Adaptive Observer-Based Fault Detection and Fault-Tolerant Control of Quadrotors under Rotor Failure Conditions

Abstract

Featured Application

Abstract

1. Introduction

2. Dynamic Modeling

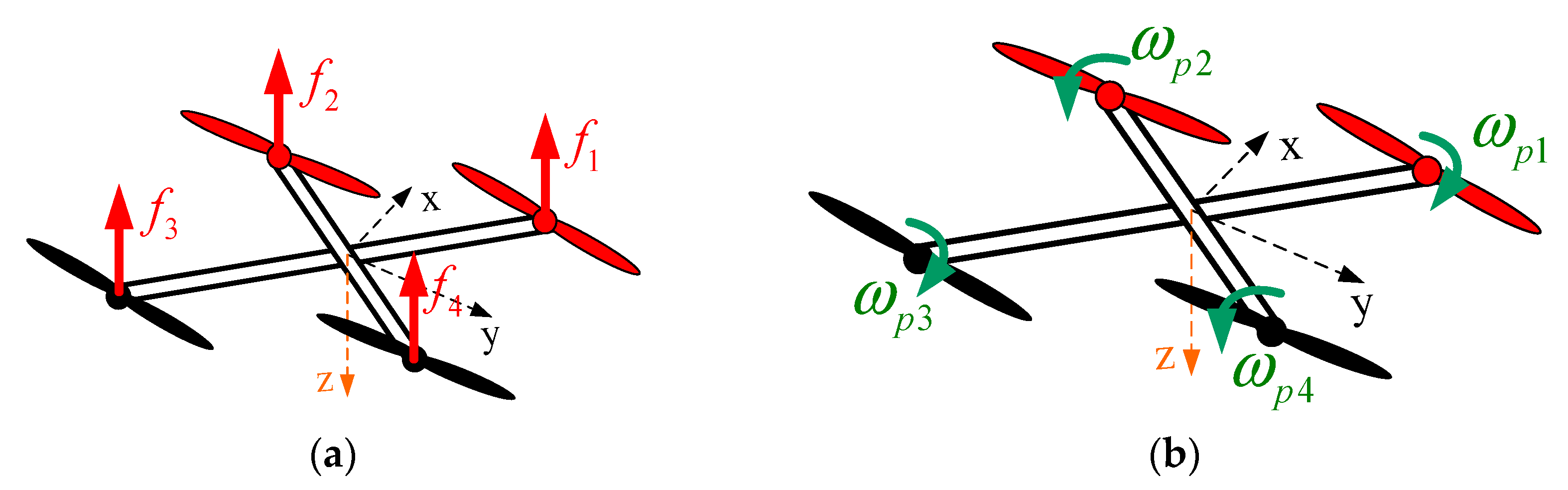

2.1. Configuration of the Quadrotor

2.2. Governing Equations

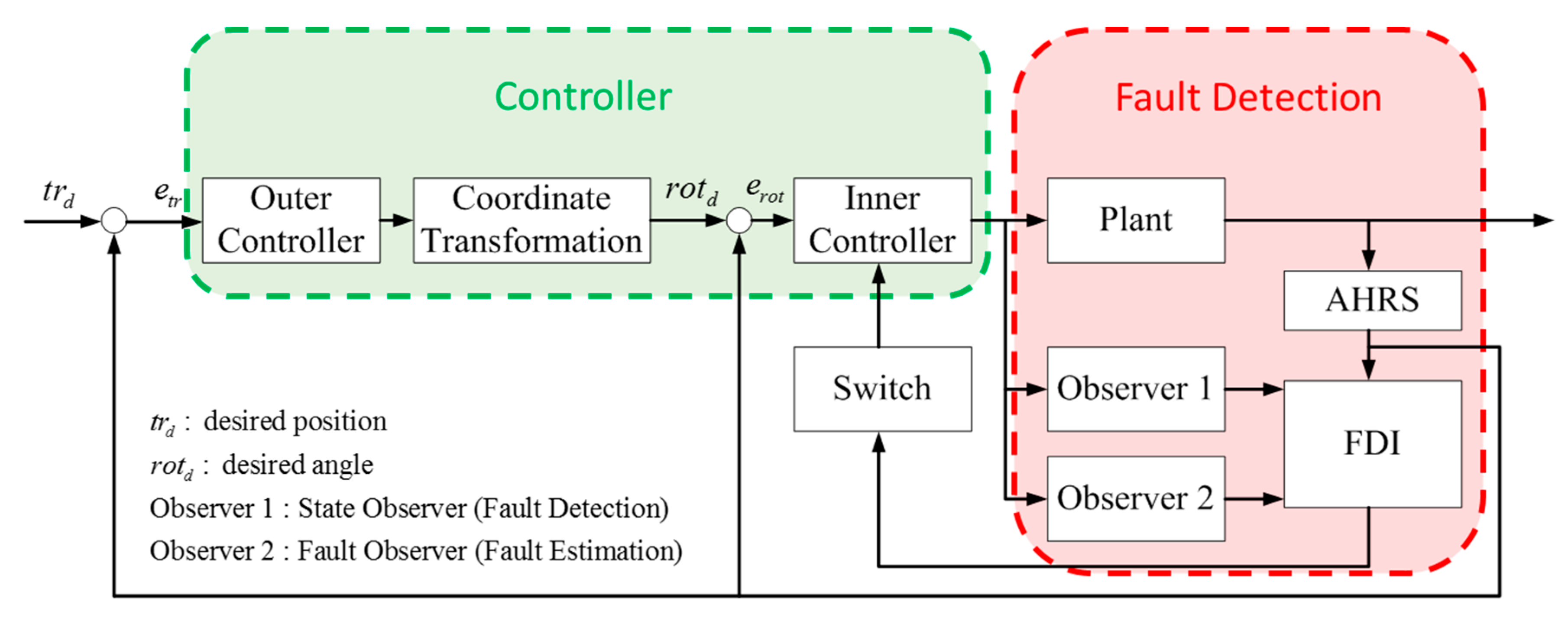

3. Coordinate Transformation-Based Fault-Tolerant Control

3.1. Controller Design

3.2. Stability Analysis

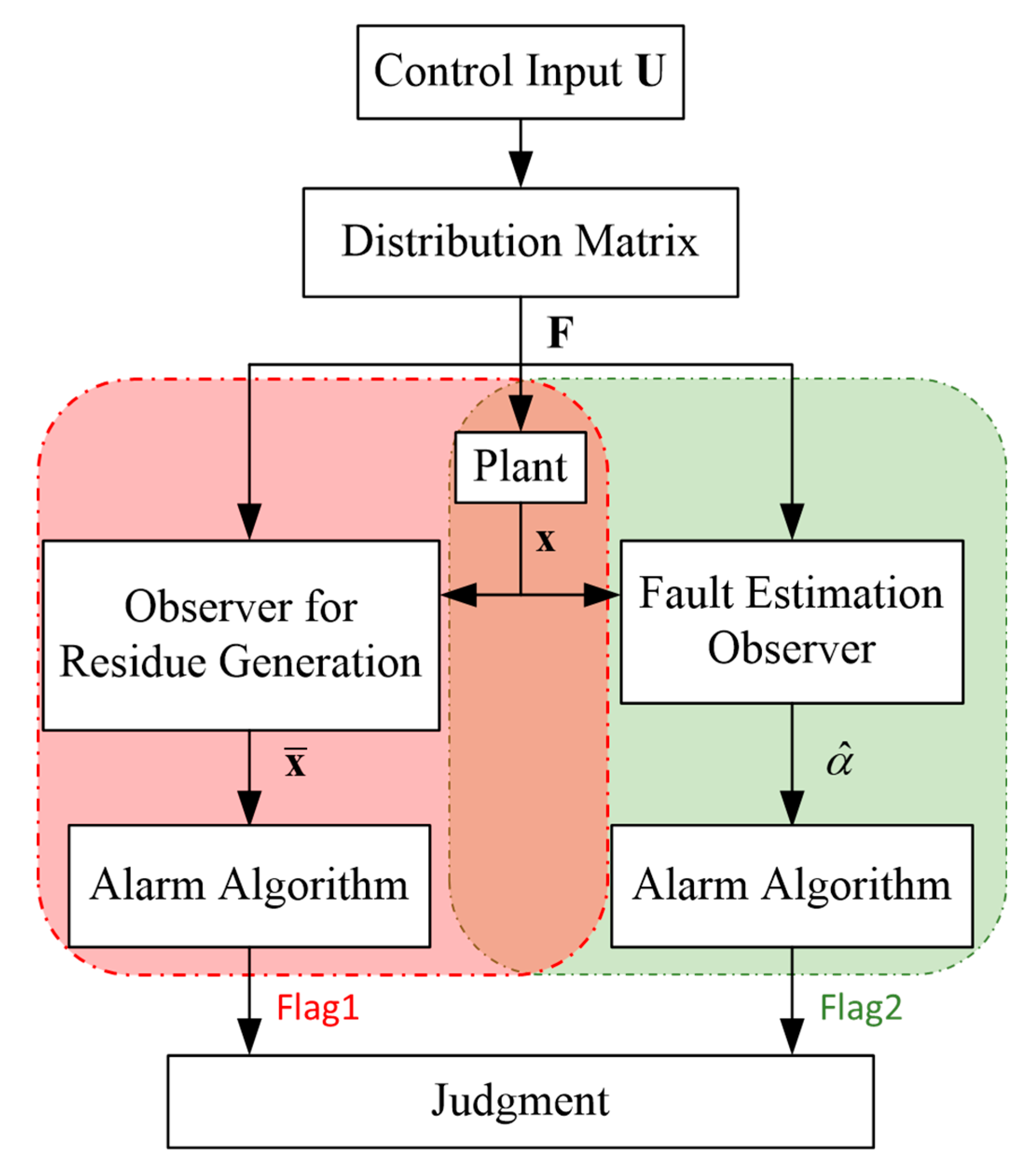

4. Fault Detection

4.1. Fault Detection Based on Residue Generation

4.2. Fault Detection Based on Fault Estimation

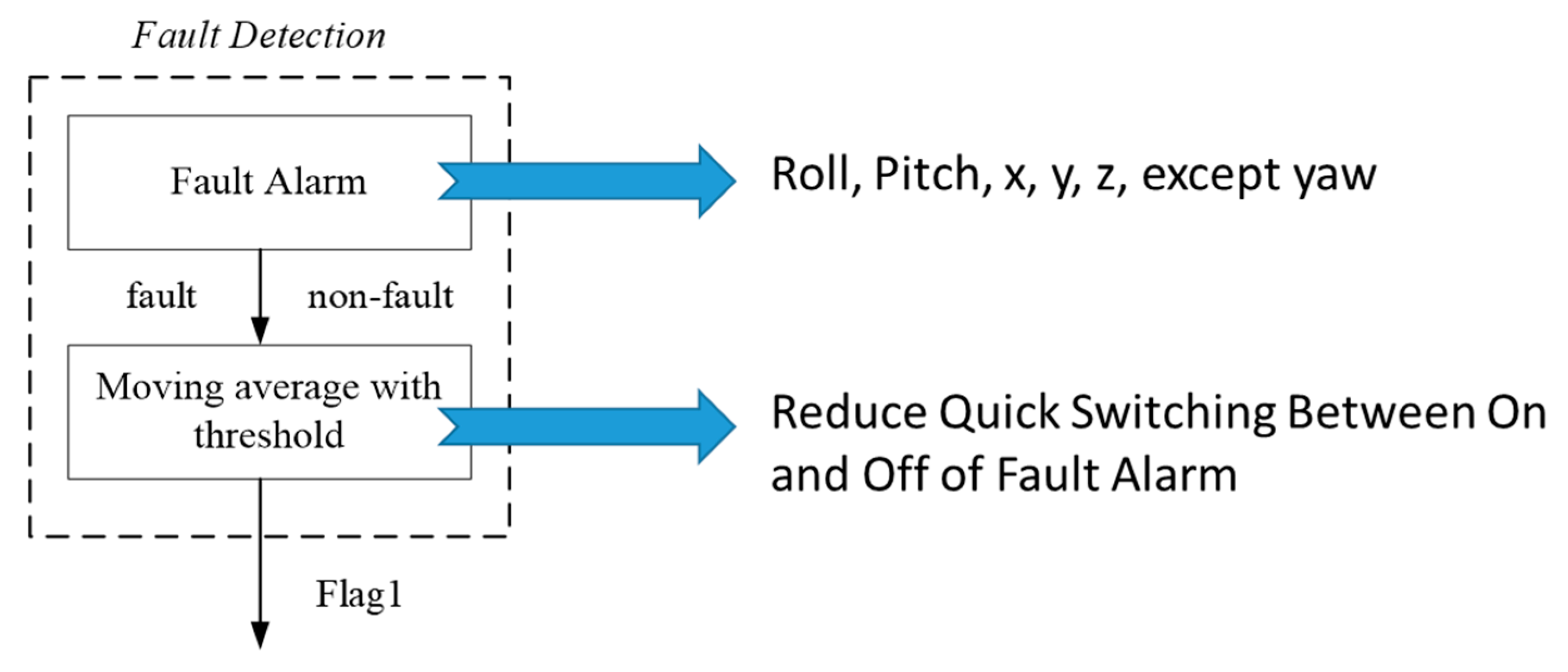

4.3. Fault Detection Making Algorithm

5. Simulation Results

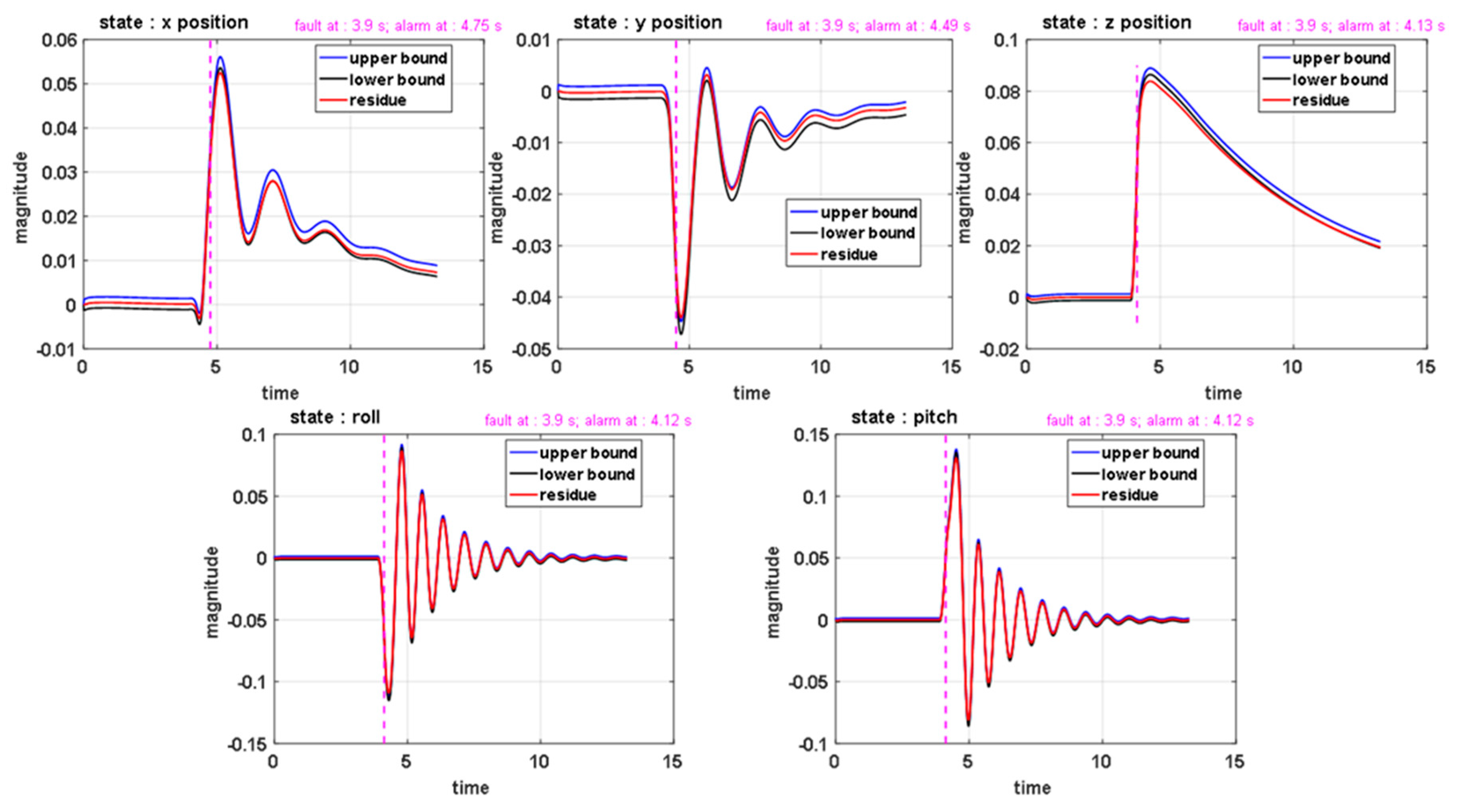

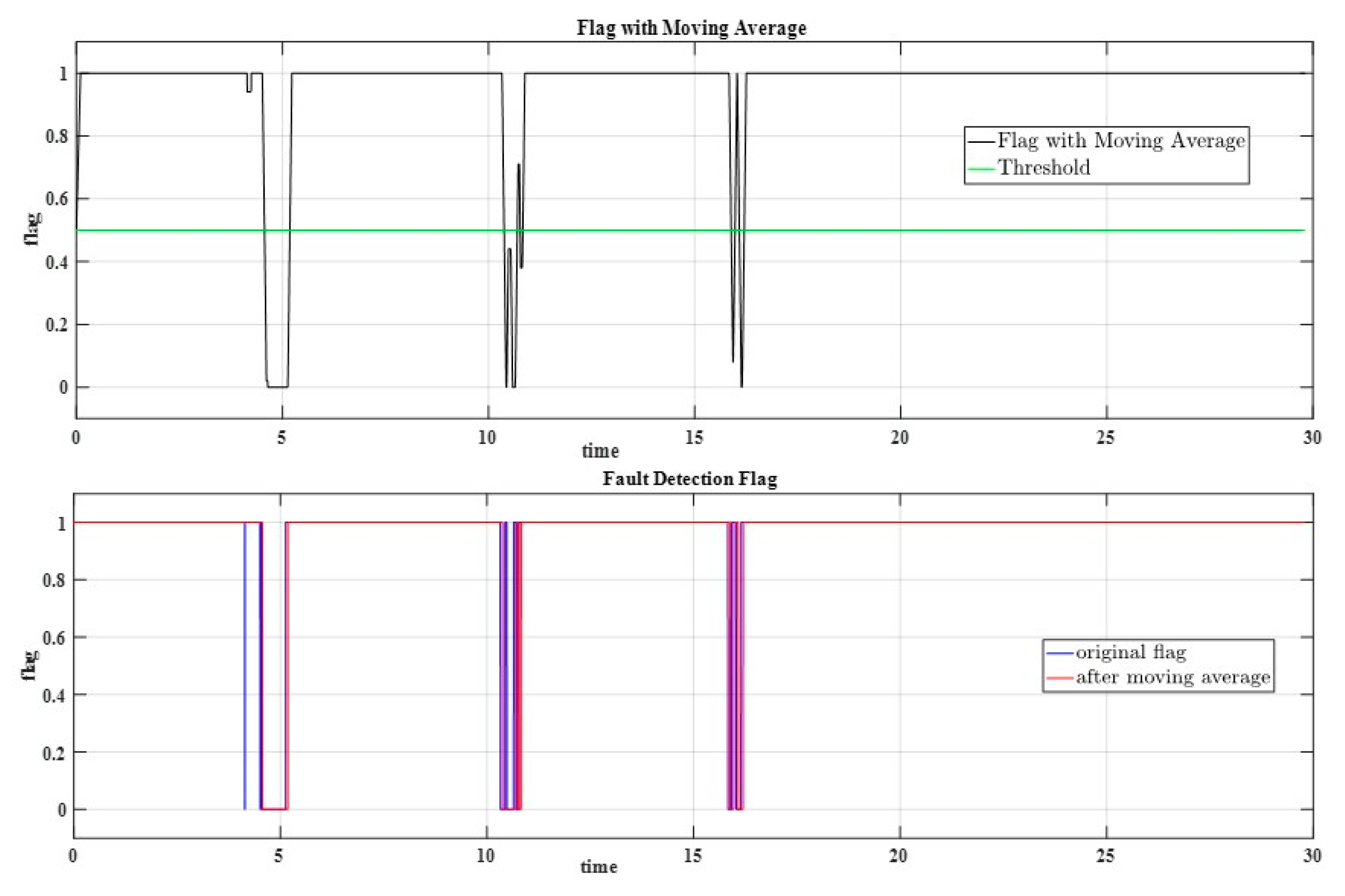

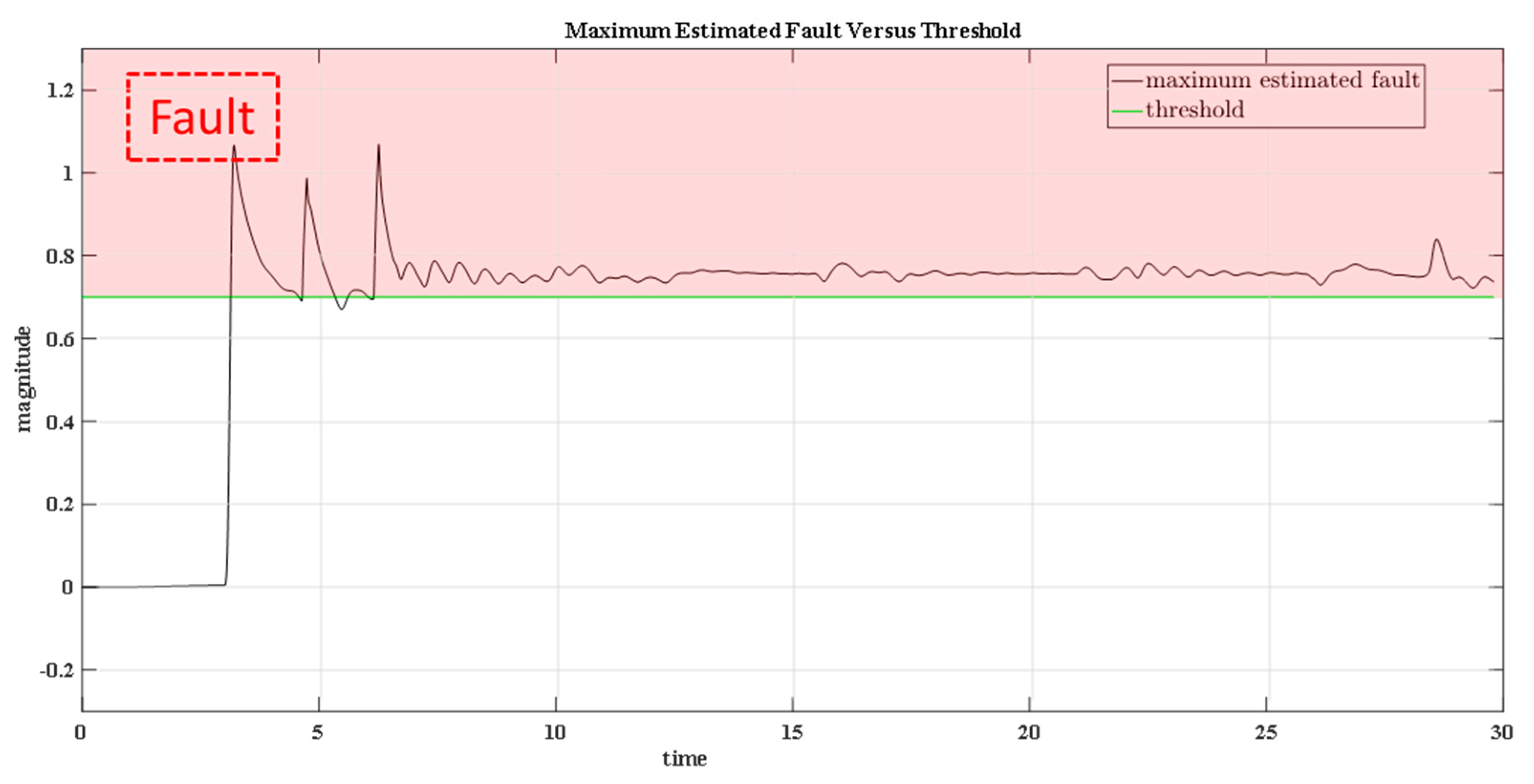

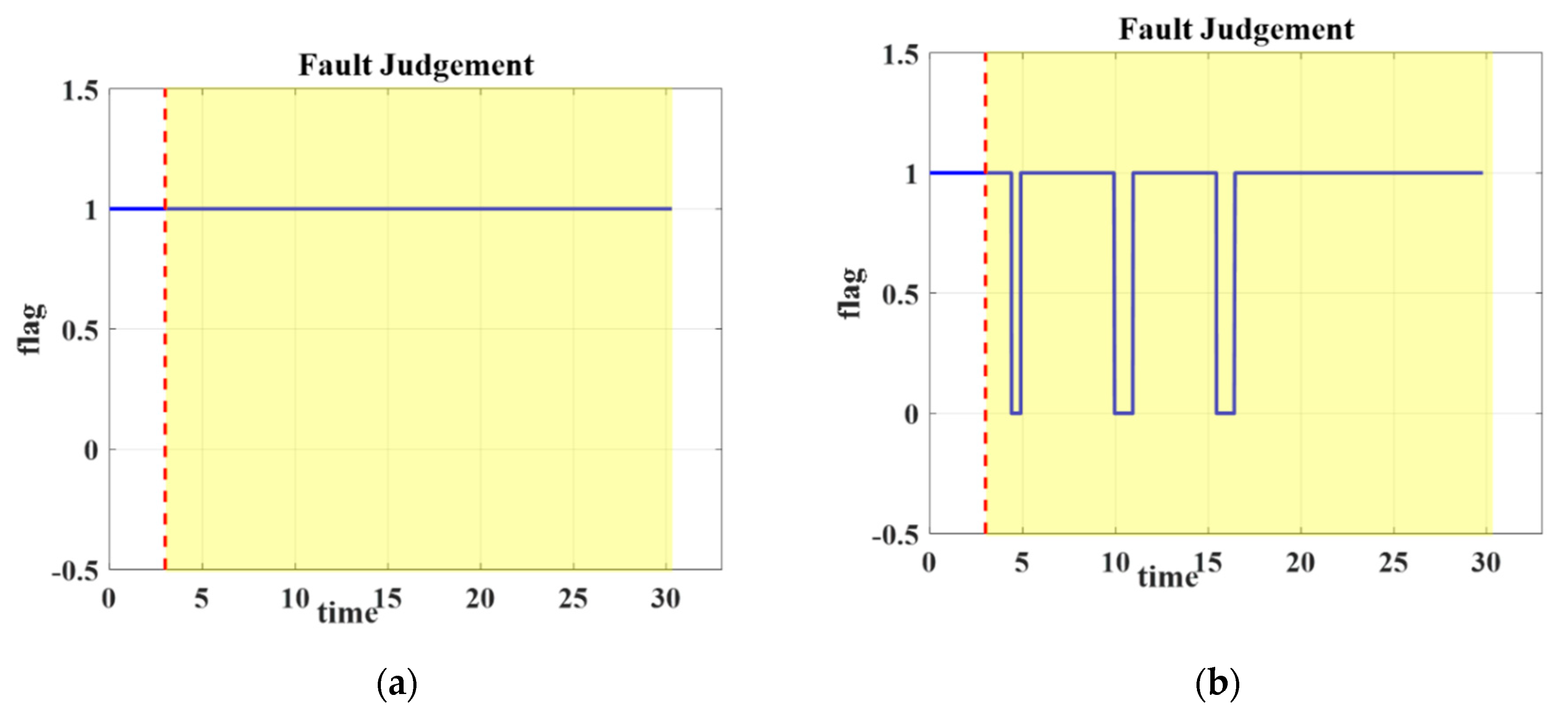

5.1. Fault Detection Results

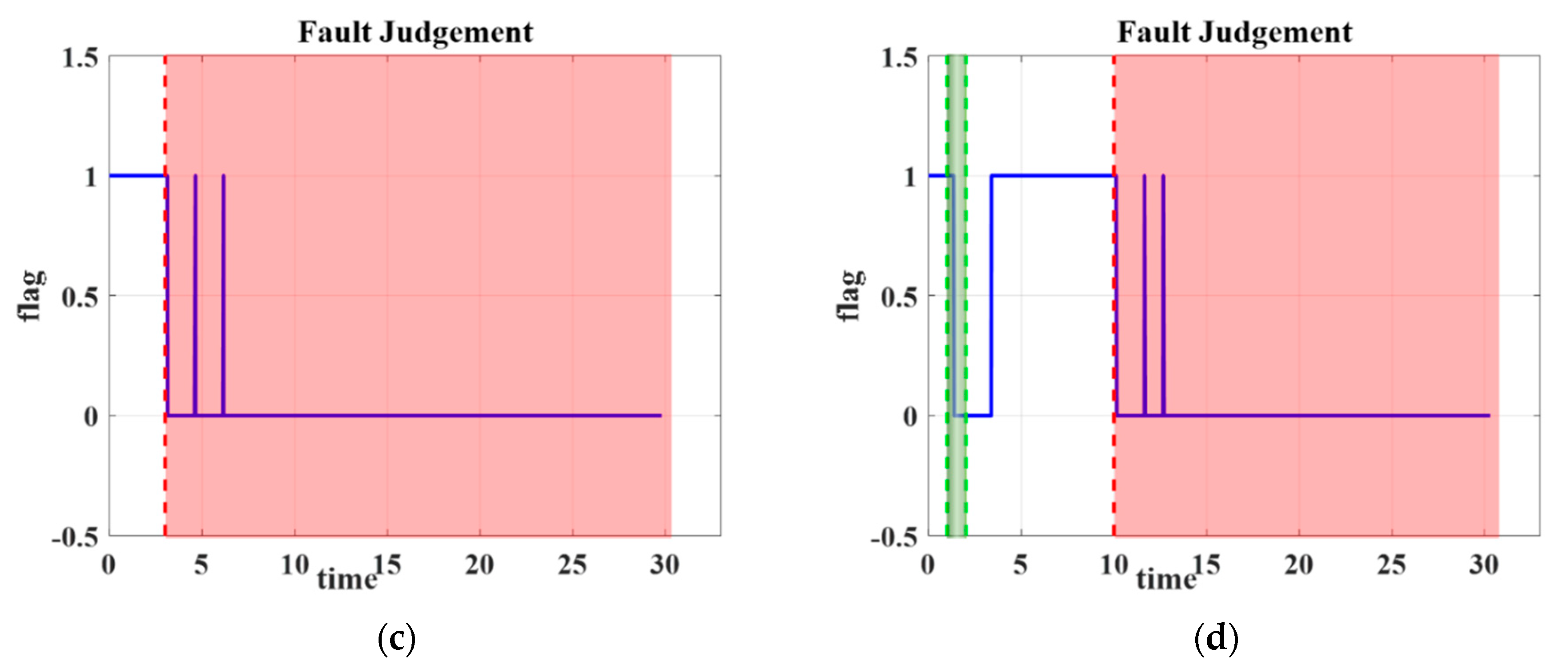

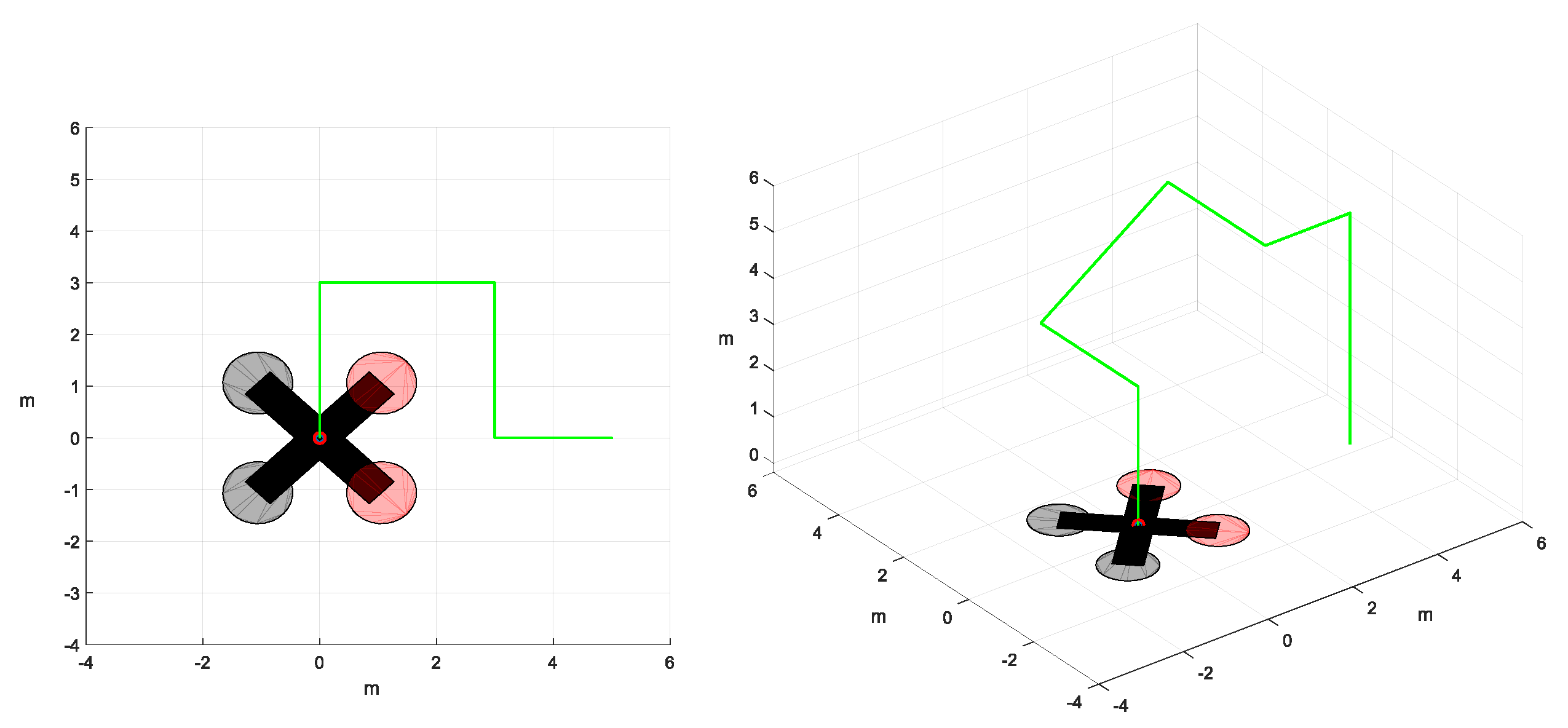

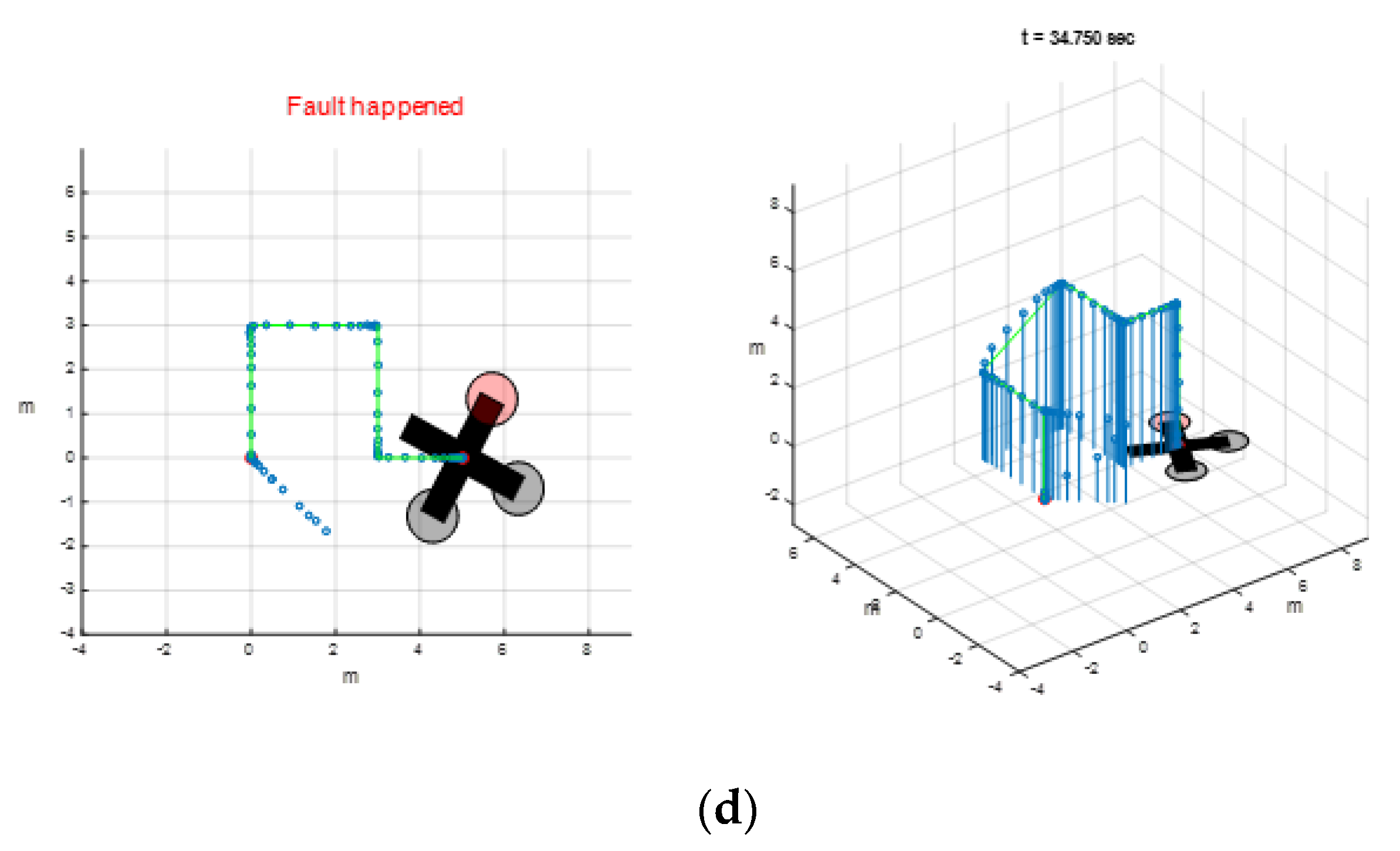

5.2. Quadcotor Flight Simulation with Rotor Fault

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Yungaicela-Naula, N.; Garza-Castañon, E.L.; Zhang, Y.; Minchala-Avila, I.L. Uav-based air pollutant source localization using combined metaheuristic and probabilistic methods. Appl. Sci. 2019, 9, 3712. [Google Scholar] [CrossRef]

- Tabbache, B.; Benbouzid, M.E.H.; Kheloui, A.; Bourgeot, J. Virtual-sensor-based maximum-likelihood voting approach for fault-tolerant control of electric vehicle powertrains. IEEE Trans. Veh. Technol. 2013, 62, 1075–1083. [Google Scholar] [CrossRef]

- Kommuri, S.K.; Defoort, M.; Karimi, H.R.; Veluvolu, K.C. A robust observer-based sensor fault-tolerant control for pmsm in electric vehicles. IEEE Trans. Ind. Electron. 2016, 63, 7671–7681. [Google Scholar] [CrossRef]

- Marino, R.; Scalzi, S.; Tomei, P.; Verrelli, C.M. Fault-tolerant cruise control of electric vehicles with induction motors. Control Eng. Pract. 2013, 21, 860–869. [Google Scholar] [CrossRef]

- Jin, J.; Youmin, Z. Accepting performance degradation in fault-tolerant control system design. IEEE Trans. Control Syst. Technol. 2006, 14, 284–292. [Google Scholar]

- Slotine, J.-J.E.; Li, W. Applied Nonlinear Control; Prentice Hall Englewood Cliffs: Bergen County, NJ, USA, 1991; Volume 199. [Google Scholar]

- Youmin, Z.; Jin, J. Fault tolerant control system design with explicit consideration of performance degradation. IEEE Trans. Aerosp. Electron. Syst. 2003, 39, 838–848. [Google Scholar] [CrossRef]

- Aravena, J.; Zhou, K.; Li, X.R.; Chowdhury, F. Fault tolerant safe flight controller bank 1. IFAC Proc. Vol. 2006, 39, 807–812. [Google Scholar] [CrossRef]

- Boskovic, J.D.; Mehra, R.K. A Multiple Model-Based Reconfigurable Flight Control System Design. In Proceedings of the 37th IEEE Conference on Decision and Control (Cat. No.98CH36171), Tampa, FL, USA, 16–18 December 1998; Volume 4504, pp. 4503–4508. [Google Scholar]

- Gopinathan, M.; Boskovic, J.D.; Mehra, R.K.; Rago, C. A Multiple Model Predictive Scheme for Fault-Tolerant Flight Control Design. In Proceedings of the 37th IEEE Conference on Decision and Control (Cat. No.98CH36171), Tampa, FL, USA, 16–18 December 1998; Volume 1372, pp. 1376–1381. [Google Scholar]

- Kanev, S.; Verhaegen, M. A bank of reconfigurable lqg controllers for linear systems subjected to failures. In Proceedings of the 39th IEEE Conference on Decision and Control (Cat. No.00CH37187), Sydney, NSW, Australia, 12–15 December 2000; Volume 3684, pp. 3684–3689. [Google Scholar]

- Narendra, K.S.; Balakrishnan, J. Adaptive control using multiple models. IEEE Trans. Autom. Control 1997, 42, 171–187. [Google Scholar] [CrossRef]

- Narendra, K.S.; Driollet, O.A. Adaptive control using multiple models, switching, and tuning. In Proceedings of the IEEE 2000 Adaptive Systems for Signal Processing, Communications, and Control Symposium (Cat. No.00EX373), Lake Louise, AB, Canada, 4 October 2000; pp. 159–164. [Google Scholar]

- Freddi, A.; Lanzon, A.; Longhi, S. A feedback linearization approach to fault tolerance in quadrotor vehicles. IFAC Proc. Vol. 2011, 44, 5413–5418. [Google Scholar] [CrossRef]

- Hess, R.A.; Wells, S.R. Sliding mode control applied to reconfigurable flight control design. J. Guid. Control Dyn. 2003, 26, 452–462. [Google Scholar] [CrossRef]

- Alwi, H.; Edwards, C. Lpv sliding mode fault tolerant control of an octorotor using fixed control allocation. In Proceedings of the 2013 Conference on Control and Fault-Tolerant Systems (SysTol), Nice, France, 9–11 October 2013; pp. 772–777. [Google Scholar]

- Edwards, C.; Chen, L.; Khattab, A.; Alwi, H.; Sato, M. Flight Evaluations of Sliding Mode Fault Tolerant Controllers. In Proceedings of the 15th International Workshop on Variable Structure Systems (VSS) Graz University of Technology, Graz, Austria, 9–11 July 2018; pp. 180–185. [Google Scholar]

- Hamayun, M.T.; Edwards, C.; Alwi, H. Fault Tolerant Control Schemes Using Integral Sliding Modes; Springer AG: Basel, Switzerland, 2016. [Google Scholar]

- Zou, Y.; Zhu, B. Adaptive trajectory tracking controller for quadrotor systems subject to parametric uncertainties. J. Frankl. Inst. 2017, 354, 6724–6746. [Google Scholar] [CrossRef]

- Thirumarimurugan, M.; Bagyalakshmi, N.; Paarkavi, P. Comparison of fault detection and isolation methods: A review. In Proceedings of the 2016 10th International Conference on Intelligent Systems and Control (ISCO), Coimbatore, India, 7–8 January 2016; pp. 1–6. [Google Scholar]

- Guo, D.; Wang, Y.; Zhong, M.; Zhao, Y. Fault detection and isolation for unmanned aerial vehicle sensors by using extended pmi filter. IFAC-PapersOnLine 2018, 51, 818–823. [Google Scholar] [CrossRef]

- Freddi, A.; Longhi, S.; Monteriù, A. A Model-Based Fault Diagnosis System for a Mini-Quadrotor. In Proceedings of the 7th Workshop on Advanced Control and Diagnosis (ACD), Zielona Gora, Poland, 19–20 November 2009; pp. 1–6. Available online: http://www.issi.uz.zgora.pl/ACD_2009/program/Papers/58_ACD_2009.pdf (accessed on 16 October 2009).

- Ghalamchi, B.; Mueller, M. Vibration-based propeller fault diagnosis for multicopters. In Proceedings of the 2018 International Conference on Unmanned Aircraft Systems (ICUAS), Dallas, TX, USA, 12–15 June 2018; pp. 1041–1047. [Google Scholar]

- Boudjedir, H.; Bouhali, O.; Rizoug, N. Adaptive neural network control based on neural observer for quadrotor unmanned aerial vehicle. Adv. Robot. 2014, 28, 1151–1164. [Google Scholar] [CrossRef]

- Li, C.; Zhang, Y.; Li, P. Extreme learning machine based actuator fault detection of a quadrotor helicopter. Adv. Mech. Eng. 2017, 9, 1687814017705068. [Google Scholar] [CrossRef]

- Monteriù, A.; Asthana, P.; Valavanis, K.; Longhi, S. Real-time model-based fault detection and isolation for ugvs. J. Intell. Robot. Syst. 2009, 56, 425–439. [Google Scholar] [CrossRef]

- Avram, R.C.; Zhang, X.; Muse, J. Quadrotor actuator fault diagnosis and accommodation using nonlinear adaptive estimators. IEEE Trans. Control Syst. Technol. 2017, 25, 2219–2226. [Google Scholar] [CrossRef]

- Avram, R.C. Fault Diagnosis and Fault-Tolerant Control of Quadrotor Uavs. Ph.D. Thesis, Wright State University, Dayton, OH, USA, 2016. [Google Scholar]

- Longhi, S. A diagnostic thau observer for a class of unmanned vehicles. J. Intell. Robot. Syst. 2012, 67, 61–73. [Google Scholar]

- Cen, Z.; Noura, H.; Susilo, T.B.; Younes, Y.A. Robust fault diagnosis for quadrotor uavs using adaptive thau observer. J. Intell. Robot. Syst. 2014, 73, 573–588. [Google Scholar] [CrossRef]

- Ganguli, S.; Marcos, A.; Balas, G. Reconfigurable lpv control design for boeing 747-100/200 longitudinal axis. In Proceedings of the 2002 American Control Conference (IEEE Cat. No.CH37301), Anchorage, AK, USA, 8–10 May 2002; Volume 3615, pp. 3612–3617. [Google Scholar]

- López-Estrada, F.R.; Ponsart, J.-C.; Theilliol, D.; Zhang, Y.; Astorga-Zaragoza, C.-M. Lpv model-based tracking control and robust sensor fault diagnosis for a quadrotor uav. J. Intell. Robot. Syst. 2016, 84, 163–177. [Google Scholar] [CrossRef]

- Nguyen, N.P.; Hong, S.K. Sliding mode thau observer for actuator fault diagnosis of quadcopter uavs. Appl. Sci. 2018, 8, 1893. [Google Scholar] [CrossRef]

- Ortiz-Torres, G.; Castillo, P.; Sorcia-Vázquez, F.D.J.; Rumbo-Morales, J.Y.; Brizuela-Mendoza, J.A.; Cruz-Soto, J.D.L.; Martínez-García, M. Fault estimation and fault tolerant control strategies applied to vtol aerial vehicles with soft and aggressive actuator faults. IEEE Access 2020, 8, 10649–10661. [Google Scholar] [CrossRef]

- Lei, Y.; Wang, H. Aerodynamic optimization of a micro quadrotor aircraft with different rotor spacings in hover. Appl. Sci. 2020, 10, 1272. [Google Scholar] [CrossRef]

- Lee, U.K.; Choi, H.Y.; Park, B.J. Inverse optimal design for position control of a quadrotor. Appl. Sci. 2017, 7, 907. [Google Scholar] [CrossRef]

- Chaturvedi, N.A.; Sanyal, A.K.; McClamroch, N.H. Rigid-body attitude control. IEEE Control Syst. Mag. 2011, 31, 30–51. [Google Scholar]

- Mueller, M.W.; Andrea, R.D. Stability and control of a quadrocopter despite the complete loss of one, two, or three propellers. In Proceedings of the 2014 IEEE International Conference on Robotics and Automation (ICRA), Hong Kong, China, 31 May–7 June 2014; pp. 45–52. [Google Scholar]

| if Flag1 || Flag2 == 0 => Fault_True = 1 |

| if Fault_True == 1 |

| if Flag1 && Flag2 == 1 holds for 0.5 sec |

| →Fault_True = 0 and reset Flag1=Flag2=1; |

| →return status is considered as normal |

| else |

| →return status is considered as a rotor fault |

| Lower Bound | Upper Bound | T(s) | ||||||

|---|---|---|---|---|---|---|---|---|

| State | ||||||||

| , | 1 | 0.05 | 0.0004 | 1 | 0.05 | 0.0004 | 0.015 | |

| , , | 1 | 0.05 | 0.002 | 1 | 0.05 | 0.002 | 0.015 | |

| Method | Moving Window | Threshold |

|---|---|---|

| residue estimation from the 1st observer | 0.01 (s) | 0.5 |

| fault estimation from the 2nd observer | 0.1 (s) | 0.7 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lien, Y.-H.; Peng, C.-C.; Chen, Y.-H. Adaptive Observer-Based Fault Detection and Fault-Tolerant Control of Quadrotors under Rotor Failure Conditions. Appl. Sci. 2020, 10, 3503. https://doi.org/10.3390/app10103503

Lien Y-H, Peng C-C, Chen Y-H. Adaptive Observer-Based Fault Detection and Fault-Tolerant Control of Quadrotors under Rotor Failure Conditions. Applied Sciences. 2020; 10(10):3503. https://doi.org/10.3390/app10103503

Chicago/Turabian StyleLien, Yu-Hsuan, Chao-Chung Peng, and Yi-Hsuan Chen. 2020. "Adaptive Observer-Based Fault Detection and Fault-Tolerant Control of Quadrotors under Rotor Failure Conditions" Applied Sciences 10, no. 10: 3503. https://doi.org/10.3390/app10103503

APA StyleLien, Y.-H., Peng, C.-C., & Chen, Y.-H. (2020). Adaptive Observer-Based Fault Detection and Fault-Tolerant Control of Quadrotors under Rotor Failure Conditions. Applied Sciences, 10(10), 3503. https://doi.org/10.3390/app10103503