Development of Sliding Mode Controller Based on Internal Model Controller for Higher Precision Electro-Optical Tracking System

Abstract

1. Introduction

- An SMC method based on IMC is proposed in this paper. Compared with the SMC method, this method can decrease chattering and the tracking error and, compared with the SMC based on the DOB, this method can reduce the tracking error and improve the disturbance suppression ability of the system.

- A continuous function with fractional power is proposed as a part of the sliding mode reaching law, which can further weaken the sliding mode chattering and solve the problem that the upper bound of disturbance compensation error is unknown.

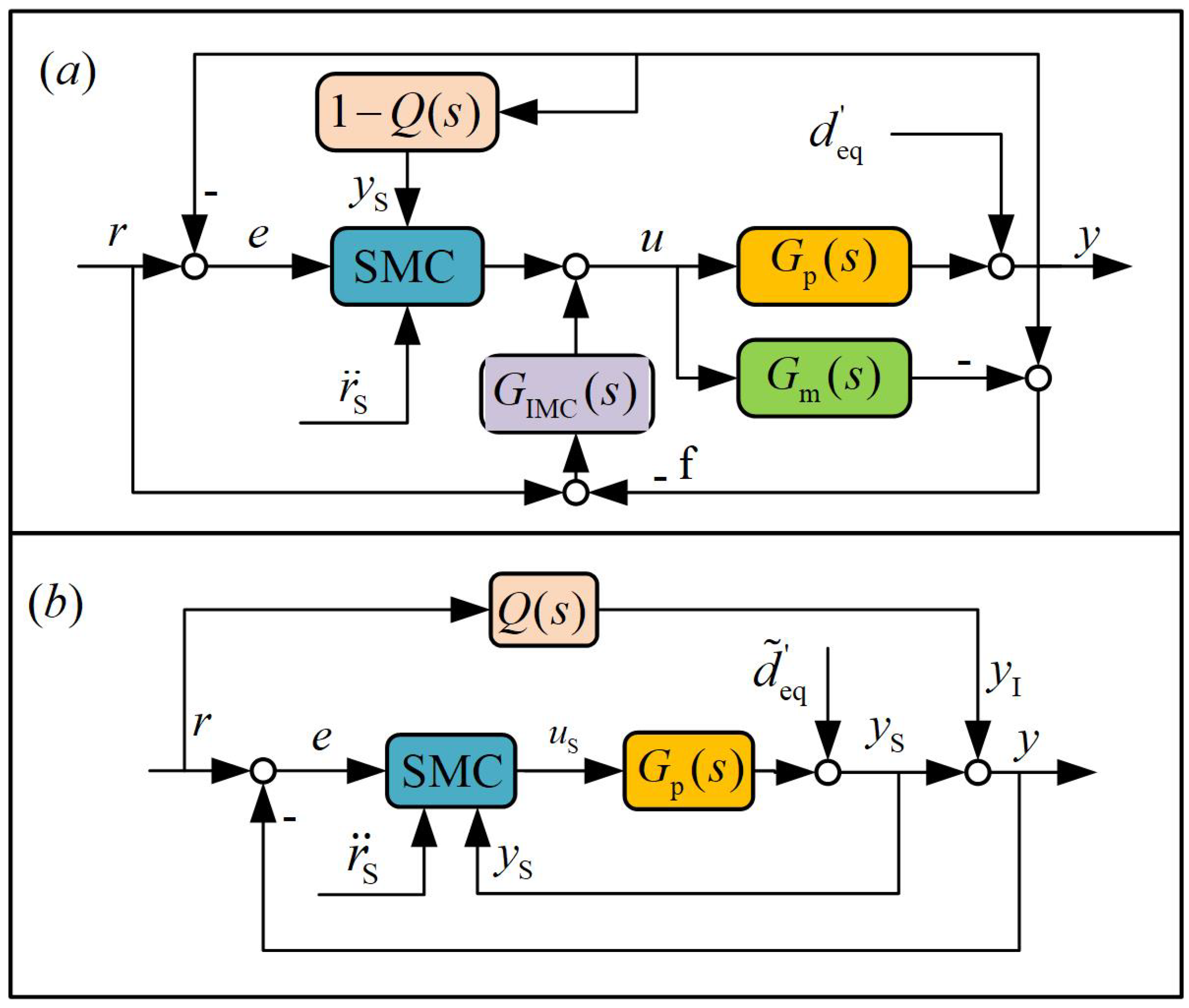

- A solution of two-controller fusion design is presented based on the principle of system state decomposition.

- The lifting wavelet threshold de-noising method was applied to the closed-loop control system for online de-noising and the feasibility and effects were verified by experiments.

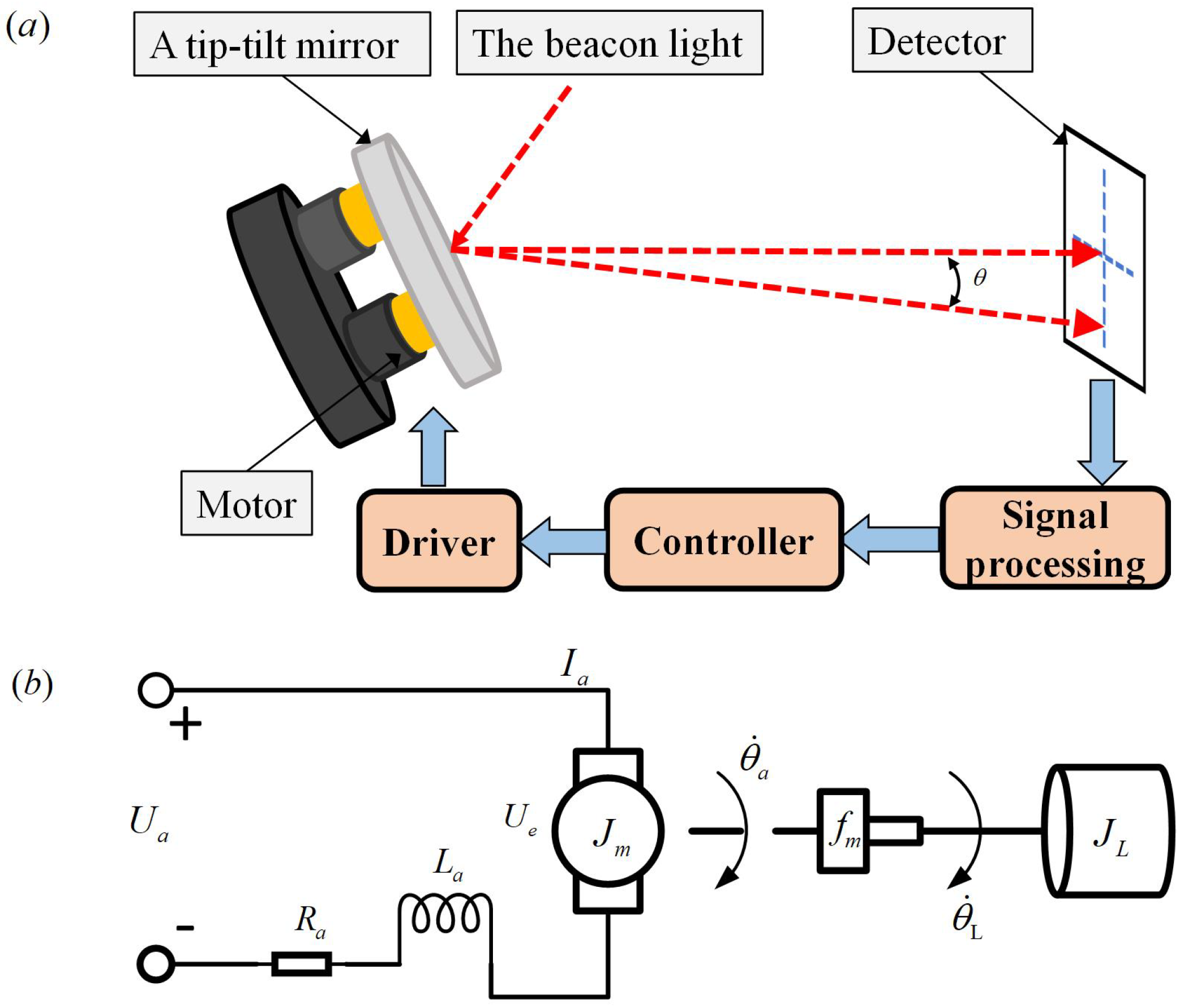

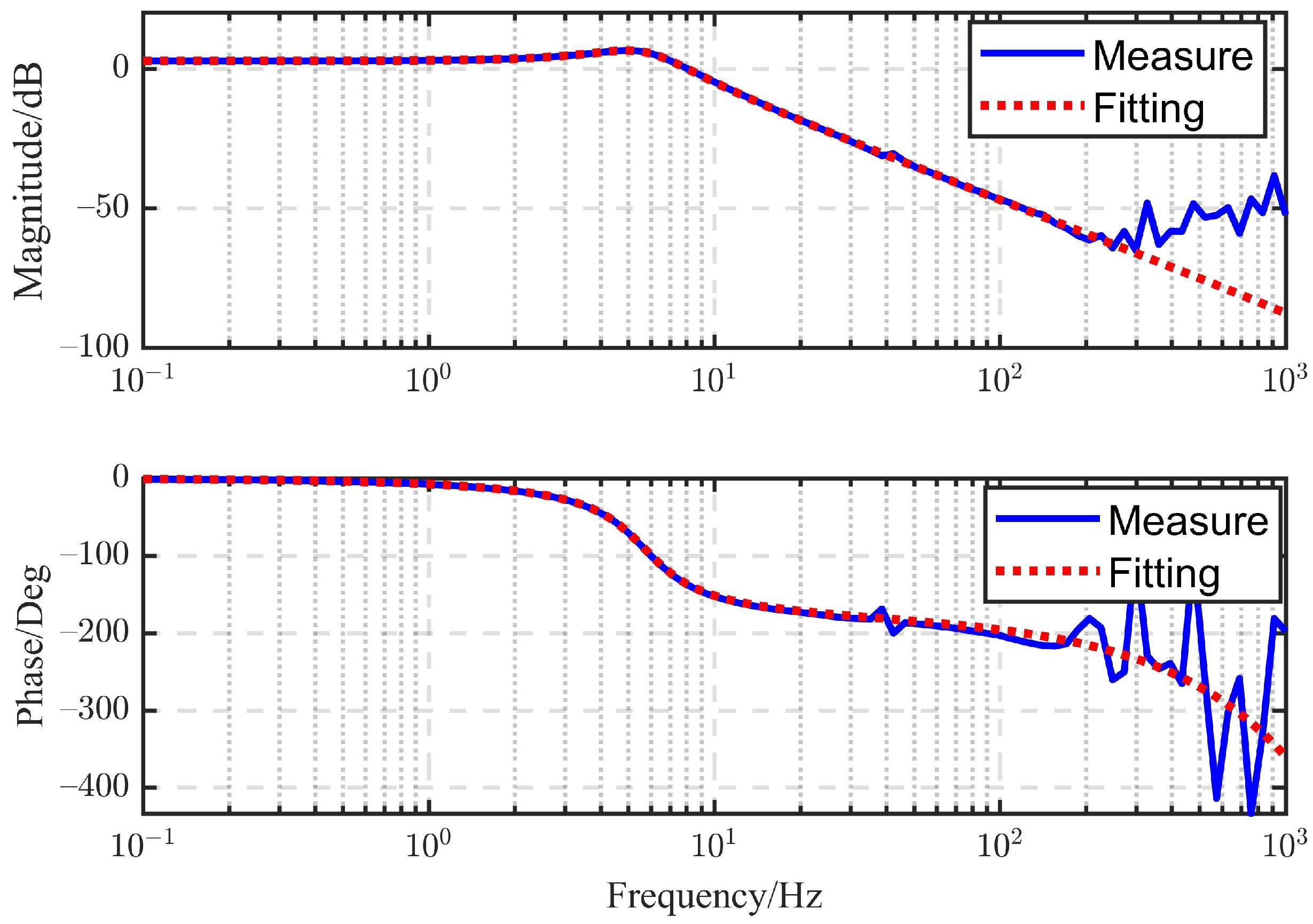

2. ETS Model Analysis

3. Traditional SMC

4. SMC Design Based on IMC

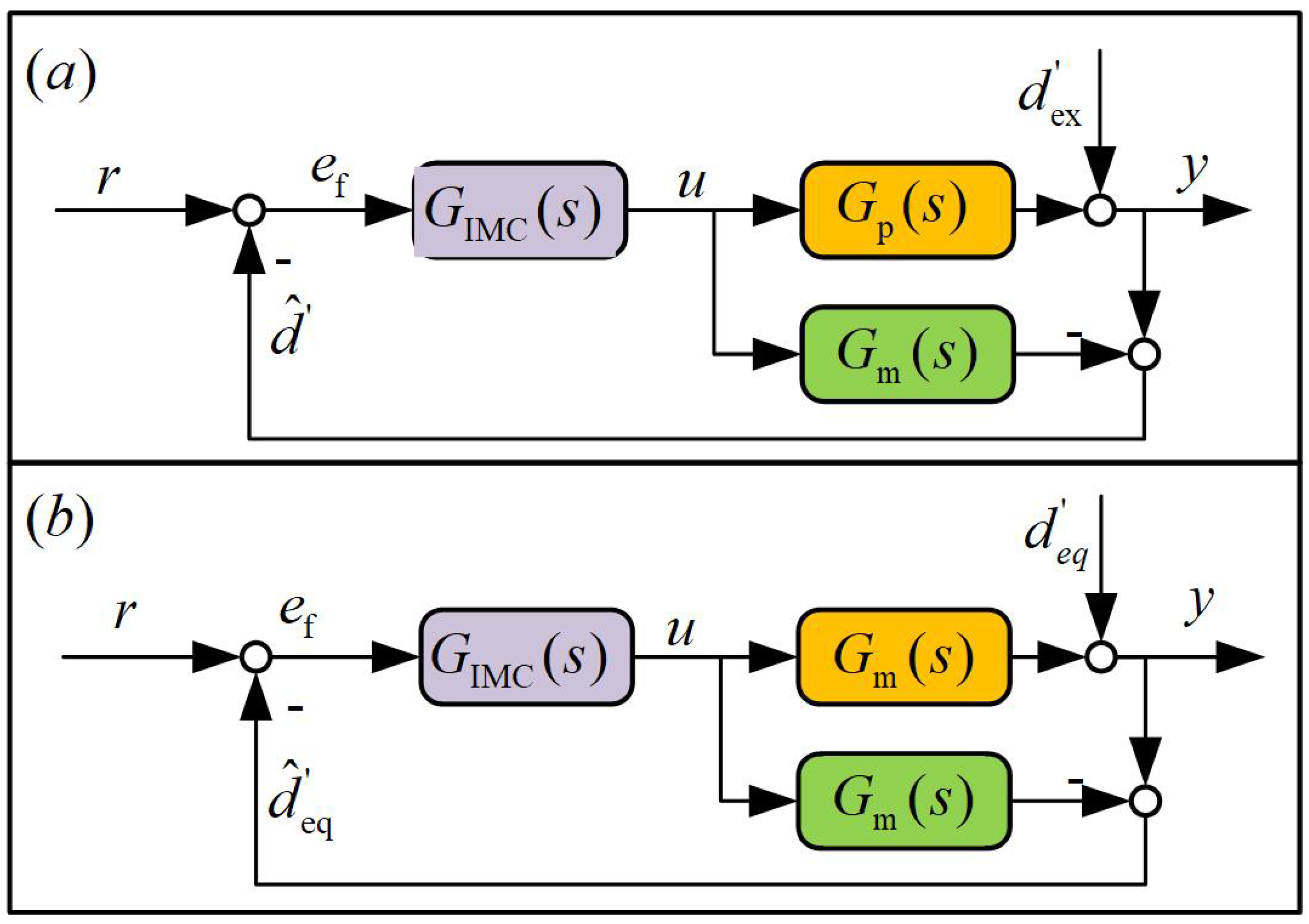

4.1. Principle and Analysis of IMC

4.2. Design of Sliding Mode Controller Based on IMC (IM-SMC)

4.3. Design of Improved Sliding Mode Controller Based on IMC (IM-ISMC)

5. Application of Lifting Wavelet Threshold De-Noising

6. Simulation Analysis and Experiments

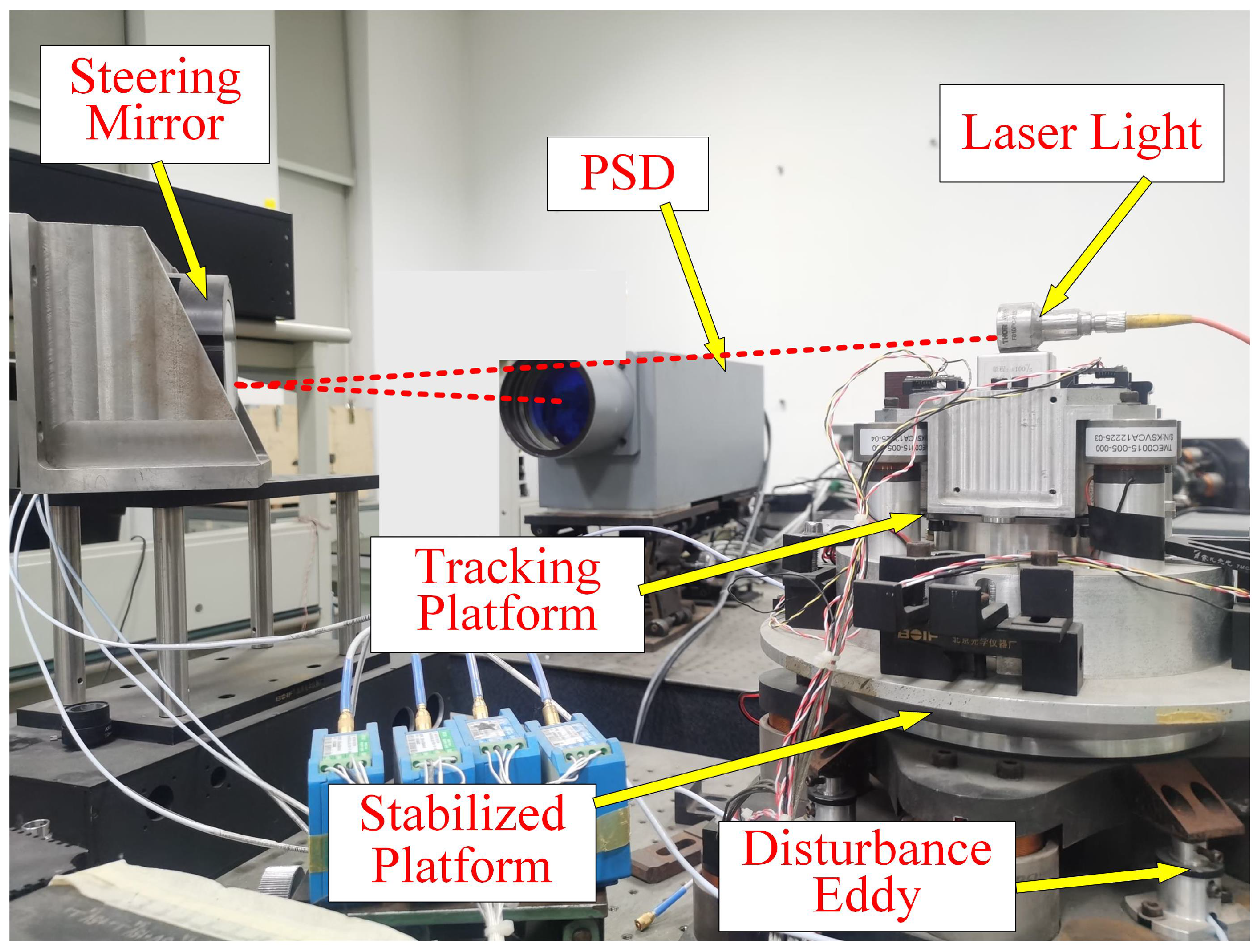

6.1. Experimental Apparatus

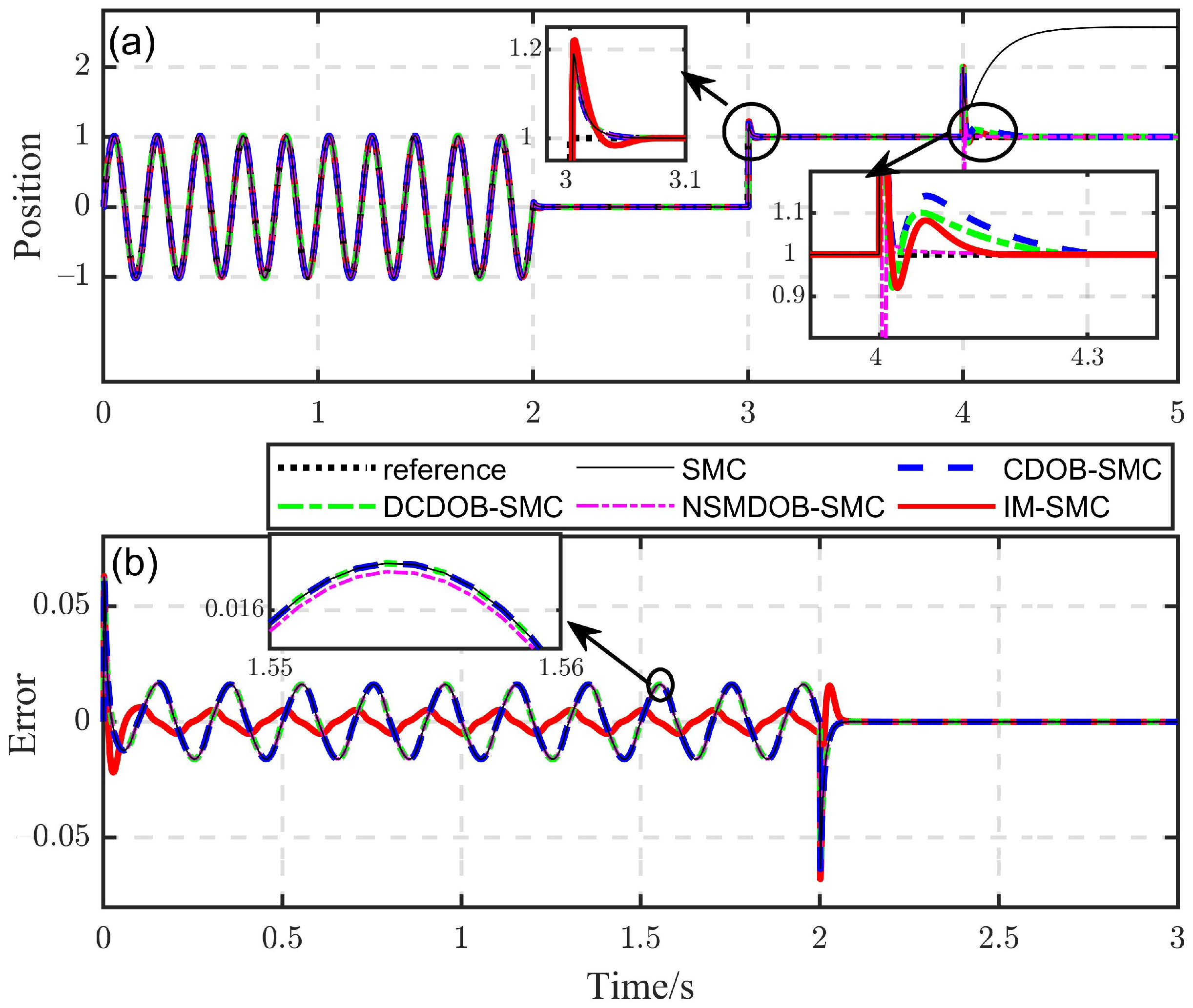

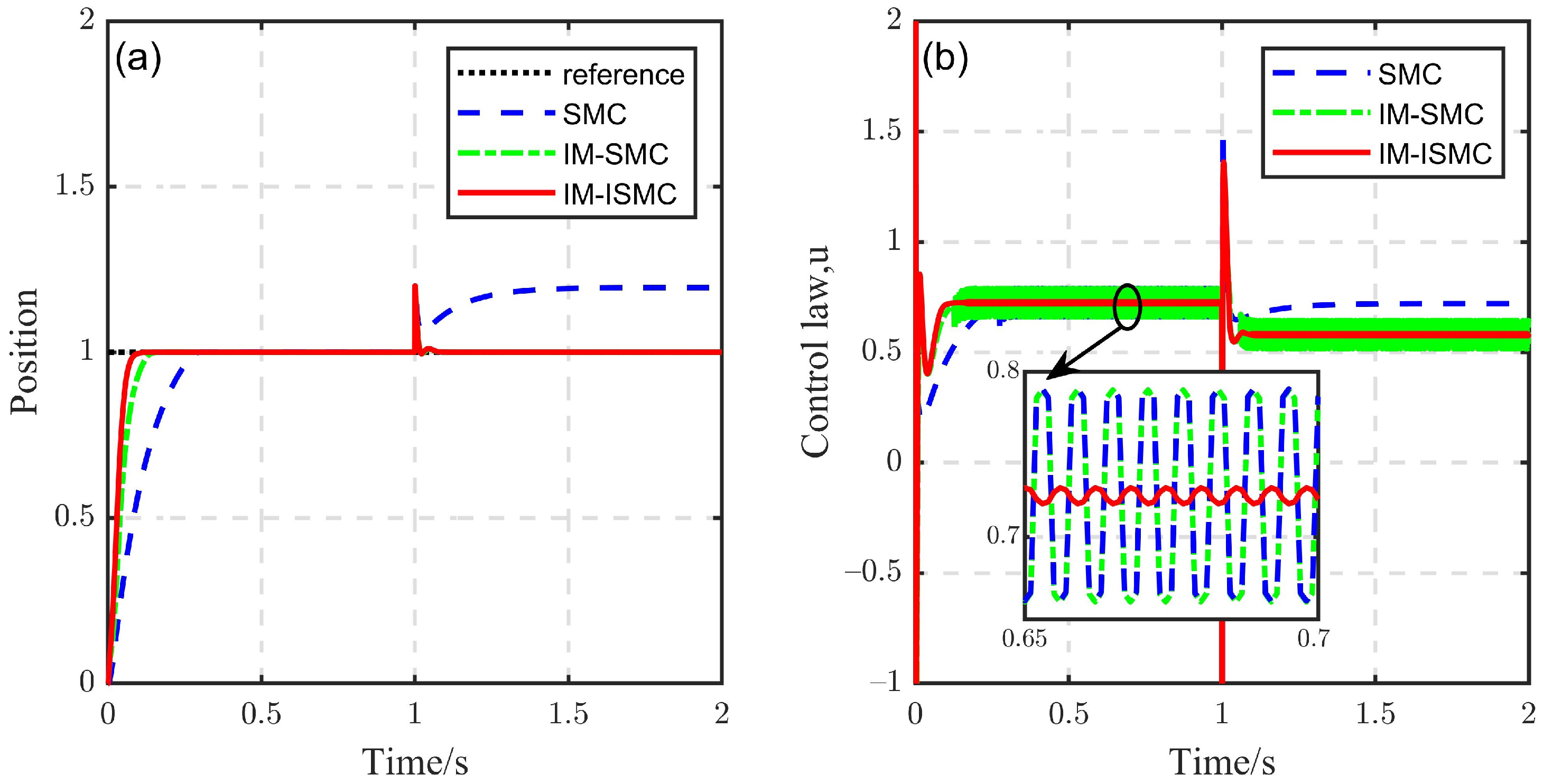

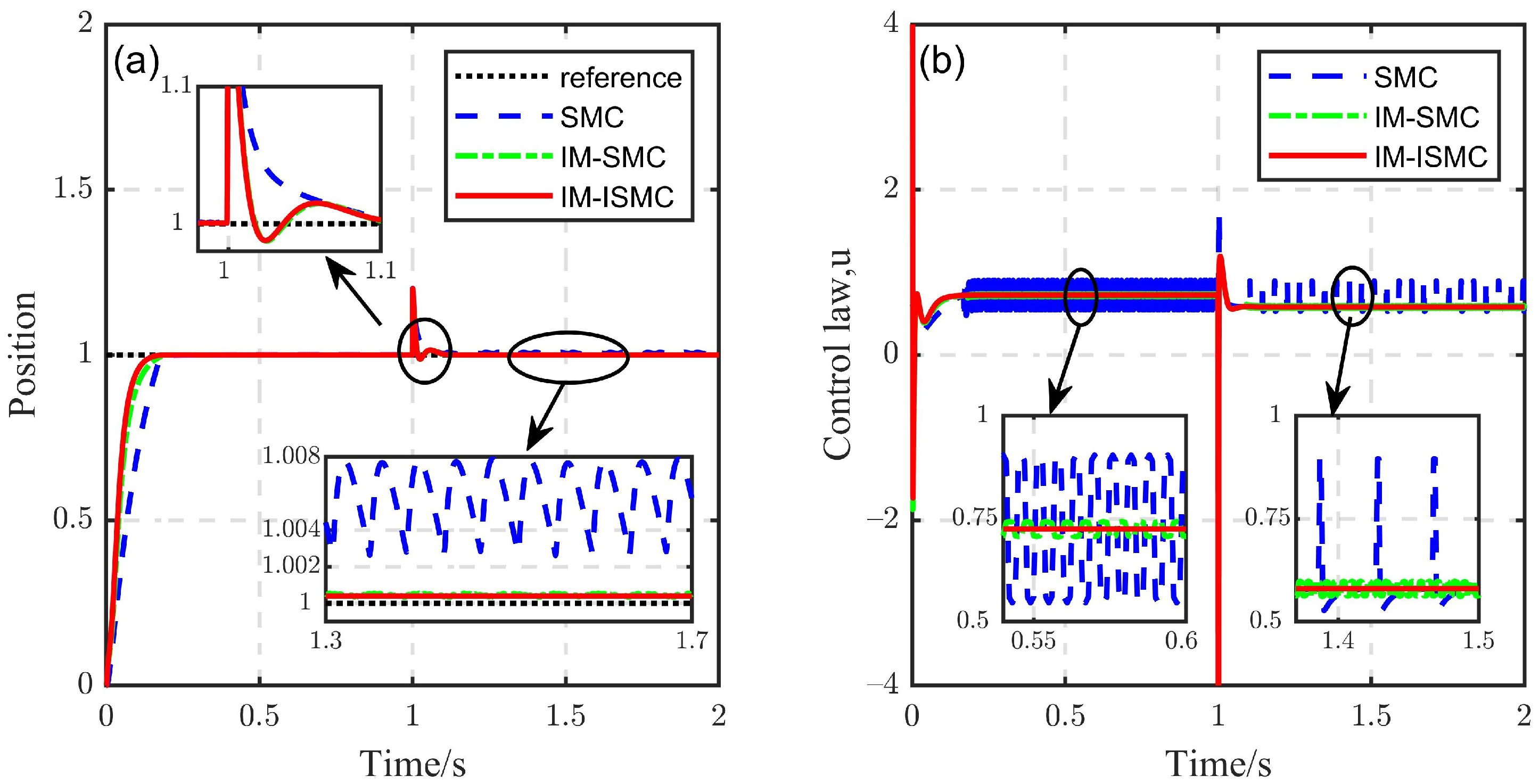

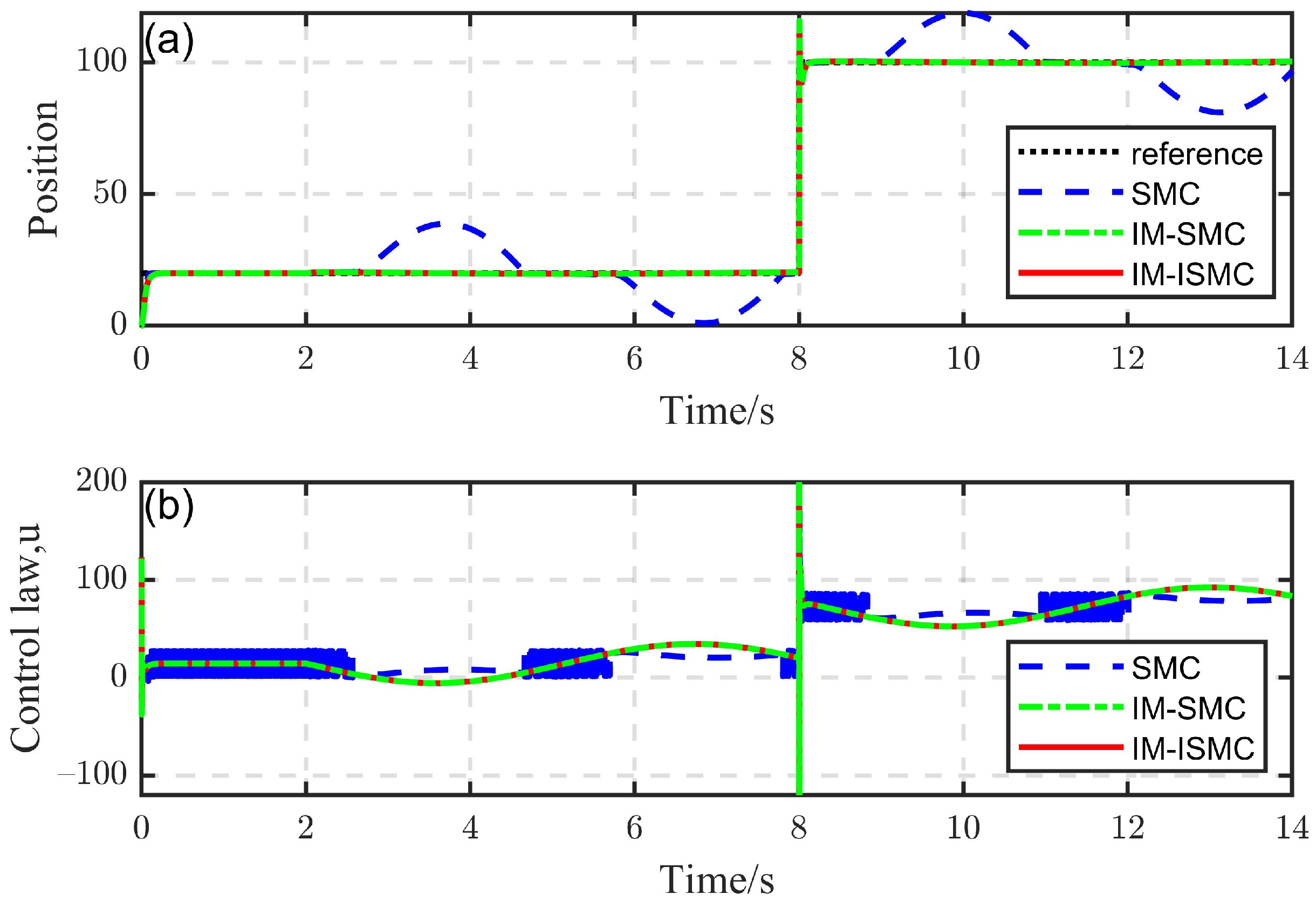

6.2. Simulation Analysis

6.3. Experiment Analysis

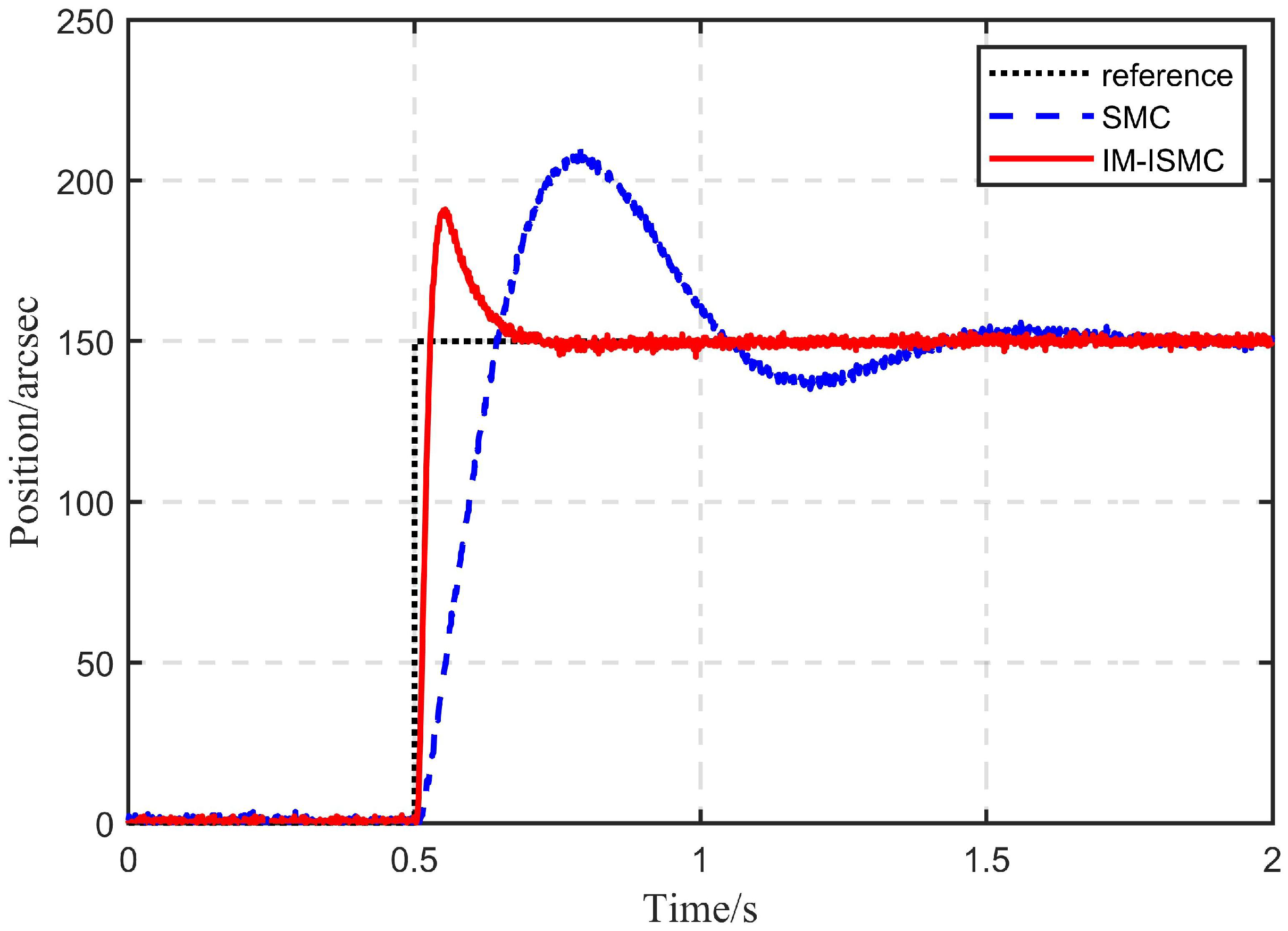

6.3.1. Tracking Performance

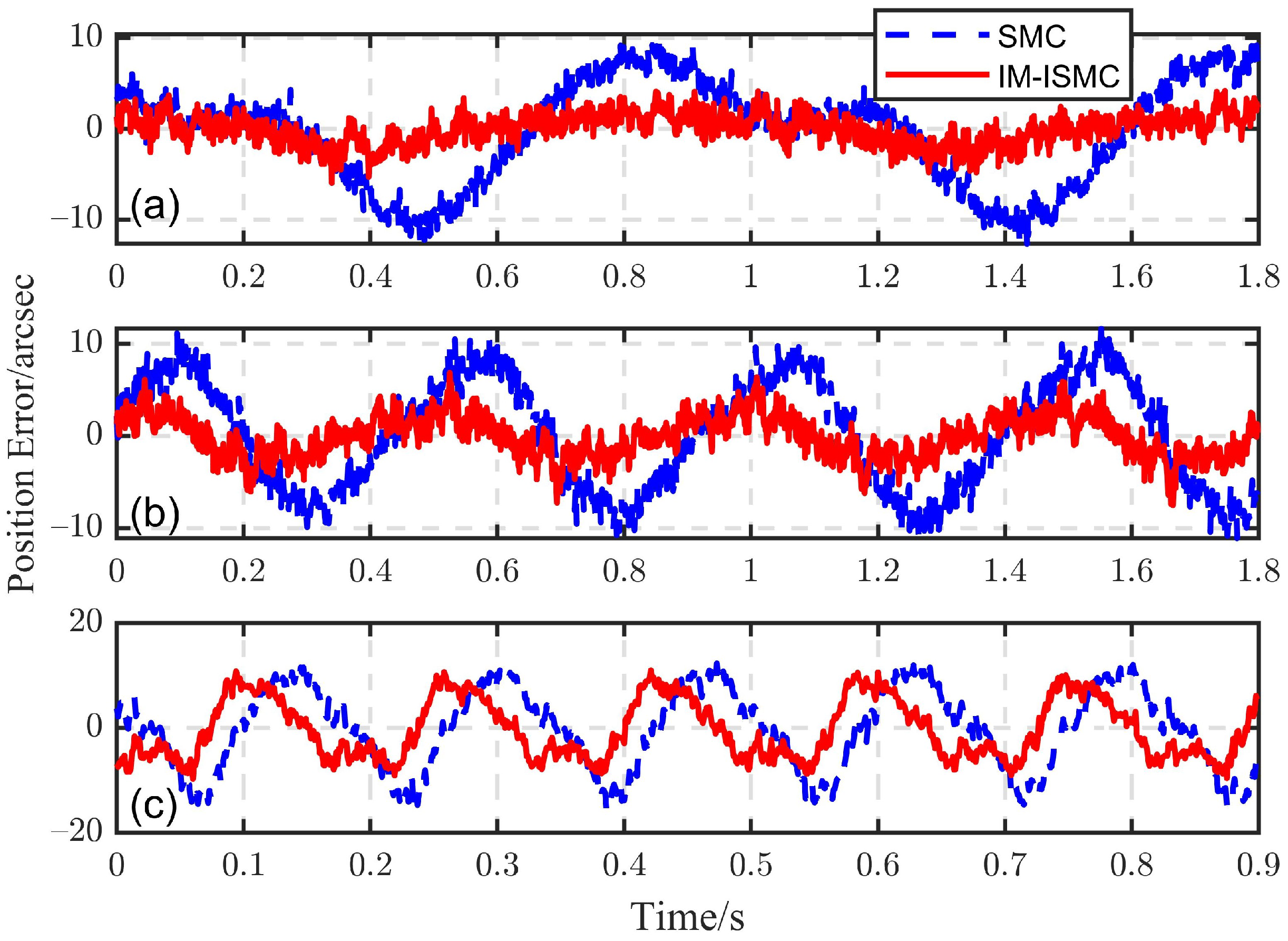

6.3.2. Disturbance Suppression Performance

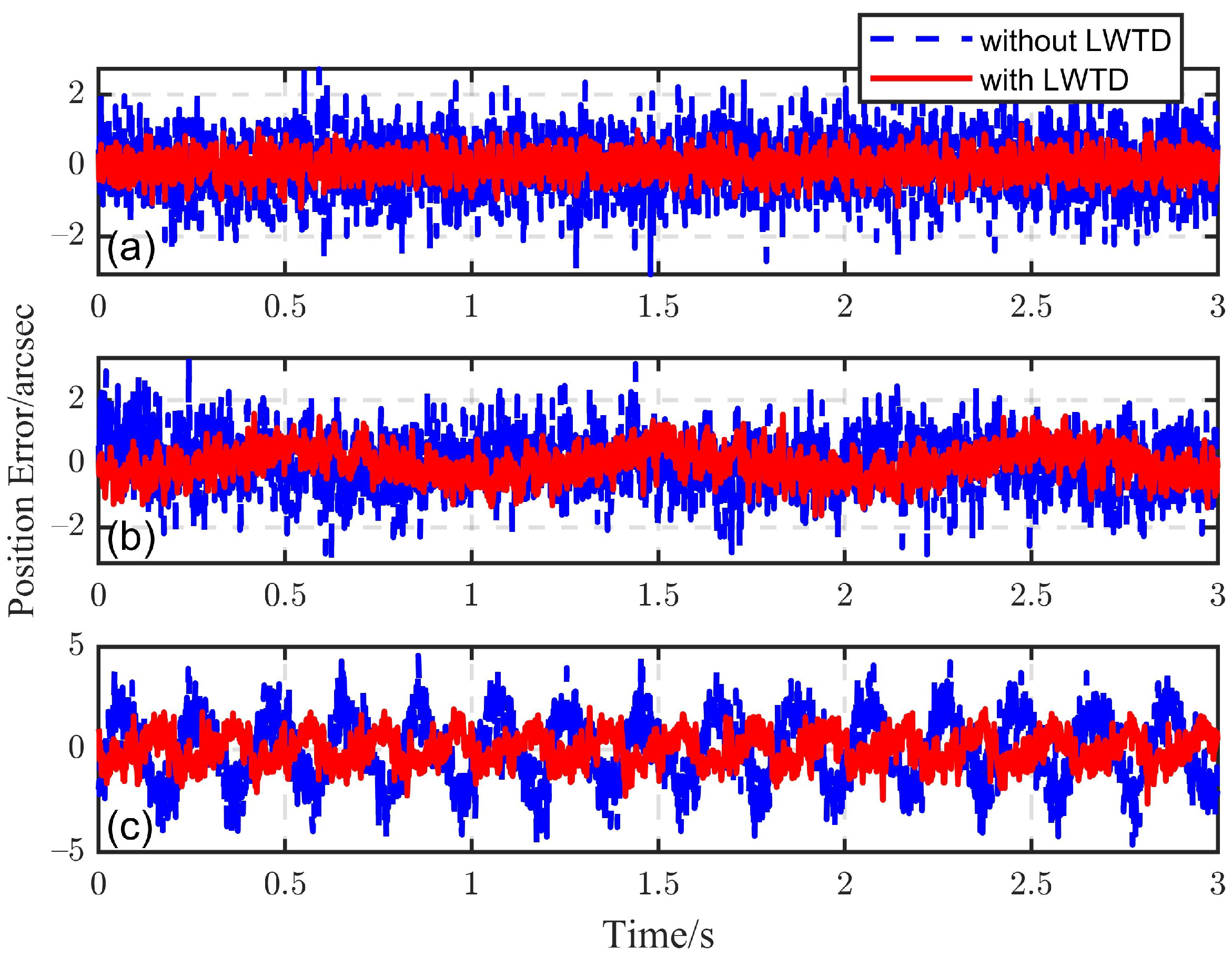

6.3.3. The Effect of LWTD

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| ETS | Electro-optical tracking system |

| SMC | Sliding mode control |

| IMC | Internal model control |

| DOB | Disturbance observer |

| CDOB | Conventional disturbance observer |

| DCDOB | Dual-compensator disturbance observer |

| NSMDOB | Novel sliding mode disturbance observer |

| CDOB-SMC | SMC based on CDOB |

| DCDOB-SMC | SMC based on DCDOB |

| NSMDOB-SMC | SMC based on NSMDOB |

| IM-SMC | SMC based on IMC |

| IM-ISMC | Improved SMC based on IMC |

| UAV | Unmanned Aerial Vehicle |

| FSM | Fast steering mirror |

| EMF | Electromagnetic forming |

| WTD | Wavelet threshold de-noising |

| LWTD | Lifting wavelet threshold de-noising |

| PSD | Position sensitive detector |

References

- Kim, J.; Lee, D.; Cho, K.; Jo, S.; Kim, J.; Min, C.; Han, D.; Cho, S. Development of an electro-optical system for small UAV. Aerosp. Sci. Technol. 2010, 14, 505–511. [Google Scholar] [CrossRef]

- Boroson, D.; Robinson, B.; Burianek, D.; Murphy, D.; Biswas, A. Overview and Status of the Lunar Laser Communications Demonstration. Proc. SPIE Int. Soc. Opt. Eng. 2012, 8246, 7–30. [Google Scholar]

- Bi, Z.; Tian, Z.; Tao, L.; Fu, S. Study on Shipborne Video Electro-Optical Tracking System Based on FPGA; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- Tian, J.; Yang, W.; Peng, Z.; Tang, T. Inertial sensor-based multiloop control of fast steering mirror for line of sight stabilization. Opt. Eng. 2016, 55, 111602. [Google Scholar] [CrossRef]

- Deng, C.; Tang, T.; Mao, Y.; Ren, G. Enhanced Disturbance Observer Based on Acceleration Measurement for Fast Steering Mirror Systems. IEEE Photonics J. 2017, 9, 1–11. [Google Scholar]

- Zhou, X.; Li, X. A Finite-Time Robust Adaptive Sliding Mode Control for Electro-Optical Targeting System with Friction Compensation. IEEE Access 2019, 7, 166318–166328. [Google Scholar]

- Ren, Y.; Tian, D.; Yu, D. Research of NSMDOB-Based Compound Control for Photoelectric Tracking Platform. IEEE Access 2020, 8, 62650–62659. [Google Scholar] [CrossRef]

- Zhou, X.; Li, X. Trajectory tracking control for electro-optical tracking system based on fractional-order sliding mode controller with super-twisting extended state observer. ISA Trans. 2021, 117, 85–95. [Google Scholar] [CrossRef] [PubMed]

- Yu, X.; Kaynak, O. Sliding-Mode Control With Soft Computing: A Survey. IEEE Trans. Ind. Electron. 2009, 56, 3275–3285. [Google Scholar]

- Zhang, G.; Wang, Y.; Wang, J.; Chen, J.; Qian, D. Disturbance observer—Based super-twisting sliding mode control for formation tracking of multi-agent mobile robots. Meas. Control 2020, 53, 908–921. [Google Scholar] [CrossRef]

- Cheng, X.; Liu, H.; Lu, W. Chattering-Suppressed Sliding Mode Control for Flexible-Joint Robot Manipulators. Actuators 2021, 10, 288. [Google Scholar] [CrossRef]

- Wang, M.; Wang, Y.; Yang, R.; Fu, Y.; Zhu, D. A Sliding Mode Control Strategy for an ElectroHydrostatic Actuator with Damping Variable Sliding Surface. Actuators 2021, 10, 3. [Google Scholar] [CrossRef]

- Qiao, Q.; Zhong, M.; Ren, W.; Duan, Q.; Chen, X.; Mao, Y. Sliding mode control of the photoelectric servo platform with input saturation. Laser Technol. 2020, 44, 429–435. [Google Scholar]

- Ren, Y.; Liu, Z.; Liu, X.; Zhang, Y. A Chattering Free Discrete-Time Global Sliding Mode Controller for Optoelectronic Tracking System. Math. Probl. Eng. 2013, 1–8. [Google Scholar] [CrossRef][Green Version]

- Wei, Y.; Ma, J.; Jing, X. Tracking control strategy for the optoelectronic system on the flexible suspended platform based on backstepping method. J. Proc. SPIE Int. Soc. Opt. Eng. 2012, 8418, 8418. [Google Scholar]

- Ren, Y.; Liu, Z.H.; Zhou, R. Adaptive Terminal Sliding Mode Control of Opto-Electronic Stabilized Platform Based on Acceleration Feedback. Adv. Mater. Res. 2012, 468-471, 523–528. [Google Scholar] [CrossRef]

- Lu, Y. Sliding-Mode Disturbance Observer with Switching-Gain Adaptation and Its Application to Optical Disk Drives. IEEE Trans. Ind. Electron. 2009, 56, 3743–3750. [Google Scholar]

- Zhang, M. Finite-time model-free trajectory tracking control for overhead cranes subject to model uncertainties, parameter variations and external disturbances. Trans. Inst. Meas. Control 2019, 41, 3516–3525. [Google Scholar] [CrossRef]

- Yang, J.; Li, S.; Yu, X. Sliding-Mode Control for Systems with Mismatched Uncertainties via a Disturbance Observer. IEEE Trans. Ind. Electron. 2013, 60, 160–169. [Google Scholar] [CrossRef]

- Seungmin, B.; Jaemin, B.; Soohee, H. An Adaptive Sliding Mode Control with Effective Switching Gain Tuning Near the Sliding Surface. IEEE Access 2019, 7, 15563–15572. [Google Scholar]

- Goel, A.; Mobayen, S. Adaptive nonsingular proportional–integral–derivative-type terminal sliding mode tracker based on rapid reaching law for nonlinear systems. J. Vib. Control 2020, 27, 2669–2685. [Google Scholar] [CrossRef]

- Alattas, K.A.; Mobayen, S.; Din, S.U.; Asad, J.H.; Fekih, A.; Assawinchaichote, W.; Vu, M.T. Design of a Non-Singular Adaptive Integral-Type Finite Time Tracking Control for Nonlinear Systems with External Disturbances. IEEE Access 2021, 9, 102091–102103. [Google Scholar] [CrossRef]

- Karami, H.; Alattas, K.A.; Mobayen, S.; Fekih, A. Adaptive Integral-Type Terminal Sliding Mode Tracker Based on Active Disturbance Rejection for Uncertain Nonlinear Robotic Systems with Input Saturation. IEEE Access 2021, 9, 129528–129538. [Google Scholar] [CrossRef]

- Saghafinia, A.; Ping, H.; Uddin, M.; Gaeid, K. Adaptive Fuzzy Sliding-Mode Control into Chattering-Free IM Drive. Ind. Appl. IEEE Trans. 2015, 51, 692–701. [Google Scholar] [CrossRef]

- Gong, C.; Hu, Y.; Gao, J.; Wang, Y.; Yan, L. An Improved Delay-Suppressed Sliding Mode Observer for Sensorless Vector-Controlled PMSM. IEEE Trans. Ind. Electron. 2020, 67, 5913–5923. [Google Scholar] [CrossRef]

- Humaidi, A.J.; Hasan, A.F. Particle swarm optimization—Based adaptive super-twisting sliding mode control design for 2-degree-of-freedom helicopter. Meas. Control-Lond.-Inst. Meas. Control 2019, 52, 1403–1419. [Google Scholar] [CrossRef]

- Sui, S.; Zhao, T. Active disturbance rejection control for optoelectronic stabilized platform based on adaptive fuzzy sliding mode control. ISA Trans. 2021. [Google Scholar] [CrossRef]

- Giap, V.; Huang, S. Effectiveness of fuzzy sliding mode control boundary layer based on uncertainty and disturbance compensator on suspension active magnetic bearing system. Meas. Control 2020, 53, 934–942. [Google Scholar] [CrossRef]

- Lu, Y.; Tan, C.; Ge, W.; Li, B.; Lu, J. Improved Sliding Mode-Active Disturbance Rejection Control of Electromagnetic Linear Actuator for Direct-Drive System. Actuators 2021, 10, 138. [Google Scholar] [CrossRef]

- Morari, M. Robust Process Control. Chem. Eng. Res. Des. 1991, 65, 462–479. [Google Scholar]

- Xu, Q. Continuous Integral Terminal Third-Order Sliding Mode Motion Control for Piezoelectric Nanopositioning System. IEEE/ASME Trans. Mechatron. 2017, 22, 1828–1838. [Google Scholar] [CrossRef]

- Nguyen, M.H.; Dao, H.V.; Ahn, K.K. Active Disturbance Rejection Control for Position Tracking of Electro-Hydraulic Servo Systems under Modeling Uncertainty and External Load. Actuators 2021, 10, 20. [Google Scholar] [CrossRef]

- Ryszard, S.G. Sliding Mode versus Parallel Compensator Based Control under Measurement Noise. IFAC Proc. Vol. 2014, 47, 4601–4606. [Google Scholar]

- Sun, J.; Pu, Z.; Yi, J.; Liu, Z. Fixed-Time Control with Uncertainty and Measurement Noise Suppression for Hypersonic Vehicles via Augmented Sliding Mode Observers. IEEE Trans. Ind. Inform. 2020, 16, 1192–1203. [Google Scholar] [CrossRef]

- Mitsantisuk, C. Estimation of Action/Reaction Forces for the Bilateral Control Using Kalman Filter. IEEE Trans. Ind. Electron. 2012, 59, 4383–4393. [Google Scholar] [CrossRef]

- Yu, X.; Li, J.; Xu, J. Nonlinear filtering in unknown measurement noise and target tracking system by variational Bayesian inference. Aerosp. Sci. Technol. 2019, 84, 37–55. [Google Scholar] [CrossRef]

- Duan, Q.; Mao, Y.; Zhang, H.; Xue, W. Add-on integration module-based proportional-integration-derivative control for higher precision electro-optical tracking system. Trans. Inst. Meas. Control 2021, 43, 1347–1362. [Google Scholar] [CrossRef]

- She, J.H.; Xin, X.; Ohyama, Y. Estimation of Equivalent Input Disturbance Improves Vehicular Steering Control. IEEE Trans. Veh. Technol. 2007, 56, 3722–3731. [Google Scholar] [CrossRef]

- Abe, N.; Yamanaka, K. Smith predictor control and internal model control—A tutorial. In Proceedings of the SICE 2003 Annual Conference (IEEE Cat. No.03TH8734), Fukui, Japan, 4–6 August 2003; Volume 2, pp. 1383–1387. [Google Scholar]

- Sweldens, W. The Lifting Scheme: A Custom-Design Construction of Biorthogonal Wavelets. Appl. Comput. Harmon. Anal. 1996, 3, 186–200. [Google Scholar] [CrossRef]

- Srivastava, M.; Anderson, C.L.; Freed, J.H. A New Wavelet Denoising Method for Selecting Decomposition Levels and Noise Thresholds. IEEE Access Pract. Innov. Open Solut. 2016, 4, 3862–3877. [Google Scholar] [CrossRef]

- Xia, R.; Meng, K.; Qian, F.; Wang, Z.L. Online Wavelet Denoising via a Moving Window. Acta Autom. Sin. 2007, 33, 897–901. [Google Scholar] [CrossRef]

- Li, S.; Yang, J.; Chen, W.H.; Chen, X. Disturbance Observer-Based Control: Methods and Applications; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Deng, J.; Xue, W.; Zhou, X.; Mao, Y. On disturbance rejection control for inertial stabilization of long-distance laser positioning with movable platform. Meas. Control 2020, 53, 1203–1217. [Google Scholar] [CrossRef]

| Methonds | Parameters |

|---|---|

| SMC | |

| IMC | |

| CDOB | |

| DCDOB | |

| NSMDOB |

| Controllers | Parameters |

|---|---|

| SMC | |

| IM-SMC | |

| IM-ISMC | , |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, B.; Nie, K.; Chen, X.; Mao, Y. Development of Sliding Mode Controller Based on Internal Model Controller for Higher Precision Electro-Optical Tracking System. Actuators 2022, 11, 16. https://doi.org/10.3390/act11010016

Zhang B, Nie K, Chen X, Mao Y. Development of Sliding Mode Controller Based on Internal Model Controller for Higher Precision Electro-Optical Tracking System. Actuators. 2022; 11(1):16. https://doi.org/10.3390/act11010016

Chicago/Turabian StyleZhang, Bing, Kang Nie, Xinglong Chen, and Yao Mao. 2022. "Development of Sliding Mode Controller Based on Internal Model Controller for Higher Precision Electro-Optical Tracking System" Actuators 11, no. 1: 16. https://doi.org/10.3390/act11010016

APA StyleZhang, B., Nie, K., Chen, X., & Mao, Y. (2022). Development of Sliding Mode Controller Based on Internal Model Controller for Higher Precision Electro-Optical Tracking System. Actuators, 11(1), 16. https://doi.org/10.3390/act11010016