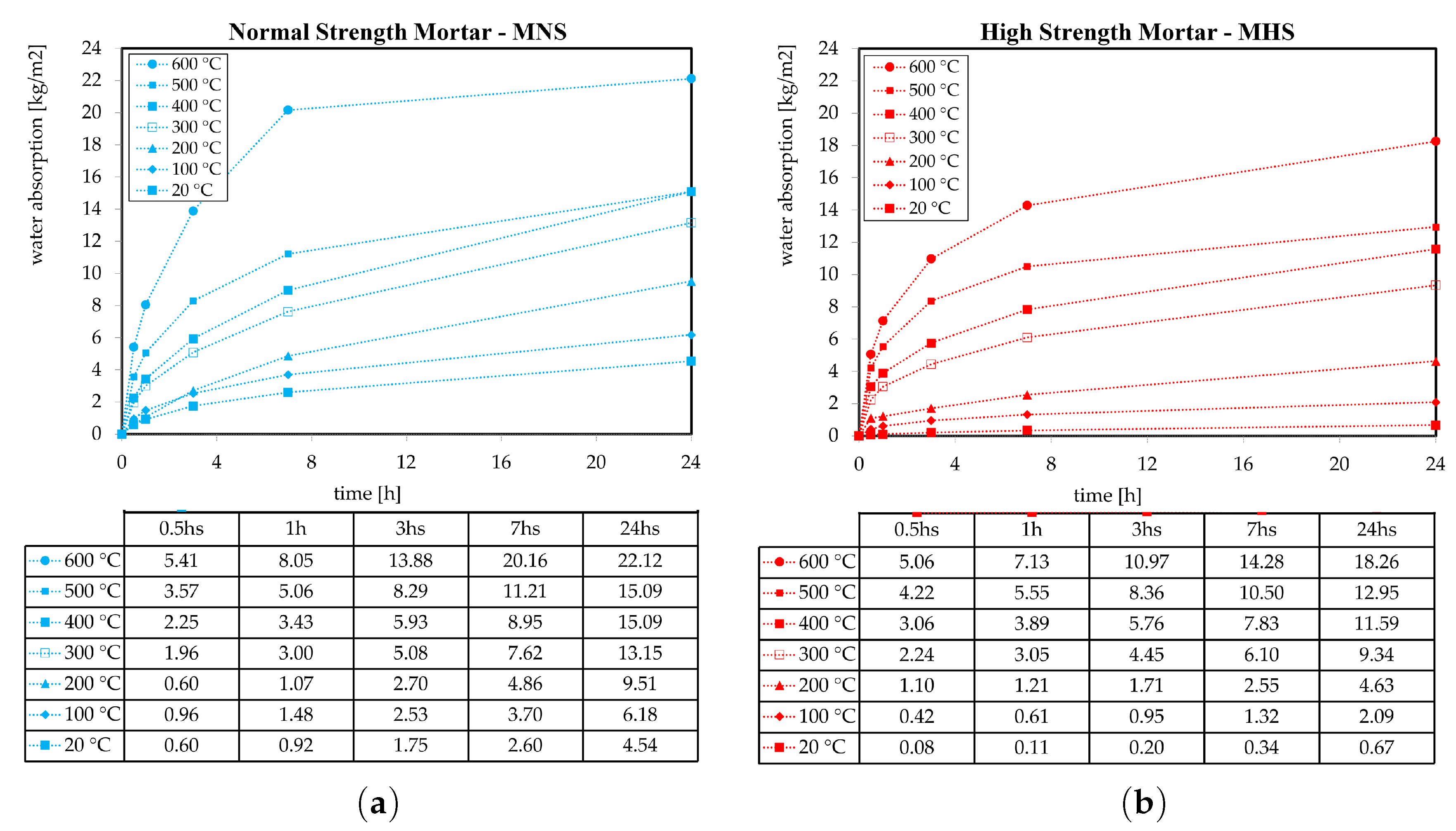

4. Capillary Water Absorption Results

5. Mechanical Tests

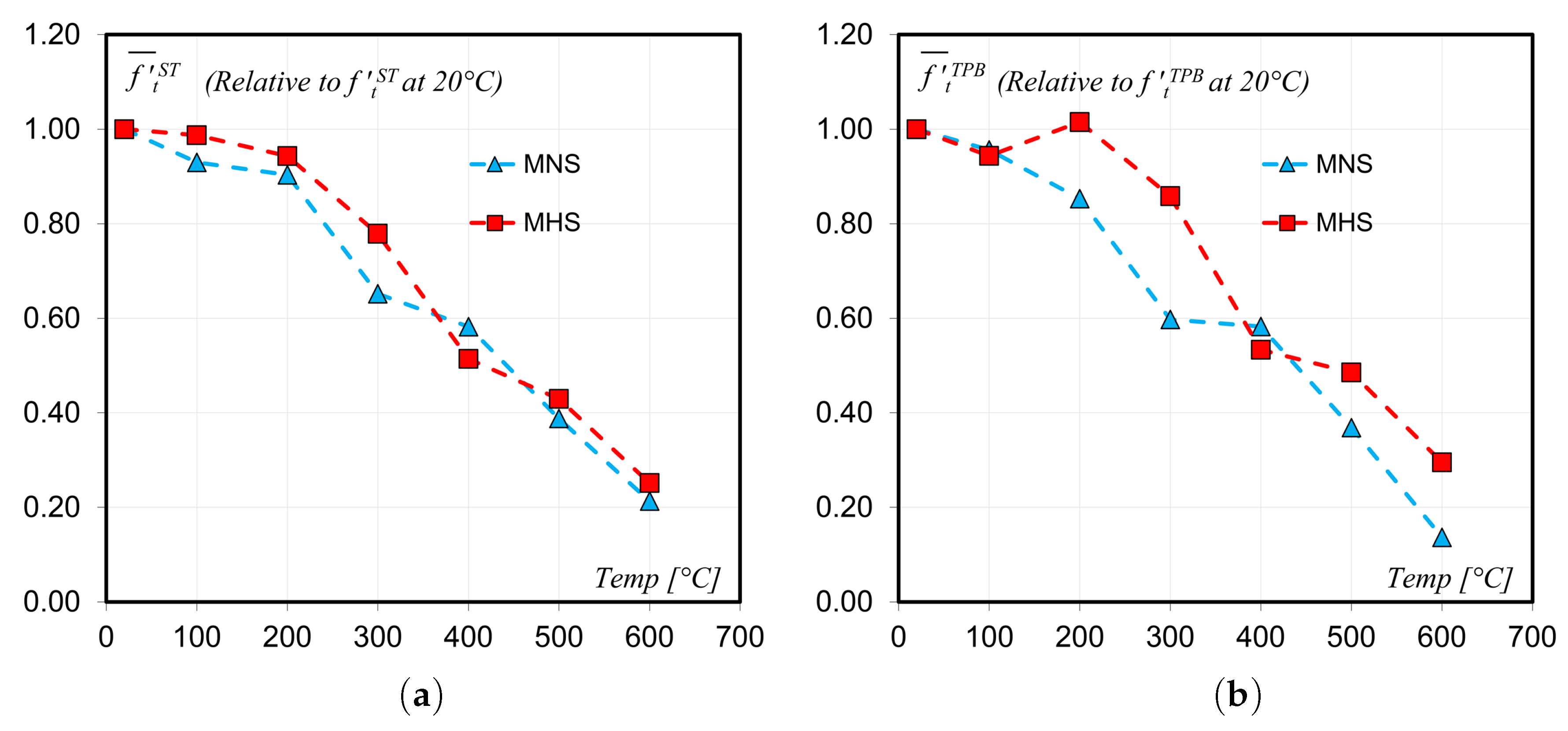

5.1. Compressive and Tensile Strenghts

5.2. Uniaxial Compression Test Results and Discussion

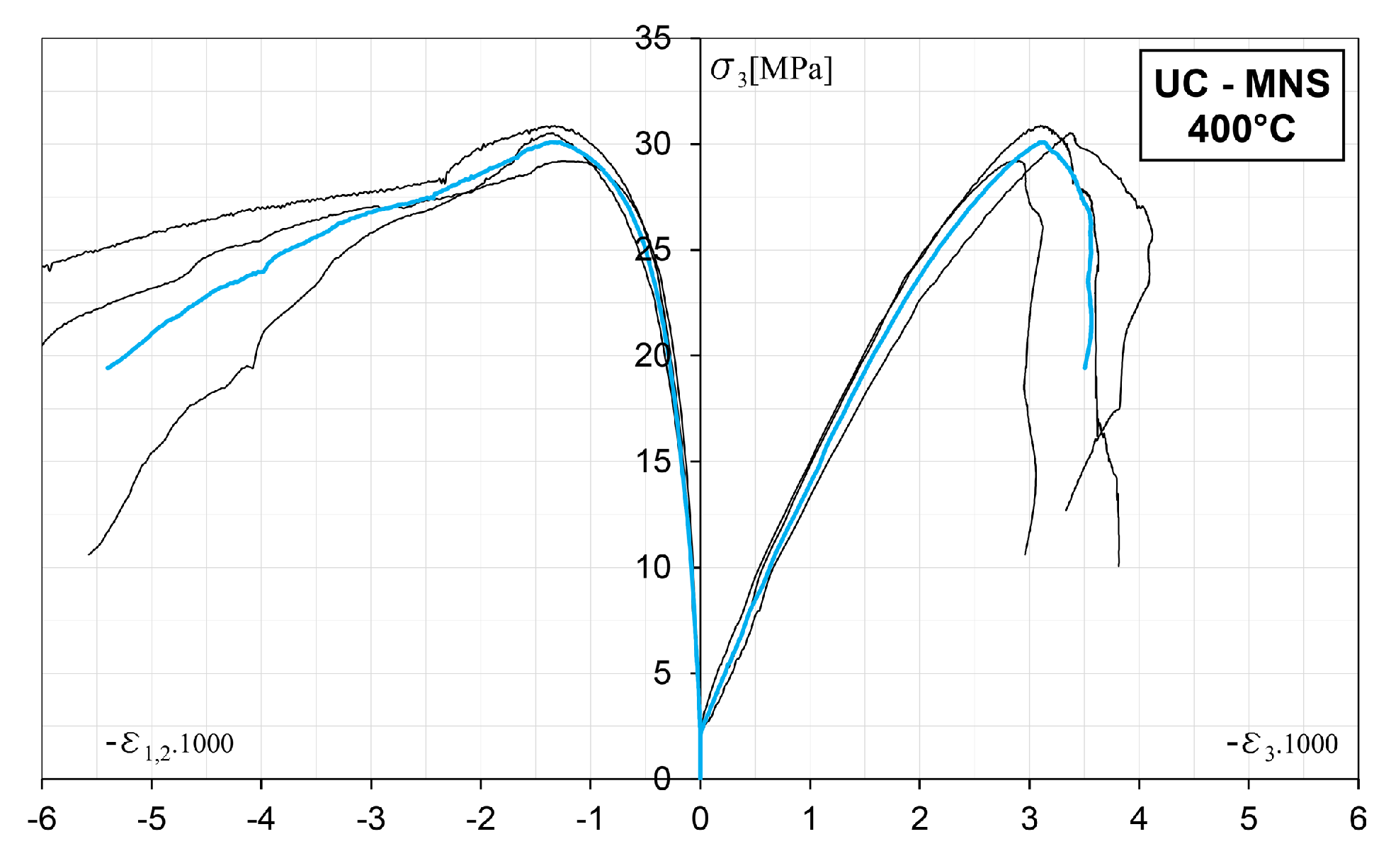

5.2.1. UC—About Obtaining the Mean Stress-Strain Curves

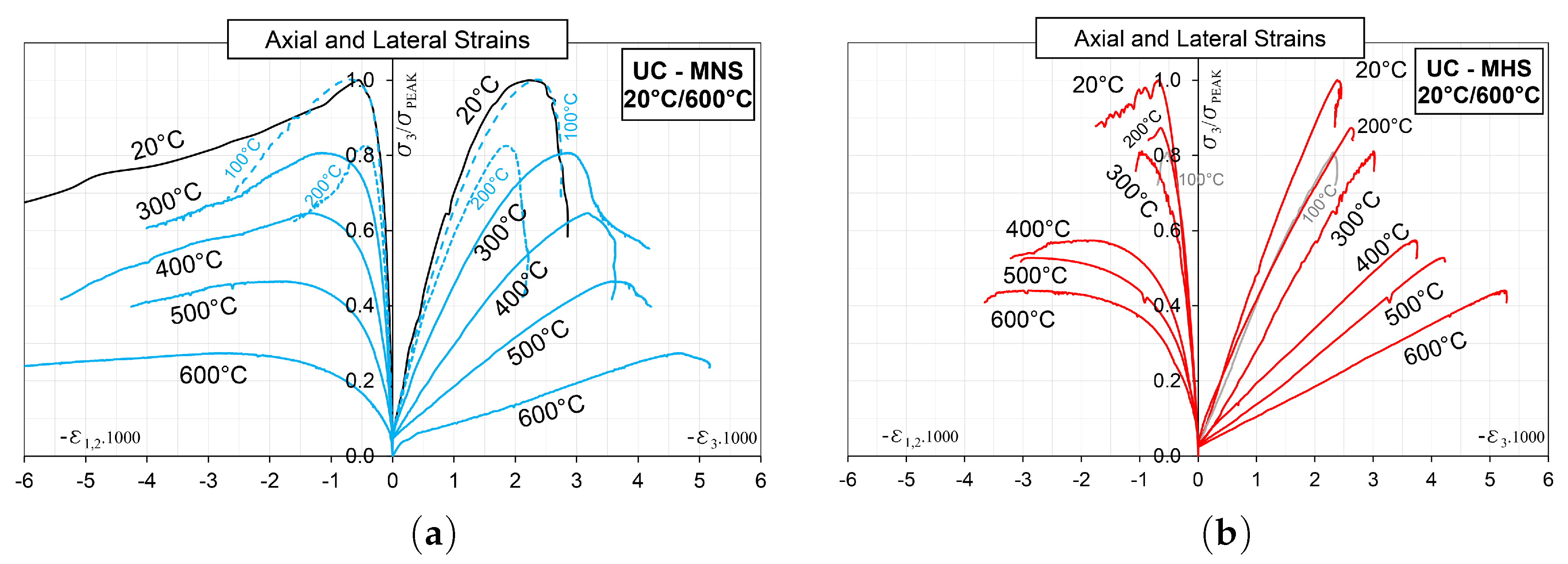

5.2.2. UC—Stress-Strain Results

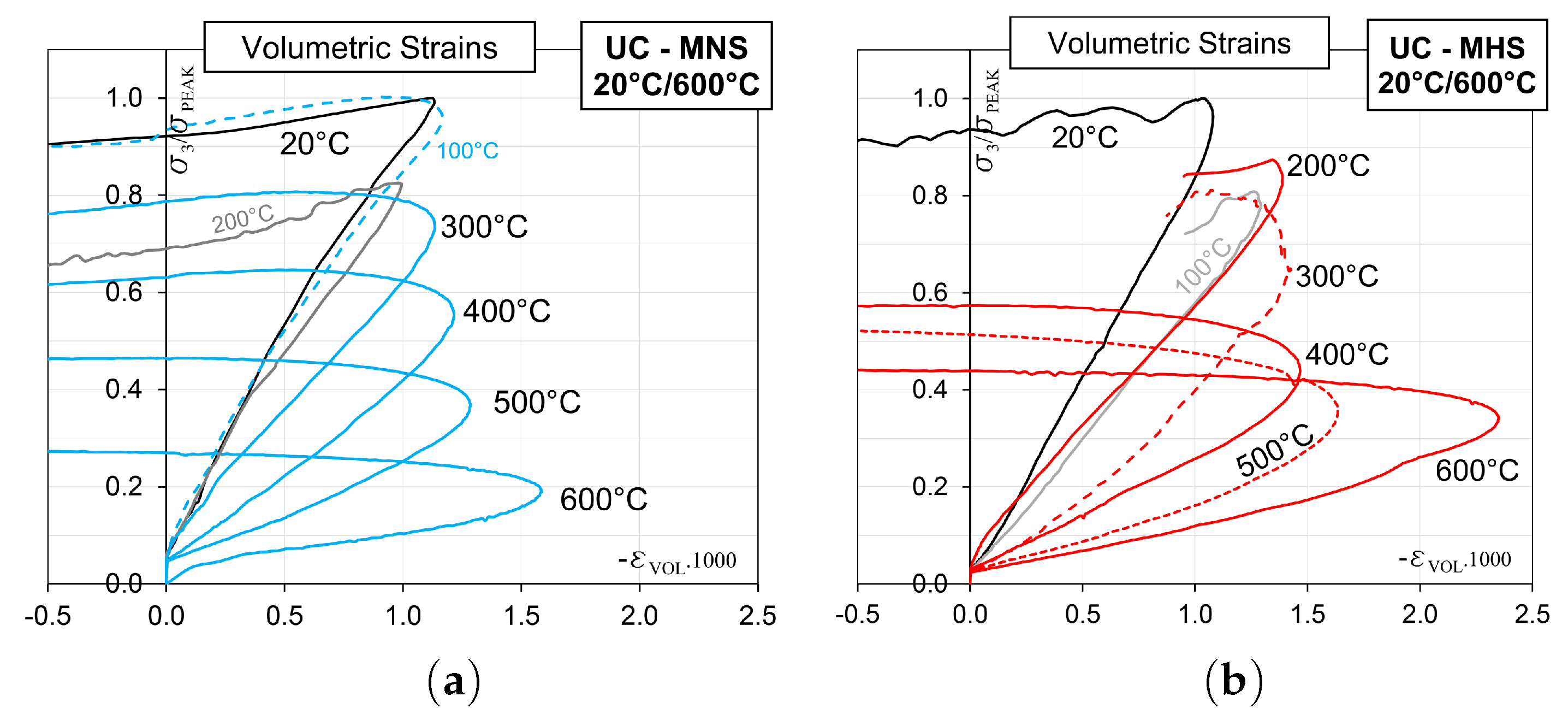

5.2.3. UC—Volumetric Strains

5.2.4. UC—Failure Behavior

6. Conclusions

- -

- Physical properties: Specific weight loss was similar for both mortar types at low temperatures (100 C and 200 C). However, for mid-to-high ranges of temperature exposures, MHS achieved higher relative weight losses than MNS. In turn, MNS showed a much higher capillarity water absorption than MHS samples. Increasing temperatures produced increasing water absorption coefficients, evidencing the thermal damage causing an increase in the accessible porosity. However, that increase was almost linear for MNS, while for MHS it was substantially more evident from low-to-medium temperatures (up to 300).

- -

- General conclusions regarding physical tests: The results demonstrated the fundamental role of the ratio in the absorption response of cement composites and consequently, in durability. At ambient temperature, the smaller accessible porosity of high strength mortars indicates a higher performance in comparison to normal strength mortar. However, under the action of increasing temperatures, the thermal damage causes the formation of micro cracks, generating further connection of the closed porosity and consequently, allowing the water, initially trapped in closed porosity, to emigrate and evaporate. As result, the internal porosity structure of lower ratio mixtures are more affected by the action of temperature.

- -

- Compressive and tensile strengths: In all cases, strengths suffered a progressive degradation due to temperature. While at low to medium temperatures, strength loss resulted similar for both mortar types, at the highest temperature, MNS presented a higher relative loss of strength than that of MHS. It was also observed that the loss of tensile strength after the exposure to the highest temperatures was higher in comparison to the loss of compressive strength.

- -

- Uniaxial compression: The action of temperature caused in all cases a decrease of Young’s Modulus and an increase in the strain corresponding to peak load. The MHS showed a much more brittle behavior in comparison with that of the MNS, for all the considered temperatures. Samples of both mortar types that were not exposed to temperature, almost did not show a critical stress where volume begins to increase instead of decrease. On the contrary, after the action of temperature, the corresponding stress-volumetric strains curves did present a turning point, showing a behavior similar to that of concrete.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Le, D.; Tran, S.; Torero, J.; Dao, V. Application of digital image correlation system for reliable deformation measurement of concrete structures at high temperatures. Eng. Struct. 2019, 192, 181–189. [Google Scholar]

- Zhai, Y.; Deng, Z.; Li, N.; Xu, R. Study on compressive mechanical capabilities of concrete after high temperature exposure and thermo-damage constitutive model. Constr. Build. Mater. 2014, 68, 777–782. [Google Scholar]

- Khaliq, W. Mechanical and physical response of recycled aggregates high-strength concrete at elevated temperatures. Fire Saf. J. 2018, 96, 203–214. [Google Scholar]

- Culfik, M.S.; Ozturan, T. Effect of elevated temperatures on the residual mechanical properties of high-performance mortar. Cem. Concr. Res. 2002, 32, 809–816. [Google Scholar]

- Zhang, Q.; Ye, G. Dehydration kinetics of Portland cement paste at high temperature. J. Therm. Anal. Calorim. 2012, 110, 153–158. [Google Scholar]

- Ma, Q.; Guo, R.; Zhao, Z.; Lin, Z.; He, K. Mechanical properties of concrete at high temperature—A review. Constr. Build. Mater. 2015, 93, 371–383. [Google Scholar]

- Fu, Y.F.; Wong, Y.L.; Poon, C.S.; Tang, C.A. Numerical tests of thermal cracking induced by temperature gradient in cement-based composites under thermal loads. Cem. Concr. Compos. 2007, 29, 103–116. [Google Scholar]

- Sahani, A.K.; Samanta, A.K.; Roy, D.K.S. Influence of mineral by-products on compressive strength and microstructure of concrete at high temperature. Adv. Concr. Constr. 2019, 7, 263–275. [Google Scholar]

- Saha, A.K.; Sarker, P.K.; Golovanevskiy, V. Thermal properties and residual strength after high temperature exposure of cement mortar using ferronickel slag aggregate. Constr. Build. Mater. 2019, 199, 601–612. [Google Scholar]

- Sonal, T.; Urmil, D.; Jay, P. Effect of high temperature on fly ash-based alkali activated concrete compared to Portland cement concrete. Int. J. Mater. Struct. Integr. 2019, 13, 257–273. [Google Scholar]

- Ahmed, W.; Baloch, W.L.; Khushnood, R.A. Fire performance of concrete containing nano-fibers and graphite nano-particles. In Smart Nanoconcretes and Cement-Based Materials; Elsevier: Amsterdam, The Netherlands, 2020; pp. 297–311. [Google Scholar]

- Cao, M.; Ming, X.; Yin, H.; Li, L. Influence of high temperature on strength, ultrasonic velocity and mass loss of calcium carbonate whisker reinforced cement paste. Compos. Part B Eng. 2019, 163, 438–446. [Google Scholar] [CrossRef]

- Akca, A.H.; Ozyurt, N. Deterioration and recovery of FRC after high temperature exposure. Cem. Concr. Compos. 2018, 93, 260–273. [Google Scholar]

- Xargay, H.; Folino, P.; Sambataro, L.; Etse, G. Temperature effects on failure behavior of self-compacting high strength plain and fiber reinforced concrete. Constr. Build. Mater. 2018, 165, 723–734. [Google Scholar]

- Wahid, N.; Stratford, T.; Bisby, L. Calibration of concrete damage plasticity model parameters for high temperature modelling of reinforced concrete flat slabs in fire. In Proceedings of the Applications of Structural Fire Engineering, Singapore, 13–14 June 2019; p. 6. [Google Scholar]

- Liu, K.; Xie, H.; Jin, C.; Huang, S.; Wang, F. The equivalent plasticity strain analysis of snow-melting heated pavement concrete exposed to inner elevated temperatures. Constr. Build. Mater. 2017, 137, 66–75. [Google Scholar]

- Neuenschwander, M.; Knobloch, M.; Fontana, M. Suitability of the damage-plasticity modelling concept for concrete at elevated temperatures: Experimental validation with uniaxial cyclic compression tests. Cem. Concr. Res. 2016, 79, 57–75. [Google Scholar]

- Grassl, P.; Pearce, C. Mesoscale approach to modeling concrete subjected to thermomechanical loading. J. Eng. Mech. 2010, 136, 322–328. [Google Scholar]

- Caggiano, A.; Etse, G. Coupled thermo-mechanical interface model for concrete failure analysis under high temperature. Comput. Methods Appl. Mech. Eng. 2015, 289, 498–516. [Google Scholar]

- Caggiano, A.; Schicchi, D.S.; Etse, G.; Ripani, M. Meso-scale response of concrete under high temperature based on coupled thermo-mechanical and pore-pressure interface modeling. Eng. Fail. Anal. 2018, 85, 167–188. [Google Scholar]

- Lammi, C.; Zhou, M. Multi-Physics Modeling of Fire-Induced Damage in High-Performance Concrete. Int. J. Multiphys. 2016, 8, 101–122. [Google Scholar]

- Lee, J.; Xi, Y.; Willam, K.; Jung, Y. A multiscale model for modulus of elasticity of concrete at high temperatures. Cem. Concr. Res. 2009, 39, 754–762. [Google Scholar]

- Burlion, N.; Pijaudier-Cabot, G.; Dahan, N. Experimental analysis of compaction of concrete and mortar. Int. J. Numer. Anal. Meth. Geomech. 2001, 25, 1467–1486. [Google Scholar] [CrossRef]

- Yurtdas, I.; Chen, D.; Huc, D.W.; Shao, J.F. Influence of alkali silica reaction (ASR) on mechanical properties of mortar. Constr. Build. Mater. 2013, 47, 165–174. [Google Scholar] [CrossRef]

- Kohees, M.; Sanjayan, J.; Rajeev, P. Stress-strain relationship of cement mortar under triaxial compression. Constr. Build. Mater. 2019, 220, 456–463. [Google Scholar] [CrossRef]

- Zemri, C.; Bouiadjra, M.B. Comparison between physical-mechanical properties of mortar made with Portland cement (CEMI) and slag cement (CEMIII) subjected to elevated temperature. Case Stud. Constr. Mater. 2020, 12, e00339. [Google Scholar] [CrossRef]

- Algourdin, N.; Hung, B.S.; Mesticou, Z.; Larbi, A.S. Effects of high temperature on mechanical behaviour and physicochemical properties of recycled mortars and its components. Constr. Build. Mater. 2020, 248, 118554. [Google Scholar] [CrossRef]

- Saridemir, M.; Çelikten, S.; Yildirim, A. Mechanical and microstructural properties of calcined diatomite powder modified high strength mortars at ambient and high temperatures. Adv. Powder Technol. 2020, 31, 3004–3017. [Google Scholar] [CrossRef]

- Benli, A.; Karatas, M.; Toprak, H.A. Mechanical characteristics of self-compacting mortars with raw and expanded vermiculite as partial cement replacement at elevated temperatures. Constr. Build. Mater. 2020, 239, 117895. [Google Scholar] [CrossRef]

- Fares, H.; Noumowe, A.; Remond, S. Self-consolidating concrete subjected to high temperature Mechanical and physicochemical properties. Cem. Concr. Res. 2009, 39, 1230–1238. [Google Scholar] [CrossRef]

- Karatas, M.; Benli, A.; Arslan, F. The effects of kaolin and calcined kaolin on the durability and mechanical properties of self-compacting mortars subjected to high temperatures. Constr. Build. Mater. 2020, 265, 120300. [Google Scholar] [CrossRef]

- Folino, P.; Ripani, M.; Xargay, H.; Rocca, N. Comprehensive analysis of Fiber Reinforced Concrete beams with conventional reinforcement. Eng. Struct. 2020, 202, 109862. [Google Scholar] [CrossRef]

- Norma IRAM 50000. Cementos para Uso General. Composición y Requisitos, 4th ed.; Instituto Argentino de Normalización y Certificación: Buenos Aires, Argentina, 2019. [Google Scholar]

- Norma IRAM 50001. Cementos con Propiedades Especiales. Requisitos, 4th ed.; Instituto Argentino de Normalización y Certificación: Buenos Aires, Argentina, 2019. [Google Scholar]

- UNE-EN (2007b); UNE-EN 1015-10:2000/A1. Methods of Test for Mortar for Masonry—Part 10: Determination of Dry Bulk Density of Hardened Mortar; AENOR: Madrid, Spain, 2007. [Google Scholar]

- UNE-EN 1015-18. Methods of Test for Mortar for Masonry—Part 18: Determination of Water Absorption Coefficient Due to Capillary Action of Hardened Mortar; AENOR: Madrid, Spain, 2003. [Google Scholar]

- Palomar, I.; Barluenga, G.; Puentes, J. Lime-cement mortars for coating with improved thermal and acoustic performance. Constr. Build. Mater. 2015, 75, 306–314. [Google Scholar] [CrossRef]

- Guardia, C.; Schicchi, D.S.; Caggiano, A.; Barluenga, G.; Koenders, E. On the capillary water absorption of cement-lime mortars containing phase change materials: Experiments and simulations. Build. Simulation. Tsinghua Univ. Press 2020, 13, 19–31. [Google Scholar] [CrossRef]

- Gonen, T.; Yazicioglu, S. The influence of compaction pores on sorptivity and carbonation of concrete. Constr. Build. Mater. 2007, 21, 1040–1045. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Rukzon, S. Strength, porosity and corrosion resistance of ternary blend Portland cement, rice husk ash and fly ash mortar. Constr. Build. Mater. 2008, 22, 1601–1606. [Google Scholar] [CrossRef]

- ASTM-C39-05. Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens; Annual Book of ASTM Standards; American Society for Testing and Materials: West Conshohocken, PA, USA, 2006. [Google Scholar]

- ASTM-C496-05. Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens; Annual Book of ASTM Standards; American Society for Testing and Materials: West Conshohocken, PA, USA, 2006. [Google Scholar]

- Norma IRAM 1622. Cemento Portland. Determinación de Resistencias Mecánicas; Instituto Argentino de Normalización y Certificación: Buenos Aires, Argentina, 2006. [Google Scholar]

- EN 196-1. Methods of Testing Cement—Part 1: Determination of Strength; European Committee for Standardisation (CEN): Brussels, Belgium, 2005. [Google Scholar]

- ASTM-C469-02. Standard Test Method for Static Modulus of Elasticity and Poisson’s Ratio of Concrete in Compression; Annual Book of ASTM Standards; American Society for Testing and Materials: West Conshohocken, PA, USA, 2002. [Google Scholar]

- Shah, S.P.; Chandra, S. Critical stress, volume change, and microcracking of concrete. ACI J. Proc. 1968, 65, 770–780. [Google Scholar]

| MNS | MHS | |

|---|---|---|

| [kg/m] | [kg/m] | |

| Water | 287.8 | 301.0 |

| Cement | 589.5 (CPN40) | 602.0 (CPN50) |

| Blast furnace slag | - | 258.0 |

| River sand | 971.0 | 393.1 |

| Crushed sand | 416.1 | 709.8 |

| Super-plasticizer | - | 4.3 |

| 0.49 | 0.35 |

| Cement | Type | Strength after 2 d | Strength after 28 d | Density | |

|---|---|---|---|---|---|

| [MPa] | [MPa] | [kg/m] | |||

| Portland | CPN40 | >10 | ≥10 | ≤60 | 3150 |

| Portland | CPN50 | >20 | ≥20 | - | 3150 |

| Sand Type | Absorption | Density |

|---|---|---|

| [%] | [kg/m] | |

| River sand | 0.50 | 2630 |

| Crushed sand | 0.80 | 2670 |

| W | CA | UC | ST | TPB | ||

|---|---|---|---|---|---|---|

| Temperature | 50 × 100 [mm] | 50 × 100 [mm] | 50 × 100 [mm] | 50 × 100 [mm] | 40 × 40 × 160 [mm] | |

| [C] | (cyl) | (cyl) | (cyl) | (cyl) | (beam) | |

| 20 | 4 | 1(MNS) | 3(MHS) | 4 | 3 | 4 |

| 100 | 4 | 1(MNS) | 2(MHS) | 4 | 3 | 4 |

| 200 | 4 | 1(MNS) | 1(MHS) | 4 | 3 | 4 |

| 300 | 4 | 2(MNS) | 1(MHS) | 4 | 3 | 4 |

| 400 | 4 | 1(MNS) | 1(MHS) | 4 | 3 | 4 |

| 500 | 4 | 1(MNS) | 2(MHS) | 4 | 3 | 4 |

| 600 | 4 | 1(MNS) | 1(MHS) | 4 | 3 | 4 |

| Temperature | UC | ST | TPB | |||

|---|---|---|---|---|---|---|

| [C] | [MPa] | [MPa] | [MPa] | |||

| MNS | MHS | MNS | MHS | MNS | MHS | |

| 20 | 46.55 | 77.12 | 5.13 | 6.99 | 8.35 | 9.42 |

| 100 | 46.65 | 62.32 | 4.77 | 6.90 | 7.99 | 8.88 |

| 200 | 38.42 | 67.36 | 4.63 | 6.60 | 7.13 | 9.56 |

| 300 | 37.58 | 62.58 | 3.34 | 5.45 | 4.99 | 8.08 |

| 400 | 30.09 | 44.28 | 2.99 | 3.59 | 4.86 | 5.02 |

| 500 | 21.66 | 40.68 | 1.99 | 3.00 | 3.08 | 4.57 |

| 600 | 12.77 | 34.00 | 1.09 | 1.76 | 1.14 | 2.78 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ripani, M.; Xargay, H.; Iriarte, I.; Bernardo, K.; Caggiano, A.; Folino, P. Thermal Action on Normal and High Strength Cement Mortars. Appl. Sci. 2020, 10, 6455. https://doi.org/10.3390/app10186455

Ripani M, Xargay H, Iriarte I, Bernardo K, Caggiano A, Folino P. Thermal Action on Normal and High Strength Cement Mortars. Applied Sciences. 2020; 10(18):6455. https://doi.org/10.3390/app10186455

Chicago/Turabian StyleRipani, Marianela, Hernán Xargay, Ignacio Iriarte, Kevin Bernardo, Antonio Caggiano, and Paula Folino. 2020. "Thermal Action on Normal and High Strength Cement Mortars" Applied Sciences 10, no. 18: 6455. https://doi.org/10.3390/app10186455

APA StyleRipani, M., Xargay, H., Iriarte, I., Bernardo, K., Caggiano, A., & Folino, P. (2020). Thermal Action on Normal and High Strength Cement Mortars. Applied Sciences, 10(18), 6455. https://doi.org/10.3390/app10186455