Rheological and Strength Behavior of Binary Blended SCC Replacing Partial Fine Aggregate with Plastic E-Waste as High Impact Polystyrene

Abstract

1. Introduction

2. Experimental Program

2.1. Materials

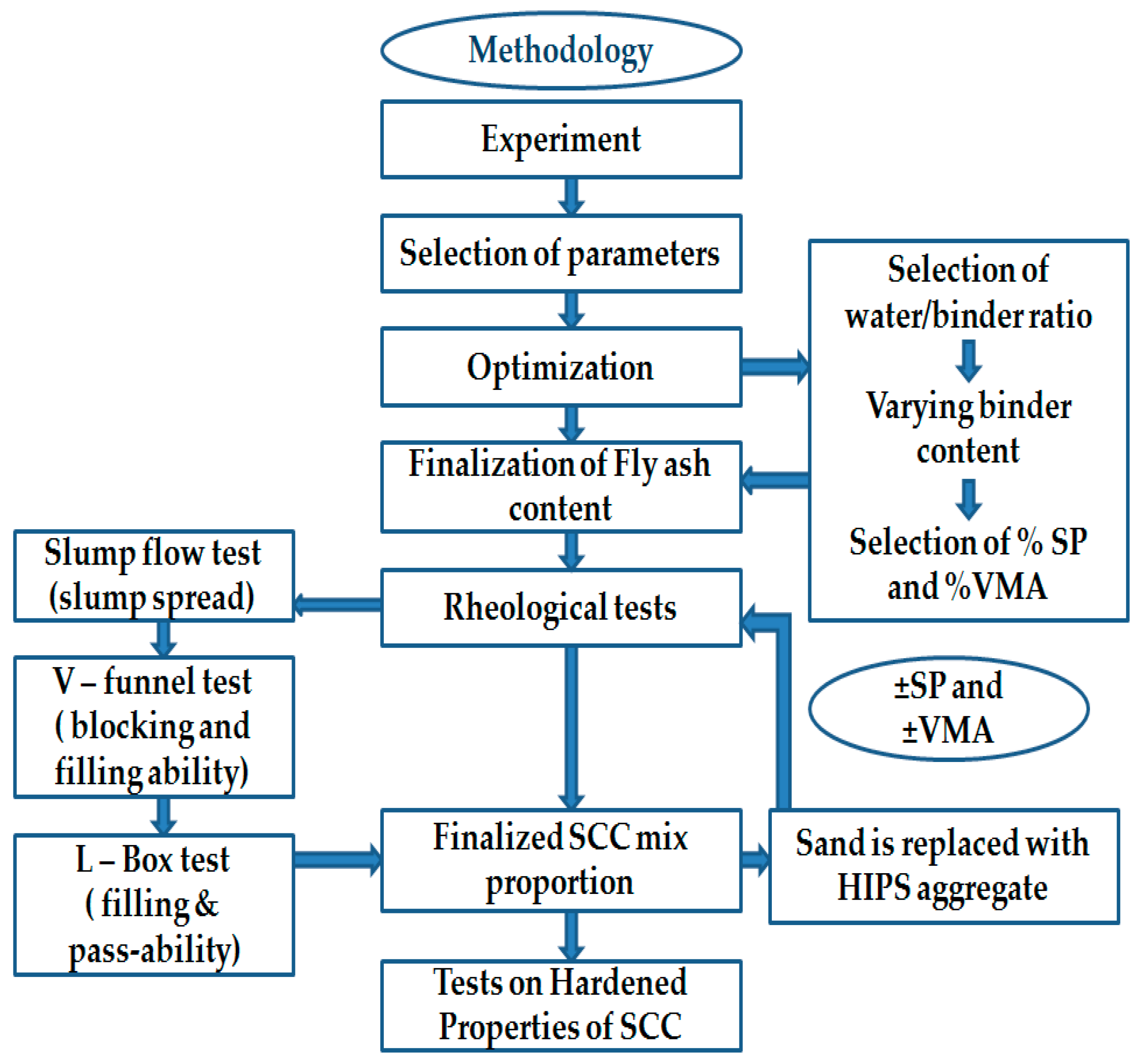

2.2. Methodology

- Air content was assumed as 2% of the concrete volume.

- The dry-rodded unit weight (DRUW) of coarse aggregate for a blend of 12.5 mm and 10 mm particles in 60:40 proportions was determined. The coarse aggregate content was calculated using DRUW.

- Minimum coarse aggregate content of 28% was maintained by the percentage weight of total aggregate. Coarse aggregate can range from 28–34% for SCC mix.

- Fine aggregate volume around 50% of the mortar volume was adopted. Mortar volume ranges from 66–72%.

- The required paste volume in the range of 36–40% can be adopted in the concrete volume. 38% was used in the SCC mix.

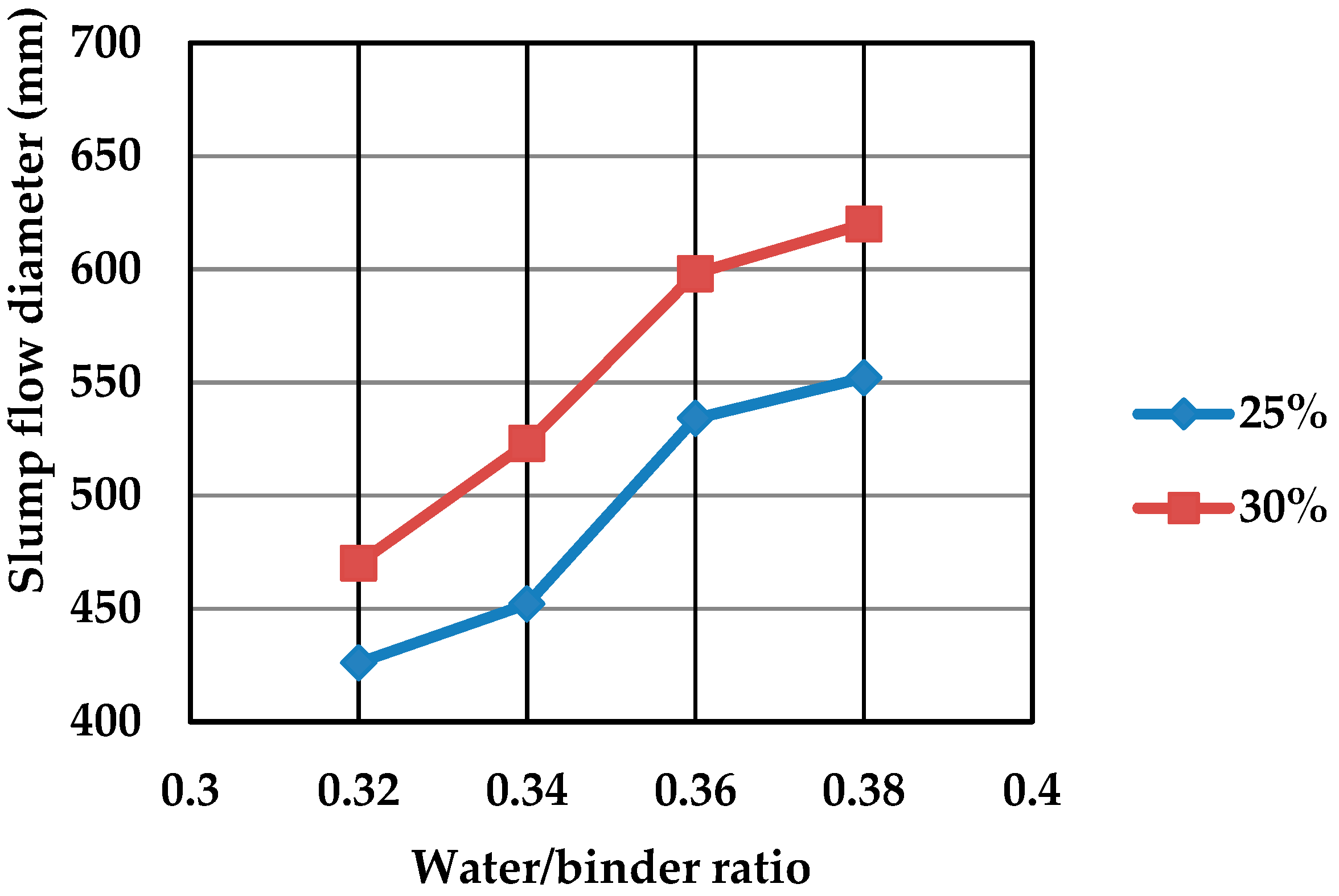

- Water/binder (w/b) ratios were finalized by performing rheological tests. The optimized binder (cementitious material) content was calculated replacing cement with fly ash by weight.

- The dosages of super plasticizer (SP) and viscosity modifying agent were optimized for the obtained w/b ratio for reference mix using Rheological tests.

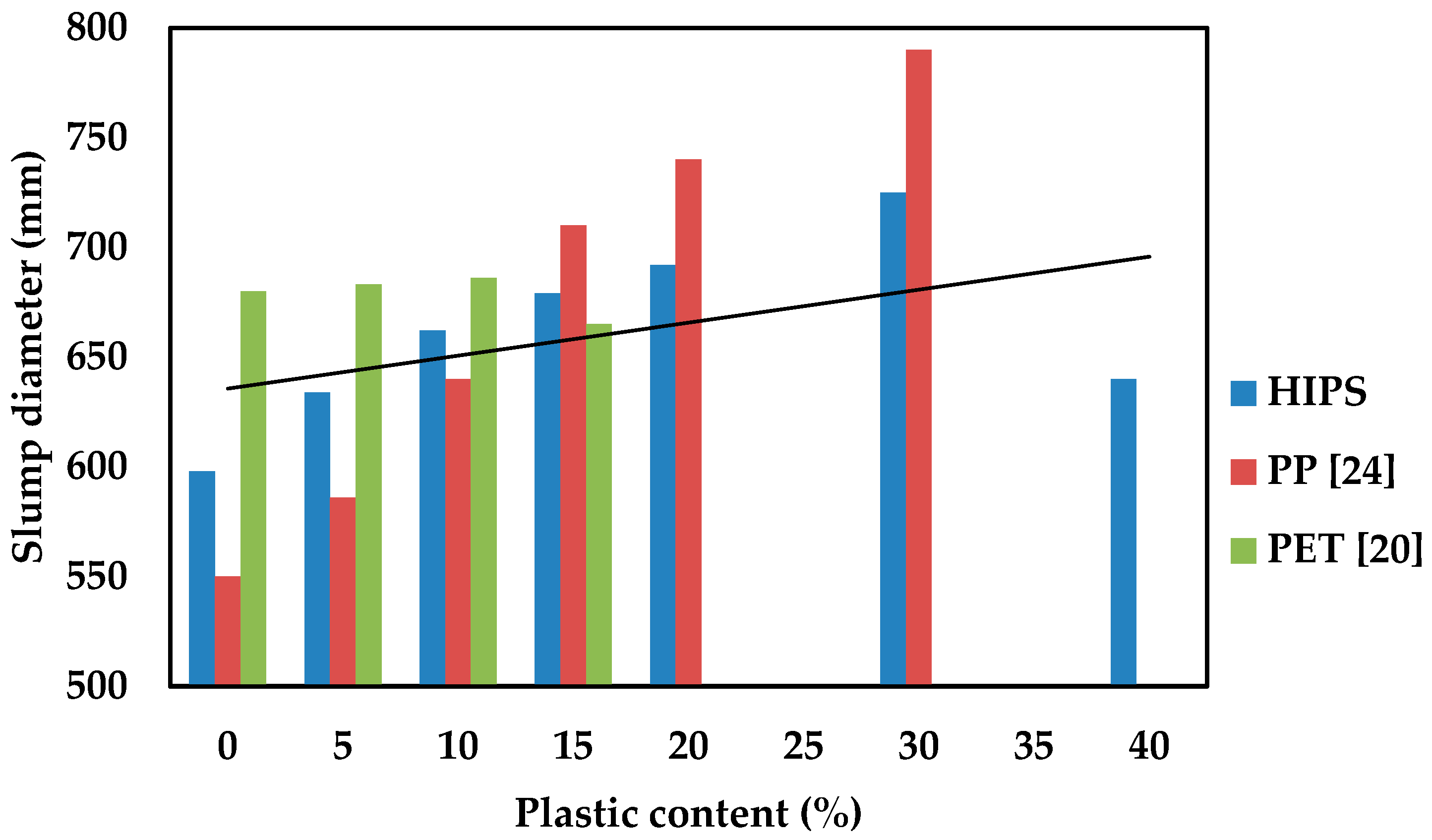

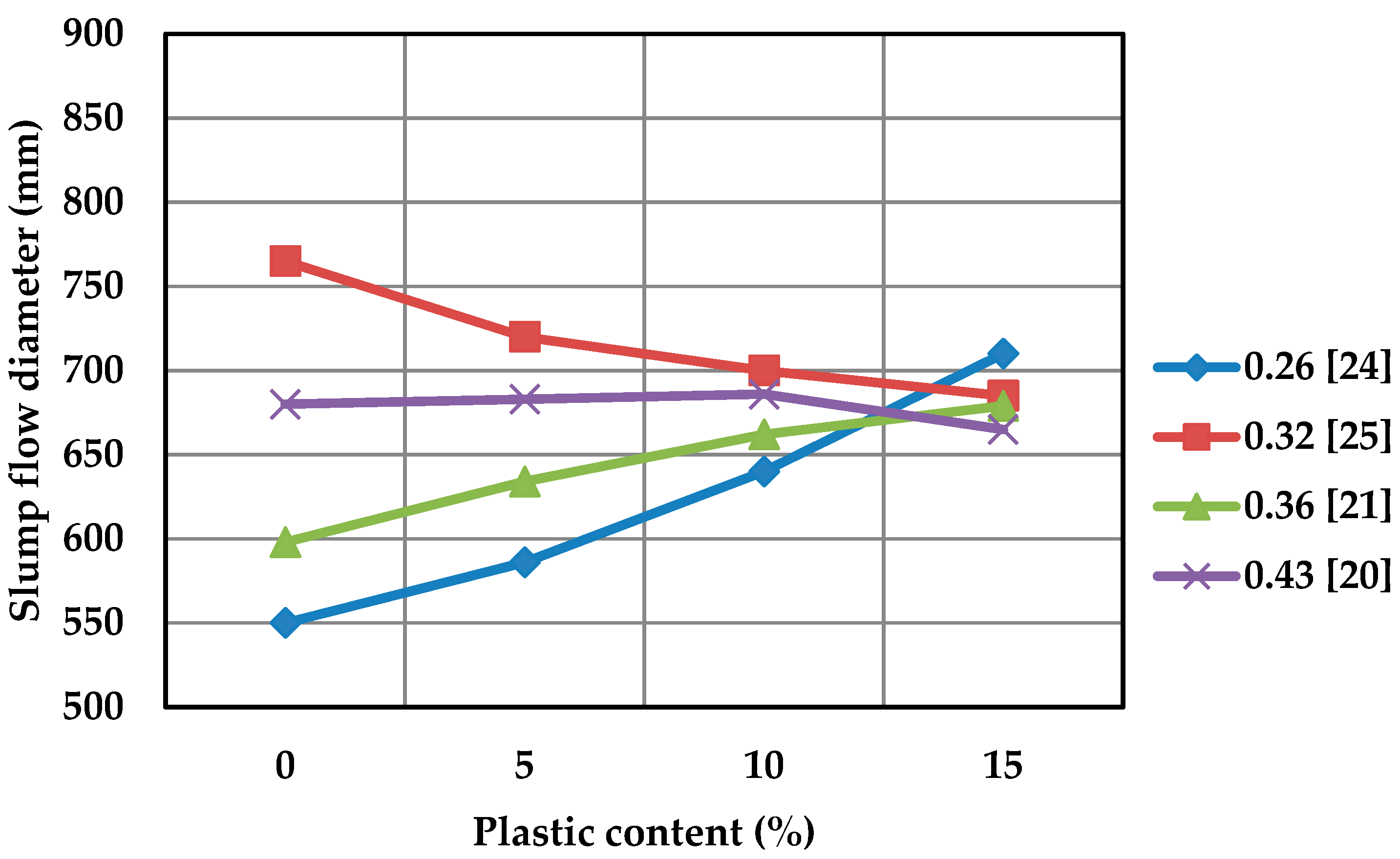

- Sand is replaced with plastic waste HIPS ranging from 10–40% by volume and SP and VMA were finalized for better flow-ability.

- Finally tests on the hardened properties were performed.

2.3. Mix Proportions

2.4. Test Procedures

3. Results and Discussion

3.1. Properties of Fresh SCC

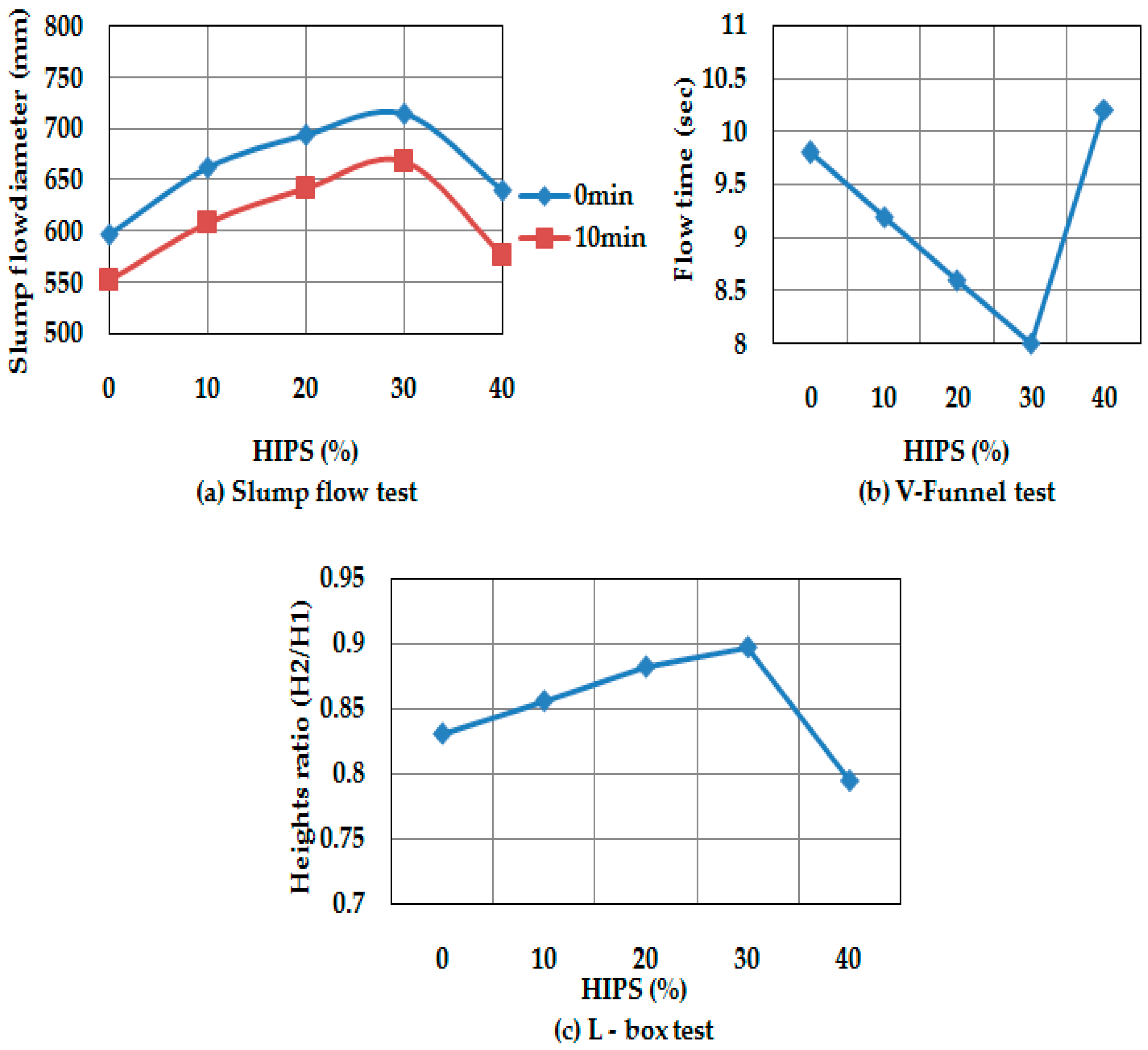

3.1.1. Slump Test Test

3.1.2. Slump Test Test

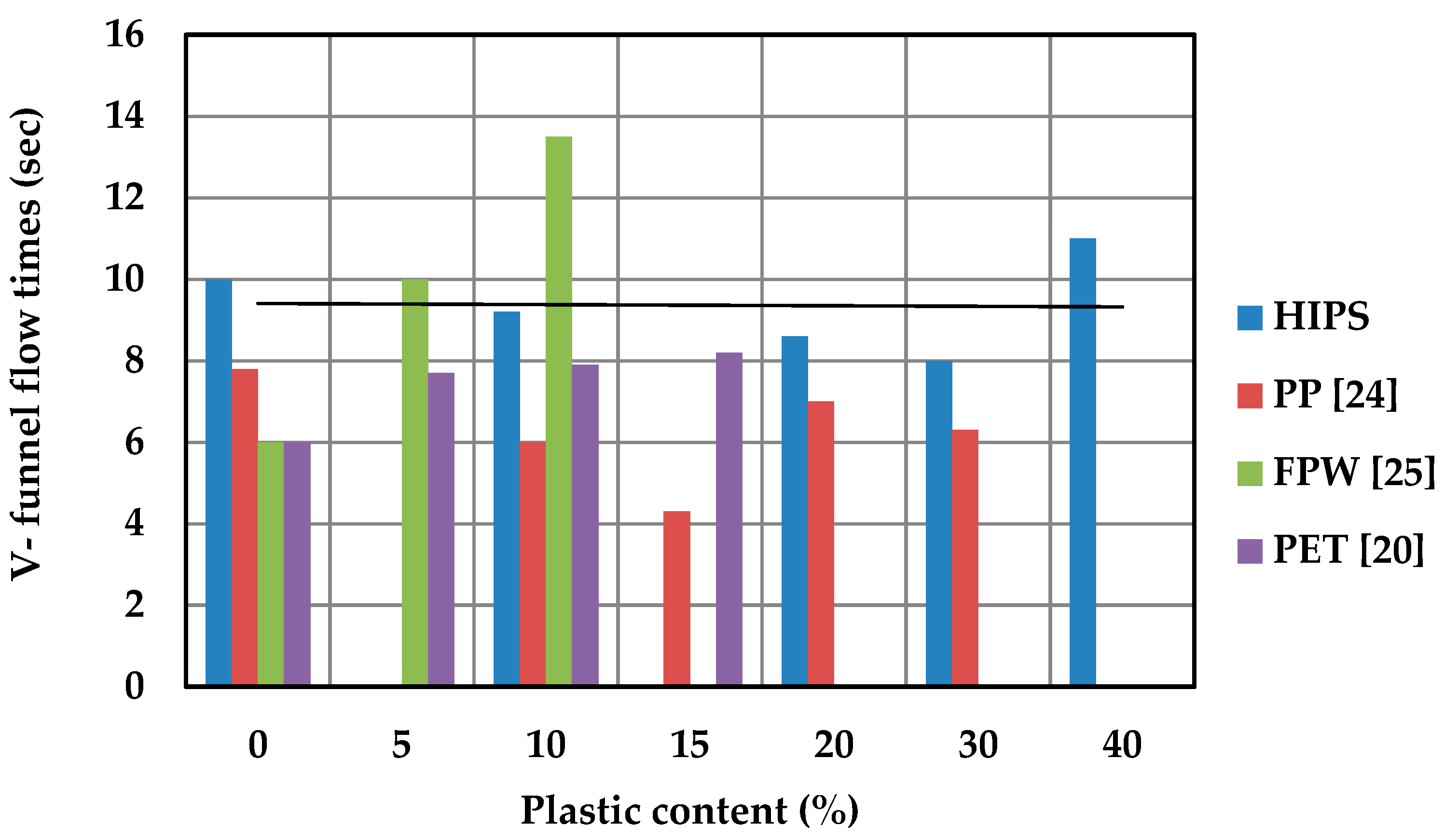

3.1.3. V-Funnel Test

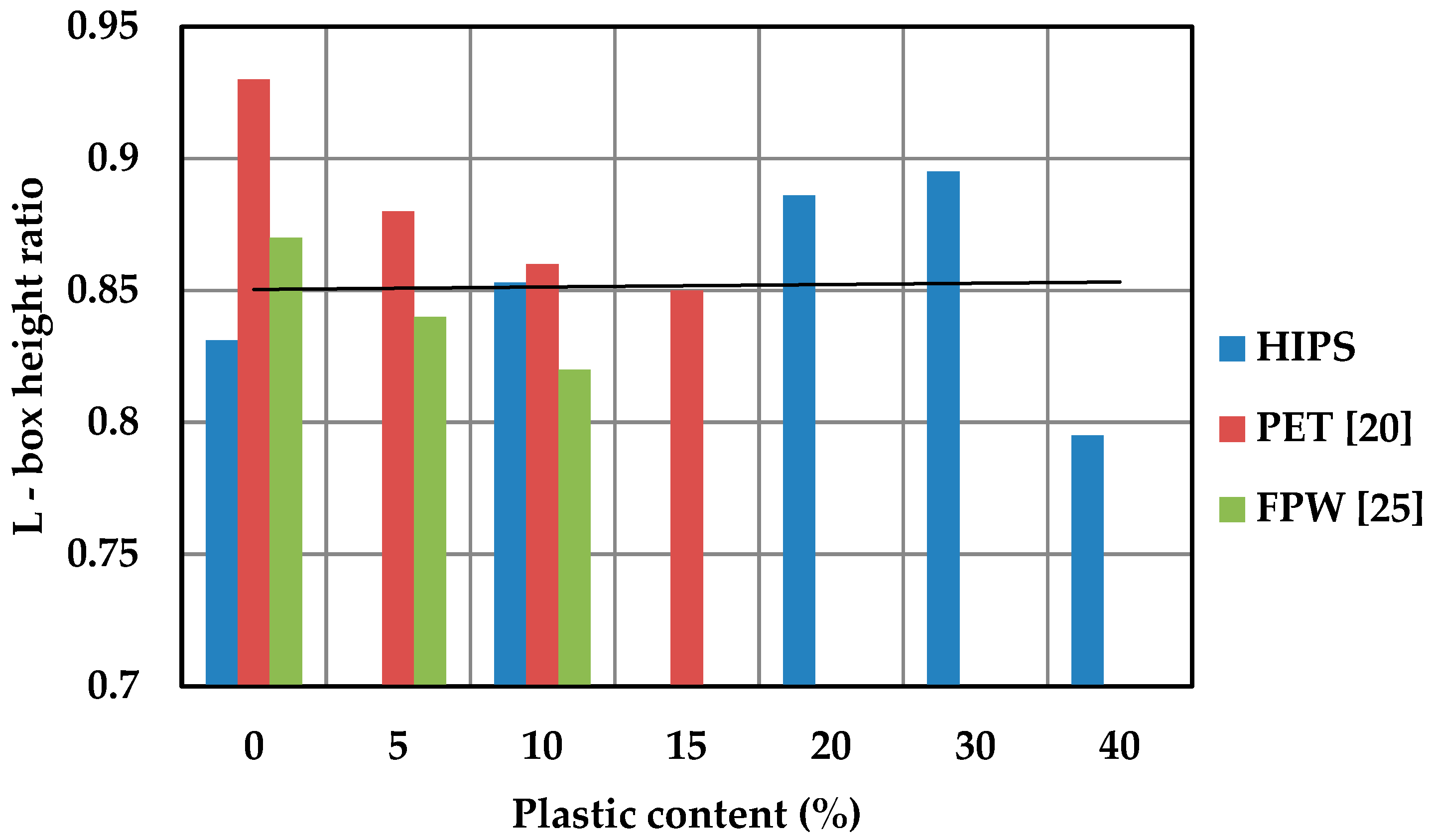

3.1.4. L-Box Test

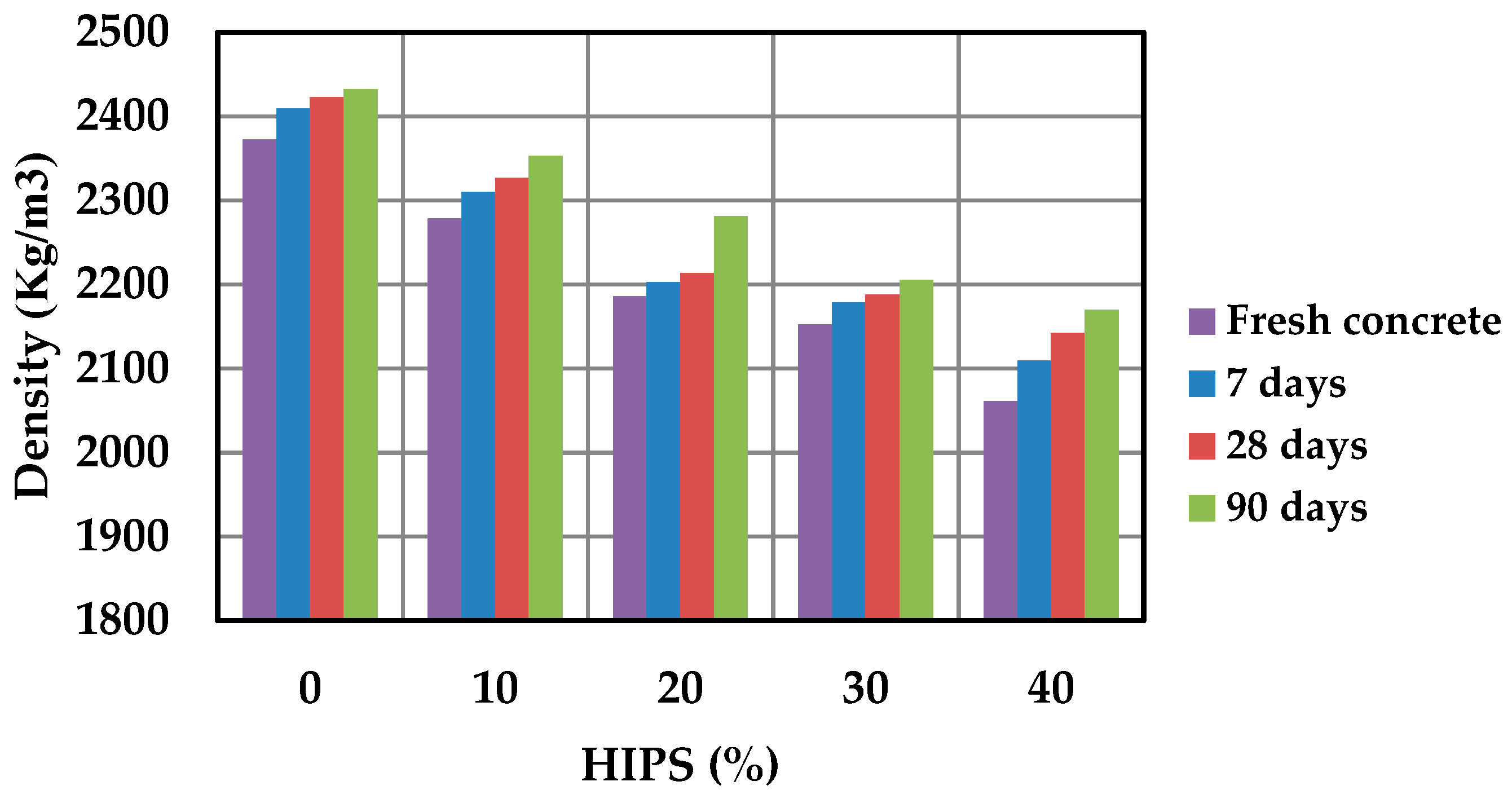

3.1.5. Density

3.1.6. Fresh Density

3.2. Properties of Hardened SCC

3.2.1. Dry Density

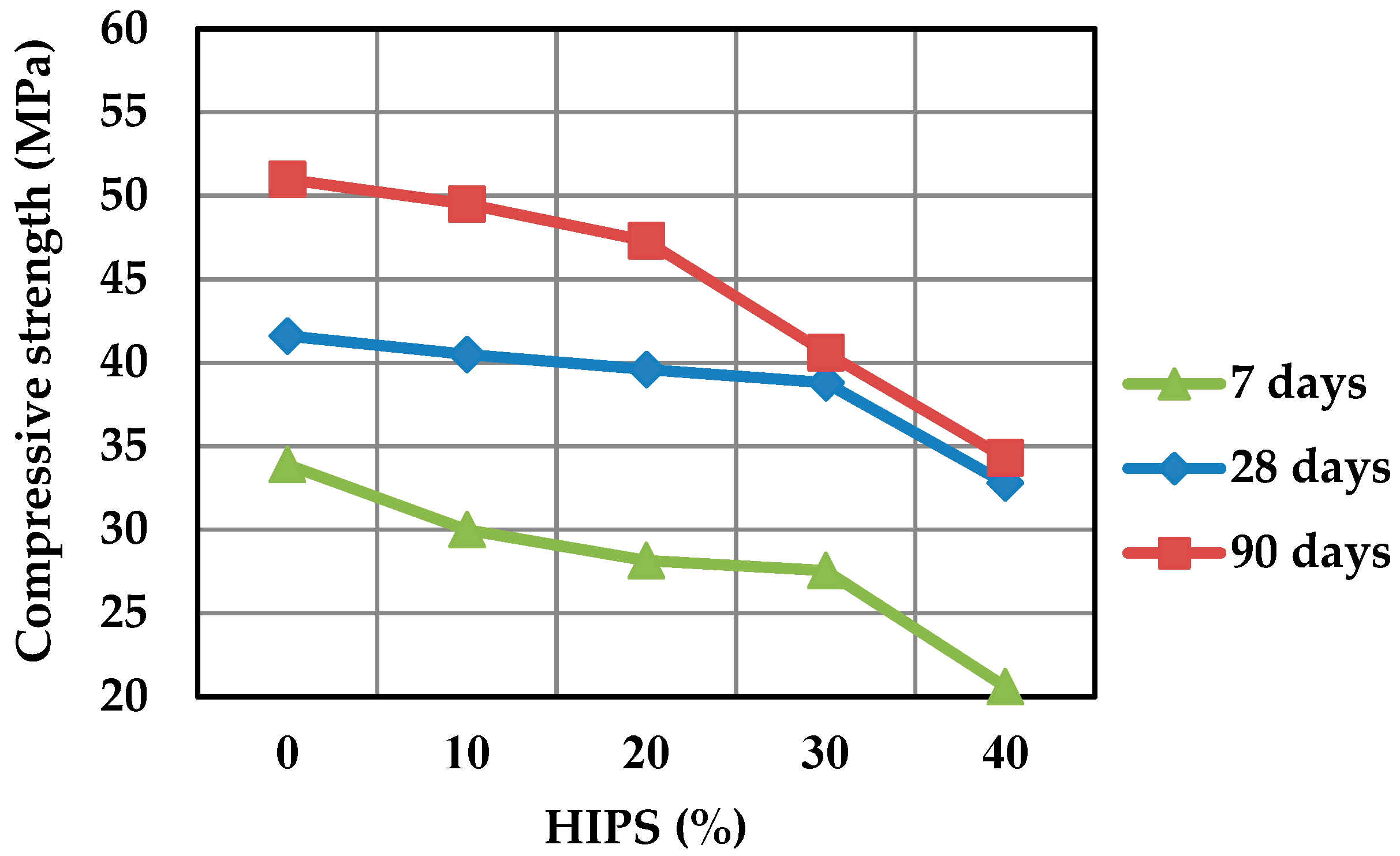

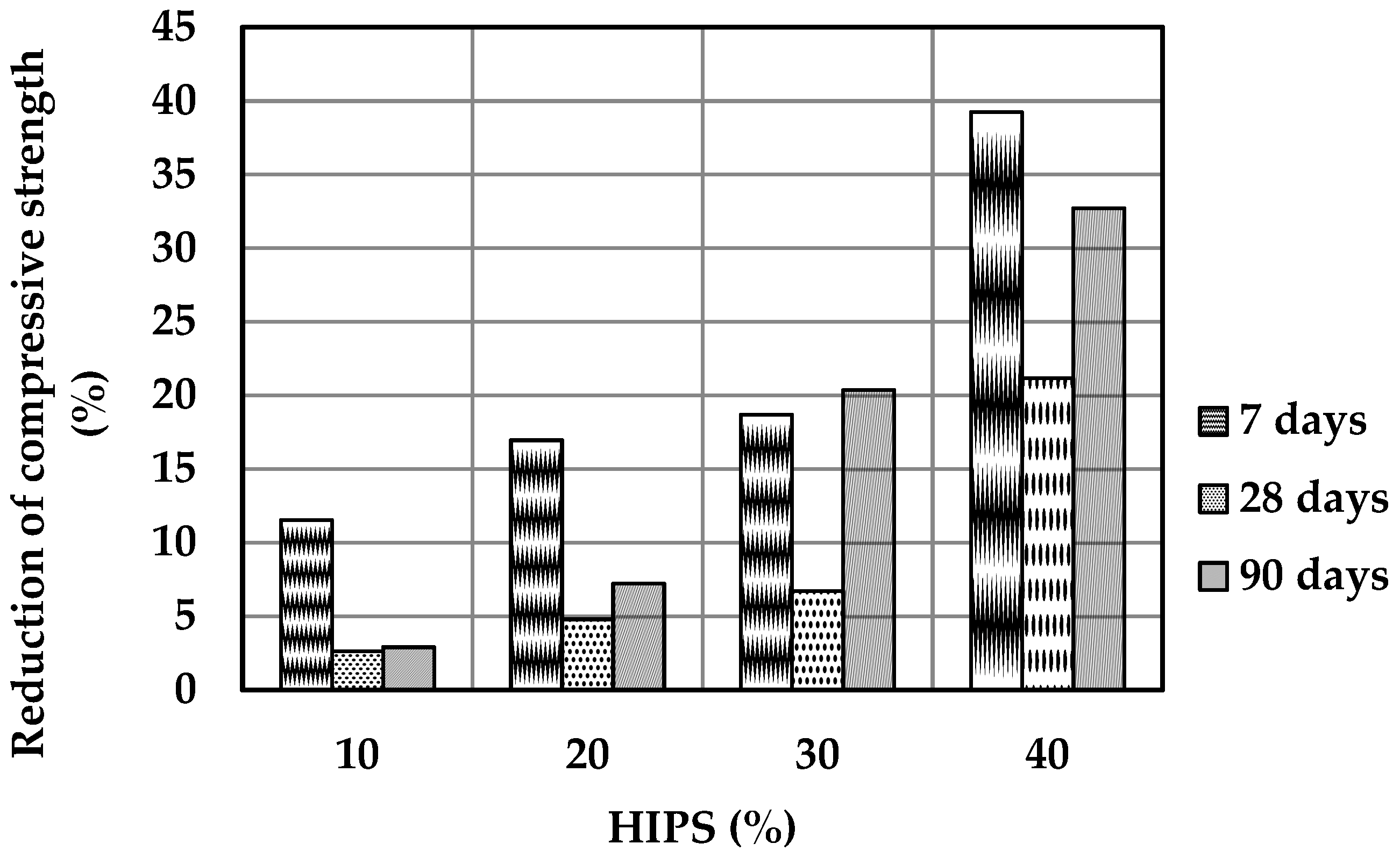

3.2.2. Compressive Strength

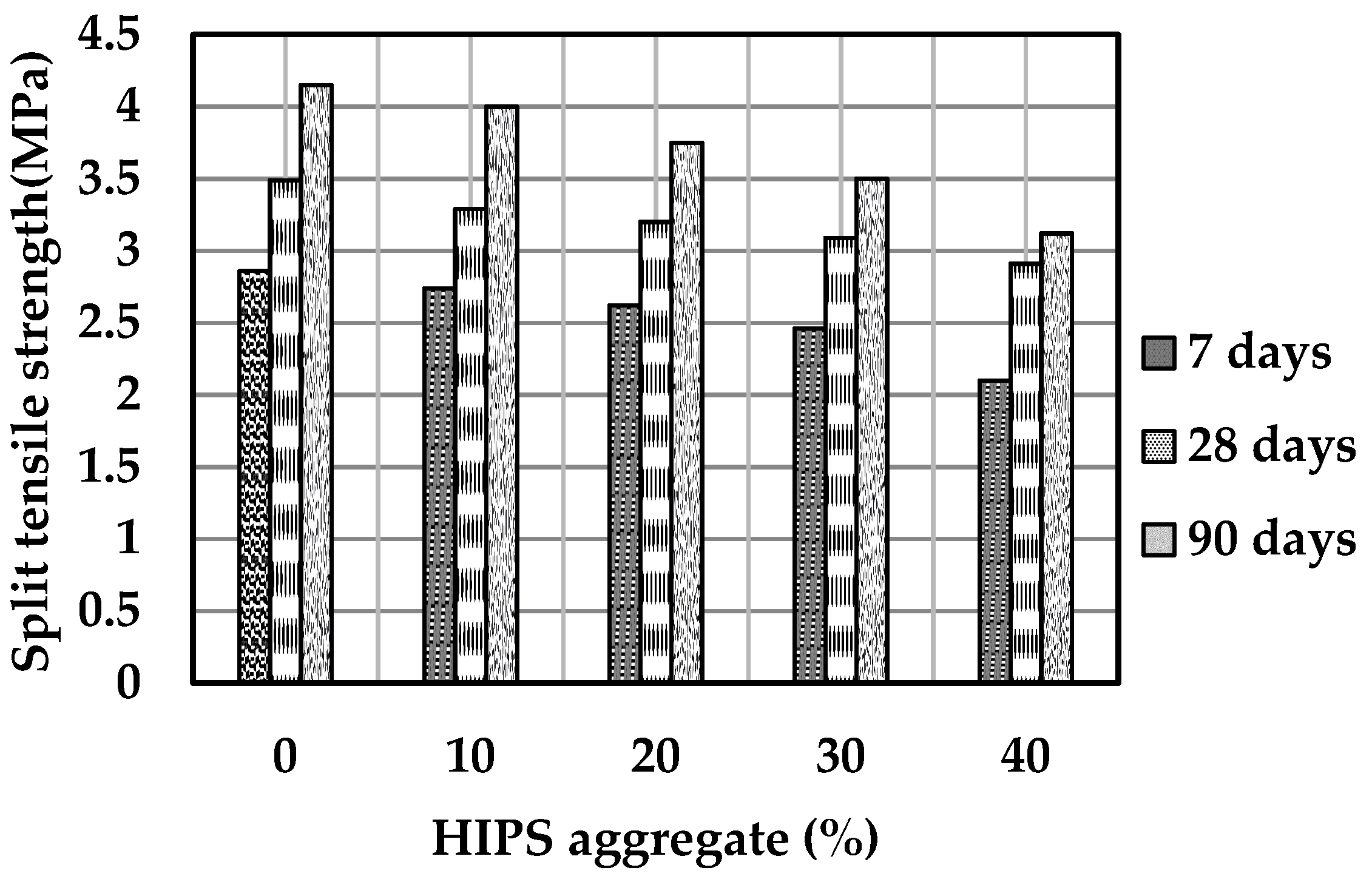

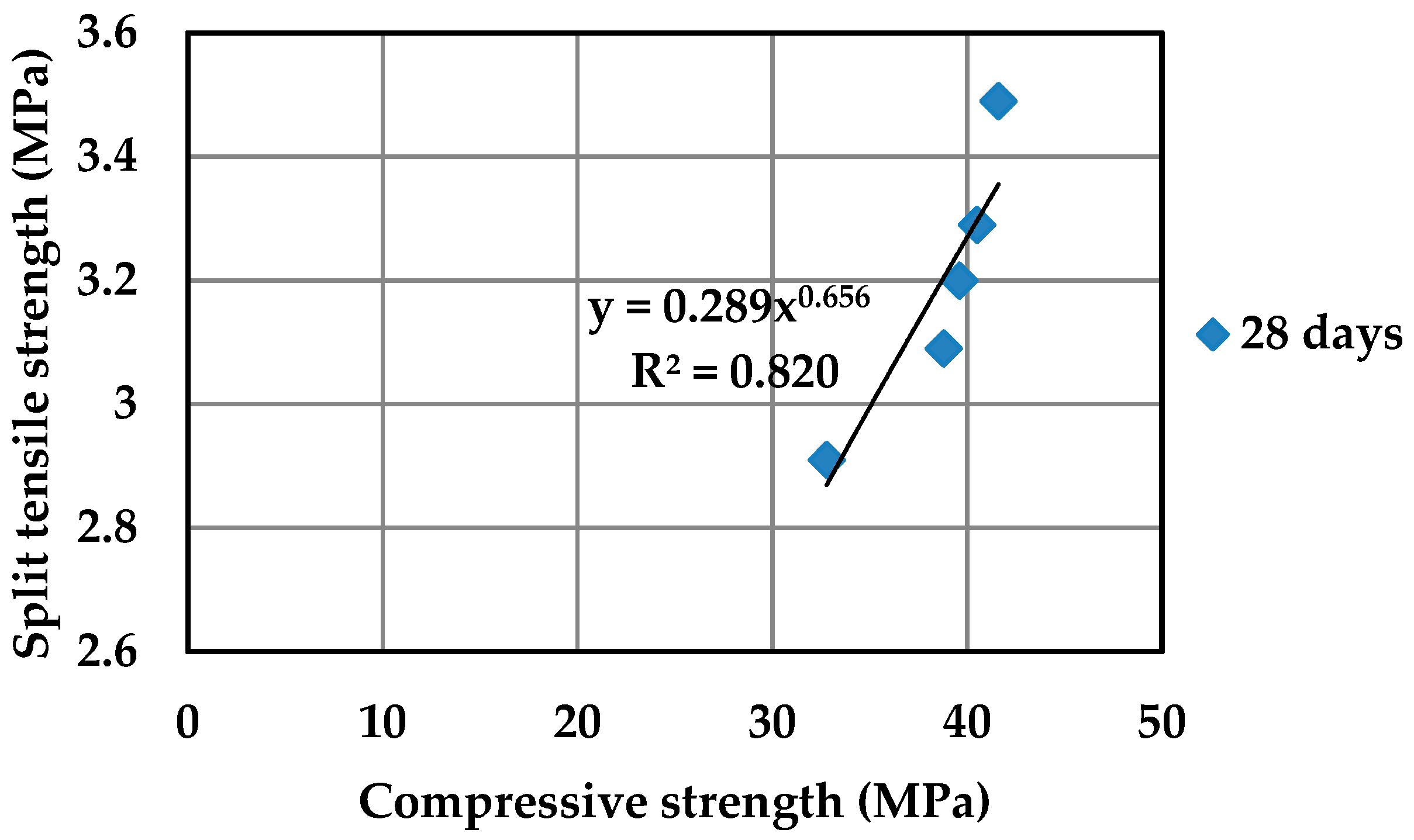

3.2.3. Split Tensile Strength

4. Conclusions

- All rheological properties are improved and satisfied EFNARC standards up to 30% of HIPS replacement for sand in SCC. HIPS spherical shape and smooth surface enhances the flow-ability.

- Density of SCC with HIPS is moderate, up to 30%, and reduces significantly replacing high volumes of fly ash and HIPS.

- Reduction of compressive and split tensile strengths are minimal (<20%) up to 30% HIPS replacement in SCC and achieved the desired strength of M30 grade concrete.

- It is a good accomplishment to say, replacement of both HIPS and fly ash up to 30% in SCC develops concrete equivalent to that of the reference concrete.

Author Contributions

Funding

Conflicts of Interest

References

- ACI237R–07. Self-Consolidating Concrete; American Concrete Institute: Farmington Hills, MI, USA, 2007. [Google Scholar]

- Al-Manaseer, A.A.; Dalal, T.R. Concrete containing plastic aggregates. Concr. Int. 1997, 19, 47–52. [Google Scholar]

- Andiç Çakır, Ö.; Yoğurtcu, E.; Yazıcı, Ş.; Ramyar, K. Self-compacting lightweight aggregate concrete: Design and experimental study. Mag. Concr. Res. 2009, 61, 519–527. [Google Scholar] [CrossRef]

- Aslani, F.; Ma, G.; Muselin, G. Development of high performance self-compacting concrete using waste recycled concrete aggregates and rubber granules. J. Clean. Prod. 2018, 182, 553–566. [Google Scholar] [CrossRef]

- Guneyisi, E. Fresh properties of self-compacting rubberized concrete incorporated with fly ash. Mater. Struct. 2010, 43, 1037–1048. [Google Scholar] [CrossRef]

- Jawahar, J.G.; Sashidhar, C.; Reddy, I.V.R.; Peter, J.A. Micro and macro level properties of fly ash blended self-compacting concrete. Mater. Des. 2013, 46, 696–705. [Google Scholar] [CrossRef]

- Jawahar, J.G.; Sashidhar, C.; Reddy, I.V.R.; Peter, J.A. Effect of coarse aggregate blending on short term mechanical properties of self-compacting concrete. Mater. Des. 2013, 43, 185–194. [Google Scholar] [CrossRef]

- Jawahar, J.G.; Sashidhar, C.; J, I.V.R.R.; Peter, A. Design of cost effective M25 grade of self compacting concrete. Mater. Des. 2013, 49, 687–692. [Google Scholar] [CrossRef]

- Okamura, H.M.; Ouchi, M. Self-compacting concrete. J. Adv. Concr. Technol. 2003, 1, 5–15. [Google Scholar] [CrossRef]

- Choi, Y.W.; Kim, Y.J.; Shin, H.C.; Moon, H.Y. An experimental research on the fluidity and mechanical properties of high strength lightweight self-compacting concrete. Cem. Concr. Res. 2006, 36, 1595–1602. [Google Scholar] [CrossRef]

- Domone, P.L.J. Self-compacting concrete: An analysis of 11 years of case studies. Cem. Concr. Compos. 2006, 28, 197–208. [Google Scholar] [CrossRef]

- Pineaud, A.; Cabrillac, R.; Remond, S.; Pimienta, P.; Rivillon, P. Mechanical properties of self-compacting concrete—Influence of composition parameters. In Proceedings of the Second North American Conference on the Design and Use of Self Consolidating Concrete and the Fourth International RILEM Symposium on Self-Consolidating Concrete, Chicago, IL, USA, 2 November 2005; pp. 863–868. [Google Scholar]

- Kim, Y.J.; Choi, Y.W.; Lachemi, M. Characteristics of self-consolidating concrete using two types of lightweight coarse aggregates. Constr. Build. Mater. 2010, 24, 11–16. [Google Scholar] [CrossRef]

- Kuroda, M.; Watanabe, T.; Terashi, N. Increase of bond strength at interfacial transition zone by the use of fly ash. Cem. Concr. Res. 2000, 30, 253–258. [Google Scholar] [CrossRef]

- Xiong, G.; Liu, J.; Li, G.; Xie, H. A way of improving interfacial transition zone between concrete substrate and repair materials. Cem. Concr. Res. 2002, 32, 1877–1881. [Google Scholar] [CrossRef]

- Scrivener, K.L.; Crumbie, A.K.; Laugesen, P. The interfacial transition zone (ITZ) between cement paste and aggregate in concrete. Interface Sci. 2004, 12, 411–421. [Google Scholar] [CrossRef]

- Siddique, R. Properties of self-compacting concrete containing class F fly ash. Mater Des. 2011, 32, 1501–1507. [Google Scholar] [CrossRef]

- Coppola, L.; Cerulli, T.; Salvioni, D. Sustainable development and durability of self-compacting concrete. In Proceedings of the Eighth CANMET/ACI International Conference on Fly Ash, Silica Fume, Slag and Natural Pozzolans in Concrete; American Concrete Institute: Farmington Hills, MI, USA, 2004; pp. 29–50. [Google Scholar]

- Monteiro, P.J.M.; Maso, J.C.; Ollivier, J.P. The aggregate-mortar interface. Cem. Concr. Res. 1985, 15, 953–958. [Google Scholar] [CrossRef]

- Sadrmomtazi, A.; Dolati-Milehsara, S.; Lotfi-Omran, O.; Sadeghi-Nik, A. The combined effects of waste Polyethylene Terephthalate (PET) particles and pozzolanic materials on the properties of selfcompacting concrete. J. Clean. Prod. 2016, 112, 2363–2373. [Google Scholar] [CrossRef]

- Krishna, C.H.B.R.; Jagadeesh, P. Fresh and Hardened Properties of Self-Compacting Concrete Replacing Fine Aggregate with High Impact Polystyrene Plastic Granules. Int. J. Civ. Eng. Technol. 2018, 9, 831–838. [Google Scholar]

- Krishna, C.H.B.R.; Jagadeesh, P. Compressive strength evaluation of eco-friendly concrete replacing sand partially with High impact polystyrene. Int. J. Civ. Eng. Technol. 2018, 9, 865–870. [Google Scholar]

- Krishna, C.B.R.; Jagadeesh, P. Influence of Admixtures on Plastic Wastes in An Eco-Friendly Concrete a Review. Int. J. Civ. Eng. Technol. 2017, 8, 388–397. [Google Scholar]

- Yang, S.; Yue, X.; Liu, X.; Tong, Y. Properties of self-compacting lightweight concrete containing recycled plastic particles. Constr. Build. Mater. 2015, 84, 444–453. [Google Scholar] [CrossRef]

- Hama, S.M.; Hilal, N.N. Fresh properties of self-compacting concrete with plastic waste as partial replacement of sand. Int. J. Sustain. Built Environ. 2017, 6, 299–308. [Google Scholar] [CrossRef]

- Senthil Kumar, K.; Baskar, K. Development of Ecofriendly Concrete Incorporating Recycled High-Impact Polystyrene from Hazardous Electronic Waste Journal of Hazardous. J. Hazard. Toxic Radioact. Waste 2014, 19, 04014042. [Google Scholar] [CrossRef]

- Aslani, F.; Kelin, J. Normal and High-Strength Lightweight Self-Compacting Concrete Incorporating Perlite, Scoria, and Polystyrene Aggregates at Elevated Temperatures. J. Mater. Civ. Eng. 2018, 30, 04018328. [Google Scholar] [CrossRef]

- Law Yim Wan, D.; Aslani, F.; Ma, G. Lightweight self compacting concrete incorporating perlite, scoria, and polystyrene aggregates. J. Mater. Civ. Eng. 2018, 30, 04018178. [Google Scholar] [CrossRef]

- Aslani, F.; Ma, G.; Wan, D.L.Y.; Le, V. Experimental investigation into rubber granules and their effects on the fresh and hardened properties of self-compacting concrete. J. Clean. Prod. 2018, 172, 1835–1847. [Google Scholar] [CrossRef]

- Bogas, J.A.; Gomes, A.; Pereira, M.F.C. Self-compacting light weight concrete produced with expanded clay aggregate. Constr. Build. Mater 2012, 35, 1013–1022. [Google Scholar] [CrossRef]

- Abouhussien, A.A.; Hassan, A.A.A.; Ismail, M.K. Properties of semi-lightweight self-consolidating concrete containing lightweight slag aggregate. Constr. Build. Mater 2015, 75, 63–73. [Google Scholar] [CrossRef]

- Gesoglu, M.; Güneyisi, E.; Ozturan, T.; Oz, H.O.; Asaad, D.S. Shear thickening intensity of self-compacting concretes containing rounded lightweight aggregates. Constr. Build. Mater. 2015, 79, 40–47. [Google Scholar] [CrossRef]

- Saikia, N.; De Brito, J. Waste polyethylene terephthalate as an aggregate in concrete. Mater Res. 2013, 16, 341–350. [Google Scholar] [CrossRef]

- Saikia, N.; De Brito, J. Mechanical properties and abrasion behaviour of concrete containing shredded PET bottle waste as a partial substitution of natural aggregate. Constr. Build Mater. 2014, 52, 236–244. [Google Scholar] [CrossRef]

- Yehia, S.; Alhamaydeh, M.; Farrag, S. High-strength lightweight SCC matrix with partial normal-weight coarse-aggregate replacement: Strength and durability evaluations. J. Mater. Civ. Eng. 2014, 26, 04014086. [Google Scholar] [CrossRef]

- Koksal, F.; Gencel, O.; Brostow, W.; Lobland, H.E.H. Effect of high temperature on mechanical and physical properties of lightweight cement based refractory including expanded vermiculite. Mater. Res. Innov. 2012, 16, 7–13. [Google Scholar] [CrossRef]

- Bozkurt, N. The high temperature effect on fibre reinforced self-compacting light weight concrete designed with single and hybrid fibers. Acta Phys. Pol. A 2014, 125, 579–583. [Google Scholar] [CrossRef]

- EPA. Advancing Sustainable Materials Management: 2013 Fact Sheet; 21 June 2016; Environmental Protection Agency: Washington, DC, USA, 2015.

- Alqahtani, F.K.; Khan, M.I.; Dirar, S.; Ghataora, G. Production of Recycled Plastic Aggregates and Its Utilization in Concrete. J. Mater. Civ. Eng. 2017, 29, 4016248. [Google Scholar]

- Fredonia.IndustryStudy#3389, WorldC onstruction Aggregates. Available online: https://www.freedoniagroup.com/World-Construction-Aggregates.html (accessed on 1 March 2016).

- Neville, A.M. Properties of Concrete, 5th ed.; Pearson Prentice Hall: England, UK, 2011. [Google Scholar]

| Material Data | Coarse Aggregate (CA) Optimization | Constituent Materials for Concrete | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Material | Specific Gravity | % Absorption | Material | % by Weight | Material (kg/m3) | Initial | Adjusted | Per cum | g/mL | ||

| 0.0062 | |||||||||||

| Cement | 3.15 | N/A | CA 10 mm | 40 | Cement | 347.90 | 347.90 | 2.16 | 2156.90 | ||

| CA 12 mm | 60 | ||||||||||

| Fly Ash | 2.20 | N/A | CA (kg/cum) | 758.44 | FA | 149.10 | 149.10 | 0.92 | 924.42 | ||

| CA 12mm | 2.70 | 0.3 | % of CA | 28.09 | Water | 178.90 | 186.50 | 1.16 | 1156.50 | ||

| CA 10mm | 2.70 | 0.3 | Sand | 861.90 | 861.90 | 5.34 | 5343.80 | ||||

| Sand | 2.60 | 1.0 | CA 12 mm | 455.00 | 455.00 | 2.82 | 2821.40 | ||||

| Input parameters | Concrete Mix proportions by volume (lit/cum) | Aggregate Proportions | CA 10 mm | 303.30 | 303.30 | 1.88 | 1880.90 | ||||

| DRUW (kg/cum) | 1656 | CA | 280.91 | Material | % Vol | % Wt | VMA (lit) | 0.99 | 0.99 | 0.01 | 6.16 |

| % of CA in DRUW | 45.80 | Mortar | 719.00 | CA 12 mm | 27.50 | 28.00 | SP (lit) | 4.47 | 4.47 | 0.03 | 27.73 |

| % of Sand | 46.10 | Sand | 331.50 | CA 10 mm | 18.30 | 18.70 | Unit Wt. | 2152 | Total(kg) | 13.39 | 13393 |

| % of Fly ash | 30 | Paste | 387.50 | FA | 54.10 | 53.10 | Total quantity for slump test | 6.09 Liters | |||

| Total | 100 | 100 | |||||||||

| Wt. Water/Binder | 0.36 | Total aggregates (kg/cum) | 1620.35 | ||||||||

| Binder (kg/cum) | 497.00 | Sand (kg/cum) | 861.90 | ||||||||

| SP (% wt. of binder) | 0.90 | Vol. Water/Powder | 1.00 | ||||||||

| VMA (% wt. of binder) | 0.20 | Paste composition | |||||||||

| % of Air content | 2.00 | kg/cum | lit/cum | ||||||||

| % of dry material (SP) | 40 | Cement | Fly Ash | Water | SP | VMA | Paste | ||||

| % of dry material (VMA) | 40 | 347.90 | 149.10 | 178.90 | 4.47 | 0.99 | 382.60 | ||||

| Materials Used (Kg/m3) for Water/Binder Ratio of 0.36 | ||||||||

|---|---|---|---|---|---|---|---|---|

| HIPS (%) | Cement (Kg/m3) | Fly Ash (Kg/m3) | Coarse Aggregate (Kg/m3) | Sand (Kg/m3) | HIPS (Kg/m3) | SP (mL) | VMA (mL) | |

| 12 mm | 10 mm | |||||||

| 0% | 347.90 | 149.10 | 455.07 | 303.38 | 861.69 | 0.00 | 4.47 | 0.99 |

| 10% | 347.90 | 149.10 | 455.07 | 303.38 | 776.18 | 34.48 | 4.65 | 1.00 |

| 20% | 347.90 | 149.10 | 455.07 | 303.38 | 690.13 | 69.01 | 4.80 | 1.10 |

| 30% | 347.90 | 149.10 | 455.07 | 303.38 | 603.85 | 103.51 | 4.83 | 1.12 |

| 40% | 347.90 | 149.10 | 455.07 | 303.38 | 517.53 | 138.00 | 4.90 | 1.15 |

| Slump Flow Classes | Slump Flow Diameter (mm) | Viscosity Classes | V-Funnel Time (sec) |

|---|---|---|---|

| SF1 | 550–650 | VS1/VF1 | ≤8 |

| SF2 | 660–750 | VS2/VF2 | 9–25 |

| SF3 | 760–850 | ||

| Passing ability classes | |||

| PA1 | ≥0.8 with two rebar | ||

| PA2 | ≥0.8 with three rebar | ||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chunchu, B.R.K.; Putta, J. Rheological and Strength Behavior of Binary Blended SCC Replacing Partial Fine Aggregate with Plastic E-Waste as High Impact Polystyrene. Buildings 2019, 9, 50. https://doi.org/10.3390/buildings9020050

Chunchu BRK, Putta J. Rheological and Strength Behavior of Binary Blended SCC Replacing Partial Fine Aggregate with Plastic E-Waste as High Impact Polystyrene. Buildings. 2019; 9(2):50. https://doi.org/10.3390/buildings9020050

Chicago/Turabian StyleChunchu, Bala Rama Krishna, and Jagadeesh Putta. 2019. "Rheological and Strength Behavior of Binary Blended SCC Replacing Partial Fine Aggregate with Plastic E-Waste as High Impact Polystyrene" Buildings 9, no. 2: 50. https://doi.org/10.3390/buildings9020050

APA StyleChunchu, B. R. K., & Putta, J. (2019). Rheological and Strength Behavior of Binary Blended SCC Replacing Partial Fine Aggregate with Plastic E-Waste as High Impact Polystyrene. Buildings, 9(2), 50. https://doi.org/10.3390/buildings9020050