1. Introduction

Most countries are currently facing energy-related challenges. Generally, fossil fuels are a major source of energy in most countries. However, the use of fossil fuels causes many problems, such as greenhouse gas emissions like CO

2. In recent years, we have produced about 29 gigatons of CO

2 annually, and around 40% of this can be absorbed naturally. Therefore, we have issues with around 60% of the CO

2 we produce. Increasing CO

2 in the atmosphere causes several challenges, such as global warming and pollution. Heavy industries have played a large role in increasing the emission rate of CO

2. Numerous components are used in heavy industries, including various types of motors. Several factors can be analyzed in attempts to increase the efficiency of motors. Among these, condition monitoring and fault diagnosis of motors are important methods that can be taken advantage of to increase efficiency and reduce CO

2 emissions. Various kinds of faults have been introduced for motors, which can be divided into two main categories: (a) mechanical faults, such as bearing faults (around 69% of faults) and the other types of mechanical faults (around 10%) and (b) electrical faults (around 21%). Bearings are clearly a significant component in motors. Inner race faults (IRF), outer race faults (ORF), and ball faults (BLF) are the main fault types in bearings. Various kinds of condition monitoring have been used for fault diagnosis of bearings, such as methods based on vibration analysis, acoustic emission (AE) analysis, lubricant/debris analysis, power quality analysis and microscope analysis, and motor current signature analysis (MCSA) [

1].

Various procedures have been recommended for fault diagnosis in bearings, including techniques based on signal processing procedures, methods based on data-driven techniques, techniques using model-based approaches, and mixtures of the above techniques using hybrid approaches [

2,

3,

4,

5,

6,

7,

8]. Regarding the advantages of signal processing techniques, they have some challenges when used in uncertain conditions. Additionally, data-driven approaches have some limitations when used with large datasets, and model-based techniques have limitations in terms of accurate system modeling. To address the above issues a hybrid technique is recommended in this work. To analyze the vibration and AE signals, the signal processing techniques play an important role. A system with a bearing fault is identified as a complex nonlinear and non-stationary one [

9]. Due to these issues and the limitation of the conventional time- and frequency-domain analysis, the researchers and engineers are forced to define two scenarios: (a) utilize complex time-frequency analysis (TFA) methods, and (b) utilize the hybrid approach for extracting valuable information about the mechanical fault and performing fault diagnosis. The most frequently used TFAs are empirical mode decomposition (EMD) [

10] and its derivative methods, such as ensemble EMD (EEMD) [

11,

12], and wavelet transform with its variations [

13,

14,

15]. Apart from various positive points of these techniques for fault diagnosis in the bearing, these methods suffer some drawbacks in real industries including mode-mixing in the EMD [

16], computational complexity in the EEMD, energy leakage and interference terms, and selection of the mother wavelet function the wavelet transform [

17,

18,

19]. Due to the complexity and the problems of TFA signal analysis techniques for extracting discriminative fault features as well as the problems of the classical machine learning methods which are dependent on the quality of the feature, two scenarios have been recommended by researchers and engineers: the family of (machine/deep) learning approaches and the family of modern control algorithms. The (machine/deep) learning techniques can be used for fault feature extraction and including convolutional neural networks [

20,

21,

22,

23,

24,

25,

26] to autonomously extract the features, generative adversarial networks [

27] to generate the new signals that resemble the original ones, different types of autoencoders [

28,

29] for latent coding for signal reconstruction; generation; compression; anomaly detection, and deep neural network (DNN) [

30] to increase the performance of classification accuracy in high-dimensional and uncertain input data. The second scenario is the modern control-based algorithm for fault feature identification. The observation-based approach is one of the powerful techniques in the family of modern control algorithms and can be classified into two main categories: linear and nonlinear observers. The modern control procedures using linear observers have been used in real industries. The main issues of these techniques are robustness and reliability. To address these issues, two different scenarios have been defined by researchers: nonlinear-based observers that have the challenge of complexities and hybrid approaches. Various kinds of hybrid approaches have been reported in [

31,

32,

33,

34]. The first step to develop a hybrid observer is a function approximation [

35]. Although function approximation using a mathematical approach is reliable, it has two important problems: high complexity and low accuracy in uncertain conditions [

36,

37,

38]. System identification techniques are the next scenario for function approximation. Several system identification techniques have been used for function approximation such as auto-regressive with external inputs (ARX), ARX-Laguerre, and intelligent-based ARX-Laguerre techniques [

35,

36,

39].

To estimate the different classes of signals using observers, diverse methods have been introduced such as sliding mode, feedback linearization, backstepping, fuzzy, and proportional-integral (PI) observers [

40,

41,

42]. High reliability and robustness are the main characteristics of sliding mode observer, but the most important negative characteristics of this technique are high-frequency fluctuation and complexity [

41,

43]. The second scenario to estimate the unknown signal is the feedback linearization observer. A lack of robustness and complexity are the main negative characteristics of this technique [

44]. To address the issues of complexity of implementation for sliding mode and feedback linearization observers, the PI observer was developed. Implementing this technique is simple, but the main drawbacks of this technique are estimation accuracy and resistance, especially when the signal is non-stationary. The ARX-Laguerre PI observer technique was recommended in [

36,

39,

45] to improve the accuracy estimation. The extended technique has been recommended to solve the challenge of robustness in the ARX-Laguerre PI observer [

39]. The ARX-Laguerre procedure does not provide a favorable result when dealing with the complex, non-stationary, and nonlinear faults that occur in rotating machinery. In this work, this issue is addressed by proposing a fuzzy orthonormal regressive technique. After approximating the normal signal of bearing using the fuzzy orthonormal regressive, the adaptive cascade observer is developed in four steps. First, the linear observation technique using a proportional-integral (PI) observer with the fuzzy orthonormal regressive signal approximation is developed. In the second step, to increase the power of uncertainties rejection in the PI observer, the structure procedure is used serially. Next, the fuzzy like observer is selected to increase the accuracy of structure PI observer. Moreover, the adaptive technique is used to develop the reliability of the cascade (fuzzy-structure PI) observer. Therefore, in this work, an adaptive cascade observer is recommended for highly accurate signal estimation.

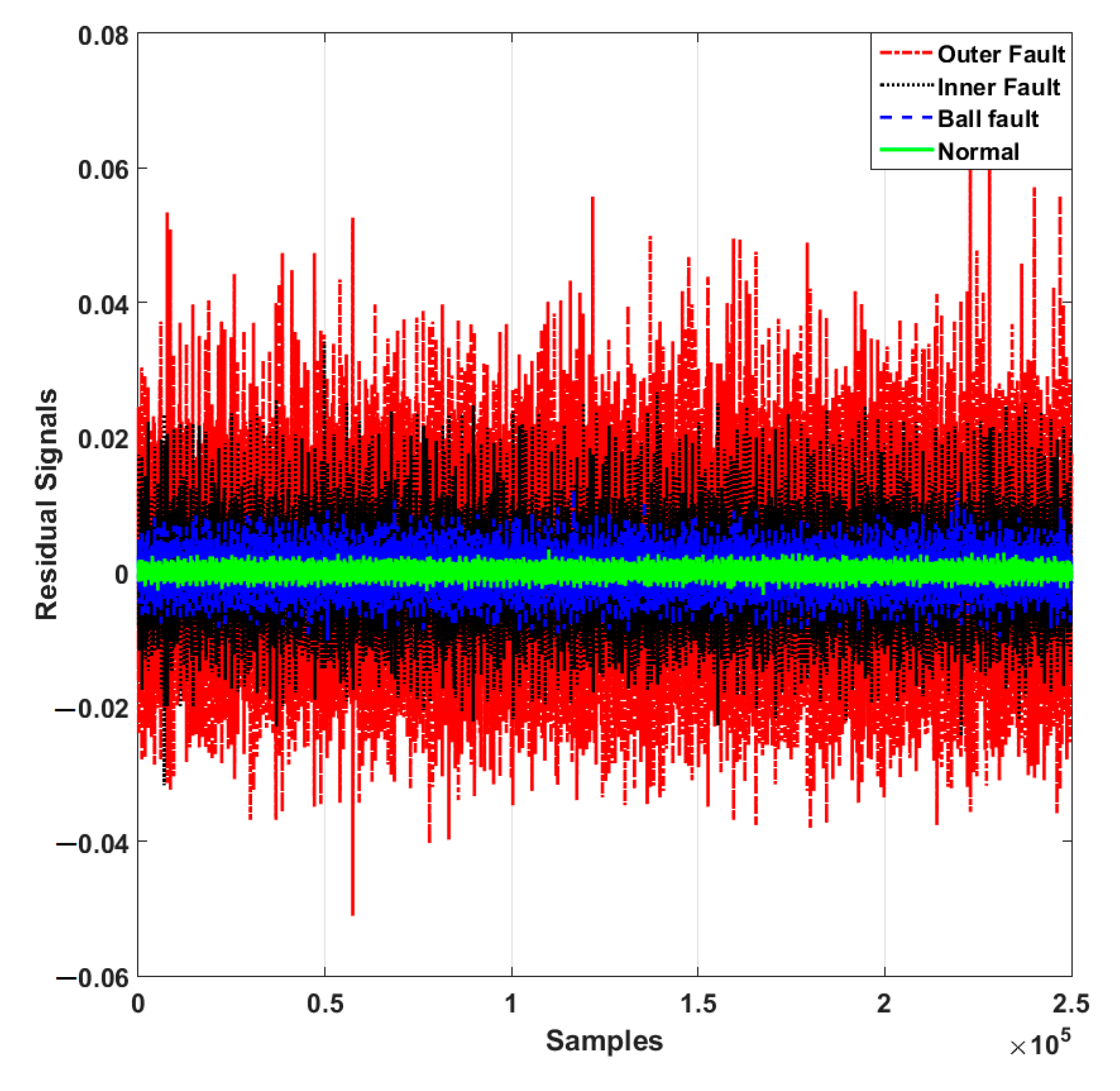

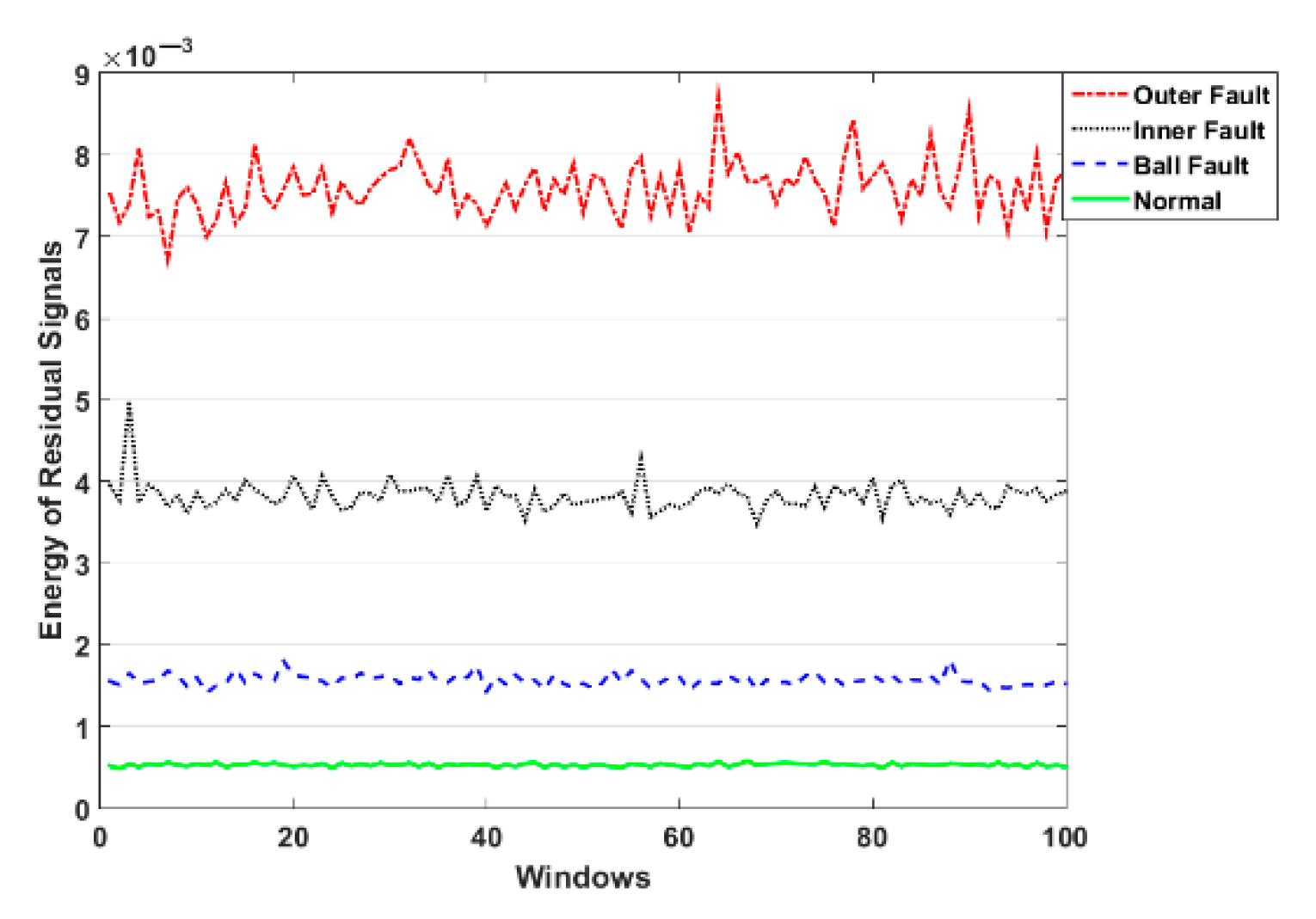

After approximating the normal signal function using a fuzzy orthonormal regressive method and estimating the signals using an adaptive cascade observer, the residual signals are generated and faults can be classified. Moreover, the residual signals are calculated by the difference between various conditions of the original signals and estimated signals obtained using an adaptive cascade observer. Since the adaptive cascade observer is tuned for working in the normal condition, the estimated signal is generated by the proposed adaptive cascade observer with minimum error for normal states. However, in the abnormal condition, the accuracy of signal estimation is reduced. Therefore, the difference between original signal and estimated signal in the abnormal condition will increase. In addition, the residual signals can be used as high discriminative features for fault detection and diagnosis of bearing. These residual signals are used at the next step as the input for machine learning technique to perform fault identification and the values of the residual of signals for adaptive cascade observer. In this work, we employ a machine learning technique for classification of the faults using the support vector machines (SVM) algorithm [

46] to complete the proposed hybrid adaptive cascade fault diagnosis method. The SVM is known as a robust machine learning algorithm that is insensitive to the curse of dimensionality problem [

47]. One of the main advantages of the SVM is that it can be efficiently applied for classification of both linear and nonlinear-separable types of datasets which is possible due to the availability of different types of kernels, such as linear, polynomial, and radial basis function kernels [

48]. However, despite its flexibility, several challenges in this classifier should be addressed to obtain the best possible performance on the target task. Specifically, the first challenge is the selection of the kernel function itself. This is an important step since it directly affects the performance of the classifier when applied to the specific dataset. The kernel selection dilemma can be resolved by applying the prior knowledge about the data being analyzed (i.e., whether it is linearly separable or not) or the kernel can be selected experimentally by trial and error. The second challenge, which is also closely related to the first one, is the selection of the hyperparameter values which is dependent on the kernel type. In this paper, the linear kernel was selected for the SVM classifier experimentally because it demonstrated the most accurate separation of the features belonging to different classes in the dataset used. The conventional grid search algorithm was applied to fine-tune its hyperparameter value (i.e., the maximum distance for the boundary).

Figure 1 illustrates the block diagram of the adaptive cascade observer with the SVM method for fault diagnosis in rotary machinery. According to this figure, this method has three main blocks: signal approximation using fuzzy orthonormal regressive (FOR), signal estimation using a FOR-adaptive cascade observer (FOR-ACO), and fault decision using SVM. For signal approximation, in the first step, a regressive technique is proposed. To increase the strength of resistance to disturbances in the regressive technique, the orthonormal regressive is used in the next step. Besides, to increase the accuracy of the signal approximation, the fuzzy orthonormal regressive technique (FOR) is developed. After approximating the normal signal using the FOR technique, the FOR-PI observer (FOR-PIO) fault estimation is developed. This technique presents two important challenges: low robustness and high estimation error. The structure fault observer is proposed to modify the robustness of FOR-PIO. Moreover, the fuzzy logic algorithm is represented to reduce the signal estimation error in FOR-SPIO. Additionally, the adaptive technique is proposed to improve the reliability of the cascade observer. The decision-making part has three sub-blocks: residual generation; windows characterization and energy feature extraction; fault classification using the SVM algorithm.

Three main contributions in this research are listed as follows:

Normal signal approximation for time-series normal signal using fuzzy orthonormal regressive technique.

Developing an adaptive cascade observer for signal estimation.

Improving the performance of the classification technique by generating the residual signals, extracting the features of energy from them, and applying to SVM for fault identification.

The remainder of this manuscript is organized as follows. The second section outlines the datasets. The third section outlines the fuzzy orthonormal regressive signal approximation. The adaptive cascade observer with SVM for unknown signal classification is represented in

Section 4. In the next section, verification of the adaptive cascade method with the SVM fault classifier is analyzed. In the last section, conclusions are explained.

3. Normal Signal of Bearing Approximation Using Fuzzy Orthonormal Regressive Technique

Designing the observer for nonlinear and nonstationary signals is a vital challenge. Therefore, to develop an observer, normal signal of bearing approximation using the time-series identification technique is the first step. In this work, we develop the fuzzy orthonormal regressive procedure. Based on

Figure 1, the orthonormal regressive technique is implemented to approximate and extract the state-space equation from the bearing signals. Moreover, the orthonormal regressive approach is selected to improve the robustness of the state-space bearing function approximation. Finally, the error of the state-space bearing model can be reduced using the fuzzy orthonormal regressive technique. The regressive (R) algorithm for approximate the REB vibration and AE normal signals is [

36,

45]:

where

, and

are the normal bearing signal approximation using the R-technique, the uncertainties for REB signal approximation, parameters to tune the function approximation, and the order of the function approximation technique, respectively. To increase the resistance of the modeled regressive function against uncertainties and disturbance, the orthonormal regressive (OR) procedure is used.

The state-space equation using the OR technique to model the REB is:

Here,

, and

are the normal bearing signal approximation using the OR technique, the function of orthonormal, and the orthonormal of uncertain condition for REB, respectively. The accuracy of the normal signal approximation is an important factor for function approximation. To reduce the signal approximation error and increase the nonlinear approximation accuracy, the fuzzy technique is recommended. Generally, the fuzzy algorithm can be introduced using the following definition:

Here,

and

are fuzzy logic input signals, linguistic variables for input signals, the fuzzy logic output signal, and the linguistic variable for the fuzzy logic output signal, respectively. Thus, the state-space function approximation for normal bearing signal using fuzzy orthonormal regressive (FOR) is represented using Equation (4).

Here,

, and

are the state of normal signal approximation for REB using the fuzzy orthonormal regressive technique, the output function of normal signal approximation for REB using the fuzzy orthonormal regressive technique, the fuzzy parameter used to reduce the error of signal approximation, and parameters to adjust the signal approximation function, respectively. To find the error of the function approximation using the FOR technique, the following formulation is used.

Here,

and

are the error of the function approximation using FOR technique and the original normal (RAW) signal, respectively.

Figure 2 illustrates the comparison between the error of function approximation using the regressive (R) technique, the orthonormal regressive (OR) algorithm, and the FOR procedure. Regarding this figure, the accuracy of the FOR technique is higher than others. Consequently, this technique is more suitable to evaluate the adaptive cascade observer, which is used for signal estimation.