Residual Mechanical Properties of Fiber-Reinforced Lightweight Aggregate Concrete after Exposure to Elevated Temperatures

Abstract

:1. Introduction

2. Experimental Procedure

2.1. Experimental Programs

2.2. Materials

2.3. Concrete Mix Design

2.4. Fabrication of Specimens

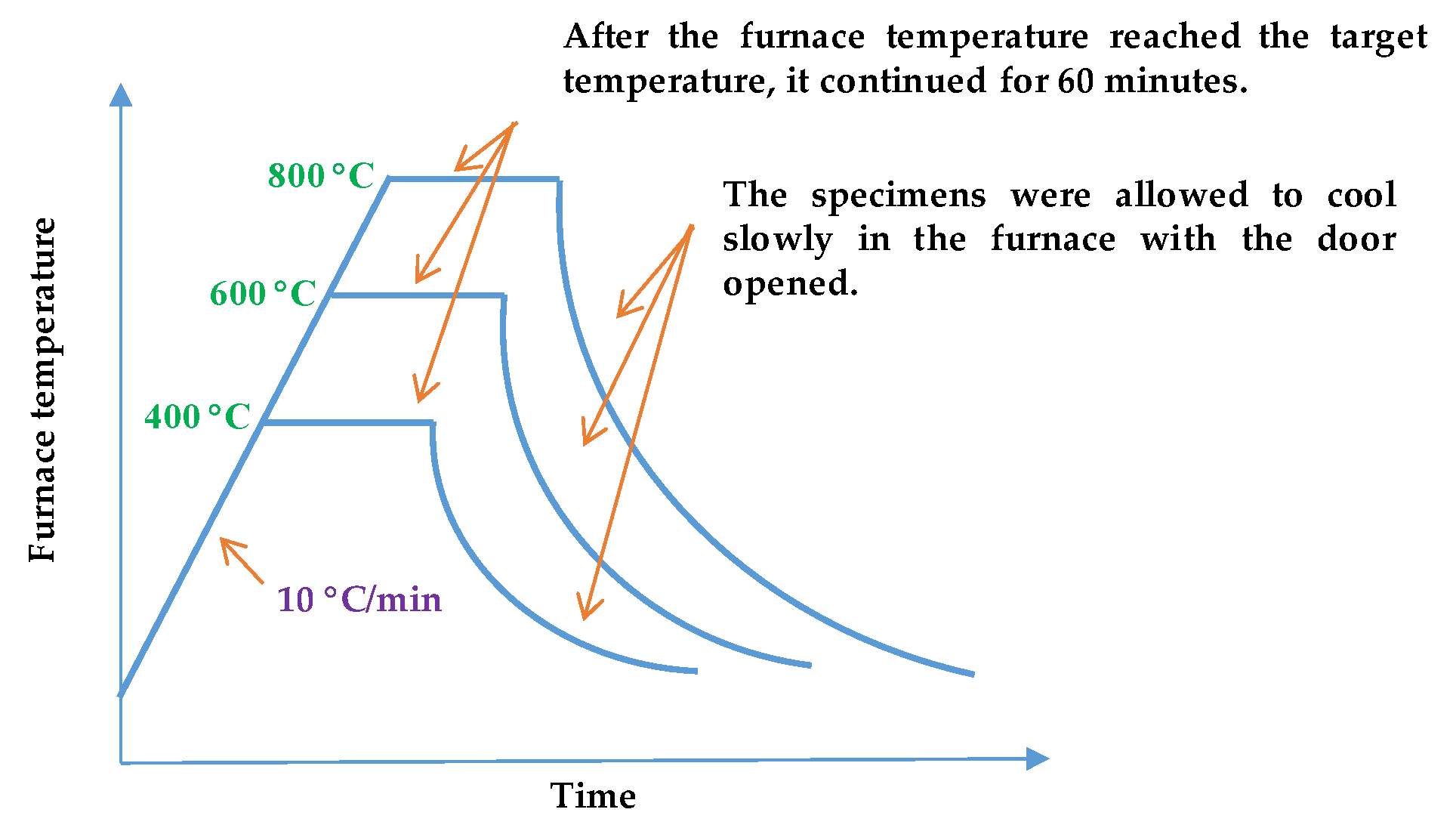

2.5. Testing Methods

3. Results and Discussion

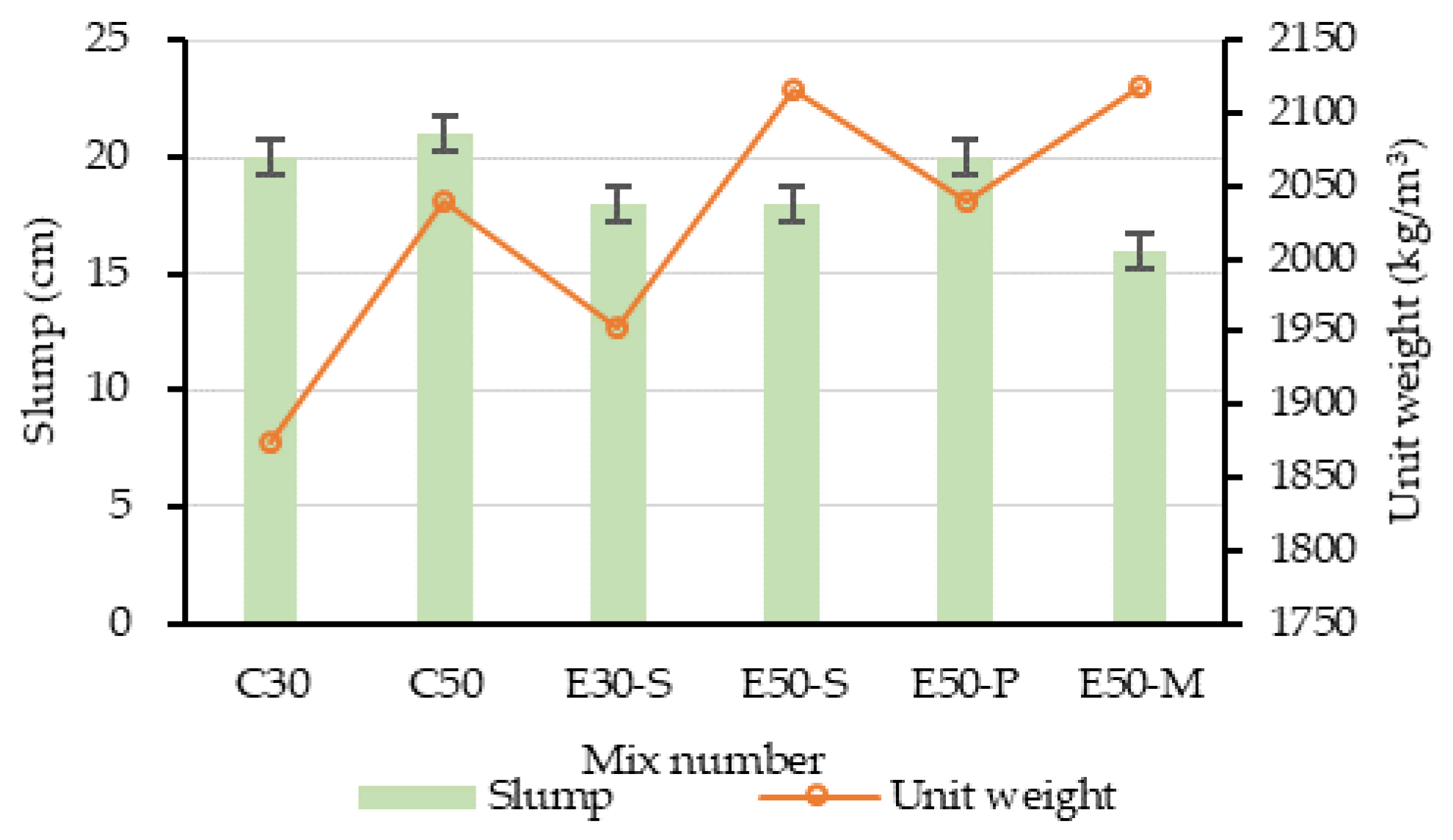

3.1. Fresh Properties of Concrete

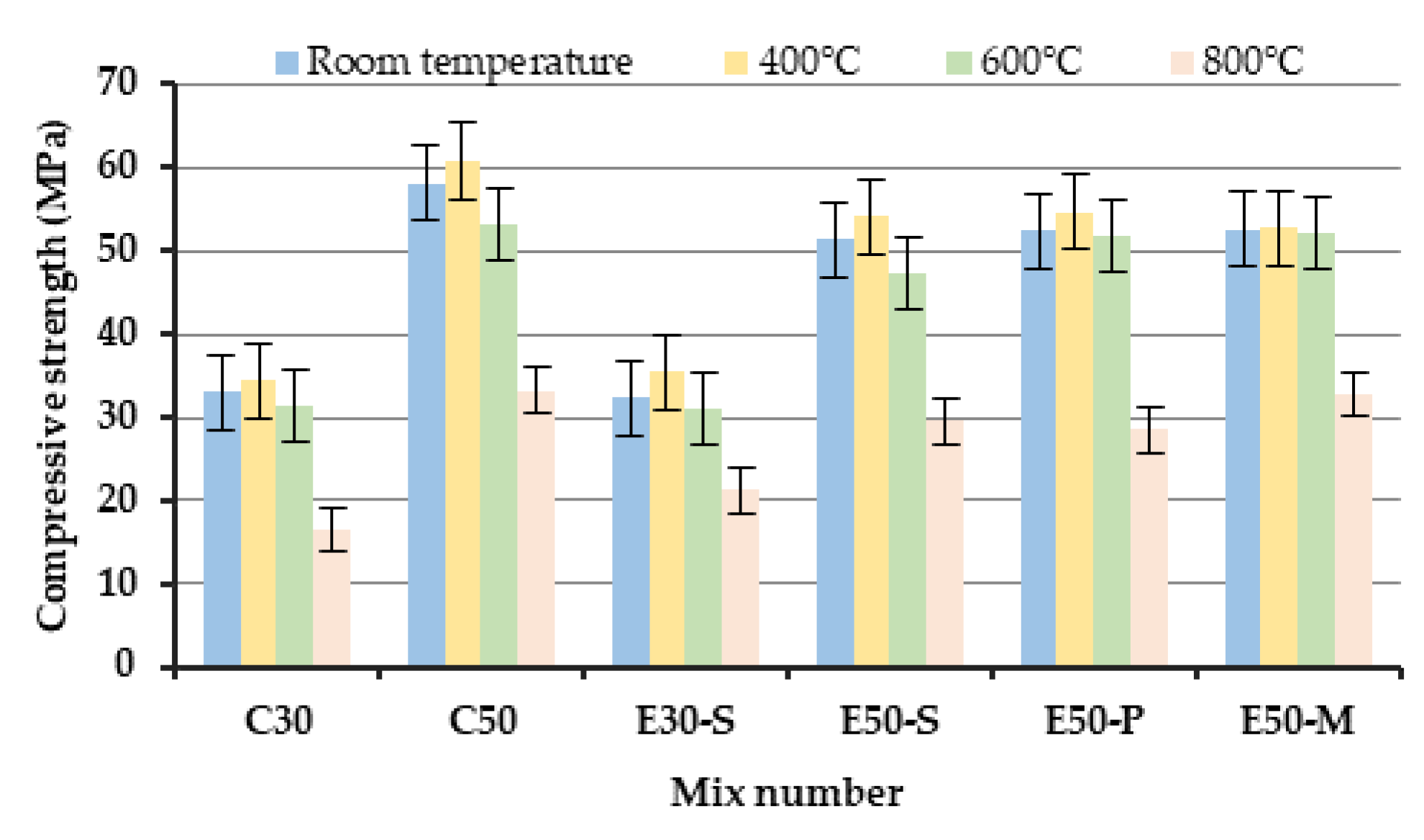

3.2. Compressive Strength

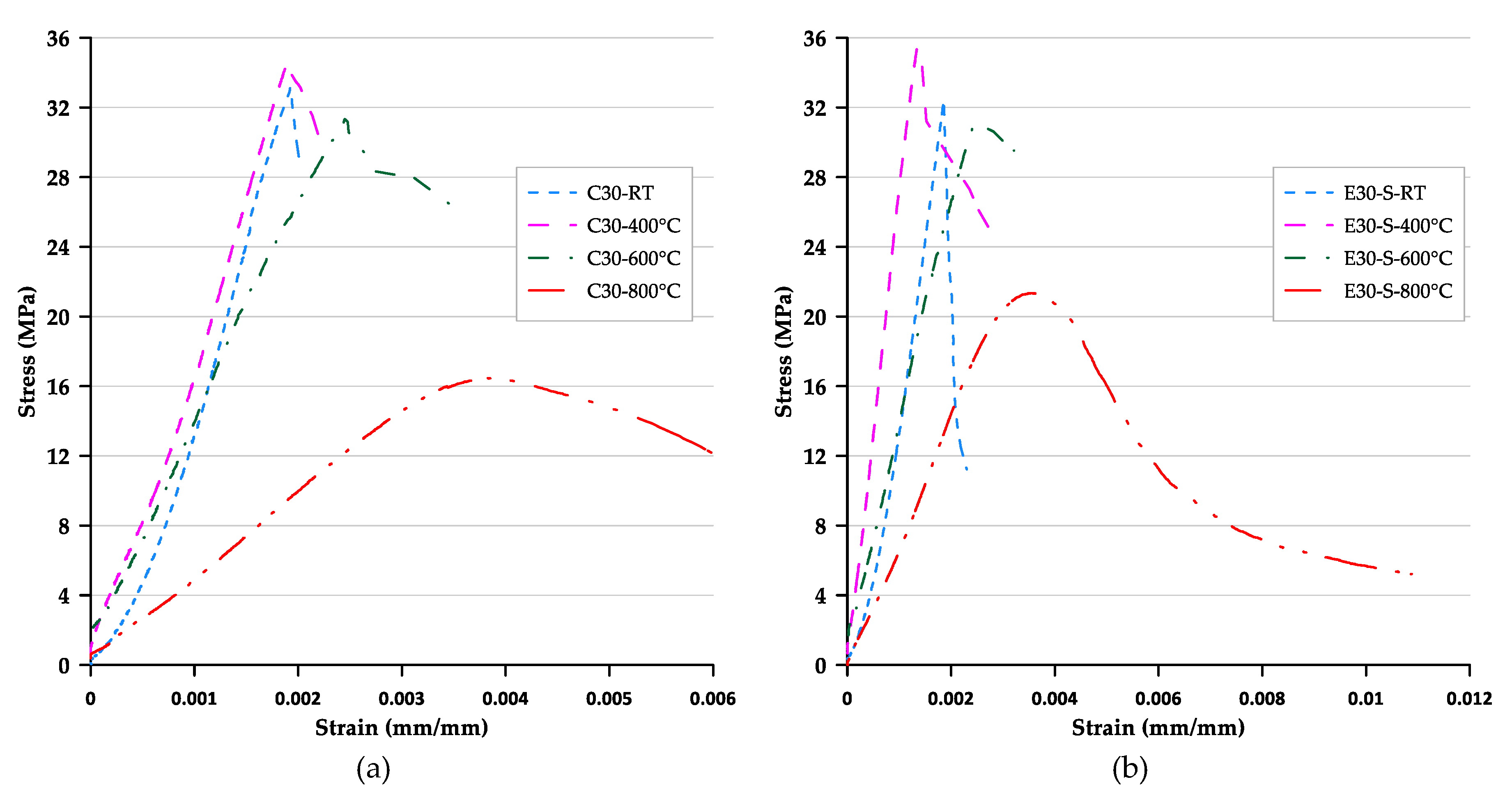

3.3. Stress–Strain Curve

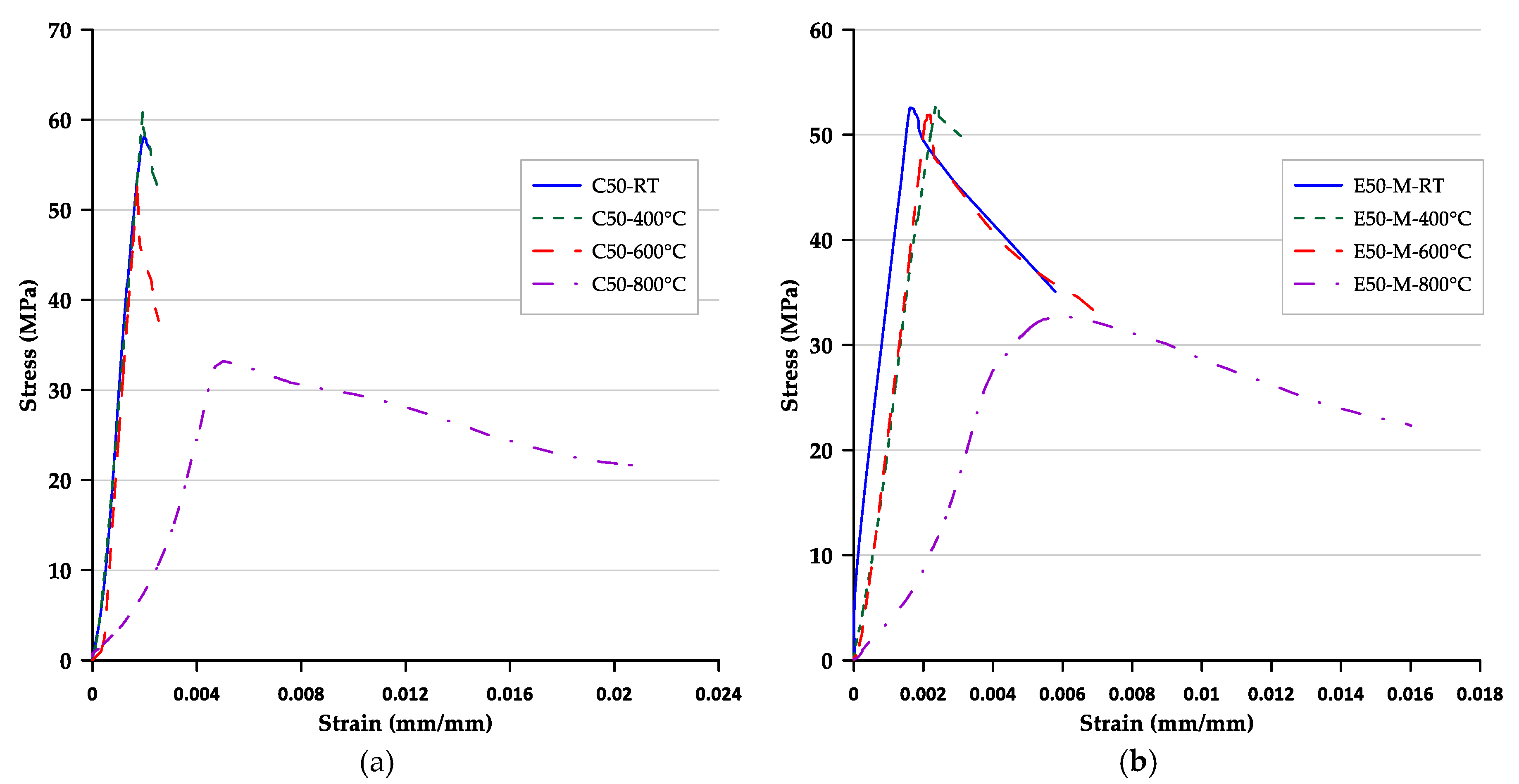

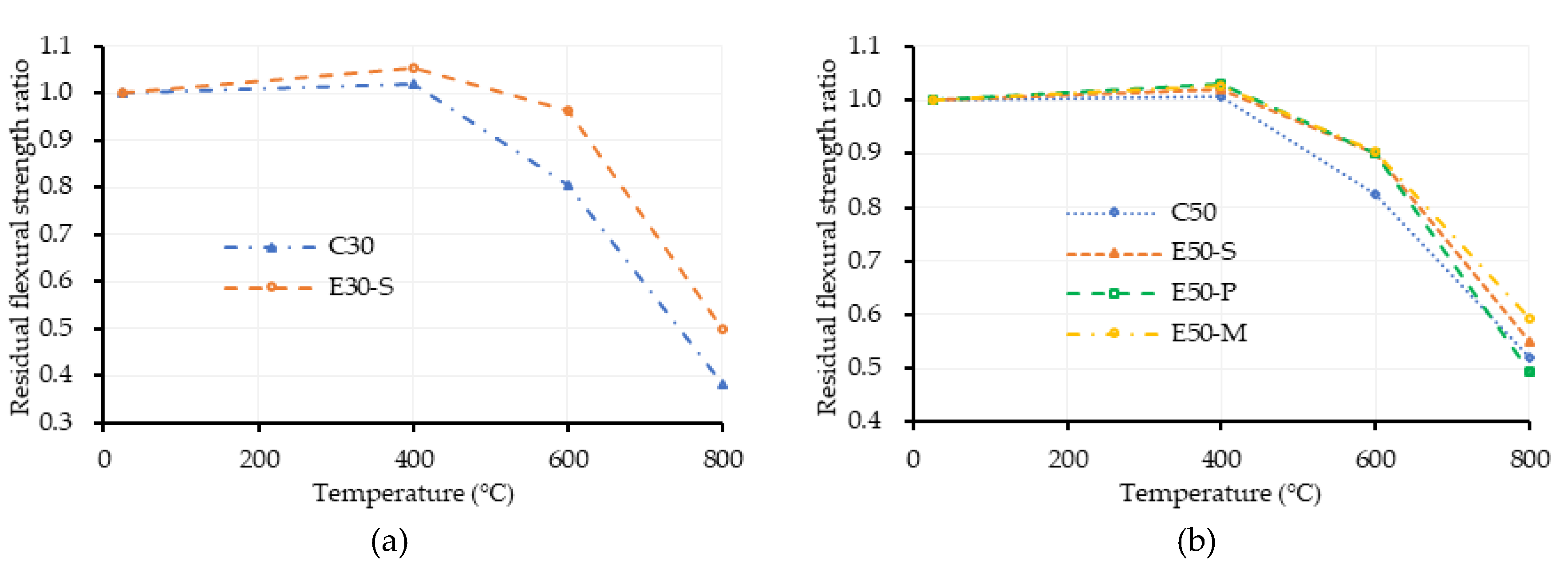

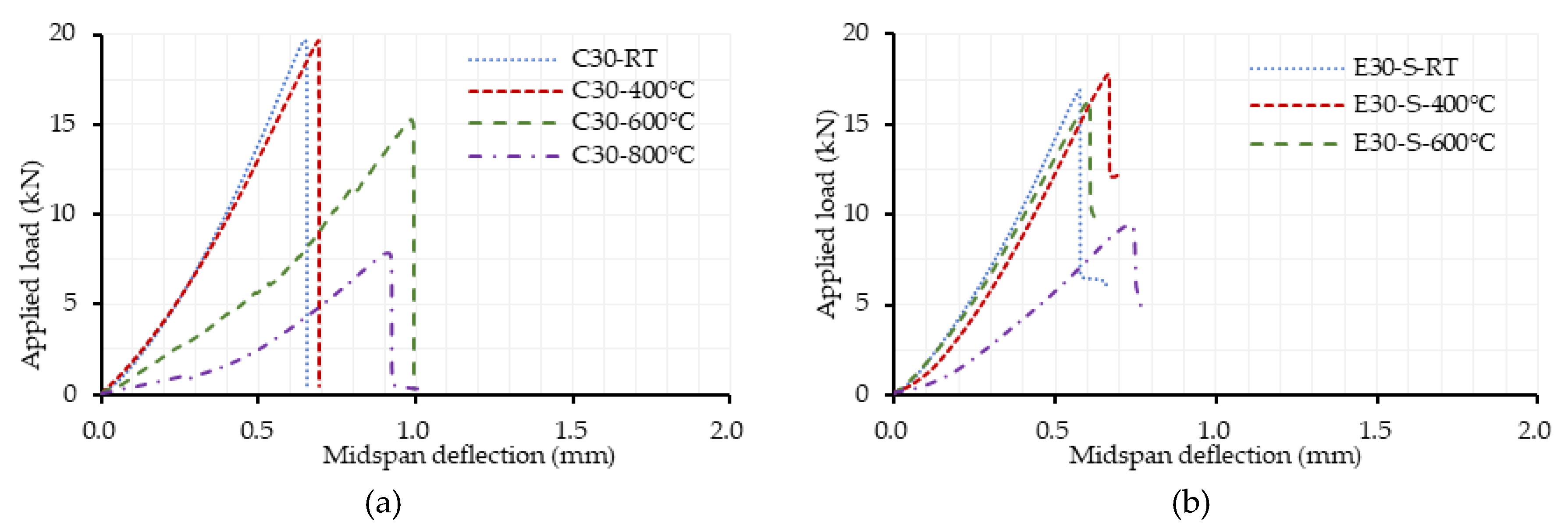

3.4. Flexural Strength

4. Conclusions

- Overall, the residual mechanical properties of each group of LWC decreased with increasing temperature. After exposure to 400 °C, the residual mechanical properties of all specimens did not attenuate due to the drying effect of high temperature. Then, after exposure to 800 °C, the residual mechanical properties significantly reduced.

- Due to the bridging effect of steel fibers and their inherent high melting temperature, the residual mechanical properties of LWC with steel fibers exposed to high temperatures significantly improved. Compared with individual fiber-reinforced LWC, the residual mechanical properties of mixed fiber-reinforced LWC were the best of the mixes tested.

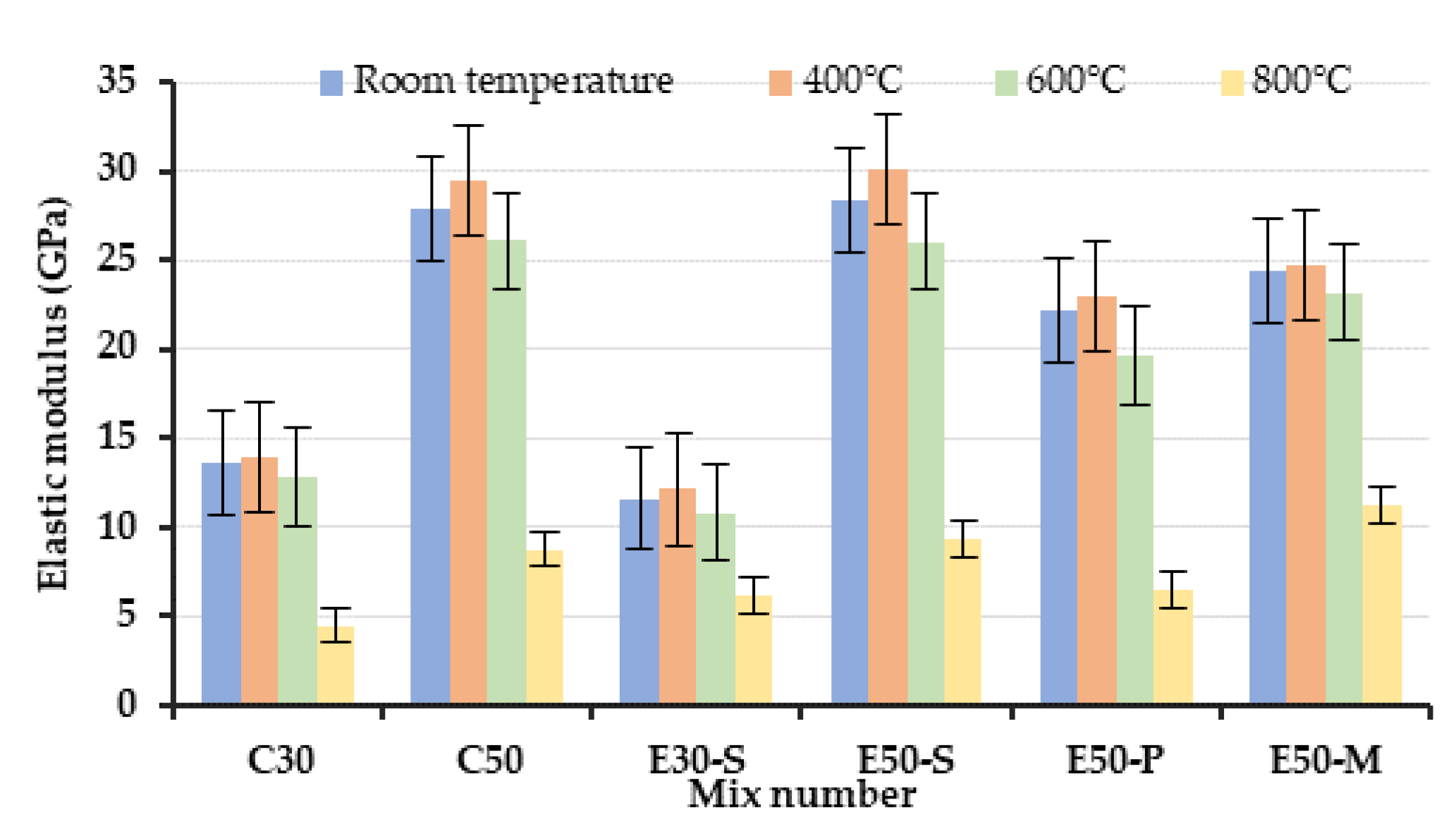

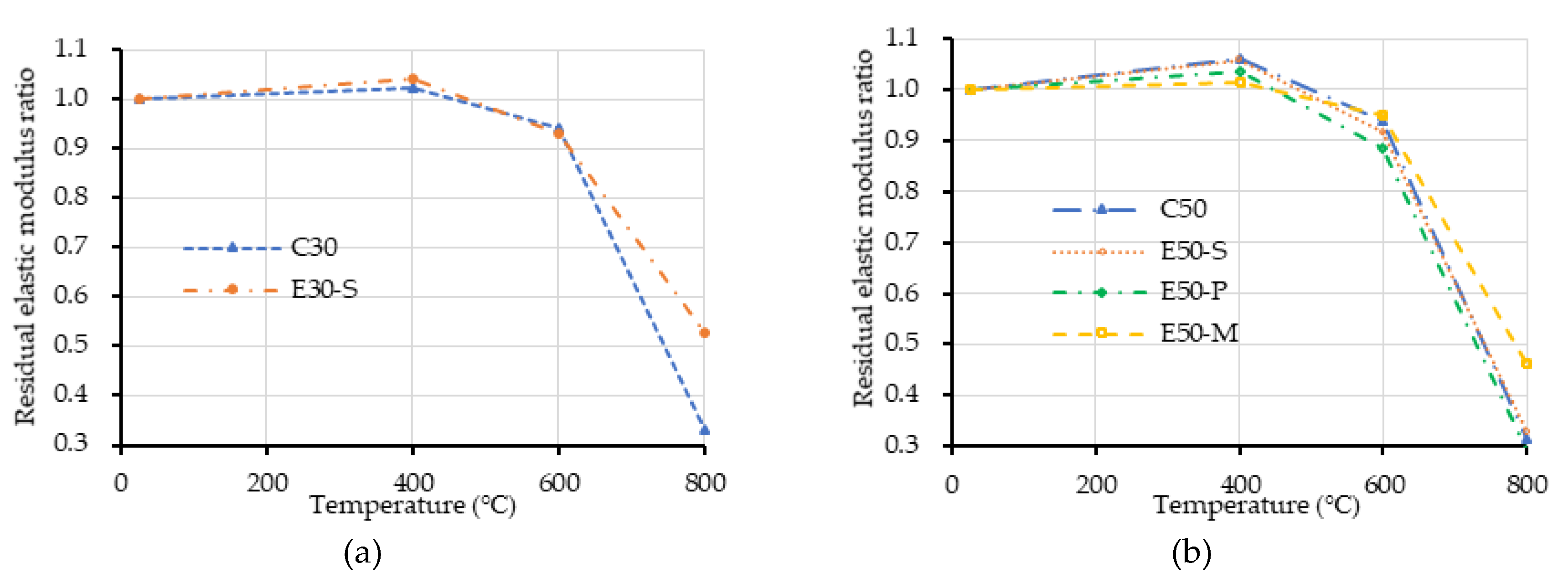

- The elastic modulus of each group of LWC changed with increasing temperature. After exposure to 800 °C, the residual elastic modulus decreased significantly and the residual elastic modulus ratio was lower than 0.53. As the temperature rose, the decreasing trend of the residual elastic modulus ratio was steeper than that of the residual compressive strength.

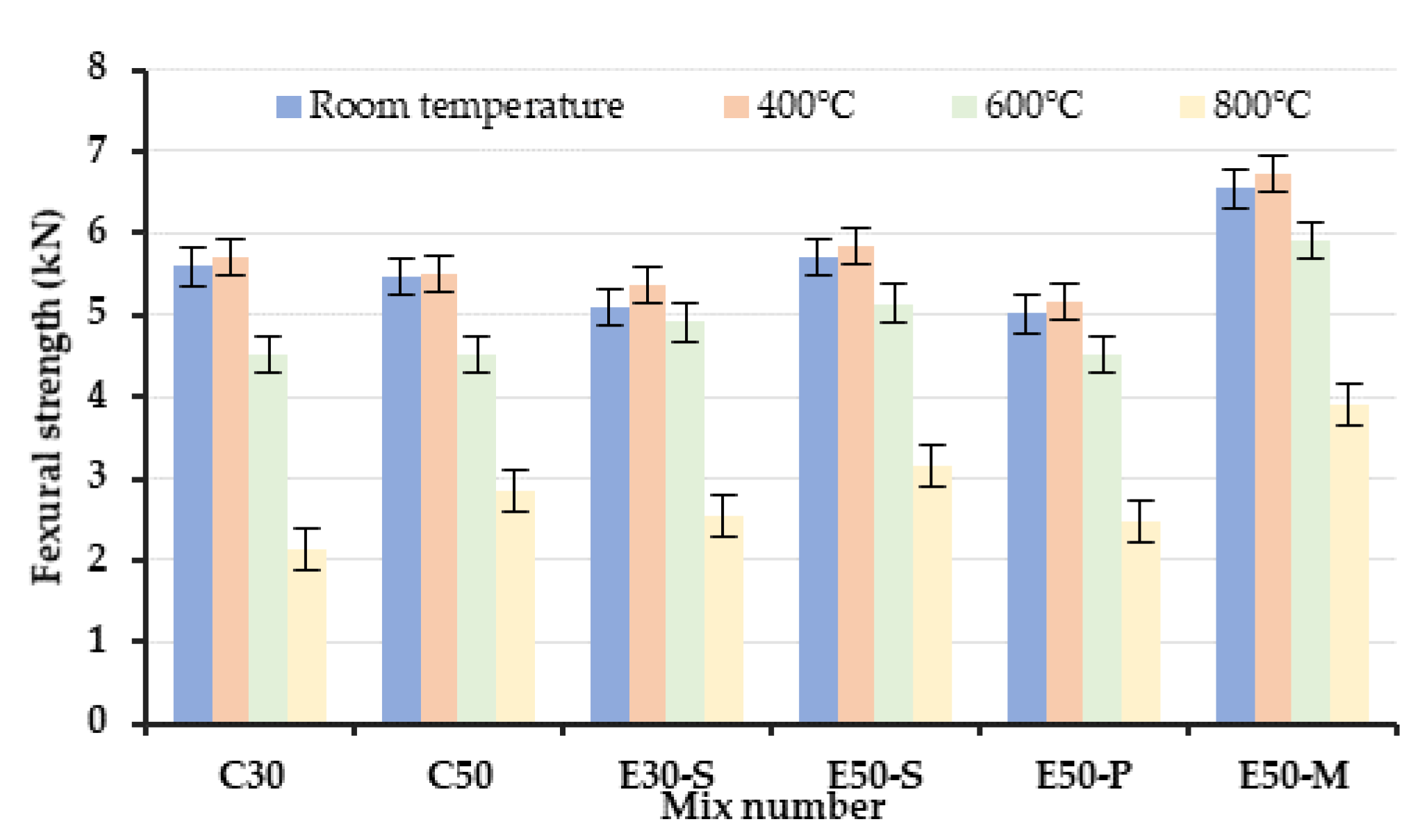

- After exposure to 400 °C, the flexural strength of each group of LWC did not attenuate. After exposure to 600 °C, the residual flexural strength of each group of LWC reduced, but the residual flexural strength ratio can be maintained above 0.83. After exposure to 800 °C, the residual flexural strength of each group of LWC was significantly attenuated, and the residual flexural strength ratio was between 0.38 and 0.59. Compared with the loss of compressive strength, the loss of flexural strength was relatively obvious.

Funding

Acknowledgments

Conflicts of Interest

References

- Somayaji, S. Civil. Engineering Materials, 3rd ed.; Prentice Hall: Upper Saddle River, NJ, USA, 2001. [Google Scholar]

- Chandra, S.; Berntsson, L. Lightweight Aggregate Concrete; Noyes Publications: New York, NY, USA, 2002. [Google Scholar]

- Tang, C.W. Uniaxial bond stress-slip behavior of reinforcing bars embedded in lightweight aggregate concrete. Struct. Eng. Mech. 2017, 62, 651–661. [Google Scholar]

- Gao, J.; Suqa, W.; Morino, K. Mechanical properties of steel fiber-reinforced, high-strength, lightweight concrete. Cem Concr Compos. 1997, 19, 307–313. [Google Scholar] [CrossRef]

- Hassanpour, M.; Shafigh, P.; Mahmud, H.B. Lightweight aggregate concrete fiber reinforcement—A review. Constr. Build. Mater. 2012, 37, 452–461. [Google Scholar] [CrossRef]

- Ding, Y.; Kusterle, W. Compressive stress—Strain relationship of steel fibre reinforced concrete at early age. Cem. Concr. Res. 2000, 30, 1573–1579. [Google Scholar] [CrossRef]

- Li, V.C. Large volume high performance applications of fibers in civil engineering. J. Appl. Polym. Sci. 2002, 83, 660–686. [Google Scholar] [CrossRef] [Green Version]

- Mehta, P.K.; Monteiro, P.J.M. Concrete: Microstructure, Properties, and Materials, 3rd ed.; The McGraw-Hill Companies, Inc.: New York, NY, USA, 2006. [Google Scholar]

- Campione, G.; Cucchiara, C.; Mendola, L.L.; Papia, M. Steel–concrete bond in lightweight fiber reinforced concrete under monotonic and cyclic actions. Eng. Struct. 2005, 27, 881–890. [Google Scholar] [CrossRef]

- Kurugol, S.; Tanacan, L.; Ersoy, H.Y. Young’s modulus of fiber-reinforced and polymer-modified lightweight concrete composites. Constr. Build. Mater. 2008, 22, 1019–1028. [Google Scholar] [CrossRef]

- Mindess, S.; Young, J.F.; Darwin, D. Concrete; Prentice Hall: Upper Saddle River, NJ, USA, 2003. [Google Scholar]

- Ko, J.; Ryu, D.; Noguchi, T. The spalling mechanism of high-strength concrete under fire. Mag. Concr. Res. 2011, 63, 357–370. [Google Scholar] [CrossRef]

- Drzymała, T.; Jackiewicz-rek, W.; Gałaj, J.; Šukys, R. Assessment of mechanical properties of high strength concrete (HSC) after exposure to high temperature. J. Civ. Eng. Manag. 2018, 24, 138–144. [Google Scholar] [CrossRef] [Green Version]

- Xiong, M.X.; Liew, J.Y.R. Spalling behavior and residual resistance of fibre reinforced Ultra-High performance concrete after exposure to high temperatures. Mater. De Constr. 2015, 65, e071. [Google Scholar] [CrossRef] [Green Version]

- Bošnjak, J.; Sharma, A.; Grauf, K. Mechanical properties of concrete with steel and polypropylene fibres at elevated temperatures. Fibers 2019, 7, 9. [Google Scholar] [CrossRef] [Green Version]

- Tang, C.W. Residual properties of high-strength fiber reinforced concrete after exposure to high temperatures. Comput. Concr. 2019, 24, 63–71. [Google Scholar]

- Seitllari, A.; Naser, M.Z. Leveraging artificial intelligence to assess explosive spalling in fire-exposed RC columns. Comput. Concr. 2019, 24, 271–282. [Google Scholar]

- Ahmad, S.; Umar, A.; Masood, A.; Nayeem, M. Performance of self-compacting concrete at room and after elevated temperature incorporating silica fume. Adv. Concr. Constr. 2019, 7, 31–37. [Google Scholar]

- Chen, B.; Liu, J. Residual strength of hybrid-fiber-reinforced high-strength concrete after exposure to high temperatures. Cem. Concr. Res. 2004, 34, 1065–1069. [Google Scholar] [CrossRef]

- Zhang, P.; Kang, L.; Wang, J.; Guo, J.; Hu, S.; Ling, Y. Mechanical Properties and Explosive Spalling Behavior of Steel-Fiber-Reinforced Concrete Exposed to High Temperature—A Review. Appl. Sci. 2020, 10, 2324. [Google Scholar] [CrossRef] [Green Version]

- Kodur, V.K.R.; Dwaikat, M. Effect of fire induced spalling on the response of reinforced concrete beams. Int. J. Concr. Struct. Mater. 2008, 2, 71–82. [Google Scholar]

- Kurtoglu, A.E.; Bakbak, D. New model for compressive strength loss of lightweight concrete exposed to elevated temperatures. Therm. Sci. 2019, 23, S285–S293. [Google Scholar] [CrossRef] [Green Version]

- Sancak, E.; Sari, Y.D.; Simsek, O. Effects of Elevated Temperature on Compressive Strength and Weight Loss of the Light-Weight Concrete with Silica Fume and Superplasticizer. Cem. Concr. Compos. 2008, 30, 715–721. [Google Scholar] [CrossRef]

- Tanyildizi, H. Fuzzy Logic Model for Prediction of Mechanical Properties of Lightweight Concrete Exposed to High Temperature. Mater. Des. 2009, 30, 2205–2210. [Google Scholar] [CrossRef]

- Tanyildizi, H.; Cevik, A. Modeling Mechanical Performance of Lightweight Concrete Containing Silica Fume Exposed to High Temperature Using Genetic Programming. Constr. Build. Mater. 2010, 24, 2612–2618. [Google Scholar] [CrossRef]

- Jiang, Y.; Huo, D.; Teng, H.; Qiao, Y. Study on performance of shale ceramsite concrete after exposure to high temperature. J. Build. Mater. 2013, 16, 888–892. (In Chinese) [Google Scholar]

- He, K.; Guo, R.; Ma, Q.; Yan, F.; Lin, Z.; Sun, Y. Experimental Research on High Temperature Resistance of Modified Lightweight Concrete after Exposure to Elevated Temperatures. Adv. Mater. Sci. Eng. 2016, 5972570. [Google Scholar] [CrossRef] [Green Version]

- Bideci, O.S. The Effect of High Temperature on Lightweight Concretes Produced with Colemanite Coated Pumice Aggregates. Constr. Build. Mater. 2016, 113, 631–640. [Google Scholar] [CrossRef]

- Torić, N.; Boko, I.; Juradin, S.; Baloević, G. Mechanical Properties of Lightweight Concrete after Fire Exposure. Struct. Concr. 2016, 17, 1071–1081. [Google Scholar] [CrossRef]

- Akcaozoglu, K.; Akcaozoglu, S. The Effect of Elevated Temperature on the Lightweight Concrete Produced by Expanded Clay Aggregate and Calcium Aluminate Cement. Bilge Int. J. Sci. Technol. Res. 2017, 1, 59–70. [Google Scholar]

- Huang, Z.; Padmaja, K.; Li, S.; Liew, J.Y.R. Mechanical properties and microstructure of ultra-lightweight cement composites with fly ash cenospheres after exposure to high temperatures. Constr. Build. Mater. 2018, 164, 760–774. [Google Scholar] [CrossRef]

- Baloch, W.L.; Khushnood, R.A.; Memon, S.A.; Ahmed, W.; Ahmad, S. Effect of Elevated Temperatures on Mechanical Performance of Normal and Lightweight Concretes Reinforced with Carbon Nanotubes. Fire Technol. 2018, 54, 1331–1367. [Google Scholar] [CrossRef]

- ACI-318. Building Code Requirements for Reinforced Concrete and Commentary; American Concrete Institute: Farmington Hills, MI, USA, 1999. [Google Scholar]

- FIP/CEB. High. Strength Concrete: State of the Art Report; Bulletin d’Information No. 197; FIP/CEB: Lausanne, Switzerland, 1990. [Google Scholar]

- Larrard, F.; Sedran, T. Mixture proportioning of high performance concrete. Cem. Concr. Res. 2002, 32, 1699–1704. [Google Scholar] [CrossRef]

- Standard Specification for Portland Cement; ASTM C150/C150M-15; ASTM International: West Conshohocken, PA, USA, 2015; Available online: www.astm.org (accessed on 10 February 2020).

- Standard Specification for Concrete Aggregates; ASTM C33/C33M-13; ASTM International: West Conshohocken, PA, USA, 2013; Available online: www.astm.org (accessed on 10 February 2020).

- Standard Test. Method for Compressive Strength of Cylindrical Concrete Specimens; ASTM C39/C39M-18; ASTM International: West Conshohocken, PA, USA, 2018; Available online: www.astm.org (accessed on 10 February 2020).

- Standard Test. Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading); ASTM C78/C78M-18 (2018); ASTM International: West Conshohocken, PA, USA, 2018; Available online: www.astm.org (accessed on 10 February 2020).

- Standard Test. Method for Static Modulus of Elasticity and Poisson’s Ratio of Concrete in Compression; ASTM C469/C469M-14 (2014); ASTM International: West Conshohocken, PA, USA, 2013; Available online: www.astm.org (accessed on 10 February 2020).

- Siddique, R.; Kaur, D. Properties of concrete containing ground granulated blast furnace slag (GGBFS) at elevated temperatures. J. Adv. Res. 2012, 3, 45–51. [Google Scholar] [CrossRef] [Green Version]

- Chen, H.J.; Yu, Y.L.; Tang, C.W. Mechanical Properties of Ultra-High Performance Concrete before and after Exposure to High Temperatures. Materials 2020, 13, 770. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, X.; Bu, F. Residual Strength for Concrete after Exposure to High Temperatures. In Innovative Computing and Information. ICCIC 2011. Communications in Computer and Information Science; Dai, M., Ed.; Springer: Berlin/Heidelberg, Germany, 2011; p. 232. [Google Scholar]

- Drzymała, T.; Jackiewicz-Rek, W.; Tomaszewski, M.; Kuś, A.; Gałaj, J.; Šukys, R. Effects of High Temperature on the Properties of High Performance Concrete (HPC). Procedia Eng. 2017, 172, 256–263. [Google Scholar] [CrossRef]

- Khoury, G.A. Effect of fire on concrete and concrete structures. Prog. Struct. Mat. Eng. 2000, 2, 429–447. [Google Scholar] [CrossRef]

- Deshpande, A.A.; Kumar, D.; Ranade, R. Influence of high temperatures on the residual mechanical properties of a hybrid fiber-reinforced strain-hardening cementitious composite. Constr. Build. Mater. 2019, 208, 283–295. [Google Scholar] [CrossRef]

- Kong, F.K.; Evans, R.H.; Cohen, E.; Roll, F. Handbook of Structural Concrete; Pitman Books Limited: London, UK, 1983. [Google Scholar]

- Babuji, B.; Varghese, S. Experimental study on the performance of hybrid fibre reinforced concrete at elevated temperatures. Int. J. Innov. Res. Adv. Eng. 2015, 8, 70–75. [Google Scholar]

- Chang, Y.F.; Cheng, Y.H.; Sheu, M.S.; Yao, G.C. Residual stress–strain relationship for concrete after exposure at high temperatures. Cem. Concr. Res. 2006, 36, 1999–2005. [Google Scholar] [CrossRef]

- Zheng, W.; Li, H.; Wang, Y. Compressive stress—Strain relationship of steel fiber-reinforced reactive powder concrete after exposure to elevated temperatures. Constr. Build. Mater. 2012, 35, 931–940. [Google Scholar] [CrossRef]

- Hsu, T.T.C.; Slate, F.O.; Sturman, G.M.; Winter, G. Microcracking of plain concrete and the shape of the stress–strain curve. ACI Mater. J. 1963, 60, 209–224. [Google Scholar]

- Lau, A.; Anson, M. Effect of high temperatures on high performance steel fibre reinforced concrete. Cem. Concr. Res. 2006, 36, 1698–1707. [Google Scholar] [CrossRef]

| Group | Mix No. | Specified Concrete Strength (MPa) | Fiber Content (Volume %) | Targeted Temperature (°C) |

|---|---|---|---|---|

| Control group | C30 | 30 | 0 | 400, 600, and 800 |

| C50 | 50 | 0 | 400, 600, and 800 | |

| Experimental group | E30-S | 30 | Steel fiber (1%) | 400, 600, and 800 |

| E50-S | 50 | Steel fiber (1%) | 400, 600, and 800 | |

| E50-P | 50 | Polypropylene fiber (0.1%) | 400, 600, and 800 | |

| E50-M | 50 | Steel fiber (1%) + Polypropylene fiber (0.1%) | 400, 600, and 800 |

| Aggregate Type | Specific Weight (SSD) | Water Absorption (SSD) (%) | FM |

|---|---|---|---|

| Fine aggregate | 2.60 | 1.25 | 2.70 |

| Dry Specific Weight | 1-h Water Absorption (%) | Unit Weight (Dry-Rodded) (kg/m3) | Crushing Strength (MPa) |

|---|---|---|---|

| 1.2 | 4.9 | 707.5 | 3.6 |

| Type of fiber | Length (mm) | Diameter (mm) | Density (g/cm3) | Elastic Modulus (GPa) | Tensile Strength (MPa) | Melting Point (°C) |

|---|---|---|---|---|---|---|

| Wavy Steel Fibers | 30 | 0.8 | 7.8 | 200 | 2000 | - |

| Polypropylene Fibers | 12 | 0.05 | 0.9 | - | 300 | 165 |

| Group | Mix No. | W/B | Cement (kg/m3) | Slag (kg/m3) | Water (kg/m3) | Aggregate (kg/m3) | SP (kg/m3) | Steel Fiber (kg/m3) | PP (kg/m3) | |

|---|---|---|---|---|---|---|---|---|---|---|

| FA | CA | |||||||||

| Control group | C30 | 0.50 | 315 | 105 | 210 | 824 | 418 | 2.9 | - | - |

| C50 | 0.32 | 412 | 138 | 176 | 957 | 348 | 7.7 | - | - | |

| Experimental group | E30-S | 0.50 | 315 | 105 | 210 | 824 | 418 | 2.9 | 78 | - |

| E50-S | 0.32 | 412 | 138 | 176 | 957 | 348 | 7.7 | 78 | - | |

| E50-P | 0.32 | 412 | 138 | 176 | 957 | 348 | 7.7 | - | 0.9 | |

| E50-M | 0.32 | 412 | 138 | 176 | 957 | 348 | 7.7 | 78 | 0.9 | |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, C.-W. Residual Mechanical Properties of Fiber-Reinforced Lightweight Aggregate Concrete after Exposure to Elevated Temperatures. Appl. Sci. 2020, 10, 3519. https://doi.org/10.3390/app10103519

Tang C-W. Residual Mechanical Properties of Fiber-Reinforced Lightweight Aggregate Concrete after Exposure to Elevated Temperatures. Applied Sciences. 2020; 10(10):3519. https://doi.org/10.3390/app10103519

Chicago/Turabian StyleTang, Chao-Wei. 2020. "Residual Mechanical Properties of Fiber-Reinforced Lightweight Aggregate Concrete after Exposure to Elevated Temperatures" Applied Sciences 10, no. 10: 3519. https://doi.org/10.3390/app10103519

APA StyleTang, C.-W. (2020). Residual Mechanical Properties of Fiber-Reinforced Lightweight Aggregate Concrete after Exposure to Elevated Temperatures. Applied Sciences, 10(10), 3519. https://doi.org/10.3390/app10103519