At-line Prediction of Gelatinized Starch and Fiber Fractions in Extruded Dry Dog Food Using Different Near-Infrared Spectroscopy Technologies

Simple Summary

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Selection

2.2. Reference Analysis

2.3. Near-Infrared Spectroscopy Analysis

2.4. Chemometric Analysis

3. Results

3.1. Chemical Composition of the Samples

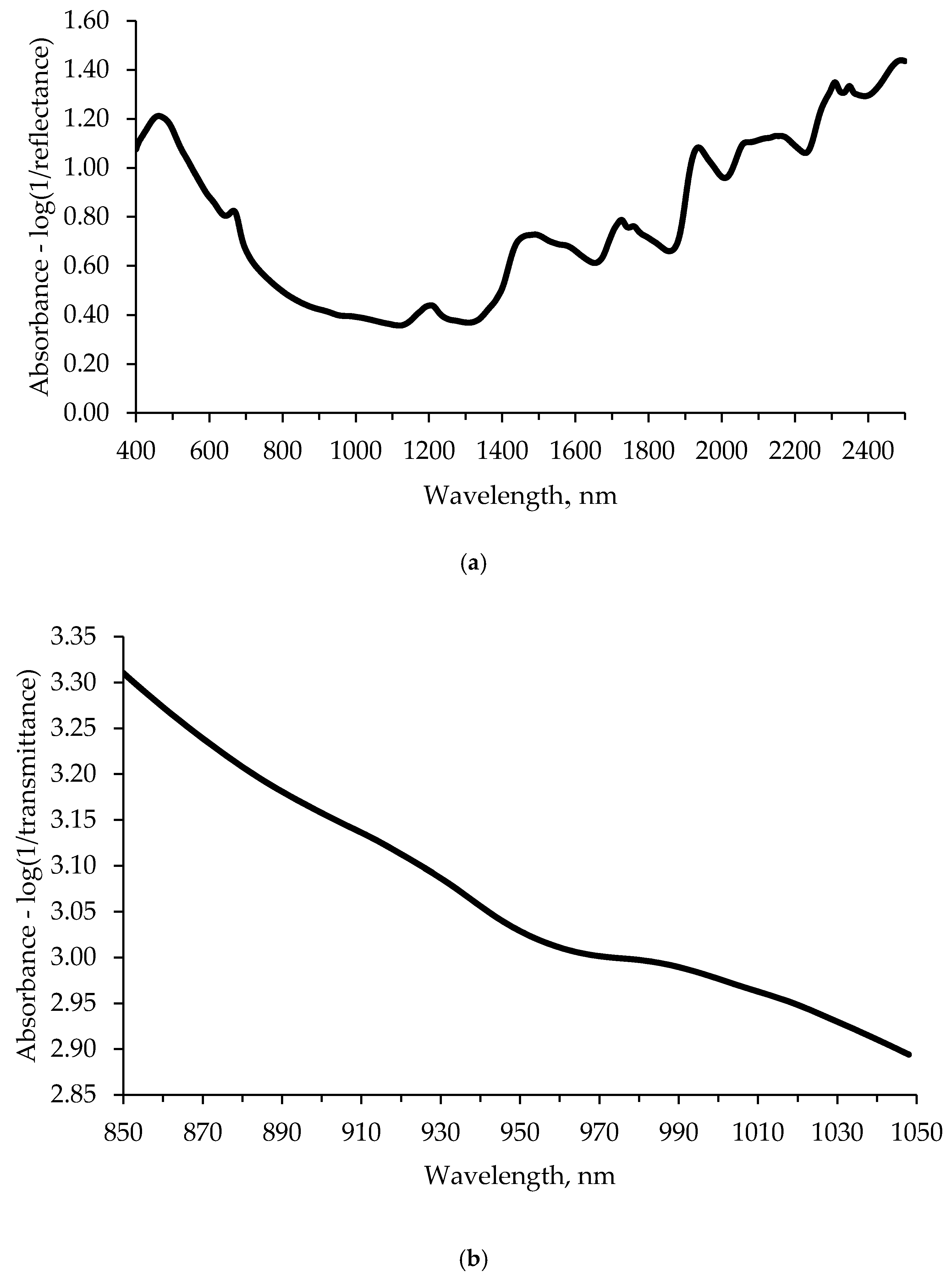

3.2. Near-Infrared Spectrum and Predictions Models

4. Discussion

4.1. Samples Composition

4.2. Vis-NIR vs. NIT Prediction Models Accuracy

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Buléon, A.; Colonna, P.; Planchot, V.; Ball, S. Starch granules: Structure and biosynthesis. Int. J. Biol. Macromol. 1998, 23, 85–112. [Google Scholar] [CrossRef]

- Tran, Q.D.; Hendrix, W.H.; van der Poel, A.F.B. Effects of extrusion processing on nutrients in dry pet food. J. Sci. Food Agric. 2008, 1926, 1487–1493. [Google Scholar] [CrossRef]

- Twomey, L.N.; Pethick, D.W.; Rowe, J.B.; Choct, M.; Pluske, J.R.; Brown, W.; Laviste, M.C. The use of sorghum and corn as alternatives to rice in dog foods. J. Nutr. 2002, 132, 1704S–1705S. [Google Scholar] [CrossRef] [PubMed]

- Inal, F.; Alatas, M.S.; Kahraman, O.; Inal, S.; Uludağ, M.; Gürbüz, E.; Polat, E.S. Barley as an alternative to rice in dog food. Turkish J. Vet. Anim. Sci. 2017, 41, 770–774. [Google Scholar] [CrossRef]

- De-Oliveira, L.D.; Takakura, F.S.; Kienzle, E.; Brunetto, M.A.; Teshima, E.; Pereira, G.T.; Vasconcellos, R.S.; Carciofi, A.C. Fibre analysis and fibre digestibility in pet foods—A comparison of total dietary fibre, neutral and acid detergent fibre and crude fibre. J. Anim. Physiol. Anim. Nutr. (Berl) 2012, 96, 895–906. [Google Scholar] [CrossRef]

- Beloshapka, A.N.; Alexander, L.G.; Buff, P.R.; Swanson, K.S. The effects of feeding resistant starch on apparent total tract macronutrient digestibility, faecal characteristics and faecal fermentative end-products in healthy adult dogs. J. Nutr. Sci. 2014, 3, 1–5. [Google Scholar] [CrossRef]

- Gibson, M.; Alavi, S. Pet Food Processing—Understanding Transformations in Starch during Extrusion and Baking. Cereal Foods World 2013, 58, 232–236. [Google Scholar] [CrossRef]

- Rokey, G.J. Petfood and fishfood extrusion. In The Technology of Extrusion Cooking; Frame, N.D., Ed.; Springer: Boston, MA, USA, 1994; pp. 144–189. [Google Scholar]

- Rosentrater, K.A.; Evers, A.D. Chemical components and nutrition. In Kent’s Technology of Cereals: An Introduction for Students of Food Science and Agriculture; Woodhead Publishing: Cambridge, UK, 2018; pp. 267–368. ISBN 9780081005293. [Google Scholar]

- Tester, R.F. Properties of damaged starch granules: Composition and swelling properties of maize, rice, pea and potato starch fractions in water at various temperatures. Food Hydrocoll. 1997, 11, 293–301. [Google Scholar] [CrossRef]

- Li, E.; Dhital, S.; Hasjim, J. Effects of grain milling on starch structures and flour/starch properties. Starch/Staerke 2013, 66, 15–27. [Google Scholar] [CrossRef]

- Stroucken, W.P.J.; Van Der Poel, A.F.B.; Kappert, H.J.; Beynen, A.C. Extruding vs pelleting of a feed mixture lowers apparent nitrogen digestibility in dogs. J. Sci. Food Agric. 1996, 71, 520–522. [Google Scholar] [CrossRef]

- İnal, F.; Alataş, M.S.; Kahraman, O.; İnal, Ş.; Uludağ, M.; Gürbüz, E.; Polat, E.S. Using of Pelleted and Extruded Foods in Dog Feeding. Kafkas Univ. Vet. Fak. Derg. 2018, 24, 131–136. [Google Scholar]

- Brouns, F.; Kettlitz, B.; Arrigoni, E. Resistant starch and “the butyrate revolution”. Trends Food Sci. Technol. 2002, 13, 251–261. [Google Scholar] [CrossRef]

- De Marchi, M.; Berzaghi, P.; Boukha, A.; Mirisola, M.; Gallo, L. Use of near infrared spectroscopy for assessment of beef quality traits. Ital. J. Anim. Sci. 2007, 6, 421–423. [Google Scholar] [CrossRef]

- De Marchi, M.; Manuelian, C.L.; Ton, S.; Cassandro, M.; Penasa, M. Feasibility of near infrared transmittance spectroscopy to predict fatty acid composition of commercial processed meat. J. Sci. Food Agric. 2018, 98, 64–73. [Google Scholar] [CrossRef] [PubMed]

- Manley, M. Near-infrared spectroscopy and hyperspectral imaging: Non-destructive analysis of biological materials. Chem. Soc. Rev. 2014, 43, 8200–8214. [Google Scholar] [CrossRef] [PubMed]

- Castrillo, C.; Baucells, M.; Vicente, F.; Mun, F.; Andueza, D. Energy evaluation of extruded compound foods for dogs by near-infrared spectroscopy. J. Anim. Physiol. Anim. Nutr. (Berl) 2005, 89, 194–198. [Google Scholar] [CrossRef] [PubMed]

- Hervera, M.; Baucells, M.D.; Torre, C.; Buj, A.; Castrillo, C. Prediction of digestible energy value of extruded dog food: Comparison of methods. J. Anim. Physiol. Anim. Nutr. (Berl) 2008, 92, 253–259. [Google Scholar] [CrossRef]

- De Marchi, M.; Righi, F.; Meneghesso, M.; Manfrin, D.; Ricci, R. Prediction of chemical composition and peroxide value in unground pet foods by near-infrared spectroscopy. J. Anim. Physiol. Anim. Nutr. (Berl) 2016, 102, 337–342. [Google Scholar] [CrossRef]

- Xiccato, G.; Trocino, A.; De Boever, J.L.; Maertens, L.; Carabaño, R.; Pascual, J.J.; Perez, J.M.; Gidenne, T.; Falcao-E-Cunha, L. Prediction of chemical composition, nutritive value and ingredient composition of European compound feeds for rabbits by near infrared reflectance spectroscopy (NIRS). Anim. Feed Sci. Technol. 2003, 104, 153–168. [Google Scholar] [CrossRef]

- Aufrère, J.; Graviou, D.; Demarquilly, C.; Perez, J.M.; Andrieu, J. Near infrared reflectance spectroscopy to predict energy value of compound feeds for swine and ruminants. Anim. Feed Sci. Technol. 1996, 8401, 77–90. [Google Scholar] [CrossRef]

- Alomar, D.; Hodgkinson, S.; Abarzúa, D.; Fuchslocher, R.; Alvarado, C.; Rosales, E. Nutritional evaluation of commercial dry dog foods by near infrared reflectance spectroscopy. J. Anim. Physiol. Anim. Nutr. (Berl) 2006, 90, 223–229. [Google Scholar] [CrossRef] [PubMed]

- De Marchi, M.; Penasa, M.; Zidi, A.; Manuelian, C.L. Invited review: Use of infrared technologies for the assessment of dairy products—Applications and perspectives. J. Dairy Sci. 2018, 101, 10589–10604. [Google Scholar] [CrossRef] [PubMed]

- Schirmer, M.; Jekle, M.; Becker, T. Starch gelatinization and its complexity for analysis. Starch/Staerke 2015, 67, 30–41. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis, 20th ed.; Latimer, G.W., Jr., Ed.; AOAC International: Rockville, MD, USA, 2016. [Google Scholar]

- Shenk, J.S.; Westerhaus, M.O.; Abrams, S. Protocol for NIR calibrations: Monitoring analysis results and recalibration. In Near Infrared Spectroscopy (NIRS): Analysis of Forage Quality; Martens, G.C., Shenk, J.S., Barton, F.E., Eds.; USDA Agriculture Handbook No 643 (revised with supplements); U.S. Department of Agriculture: Washington, DC, USA, 1989; pp. 104–110. [Google Scholar]

- Williams, P.; Sobering, D. Comparison of commercial near infrared transmittance and reflectance instruments for analysis of whole grains and seeds. J. Near Infrared Spectrosc. 1993, 1, 25–32. [Google Scholar] [CrossRef]

- The European Pet Food Industry (FEDIAF). Nutritional Guidelines for Complete and Complementary Pet Food for Cats and Dogs; FEDIAF: Bruxelles, Belgium, 2018. [Google Scholar]

- Hall, M.B. Determination of dietary starch in animal feeds and pet food by an enzymatic-colorimetric method: Collaborative study. J. AOAC Int. 2015, 98, 397–409. [Google Scholar] [CrossRef]

- Tran, Q.D.; van Lin, C.G.J.M.; Hendriks, W.H.; van der Poel, A.F.B. Lysine reactivity and starch gelatinization in extruded and pelleted canine diets. Anim. Feed Sci. Technol. 2007, 138, 162–168. [Google Scholar] [CrossRef]

- Biagi, G.; Cipollini, I.; Grandi, M.; Pinna, C.; Vecchiato, C.G.; Zaghini, G. A new in vitro method to evaluate digestibility of commercial diets for dogs. Ital. J. Anim. Sci. 2016, 15, 617–625. [Google Scholar] [CrossRef]

- Lankhorst, C.; Tran, Q.D.; Havenaar, R.; Hendriks, W.H.; van der Poel, A.F.B. The effect of extrusion on the nutritional value of canine diets as assessed by in vitro indicators. Anim. Feed Sci. Technol. 2007, 138, 285–297. [Google Scholar] [CrossRef]

- Opitz, B.; Smith, P.M.; Kienzle, E.; Earle, K.E.; Maskell, I.E. Comparison of various methods of fiber analysis in pet foods. J. Nutr. 1998, 128, 2795S–2797S. [Google Scholar] [CrossRef]

- Cipollini, I. Pet food: Quality and Quality Improvement. Ph.D. Thesis, Alma Mater Studiorum-Università di Bologna, Bologna, Italy, 2008. [Google Scholar]

- Hervera, M.; Castrillo, C.; Albanell, E.; Baucells, M.D. Use of near-infrared spectroscopy to predict energy content of commercial dog food. J. Anim. Sci. 2012, 90, 4401–4407. [Google Scholar] [CrossRef]

- Goi, A.; Manuelian, C.L.; Currò, S.; De Marchi, M. Prediction of mineral composition in commercial extruded dry dog food by near-infrared reflectance spectroscopy. Animals 2019, 9, 640. [Google Scholar] [CrossRef] [PubMed]

- Miller, C.E. Chemistry principles of near infrared technology. In Near Infrared Technology in the Agricultural and Food Industries, American Association of Cereal Chemist; Williams, P.C., Norris, K.H., Eds.; American Association of Cereal Chemists: St. Paul, MN, USA, 2001; pp. 19–37. [Google Scholar]

- Workman, J., Jr. The Handbook of Organic Compounds: NIR, IR, R, and UV-Vis Spectra Featuring Polymers and Surfactants; Academic Press: St Louis, MO, USA, 2000. [Google Scholar]

- Williams, C.; Norris, K.H. Near Infrared Technology in the Agricultural and Food Industries; American Association of Cereal Chemistry: St. Paul, MN, USA, 2001. [Google Scholar]

- Osborne, B.G.; Fearn, T.; Hindle, P.H. Practical NIR Spectroscopy with Applications in Food and Beverage Analysis; Longman Scientific and Technical: Harlow, UK, 1993. [Google Scholar]

- Hervera, M.; Baucells, M.D.; González, G.; Pérez, E.; Castrillo, C. Prediction of digestible protein content of dry extruded dog foods: Comparison of methods. J. Anim. Physiol. Anim. Nutr. (Berl.) 2009, 93, 366–372. [Google Scholar] [CrossRef] [PubMed]

- Williams, P. The RPD Statistic: A Tutorial Note. NIR News 2014, 25, 22–26. [Google Scholar] [CrossRef]

- Manuelian, C.L.; Currò, S.; Penasa, M.; Cassandro, M.; De Marchi, M. Prediction of minerals, fatty acid composition and cholesterol content of commercial cheeses by near infrared transmittance spectroscopy. Int. Dairy J. 2017, 71, 107–113. [Google Scholar] [CrossRef]

- Schmitt, S.; Garrigues, S.; de la Guardia, M. Determination of the mineral composition of foods by infrared spectroscopy: A review of a green alternative. Crit. Rev. Anal. Chem. 2014, 44, 186–197. [Google Scholar] [CrossRef]

- De Marchi, M.; Penasa, M.; Cecchinato, A.; Bittante, G. The relevance of different near infrared technologies and sample treatments for predicting meat quality traits in commercial beef cuts. Meat Sci. 2013, 93, 329–335. [Google Scholar] [CrossRef]

- Sinnaeve, G.; Dardenne, P.; Agneessens, R.; Biston, R. The Use of near Infrared Spectroscopy for the Analysis of Fresh Grass Silage. J. Near Infrared Spectrosc. 1994, 2, 79–84. [Google Scholar] [CrossRef]

- Manuelian, C.L.; Currò, S.; Visentin, G.; Penasa, M.; Cassandro, M.; Dellea, C.; Bernardi, M.; De Marchi, M. Technical note: At-line prediction of mineral composition of fresh cheeses using near-infrared technologies. J. Dairy Sci. 2017, 100, 6084–6089. [Google Scholar] [CrossRef]

| Main Carbohydrates Source | Main Protein Sources | Dog Size | Life Stage | Number of Packages |

|---|---|---|---|---|

| Oats | only chicken | medium | adult | 2 |

| Corn | chicken, duck, fish, lamb, rabbit | small, medium, medium/large, large | puppy, adult | 25 |

| Potato | chicken, duck, horse, rabbit venison | small, medium/large | puppy, adult | 14 |

| Pea | chicken, pork | small, medium/large | adult | 14 |

| Rice | fish, lamb, pork | small, medium, medium/large, large | adult | 13 |

| Sorghum | chicken, pork | small, medium, medium/large, large | puppy, adult | 13 |

| Trait | Mean | SD | Minimum | Maximum | CV |

|---|---|---|---|---|---|

| Dry matter | 92.00 | 0.00 | 92.00 | 92.00 | 0.00 |

| Crude protein | 28.98 | 4.68 | 23.91 | 40.22 | 16.10 |

| Crude fats | 15.90 | 3.45 | 10.33 | 21.74 | 21.71 |

| Crude Fibers | 3.62 | 2.59 | 2.28 | 15.22 | 71.56 |

| Crude Ash | 7.32 | 1.34 | 2.50 | 9.78 | 18.34 |

| Trait | Mean | SD | Minimum | Maximum | CV |

|---|---|---|---|---|---|

| Total starch | 34.22 | 7.64 | 11.87 | 46.77 | 22.3 |

| Gelatinized starch | 22.99 | 6.20 | 9.49 | 36.98 | 27.0 |

| NDF | 17.48 | 6.52 | 8.21 | 37.74 | 37.3 |

| ADF | 4.67 | 2.65 | 2.28 | 17.39 | 56.7 |

| ADL | 1.85 | 0.82 | 0.43 | 4.58 | 44.3 |

| Trait | LF | Mean | SD | R2C | SEC | R2CrV | SECrV | RPDCrV |

|---|---|---|---|---|---|---|---|---|

| Vis-NIR, 400–2500 nm | ||||||||

| Total starch | 8 | 34.89 | 7.34 | 0.99 | 0.59 | 0.97 | 1.16 | 6.33 |

| Gelatinized starch | 9 | 23.04 | 6.10 | 0.98 | 0.89 | 0.95 | 1.32 | 4.62 |

| NDF | 10 | 16.81 | 5.97 | 0.97 | 1.03 | 0.93 | 1.52 | 3.93 |

| ADF | 9 | 4.53 | 2.67 | 0.99 | 0.26 | 0.97 | 0.46 | 5.80 |

| ADL | 9 | 1.81 | 0.82 | 0.98 | 0.11 | 0.93 | 0.22 | 3.73 |

| NIT, 850–1050 nm | ||||||||

| Total starch | 8 | 34.84 | 7.02 | 0.88 | 2.42 | 0.84 | 2.77 | 2.53 |

| Gelatinized starch | 10 | 22.82 | 6.15 | 0.83 | 2.55 | 0.77 | 2.94 | 2.09 |

| NDF | 9 | 17.46 | 6.55 | 0.89 | 2.18 | 0.80 | 2.90 | 2.26 |

| ADF | 10 | 4.10 | 1.21 | 0.80 | 0.54 | 0.67 | 0.69 | 1.75 |

| ADL | 10 | 1.89 | 0.81 | 0.88 | 0.28 | 0.85 | 0.31 | 2.61 |

| Trait | Calibration Set (n = 60) | Validation Set (n = 21) | ||||||

|---|---|---|---|---|---|---|---|---|

| LF | SECrV | R2CrV | Bias | Slope | SEP | R2ExV | RPDExV | |

| Vis-NIR, 400–2500 nm | ||||||||

| Total starch | 6 | 1.31 | 0.97 | −0.29 | 0.90 | 1.60 | 0.96 | 4.43 |

| Gelatinized starch | 9 | 1.60 | 0.93 | 0.36 | 1.03 | 1.58 | 0.95 | 4.36 |

| NDF | 10 | 1.68 | 0.91 | −1.12 | 1.04 | 1.63 | 0.95 | 4.31 |

| ADF | 10 | 0.54 | 0.95 | −0.08 | 1.03 | 0.60 | 0.97 | 5.67 |

| ADL | 10 | 0.23 | 0.89 | −0.04 | 1.02 | 0.28 | 0.84 | 2.46 |

| NIT, 850–1050 nm | ||||||||

| Total starch | 9 | 2.91 | 0.83 | −0.16 | 0.89 | 3.28 | 0.80 | 2.16 |

| Gelatinized starch | 10 | 3.16 | 0.71 | 0.42 | 0.91 | 3.77 | 0.71 | 1.83 |

| NDF | 8 | 2.64 | 0.78 | 0.11 | 0.96 | 2.90 | 0.74 | 1.97 |

| ADF | 6 | 0.66 | 0.70 | −0.18 | 0.77 | 0.72 | 0.75 | 1.77 |

| ADL | 9 | 0.26 | 0.83 | −0.12 | 0.77 | 0.38 | 0.72 | 1.71 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Goi, A.; Manuelian, C.L.; Righi, F.; De Marchi, M. At-line Prediction of Gelatinized Starch and Fiber Fractions in Extruded Dry Dog Food Using Different Near-Infrared Spectroscopy Technologies. Animals 2020, 10, 862. https://doi.org/10.3390/ani10050862

Goi A, Manuelian CL, Righi F, De Marchi M. At-line Prediction of Gelatinized Starch and Fiber Fractions in Extruded Dry Dog Food Using Different Near-Infrared Spectroscopy Technologies. Animals. 2020; 10(5):862. https://doi.org/10.3390/ani10050862

Chicago/Turabian StyleGoi, Arianna, Carmen L. Manuelian, Federico Righi, and Massimo De Marchi. 2020. "At-line Prediction of Gelatinized Starch and Fiber Fractions in Extruded Dry Dog Food Using Different Near-Infrared Spectroscopy Technologies" Animals 10, no. 5: 862. https://doi.org/10.3390/ani10050862

APA StyleGoi, A., Manuelian, C. L., Righi, F., & De Marchi, M. (2020). At-line Prediction of Gelatinized Starch and Fiber Fractions in Extruded Dry Dog Food Using Different Near-Infrared Spectroscopy Technologies. Animals, 10(5), 862. https://doi.org/10.3390/ani10050862