Requirements Engineering for an Industrial Symbiosis Tool for Industrial Parks Covering System Analysis, Transformation Simulation and Goal Setting

Abstract

1. Introduction

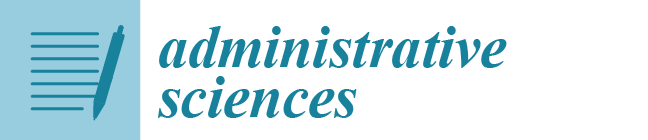

- (a)

- recycling reflow from the end of life phase back to the (raw) material processing stage,

- (b)

- remanufacturing reflow either from the end of life phase or from the consumption/usage step back to the manufacturing phase,

- (c)

- reusing reflow from the end of life stage back to the usage phase,

- (d)

- and the extended/internal cascading loops in IS systems in the manufacturing phase in form of water, material and energy networks, networks of shared utilities and infrastructure (incl. storage capacity and logistics) and networks of joint disposal and procurement processes. This is a further point of contact for increasing resource productivity/efficiency and reducing consumption of primary resources, while mitigating/reducing negative environmental burden and economic costs.

2. Results

2.1. Applied Methods in Industrial Symbiosis Systems

2.2. Industrial Symbiosis Material Exchanges and Activities

- Non-material exchanges: sharing of knowledge/expertise, utilities/infrastructure, management of joint procurement and disposal/recycling processes. Mirata and Emtairah (2005) studied the Landskrona industrial symbiosis programme (LISP) in Sweden and found out that inter-organizational collaboration was not only important in implementing identified IS solutions, but also contributed to mutual learning in various forms. LISP actors were engaged not only in material exchanges, as this is more common in IS networks, but rather in cooperation on non-material synergies such as management routines, new business arrangements, collective bargaining, and envisioning joint goals towards sustainable development (Mirata and Emtairah 2005).Beside non-material exchanges, there are physical exchanges of water, energy and materials.

- Input-related material and energy resources:

- 2.1.

- Secondary raw/substitute materials:Liwarska-Bizukojc et al. (2009) presented an Austrian IS example, in which the manufacturer of cellulose insulation collected wastepaper from onsite companies to re-process and re-utilized it as secondary raw material.

- 2.2.

- Energy

- 2.2.1.

- (process) heat/cold (process):Martin and Eklund (2011) studied the Händelö IS in Sweden, where the municipal wastes, process waste and biomass from local forestry industries feed a combined heat and power unit (CHP). Heat is injected in the district heating network, electricity to the grid, and steam to the nearby ethanol production plant, which also produces by-products that are forwarded to the biogas plant (Martin and Eklund 2011).

- 2.2.2.

- 2.3.

- (process) water:Shi et al. (2010) showed the water and energy cascading system of an IS network in China, which included additional waste and wastewater recovery and by-product exchanges.

- Output-related emissions:

- 3.1.

- Waste heat/steam: can be forwarded to other companies (Mirata 2004; Pakarinen et al. 2010; Yu et al. 2015; Earley 2015). Li (2011) presented an IS complex in China, comprising power generation, desalinization, sea salt production, brick production and a chemical plant. The IS network predominantly covers waste heat recovery and by-product exchanges such as the material utilization of coal ashes for brick production (Li 2011).

- 3.2.

- Gaseous waste/aerosols:Melanen et al. (2008) studied an IS network in Finland, which has been established around a large pulp and paper mill. Among other things, the CO2 emissions are passed on to a calcium carbonate plant as a secondary raw material. Aerosol waste streams such as fly ash can be used as cement additive (Dong et al. 2013; Golev et al. 2014; Cui et al. 2018) or soil additive (Korhonen and Snäkin 2005; Notarnicola et al. 2016; Bain et al. 2010).

- Output-related waste:

- 4.1.

- Solid waste/residuals:Costa and Ferrão (2010) explored an IS system in Portugal, which is mainly characterized by the economic sectors of waste management and recovering industry (inter alia aluminium slag, plastic, battery recycler). Organic residual (solid) waste can be converted to animal/fish feeding (material utilization) (Chertow 2007; Alkaya et al. 2014), or where health and hygiene reasons need to be considered, can be processed into biogas and biofuel (energetic utilization) (Alkaya et al. 2014). The digestate of a biogas plant can be reused as fertilizer (Martin 2013; Alkaya et al. 2014).

- 4.2.

- Liquid waste:

- 4.2.1.

- (waste/process) water: Wastewater from a company that processes food such as olives, cereals, fruit and vegetables can be further used for the fertilized irrigation of agricultural land (Chertow et al. 2008; Notarnicola et al. 2016) or further processed into a fertilizer product.

- 4.2.2.

- Sludge/mud: the Guitang Group in China solved a disposal problem by using their sludge as the calcium carbonate feedstock to a new cement plant, while reducing residual and waste flows (Zhu et al. 2008).

2.3. Requirements Engineering Results for the IT-supported Industrial Symbiosis Tool

- (1)

- Knowledge acquisition component (creating and improving the knowledge base): Therefore, several IS activity patterns based on real concrete case studies and IS measures need to be gathered and stored, so that the IS tool can access the information and provide concrete recommendations. This requires the setup of (relational) databases, which comprises data and information of inter alia IS activities/measures, structural IS classification, and sector and material specific information. So, a comprehensive knowledge of the material and energy flows, their type, quantity and composition are essential (Li 2018). With such a knowledge/data base, concrete recommendations for IS action and connections can be suggested for the existing area under consideration.

- (2)

- Problem solving component (to process the knowledge base provided and find appropriate solutions): Very different models can be used both to represent knowledge and to draw conclusions. The following two models should be taken into account in the concept for an IT-supported IS tool, since the most suitable one should be selected automatically depending on the application context:

- In case-based systems there is a case database, which contains concrete problems in their context including a description of the solution (IS activity/measurement catalogue). The system tries to find a comparable case for a given case in its database and to transfer its solution to the current case (so in this application context of IS systems, real concrete case studies).

- Rule-based systems or Business Rule Management Systems (BRMS) are based on rules of the type "If A, then B". The rules therefore tend to follow general laws from which conclusions are to be drawn for concrete situations. (Business) Rules must usually be defined beforehand by human experts and entered into the system manually. For example, “if there is a company with an output flow of coal fly ash, then this material can be further utilized as fertilizer”. The rules can be derived from a knowledge base to be developed (IS resource catalogue of compatible material exchanges) that needs to cover sector-specific resource data allowing compatible cross-sectoral resource output-input match-makings.

- Planning: Generation and evaluation of action sequences to achieve target states

- Design: Description of structures that meet given requirements

- Prognosis: Prediction and evaluation of achievable states of time-varying systems

- (3)

- Explanation component (making the results/solutions understandable to the user): The IT-supported IS tool shall provide various visualization formats to present the results and recommendations for action (e.g., interactive Sankey diagrams, social networks, tables, input-output balances, statistics, written text).

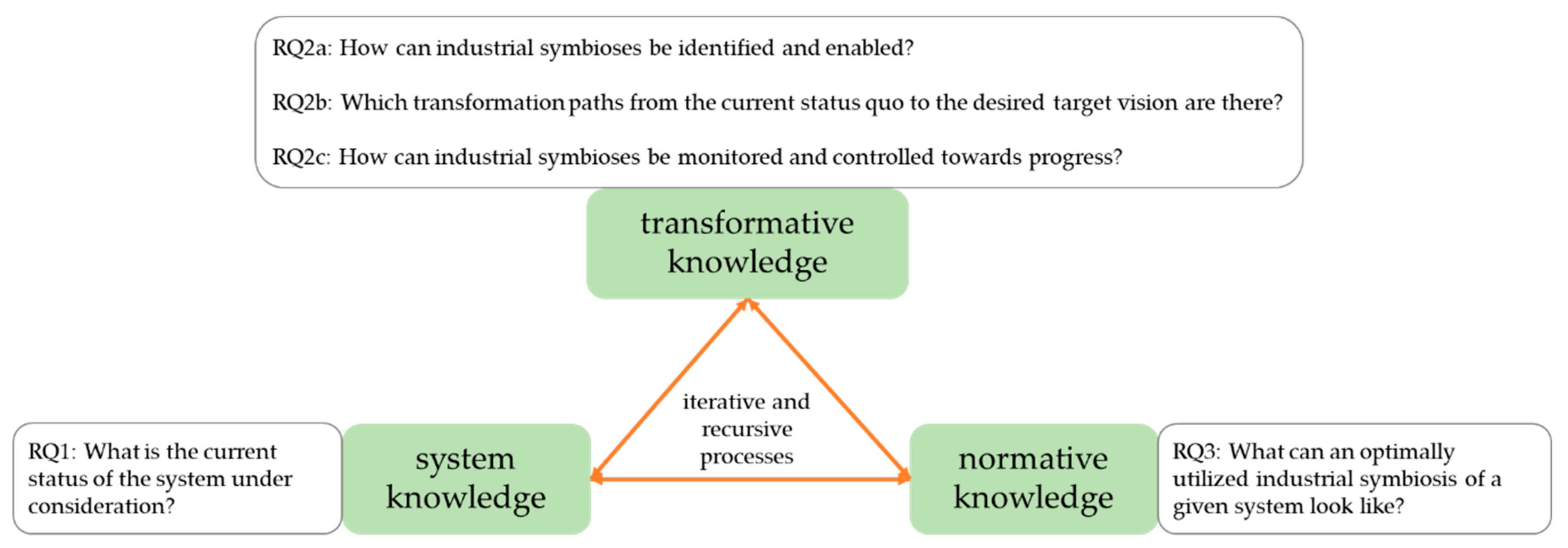

3. Discussion and Concluding Impulses for Future Research

- the detection of IS key entities in order to ensure resilient IS systems,

- the investigation of recurring composition patterns in IS systems (repetitious cooperating IS industries) in order to facilitate the recommendation of potential IS partners,

- the mapping of common resource exchange flows in IS systems (which output flows can function as which input flows?) in order to create an IS resource catalog for the facilitated recommendation of concrete IS resource flow connections.

4. Materials and Methods

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Nr. | Main author (Publication year) | Publication Title | Region of IS system |

| 1 | Alkaya et al. (2014) | Industrial Symbiosis in Iskenderun Bay: A journey from Pilot Applications to a National Program in Turkey. | Turkey |

| 2 | Ashton (2008) | Understanding the organisation of Industrial Ecosystems - A social network approach. | Puerto Rico |

| 3 | Bain et al. (2010) | Industrial Symbiosis and waste recovery in an Indian industrial area. | India |

| 4 | Behera et al. (2012) | Evolution of ‘designed’ industrial symbiosis networks in the Ulsan Eco-industrial Park: ‘research and development into business’ as the enabling framework. | South Korea |

| 5 | Chertow et al. (2008) | Industrial Symbiosis in Puerto Rico: Environmentally Related Agglomeration Economies. | Puerto Rico |

| 6 | Chertow and Ashton (2009) | The social embeddedness of Industrial Symbiosis linkages in Puerto Rican industrial regions. | Puerto Rico |

| 7 | Chertow et al. (2009) | Industrial symbiosis potential and urban infrastructure capacity in Mysuru, India. | India |

| 8 | Chopra et al. (2014) | Understanding resilience in industrial symbiosis networks: Insights from network analysis. | Denmark |

| 9 | Costa et al. (2010) | A case study of Industrial Symbiosis development using a middle-out approach. | Portugal |

| 10 | Cui et al. (2018) | Understanding the Evolution of Industrial Symbiosis with a System Dynamics Model: A Case Study of Hai Hua Industrial Symbiosis, China. | China |

| 11 | Dai (2010) | Two quantitative indices for the planning and evaluation of eco-industrial parks. | China |

| 12 | Doménech et al. (2011) | Structure and morphology of industrial symbiosis networks: the case of Kalundborg. | Denmark |

| 13 | Dong et al. (2013) | Promoting low-carbon city through industrial symbiosis: A case in China by applying HPIMO model. | China |

| 14 | Dong et al. (2016) | Towards preventative eco-industrial development: an industrial and urban symbiosis case in one typical industrial city in China. | China |

| 15 | Francis (2003) | The chemical industry from an industrial ecology perspective. | United States of America |

| 16 | Geng et al. (2014) | Emergy-based assessment on industrial symbiosis: a case of Shenyang Economic and Technological Development Zone. | China |

| 17 | Golev et al. (2014) | Industrial symbiosis in Gladstone: a decade of progress and future development. | Australia |

| 18 | Hatefipour et al. (2011) | The Händelö area in Norrköping, Sweden - Does it fit for Industrial Symbiosis development? | Sweden |

| 19 | Heeres et al. (2004) | Eco-industrial park initiatives in the USA and the Netherlands: first lessons. | United States of America and Netherlands |

| 20 | Jacobsen (2006) | Industrial Symbiosis in Kalundborg, Denmark: a quantitative assessment of economic and environmental aspects. | Denmark |

| 21 | Jyrki (2009) | Harjavalta industrial eco park—A success story of the industrial ecology in the area of metallurgical industry to increase regional sustainability. | Finland |

| 22 | Korhonen and Snäkin (2005) | Analysing the evolution of industrial ecosystems: concepts and application. | Finland |

| 23 | Laybourn (2013) | Opportunities through Industrial Symbiosis: UK NISP and Global Experience. | United Kingdom |

| 24 | Li (2011) | A case study of Industrial Symbiosis: the Beijiang power plant complex in Tianjing, China. | China |

| 25 | Li et al. (2015) | Industrial symbiosis as a countermeasure for resource dependent city: a case study of Guyang, China. | China |

| 26 | Li et al. (2017) | The vulnerability of industrial symbiosis: a case study of Qijiang Industrial Park, China. | China |

| 27 | Liu et al. (2018) | Co-benefits accounting for the implementation of eco-industrial development strategies in the scale of industrial park based on emergy analysis. | China |

| 28 | Liwarska-Bizukojc et al. (2009) | The conceptual model of an eco-industrial park based upon ecological relationships. | Austria |

| 29 | Lu et al. (2015) | Ecological Network Analysis for Carbon Metabolism of Eco-industrial Parks: A Case Study of a Typical Eco-industrial Park in Beijing. | China |

| 30 | Marconi et al. (2018) | An approach to favor industrial symbiosis: the case of waste electrical and electronic equipment. | Italy |

| 31 | Marinos-Kouris et al. (2013) | Environmental limits of industrial symbiosis: the case of aluminium eco-industrial network. | Greece |

| 32 | Martin (2015) | Quantifying the environmental performance of an industrial symbiosis network of biofuel producers. | Sweden |

| 33 | Martin et al. (2011) | Improving the environmental performance of biofuels with industrial symbiosis. | Sweden |

| 34 | Martin et al. (2018) | Prospecting the sustainability implications of an emerging industrial symbiosis network. | Sweden |

| 35 | Mathews and Tan (2011) | Progress toward a circular economy in China. | China |

| 36 | Mauthoor (2017) | Uncovering industrial symbiosis potentials in a small island developing state: The case study of Mauritius. | Mauritius |

| 37 | Melanen et al. (2008) | Industrial Symbiosis for global climate change mitigation. | Finland |

| 38 | Mirata (2004) | Experiences from early stages of a national industrial symbiosis programme in the UK: determinants and coordination challenges. | United Kingdom |

| 39 | Mirata et al. (2005) | Industrial Symbiosis networks and the contribution to environmental innovation: the case of the Landskrona Industrial Symbiosis programme. | Sweden |

| 40 | Morales et al. (2019) | “By-product synergy” changes in the industrial symbiosis dynamics at the Altamira-Tampico industrial corridor: 20 years of industrial ecology in Mexico. | Mexico |

| 41 | Notarnicola et al. (2016) | Industrial Symbiosis in the Taranto industrial district: current level, constraints and potential new synergies. | Italy |

| 42 | Pakarinen et al. (2010) | Sustainability and industrial symbiosis - The evolution of a Finnish forest industry complex. | Finland |

| 43 | Park (2010) | Eco-industrial development in South Korea and its future | South Korea |

| 44 | Park et al. (2008) | Strategies for sustainable development of industrial park in Ulsan, South Korea—From spontaneous evolution to systematic expansion of industrial symbiosis. | South Korea |

| 45 | Pearce (2008) | Industrial symbiosis of very large-scale photovoltaic manufacturing. | United States of America |

| 46 | Raabea et al. (2017) | Collaboration platform for enabling industrial symbiosis: Application of the by-product exchange network model. | Model |

| 47 | Roberts (2004) | The application of industrial ecology principles and planning guidelines for the development of eco-industrial parks: an Australian case study. | Australia |

| 48 | Sacchi et al. (2017) | The effect of price regulation on the performances of industrial symbiosis: a case study on district heating. | Denmark |

| 49 | Saikku (2006) | Eco-industrial parks: a background report for the eco-industrial park project at Rantasalmi. | Finland |

| 50 | Sakr et al. (2011) | Critical success and limiting factors for eco-industrial parks: global trends and Egyptian context. | Egypt |

| 51 | Sendra et al. (2007) | Material flow analysis adapted to an industrial area. | Spain |

| 52 | Senlier and Albayrak (2011) | Opportunities for sustainable industrial development in turkey: Eco-industrial parks. | Turkey |

| 53 | Shi et al. (2010) | Developing country experience with eco-industrial parks: a case study of the Tianjin Economic Technological Development Area in China. | China |

| 54 | Short et al. (2014) | From Refining Sugar to Growing Tomatoes: Industrial Ecology and Business Model Evolution. | United Kingdom |

| 55 | Simboli et al. (2014) | Analysing the development of Industrial Symbiosis in a motorcycle local industrial network: the role of contextual factors. | Italy |

| 56 | Sokka et al. (2010) | Analyzing the Environmental Benefits of Industrial Symbiosis - Life Cycle Assessment Applied to a Finnish Forest Industry Complex. | Finland |

| 57 | Song et al. (2018) | Social network analysis on industrial symbiosis: A case of Gujiao eco-industrial park. | China |

| 58 | Sun et al. (2016) | Eco-benefits assessment on urban industrial symbiosis based on material flow analysis and emergy evaluation approach: a case of Liuzhou City, China. | China |

| 59 | Taddeo et al. (2017) | The development of Industrial Symbiosis in Existing Contexts. Experiences from three Italian clusters. | Italy |

| 60 | Ulhasanah et al. (2012) | Preliminary Design of Eco-City by Using Industrial Symbiosis and Waste Co-Processing Based on MFA, LCA, and MFCA of Cement Industry in Indonesia. | Indonesia |

| 61 | UNIDO (2016) | Eco-industrial parks in emerging and developing countries: Achievements, good practices and lessons learned, a comparative assessment of 33 cases in 12 emerging and developing countries. | various countries |

| 62 | Van Beers et al. (2007) | Industrial Symbiosis in the Australian minerals industry: the cases of Kwinana and Gladstone. | Australia |

| 63 | Van Berkel et al. (2009) | Quantitative assessment of Urban and Industrial Symbiosis in Kawasaki, Japan. | Japan |

| 64 | Velenturf (2016) | Promoting industrial symbiosis: empirical observations of low-carbon innovations in the Humber region, UK. | United Kingdom |

| 65 | Wen and Meng (2015) | Quantitative assessment of industrial symbiosis for the promotion of circular economy: a case study of the printed circuit boards industry in China´s Suzhou New District. | China |

| 66 | Yang et al. (2008) | A case study of industrial symbiosis: Nanning Sugar Co., Ltd. in China. | China |

| 67 | Yazan et al. (2019) | Sustainable operations of industrial symbiosis: an enterprise input-output model integrated by agent-based simulation. | Numeric example model |

| 68 | Yazdanpan-ah et al. (2018) | Industrial Symbiotic Networks as Coordinated Games. | Model |

| 69 | Yu et al. (2015) | Evolution of industrial symbiosis in an eco-industrial park in China. | China |

| 70 | Yuan et al. (2009) | Improving enterprise competitive advantage with industrial symbiosis: case study of a smeltery in China. | China |

| 71 | Zabaniotou et al. (2015) | Boosting circular economy and closing the loop in agriculture: Case study of a small-scale pyrolysis-biochar based system integrated in an olive farm in symbiosis with an olive mill. | Italy |

| 72 | Zhang et al. (2013a) | Social network analysis and network connectedness analysis for industrial symbiotic systems: model development and case study. | China |

| 73 | Zhang et al. (2013b) | Analysis of low-carbon industrial symbiosis technology for carbon mitigation in a Chinese iron/steel industrial park: A case study with carbon flow analysis. | China |

| 74 | Zhang et al. (2015) | Ecological network analysis of an industrial symbiosis system: A case study of the Shandong Lubei eco-industrial park. | China |

| 75 | Zhu et al. (2018) | Industrial Symbiosis in China. A Case Study of the Guitang Group. | China |

References

- Alkaya, Emrah, Merve Böğürcü, and Ferda Ulutaş. 2014. Industrial Symbiosis in Iskenderun Bay: A journey from Pilot Applications to a National Program in Turkey. Paper presented at the SYMBIOSIS 2014, Athens, Greece, June 19–21. [Google Scholar]

- Ashton, Weslynne Stacey. 2008. Understanding the organization of industrial ecosystems: A social network approach. Journal of Industrial Ecology 12: 34–51. [Google Scholar] [CrossRef]

- Axtell, Robert L., Clinton J. Andrews, and Mitchell J. Small. 2001. Agent-based modeling and industrial ecology. Journal of Industrial Ecology 5: 10–13. [Google Scholar] [CrossRef]

- Bacudio, Lindley R., Michael Francis D. Benjamin, Ramon Christian P. Eusebio, Sed Anderson K. Holaysan, Michael Angelo B. Promentilla, Krista Danielle S. Yu, and Kathleen B. Aviso. 2016. Analyzing barriers to implementing industrial symbiosisnetworks using DEMATEL. Sustainable Production and Consumption 7: 57–65. [Google Scholar] [CrossRef]

- Bain, Ariana, Megha Shenoy, Weslynne Stacey Ashton, and Marian Ruth Chertow. 2010. Industrial symbiosis and waste recovery in an Indian industrial area. Resources, Conservation and Recycling 54: 1278–87. [Google Scholar] [CrossRef]

- Behera, Shishir Kumar, Jung-Hoon Kim, Sang-Yoon Lee, Sangwon Suh, and Hung-Suck Park. 2012. Evolution of ‘designed’ industrial symbiosis networks in the Ulsan Eco-industrial Park: ‘research and development into business’ as the enabling framework. Journal of Cleaner Production 29: 103–12. [Google Scholar] [CrossRef]

- Boons, Frank A.A., and Leo W. Baas. 1997. Types of industrial ecology: The problem of coordination. Journal of Cleaner Production 5: 79–86. [Google Scholar] [CrossRef]

- Chertow, Marian Ruth. 2004. Industrial Symbiosis. Encyclopedia of Energy 3: 407–15. [Google Scholar] [CrossRef]

- Chertow, Marian Ruth. 2007. Uncovering industrial symbiosis. Journal of Industrial Ecology 11: 11–30. [Google Scholar] [CrossRef]

- Chertow, Marian Ruth. 2008. Industrial Ecology in a Developing Context. In Sustainable Development and Environmental Management. Edited by C. I. Clini, M. Musu and ullino. Dordrecht: Springer, pp. 1–19. [Google Scholar]

- Chertow, Marian Ruth, Weslynne S. Ashton, and Juan C. Espinosa. 2008. Industrial Symbiosis in Puerto Rico: Environmentally Related Agglomeration Economies. Regional Studies 42: 1299–1312. [Google Scholar] [CrossRef]

- Chertow, Marian Ruth, and Weslynne Stacey Ashton. 2009. The social embeddedness of Industrial Symbiosis linkages in Puerto Rican industrial regions. In The Social Embeddedness of Industrial Ecology. Edited by Frank A. Boons and J.A. Howard-Grenville. Cheltenham: Edward Elgar. [Google Scholar]

- Chertow, Marian Ruth, Matthew Gordon, Peter Hirsch, and Anu Ramaswami. 2019. Industrial symbiosis potential and urban infrastructure capacity in Mysuru, India. Environmental Research Letters 14. [Google Scholar] [CrossRef]

- Chopra, Shauhrat, and Vikas Khanna. 2014. Understanding resilience in industrial symbiosis networks: Insights from network analysis. Journal of Environmental Management 141: 86–94. [Google Scholar] [CrossRef] [PubMed]

- Costa, Inês Santos, and Paulo Ferrão. 2010. A case study of Industrial Symbiosis development using a middle-out approach. Journal of Cleaner Production 18: 984–992. [Google Scholar] [CrossRef]

- Côté, Raymond, and Jeremy Hall. 1995. Industrial parks as ecosystems. Journal of Cleaner Production 3: 41–46. [Google Scholar] [CrossRef]

- Cui, Hua, Changhao Liu, Raymond Côté, and Weifeng Liu. 2018. Understanding the Evolution of Industrial Symbiosis with a System Dynamics Model: A Case Study of Hai Hua Industrial Symbiosis, China. Sustainability 10: 3873. [Google Scholar] [CrossRef]

- Dai, Tiejun. 2010. Two quantitative indices for the planning and evaluation of eco-industrial parks. Resources. Conservation and Recycling 54: 442–48. [Google Scholar] [CrossRef]

- Doménech, Teresa, and Michael Davies. 2009. The social aspects of industrial symbiosis: The application of social network analysis to industrial symbiosis networks. Progress in Industrial Ecology 6: 68–99. [Google Scholar] [CrossRef]

- Doménech, Teresa, and Michael Davies. 2011. Structure and morphology of industrial symbiosis networks: The case of Kalundborg. Procedia Social Behavior Science 10: 79–89. [Google Scholar] [CrossRef]

- Doménech, Teresa, Raimund Bleischwitz, Asel Doranova, Dimitris Panayotopoulos, and Laura Roman. 2019. Mapping Industrial Symbiosis Development in Europe—Typologies of networks, characteristics, performance and contribution to the Circular Economy. Resources, Conservation & Recycling 141: 76–98. [Google Scholar] [CrossRef]

- Dong, Liang, Tsuyoshi Fujita, Hui Zhang, Ming Dai, Minoru Fujii, Satoshi Ohnishi, Yong Geng, and Zhu Liu. 2013. Promoting low-carbon city through industrial symbiosis: A case in China by applying HPIMO model. Energy Policy 61: 864–73. [Google Scholar] [CrossRef]

- Earley, Katharine. 2015. Industrial symbiosis: Harnessing waste energy and materials for mutual benefit. Renewable Energy Focus 16: 75–77. [Google Scholar] [CrossRef]

- European Environment Agency (EEA). 2016. More from less—Material resource efficiency in Europe. EEA report No 10/2016 Technical report European Environment Agency. Luxembourg: EEA. [Google Scholar] [CrossRef]

- Ehrenfeld, John, and Nicholas Gertler. 1997. Industrial Ecology in Practice—The Evolution of Interdependence at Kalundborg. Journal of Industrial Ecology 1: 67–79. [Google Scholar] [CrossRef]

- Erkman, Suren. 2001. Industrial ecology: A new perspective on the future of the industrial system. Swiss Medical Weekly 131: 531–38. [Google Scholar]

- Francis, Colin G. 2003. The chemical industry from an industrial ecology perspective. In Perspectives on Industrial Ecology. Edited by D. Bourg and S. Erkman. Sheffield: Greenleaf Publishing Limited. [Google Scholar]

- Frosch, Robert A., and Nicholas E. Gallopoulos. 1989. Strategies for manufacturing. Scientific American 189: 1–7. [Google Scholar] [CrossRef]

- Geng, Yong, Jia Fu, Joseph Sarkis, and Bing Xue. 2012. Towards a national circular economy indicator system in China: An evaluation and critical analysis. Journal of Cleaner Production 23: 216–24. [Google Scholar] [CrossRef]

- Geng, Yong, Zuoxi Liu, Bing Xue, Huijuan Dong, Tsuyoshi Fujita, and Anthony Chiu. 2014. Emergy-based assessment on industrial symbiosis: A case of Shenyang Economic and Technological Development Zone. Environmental Science and Pollution Research 21: 13572–87. [Google Scholar] [CrossRef]

- Golev, Artem, Glen Corder, and Damien P. Giurcob. 2014. Industrial symbiosis in Gladstone: A decade of progress and future development. Journal of Cleaner Production 84: 421–29. [Google Scholar] [CrossRef]

- Grant, Gabriel B., Thomas P. Seager, Guillaume Massard, and Loring Nies. 2010. Information and communication technology for industrial symbiosis. Journal of Industrial Ecology 14: 740–53. [Google Scholar] [CrossRef]

- Hatefipour, Saeid, Leenard Baas, and Mats Eklund. 2011. The Händelö area in Norrköping, Sweden Does it fit for Industrial Symbiosis Development? Linköpin: World Renewable Energy Congress. [Google Scholar]

- Heeres, R.R., Walter J.V. Vermeulen, and F. B. de Walle. 2004. Eco-industrial park initiatives in the USA and the Netherlands: First lessons. Journal of Cleaner Production 12: 985–95. [Google Scholar] [CrossRef]

- Herczeg, Gabor, Renzo Akkerman, and Michael Zwicky Hauschild. 2016. Supply Chain Management in Industrial Symbiosis Networks. Ph.D. Dissertation, Technical University of Denmark, Copenhagen, Denmark; pp. 7–45. [Google Scholar]

- Hewes, Anne K., and Donald I. Lyons. 2008. The humanistic side of eco-industrial parks: Champions and the role of trust. Regional Studies 42: 1329–42. [Google Scholar] [CrossRef]

- Holgado, Maria, Dai K. J. Morgan, and Steve Ross Evans. 2016. Exploring the scope of industrial symbiosis: Implications for practitioners. In Sustainable Design and Manufacturing 2016. SDM 2016. Smart Innovation, Systems and Technologies. Edited by Rossi Setchi, Robert J. Howlett, Ying Liu and Peter Theobald. Cambridge: Springer, vol. 52. [Google Scholar] [CrossRef]

- Huang, Maoxing, Zhenzhen Wang, and Ting Chen. 2019. Analysis on the theory and practice of industrial symbiosis based on bibliometrics and social network analysis. Journal of Cleaner Production 213: 956–967. [Google Scholar] [CrossRef]

- Isenmann, Ralf. 2013. Beitrag betrieblicher Umweltinformatik für die Industrial Ecology—Analyse von BUIS-Software-Werkzeugen zur Unterstützung von Industriesymbiosen. In IT-gestütztes Ressourcen- und Energiemanagement. Edited by Jorge Marx Gómez and Corinna Lang. Berlin and Heidelberg: Springer-Verlag. [Google Scholar] [CrossRef]

- Ismail, Yunita. 2014. Industrial Symbiosis at Supply Chain. International Journal of Business, Economics and Law 4: 119–22. [Google Scholar]

- Jackson, Tim, and Roland Clift. 1998. Where’s the profit in industrial ecology? Journal of Industrial Ecology 2: 3–5. [Google Scholar] [CrossRef]

- Jacobsen, Noel Brings. 2006. Industrial Symbiosis in Kalundborg, Denmark: A quantitative assessment of economic and environmental aspects. Journal of Industrial Ecology 10: 239–55. [Google Scholar] [CrossRef]

- Ji, Yijun, Zhikan Liu, Jing Wu, Ying He, and He Xu. 2020. Which factors promote or inhibit enterprises’ participation in industrial symbiosis? An analytical approach and a case study in China. Journal of Cleaner Production 244: 118600. [Google Scholar] [CrossRef]

- Jyrki, H. 2009. Harjavalta Industrial eco park—A Success Story of the Industrial Ecology in the Area of Metallurgical Industry to Increase Regional Sustainability. Oulu: University of Oulu. [Google Scholar]

- Kastner, Catharine A., Raymond Lau, and Markus Kraft. 2015. Quantitative Tools for Cultivating Symbiosis in Industrial Parks; A Literature Review. Cambridge: Centre for Computational Chemical Engineering, University of Cambridge. ISSN 1473-4273. [Google Scholar]

- Korhonen, Jouni, and Juha-Pekka Snäkin. 2005. Analysing the evolution of industrial ecosystems: Concepts and application. Ecological Economics 52: 169–86. [Google Scholar] [CrossRef]

- Kurup, Biji, and Daniela Stehlik. 2009. Towards a model to assess the sustainability implications of industrial symbiosis in eco-industrial parks. Progress in Industrial Ecology 6: 103–19. [Google Scholar] [CrossRef]

- Lang, Daniel J., Arnim Wiek, Matthias Bergmann, Michael Stauffacher, Pim Martens, Peter Moll, Mark Swilling, and Christopher J. Thomas. 2012. Transdisciplinary research in sustainability science: Practice, principles, and challenges. Sustainability Science 7: 25–43. [Google Scholar] [CrossRef]

- Li, Peng-mei. 2011. A case study of Industrial Symbiosis: The Beijiang power plant complex in Tianjing, China. Paper Presented at International Conference on E -Business and E -Government (ICEE), Shanghai, China, May 6–8. [Google Scholar]

- Li, Xiaohong. 2018. Industrial Ecology and Industrial Symbiosis for Environmental Sustainability—Definitions, Frameworks and Applications. London: Palgrave Pivot. ISBN 978-3-319-67500-8. [Google Scholar]

- Li, Bo, Pengcheng Xiang, Mingming Hu, Chunbo Zhang, and Liang Dong. 2017. The vulnerability of industrial symbiosis: A case study of Qijiang Industrial Park, China. Journal of Cleaner Production 157: 267–77. [Google Scholar] [CrossRef]

- Liu, Zhe, Michelle Adams, Raymond P. Cote, Yong Geng, Jingzheng Ren, Qinghua Chen, Weili Liu, and Xuesong Zhu. 2018. Co-benefits accounting for the implementation of eco-industrial development strategies in the scale of industrial park based on emergy analysis. Renewable and Sustainable Energy Reviews 81: 1522–29. [Google Scholar] [CrossRef]

- Liwarska-Bizukojc, Ewa, Marcin Bizukojc, Andrzej Marcinkowski, and Andrzej Doniec. 2009. The conceptual model of an eco-industrial park based upon ecological relationships. Journal of Cleaner Production 17: 732–41. [Google Scholar] [CrossRef]

- Lütje, Anna, and Volker Wohlgemuth. 2020. Tracking Sustainability Targets with Quantitative Indicator Systems for Performance Measurement of Industrial Symbiosis in Industrial Parks. Administrative Science 1: 3. [Google Scholar] [CrossRef]

- Lütje, Anna, Andreas Möller, and Volker Wohlgemuth. 2018. A preliminary concept for an IT-supported industrial symbiosis (IS) tool using extended material flow cost accounting (MFCA)—Impulses for environmental management information systems (EMIS). In Advances and New Trends in Environmental Informatics. Edited by Hans-Joachim Bungartz, Dieter Kranzlmüller, Volker Weinberg, Jens Weismüller and Volker Wohlgemuth. Basel: Springer Nature Switzerland AG, pp. 167–81. [Google Scholar] [CrossRef]

- Lütje, Anna, Martina Willenbacher, Andreas Möller, and Volker Wohlgemuth. 2019a. Enabling the aidentification of industrial symbiosis (IS) through information communication technology (ICT). Paper Presented at the 52nd Hawaii International Conference on System Sciences (HICSS), Maui, HI, USA, January 8–11; pp. 709–19, ISBN 978-0-9981331-2-6. [Google Scholar] [CrossRef]

- Lütje, Anna, Martina Willenbacher, Martin Engelmann, Christian Kunisch, and Volker Wohlgemuth. 2019b. Exploring the system dynamics of industrial symbiosis (IS) with machine learning (ML) techniques—A framework for a hybrid-approach. In Advances and New Trends in Environmental Informatics—ICT for Sustainable Solutions. Edited by Rüdiger Schaldach, Karl-Heinz Simon, Jens Weismüller and Volker Wohlgemuth. Basel: Springer Nature Switzerland AG, pp. 117–30. [Google Scholar]

- Maqbool, Amtul Samie, Francisco Mendez Alva, and Greet Van Eetvelde. 2019. An Assessment of European Information Technology Tools to Support Industrial Symbiosis. Sustainability 11: 131. [Google Scholar] [CrossRef]

- Marconi, Marco, Fabio Gregori, Michele Germani, Alessandra Papetti, and Claudio Favi. 2018. An approach to favor industrial symbiosis: The case of waste electrical and electronic equipment. Procedia Manufacturing 21: 502–9. [Google Scholar] [CrossRef]

- Marinos-Kouris, Dimitrios, and Andreas Mourtsiadis. 2013. Industrial symbiosis in Greece: A study of spatial allocation patterns. Fresenius Environmental Bulletin 22: 2174–81. [Google Scholar]

- Martin, Michael. 2013. Industrial Symbiosis in the Biofuel Industry: Quantification of the Environmental Performance and Identification of Synergies. Ph.D. Dissertation, Dissertation No. 1507. Linköping University, Linköping, Sweden, April 26. [Google Scholar]

- Martin, Michael, and Mats Eklund. 2011. Improving the environmental performance of biofuels with industrial symbiosis. Biomass and Bioenergy 35: 1747–55. [Google Scholar] [CrossRef]

- Martin, Michael, and Steve Harris. 2018. Prospecting the sustainability implications of an emerging industrial symbiosis network. Resources, Conservation & Recycling 138: 246–56. [Google Scholar] [CrossRef]

- Mathews, John A., and Hao Tan. 2011. Progress toward a circular economy in China. Journal of Industrial Ecology 15: 435–57. [Google Scholar] [CrossRef]

- Mauthoor, Sumayya. 2017. Uncovering industrial symbiosis potentials in a small island developing state: The case study of Mauritius. Journal of Cleaner Production 147: 506–13. [Google Scholar] [CrossRef]

- Melanen, Matti, Laura Sokka, Suvi Pakarinen, and Ari Nissinen. 2008. Industrial Symbiosis for global climate change mitigation. Paper Presented at the 14th Annual International Sustainable Development Research Conference, New Delhi, India, September 21–23. [Google Scholar]

- Mirata, Murat. 2004. Experiences from early stages of a national industrial symbiosis programme in the UK: Determinants and coordination challenges. Journal of Cleaner Production 12: 967–83. [Google Scholar] [CrossRef]

- Mirata, Murat, and Tareq Emtairah. 2005. Industrial Symbiosis networks and the contribution to environmental innovation: The case of the Landskrona industrial symbiosis programme. Journal of Cleaner Production 13: 993–1002. [Google Scholar] [CrossRef]

- Morales, Manuel Eduardo, Arnaud Diemer, Gemma Cervantes, and Graciela Carrillo-González. 2019. “By-product synergy” changes in the industrial symbiosis dynamics at the Altamira-Tampico industrial corridor: 20 years of industrial ecology in Mexico. Resources, Conservation & Recycling 140: 235–45. [Google Scholar] [CrossRef]

- Notarnicola, Bruno, Giuseppe Tassielli, and Pietro Alexander Renzulli. 2016. Industrial Symbiosis in the Taranto industrial district: Current level, constraints and potential new synergies. Journal of Cleaner Production 122: 133–43. [Google Scholar] [CrossRef]

- Pakarinen, Suvi, Tuomas Mattila, Matti Melanen, Ari Nissinen, and Laura Sokka. 2010. Sustainability and industrial symbiosis—The evolution of a Finnish forest industry complex. Resources, Conservation and Recycling 54: 1393–404. [Google Scholar] [CrossRef]

- Park, Hung Suck, Eldon R. Rene, Soo-Mi Choi, and Anthony S.F. Chiu. 2008. Strategies for sustainable development of industrial park in Ulsan, South Korea—From spontaneous evolution to systematic expansion of industrial symbiosis. Journal of Environmental Management 87: 1–13. [Google Scholar] [CrossRef] [PubMed]

- Raabea, Benjamin, Jonathan Sze Choong Lowb, Max Jurascheka, Christoph Herrmanna, Tobias Bestari Tjandrab, Yen Ting Ngb, Denis Kurlea, Felipe Cerdasa, Jannis Lueckengaa, Zhiquan Yeob, and et al. 2017. Collaboration platform for enabling industrial symbiosis: Application of the by-product exchange network model. Procedia Conference on Life Cycle Engineering CIRP 61: 263–68. [Google Scholar] [CrossRef]

- Roberts, Brian H. 2004. The application of industrial ecology principles and planning guidelines for the development of eco-industrial parks: An Australian case study. Journal of Cleaner Production 12: 997–1010. [Google Scholar] [CrossRef]

- Rockström, Johan, Will Steffen, Kevin Noone, Åsa Persson, F. Stuart Chapin, III, Eric F. Lambin, Timothy M. Lenton, Marten Scheffer, Carl Folke, Hans Joachim Schellnhuber, and et al. 2009. A safe operating space for humanity. Nature 461: 472–75. [Google Scholar] [CrossRef]

- Ruiz-Puente, Carmen, and Erik Bayona. 2017. Modelling of an industrial symbiosis network as a supply chain. Paper Presented at ATHENS 2017 5th International Conference on Sustainable Solid Waste Management, Athens, Greece, June 21–24. [Google Scholar]

- Sacchi, Romain, and Yana Konstantinova Ramsheva. 2017. The effect of price regulation on the performances of industrial symbiosis: A case study on district heating. International Journal of Sustainable Energy Planning and Management 14: 39–56. [Google Scholar] [CrossRef]

- Saikku, Laura. 2006. Eco-Industrial Parks: A Background Report for the Eco Industrial Park Project at Rantasalmi. Tampere: Regional Council of Etelä-Savo. [Google Scholar]

- Sakr, D., Leo Baas, S. El-Haggar, and D. Huisingh. 2011. Critical success and limiting factors for eco-industrial parks: Global trends and Egyptian context. Journal of Cleaner Production 19: 1158–69. [Google Scholar] [CrossRef]

- SBTi. 2019. Science Based Targets Initiative. Available online: https://sciencebasedtargets.org/ (accessed on 23 May 2019).

- Sendra, Cristina, Xavier Gabarrell, and Teresa Vicent. 2007. Material flow analysis adapted to an industrial area. Journal of Cleaner Production 15: 1706–15. [Google Scholar] [CrossRef]

- Şenlier, Nihal, and Ayşe Albayrak. 2011. Opportunities for sustainable industrial development in turkey: Eco-industrial parks. Gazi University Journal of Science 24: 637–46. [Google Scholar]

- Shi, Han, Marian Chertow, and Yuyan Song. 2010. Developing country experience with eco-industrial parks: A case study of the Tianjin EconomicTechnological Development Area in China. Journal of Cleaner Production 18: 191–99. [Google Scholar] [CrossRef]

- Sokka, Laura, Suvi Lehtoranta, Ari Nissinen, and Matti Melanen. 2010. Analyzing the Environmental Benefits of Industrial Symbiosis. Journal of Industrial Ecology 15: 137–55. [Google Scholar] [CrossRef]

- Sokka, Laura, Suvi Pakarinen, and Matti Melanen. 2011. Industrial symbiosis contributing to more sustainable energy use—An example from the forest industry in Kymenlaakso, Finland. Journal of Cleaner Production 19: 285–93. [Google Scholar] [CrossRef]

- Song, Xiaoqian, Yong Geng, Huijuan Dong, and Wei Chen. 2018. Social network analysis on industrial symbiosis: A case of Gujiao eco-industrial park. Journal of Cleaner Production 193: 414–23. [Google Scholar] [CrossRef]

- Sterr, Thomas, and Thomas Ott. 2004. The industrial region as a promising unit for eco-industrial development reflections, practical experience and establishment of innovative instruments to support industrial ecology. Journal of Cleaner Production 12: 947–65. [Google Scholar] [CrossRef]

- Sun, Lu, Hong Li, Liang Dong, Kai Fang, Jingzheng Ren, Yong Geng, Minoru Fujii, Wei Zhang, Ning Zhang, and Zhe Liu. 2016. Eco-benefits assessment on urban industrial symbiosis based on material flow analysis and emergy evaluation approach: A case of Liuzhou City, China. Resources, Conservation & Recycling 119: 78–88. [Google Scholar] [CrossRef]

- Taddeo, Raffaella, Alberto Simboli, Anna Morgante, and Suren Erkman. 2017. The development of Industrial Symbiosis in Existing Contexts. Experiences from three Italian clusters. Ecological Economics 139: 55–67. [Google Scholar] [CrossRef]

- Ulhasanah, Nova, and Naohiro Goto. 2012. Preliminary Design of Eco-City by Using Industrial Symbiosis and Waste Co-Processing Based on MFA, LCA, and MFCA of Cement Industry in Indonesia. International Journal of Environmental Science and Development 3: 553–61. [Google Scholar] [CrossRef]

- United Nations Industrial Development Organization (UNIDO). 2016. Global Assessment of Eco-Industrial Parks in Developing and Emerging Countries, UNIDO Report, Vienna. Available online: https://www.unido.org/sites/default/files/2017-02/2016_Unido_Global_Assessment_of_Eco-Industrial_Parks_in_Developing_Countries-Global_RECP_programme_0.pdf (accessed on 12 November 2019).

- Van Beers, Dick, Albena Bossilkov, Glen Corder, and Rene Van Berkel. 2007. Industrial Symbiosis in the Australian Minerals Industry—The Cases of Kwinana and Gladstone. Journal of Industrial Ecology 11: 55–72. [Google Scholar] [CrossRef]

- Van Berkel, Rene, Tsuyoshi Fujita, Shizuka Hashimoto, and Minoru Fujii. 2009. Quantitative Assessment of Urban and Industrial Symbiosis in Kawasaki, Japan. Environmental Science & Technology 43: 1271–81. [Google Scholar] [CrossRef]

- Viere, Tobias, Martina Prox, Andreas Möller, and Mario Schmidt. 2011. Implications of material flow cost accounting for life cycle engineering. Paper Presented at the 18th CIRP International Conference on Life Cycle Engineering, Braunschweig, Germany, May 2–4. [Google Scholar]

- Wallner, Heinz Peter. 1999. Towards sustainable development of industry: Networking, complexity and eco-clusters. Journal of Cleaner Production 7: 49–58. [Google Scholar] [CrossRef]

- Wen, Zongguo, and Xiaoyan Meng. 2015. Quantitative assessment of industrial symbiosis for the promotion of circular economy: A case study of the printed circuit boards industry in China´s Suzhou New District. Journal of Cleaner Production 90: 211–19. [Google Scholar] [CrossRef]

- Yang, Shanlin, and Nanping Feng. 2008. A case study of industrial symbiosis: Nanning Sugar Co., Ltd. in China. Resources, Conservation & Recycling 52: 813–20. [Google Scholar] [CrossRef]

- Yazan, Devrim Murat, and Luca Fraccascia. 2019. Sustainable operations of industrial symbiosis: An enterprise input-output model integrated by agent-based simulation. International Journal of Production Research. [Google Scholar] [CrossRef]

- Yazdanpanah, Vahid, Devrim Murat Yazan, and Henk Zijm. 2018. Industrial Symbiotic Networks as Coordinated Games. Paper Presented at the 17th International Conference on Autonomous Agents and Multiagent Systems (AAMAS 2018), Stockholm, Sweden, July 10–15. [Google Scholar]

- Yong, Geng, Zhang Pan, Raymond P. Côté, and Tsuyoshi Fujita. 2009. Assessment of the National Eco-Industrial Park Standard for Promoting Industrial Symbiosis in China. Journal of Industrial Ecology 13: 15–26. [Google Scholar] [CrossRef]

- Yu, Fei, Feng Han, and Zhaojie Cui. 2015. Evolution of industrial symbiosis in an eco-industrial park in China. Journal of Cleaner Production 87: 339–47. [Google Scholar] [CrossRef]

- Yuan, Zengwei, and Lei Shi. 2009. Improving enterprise competitive advantage with industrial symbiosis: Case study of a smeltery in China. Journal of Cleaner Production 17: 1295–302. [Google Scholar] [CrossRef]

- Zhang, Hui, Liang Dong, Huiquan Li, Tsuyoshi Fujita, Satoshi Ohnishi, and Qing Tang. 2013a. Analysis of low-carbon industrial symbiosis technology for carbon mitigation in a Chinese iron/steel industrial park: A case study with carbon flow analysis. Energy Policy 61: 1400–11. [Google Scholar] [CrossRef]

- Zhang, Yan, Hongmei Zheng, Bin Chen, and Naijin Yang. 2013b. Social network analysis and network connectedness analysis for industrial symbiotic systems: Model development and case study. Frontiers of Earth Science 7: 169–81. [Google Scholar] [CrossRef]

- Zhang, Yan, Hongmei Zheng, and Brian D. Fath. 2015. Ecological network analysis of an industrial symbiosis system: A case study of the Shandong Lubei eco-industrial park. Ecological Modelling 36: 174–84. [Google Scholar] [CrossRef]

- Zhu, Qinghua, Ernest A. Lowe, Yuan-an Wei, and Donald Barnes. 2008. Industrial Symbiosis in China: A Case Study of the Guitang Group. Journal of Industrial Ecology 11: 31–42. [Google Scholar] [CrossRef]

- Zhu, Li, Jianren Zhou, Zhaojie Cui, and Lei Liu. 2010. A method for controlling enterprises access to an eco-industrial park. Science of The Total Environment 408: 4817–25. [Google Scholar] [CrossRef] [PubMed]

- Park, H.-S. 2010. Eco-industrial development in South Korea and its future. Paper Presented at the 7th Annual Industrial Symbiosis Research Symposium, Kawasaki, Japan, November 4–6. [Google Scholar]

| 1 | A Sankey diagram is a graphic representation of physical quantity flows of the respective resources with arrows proportional to the quantity. |

| 2 | A material flow cost matrix shows the process-specific material flow cost allocation of a company in accordance to the four major cost items: material, energy, system and waste management costs. |

| 3 | A sociogram is a graphic representation of the connections and relationships among group members. |

| 4 | Science based targets (SBT) were established by the Science Based Targets initiative to drive corporate climate action that is aligned to meet the goals of the Paris agreement in 2015—to limit global warming to well below 2 °C above pre-industrial levels. |

| Method | Description | Application Context | References |

|---|---|---|---|

| Material Flow Analysis (MFA) | Quantifies the flows and stocks of materials and energy of the system under consideration in physical units (e.g., kg), distinguishing between input and output streams of the respective processes | Applicable to material and energy flows, crossing exchange type boundaries (water, power, materials), first starting point to visualize the (production) system with its respective input and output flows and screen first possible IS matchings | (Chertow et al. 2008; Park et al. 2008; Yang and Feng 2008; Zhu et al. 2008; Van Berkel et al. 2009; Yuan and Shi 2009; Bain et al. 2010; Ulhasanah and Goto 2012; Sun et al. 2016; Li et al. 2017; Taddeo et al. 2017; Mauthoor 2017; Morales et al. 2019) |

| Substance Flow Analysis (SFA) | Quantifies and traces the flows and stocks of one specific substance/chemical or a group of substances within the system under consideration | Detailed investigation to determine the flows and stocks of one specific substance, suitable, if further clues have already been identified in the system/context, for disclosing IS possibilities for a particular substance. | (Zhang et al. 2013a; Wen and Meng 2015) |

| Material Flow Cost Accounting (MFCA) | Traces and quantifies the flows and stocks of materials and energy of the system under consideration in physical and monetary units, especially the material losses, non-/by-products and waste flows are evaluated (standardized to ISO 4051) | MFCA is based on the method of MFA, additionally all input and output flows are attributed an economic value, especially the material losses/waste flows, which incentivizes the optimization of processes as well as the use of resources and provides a better decision-making basis regarding economic viability and prioritization of IS measures | (Viere et al. 2011; Ulhasanah and Goto 2012; Lütje et al. 2018; Lütje et al. 2019a, 2019b) |

| Life Cycle Assessment (LCA) | Quantifies the flows and stocks of materials and energy of the system under consideration and assesses the associated environmental impacts, such as global warming and eutrophication potential (standardized to ISO 14040) | LCA is based on the method of MFA, applicable to material, water and energy flows, considers all exchange type boundaries throughout an entire product life cycle (from raw material extraction, production, distribution/retail, to usage and disposal), assesses the environmental impacts of products and services. | (Sokka et al. 2010; Ulhasanah and Goto 2012; Marinos-Kouris and Mourtsiadis 2013; Sacchi and Ramsheva 2017; Marconi et al. 2018; Martin and Harris 2018; Chertow et al. 2019) |

| Emergy Analysis | Emergy is an expression of all the energy consumed in direct and indirect transformations in the processes to generate a product or service. Therefore, emergy analysis converts the thermodynamic basis of all forms of energy, resources and human services into equivalents of a single form of energy(usually solar emjoules). | Emergy is a more comprehensive and adequate way to value ecosystem goods and services, as they convey the past work performed by the environment, economy and society and does not consider only the amount of available energy that is used in the present to produce a good or service. | (Geng et al. 2014; Sun et al. 2016; Liu et al. 2018) |

| Social Network Analysis (SNA) | Investigates social structures of networks and characterizes elements within the network in terms of nodes (e.g., individual actors, companies, people) and the connecting tie or links (relationships or interactions). | SNA analyzes the characteristics, power quantification and structure of the IS network and can provide insights for understanding the social aspects of an IS system and how (social) business relationships drive the exchanges of materials, energy and information | (Ashton 2008; Doménech and Davies 2009; Doménech and Davies 2011; Zhang et al. 2013a; Chopra and Khanna 2014; Song et al. 2018) |

| Agent-Based Modelling (ABM) | ABM is a class of computational models for simulating various scenarios of the outcome of the actions and interactions of autonomous agents within a system (both individual or collective (both individual or collective entities such as originations or groups) | In an ABM model, entities such as plants or facilities in the IS network are represented by agents that are programmed based on rules to actively consume and/or produce resources, while resources are represented by agents that passively change their states such as quantities and locations, suitable for simulating and modelling various IS scenarios and considering potential effects regarding vulnerability and resilience of the IS system. | (Axtell et al. 2001; Raabea et al. 2017; Yazdanpanah et al. 2018; Yazan and Fraccascia 2019) |

| Nr. | System Knowledge (SK) | Remarks |

|---|---|---|

| SK1.0 | Analysis Toolbox | |

| SK1.1 | Energy and Material Flow Analysis (MFA) | System analysis of physical input-output resource flows in order to identify compatible IS resource exchanges and increase resource productivity and efficiency by reducing primary resource consumption. |

| SK1.2 | Material Flow Cost Accounting (MFCA) | Economic evaluation of resource flows, especially waste flows, in order to generate cost savings and incentivize/prioritize IS measures. |

| SK1.3 | Life Cycle Assessment (LCA) | Environmental evaluation (e.g., global warming potential, eutrophication potential, ozone depletion potential) in order to reduce environmental impacts and drive/prioritize IS measures. |

| SK1.4 | Social Network Analysis (SNA) | Investigation of the as-is structure/composition of participating companies and their (power) relationships in order to intensify network connections, identify same suppliers and disposal companies and to evaluate the system resilience of IS activities. |

| Transformative Knowledge (TK) | ||

| TK1.0 | Information exchange | |

| TK1.1 | Integrated social network platform with social add-ons | Inter-company communication, nurturing social relationships, trust and community building shall be supported. |

| TK1.2 | Knowledge exchange | Enabling knowledge transfer between participating companies (e.g., experienced companies in auditing/certification processes can share their knowledge with unexperienced companies which plan certain audits and certifications). |

| TK1.3 | Cross-company IS management | Enabling joint management of e.g., storage and logistics capacities, joint procurement and recycling/disposal processes. |

| TK2.0 | Facilitated Synergy Identification | |

| TK2.1 | Resource Output-Input Matchings | Matching of actively supplied and demanded resource output-input flows of participating companies. |

| TK2.2 | Supply-Demand Matchings | Referring to actively supplied and demanded technologies, human resources, expertise, storage and logistics capacities. |

| TK2.3 | Integrated expert system | For the facilitated recommendation of compatible IS partners, matching IS resource exchanges and additional IS activities in order to exhaust further IS potentials. |

| TK3.0 | Simulation and Modelling | |

| TK3.1 | simulation and modelling of possible transformation pathways | which are aligned to defined goals (e.g., via Agent-Based Modelling and/or other methods of (scenario) analysis of system dynamics). |

| TK3.2 | roadmaps | Developing roadmaps with concrete milestones and measures. |

| TK3.3 | (key performance) indicator system | Continuously tracking the performance and progress towards the defined goals. |

| TK4.0 | IS administration and management | |

| TK4.1 | overarching organizational unit | For IS coordination and management with administrator function of the IT-supported IS tool. |

| Normative Knowledge (NK) | ||

| NK1.0 | Desired future visions | |

| NK1.1 | Goal setting | Participating companies are encouraged to collaboratively define quantifiable (sustainability) goals for the IS network (e.g., zero waste park, zero emission park, CO2-neutral park). |

| NK1.2 | Possible future scenarios | Simulation and modelling of concrete possible future scenarios that allow the full range of IS potential to be exploited. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lütje, A.; Wohlgemuth, V. Requirements Engineering for an Industrial Symbiosis Tool for Industrial Parks Covering System Analysis, Transformation Simulation and Goal Setting. Adm. Sci. 2020, 10, 10. https://doi.org/10.3390/admsci10010010

Lütje A, Wohlgemuth V. Requirements Engineering for an Industrial Symbiosis Tool for Industrial Parks Covering System Analysis, Transformation Simulation and Goal Setting. Administrative Sciences. 2020; 10(1):10. https://doi.org/10.3390/admsci10010010

Chicago/Turabian StyleLütje, Anna, and Volker Wohlgemuth. 2020. "Requirements Engineering for an Industrial Symbiosis Tool for Industrial Parks Covering System Analysis, Transformation Simulation and Goal Setting" Administrative Sciences 10, no. 1: 10. https://doi.org/10.3390/admsci10010010

APA StyleLütje, A., & Wohlgemuth, V. (2020). Requirements Engineering for an Industrial Symbiosis Tool for Industrial Parks Covering System Analysis, Transformation Simulation and Goal Setting. Administrative Sciences, 10(1), 10. https://doi.org/10.3390/admsci10010010