Tracking Sustainability Targets with Quantitative Indicator Systems for Performance Measurement of Industrial Symbiosis in Industrial Parks

Abstract

1. Introduction

2. Results

2.1. Industrial Symbiosis Case Studies

2.2. Applied Methods in Industrial Symbiosis Systems

2.3. Quantitative Indicator System

3. Discussion and Future Research

4. Materials and Methods

Author Contributions

Funding

Conflicts of Interest

References

- Alkaya, Emrah, Merve Böğürcü, and Ferda Ulutaş. 2014. Industrial Symbiosis in Iskenderun Bay: A journey from Pilot Applications to a National Program in Turkey. Paper presented at the SYMBIOSIS 2014, Athens, Greece, June 19–21. [Google Scholar]

- Ashton, Weslynne Stacey. 2008. Understanding the organization of industrial ecosystems: A social network approach. Journal of Industrial Ecology 12: 34–51. [Google Scholar] [CrossRef]

- Azapagic, Adisa, and Slobodan Perdan. 2000. Indicators of sustainable development for industry: A General Framework. Process Safety and Environmental Protection 78: 243–61. [Google Scholar] [CrossRef]

- Bain, Ariana, Megha Shenoy, Weslynne Stacey Ashton, and Marian Ruth Chertow. 2010. Industrial symbiosis and waste recovery in an Indian industrial area. Resources, Conservation and Recycling 54: 1278–87. [Google Scholar] [CrossRef]

- Chertow, Marian Ruth. 2000. Industrial symbiosis: Literature and taxonomy. Annual Reviews Energy Environment 25: 313–37. [Google Scholar] [CrossRef]

- Chertow, Marian Ruth. 2004. Industrial Symbiosis. Encyclopedia of Energy 3: 407–15. [Google Scholar]

- Chertow, Marian Ruth. 2007. Uncovering industrial symbiosis. Journal of Industrial Ecology 11: 11–30. [Google Scholar] [CrossRef]

- Chertow, Marian Ruth. 2008. Industrial Ecology in a Developing Context. In Sustainable Development and Environmental Management. Edited by Corrado Clini and Maria Lodovica Gullino. Dordrecht: Springer, pp. 1–19. [Google Scholar]

- Chertow, Marian Ruth, Matthew Gordon, Peter Hirsch, and Anu Ramaswami. 2019. Industrial symbiosis potential and urban infrastructure capacity in Mysuru, India. Environmental Research Letters. in press. [Google Scholar] [CrossRef]

- Chopra, Shauhrat, and Vikas Khanna. 2014. Understanding resilience in industrial symbiosis networks: Insights from network analysis. Journal of Environmental Management 141: 86–94. [Google Scholar] [CrossRef]

- Cui, Hua, Changhao Liu, Raymond Côté, and Weifeng Liu. 2018. Understanding the Evolution of Industrial Symbiosis with a System Dynamics Model: A Case Study of Hai Hua Industrial Symbiosis, China. Sustainability 10: 3873. [Google Scholar] [CrossRef]

- Doménech, Teresa, and Michael Davies. 2009. The social aspects of industrial symbiosis: The application of social network analysis to industrial symbiosis networks. Progress in Industrial Ecology 6: 68–99. [Google Scholar] [CrossRef]

- Doménech, Teresa, and Michael Davies. 2011. Structure and morphology of industrial symbiosis networks: The case of Kalundborg. Procedia Social Behavior Science 10: 79–89. [Google Scholar] [CrossRef]

- Domenech, Teresa, Raimund Bleischwitz, Asel Doranova, Dimitris Panayotopoulos, and Laura Roman. 2019. Mapping Industrial Symbiosis Development in Europe—Typologies of networks, characteristics, performance and contribution to the Circular Economy. Resources, Conservation & Recycling 141: 76–98. [Google Scholar] [CrossRef]

- Dong, Liang, Tsuyoshi Fujita, Hui Zhang, Ming Dai, Minoru Fujii, Satoshi Ohnishi, Yong Geng, and Zhu Liu. 2013. Promoting low-carbon city through industrial symbiosis: A case in China by applying HPIMO model. Energy Policy 61: 864–73. [Google Scholar] [CrossRef]

- Earley, Katharine. 2015. Industrial symbiosis: Harnessing waste energy and materials for mutual benefit. Renewable Energy Focus 16: 75–77. [Google Scholar] [CrossRef]

- Ehrenfeld, John, and Nicholas Gertler. 1997. Industrial Ecology in Practice—The Evolution of Interdependence at Kalundborg. Journal of Industrial Ecology 1: 67–79. [Google Scholar] [CrossRef]

- Felicio, Miriã, Daniel Amaral, Kleber Esposto, and Xavier Gabarrell Durany. 2016. Industrial symbiosis indicators to manage eco-industrial parks as dynamic systems. Journal of Cleaner Production 118: 54–64. [Google Scholar] [CrossRef]

- Geng, Yong, Jia Fu, Joseph Sarkis, and Bing Xue. 2012. Towards a national circular economy indicator system in China: An evaluation and critical analysis. Journal of Cleaner Production 23: 216–24. [Google Scholar] [CrossRef]

- Geng, Yong, Zuoxi Liu, Bing Xue, Huijuan Dong, Tsuyoshi Fujita, and Anthony Chiu. 2014. Emergy-based assessment on industrial symbiosis: A case of Shenyang Economic and Technological Development Zone. Environmental Science and Pollution Research 21: 13572–87. [Google Scholar] [CrossRef]

- Golev, Artem, Glen Corder, and Damien P. Giurcob. 2014. Industrial symbiosis in Gladstone: A decade of progress and future development. Journal of Cleaner Production 84: 421–29. [Google Scholar] [CrossRef]

- Herczeg, Gabor, Renzo Akkerman, and Michael Zwicky Hauschild. 2016. Supply Chain Management in Industrial Symbiosis Networks. Ph.D. thesis, Technical University of Denmark, Copenhagen, Denmark, March; pp. 7–45. [Google Scholar]

- Huang, Maoxing, Zhenzhen Wang, and Ting Chen. 2019. Analysis on the theory and practice of industrial symbiosis based on bibliometrics and social network analysis. Journal of Cleaner Production 213: 956–67. [Google Scholar] [CrossRef]

- Kastner, Catharine A., Raymond Lau, and Markus Kraft. 2015. Quantitative Tools for Cultivating Symbiosis in Industrial Parks; A Literature Review. Cambridge: Centre for Computational Chemical Engineering, University of Cambridge. [Google Scholar]

- Krajnc, Damjan, and Peter Glavič. 2003. Indicators of Sustainable Production. Clean Technologies and Environmental Policy 5: 279–88. [Google Scholar] [CrossRef]

- Kurup, Biji, and Daniela Stehlik. 2009. Towards a model to assess the sustainability implications of industrial symbiosis in eco-industrial parks. Progress in Industrial Ecology 6: 103–19. [Google Scholar] [CrossRef]

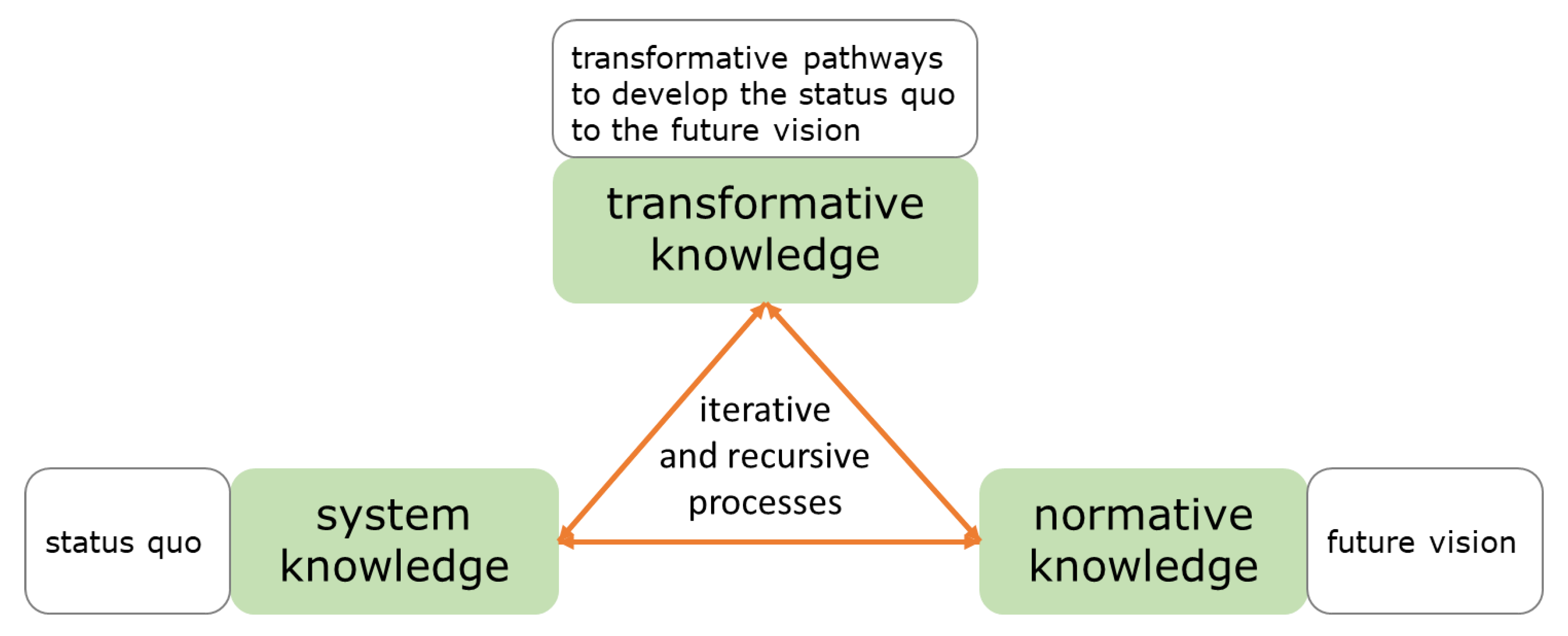

- Lang, Daniel J., Arnim Wiek, Matthias Bergmann, Michael Stauffacher, Pim Martens, Peter Moll, Mark Swilling, and Christopher J. Thomas. 2012. Transdisciplinary research in sustainability science: Practice, principles, and challenges. Sustainability Science 7: 25–43. [Google Scholar] [CrossRef]

- Li, Xiaohong. 2018. Industrial Ecology and Industrial Symbiosis for Environmental Sustainability—Definitions, Frameworks and Applications. London: Palgrave Pivot. ISBN 978-3-319-67500-8. [Google Scholar]

- Li, Bo, Pengcheng Xiang, Mingming Hu, Chunbo Zhang, and Liang Dong. 2017. The vulnerability of industrial symbiosis: A case study of Qijiang Industrial Park, China. Journal of Cleaner Production 157: 267–77. [Google Scholar] [CrossRef]

- Liu, Zhe, Michelle Adams, Raymond P. Cote, Yong Geng, Jingzheng Ren, Qinghua Chen, Weili Liu, and Xuesong Zhu. 2018. Co-benefits accounting for the implementation of eco-industrial development strategies in the scale of industrial park based on emergy analysis. Renewable and Sustainable Energy Reviews 81: 1522–29. [Google Scholar] [CrossRef]

- Lütje, Anna, Andreas Möller, and Volker Wohlgemuth. 2018. A preliminary concept for an IT-supported industrial symbiosis (IS) tool using extended material flow cost accounting (MFCA)—Impulses for environmental management information systems (EMIS). In Advances and New Trends in Environmental Informatics. Edited by Hans-Joachim Bungartz, Dieter Kranzlmüller, Volker Weinberg, Jens Weismüller and Volker Wohlgemuth. Basel: Springer Nature Switzerland AG, pp. 167–81. [Google Scholar] [CrossRef]

- Lütje, Anna, Martina Willenbacher, Andreas Möller, and Volker Wohlgemuth. 2019a. Enabling the identification of industrial symbiosis (IS) through information communication technology (ICT). Paper presented at the 52nd Hawaii International Conference on System Sciences (HICSS), Maui, HI, USA, January 8–11; pp. 709–19, ISBN 978-0-9981331-2-6. [Google Scholar] [CrossRef]

- Lütje, Anna, Martina Willenbacher, Martin Engelmann, Christian Kunisch, and Volker Wohlgemuth. 2019b. Exploring the system dynamics of industrial symbiosis (IS) with machine learning (ML) techniques—A framework for a hybrid-approach. In Advances and New Trends in Environmental Informatics—ICT for Sustainable Solutions. Edited by Rüdiger Schaldach, Karl-Heinz Simon, Jens Weismüller and Volker Wohlgemuth. Basel: Springer Nature Switzerland AG, pp. 117–30. [Google Scholar]

- Marconi, Marco, Fabio Gregori, Michele Germani, Alessandra Papetti, and Claudio Favi. 2018. An approach to favor industrial symbiosis: The case of waste electrical and electronic equipment. Procedia Manufacturing 21: 502–9. [Google Scholar] [CrossRef]

- Marinos-Kouris, Dimitrios, and Andreas Mourtsiadis. 2013. Industrial symbiosis in Greece: A study of spatial allocation patterns. Fresenius Environmental Bulletin 22: 2174–81. [Google Scholar]

- Martin, Michael. 2013. Industrial Symbiosis in the Biofuel Industry: Quantification of the Environmental Performance and Identification of Synergies. Ph.D. dissertation, Dissertation No. 1507. Linköping University, Linköping, Sweden, April 26. [Google Scholar]

- Martin, Michael, and Steve Harris. 2018. Prospecting the sustainability implications of an emerging industrial symbiosis network. Resources, Conservation & Recycling 138: 246–56. [Google Scholar] [CrossRef]

- Mauthoor, Sumayya. 2017. Uncovering industrial symbiosis potentials in a small island developing state: The case study of Mauritius. Journal of Cleaner Production 147: 506–13. [Google Scholar] [CrossRef]

- Mirata, Murat. 2004. Experiences from early stages of a national industrial symbiosis programme in the UK: Determinants and coordination challenges. Journal of Cleaner Production 12: 967–83. [Google Scholar] [CrossRef]

- Morales, Manuel Eduardo, Arnaud Diemer, Gemma Cervantes, and Graciela Carrillo-González. 2019. “By-product synergy” changes in the industrial symbiosis dynamics at the Altamira-Tampico industrial corridor: 20 years of industrial ecology in Mexico. Resources, Conservation & Recycling 140: 235–45. [Google Scholar] [CrossRef]

- Notarnicola, Bruno, Giuseppe Tassielli, and Pietro Alexander Renzulli. 2016. Industrial Symbiosis in the Taranto industrial district: Current level, constraints and potential new synergies. Journal of Cleaner Production 122: 133–43. [Google Scholar] [CrossRef]

- Pakarinen, Suvi, Tuomas Mattila, Matti Melanen, Ari Nissinen, and Laura Sokka. 2010. Sustainability and industrial symbiosis—The evolution of a Finnish forest industry complex. Resources, Conservation and Recycling 54: 1393–404. [Google Scholar] [CrossRef]

- Park, Hung Suck, Eldon R. Rene, Soo-Mi Choi, and Anthony S. F. Chiu. 2008. Strategies for sustainable development of industrial park in Ulsan, South Korea—From spontaneous evolution to systematic expansion of industrial symbiosis. Journal of Environmental Management 87: 1–13. [Google Scholar] [CrossRef] [PubMed]

- Ruiz-Puente, Carmen, and Erik Bayona. 2017. Modelling of an industrial symbiosis network as a supply chain. Paper presented at ATHENS 2017 5th International Conference on Sustainable Solid Waste Management, Athens, Greece, June 21–24. [Google Scholar]

- Sacchi, Romain, and Yana Konstantinova Ramsheva. 2017. The effect of price regulation on the performances of industrial symbiosis: A case study on district heating. International Journal of Sustainable Energy Planning and Management 14: 39–56. [Google Scholar] [CrossRef]

- SBTi. 2019. Science Based Targets initiative. Available online: https://sciencebasedtargets.org/ (accessed on 23 May 2019).

- Seager, Thomas P., and Thomas L. Theis. 2002. A uniform definition and quantitative basis for industrial ecology. Journal of Cleaner Production 10: 225–35. [Google Scholar] [CrossRef]

- Sendra, Cristina, Xavier Gabarrell, and Teresa Vicent. 2007. Material flow analysis adapted to an industrial area. Journal of Cleaner Production 15: 1706–15. [Google Scholar] [CrossRef]

- Sokka, Laura, Suvi Lehtoranta, Ari Nissinen, and Matti Melanen. 2010. Analyzing the Environmental Benefits of Industrial Symbiosis. Journal of Industrial Ecology 15: 137–55. [Google Scholar] [CrossRef]

- Sokka, Laura, Suvi Pakarinen, and Matti Melanen. 2011. Industrial symbiosis contributing to more sustainable energy use—An example from the forest industry in Kymenlaakso, Finland. Journal of Cleaner Production 19: 285–93. [Google Scholar] [CrossRef]

- Song, Xiaoqian, Yong Geng, Huijuan Dong, and Wei Chen. 2018. Social network analysis on industrial symbiosis: A case of Gujiao eco-industrial park. Journal of Cleaner Production 193: 414–23. [Google Scholar] [CrossRef]

- Sun, Lu, Hong Li, Liang Dong, Kai Fang, Jingzheng Ren, Yong Geng, Minoru Fujii, Wei Zhang, Ning Zhang, and Zhe Liu. 2016. Eco-benefits assessment on urban industrial symbiosis based on material flow analysis and emergy evaluation approach: A case of Liuzhou City, China. Resources, Conservation & Recycling 119: 78–88. [Google Scholar] [CrossRef]

- Taddeo, Raffaella, Alberto Simboli, Anna Morgante, and Suren Erkman. 2017. The development of Industrial Symbiosis in Existing Contexts. Experiences from three Italian clusters. Ecological Economics 139: 55–67. [Google Scholar] [CrossRef]

- Trokanas, Nikolaos, Franjo Cecelja, and Tara Raafat. 2014. Semantic approach for pre-assessment of environmental indicators in industrial symbiosis. Journal of Cleaner Production 96: 349–61. [Google Scholar] [CrossRef]

- Ulhasanah, Nova, and Naohiro Goto. 2012. Preliminary Design of Eco-City by Using Industrial Symbiosis and Waste Co-Processing Based on MFA, LCA, and MFCA of Cement Industry in Indonesia. International Journal of Environmental Science and Development 3: 553–61. [Google Scholar] [CrossRef]

- UNIDO. 2019. Eco-Industrial Parks—Achievements and key insights from the global RECP programme 2012–2018. UNIDO Report. Vienna: United Nations Industrial Development Organization, pp. 8–51. [Google Scholar]

- Valenzuela-Venegas Guillermo, Henríquez-Henríquez Francisco, Marianne Boix, Ludovic Montastruc, Fernando Arenas-Araya, Jenny Miranda-Péreza, and Felipe A. Díaz-Alvarado. 2018. A resilience indicator for Eco-Industrial Parks. Journal of Cleaner Production 174: 807–20. [Google Scholar] [CrossRef]

- van Berkel, Rene, Tsuyoshi Fujita, Shizuka Hashimoto, and Minoru Fujii. 2009. Quantitative Assessment of Urban and Industrial Symbiosis in Kawasaki, Japan. Environmental Science & Technology 43: 1271–81. [Google Scholar] [CrossRef]

- van Capelleveen, Guido, Chintan Amrit, and Devrim Murat Yazan. 2018. A Literature Survey of Information Systems Facilitating the Identification of Industrial Symbiosis. In From Science to Society. Progress in IS. Edited by Benôit Otjacques, Patrik Hitzelberger, Stefan Naumann and Volker Wohlgemuth. Cham: Springer International Publishing AG. [Google Scholar] [CrossRef]

- Viere, Tobias, Martina Prox, Andreas Möller, and Mario Schmidt. 2011. Implications of material flow cost accounting for life cycle engineering. Paper presented at 18th CIRP International Conference on Life Cycle Engineering, Braunschweig, Germany, May 2–4. [Google Scholar]

- Wen, Zongguo, and Xiaoyan Meng. 2015. Quantitative assessment of industrial symbiosis for the promotion of circular economy: A case study of the printed circuit boards industry in China´s Suzhou New District. Journal of Cleaner Production 90: 211–19. [Google Scholar] [CrossRef]

- Yang, Shanlin, and Nanping Feng. 2008. A case study of industrial symbiosis: Nanning Sugar Co., Ltd. in China. Resources, Conservation & Recycling 52: 813–20. [Google Scholar] [CrossRef]

- Yong, Geng, Zhang Pan, Raymond P. Côté, and Tsuyoshi Fujita. 2009. Assessment of the National Eco-Industrial Park Standard for Promoting Industrial Symbiosis in China. Journal of Industrial Ecology 13: 15–26. [Google Scholar] [CrossRef]

- Yu, Fei, Feng Han, and Zhaojie Cui. 2015. Evolution of industrial symbiosis in an eco-industrial park in China. Journal of Cleaner Production 87: 339–47. [Google Scholar] [CrossRef]

- Yuan, Zengwei, and Lei Shi. 2009. Improving enterprise competitive advantage with industrial symbiosis: Case study of a smeltery in China. Journal of Cleaner Production 17: 1295–302. [Google Scholar] [CrossRef]

- Zhang, Hui, Liang Dong, Huiquan Li, Tsuyoshi Fujita, Satoshi Ohnishi, and Qing Tang. 2013. Analysis of low-carbon industrial symbiosis technology for carbon mitigation in a Chinese iron/steel industrial park: A case study with carbon flow analysis. Energy Policy 61: 1400–11. [Google Scholar] [CrossRef]

- Zhu, Qinghua, Ernest A. Lowe, Yuan-an Wei, and Donald Barnes. 2008. Industrial Symbiosis in China: A Case Study of the Guitang Group. Journal of Industrial Ecology 11: 31–42. [Google Scholar] [CrossRef]

- Zhu, Li, Jianren Zhou, Zhaojie Cui, and Lei Liu. 2010. A method for controlling enterprises access to an eco-industrial park. Science of The Total Environment 408: 4817–25. [Google Scholar] [CrossRef] [PubMed]

| 1 | Science-based targets (SBT) were established by the Science-Based Targets initiative to drive corporate climate action that is aligned to meet the goals of the Paris agreement in 2015—to limit global warming to well below 2 °C above pre-industrial levels. |

| Method | Description | References |

|---|---|---|

| Social Network Analysis (SNA) | Investigates social structures of networks and characterizes elements within the network in terms of nodes (e.g., individual actors, companies, people) and the connecting ties or links (relationships or interactions). | (Ashton 2008; Doménech and Davies 2009; Doménech and Davies 2011; Zhang et al. 2013; Chopra and Khanna 2014; Song et al. 2018) |

| Substance Flow Analysis (SFA) | Quantifies and traces the flows and stocks of one specific substance/chemical or a group of substances within the system under consideration. | (Zhang et al. 2013; Wen and Meng 2015) |

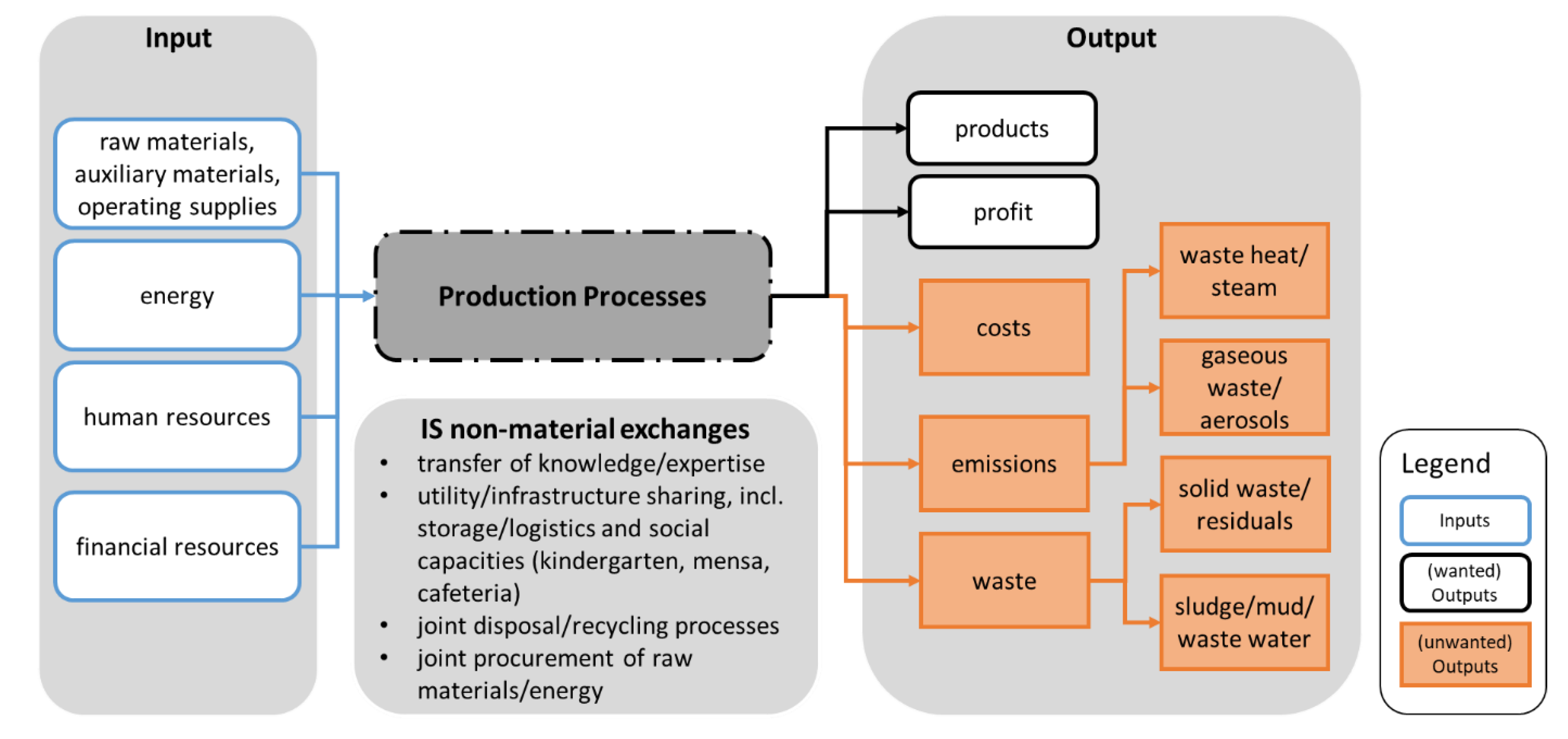

| Material Flow Analysis (MFA) | Quantifies the flows and stocks of materials and energy of the system under consideration in physical units (e.g., kg), distinguishing between input and output streams of the respective processes. | (Chertow 2008; Park et al. 2008; Yang and Feng 2008; Zhu et al. 2008; van Berkel et al. 2009; Yuan and Shi 2009; Bain et al. 2010; Ulhasanah and Goto 2012; Sun et al. 2016; Li et al. 2017; Taddeo et al. 2017; Mauthoor 2017; Morales et al. 2019) |

| Material Flow Cost Accounting (MFCA) | Traces and quantifies the flows and stocks of materials and energy of the system under consideration in physical and monetary units; especially the material losses, non-/by-product, and waste flows are evaluated. | (Viere et al. 2011; Ulhasanah and Goto 2012; Lütje et al. 2018; Lütje et al. 2019a) |

| Life Cycle Assessment (LCA) | Quantifies the flows and stocks of materials and energy of the system under consideration and assesses the associated environmental impacts, such as global warming and eutrophication potential. | (Sokka 2010; Ulhasanah and Goto 2012; Marinos-Kouris and Mourtsiadis 2013; Sacchi and Ramsheva 2017; Marconi et al. 2018; Martin and Harris 2018; Chertow et al. 2019) |

| Emergy analysis | Emergy is an expression of all the energy consumed in direct and indirect transformations in the processes to generate a product or service; therefore, emergy analysis converts the thermodynamic basis of all forms of energy, resources, and human services into equivalents of a single form of energy (usually solar emjoules). | (Geng et al. 2014; Sun et al. 2016; Liu et al. 2018) |

| Exergy Analysis | Is a thermodynamic analysis technique, assessing the thermodynamic performance of processes and systems, identifying the causes and locations of thermodynamic losses. | (Seager and Theis 2002) |

| Indicator | Unit | References |

|---|---|---|

| IS Structure | ||

| number of overarching/special IS organizational units | # | (UNIDO 2019; own suggestions) |

| number of participating entities in the IS system | # | |

| density of IS system | ||

| number of joint disposal companies | # | |

| number of joint supplier companies | # | |

| number of joint logistics companies | # | |

| IS Activity | ||

| number of IS connections | # | (UNIDO 2019; own suggestions) |

| degree of interconnectivity | ||

| number of exchanged resources | # | |

| degree of resource exchange activity | ||

| number of water networks | # | |

| activity degree of water network | ||

| number of material networks | # | |

| activity degree of material network | ||

| number of energy networks | # | |

| activity degree of energy network | ||

| number of knowledge networks | # | |

| number of IS meetings addressing IS measures | # | |

| number of identified IS opportunities | # | |

| number of planned IS activities | # | |

| number of IS activities that are being implemented | # | |

| number of implemented IS activities | # | |

| number of IS consultations | # | |

| number of IS system analyses | # | |

| investments in IS consultations | $ | |

| investments in IS system analyses | $ | |

| investments in IS measures | $ | |

| received (public) funding to expand IS system | $ | |

| IS Knowledge Transfer | ||

| number of education/training events addressing IS | # | (UNIDO 2019; own suggestions) |

| number of educated/trained persons concerning IS | # | |

| IS System Resilience and Adaptability | ||

| network connectivity indexflows adaptability index | (Valenzuela-Venegas et al. 2018) |

| Indicator | Unit | References |

|---|---|---|

| Input-Related Indicators | ||

| cost savings for human resources | $ | (Ulhasanah and Goto 2012; Lütje et al. 2018; Lütje et al. 2019a; UNIDO 2019) |

| cost savings for material | $ | |

| cost savings for water | $ | |

| cost savings for energy | $ | |

| cost savings for land use | $ | |

| production-cost-specific IS cost savings | ||

| Emdollar value of Total Emergy Savings (ETS) | $ | (Geng et al. 2014; Sun et al. 2016; Liu et al. 2018) |

| Output-Related Indicators | ||

| cost savings for disposal/recycling | $ | (Trokanas et al. 2014; own suggestions) |

| cost savings for CO2 taxes | $ | |

| cost savings for (CO2) emission trading certificates | $ | |

| created added value | $ | |

| created yield | $ | |

| specific resource productivity | (Wen and Meng 2015) | |

| yield-specific IS cost savings | own suggestions | |

| specific area-related IS value-added ratio | ||

| Indicator | Unit | References |

|---|---|---|

| Input-Related Indicators | ||

| created number of jobs | # | (UNIDO 2019; Geng et al. 2012) |

| number of joint organized social/charity events within the IS system | # | |

| investments in joint/cross-company organized social activities | $ | own suggestions |

| number of utility-sharing and joint infrastructure projects | # | |

| investments in utility-sharing and joint infrastructure (kindergarten, mensa, canteen, cafeteria, mobility) | ||

| Output-Related indicators | ||

| through shared IS utilities and human resources: improved environmental, health, and safety (EHS) aspects (e.g., number of trainings, audits, workshops, activities) | # | (Azapagic and Perdan 2000; UNIDO 2019; own suggestions) |

| improved working conditions (e.g., number of joint bargaining activities, number of joint organizations for kindergarten, canteen, cafeteria, mobility) | # |

| Environmental Dimension | Economic Dimension | Social Dimension | |

|---|---|---|---|

| Input-Related Indicators | e.g., through IS saved primary resources | e.g., through IS saved primary material costs | e.g., through IS created jobs |

| Output-Related Indicators | e.g., through IS reduced emissions | e.g., through IS saved disposal costs | e.g., through IS improved working conditions |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lütje, A.; Wohlgemuth, V. Tracking Sustainability Targets with Quantitative Indicator Systems for Performance Measurement of Industrial Symbiosis in Industrial Parks. Adm. Sci. 2020, 10, 3. https://doi.org/10.3390/admsci10010003

Lütje A, Wohlgemuth V. Tracking Sustainability Targets with Quantitative Indicator Systems for Performance Measurement of Industrial Symbiosis in Industrial Parks. Administrative Sciences. 2020; 10(1):3. https://doi.org/10.3390/admsci10010003

Chicago/Turabian StyleLütje, Anna, and Volker Wohlgemuth. 2020. "Tracking Sustainability Targets with Quantitative Indicator Systems for Performance Measurement of Industrial Symbiosis in Industrial Parks" Administrative Sciences 10, no. 1: 3. https://doi.org/10.3390/admsci10010003

APA StyleLütje, A., & Wohlgemuth, V. (2020). Tracking Sustainability Targets with Quantitative Indicator Systems for Performance Measurement of Industrial Symbiosis in Industrial Parks. Administrative Sciences, 10(1), 3. https://doi.org/10.3390/admsci10010003