Repair of Heavily Damaged RC Beams Failing in Shear Using U-Shaped Mortar Jackets

Abstract

1. Introduction

1.1. Jacketing as a Repair Technique in Damaged RC Structural Members

1.2. Research Significance

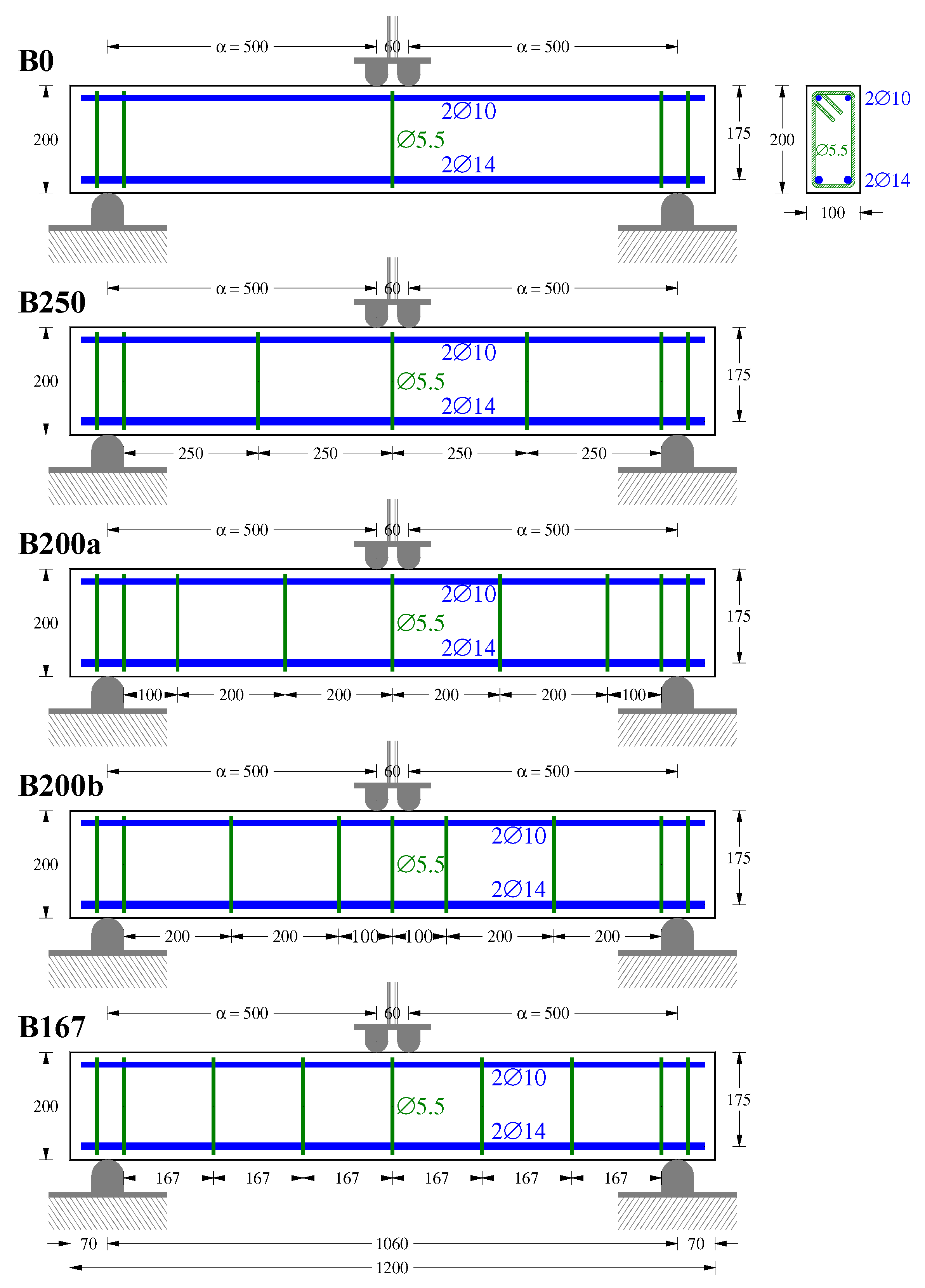

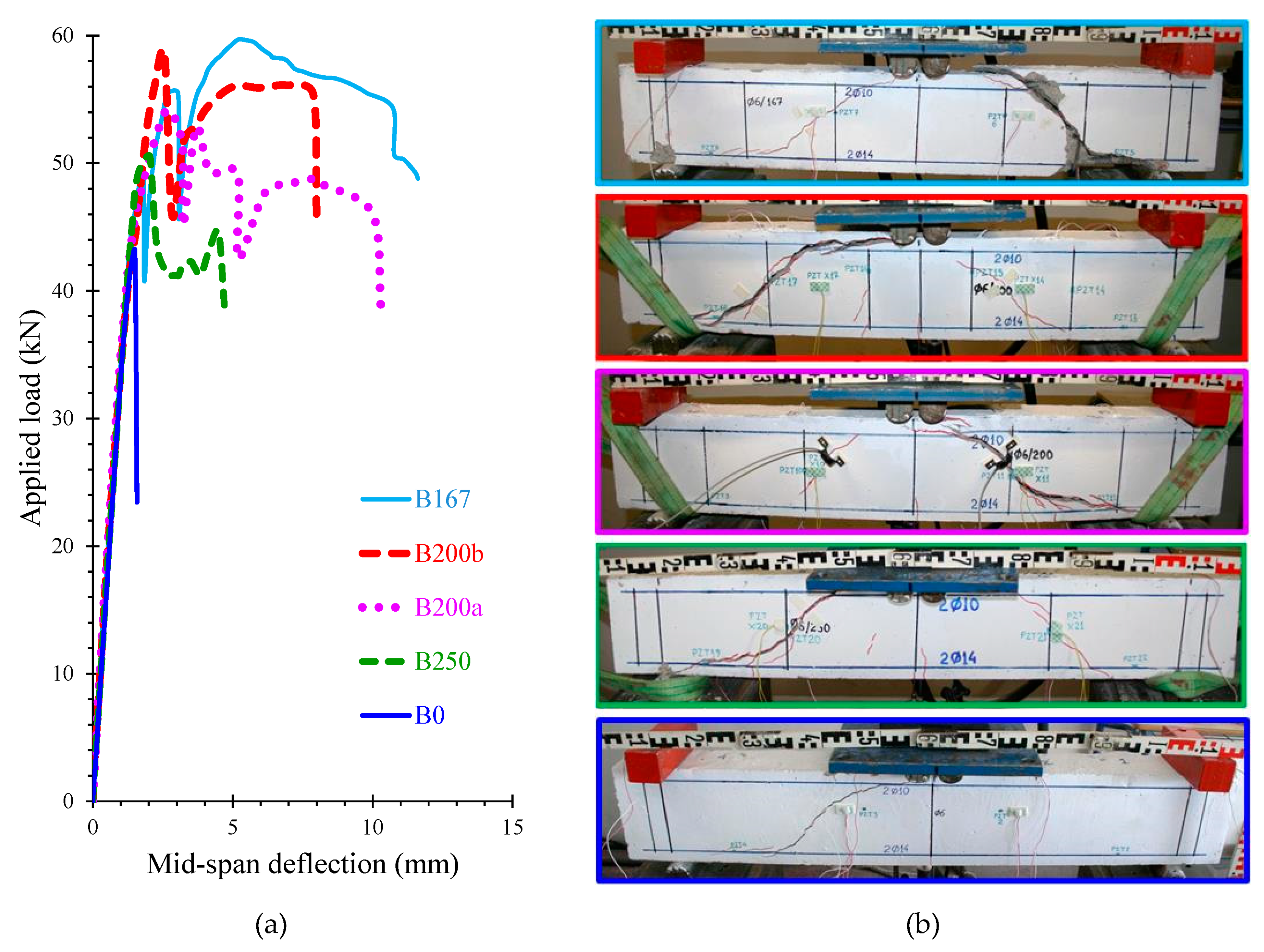

2. Experimental Program of the Initially Tested Shear-Critical Beams

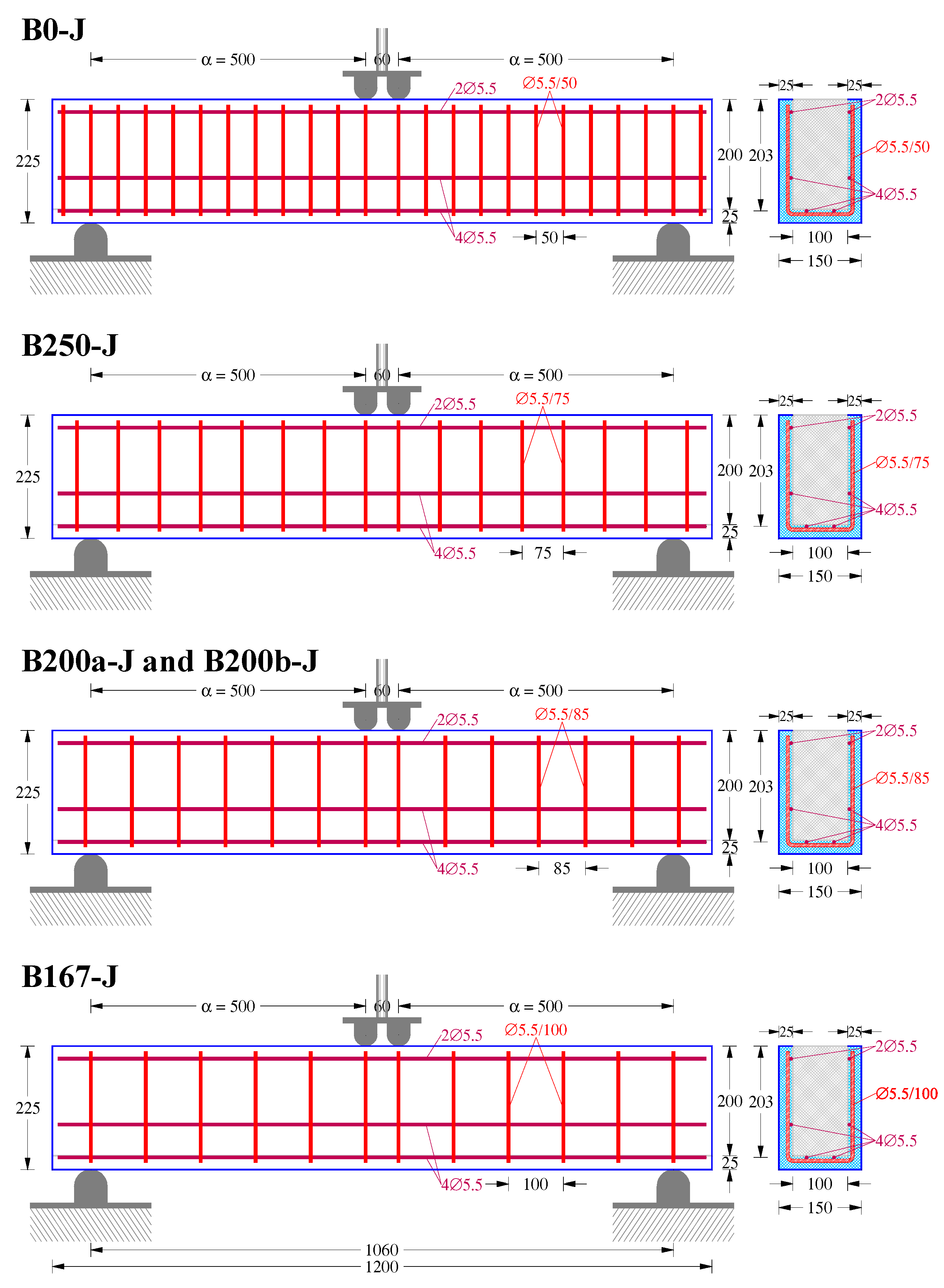

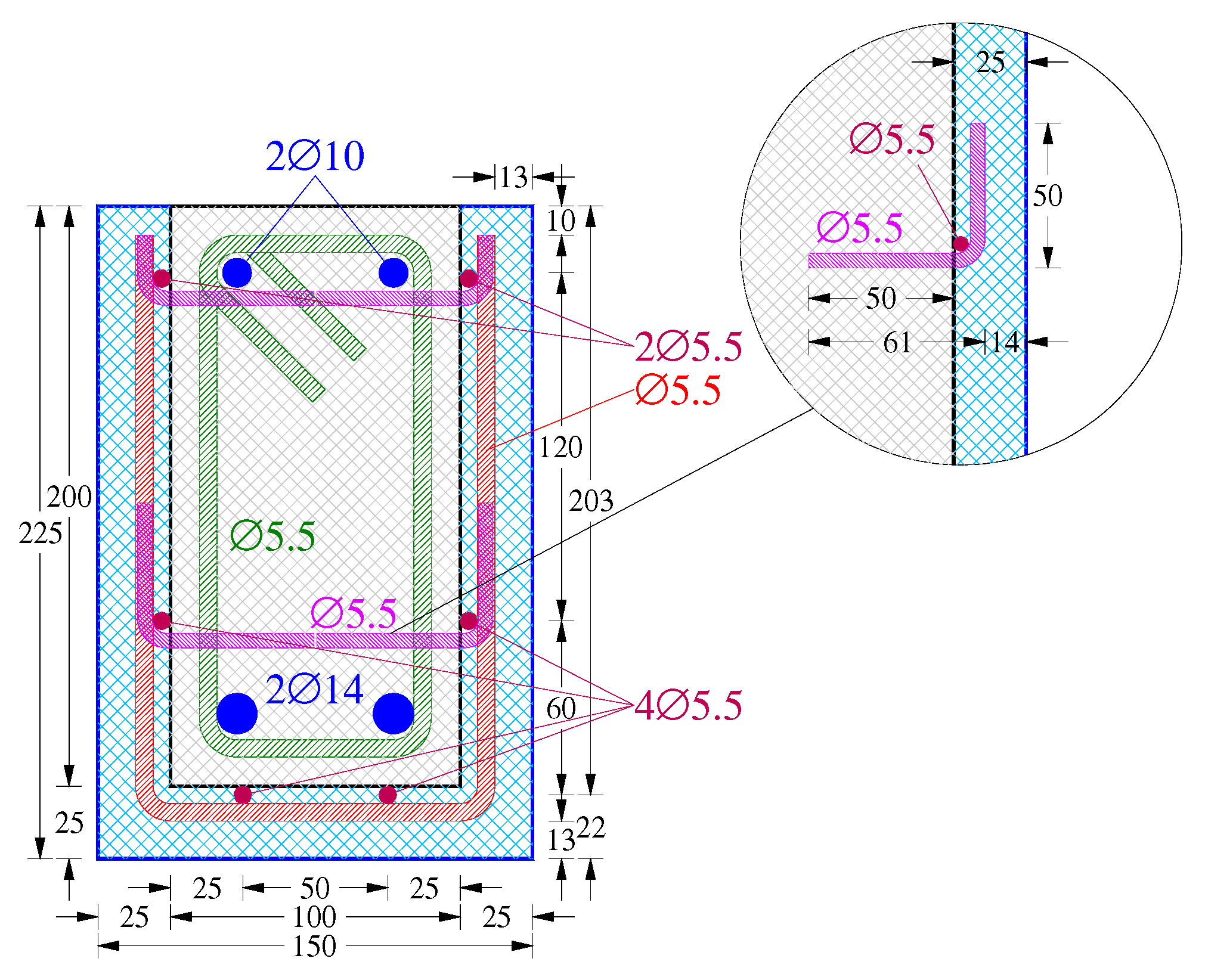

3. Experimental Testing of the Retrofitted Beams

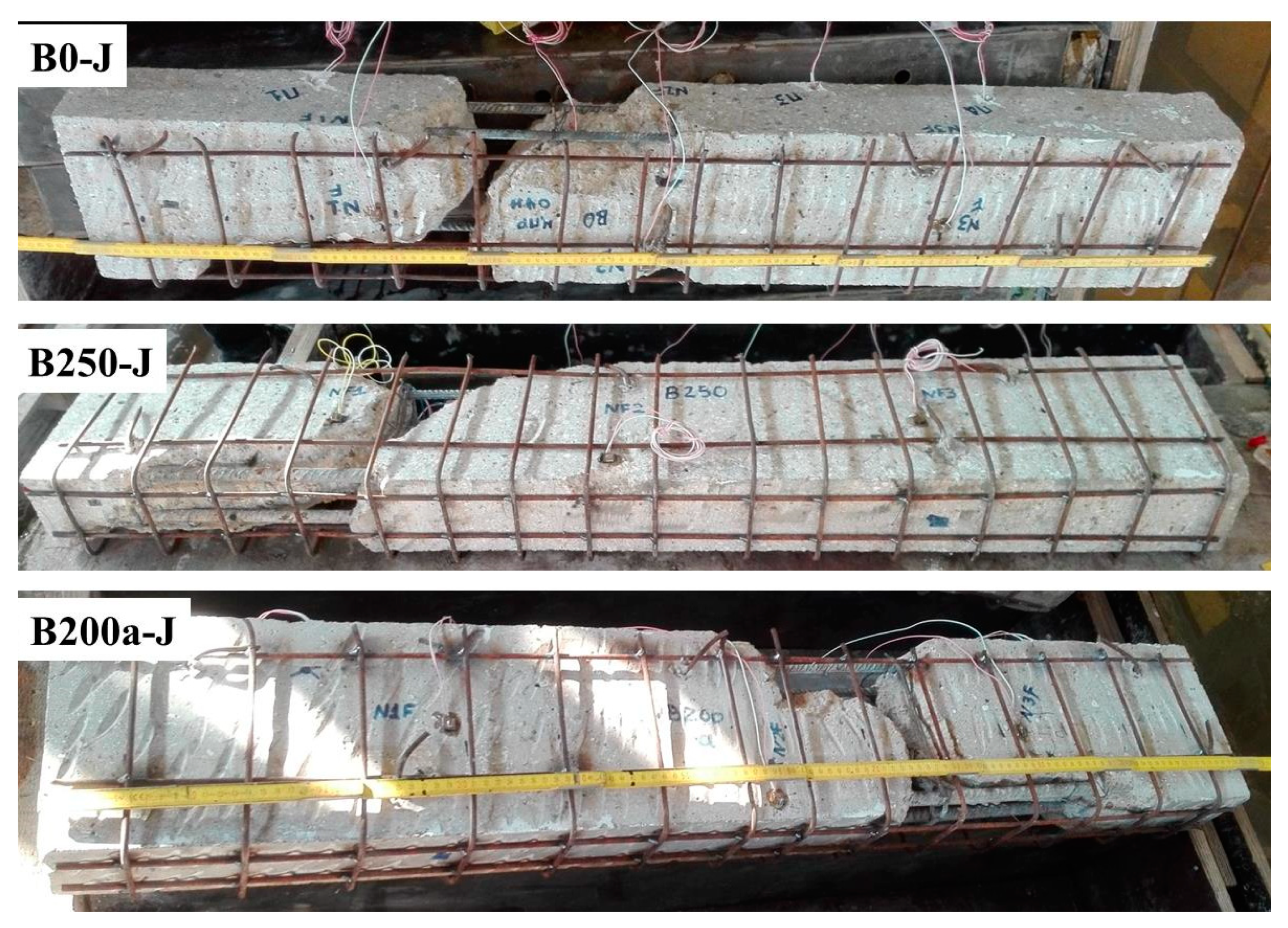

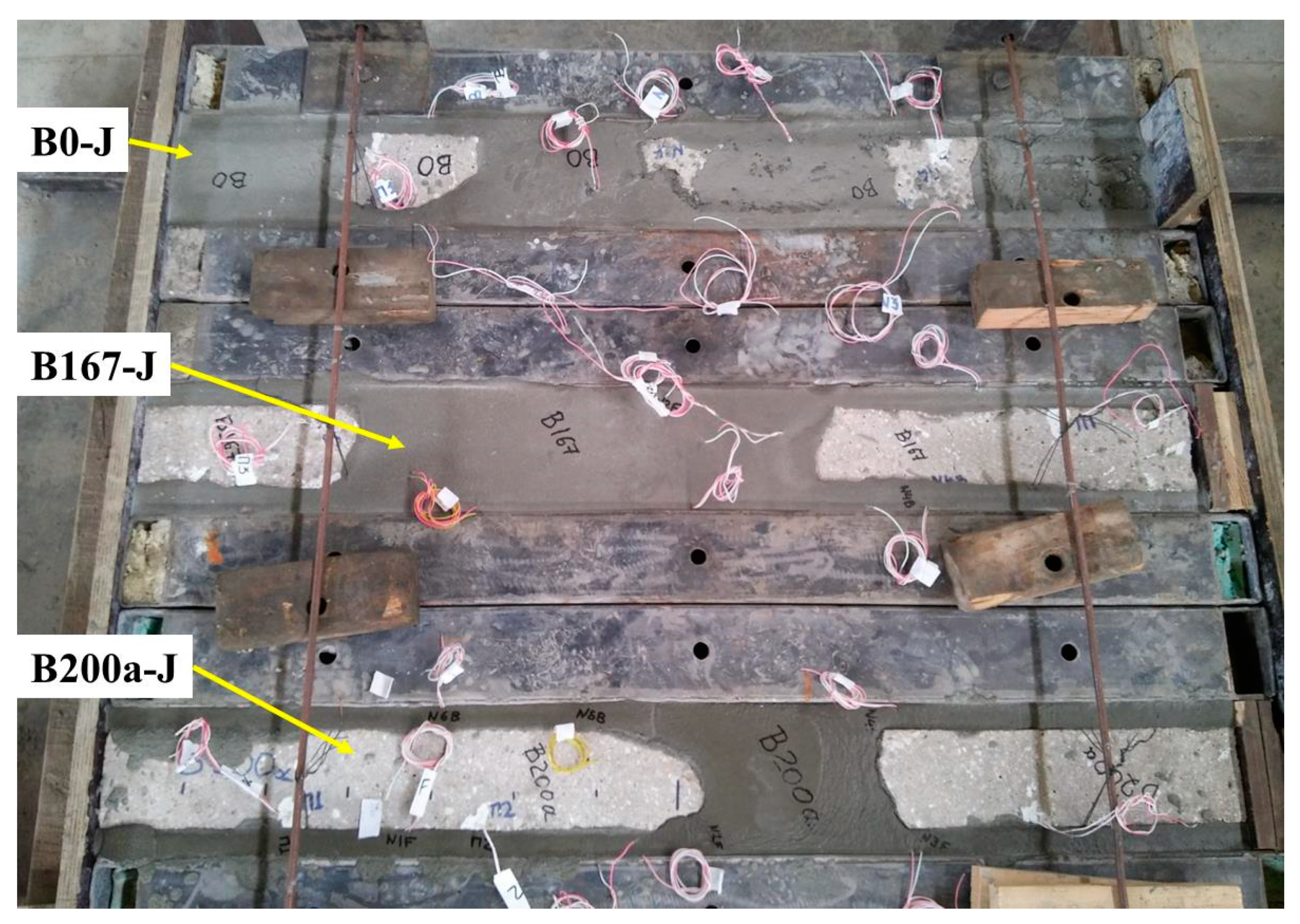

- Surface preparation: (a) Removal of the damaged concrete fragments using a chisel and hammer; (b) cleaning and roughening the concrete surface using a grinder and a small electric concrete breaker, respectively; and (c) abrasive sandblasting to remove debris, dislodge unsound concrete parts, and impart a clean, adequately rough and profiled surface. Thus, the final substrate concrete was not too smooth, too rough, nor too irregular, as shown in Figure 6.

- Installation of jacketing reinforcement: (a) Drilling 7 mm holes in the vertical sides of the beams for the installation of the dowels; (b) cleaning dust from the holes using compressed air with a thin and long nozzle; (c) filling the holes with epoxy resin (Sikadur-52) (Sika Hellas ABEE, Kryoneri, Greece) using a resin gun; (d) mild steel L-shaped ∅5.5 dowels (see dimensions in Figure 5) were inserted inside the drilled holes and resin flowed out to ensure successful anchoring, whereas their free lengths were carefully placed to support the longitudinal reinforcing bars of the jacket; (e) epoxy-bonded dowels and bars remained still until resin had fully hardened; and (f) installation of the U-shaped open stirrups by welding in the longitudinal bars to be held in place.

- Casting the cementitious mortar of the jacket: (a) Saturation of the existing concrete surface after cleaning; (b) priming the substrate concrete with a 2 mm thick slush coat of the same jacketing mortar; (c) placing beams into the formwork; and (d) casting-in-place the U-shaped jackets of the beams using the flowable cement-based mortar grout matrix (SikaGrout-212) (Sika Hellas ABEE, Kryoneri, Greece), as shown in Figure 7. The mean compressive and flexural strengths of the cement-based mortar of the jackets were 41.3 MPa and 7.80 MPa, respectively.

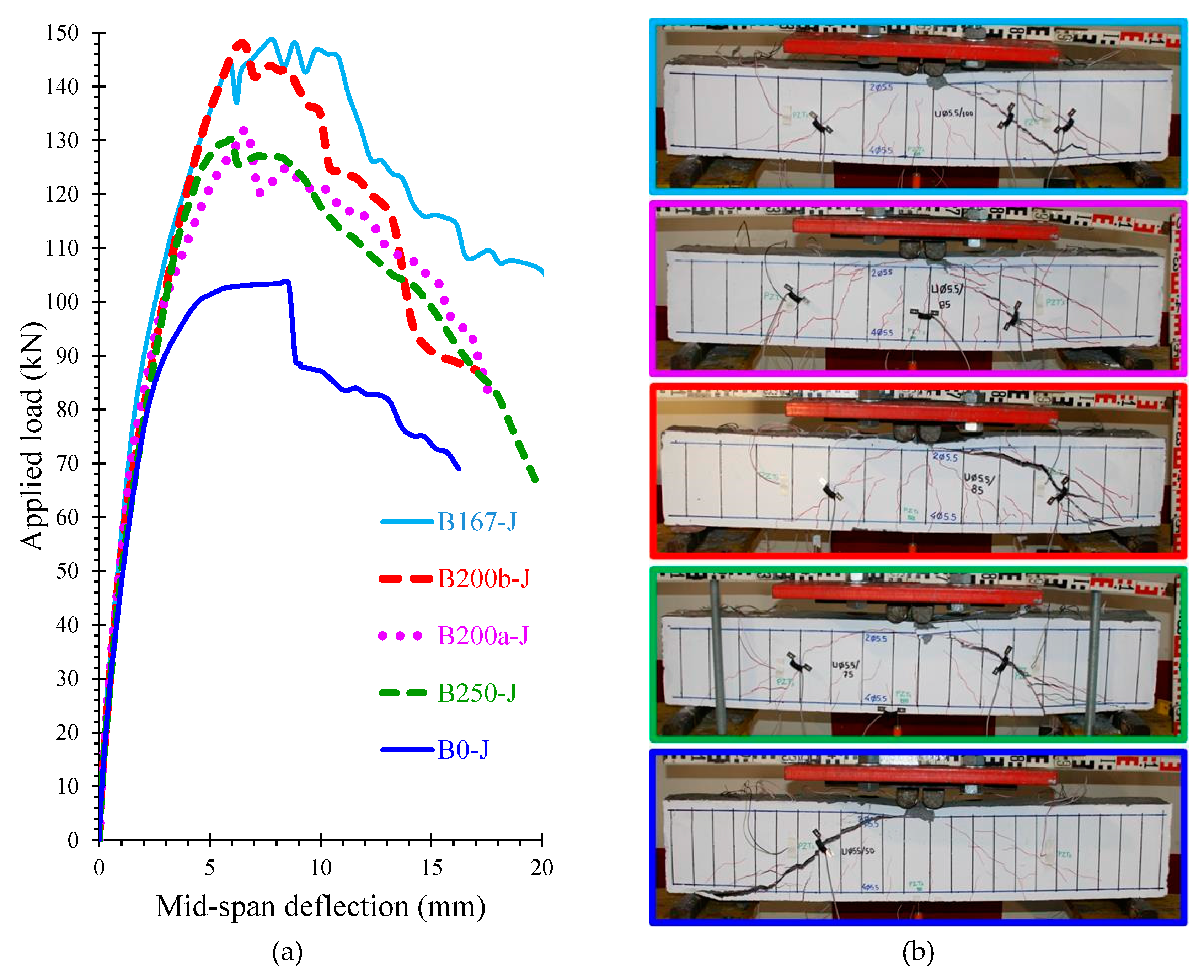

4. Comparisons and Discussion of Test Results

- Applied load, PFLC, and corresponding average shear stress, vFLC, for the formation of the first flexural crack.

- Applied load, PODC, and corresponding average shear stress, vODC, at the onset of diagonal cracking (formation of the first shear inclined crack).

- Ultimate applied load, Pu, and corresponding ultimate average shear stress, vu (shear strength).

- Based on the values of vu, the percentage increase of the shear strength attained in the jacketed beams with respect to the shear strength of the corresponding initially tested beams is also presented in Table 3 as “Shear strength increase”.

- Maximum acceptable deflection of the beam, δ85%Pu, that corresponds to average shear stress versus deflection point of 85% of the ultimate shear strength that is assumed as the end of the reliable post-peak response range.

- Based on the values of δ85%Pu, the ratio of the increased maximum acceptable deflection attained in the jacketed beams to the maximum acceptable deflection of the corresponding initially tested beams is also presented in Table 3 as “Deflection increase ratio”.

5. Comparisons with Test Data from the Literature

6. Concluding Remarks

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Karayannis, C.G.; Favvata, M.J.; Kakaletsis, D.J. Seismic behaviour of infilled and pilotis RC frame structures with beam–column joint degradation effect. Eng. Struct. 2011, 33, 2821–2831. [Google Scholar] [CrossRef]

- Repapis, C.C. Seismic performance evaluation of existing RC buildings without seismic details. Comparison of nonlinear static methods and IDA. Open Constr. Build. Technol. J. 2016, 10, 158–179. [Google Scholar] [CrossRef][Green Version]

- Lampropoulos, A.P.; Tsioulou, O.T.; Dritsos, S.E. Monolithic coefficient values for design when seismically strengthening RC columns with jackets. J. Earthq. Eng. 2012, 16, 1023–1042. [Google Scholar] [CrossRef][Green Version]

- Rousakis, T.C.; Karabinis, A.I. Substandard reinforced concrete members subjected to compression: FRP confining effects. Mater. Struct. 2008, 41, 1595. [Google Scholar] [CrossRef]

- Gudonis, E.; Timinskas, E.; Gribniak, V.; Kaklauskas, G.; Arnautov, A.K.; Tamulėnas, V. FRP reinforcement for concrete structures: State-of-the-art review of application and design. Eng. Struct. Technol. 2013, 5, 147–158. [Google Scholar] [CrossRef]

- Rodrigues, H.; Pradhan, P.M.; Furtado, A.; Rocha, P.; Vila-Pouca, N. Structural repair and strengthening of RC elements with concrete jacketing. In Strengthening and Retrofitting of Existing Structures; Costa, A., Arêde, A., Varum, H., Eds.; Springer: Singapore, 2018; Volume 9, pp. 181–198. [Google Scholar]

- Ma, C.K.; Apandi, N.M.; Yung, S.C.S.; Hau, N.J.; Haur, L.W.; Awang, A.Z.; Omar, W. Repair and rehabilitation of concrete structures using confinement: A review. Constr. Build. Mater. 2017, 133, 502–515. [Google Scholar] [CrossRef]

- Lampropoulos, A.P.; Dritsos, S.E. Modeling of RC columns strengthened with RC jackets. Earthq. Eng. Struct. Dyn. 2011, 40, 1689–1705. [Google Scholar] [CrossRef]

- Alhadid, M.M.A.; Youssef, M.A. Analysis of reinforced concrete beams strengthened using concrete jackets. Eng. Struct. 2017, 132, 172–187. [Google Scholar] [CrossRef]

- Fukuyama, K.; Higashibata, Y.; Miyauchi, Y. Studies on repair and strengthening methods of damaged reinforced concrete columns. Cem. Concr. Compos. 2000, 22, 81–88. [Google Scholar] [CrossRef]

- Bousias, S.N.; Biskinis, D.; Fardis, M.N.; Spathis, A.-L. Strength, stiffness, and cyclic deformation capacity of concrete jacketed members. ACI Struct. 2007, 104, 521–531. [Google Scholar]

- Kalogeropoulos, G.I.; Tsonos, A.-D.G. Effectiveness of R/C jacketing of substandard R/C columns with short lap splices. Struct. Monit. Maint. 2014, 1, 273. [Google Scholar] [CrossRef]

- Kakaletsis, D.J.; David, K.N.; Karayannis, C.G. Effectiveness of some conventional seismic retrofitting techniques for bare and infilled R/C frames. Struct. Eng. Mech. 2011, 39, 499–520. [Google Scholar] [CrossRef]

- Tsonos, A.-D.G.; Rentzeperis, I.P. Investigation of the effectiveness of two styles of R/C jackets in pre-earthquake retrofitting of columns and b/c joints of R/C structures. WIT Trans. Built Environ. 2005, 81. [Google Scholar] [CrossRef]

- Al-Salloum, Y.A.; Almusallam, T.H.; Alsayed, S.H.; Mosallam, A.S. Traditional and modern techniques for retrofitting of RC beam-column joints. In Proceedings of the Energy Efficient and Environmentally Compatible Civil Infrastructure Systems, 5th International Engineering and Construction Conference, Irvine, CA, USA, 27–29 August 2008. [Google Scholar]

- Altun, F. An experimental study of the jacketed reinforced-concrete beams under bending. Constr. Build. Mater. 2004, 18, 611–618. [Google Scholar] [CrossRef]

- Liu, X.; Lu, Z.-D.; Li, L.-Z. The use of bolted side plates for shear strengthening of RC beams: A review. Sustainability 2018, 10, 4658. [Google Scholar] [CrossRef]

- Demir, A.; Ercan, E.; Demir, D.D. Strengthening of reinforced concrete beams using external steel members. Steel Compos. Struct. 2018, 27, 453–464. [Google Scholar]

- Christidis, K.I.; Vougioukas, E.; Trezos, K.G. Strengthening of non-conforming RC shear walls using different steel configurations. Eng. Struct. 2016, 124, 258–268. [Google Scholar] [CrossRef]

- Karayannis, C.G.; Sirkelis, G.M. Strengthening and rehabilitation of RC beam-column joints using carbon-FRP jacketing and epoxy resin injection. Earthq. Eng. Struct. Dyn. 2008, 37, 769–790. [Google Scholar] [CrossRef]

- Chalioris, C.E.; Kosmidou, P.-M.K.; Papadopoulos, N.A. Investigation of a new strengthening technique for RC deep beams using carbon FRP ropes as transverse reinforcements. Fibers 2018, 6, 52. [Google Scholar] [CrossRef]

- Mosallam, A.S.; Mosalam, K.M. Strengthening of two-way concrete slabs with FRP composite laminates. Constr. Build. Mater. 2003, 17, 43–54. [Google Scholar] [CrossRef]

- Tsonos, A.-D.G. Effectiveness of CFRP jackets in post-earthquake and pre-earthquake retrofitting of beam-column subassemblages. Struct. Eng. Mech. 2007, 27, 393–408. [Google Scholar] [CrossRef]

- Gribniak, V.; Arnautov, A.K.; Kaklauskas, G.; Jakstaite, R.; Tamulėnas, V.; Gudonis, E. Deformation analysis of RC ties externally strengthened with FRP sheets. Mech. Compos. Mater. 2014, 50, 669–676. [Google Scholar] [CrossRef]

- Nguyen-Minh, L.; Rovnak, M. Size effect in uncracked and pre-cracked reinforced concrete beams shear-strengthened with composite jackets. Compos. B Eng. 2015, 78, 361–376. [Google Scholar] [CrossRef]

- Triantafillou, T.C.; Papanicolaou, C.G. Shear strengthening of reinforced concrete members with textile reinforced mortar (TRM) jackets. Mater. Struct. 2006, 39, 93–103. [Google Scholar] [CrossRef]

- Gopinath, S.; Murthy, A.R.; Iyer, N.R.; Dharinee, R. Investigations on textile-reinforced concrete as cover for RC beams. Mag. Concr. Res. 2016, 68, 1040–1050. [Google Scholar] [CrossRef]

- Jabr, A.; El-Ragaby, A.; Ghrib, F. Effect of the fiber type and axial stiffness of FRCM on the flexural strengthening of RC beams. Fibers 2017, 5, 2. [Google Scholar] [CrossRef]

- Contamine, R.; Larbi, A.S.; Hamelin, P. Identifying the contributing mechanisms of textile reinforced concrete (TRC) in the case of shear repairing damaged and reinforced concrete beams. Eng. Struct. 2013, 46, 447–458. [Google Scholar] [CrossRef]

- Rius, J.M.; Cladera, A.; Ribas, C.; Mas, B. Shear strengthening of reinforced concrete beams using shape memory alloys. Constr. Build. Mater. 2019, 200, 420–435. [Google Scholar] [CrossRef]

- Mas, B.; Cladera, A.; Ribas, C. Experimental study on concrete beams reinforced with pseudoelastic Ni-Ti continuous rectangular spiral reinforcement failing in shear. Eng. Struct. 2016, 127, 759–768. [Google Scholar] [CrossRef]

- Mas, B.; Biggs, D.; Vieito, I.; Cladera, A.; Shaw, J.; Martínez-Abella, F. Superelastic shape memory alloy cables for reinforced concrete applications. Constr. Build. Mater. 2017, 148, 307–320. [Google Scholar] [CrossRef]

- Soman, M.; Mohan, J. Rehabilitation of RC columns using ferrocement jacketing. Constr. Build. Mater. 2018, 181, 156–162. [Google Scholar] [CrossRef]

- Behera, G.C.; Rao, T.D.G.; Rao, C.B.K. Torsional behaviour of reinforced concrete beams with ferrocement U-jacketing—Experimental study. Case Stud. Constr. Mater. 2016, 4, 15–31. [Google Scholar] [CrossRef]

- Bansal, P.P.; Kumar, M.; Kaushik, S.K. Effect of wire mesh orientation on strength of beams retrofitted using Ferrocement jackets. Int. J. Eng. 2008, 2, 8–19. [Google Scholar]

- Li, B.; Lam, E.S.S.; Wu, B.; Wang, Y.Y. Experimental investigation on reinforced concrete interior beam–column joints rehabilitated by ferrocement jackets. Eng. Struct. 2013, 56, 897–909. [Google Scholar] [CrossRef]

- Martinola, G.; Meda, A.; Plizzari, G.A.; Rinaldi, Z. Strengthening and repair of RC beams with fiber reinforced concrete. Cem. Concr. Compos. 2010, 32, 731–739. [Google Scholar] [CrossRef]

- Achillopoulou, V.D.; Karabinis, A.I. Assessment of concrete columns repaired with fiber reinforced mortar through damage indexes and numerical model. Constr. Build. Mater. 2015, 81, 248–256. [Google Scholar] [CrossRef]

- Tsonos, A.-D.G. Steel fiber high-strength reinforced concrete: A new solution for earthquake strengthening of old R/C structures. WIT Trans. Built Environ. 2009, 104, 153–164. [Google Scholar]

- Katakalos, K.; Manos, G.; Papakonstantinou, C. Seismic retrofit of R/C T-beams with steel fiber polymers under cyclic loading conditions. Buildings 2019, 9, 101. [Google Scholar] [CrossRef]

- Al-Osta, M.A. Exploitation of ultrahigh-performance fibre-reinforced concrete for the strengthening of concrete structural members. Adv. Civ. Eng. 2018, 2018, 8678124. [Google Scholar] [CrossRef]

- Tsonos, A.-D.G. Ultra-high-performance fiber reinforced concrete: An innovative solution for strengthening old R/C structures and for improving the FRP strengthening method. WIT Trans. Eng. Sci. 2009, 64, 273–284. [Google Scholar]

- Mohammed, T.J.; Bakar, B.H.A.; Bunnori, N.M. Torsional improvement of reinforced concrete beams using ultra high-performance fiber reinforced concrete (UHPFC) jackets—Experimental study. Constr. Build. Mater. 2016, 106, 533–542. [Google Scholar] [CrossRef]

- Bahraq, A.A.; Al-Osta, M.A.; Ahmad, S.; Al-Zahrani, M.M.; Al-Dulaijan, S.O.; Rahman, M.K. Experimental and numerical investigation of shear behavior of RC beams strengthened by ultra-high performance concrete. Int. J. Concr. Struct. Mater. 2019, 13, 6. [Google Scholar] [CrossRef]

- Tsonos, A.-D.G.; Kalogeropoulos, G.I.; Iakovidis, P.E.; Konstantinidis, D. Seismic retrofitting of pre-1970 RC bridge columns using innovative jackets. Int. J. Struct. Eng. 2017, 8, 133–147. [Google Scholar] [CrossRef]

- Murthy, A.R.; Karihaloo, B.L.; Priya, D.S. Flexural behavior of RC beams retrofitted with ultra-high strength concrete. Constr. Build. Mater. 2018, 175, 815–824. [Google Scholar] [CrossRef]

- Khosravani, M.R.; Weinberg, K. A review on split Hopkinson bar experiments on the dynamic characterisation of concrete. Constr. Build. Mater. 2018, 190, 1264–1283. [Google Scholar] [CrossRef]

- Hou, L.; Wang, J.; Huang, T.; Shen, C.; Aslani, F.; Chen, D. Flexural behaviour of corroded reinforced concrete beams repaired with ultra-high toughness cementitious composite. Constr. Build. Mater. 2019, 211, 1127–1137. [Google Scholar] [CrossRef]

- Zhang, X.; Luo, Y.; Wang, L.; Zhang, J.; Wu, W.; Yang, C. Flexural strengthening of damaged RC T-beams using self-compacting concrete jacketing under different sustaining load. Constr. Build. Mater. 2018, 172, 185–195. [Google Scholar] [CrossRef]

- Tsakiris, S.A.; Rousakis, T.C.; Karabinis, A.I. Confinement effects and strain transfer in reinforced concrete jackets of different detailing for the strengthening of old-type concrete columns. In Proceedings of the 15th World Conference on Earthquake Engineering, Lisbon, Portugal, 24–28 September 2012. [Google Scholar]

- Dubey, R.; Kumar, P. Experimental study of the effectiveness of retrofitting RC cylindrical columns using self-compacting concrete jackets. Constr. Build. Mater. 2016, 124, 104–117. [Google Scholar] [CrossRef]

- Chalioris, C.E.; Thermou, G.E.; Pantazopoulou, S.J. Behaviour of rehabilitated RC beams with self-compacting concrete jacketing—Analytical model and test results. Constr. Build. Mater. 2014, 55, 257–273. [Google Scholar] [CrossRef]

- Chalioris, C.E.; Pourzitidis, C.N. Rehabilitation of shear-damaged reinforced concrete beams using self-compacting concrete jacketing. ISRN Civ. Eng. 2012, 2012, 816107. [Google Scholar] [CrossRef]

- Chalioris, C.E.; Papadopoulos, C.P.; Pourzitidis, C.N.; Fotis, D.; Sideris, K.K. Application of a reinforced self-compacting concrete jacket in damaged reinforced concrete beams under monotonic and repeated loading. Engineering 2013, 2013, 912983. [Google Scholar] [CrossRef]

- Karayannis, C.G.; Chalioris, C.E.; Sirkelis, G.M. Local retrofit of exterior RC beam-column joints using thin RC jackets—An experimental study. Earth. Eng. Struct. Dyn. 2008, 37, 727–746. [Google Scholar] [CrossRef]

- Georgiadi-Stefanidi, K.; Mistakidis, E.; Perdikaris, P.; Papatheocharis, T. Numerical simulation of tested reinforced concrete beams strengthened by thin fibre-reinforced cementitious matrix jackets. Earth. Struct. 2010, 1, 345–370. [Google Scholar] [CrossRef]

- Achillopoulou, V.D. Investigation of load transfer along interfaces of jacketed square columns. Struct. Eng. Mech. 2017, 63, 293–302. [Google Scholar]

- Achillopoulou, V.D.; Karabinis, I.A. Investigation of shear transfer mechanisms in repaired damaged concrete columns strengthened with RC jackets. Struct. Eng. Mech. 2013, 47, 575–598. [Google Scholar] [CrossRef]

- Achillopoulou, V.D.; Rousakis, T.C.; Karabinis, A.I. Force transfer between existing concrete columns with reinforced concrete jackets subjected to pseudoseismic axial loading. In Proceedings of the 15th World Conference on Earthquake Engineering, Lisbon, Portugal, 24–28 September 2012. [Google Scholar]

- European Committee for Standardization. Eurocode 2: Design of Concrete Structures—Part 1-1: General Rules and Rules for Buildings (EN 1992-1-1); CEN: Brussels, Belgium, 2004. [Google Scholar]

- Júlio, E.N.B.S.; Branco, F.A.B. Reinforced concrete jacketing—Interface influence on cyclic loading response. ACI Struct. 2008, 105, 471–477. [Google Scholar]

- Tsioulou, O.T.; Lampropoulos, A.P.; Dritsos, S.E. Experimental investigation of interface behaviour of RC beams strengthened with concrete layers. Constr. Build. Mater. 2013, 40, 50–59. [Google Scholar] [CrossRef]

| Beam Codified Name | ρl | ρl fyl/fc | ρv | ρv fyv/fc | fc (MPa) | fct,spl (MPa) |

|---|---|---|---|---|---|---|

| B0 | 1.76% | 0.340 | - | - | 28.5 (0.53) | 2.60 (0.26) |

| B250 | 1.76% | 0.325 | 0.19% | 0.014 | 29.8 (1.06) | 2.30 (0.27) |

| B200a | 1.76% | 0.334 | 0.24% | 0.018 | 29.0 (0.98) | 2.32 (0.14) |

| B200b | 1.76% | 0.328 | 0.24% | 0.018 | 29.5 (0.70) | 2.40 (0.20) |

| B167 | 1.76% | 0.346 | 0.28% | 0.023 | 28.0 (0.92) | 2.35 (0.32) |

| Beam Codified Name | Tension Reinforcement: ρl fyl/fc | Shear Reinforcement: ρv fyv/fc | ||||

|---|---|---|---|---|---|---|

| Initial | Jacket | Total | Initial | Jacket | Total | |

| B0-J | 0.195 | 0.025 | 0.220 | - | 0.050 | 0.050 |

| B250-J | 0.187 | 0.024 | 0.211 | 0.009 | 0.032 | 0.041 |

| B200a-J | 0.192 | 0.024 | 0.216 | 0.012 | 0.029 | 0.041 |

| B200b-J | 0.189 | 0.024 | 0.213 | 0.012 | 0.029 | 0.041 |

| B167-J | 0.199 | 0.025 | 0.224 | 0.015 | 0.026 | 0.041 |

| Beam Codified Name | PFLC (kN) | vFLC (MPa) | PODC (kN) | vODC (MPa) | Pu (kN) | vu (MPa) | Shear Strength Increase | δ85%Pu (mm) | Deflection Increase Ratio |

|---|---|---|---|---|---|---|---|---|---|

| B0 | 11.6 | 0.33 | 41.8 | 1.20 | 43.1 | 1.23 | - | 1.51 | - |

| B0-J | 22.8 | 0.37 | 88.0 | 1.44 | 103.5 | 1.70 | 38% | 9.11 | 6.0 |

| B250 | 10.3 | 0.29 | 42.3 | 1.21 | 50.6 | 1.45 | - | 2.30 | - |

| B250-J | 19.7 | 0.32 | 86.0 | 1.41 | 130.0 | 2.13 | 48% | 11.92 | 5.2 |

| B200a | 10.8 | 0.31 | 41.1 | 1.17 | 54.2 | 1.55 | - | 3.23 | - |

| B200a-J | 29.4 | 0.48 | 88.5 | 1.45 | 131.7 | 2.16 | 40% | 12.98 | 4.0 |

| B200b | 11.3 | 0.32 | 42.1 | 1.20 | 58.6 | 1.67 | - | 2.60 | - |

| B200b-J | 26.0 | 0.43 | 95.2 | 1.56 | 147.7 | 2.43 | 45% | 10.40 | 4.0 |

| B167 | 11.8 | 0.34 | 40.8 | 1.17 | 59.7 | 1.71 | - | 10.77 | - |

| B167-J | 25.0 | 0.41 | 82.0 | 1.35 | 148.7 | 2.44 | 43% | 12.28 | 1.1 |

| Beam Codified Name | b/h and bj/hj | a/d and a/dj | ρlfyl/fc | ρv fyv/fc | PFLC (kN) | PODC (kN) | Pu (kN) | Strength Increase Ratio | δ85%Pu (mm) | Deflection Increase Ratio | Failure Mode 1 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Chalioris et al. [52] | |||||||||||

| A2 | 200/300 | 2.18 | 0.234 | 0.000 | 43.7 | 77.8 | 108.0 | - | 2.0 | - | S |

| A2-J | 250/325 | 1.97 | 0.184 | 0.061 | 47.2 | 112.4 | 322.3 | 3.0 | 9.0 | 4.5 | S |

| B2 | 125/200 | 3.43 | 0.093 | 0.009 | 13.7 | 25.8 | 36.4 | - | 18.0 | - | S-F |

| B2-J | 175/225 | 2.93 | 0.076 | 0.020 | 22.3 | 32.3 | 55.2 | 1.5 | 46.6 | 2.6 | S-F |

| B3 | 125/200 | 3.43 | 0.193 | 0.010 | 12.1 | 31.9 | 56.2 | - | 6.0 | - | S |

| B3-J | 175/225 | 2.93 | 0.128 | 0.033 | 23.3 | 35.6 | 84.0 | 1.5 | 100.9 | 16.8 | F |

| B4 | 125/200 | 3.43 | 0.224 | 0.017 | 13.7 | 32.0 | 57.2 | - | 6.0 | - | S |

| B4-J | 175/225 | 2.93 | 0.148 | 0.037 | 19.2 | 35.4 | 79.9 | 1.4 | 104.4 | 17.4 | F |

| B5 | 125/200 | 3.43 | 0.220 | 0.022 | 13.7 | 28.3 | 61.7 | - | 9.0 | - | S |

| B5-J | 175/225 | 2.93 | 0.146 | 0.040 | 23.3 | 32.9 | 83.0 | 1.3 | 103.6 | 11.5 | F |

| Present study | |||||||||||

| B0 | 100/200 | 2.86 | 0.340 | 0.000 | 11.6 | 41.8 | 43.1 | - | 1.51 | - | S |

| B0-J | 150/225 | 2.46 | 0.220 | 0.050 | 22.8 | 88.0 | 103.5 | 2.4 | 9.11 | 6.0 | S |

| B250 | 100/200 | 2.86 | 0.325 | 0.014 | 10.3 | 42.3 | 50.6 | - | 2.30 | - | S |

| B250-J | 150/225 | 2.46 | 0.211 | 0.041 | 19.7 | 86.0 | 130.0 | 2.6 | 11.92 | 5.2 | S |

| B200a | 100/200 | 2.86 | 0.334 | 0.018 | 10.8 | 41.1 | 54.2 | - | 3.23 | - | S |

| B200a-J | 150/225 | 2.46 | 0.216 | 0.041 | 29.4 | 88.5 | 131.7 | 2.4 | 12.98 | 4.0 | S |

| B200b | 100/200 | 2.86 | 0.328 | 0.018 | 11.3 | 42.1 | 58.6 | - | 2.60 | - | S |

| B200b-J | 150/225 | 2.46 | 0.213 | 0.041 | 26.0 | 95.2 | 147.7 | 2.5 | 10.40 | 4.0 | S |

| B167 | 100/200 | 2.86 | 0.346 | 0.023 | 11.8 | 40.8 | 59.7 | - | 10.77 | - | S |

| B167-J | 150/225 | 2.46 | 0.224 | 0.041 | 25.0 | 82.0 | 148.7 | 2.5 | 12.28 | 1.1 | S |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chalioris, C.E.; Kytinou, V.K.; Voutetaki, M.E.; Papadopoulos, N.A. Repair of Heavily Damaged RC Beams Failing in Shear Using U-Shaped Mortar Jackets. Buildings 2019, 9, 146. https://doi.org/10.3390/buildings9060146

Chalioris CE, Kytinou VK, Voutetaki ME, Papadopoulos NA. Repair of Heavily Damaged RC Beams Failing in Shear Using U-Shaped Mortar Jackets. Buildings. 2019; 9(6):146. https://doi.org/10.3390/buildings9060146

Chicago/Turabian StyleChalioris, Constantin E., Violetta K. Kytinou, Maristella E. Voutetaki, and Nikos A. Papadopoulos. 2019. "Repair of Heavily Damaged RC Beams Failing in Shear Using U-Shaped Mortar Jackets" Buildings 9, no. 6: 146. https://doi.org/10.3390/buildings9060146

APA StyleChalioris, C. E., Kytinou, V. K., Voutetaki, M. E., & Papadopoulos, N. A. (2019). Repair of Heavily Damaged RC Beams Failing in Shear Using U-Shaped Mortar Jackets. Buildings, 9(6), 146. https://doi.org/10.3390/buildings9060146